Page 1

INSTALLATION

USE AND

MAINTENANCE

MANUAL

B350M

GRAVITY FEED MANUAL SLICER

13-3/4”

NOTE:

This Manual contains important

safety instructions which must

be strictly followed when using

this Slicer.

Page 2

Page 3

THE BIRO MANUFACTURING COMPANY

1114 WEST MAIN STREET

MARBLEHEAD, OHIO 43440-2099 U.S.A.

MODEL B350M

Compliant to NSF/ANSI Standard 8: Commercial Powered Food Preparation

Equipment.

This machine was designed and built to slice food in compliance to the norms

of the 89/392-89/336 Directive and following amendments CE 91/368-93/4493/68 CE, EN 1974 directive 89-109.

#Material and objects destined to the food products contact directive (89/109

CEE) and subsequent modification (2002/72/CEE).

#EN 60204-1 Machines electrical equipments.

#EN 60335-2-64 Particular requisition for kitchen machines.

#UNI EN 1974 Machines for food industries-Slicing Machines

-Security and hygiene features.

1

Page 4

SLICING MACHINES

GRAVITY VERSION

B350M

2

Page 5

SAFETY TIPS

WARNING: SHARP BLADE AND MOVING PARTS!

To Avoid the Risk of Personal Injury, Follow These Safety Tips

When Installing, Using, Cleaning, or Otherwise Maintaining This

Slicer:

1. This slicer uses an extremely sharp blade. ALWAYS keep your hands away

from the edge of this blade, at all times.

2. NEVER use this slicer without reading this manual beforehand, without proper

training or when drowsy or not fully alert.

3. ALWAYS install the slicer on solid level support and only to the

manufacturer’s instructions contained in this manual.

4. ALWAYS connect the slicer to an AC wall socket using the three-pronged

plug provided. Use the ON-OFF to power the slicer. ALWAYS unplug the

slicer when cleaning or moving it.

5. NEVER remove any guards except as provided in this manual.

6. ALWAYS keep hands, arms, wrists, hair, loose clothing and jewelry clear of

all moving parts.

7. ALWAYS STOP using the slicer and unplug it from the power source in any

case of unusual noise, incorrect movement, vibration or other abnormalities.

Consult your equipment repairman or manager IMMEDIATELY.

8. ALWAYS keep Adjustment Thickness Knob in “0” mm position when not

using the slicer

9. ALWAYS use non-slip, cut resistant gloves when using, cleaning or

maintaining the slicer.

10. NEVER use the weight assembly to push the slicer carriage back and forth,

Use the (PUSH HANDLE) for this!

Additional warnings are contained throughout this manual. If any warning label

On the slicer comes off or becomes unreadable, Contact Biro for an immediate

replacement.

3

Page 6

• Warnings affecting your personal safety are indicated by:

WARNING

• Cautions affecting the usefulness or life of the slicer are indicated by:

• Environmental hazards or issues are indicated by:

4

Page 7

TABLE OF CONTENTS

SAFETY TIPS ………………………………………………………………………… 3

TABLE OF CONTENTS.…………………………………………………………….... 5

FOREWARD …………………………………………………………………………... 6

SCOPE OF THIS MANUAL …………………………………………………..….. 6

GENEARL SAFETY RULES …………………………………………………….. 6

LIMITED WARRANTY ……………………………………………………………….. 7

DATA PLATE – COMFORMITY MARKS ………………………………………..…. 8

ENVIRONMENTAL CONDITIONS OF USE ……………………………………..… 8

UNPACKING AND INSTALLATION ……………………………………………..….. 9

OPENING THE BOX ………………………………………………………..……. 9

TECHNICAL DESCRIPTION AND PROPOSED CONDITIONS OF USE …….. 10

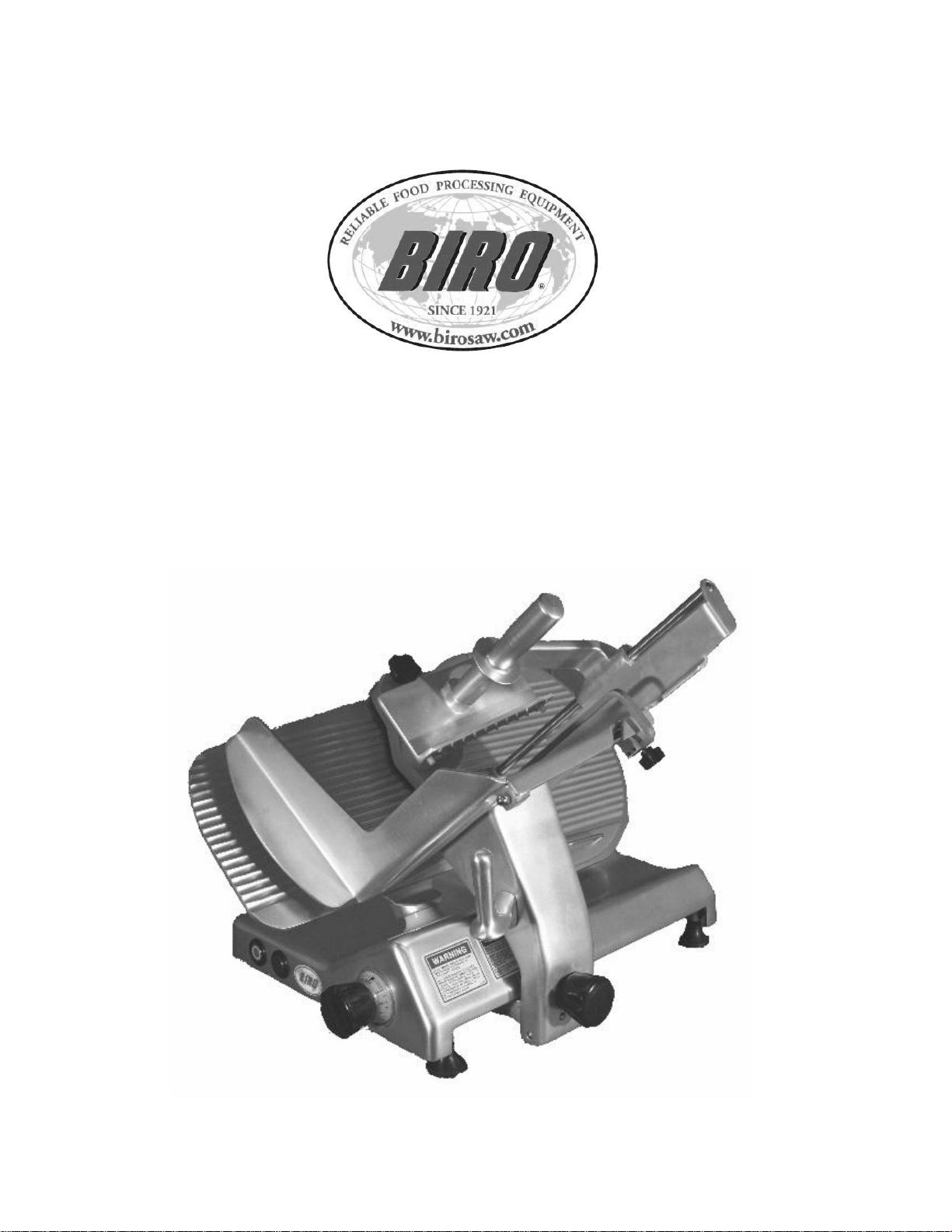

GENERAL DESCRIPTION …………………………………….……………….. 10

DIMENSIONS/MAIN TECHNICAL DATA …………………………………………. 10

MAIN COMPONENTS ………………………………………………………………. 11

INSTALLATION ……………………………………………………………………… 12

INSTALLING THE SLICER …………………………………………………...... 12

ELECTRICAL CONNECTION ………………………………….………………. 12

TEST THE CONTROLS …………………………………………………………….. 12

START AND STOP BUTTONS …………………………………………..……. 12

WARNING LABELS ……………………………………………………...……… 12

SLICE THICKNESS ADJUSTMENT KNOB ………………………………….. 13

SLICER CARRIAGE ……………………………….……………………………. 13

FUNCTIONAL TEST …………………………………………………………….. 13

USING THE SLICER ………………………………………………………………... 14

PRODUCTS THAT CAN BE SLICED …………………………………………. 14

PRODUCTS THAT MUST NOT BE SLICED …………………………………. 14

START AND STOP BUTTONS ………………………………………………… 14

SLICE THICKNESS AND ADJUSTMENT KNOB ……………………………. 14

SLICER CARRIAGE …………………………………………………………….. 14

SLICING ………………………………………………………………………….. 15

CLEANING THE SLICER B350M ………………………………………………….. 16

GENERAL ………………………………………………………………………… 16

DISASSEMBLING THE SLICER FOR CLEANING ………………………….. 16

CLEANING THE SLICER CARRIAGE ………………………………………… 16

SANITIZING INSTRUCTIONS …………………………………………………. 18

REASSEMBLE THE MACHINE …………………………………………………18

SHARPENING THE SLICER …………………………………………...…………….... 19

GENERAL ………………………………………………………………………… 19

MAINTENANCE ……………………………………………………………………...….. 22

GENERAL ………………………………………………………………………… 22

OPERATOR MAINTENANCE ………………………………………………………….. 23

TROUBLESHOOTING AND REMEDIES ……………………………………...……… 24

ELECTRICAL DIAGRAM ……………………………………………………………….. 25

5

Page 8

FOREWARD

SCOPE OF THIS MANUAL

This manual contains information to install, use and service Biro Gravity Slicers for

food products. (Please see models in paragraph “Technical Description”). This

manual designed to permit users, and especially end users, to take the necessary

precautions and procedures to avoid injuring themselves or damaging the equipment

when using, cleaning or maintaining this slicer.

GENERAL SAFETY RULES

The slicer must only be operated by trained, authorized personnel. No one should

use this slicer before reading this manual carefully, and reviewing it contents with

his/her supervisor.

This slicer is designed to comply with all National Sanitation Foundation (“NSF”) and

American National Standards Institute (“ANSI”) requirements. However, you state or

municipality may have additional requirements which must be strictly followed when

