Page 1

ABM Food Former

NSF MODELS

F2000N – F3000N - F4000N - B1200N – HD3000N

OPERATION, SERVICE MANUAL &

PARTS LIST

* IMPORTANT SAFETY NOTICE *

This Manual contains important safety instructi ons

which must be strictly followed when using this equipment.

Item No. #356-8-13-4

REVISED JULY 23, 2014

Page 2

TABLE OF CONTENTS

INTRODUCTION Page

Warranty…………………………………………………………. 3

Reliability………………………………………………………… 3

GENERAL TECHNICAL FEATURES

Description……………………………………………………….. 4

Main features…………………………………………………….. 4

Safety devices……………………………………………………. 5

Components description…………………………………………. 5

Overall measurements…………………………………………… 6

INSTALLATION

Packing check……………………………………………………. 6

Placing the machine……………………………………………… 6

Electrical connections……………………………………………. 6

Control panel…………………………………………………….. 7

Operating test……………………………………………………. 7

UTILITY

Loading the automatic paper attachment………………………… 8

Product thickness regulation……………………………………… 9

Loading the product and use……………………………………… 10

CLEANING AND HYGIENE

Complete cleaning………………………………………………… 11

Disassembly of the removable accessories………………………... 11

Disassembly of the paddle………………………………………… 11

Disassembly of the hopper………………………………………… 11

Disassembly of the conveyor belt…………………………………. 11

Disassembly of the regulation drum………………………………. 12

Disassembly of the scraper………………………………………… 12

Cleaning of the disassembled components………………………… 12

Assembly of the accessories……………………………………….. 12

MAINTENANCE

Ordinary maintenance……………………………………………… 12

WIRING DIAGRAMS & SPARE PARTS

Wiring diagrams…………………………………………………… 13

Spare Parts…………………………………………………………. 16

2

Page 3

WARRANTY

The installation, the starting, and the operating of the machine must be performed by

skilled personnel only, who knows the machine. The personnel assigned to the assistance

and maintenance must always follow the instructions contained in the manual. The food

forming machine must be used by trained personnel only. If necessary provide for the

personnel’s training, to learn the usual operations in order to assure the correct use of the

machine.

ABM disclaims all responsibility in case of:

• Assembly of the components of the machine and the electric connection not

effected according to the established rules;

• Improper use of the machine;

• Tampering the controls or the security protection;

• Use of non-original spare parts;

The warranty does not cover the normal use of the parts.

RELIABILITY

In case of improper use of the machine, it is possible to have injuries and accidents.

The food forming machine must be used only by the personnel who must know the

machine and the content of the manual:

• Make sure that unskilled personnel – and especially children – do not operate the

machine;

• Do not modify or remove the safety devices (covers and protections), especially

those installed at the meat inlet;

• Never tamper with the electric system;

• Use the machine with concentration avoiding distractions;

• Before cleaning and maintenance, always disconnect the machine from the supply

system;

• Periodically check the main supply wire, in case of breaks or bad functioning,

provide for the replacement by skilled personnel.

• Never go near the machine with loose hair, clothes, bracelets, chains, rings, ties, etc.

to avoid the chance that they become tangled in the moving parts of the machine;

• Stop the machine whenever it makes strange noises during the functioning;

• Always keep the working area clean and dry;

• Do not deal with the repairs if you are not able to eliminate the possible breakdowns,

but contact the technical assistance;

• The machine is made of accessories and parts especially designed in order to reduce

the maintenance and minimum.

3

Page 4

GENERAL TECHNICAL FEATURES

Description

• The ABM Food Forming machine is characterized by:

• Compactness and small overall measurements and with special features, able to

satisfy the producing requirements of both the great and the small distribution;

• Reliability and safety in the operation and the cleaning processes;

• Hygiene of the parts in contact with the product through the use of innovative

materials conformed to the current regulations;

• Precision and compactness of the finished product;

• Strength, easy use, controls and working stationing especially designed to optimize

ergonomics.

Main Features

• The castings are made of anticorrodal thermically treated with innovative material

for food, while all the other components have been made of stainless steel. These

parts are particularly fit to resist the corrosive agents of the products used and are in

conformity with the hygienic regulations for food;

• The moving parts are started by an electronic motor and the movement transmission

operates through a chain and mechanism;

• The hopper, the paddle, the conveyor belt, the drum and the accessories are easily

disassembled to effect a regular cleaning.

• The thickness of the product is adjustable;

• The quantity of the hamburgers produced per hour can be varied on request in the

models with current continue motors;

• The hopper and the moving of the product operate in a continuous way and this

allows a homogenous dough;

• The controls are easily identifiable and suitable to prevent accidental starting;

• The transmission parts are located inside the crankcase;

• The machine is equipped with a device which allows the cleaning of the roll during

functioning (scraper) and permits the separation of the products;

• Different drums are available, suitable o the forming of products with different

shapes;

• On request, the machine can be supplied with electrical motors of different tensions.

4

Page 5

Safety Devices

The Food Forming Machine is equipped with the following protection and safety devices:

• Safety micromagnet on the hopper;

• Plastic cover servo-assisted by a micromagnet;

• Protection and front cover of the removable parts;

• Handle of the paddle optimized to avoid crushing and use of keys or particular tools;

• Starting of the machine through reverser for servo-assisted manual or automatic

control;

• Emergency button

• Materials in conformity with the food hygienic regulations and fit to guarantee the

good resistance to oxidation.

