Page 1

INSTALLATION

USE AND

MAINTENANCE

MANUAL

B 350 A

Page 2

DECLARATION OF CONFORMITY “CE”

(Directive 98/37 cee, attached 2 part A)

WWW.BIROSAW.COM

THE BIRO MANUFACTURING COMPANY, 1114 W. MAIN ST., MARBLEHEAD,

OH 43440-2099 U.S.A.

Model: B 350 A

s/n: ___________________________

Compliant to NSF/ANSI Standard 8: Commercial powered food preparation equipment.

This machine was designed and built to slice food in compliance to the norms

of the 89/392 - 89/336 Directive and following amendments CE 91/368 - 93/44 93/68 CE, EN 1974 directive 89/109.

*Materials and objects destined to the food products contact directive (89/109

CEE) and subsequent modication (2002/72/CEE)

*EN 60204-1 Machines electrical equipments

*EN 60335-2-64 Particular requisition for kitchen machines

Page 3

SLICING MACHINES

AUTOMATIC VERSION

B 350 A

This manual consists of 29 pages as follows:

Title page with notes for the user;•

Contents, page 3;•

Page 4 to page 28 carrying progressive numeration •

Pag. 1

Page 4

Pag. 2

Page 5

Pag. 3

CONTENTS

FOREWORD 4

SCOPE OF THIS MANUAL 4

GENERAL INFORMATION 4

LIMITS OF USE – SAFETY NORMS 4

GENERAL SAFETY REGULATIONS 4

MANUFACTURER’S WARRANTY AND LIABILITY 5

PLATES – CONFORMITY MARKS 5

ENVIRONMENTAL CONDITIONS OF USE 5

PACKING 6

OPENING THE BOX 6

TECHNICAL DESCRIPTION AND PROPOSED CONDITIONS OF USE 7

GENERAL DESCRIPTION 7

MECHANICAL AND ELECTRICAL SAFETY DEVICES 7

WARNING: RESIDUAL RISKS 7

DIMENSIONS 7

MAIN TECHNICAL DATA 7

SUPPLIED LITERATURE AND ACCESSORIES 7

PRODUCTS THAT CAN BE SLICED 7

PRODUCTS THAT MUST NOT BE SLICED 7

DIMENSION MAIN TECHNICAL DATA 8

MAIN COMPONENTS

LAYOUT CONTROL PANEL 8

MACHINE COMMISSIONING AND FUNCTION TESTS 10

INSTALLING THE MACHINE 10

ELECTRICAL CONNECTION 10

COMMANDS 10

USING THE MACHINE 11

LOADING THE PRODUCT ON THE TRAY AND SLICING 11

PROGRAMMING THE MACHINE 15

CLEANING THE SLICER 17

GENERAL 17

DISASSEMBLING THE MACHINE FOR CLEANING 17

CLEANING B 350 A 18

REASSEMBLING THE MACHINE 20

MAINTENANCE 20

GENERAL 20

BLADE SHARPENING 20

SHARPENING 21

LUBRICATION 25

TROUBLESHOOTING AND REMEDIES 26

DISMANTLING THE SLICER 27

ELECTRICAL DIAGRAM 28

RECCOMMENDED SPARE PARTS 29

Page 6

Pag. 4

FOREWORD

SCOPE OF THIS MANUAL

This manual contains all the necessary information to install, use and service the gravity

slicers for food (please see models in paragraph “Technical Description”). The scope of this

document, hereinafter the “manual”, is to permit users, and especially end users, to take all

the cautions and provisions possible for using this machine safely and for a long time.

GENERAL SAFETY REGULATIONS

The slicers must only be used by, suitably trained personnel. Furthermore, they must have

read this manual carefully.

In particular, please comply to the following instructions

• Install the machine according to the instructions contained in the “Installation” section.

• Do not remove the transparent protections, do not modify nor exclude the mechanical and

electrical safety devices.

• Do not use the machine with improvised connections, or provisional or non - insulated

cables.

• Check the power cable and gland plate on the machine body regularly, and when

necessary have them replaced by a qualied personnel.

• In case of abnormalities, defective operation, incorrect movement, unusual noise, etc stop

the machine immediately.

• Before cleaning or servicing, disconnect the machine from the mains.