using this slicer.

6

Page 9

LIMITED WARRANTY:

WARRANTY: The BIRO Manufacturing Company warrants that the Model B350M

Gravity Feed Slicer will be free from defects in material and workmanship under

normal use and with recommended service. Biro will replace defective parts, which

are covered by this limited warranty, provided that the defective parts are authorized

for return, shipping charges prepaid, to a designated factory for inspection and/or

testing.

DURATION OF WARRANTY: The warranty period for all part covered by this

limited warranty is one (1) year from date of Inspection/Demonstration advised on

the returned Warranty Registration Card, or eighteen (18) months from original

factory ship date, whichever occurs first, except as noted below.

NOT COVERED BY WARRANTY: This limited warranty does not apply to

machines sold as used, rebuilt, modified, or altered from the original construction in

which the machine was shipped from the factory. (Water contaminated electrical

systems are no covered under this limited warranty.) BIRO is not responsible for

electrical connection of equipment, adjustments to switch components or any other

electrical requirements, which must be performed only by a certified electrician.

BIRO is also not responsible for service charges or labor required to replace any

part covered by this limited warranty or for any damages resulting from misuse,

abuse, lack of proper or recommended service.

EXCLUSION OF WARRANTIES AND LIMITATION OF REMEDIES: BIRO gives no

warranties other than those expressly stated in this limited warranty. THE IMPLIED

WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS

FOR PROCESSING OF FOOD PRODUCTS, AND ALL OTHER IMPLIED

WARRANTIES ARE SPECIFICALLY EXCLUDED. BIRO IS NOT LIABLE FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, EXPENSES, OR LOSSES. THE

REMEDIES PROVIDED IN THIS BIRO LIMITED WARRANTY ARE PURCHASER’S

SOLE AND EXCLUSIVE REMEDIES AGAINST BIRO.

REGISTRATION CARDS: You must sign, date and complete the warranty

registration card supplied with each machine. The warranty card must be returned to

The Biro Manufacturing Company for proper registration. If no warranty card is

returned to BIRO, the warranty period will begin from the date the machine is

originally shipped from the factory.

HOW TO GET SERVICE:

1. Contact the entity from whom your purchased the machine; or

2. Consult the yellow pages of the phone directory for the nearest authorized dealer;

or

3. Contact BIRO Mfg. Co. for the authorized service entity (250 plus worldwide) in

your area.

7

Page 10

DATA PLATE – CONFORMITY MARKS

The machine has been constructed in compliance with the European Directive

89/392 and subsequent amendments. All parts used in the machine meet terms of

the Directive and the CE marks have been applied to substantiate this compliance.

The plate carrying the Manufacturer’s data, the machine data and the CE mark are

applied onto the machine base under the blade guard tie-rod knob.