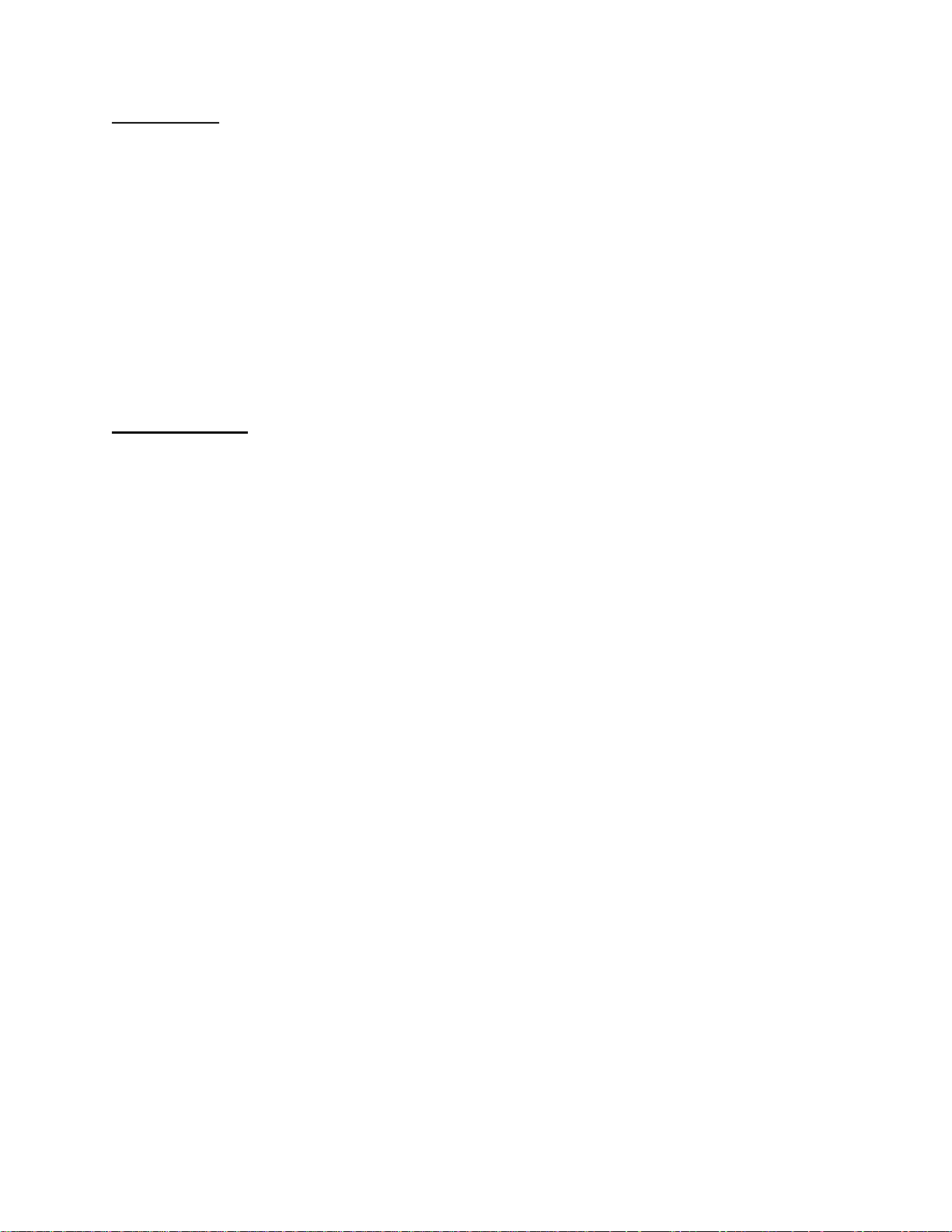

Components Description

CONTENTS

1. Cover

2. Hopper

3. Protection

4. Papering attachment

5. Drum stop ring nut

6. Drum

7. Scraper

8. Leading roll

9. Led roll

10. Conveyor belt

11. Footswitch

12. Speed variator for the mod. with current continuous

13. Manual/automatic switch

14. Stop button

15. Feeding signal light

16. Stop signal light

17. Transmission protection crankcase

18. Base

19. Cover shaft

5

Page 6

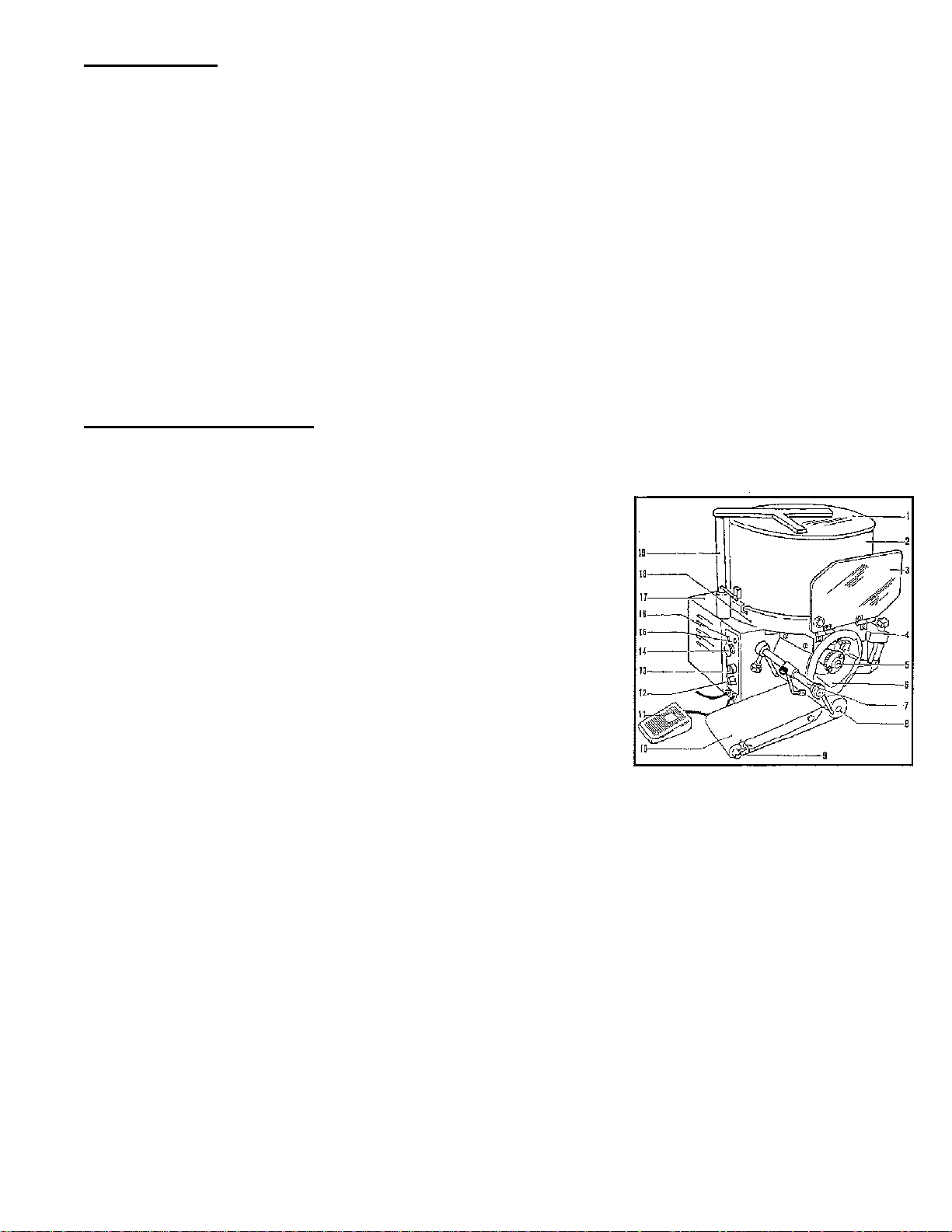

Overall Measurements

F2000/4000

Length (A) 620

Width (B) 500

Height (C) 610

Gross Created Weight – 72 kg.

Net Uncrated Weight – 67 kg.

Hopper capacity – 20 kg.

Optional Conveyor Belt – 1850 x 145

Hopper Power – see identification tag

Motor Power – see identification tag

INSTALLATION

Packing Check

• At the receipt of the machine, check the package to verify that the machine has not

been damaged.

The components of the package can be assimilated to the urban solid rubbish.

Placing the Machine

• It is advisable to place the Food Forming Machine

on a stable working table positioned on a height of

about 800mm from the ground.

• The installation area must allow the use of the machine

in an optimal and ergonomic way. It is advisable to

place it in a dry, breezy place, far from warmth sources;

it can be used without any special arrangement of a

normal working place.

Electrical Connections

• The machine is equipped with a feeding wire. Before

connecting it to the socket, verify the functioning tension

showed on the identification tag.

• In case the details do not correspond, contact the

distributor for the assistance service.

• The socket for the connection must correspond to

the current rules.