• Always use scratch proof and non-slip gloves during cleaning or maintenance.

• Lay or remove the goods to be sliced on the sliding plate only when the latter is

completely pushed back and the thickness control knob is positioned to 0.

• To move the carriage tray when slicing, use the handle or the product grip handle.

• For extraordinary maintenance (to replace the sharpener wheels, the blade, or others)

please contact the manufacturer or qualied and duly authorized personnel.

• Avoid running the slicers with no product on it

• The slicers are equipped with a ventilated motor

• WARRANTY: 1 YEAR except for the electrical parts

Page 7

Pag. 5

MANUFACTURER’S WARRANTY AND LIABILITY

B300M

The manufacturer’s warranty covering the functioning of the machines and their compliance to the service for which they have been designed depends on the correct application of

the instructions contained in this manual.

The Manufacturer assumes no liability either direct or indirect deriving from:

• Failure to comply with the instructions contained in this manual;

• Use of the machine by personnel who has not read or fully understood the content of this

manual

• Use not complying to the specic norms currently applicable in the country of installation

• Unauthorized modications and/or repairs

• Use of non original accessories or spare parts.

• Exceptional events.

PLATES – CONFORMITY MARKS

The machines have been constructed in compliance with the European Directive 89/392

and subsequent amendments. All the parts used in the machine meet the terms of the

Directive and the CE marks have been applied to substantiate this compliance.

The plate carrying the Manufacturer’s data, the machine data and the CE mark are applied

onto the machine base under the blade guard tie-rod knob.

In case of wear or damage, the user must replace it.

ENVIRONMENTAL CONDITIONS OF USE

- Temperature from -5 °C to + 40 °C

- Relative humidity max 95%

Page 8

Pag. 6

PACKING

OPENING THE BOX

On receipt, check packaging integrity, otherwise inform the forwarding agent or the area

agent immediately.

To unpack the machine, proceed as follows:

• Open the box and remove your copy of the manual of use and maintenance, then

proceed according to the instructions found in that manual;

• Lift the machine still wrapped in a transparent polyethylene sheet and extract it from the

box

• Now check the box contents and make sure it corresponds to what is shown on the

external label.

WARNING:

The packaging components (cardboard, polyethylene, and others) are classied as normal

solid urban waste and can therefore be disposed of without difculty. In any case, for suitable

recycling, we suggest disposing of the products separately (differentiated waste) according

to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

Page 9

Pag. 7

TECHNICAL DESCRIPTION AND PROPOSED CONDITIONS OF USE

GENERAL DESCRIPTION

The machine is essentially made of a base supporting a circular blade mounted in tilted

position. This blade is driven by an electrical motor to slice food. The machine is equipped

with a carriage holding a product tray and sliding on tracks mounted under the base top,

parallel to the blade.

Slice thickness is adjusted by means of a gauge plate mounted in front of the blade. This

plate, against which rests the product to be sliced is moved transversally with respect to

the blade by a value corresponding to the desired slice thickness. The product is fed to the

machine (towards the gauge plate) by gravity.

All the machine components are made of polished and anodized oxidized aluminum alloy,

of stainless steel and food grade plastic material.

The blade is driven by an electrical motor, transmission is by means of a longitudinally

grooved belt.

The machine is started and stopped by a control button provided with auxiliary circuit preventing accidental restarts after an outage.

Some of the machine models have a user-friendly and safe built-in blade sharpener.

MECHANICAL AND ELECTRICAL SAFETY DEVICES

The following mechanical safety devices were installed:

• A series of aluminum and transparent plastic guards on the product carriage.

The following electrical safety devices were installed:

• Start/stop button system requiring a voluntary restart of the machine in the case of an

outage or interruption of the power supply.

• Safety micro-switch preventing the motor from starting when the blade guard is removed

(not on the CE VERSION).

PRODUCTS THAT CAN BE SLICED

All types of cold cuts (raw, cooked, smoked);•

Meat without bone (raw or cooked, at a temperature not less than + 3 °C;•

Cheese cuts (obviously types that can be sliced such as gruyere, fontina, etc.).•

PRODUCTS THAT MUST NOT BE SLICED:

Frozen or deep-frozen food•

Food containing bones (meat or sh)•

Any other non-food product •

WARNING: RESIDUAL RISKS

Not with standing all the possible cautions taken during the design and the construction of the machine, residual risks (cutting) still exist during use or during

cleaning or maintenance. Therefore be careful and PAY THE UTMOST ATTENTION to

what you are doing.