ENVIRONMENTAL CONDITIONS OF USE

- Temperature from 41oF to 104oF

- Relative Humidity max 95%

8

Page 11

UNPACKING AND INSTALLATION

WARNING: SHARP BLADE

To Avoid Risk of Personal Injury,

Keep Hands Away From Blade

While Unpacking Slicer.

OPENING THE BOX

On receipt, check packaging integrity. If packaging is ripped, torn or otherwise

disturbed, inform the shipping agent or your equipment dealer immediately.

To unpack the machine, proceed as follows:

• Open the box, and remove the Installation, Use and Maintenance Manual.

Review the manual, particularly the sections on Unpacking and Installation,

before proceeding to the next step.

• Cut the banding holding the machine to the internal wood support frame and lift

the machine out of the shipping box or container.

• Check the box contents and make sure it corresponds to what is shown on the

external label.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE

ENVIRONMENT !

The packaging components (cardboard, polythene, and others)

are classified as normal solid urban waste and can be

disposed of without difficulty. However, for suitable recycling,

dispose of the packaging materials separately (differentiated

waste)

according to local regulations.

Page 12

9

TECHNICAL DESCRIPTION AND

PROPOSED CONDITIONS OF USE

ENERAL DESCRIPTION

G

The machine is essentially made of a base supporting a circular blade mounted in a

tilted position. This blade is driven by an electric motor to slice food. The machine is

equipped with a carriage,

p, parallel to the blade.

to

a product tray and sliding tracks mounted under the base

Slice thickness is adjusted by a gauge plate mounted in front of the blade. This plate

is moved traversaly with respect to the blade up to the desired slice thickness. When

the slicer is not in use or is being sharpened, the slice thickness knob must be in the

0

or closed position.

0

All the machine components are made of polished and anodized oxidized aluminum

alloy, stainless steel or food grad

otor, powering a grooved belt.

m

e plastic material. The blade is driven by an electric

The machine is started and stopped by control butt

ircuit preventing accidental restarts after an outage.

c

ons provided with an auxiliary

DIMENSIONS / MAIN TECHNICAL DATA

B

IRO MODEL B350M

GRAVITY SLICER

LEGEND US METRIC

MOTOR 1/2 hp 0.35 kw

BLADE DIAMETER 13-3/4” 350 mm

RPM 200 200

SLICE THICKNESS 0 – 1” 0 – 25 mm

MAX CUT ROUND 10” 250 mm

M 12-1/2” X 9” 320 mm X 230 mm AX CUT RECTANGLE

MACHINE LENGTH 18” 460 mm

MACHINE WIDTH 25-1/2” 650 mm

M 440 mm ACHINE HEIGHT 17-1/2”

GROSS WEIGHT 121 lbs. 55 kg.

NET WEIGHT 106 lbs. 48 kg.

CARTON DIMENSION 28” X 32-1/2” X 24-1/2” 710 mm X 830 mm X 620 m

Page 13

10

MAIN COMPONENTS

1. START BUTTON (GREE 10. BLADE

2. STOP BUTTON (RED 11. PUSHER HANDLE

3. THICKNESS KNOB 12. IDENTIFICATION PLA

4. ADJUSTABLE FOOT 13. CARRIAGE HANDLE

5. CARRIAGE P 14. BLADE GUARD

6. FRAME 15. POWER CORD

7. CARRIAGE 16. GAUGE PLATE

8. BLADE GU

. PUSHER

9

SUP ORT ROD

ARD 17. SHARPENER

N)

)

TE

Page 14

11

INSTALLATION

STALLING THE SLICER

IN

Position the slicer on a well-leveled, smooth dry area that is able to hold the weight

of the slicer. Make sure the installation area is open to

bstacles that might interfere with the use of the slicer.

o

LECTRICAL CONNECTION

E

Check to ensure the Start/Stop Button is in the Stop (Off) position and the slice

adjustment knob is set to “0” mm or closed. Insert the three-prong plug supplied

e slicer into an approved socket that meets local building and electrical codes.

th

ALWAYS use the Start/Stop Button to operate the slicer

all mounted or other switch to turn the slicer on or off.

w

The user is responsible for the proper electrical connection to the slic

utlet, distribution panel, circuit breaker or fuse box, grounding, etc.).

o

the operator and free of any

with

. NEVER use a

er (supply line,

Only use 1

with the slicer.

TEST THE CONTROLS

START AND STOP BUTTONS

• Press the green button (1) to start running the blade.