6

Page 7

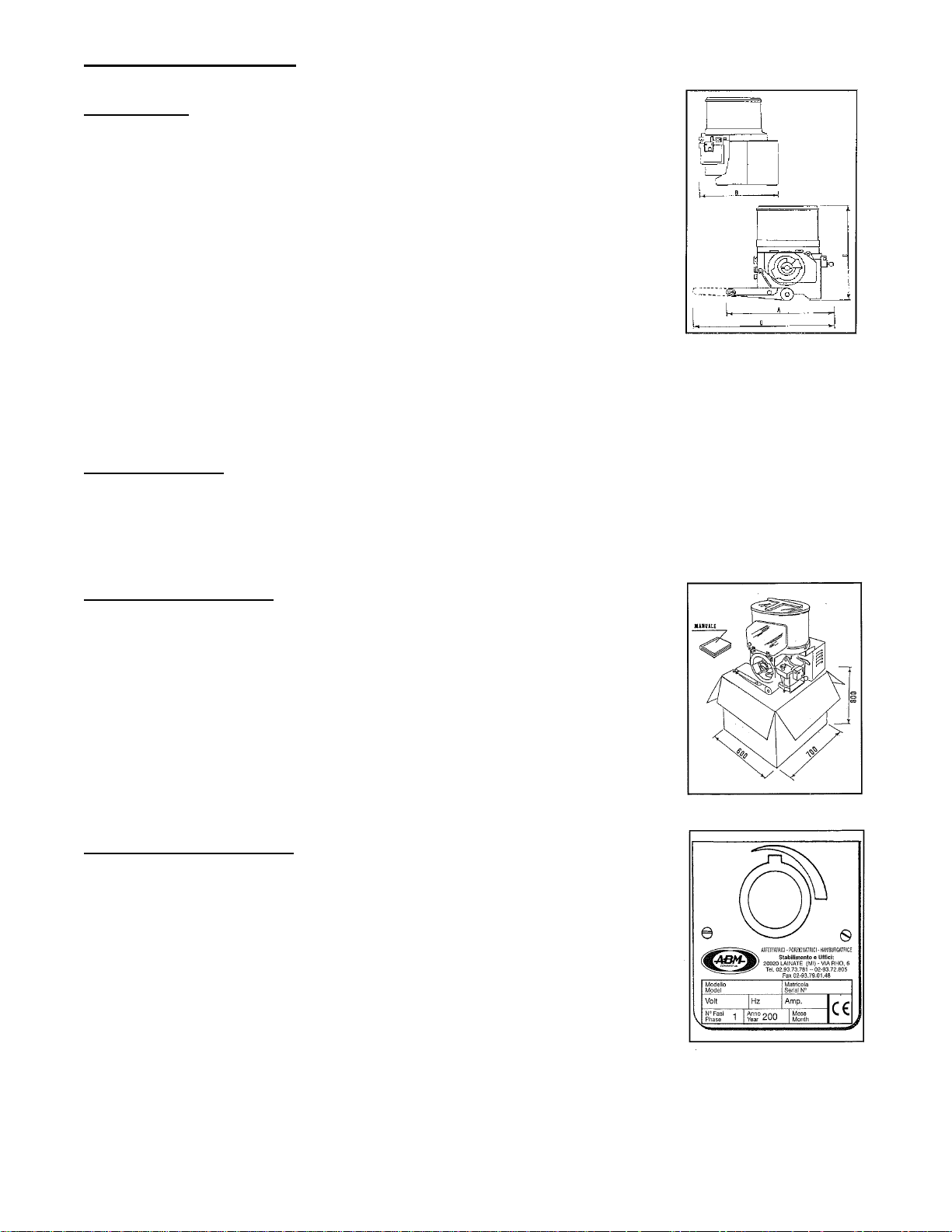

Control Panel

• Starting switch (automatic/manual) (1)

• Red stop button (2)

• Machine operating signal lamp (3)

• Machine stop signal lamp (4)

• Handle for speed regulation (5)

(only for model at variable speed)

Note – in the Model F4000 the regulation of the speed and the quantity of hamburgers

is made by rotating the regulating handle with a quantity of products variable from… to a

maximum of 4000 pieces per hour.

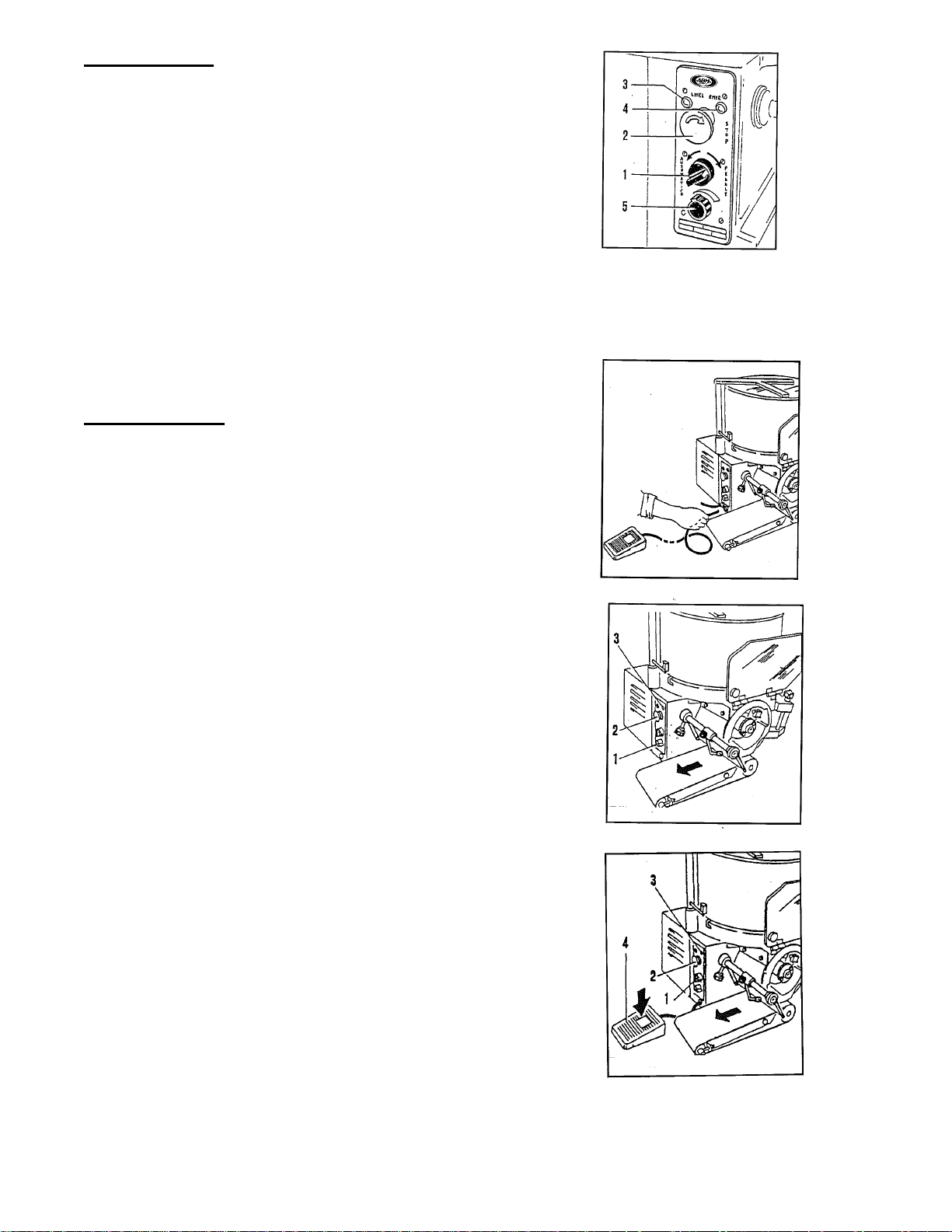

Operating Test

• Before controlling the operation, if you

have not already done, you must assemble

the hopper, assemble the conveyor belt,

close the cover and the front protection.

• Connect the footswitch, inserting the control

pipe into the bush on the control panel side.

• Connect the plug to the socket.

• Position the switch handle (1) on automatic.

• Verify the rotation of the drum and the

conveyor belt (see the arrow).

• Verify the lighting of the light.

• Push the stop button (2), the machine must

stop and the light (3) must light up.

• Position the switch handle (1) on manual.

• Press the footswitch.

• Verify the rotation of the drum and the

conveyor belt (see the arrow).

• Verify the lighting of the light.

• Push the stop button (2). The machine must stop

and the light (3) must light up.

7

Page 8

• During the operation, when lifting the front

drum protection, the machine must stop.

• To continue, close drum protection,

turn the operating switch again.

• During the operation, when rotating the

hopper cover, the machine must stop.

• To continue, close hopper cover,

turn the operating switch again.

UTILITY

To obtain good results you must use fitted meats and doughs. Arrange the machine with

all the accessories disassembled.

It is advisable not to use and let the machine function without any product in the

hopper.