DO NOT use the machine if you are not in perfect psychological and physical conditions. DO NOT ALLOW anyone near the machine when it is in use. ALWAYS wear

gloves that can resist cuts or tears when cleaning, lubricating or sharpening the

blade.

Slice only the products mentioned as sliceable. NEVER try to slice products that

have been mentioned as non sliceable.

Page 10

Pag. 8

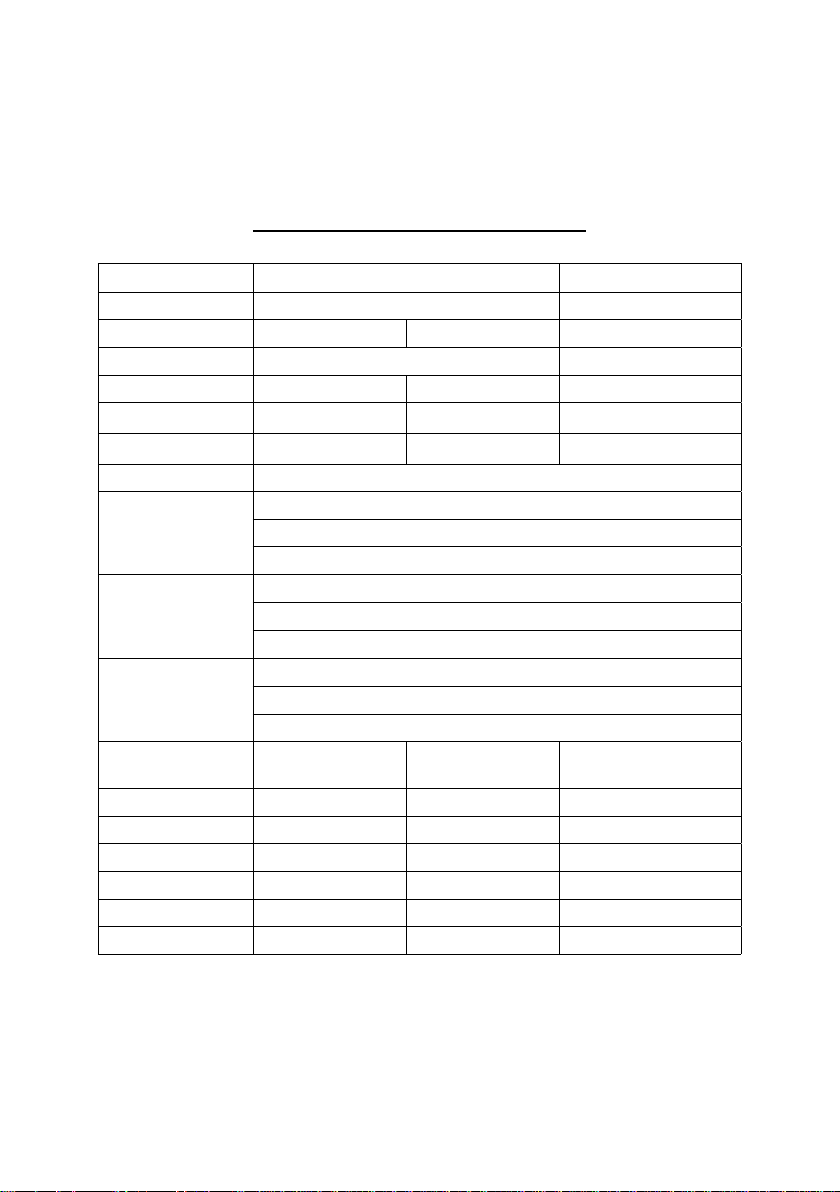

DIMENSIONS MAIN TECHNICAL DATA

AUTOMATIC GRAVITY SLICERS

MODEL B 350 A MODEL

motor Kw 0,35 motor Kw

blade diam 14" 350 blade diam

rpm 200 rpm

slice thicness 0 - 1" 0 - 25 slice thicness

max cut

max cut

Cutting Speed

Speed Min

Speed Medium

Speed Max

dimensions

gross weight - Lbs 121 Lbs 55 gross weight - Kg

net weight - Lbs 106 Lbs 48 net weight - Kg

box dimensions 28"x32,5"x24,5" 710x830x850 box dimensions mm

ס

□

Overall

lenght 18" 460 lenght

width 25,5" 650 width

height 18" 455 height

10" 250

12,5"x9" 320x230

48 with min stroke

56 with medium stroke

60 with large stroke

40 with min stroke

45 with medium stroke

50 with large stroke

38 with min stroke

45 with medium stroke

50 with large stroke

dimensions - mm

max cut mm

max cut mm

Overall

ס

□

Page 11

Pag. 9

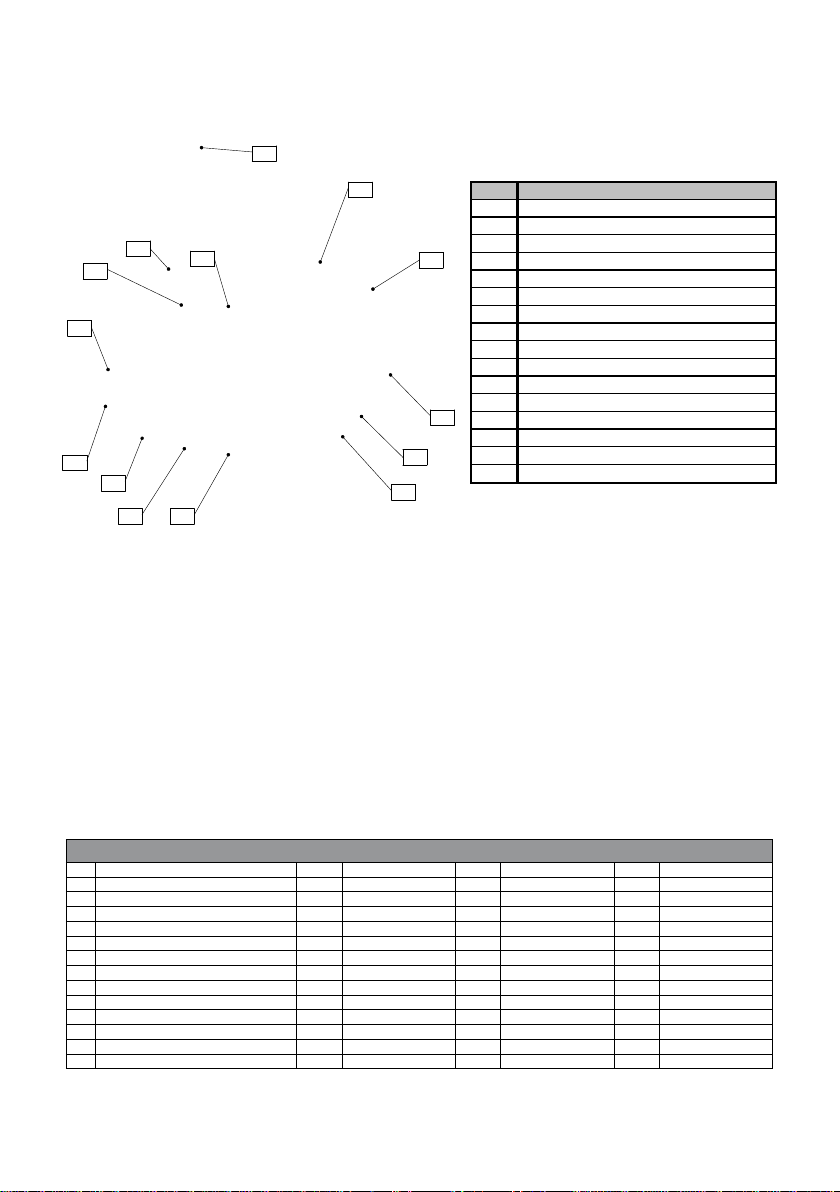

MAIN COMPONENTS gravity version

8

1

2

10

3

6

14

7

11

5

13

9

4

12

CODE DESCRIPTION

1 CONTROL PANEL

2 THICKNESS KNOB

3 CARRIAGE SUPPORT

4 FRAME

5 CARRIAGE

6 BLADE GUARD

7 GAUGE PLATE

8 BLADE

9 PUSHER HANDLE

10 MANUFACTURER

CODE DESCRIPTION

1 CONTROL PANEL

2 THICKNESS KNOB

3 CARRIAGE SUPPORT

4 FRAME

5 CARRIAGE

6 BLADE GUARD

7 GAUGE PLATE

8 BLADE

9 PUSHER HANDLE

10 MANUFACTURER

IDENTIFICATION PLATE

MACHINE DATA AND UE MARKS

11 CARRIAGE HANDLE

12 BLADE GUARD ROD