• The power light turns on to indicate the ma

• to stop the blade (2).

Press the red button

WARNING LABELS

• Check to ensure all labe

affixed to the machine.

ls supplied with the slicer are in place and properly

10 volt 60 Hz power source at 15 amps

chine works properly.

12

Page 15

SLICE THICKNESS ADJUSTMENT KNOB

• Rotate the slice thickness adjustment knob counter-clockwise until it reaches its

“thickest” position (25 mm). Rotate the knob clockwise to the “0” mm or closed

position.

•

ALWAYS use the Start/Stop Button to operate the slicer. NEVER use a

wall mounted or other switch to turn the slicer on or off.

SLICER CARRIAGE

• Using the carriage handle, move the carriage back and forth to ensure it moves

smoothly and without obstruction

FUNCTIONAL TEST

• Make sure that the slice thickness adjustment knob is correctly positioned to “0”.

• Draw back the carriage completely (towards the operator) to loading position.

• Lift the pusher by pulling it away (approximately 4” or 10 cm) from the blade, put

the pusher in the rest position.

• Lay the test product to be sliced against the gauge plate on the operator side.

• Secure the pusher by exerting slight pressure.

• Adjust the thickness adjustment knob, Start the blade by pressing the green Start

button. (Make sure power light is illuminated.)

• Grip the handle on the plate and start the forward and backward cutting

movement. The product travels toward the gauge plate by gravity.

• When finished testing the slicer, return the adjustment knob to “0” and pull the

carriage back.

• Stop the blade by pressing the stop button.

13

Page 16

USING THE SLICER

WARNING: SHARP BLADE AND MOVING PARTS!

Keep Hands Away From Blade Edge At All Times!

Review Safety Tips On Page Of This Manual Before Using

This Slicer.

PRODUCTS THAT CAN BE SLICED

• All types of cold cuts (raw, cooked, smoked).

• Meat without bone (raw or cooked, at a temperature not less than 37.4o F (3o C).

• Hard and semi-hard cheese cuts (obviously types that can be sliced such as

gruyere, mozzarella, etc).

PRODUCTS THAT MUST NOT BE SLICED

• Frozen or deep-frozen foods.

• Food containing bones (meat or fish).

• Any other non-food products.

• Soft cheeses.

START AND STOP BUTTONS

• Press the green button (1) to start running the blade.

• The power light turns on to indicate that the machine works properly.

• Press the red button (2) to stop the blade

WARNING LABELS

• Check to ensure all warnings supplied with the slicer are in place and properly

affixed to the machine.

SLICE THICKNESS AND ADJUSTMENT KNOB

• Rotate the slice thickness adjustment knob counter-clockwise until it reaches the

thickness desired.

SLICER CARRIAGE

• Using the handle, move the carriage back and forth to slice the product. If the

slicer carriage does not move smoothly and without obstruction, ????????

14

Page 17

SLICING

• Let the slice fall to the catch tray. NEVER use your hand to collect the slices.

• When the appropriate amount has been sliced, turn the thickness control knob

back to the “0” or closed position and press the STOP button to turn off the slicer.

If sliced food has a torn or shredded appearance, you

will need to sharpen the slicer blade. See page for

instructions.

15

Page 18

CLEANING THE SLICER B350M (1)

WARNING: SHARP BLADE AND MOVING PARTS!

Keep Hands Away From Blade Edge At All Times!

GENERAL

• The machine must always be cleaned carefully at least once a day, and more

often if necessary.

• ALWAYS follow NSF requirements and any applicable state and local regulations

as to the frequency and manner of cleaning and sanitizing.

• ALWAYS use protective gloves when cleaning the slicer.

DISASSEMBLING THE SLICER FOR CLEANING

• Place START/STOP switch in the stop or off position.

• Disconnect the plug from the outlet.

• Turn the slice thickness knob to 00 or the “closed” position.

• Remove the various components.

¾ Unscrew (counterclockwise) the blade guard rod (1).

¾ Remove the blade cover blade (2).

CLEANING THE SLICER CARRIAGE

• Return the carriage to the operator’s start position

• Turn the knob (3) counterclockwise, until loose, the carriage will then drop back

for cleaning (4).

16

Page 19

17

Page 20

• Clean the machine body and the blade using a damp cloth with water and

bidegradeable soapy detergent having 708 pH an at a temperature not below

o

+ 30

C.

SANITIZING INSTRUCTIONS ????