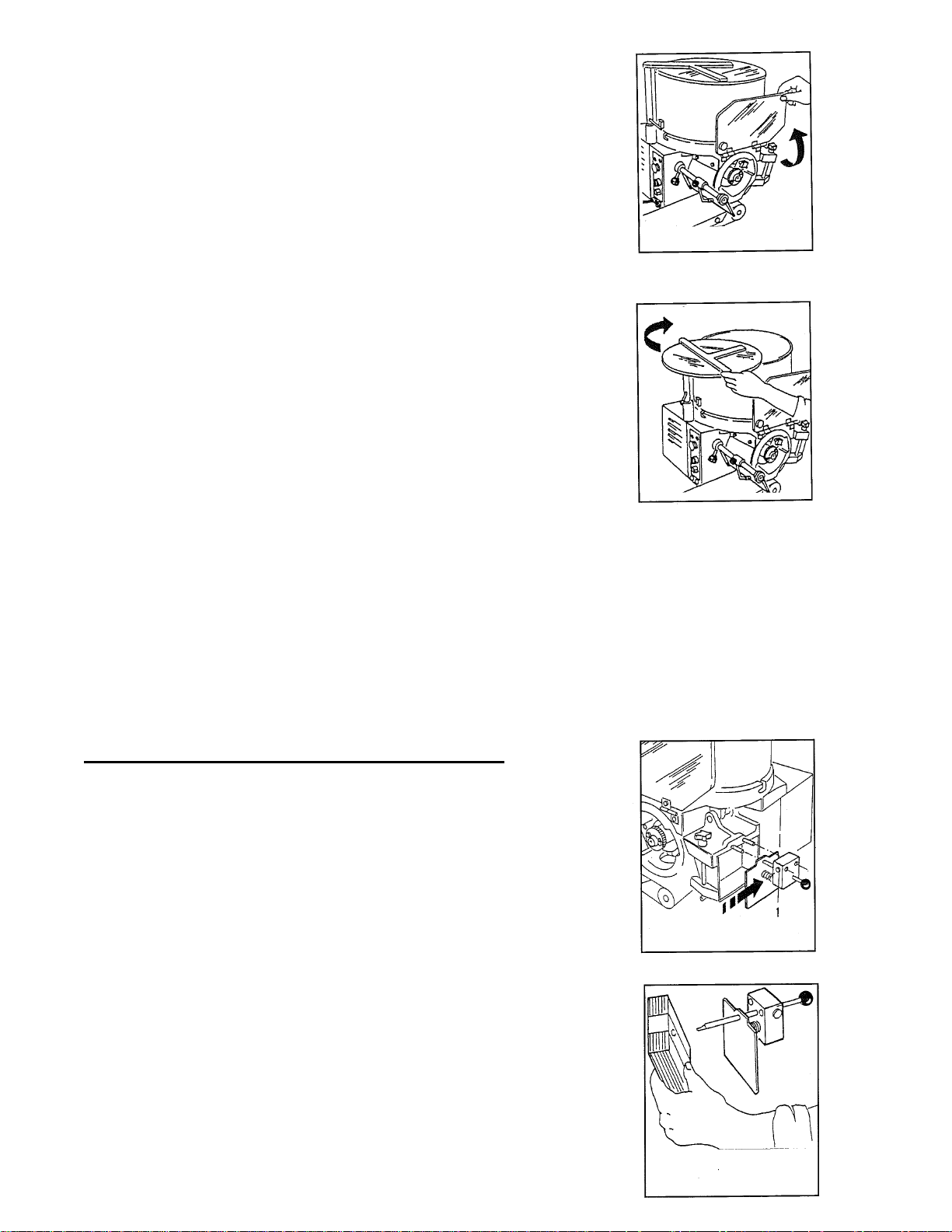

Loading the Automatic Papering Attachment

• Take out the papering attachment by pushing

the button (I) and slipping it off from the guide pins.

• Replace the pushing spring.

• Insert the paper block and take away the wrapper.

8

Page 9

• Reassemble the papering attachment in the guide pins,

until the stop click.

• Release the spring using the button placed under

the papering attachment (2).

• Position the papering attachment, freeing the

locking lever (2).

• Regulate the center of the paper, turning the

centering knob (4).

Before cleaning the machine, always make sure that the machine

Is stopped and disconnected from main supply.

Never use high pressure sprays during cleaning.

Never use solvents, thin ners , alcohol, etc. during cleaning.

Only use lukewarm water and some neutral detergent.

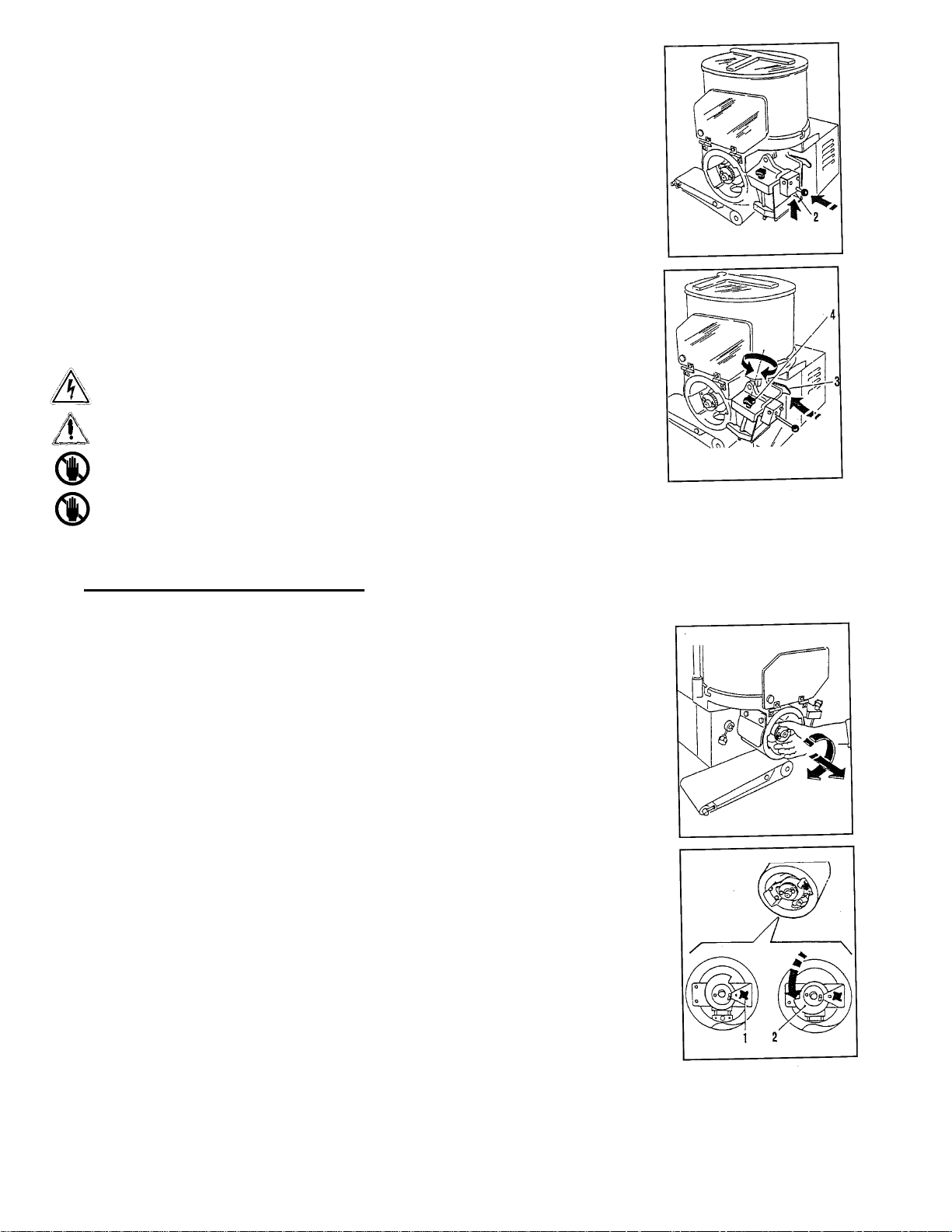

Product Thickness Regulation

The machine is regulated in the factory with a medium thickness; to obtain another

thickness, follow the instructions indicated below:

• Take out the regulation drum by operating on the

ring nut clockwise and taking out the drum.

• Loosen the stop knob of the gauging device (I).

• Turn the gauging device, to regulate the thickness (2).

• Lock the stop knob (1).

• Reassemble the drum, inserting it in the guide shaft,

until the stop click.