13 LIFT/CLEANING HANDLE

14 SHARPENER

1 START SWITCH

2 STOP SWITCH

3 SPEED MIN 48 with min stroke 40 with medium stroke 38 with large stroke

4 SPEED MEDIUM 56 with min stroke 45 with medium stroke 45 with large stroke

5 SPEED MAX 60 with min stroke 50 with medium stroke 50 with large stroke

6 STROKE 150 mm

7 STROKE 250 mm

8 STROKE 350 mm

9 AUTO CARRIAGE START

10 AUTO CARRIAGE STOP

11 COUNTER +

12 COUNTER 13 COUNTER DISPLAY

14 AUTOMATIC START/STOP MECHANISM

CONTROL PANEL

Page 12

Pag. 10

MACHINE COMMISSIONING AND FUNCTION TESTS

INSTALLING THE MACHINE

Position the machine on a well leveled, smooth and dry top suitably dimensioned to withstand the machine weight.

ELECTRICAL CONNECTION

Install the machine near a compliant outlet derived from a system meeting the current

norms.

The user is responsible for ascertaining that the electrical system is suitably dimensioned

and functions correctly (supply line, outlet, distribution panel, differential protecting breaker,

grounding).

Before carrying out the connection ascertain that the mains characteristics correspond to

those indicated on the machine plate.

COMMANDS

START AND STOP BUTTONS

Press the green button (1) to start running the blade.•

The light turns on to indicate that the machine works correctly.•

Press the red button to stop the blade (2).•

Slice thickness can be adjusted by turning the graduated knob (3) anti clockwise.

Thickness adjustment range: see paragraph "Technical description and conditions of

use”.

FUNCTIONING TEST AND BLADE ROTATION DIRECTION

Start the machine and check whether the light is on; make sure that the blade rotates in the

direction indicated by the arrow (anti clockwise if you look at the machine from the blade

plate side).

Ascertain that the carriage and the pusher slide correctly;•