REASSEMBLE THE MACHINE REVERSING THE INSTRUCTIONS ABOVE

18

Page 21

SHARPENING THE SLICER

GENERAL

WARNING: SHARP BLADE AND MOVING PARTS!

Keep Hands Away From Blade Edge At All Times!

• Sharpen the blade periodically to ensure best slices.

• ALWAYS follow NSF requirements and state and local regulations when cleaning

and sharpening the slicer.

• ALWAYS wear protective gloves during sharpening process.

• Clean the blade.

• Assure the sharpener is in the zero position.

19

Page 22

• Turn the thickness knob to the 25mm position.

• Position the meat gauge plate in the middle of its travel.

20

Page 23

• Position the sharpening mechanism in the small recess on the thickness plate.

• Tighten the lock knob.

• Double check the positioning of the sharpener on the thickness plate.

• The START/ON button to start the blade rotating.

• Turn the sharpener dial to Postion 1 and run for 30 seconds. This will sharpen

the rear of the blade.

21

Page 24

• Turn the sharpener dial to position 2 and run for 15 seconds to take the burr off

the front edge of the blade.

• Stop the machine using the STOP/OFF button.

• Remove the sharpener from the slicer.

• Reset the thickness knob to the 00 or closed position.

• Clean the blade.

MAINTENANCE

GENERAL

WARNING: SHARP BLADE AND MOVING PARTS!

To Avoid Serious Personal Injury:

• ALWAYS place the slicer in the STOP/OFF position and remove the plug from

the outlet/power source (before performing any maintenance on the slicer).

• ALWAYS place slicer thickness dial in 00 or closed position (before performing

any maintenance on the slicer).

• ALWAYS wear protective gloves when maintaining the slicer.

• NEVER perform any unauthorized maintenance on the slicer.

22

Page 25

OPERATOR MAINTENANCE

The operator is permitted to perform ONLY the following maintenance on the

slicer:

• Sharpen the blade reguarly, depending on duration of use and type of product

sliced.

• ALWAYS make sure the slicer is cleaned and sanitized whenever used.

• Lubricate the carriage sliding guides weekly as follows:

¾ Use only food grade lubricants. DO NOT USE VEGETABLE OILS

¾ Spread a small quantity of oil on the bar and move the assembly back and

forth 3 or 4 times.

¾ Lubricate the product grip sliding bar weekly.

¾ Clean as required to remove any excess oil.

The following maintenance operations are to be done only by BIRO or

personnel authorized by BIRO:

• Replace the Blade;

Sharpening can be done only up to 0.5 inches of the blade diameter

value. Beyond this point, the BLADE MUST BE REPLACED ONLY by

personnel AUTHORIZED BY BIRO.

• Replace motor transmission belt.

• Replace electrical system components under machine frame.

• Repair structural parts, or components under the frame.

23

Page 26

TROUBLESHOOTING AND REMEDIES

The following table indicates the most common problems that may arise during slicing and

the suggested remedies:

Problem Possible Cause Remedy

The slicer does not start No power supply Ensure the plug is

When the green button The blade guard is not correctly inserted (in

Pressed. correctly positoned. the outlet).

Defective fuse, circuit Check the blade guard.

breaker or circuit. Called a qualified

electrician for technical

assistance.

The slicer does not start; The motor is running on Press the red button

and there is continuous single-phase mode. Immediately, remove

buzzing noise. the power plug from

outlet and call a

qualified electrician for

technical assistance.

The slicer starts, but there Defective motor or Do not use machine.

are vibrations. The motor transmission. Call for technical

is very hot and there is a assistance.

bad smell.

Under strain, the slicer Defective transmission. Call for technical

slows down or comes assistance.

to a stop.

Excessive resistance to The blade is dull. Sharpen the blade.

product slicing, shredding

or tearing.

The slices are ragged The blade is dull. Sharpen the blade.

and/or shaped irregular. The blade is excessively Call for technical

worn out. assistance.

Unsatisfactory blade Worn sharpening stones. Replace sharpening

sharpening. stones. Call for

technical assistance.

The meat carriage Guides are unsufficiently Lubricate.

does not slide. lubricated.

When the red button is Defective electrical Press the red button

pressed the machine control circuit. immediately, remove the

does not stop. power plug from outlet.

Call for technical

assistance.

24

Page 27

ELECTRICAL DIAGRAM

25

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Loading...

Loading...