9

Page 10

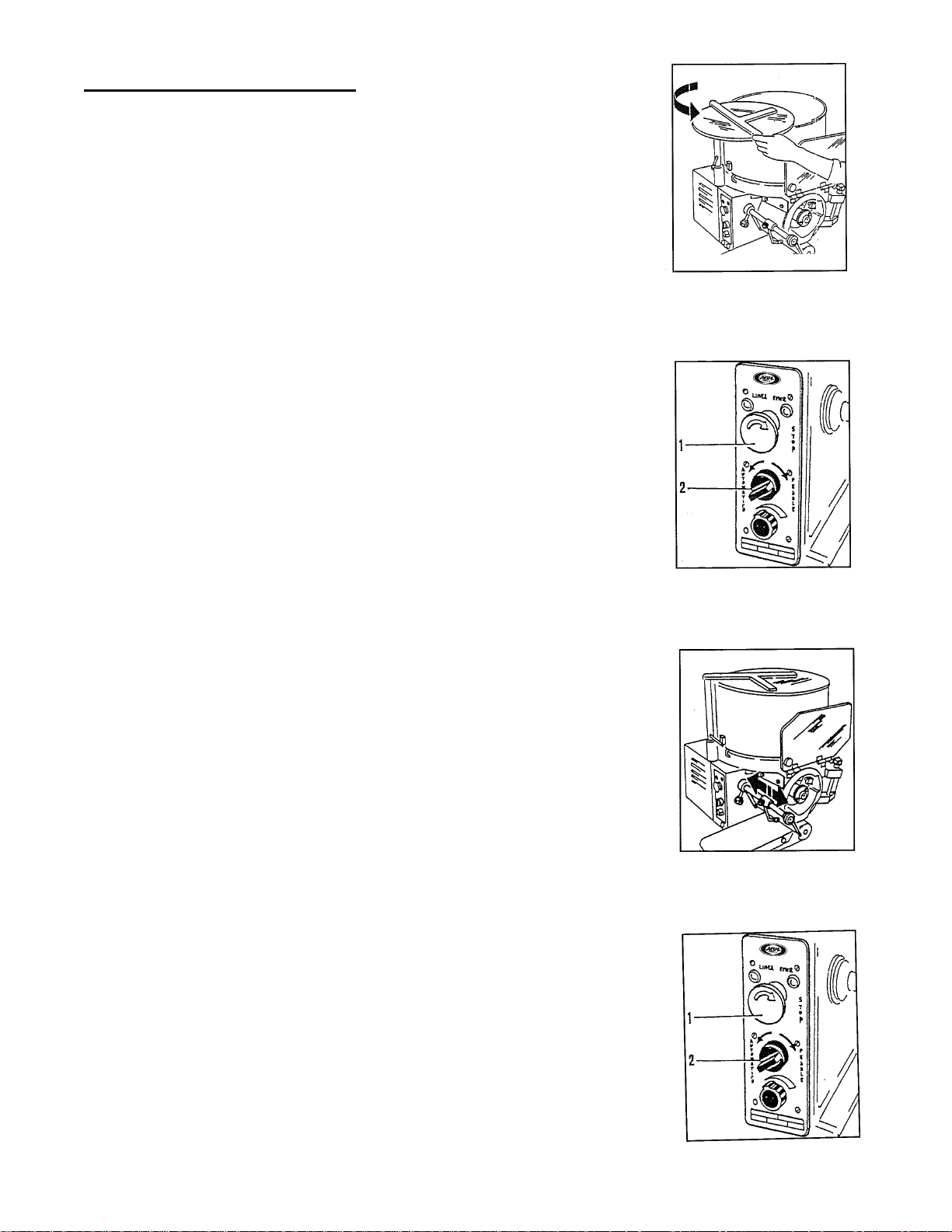

Loading the Product and Use

• Open the cover and load the product in the hopper

and close the cover again.

• Connect the plug to the socket.

• Start the machine: push the automatic switch (1).

• Regulate the production speed with the regulation handle (2)

(only for model with selector).

• During the operation, operate intermittently, in order

to clean the drum from residual product.

• The product will come down on the conveyor belt and

will be moved to its end.

• To stop the machine, operate on the stop button (I) or

open the protections.

• To continue, release the stop button and turn the start

switch again (2).

10

Page 11

CLEANING AND HYGIENE

Complete Cleaning

• It is advisable to clean the machine daily or if necessary more frequently, in case it

was very dirty or after long periods of inactivity.

• The cleaning must be carefully made for the parts in contact with the product.

• Clean the structure of the machine with soft cloths, sponges, and rinse with water

frequently. Finally dry with soft and dry cloths.

Attention: the machine is not protected against steam cleaners, high pressure power

washer, or similar systems. In this case there is risk of short circuit or serious damages to

the machine.

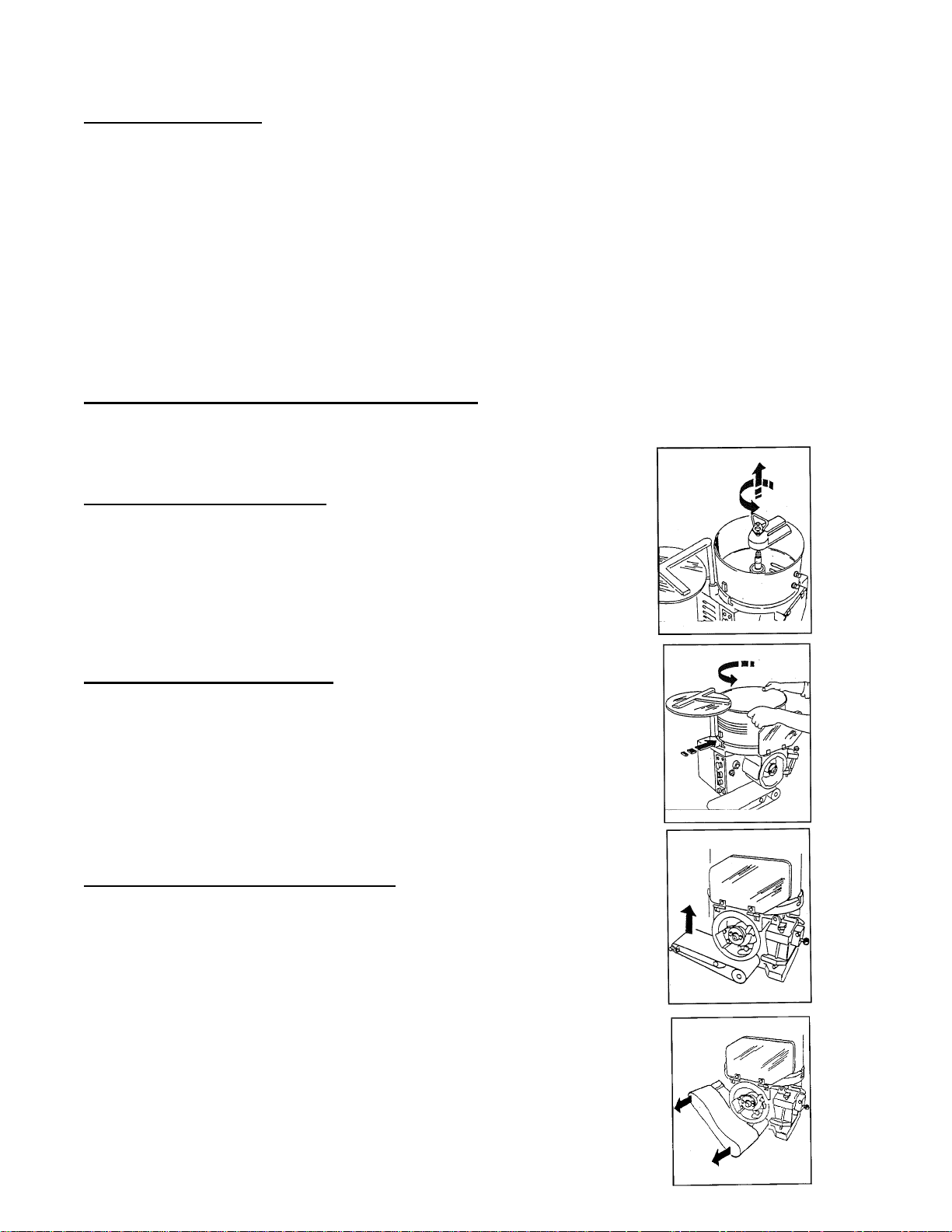

Disassembly of the Removable Accessories

• All the cleaning operations of the machine must always be done with the machine not

equipped with hopper, taking out the plug from the socket.

Disassembly of the Paddle

• Hold the handle, turn anti-clockwise and lift.

• To avoid accidents before disassembling, position

the paddle away from the hopper pins.

Disassembly of the Hopper

• Open the cover completely.

• Turn the hopper anti-clockwise,

lift it and take it away from the base.

Disassembly of the Conveyor Belt

• Lift the belt on the side of the return pulley.

• Take off and disassemble the conveyor belt.

11

Page 12

• Disassemble the complete conveyor from the guide pin.

Disassembly of the Regulation Drum

• Turn the stop ring nut anti-clockwise, pull the drum and disassemble it from the

control pin.

Disassembly of the Scraper

• Loosen the stop knob of the scraper shaft.

• Take off the complete scraper.

Cleaning of the Disassembled Components

• All the disassembled components must be washed with warm water, neutral detergent,

rinsed in water and dried.