Ascertain that the gauge plate works and adjust thickness to desired value. •

Page 13

Pag. 11

USING THE MACHINE

LOADING THE PRODUCT ON THE TRAY AND SLICING

Lift the gripper arm

Lock the gripper arm into the rest position as shown in photo B

Page 14

Pag. 12

Unscrew the fence retaining knob and slide the fence in to the outer position

1. Load the product on to the meat platform

2. Slide the fence against the product

3. Lock the fence in place rmly using the locking knob

Page 15

Pag. 13

Locate the gripper arm onto the product

Select the thickness of the product to be sliced using the portion thickness control knob

Page 16

Pag. 14

1 START SWITCH

2 STOP SWITCH

3 SPEED MIN 48 with min stroke 40 with medium stroke 38 with large stroke

4 SPEED MEDIUM 56 with min stroke 45 with medium stroke 45 with large stroke

5 SPEED MAX 60 with min stroke 50 with medium stroke 50 with large stroke

6 STROKE 150 mm

7 STROKE 250 mm

8 STROKE 350 mm

9 AUTO CARRIAGE START

10 AUTO CARRIAGE STOP

11 COUNTER +

12 COUNTER 13 COUNTER DISPLAY

14 AUTOMATIC START/STOP MECHANISM

Control panel

CONTROL PANEL

To activate the automatic slicing action pull the knob located at the front of the machine

towards youIf manual slicing is required push the knob in toward the machine.

If the automatic slicing action is not connected, ALARM 01 will ash.

Page 17

Pag. 15

Push the green button to start the machine running

Programming the machine:

1.The machine can be programmed to slice a set number of slices

automatically and then stop

a) If the display shows 00 the machine will continuously run until

stopped by the operator

b) Set the display e.g. 12 on the counter using the + key, the machine will

then slice 12 portions and then stop.

Page 18

Pag. 16

Speed & Stroke Programming:

Speed:

There are 3 speed settings on the machine using the > key, select

> >> or >>> to increase or decrease the speed

Stroke: Dependent on the size of the product that is to be sliced, the ma-

chine can be programmed more efciently using the stroke keys

e.g. The small black circle is ideal for salami and sausage type products

etcThe medium black circle is ideal for cheese etc

The large black circle is ideal for full hams, beef etc

SPEED MIN

SPEED MEDIUM

SPEED MAX

STROKE MIN

STROKE MEDIUM

STROKE LARGE

Press the 1 key to operate the machine in the programme that is set

Page 19

Pag. 17

CLEANING THE SLICER

GENERAL

The machine must always be accurately cleaned at least once a day, and more often if

necessary.

Always use protective gloves.

DISASSEMBLING THE MACHINE FOR CLEANING

• Disconnect the plug from the mains;

• Turn the gauge plate to ‘0’;

• Remove the various components as described in the following paragraphs:

• Unscrew (anticlockwise) the blade guard rod (ref. 1);

• Remove the blade guard using for this operation only cover handle (ref. 2).

• Remove the slice guard.

To clean the machine body and the blade use only a cloth damped with water and

biodegradable lathery detergent having 7-8 pH and at a temperature not below +

30°C.

Do not clean the machine by using water or vapor spruìys or similar systems.

WARNING:

Use scratch-proof and non-slip gloves to carry out the following operations.

Proceed carefully and pay attention to what you are doing.

Danger of cutting!

Page 20

Pag. 18

CLEANING THE SLICER UNI 350 G-A (2: UP SETTING PLATE)

• Stop the machine, rotate the adjustable knob to regulate the gauge plate and position it

on 0 (1)

• Return the carriage to the operators side (2)

• Turn the knob (3) anti clockwise, until loose, the carriage will then drop back for cleaning

(4).

1

2

3

4

Page 21

Pag. 19

(1) Hold the Lever

(2) Lift the Machine

Page 22

Pag. 20

REASSEMBLING THE MACHINE

Proceed as indicated for the previous operations but in reverse order.

MAINTENANCE

GENERAL

The operator is allowed to perform the following maintenance operations:

• Blade sharpening: regularly (intervals and duration obviously depend on the use of the

machine, time of use and type of product sliced);

• Lubrication of product grip sliding bar: once a week.

• Checking the power supply cord conditions and the gland plate: from time to time.

WARNING

Maintenance must always be carried out when the machine is disconnected from the

mains.

Always make sure that the adjustable knob is in the “O” position

The following maintenance operations are to be entrusted only to personnel authorized by

the manufacturer:

• Replacing the blade;

• Replacing the sharpener stones;

• Replacing the motor transmission belt;

• Replacing electrical system components under the machine base;

• Repairing structural parts, repairing the components under the base.

BLADE SHARPENING

Before proceeding, clean the machine accurately as explained in the previous paragraphs:

WARNING

Sharpening can be done only up to 12 mm of the blade diameter value.

Beyond this value, the BLADE MUST BE REPLACED ONLY by personnel AUTHORIZED BY THE MANUFACTURER.

Page 23

Pag. 21

SHARPENING B 350 A

Versions with separated sharpener

To sharpen the blade periodically as soon as the cutting capacity decreases. Please proceed

as per the following instructions:

1) CLEAN THE BLADE

2) ASSURE THE SHARPENER IS AT ZERO POSITION

Page 24

Pag. 22

3) MOVE THICKNESS REGULATOR TO THE 25mm POSITION

ONCE THE GAUDE PLATE IS OPENED AT MAX POSITION, THE AUTOMATIC

MOUVEMENT DOESN'T RUN, IN ORDER TO PERMIT THE SHARPENING

002 ALARM WILL FLASH

4) THIS OPENED THE BLADE TO THE DESIRED POSITION READY FOR POSITIONING

THE SHARPENER.MEAT PLATE POSITIONED IN THE MIDDLE.

Page 25

Pag. 23

5) THE SMALL RECESS ON THE GAUGE PLATE IS FOR THE POSITIONING OF THE

SHARPENING MECHANISM.