Assembly of the Accessories

To effect the reassembly of the accessories, proceed in the inverse way to what previously

described in the disassembly. Pay special attention to the assembly of the following

accessories:

• Hopper: Insert the hopper with the two guide pins in the fusion taking care to

position the micro-magnet on the side of the cover shaft and turn it until it hooks the

pins.

• Paddle: position the inserting shaft of the paddle so that the pins in the hopper do not

overlap the paddle, then hold the paddle, put it on the shaft, making the shaft plug

coincide with the housing in the drum.

• Drum: assembly the drum in the guide pin, making the shaft plug coincide with the

housing in the drum.

MAINTENANCE

Ordinary Maintenance

The machine does not require a special maintenance for the regulations or replacements of

parts, but only requires a normal maintenance carried out by the operator which consists of

the following operations:

• Verify the operation of the micro-switches and of the electric buttons.

• Verify the state of use of the feeding wire.

Whenever there was the necessity of repairs or special maintenance, contact the assistance

service or a qualified technician.

12

Page 13

ABM

F2000N - F3000N - F4000N - B1200N

NSF / ETL VERSION

RECOMMENDED SPARE PARTS

77700 220V/50Hz.

77800 115V/60Hz.

76800

77100

40403

76600

597100

77000

19202

19201

Z9AMR

60600

60900

60000 COMPLETE ASSEMBLY

CODE DESCRIPTION Q.TY

F9319201 LONG CONVEYOR BELT 145x1850mm 1

F9319202 SHORT CONVEYOR BELT 145x840mm 1

F9340403 CERAMIC MAGNET 16x9, 5x8 1

F9360600 WIRE CLEANER 1

F9360900 S.S. WIRE 1

F9376800 MAGNET 1

F9377000 FOOTSWITCH 6210-OB 1

F9377100 PNEUM. SWITCH MOM.6871-01 1

F9377700 CARD 220/50 HZ START STOP FROM SN. 1710 1

F9377800 CARD 115/60 HZ START STOP FROM SN. 1710 1

F93597100 MALE COUPLING BODY 1

Z9AMR SAFETY CONTACT 1

CODE DESCRIPTION Q.TY

F9360000 CLEANER ASSEMBLY 1

F9313701 PADDLE NSF VERSION 1

NSF VERSION

13701-COMPLETE ASSEMBLY

PAG-0

Page 14

ABM

PNEUMATIC VERSION / ALL

NSF / ETL VERSION

RECOMMENDED SPARE PARTS

38003

38002

62600

60600

38006

38001

13701 Complete Assembly

60900

3800A Complete Assembly

CODE DESCRIPTION Q.TY

F9338001 CILINDER - ISO 6432 1

F9338002 AIR FILTER 1

F9338003 FIL BIT 1/8 20 RMSA 1

F9338006 SWITCH 1

F933800A COMPLETE PNEUMATIC CLEANER ASSEMBLY 1

F9362600 PNEUMATIC PISTON 1

F9360600 WI RE CLEANER 1

F9360900 S.S.WIRE 1

CODE DESCRIPTION Q.TY

F933800A CLEANER ASSEMBLY 1

F9313701 PADDLE 1

PAG-01

Page 15

ABM

F2000N - F3000N - F4000N - B1200N

NSF / ETL VERSION

12403

12401

10100

12702

F9314100

F9314100

11202

06300

12100

Z9CUS

12000

11900

19401

10600

10700

06800

CODE DESCRIPTION Q.TY

F9306300 BE ARING 51108 40x60x13 1

F9306800 SE AL A S 30x42x7 NB R 1

F9307000 BEA RING 6205 2RSH 25x 52x15 1

F9310100 F RA M E 1

F9310600 S HAFT HOUSING 1

F9310700 CA M 1

F9311202 CONIC GEA R 25x28,2 M 3 Z=25 1

F9311900 SHA F T d30x248 1

F9312000 P L UG 10x 46 h8 1

F9312100 KE Y 8x7x35 UNI 6605 69 A C 40 1

F9312401 B US HING 40x 16 E RTALON 1

F9312403 BUS HING 1

F9312702 BUS HING 26,7x32x39 1

F9314100 RUBB E R F OO T 4

F9319401 O RING 80x 3 1

PAG-1

Page 16

10302

A

ABM

F2000N - F3000N - F4000N - B1200N

NSF / ETL VERSION

06700

15100

19402

8401

8400

06300

12500

8501

8500

12600

11201

CODE DESCRIPTION Q.TY

F9306300 BE A RING 51108 40x60x 13 1

F9306700 SE A L A S 30x 42x7 NBR 1

F9308300 CHAIN P.8 ISO 9001 1

F9308400 BUS HING HK4020 1

F9308401 RING IR 35x40x 20. 5 1

F9308500 BUS HING 36x42x 20 HK 3520 1

F9308501 RING IR 30x35x 20 1

F9310301 HOPPER PLATE 1

F9311201 CONIC GEAR 30x 33, 2 M 3 Z=25 1

F93125V02 PA DDLE S HA F T d30x195 1

F9312600 KE Y 8x8x 45 1

F9315100

F9319402 O RING 69,3x5, 7 1

LU BUSHING 87x33,5 1

PAG-2

Page 17

10301

ABM

F2000 - F 3000 - F4000 - B1200 - HD3000

06800

15100

19402

8501

8500

8501

8500

06300

12600

12500

12600

11201

CODE DESCRIZIONE ARTICOLO DESCRIPTION Q.TY

F9306300 CUSCIN.51108 40x60x13 BEARING 51108 40x60x13 1

F9306800 ANELLO TEN. AS 30x42x7 NBR SEAL AS 30x42x7 NBR 2

F9308300 CATENA RCX P.8 semp.ISO 9001 L=568 (570) CHAIN P.8 ISO 9001 1

F9308500 BOCC.a RULL.36x42x20 HK3520 ordinare+ANELLO IR 30x35x20 BUSHING 36x42x20 HK3520 1