PLACE SHARPENING MECHANISM ONTO PLATE.

6) VERIFY POSITION

Page 26

Pag. 24

7) START BLADE ROTATING

8) TURN DIAL TO POSITION 1. THIS WILL SHARPEN THE REAR OF THE BLADE.

RUN FOR 15 SECONDS, TURN DIAL TO POSITION 2 FOR 5 SECONDS. THIS WILL

TAKE THE BURR OF THE FRONT SURFACE OF BLADE

9) STOP MACHINE. REMOVE SHARPENER AND CLEAN BLADE BEFORE

USING THE MACHINE AGAIN.

Page 27

Pag. 25

LUBRICATION

Carriage sliding guides product grip (once a week)

Use only the oil provided, otherwise use white Vaseline oil.

DO NOT USE VEGETABLE OILS.

• Spread a small quantity of oil on the bar and move the assembly 3 or 4 times.

• Clean as required to remove excess of oil.

Page 28

Pag. 26

TROUBLESHOOTING AND REMEDIES

The table below indicates the most common problems that may arise during slicing and the

necessary remedies.

PROBLEM POSSIBLE CAUSE REMEDY

The machine does not start

when the green button is

pressed

The machine does not start,

and there is continuous

noise like a buzz (only in the

case of machines equipped

with three-phase motors.

ALARM 01 Automatic mechanism not

ALARM 02 Once the gaude plate is

When the green button is

pressed, the machine starts,

but the white functioning

light is not on.

The machine starts, but

there are vibrations. The

motor is very hot and there

is a bad smell.

Under strain, the machine

slows down or comes to a

stop.

Excessive resistance to

product slicing.

The slices are ragged and/or

shaped irregularly

Unsatisfactory blade shar-

pening

The product tray does not

slide

When the red button is

pressed, the machine does

not stop

No power supplyThe blade

guard is not correctly positioned.Defective electrical

control circuit.

The motor is running on

single-phase mode

connected

opened at max position, the

automatic mouvement doesn't run, in order to permit

the sharpening

Defective indicator Do not use the machine

Defective motor or transmission.

Defective transmission Call technical assistance

The blade is blunt Sharpen the blade

The blade is bluntThe blade

is excessively worn out

Worn wheels Replace the wheels. Call

Guides are insufciently

lubricated

Defective electrical control

circuit

Ascertain that the plug is

correctly inserted. Check

Call technical assistance

Press the red button immediately and have the power

supply cord and the circuits

upstream veried by quali-

ed personnel.

when the pilot lamp is not

on. Call technical assistance

Do not use the machine.

Call technical assistance.

Sharpen the bladeCall technical assistance

technical assistance

Lubricate

Stop the machine, unplug

from mains and call technical assistance

Page 29

Pag. 27

DISMANTLING THE SLICER

These machines are made of the following elements:

• Aluminum frame;

• Stainless steel ttings and others;

• Electrical parts and cords;

• Electrical motor;

• Plastic materials, etc.

Whether dismantling is entrusted to third parties or done in-house (in that last case you will

have to separate the various materials) please note that disposal of the materials can only

be carried out by duly authorized businesses.

In any case, please comply to the current norms of your country.

WARNING

In any case, to remove the blade and dispose of it, you must contact the

manufacturer or personnel duly authorized by the manufacturer.

NEVER DISPOSE OF WASTE IN AREAS WHERE ACCESS IS NOT

DELIMITED BY BARRIERS AND FORBIDDEN BY WARNING SIGNS AS THIS

WASTE REPRESENTS A SERIOUS DANGER, ESPECIALLY FOR CHILDREN

AND ANIMALS. ANY RESPONSIBILITY ARISING OUT OF INCORRECT

DISPOSAL FALLS ON THE OWNER.