F9308501 ANELLO IR 30x35x20xBOCC.HK3520 RING IR 30x35x20xBOCC.HK3520 1

F9310301 CUPOLA F93 # HOPPER PLATE 1

F9311201 INGRAN.CONICO 25x28,2 M 3 Z=25 CONIC GEAR 25x28,2 M3 Z=25 1

F9312500 ALBERO RACLA d30x195 PADDLE SHAFT d30x195 1

F9312600 LINGUETTA 8x8x45 INOX 316 Tipo A non unificato con foro KEY 8x8x45 1

F9315100 BOCC.87x33,5 Alluminio ALU BUSHING 87x33,5 1

F9319402 ANELLO OR 69.3 x 5.7 NBR O RING 69,3x5,7 1

PAG-2

Page 18

ABM

F2000N - F3000N - F4000N - B1200N

NSF / ETL VERSION

11000

08000

08100

08101

10900

13101

19400

07600

19500

11500

11400

07600

11300

08300

13001

12301

CODE DESCRIPTION Q.TY

F9306400 RING 80x100x 10 1

F9307600 BE ARING 6003 2RS 17x35x10 2

F9308000 SE AL 17x28x 7 NB R 1

F9308100 BUS HING 1720x 16 NK 20 / 16 1

F9308101 RING 17x20x 16 1

F9308300 CHAIN P8 ISO 9001 1

F9308600 GEAR B O X RC 220 B5 1:30 1

F9308601 GEAR B O X RC 220 B5 1:46 - B 1200 1

F9310801 GEAR 80x 66 1

F9310900 CONVEY OR S HA F T SUP P ORT 60x67 1

F9311000 SHA F T 17 x 179 1

F9311100 CHAIN PINION 8x3 Z=21 1

F9311300 CHAIN PINION 8x3 Z=18 1

F9311400 RELEA S E GE AR M 1, 5 Z=32 1

F9311500 GEAR M 1,5 Z=38 1

F9311600 CAM P INION 8x3 Z=21 1

F9311700 SCRA P ER CAM 1

F9312301 RELEA S E S UP P O RT 1

F9312900 CAM P IN 12x 37 1

F9313001 RELEA S E S HA F T 17x115 1

F9313101 RELEA S E P IN 1

F9313202 GEAR P ULLE Y 53 x 31 - F 4000 1

F9313203 GEAR P ULLEY 53x31 F 4000 1

F9313204 GEAR P ULLEY 110x31 1

F9319400 O RING 9,25x1, 78 1

F9319500 BE ARING 6201 2RS 12x32x10 1

F9319905 BUS HING 12x 21x16 1

F9319906 RING 12x15x 16 1

06400

12900

11100

19906

19905

11600

10801

11700

08600

08601

13203

13204

13202

PAG-3

Page 19

12201

12800

13400

14300

14200

F9319600

ABM

F2000N - F3000N - F4000N - B1200N

NSF / ETL VERSION

60000

Complete Assembly

11800

G302

60600

60900

15400

14600

14500

14700

14800

CODE DESCRIPTION Q.TY

F9309400 S.S. LONG BELT 1

F9311800 SLIDING SUPPORT 1

F9312201 SCRAPER CONTROL LEVER 1

F9312800 PULLEY PIN 6x30 1

F9313400 CLEANER SPRING 1

F9314200 ARM ASSY 20x187 1

F9314300 RING 1

F9314400 CONVEYOR ROLL 64x140 1

F9314401 SS BELT DRIVER 64 x 140 1

F9314500 ROLL 28x140 1

F9314600 ROLL PIN 12x193 1

F9314700 LOCKING SCREW M8x38 1

F9314800 ROLL BUSHING 1

F9314901 SHORT CONVEYOR ARM 1

F9314902 LONG CONVEYOR ARM 1

F9315400 CONVEYOR ARM PIN 6x30 1

F9319201 LONG CONVEYOR BELT 145x1850mm 1

F9319202 SHORT CONVEYOR BELT 145x840mm 1

F9319600 BEARING 626-2RSH 1

G302 PLAST

F93606

F9360900 S.S. WIRE 1

CODE DESCRIPTION Q.TY

F9360000 CLEANER ASSEMBLY 1

14901

14902

IC KNOB D5 6G 1

00 WIRE CLEANER 1

09400

19202-SHORT

14400

14401

19201-LONG

PAG-4

Page 20

20301

ABM

F2000N - F3000N - F4000N - B1200N

NSF / ETL VERSION

20700

20801

20400

20000 - 20002 - 20003 - 20004

Complete Assembly

20300

20200

20600

20900

21100

21000

20500

25700

CODE DESCRIPTION Q.TY

F9320200 ALLUMINIUM FRAME 1

F932030

F9320301 PUSHER - 1

F9320400 PLATE SUPPORT 1

F9320500 GUIDE PLATE 1

F9320600 PUSHER SHAFT 2

F9320700 PIN 8X56,5 1

F9320801 PLASTIC BEARING d.14,5 2

F9320900 PUSHER SPRING 1

F9321000 LOCKING MECHANISM 1

F9321100 LOCKING MECHANISM SPRING 1

F9321200 THICKNESS CAM 1

F9321300 LOCKING THICKNESS MECHANISM 1

G305 PLASTIC KNOB - D3 6G 1

F9325700 RING . d 8 UNI 7435 2

CODE COMPLETE ASSEMBLY Q.TY

F9320000 DRUM SINGLE SHAPE ON REQUEST 1

F9320002 DRUM DOUBLE SHAPE ON REQUEST 1

F9320003 DRUM FOUR SHAPE ON REQUEST 1

F9320004 DRUM COOKIE ALLU - SHAPE ON REQUEST 1

0 PLASTIC DRUM 1

21200

21300

G305

PAG-5

Page 21

ABM

F2000N - F3000N - F4000N - B1200N

NSF / ETL VERSION

31500

31700

31900

31800

3010B-135MM

30100

30300

3030B-135MM

30202 Complete assembly

3160B-135MM

31600

21500

32000

32100

30500

30600

30400

30800

31000

30900

31300

31300

31100

30201 Complete assembly

30701

31100

CODE DESCRIPTION Q.TY

F9330400 PAPER HOUSING 1

F9321500 PLASTIC KNOB - D3 6G 1

F9330100 ALU PAPER ATTACH HOLDER 1

F9330300 PAPER MAGAZINE 1

F9330500 SCREW 6x160 1

F9330600 CAM 1

F9330700 GUIDING PIN 6x117 1

F9330701 KNOB 1

F9330800 PIN 1

F9330900 PAPER PUSHER 1

F9331000 PAPER PUSHER SPRING 1

F9331100 LOCKING PAPER PIN 2

F9331200 PIN 12x7,5 2

F9331300 SPRING 05 DE 11 2

F9331400 BUSHING 8x7,5 1

F9331500 SPRING d 10 L 55 1

F9331600 PIN 1

F9331700 RELEASE LEVER 1

F9331800 STOPPING SEAL 1

F9331900 PAPER ATTACHMENT SUPPORT PIN 1

F9332000 GUIDING PIN 8x55 1

F9332100 GUIDING PIN 6x48 1

F9332200 BUSHING 12x14x15 2

CODE COMPLETE ASSEMBLY Q.TY

F9330000 PAPER ATTACHMENT COMPLETE 1

F9330201 PAPER PUSHER ASSEMBLY 1

F9330202 PAPER SUPPORT ASSEMBLY 1

30000 Complete assembly

3000B-135MM Complete assembly

CODE DESCRIPTION Q.TY

F933160B SPRING PIN - 135 mm PAPER ATT. 1

F933010B ALU PAPER ATTACH HOLDER 135mm 1

F933030B PAPER MAGAZINE - 135 mm 1

CODE COMPLETE ASSEMBLY Q.TY

F933000B PAPE R ATTACH. COMPLETE 135 mm 1

PAG-6

Page 22

ABM

F2000N - F3000N - F4000N - B1200N

NSF / ETL VERSION

13701-COMPLETE ASSEMBLY

NSF VERSION

40302 EXTENDED HOPER

40300 STANDARD

76600

12402

50102 F4000

50100 STANDARD

12701

40202

40201

40100 STANDARD

40102 EXTENDED HOPER

50700

50400

50300

PAG-7

05600

06200

AF021

AF025

05701 COMPLETE ASSEMBLY

50200

CODE DESCRIPTION Q,TY

AF021 KNOB Ø40 M10 1

F9312402 BUSHING 1

F9305600 GUIDE 2

F9306200 METAL PLATE 2

AF025 PTFE WHEEL 2

F9312701 BUSHING 1

F9340100 HOPPER d360x260h 1

F9340102 HOPPER d360x430h 1

F9340201 HOPPER SHORT PIN 12x110 1

F9340202 HOPPER LONG PIN 12x130 1

F9340300 HOPPER COVER ARM 1

F9340302 EXT.HOPPER COVER ARM 1

F9376600 MAGNET SUPPORT 1

F9350100 SS REAR PROTECTION 1

F9350102 REAR PROTECTION F4000 1

F9350200 LEF T SIDE PROTECTION 1

F9350300 SS DRUM PROTECTION 205x300 1

F9350400 LOCKING KEY PIN 8x177 M4 1

F9350700 LOCKING LEFT AND RIGHT KEY 1

CODE DESCRIPTION Q,TY

F9305701 TILTING DEVICE - COMPLETE ASSEMBL 1

F9313701 PADDLE - COMPLETE ASSEMBL 1

Page 23

ABM

F2000N - F3000N - F4000N - B1200N

NSF / ETL VERSION

77700 220V-50Hz

77800 115V-60Hz

77500

K20004

77900

K20003

76200

77100

75300

76100

597800

76000

Z9AMR

50800

77000

40403

76400

76300

Z9AMR

76800

50801 COMPLETE ASSEMBLY

597100

CODE DESCRIPTION Q.TY

F9340403 CERAMIC MAGNET 16x9, 5x8 1

F9350800 PNEUM. FOOTSWITCH SUP. PROTEC. 1

F9375300 POTENTIOMETER F4000 R10K1 M22 MOELLER 1

F9376000 DOUBLE SWITCH 1

F9376100 HAND/FOOT SWITCH 1

F9376200 STOP BUTTON 1

F93763 SWITCH 1 NC SCREW 1

F93764 SWITCH 1 NO SCREW 1

F9376800 MAGNET 1

F9377000 FOOTSWITCH 6210-OB 1

F9377100 PNEUM. SWITCH MOM.6871-01 1

F93597100 MALE COUPLING BODY 1

F93597800 FEMALE COUPLING BODY 1

F9377500 INVERTER SYN10 S 220 05 AF IP65 S 50/60H Kw. 0,75 220V 1

F9377900 INVERTER SYN10 S 220 05 AF IP65 S 50/60H Kw. 0,75 115V 1

K20003 RED LAMP 1

K20004 GREEN LAMP 1

F9377700 CARD 220/50 HZ START STOP FROM SN. 1710 1

F9377800 CARD 115/60 HZ START STOP FROM SN. 1710 1

Z9AMR SAFETY CONTACT 1

CODE DESCRIPTION Q.TY

F9350801 FOOT SWITCH - COMPLETE ASSEMBL

1

PAG-8

Page 24

ABM

F2000N - F3000N - F4000N - B1200N

NSF / ETL VERSION

13300

13500

F2000/B1200

13201

08800

F3000/HD3000

13201

08900

F4000

13201

08700

13204

13203

13202

13201

75500

76101

76102

CODE DESCRIPTION Q.TY

F9308700 BELT - F 4000 PJ 457 J8 1

F9308800 BELT - F 2000 B 1200 PJ 559 J8 220 mm 1

F9308900 BELT - F3000 HD 3000 - PJ508 1

F9313201 MOTOR PULLEY 38 x 31- ALL 1

F9313202 GEAR PULLEY 53 x 31 - F 4000 1

F9313203 GEAR PULLEY - F 3000 HD 3000 83 x 31 1

F9313204 GEAR PULLEY - F 2000 110 x 31 1

F9313300 MOTOR SUPPORT 1

F9313500 MOTOR SPRING TENS 1

F9375500 MOTOR - LMR 71 230 V. 50 Hz F 2 - 3 - HD 3000 - B 1200 1

F9375501 MOTOR - LMR 71 115 V. 60 Hz F 2 - 3 - HD 3000 - B 1200 1

F9376101 MOTOR CAPACITOR BLACK 31,5 - 40 mf VLCA 280 40 : 60 1

F9376102 MOTOR F 2-3- B 1200 CAPACITOR WHITE 1

F9377600 MOTOR THREE PHASE F 4000 only 0,55 Kw 230/400 V 50Hz B14 1

75501

77600

PAG-9

Page 25

ABM

F2000N - F3000N - F4000N - B1200N

NSF / ETL

PNEUMATIC VERSION

3800A COMPLETE ASSEMBLY

60900

60600

38001

38006

62600

38002

38003

CODE DE SCRIPTION Q.TY

F9338001 CILINDER - ISO 6432 1

F9338002 AIR FILTER 1

F9338003 FIL BIT 1/8 20 RMSA 1

F9338006 SWITCH - 1

F9362600 PNEUMATIC PISTON 1

F9360600 WIRE CLEANER 1

F9360900 S.S.WIRE 1

CODE DE SCRIPTION Q.TY

F933800A COMPLETE PNEUMATIC CLEANER ASSEMBLY 1

PAG-10

Page 26

ABM COMPANYsrl

Page 27

ABM COMPANYsrl

Page 28

ABM COMPANYsrl

Page 29

ABM COMPANYsrl

Page 30

ABM COMPANYsrl

Page 31

ABM

CONVEYOR BELT FOR HD 3000

EDITION 2014-06-16

0-140616

Page 32

VT209

VT032

VA0027

VA0046

ZZVOL

VA0028

VA0060

VA0029

PA39

VA0030

VT126

VT458

ABM

CONVEYOR BELT FOR HD 3000

1-140616

CODE DESCRIPTION

PA39 SEAL 25-42-7

VA0027 ROLL OF REFERENCE

VA0028 SHAFT OF REFERENCE FOR ROLLER

VA0029 SHAFT ALIGNMENT

VA0030 DISK

VA0046 FLAT WASHER Ø30

VA0060 BEARING 61905-2RS (25-42-9)

VT032 RETAINING RING INTERNAL M42 SS

VT126

FLAT WASHER M6 SS

VT209 HEX HEAD SCREW M6-1.0x20 SS

VT458 HEX SOCKET SET SCREW FLAT POINT M8-1.25x35 SS

ZZVOL KNOB Ø40 M8 FEMALE

Page 33

ABM

CONVEYOR BELT FOR HD 3000

2-140616

VT126

VA0034

F9375504

VT063

VA0046

VA0059

VA0032

VA0033

VT491

VA0057

VT128

VT106

VA0055

VT206

VT231

F9375503

CODE DESCRIPTION

F9375503 MOTOR Kw 0,18 - Gr.63 - B14 - 230V SINGLE PHASE - IP55 + CAPACITOR 8µF

F9375504 MOTOR Kw 0,18 - Gr.63 - B14 - 115V-60Hz - IP55 + CAPACITOR 25µF

VA0032 SHAFT ROLLER MOTOR

VA0033 ROLLER MOTOR

VA0034 REACTION ARM

VA0046 FLAT WASHER Ø30

VA0055 PLASTIC SUPPORT UCFL 204 OPEN COD.69026

VA0057 PLASTIC SUPPORT UCFL 204 CLOSED COD.69016

VA0059 GEAR MT MRV40 RAPP 1:30 PAM 63 B14 VER. FOOD WHIT WHITE EPOXY COATING

VT063 PARRALLEL PIN M6m6x40 SS

VT106 ACORN HEX CAP M10-1.5 SS

VT126 FLAT WASHER M6 SS

VT128 FLAT WASHER M10 SS

VT206 HEX HEAD SCREW M6-1.0x12 SS

VT231 HEX HEAD SCREW M8-1.25x20 SS

VT491 KEY 6x6x20 INOX

Page 34

VA0042

VT229

VT127VT231

VT238

VA0046

PA43

VT127

VT127

VA0045

VA0043

VT105

VT127

VA0044

VT105

ABM

CONVEYOR BELT FOR HD 3000

3-140616

CODE DESCRI PTION

PA43 WHEELS PIVOTING Ø80 SS

VA0042 SUPPORT BAR

VA0043 SHORT LEG

VA0044 LONG LEG

VA0045 CROSS LEG

VA0046 FLAT WASHER Ø30

VT105 ACORN HEX CAP M8-1.25 SS

VT127 FLAT WASHER M8 SS

VT229 HEX HEAD SCREW M8-1.25x14 SS

VT231 HEX HEAD SCREW M8-1.25x20 SS

VT238 HEX HEAD SCREW M8-1.25x60 SS

S

S

PIVOTING WHEEL d.80 SS

Page 35

VA0040

VA0049

VA0038

VA0035

VA0037SX

VA0041

VA0039

VT127

VA0058

ZZVOL

VT126

VA0047

VT206

VT206

VA0024

VT104

VA0031

VT126

VA0026

VT206

VA0025

VT113

VA0048

VT127

VA0037DX

VA0050

VA0036

VT229

ABM

CONVEYOR BELT FOR HD 3000

4-140616

CODE DESCRI PTION

VA0024 MAIN BODY

VA0025 TILTING BODY

VA0026 PLATE FOR TILTING BODY

VA0031 HINGE SPACER

VA0035 PLATES RIGHT WITH REACTION

VA0036 PLATES LEFT

VA0037DX PLATE WITH ROD RIGHT

VA0037SX PLATE WITH ROD LEFT

VA0038 ROD

VA0039 BLIND NUT

VA0040 THROUGH NUT

VA0041 PIVOT BUSH

VA0047 BOX SCRAP COLLECTION

VA0048 ROD MOUNTING BOX

VA0049 HINGE PIN FOR CARTER

VA0050 CARTER OF MOTOR

VA0058 BELT 1N4B07PA_HBHACCP 145 X 2440

VT104 ACORN HEX CAP M6-1.0 SS

VT113 NYLOK NUT M8-1.25 SS

VT126 FLAT WASHER M6 SS

VT127 FLAT WASHER M8 SS

VT206 HEX HEAD SCREW M6-1.0x12 SS

VT229 HEX HEAD SCREW M8-1.25x14 SS

ZZVOL KNOB Ø40 M8 FEMALE

Page 36

THE BIRO MANUFACTURING COMPANY

1114 W. Main Street

Marblehead, Ohio 43440 U.S.A.

Ph. 419-798-4451 Fax 419-798-9106

service@birosaw.com; www.birosaw.com

Loading...

Loading...