Page 30

Z9MAF

Sharpening stone

Z9MSB

Cleaning stone

ABM COMPANY

UNI 350 G AUTO

Automatic Slicer

Recommended Spare Parts

Z9PIE

Foot

AF01US

Sharpening assembly

G111

Water-ring protection

Z5L3G

Blade

GG5CIN

Trasmission Belt

01

Page 31

ABM COMPANY

UNI 350 G AUTO

Automatic Slicer

118

119

121

38

39

36

1

2

G122

F9331500

G102

Z8BCN

CODE DESCRIPTION Q,TY

F9331500 SPRING d 10 L 55 1

G0170 ROD - INDEX SLIDE 1

G102 SLIDE - INDEX MECHANISM 1

G110 ROD - INDEX ANTI ROTATION 1

G119C SLIDE ROD - 25 x 578 1

G122 PIN - INDEX CAM 1

W6CUS SS BEARING 6000 ZZ 10 x 20 X 6 1

X0180C SS BAR - TRANSPORT ROLLER 1

X0270 BEARING PING 10 x 30 M6 1

X0290 GUIDE - INDEX MECHANISM 1

X0560 SS FOOT SPACER 25 x 44 M8 2

Z8BCN BUSHING 20 23 20E 2

Z9PIE FOOT 4

Z8BCN

X0290

G9361

G0170

Complete Assembly

W6CUS

X0270

G110

SLIDE INDEX COMPLETE ASSEMBLY

G9361

02

Page 32

ABM COMPANY

UNI 350 G AUTO

Automatic Slicer

8

5

9

6

4

7

11

3

12

15

16

14

17

1

10

CODE DESCRIPTION Q,TY

C2032 MEAT GRIP HOLDER 1

C2041 MEAT GRIP 1

C2080 BUSHING 2

C2091 HANDLE ASSY 1

F9321500 KNOB - LOCKING FENCE ASSEMBLY 1

G0122 CARRIAGE TRAY 1

G0124 SLIDE ROD ASSY 1

G0160A HANDLE 1

G103 SUPPORT - TRAY ASSY 1

G118 KNOB SHAFT 1

G127 FENCE SHAFT 1

G9362

X0360 ALU KNOB 1

G121 HANDLE - CARRIAGE 1

Z9MBP KNOB - SUPPORT TRAY 1

FENCE ASSEMBLY

2

03

Page 33

28

ABM COMPANY

UNI 350 G AUTO

Automatic Slicer

14

12

13

11

10

9

4

3

11

15

14

27

20

21

4

1

28

27

24

8

6

5

22

2

1118

23

1119

14

22

CODE DESCRIPTION Q,TY

C2032 MEAT GRIP HOLDER 1

C2041 MEAT GRIP 1

C2080 BUSHING 2

C2091 HANDLE ASSY 1

F9321500 KNOB - LOCKING FENCE ASSEMBLY 1

G0122 CARRIAGE TRAY 1

G0124 SLIDE ROD ASSY 1

G0160A HANDLE 1

G103 SUPPORT - TRAY ASSY 1

G118 KNOB SHAFT 1

G127 FENCE SHAFT 1

G9362

X0360 ALU KNOB 1

G121 HANDLE - CARRIAGE 1

Z9MBP KNOB - SUPPORT TRAY 1

FENCE ASSEMBLY

04

Page 34

ABM COMPANY

UNI 350 G AUTO

Automatic Slicer

CODE DESCRIPTION Q.TY

G100 FRAME 1

G101 GAUGE PLATE 1

G105B RING STUDBOLT 1

G111 W ATER RING PROTECTION 1

G112 RING - GAUGE PLATE 1

G117 SPACER - PROTECTION RING 2

G120 KNIFE RING 1

G124 CAM - INEXING 25 mm 1

G125 BLADE GUARD ROD 1

G9364

X0080 SPACER - CAM 1

X0280 BUS HING 1

X0360 KNIFE G UA RD 1

X0491 HANDLE - COV E R B LA DE 1

Z3ATQ KNIFE GUARD LOCKING SCREW 1

Z5L4G K NIFE 350 m m 14" 1

Z8MGR K NOB - INEXING 1

Z9GHI KNOB SPACER 1

ZZVOL KNOB - BLADE GUARD ROD 1

BLADE GUARD ROD - ASSEM BLY

05

Page 35

ABM COMPANY

UNI 350 G AUTO

Automatic Slicer

M9372

115/60 Hz

IP65

X0060

X0070

M9314

M9313

M9310

M9315

W6CUS

G5CIN

W6CUS

W2CUS

G109

G106

G108

W2CUS

Motor Assembly

A62GM

115/60Hz

IP65

CODE DESCRIPTION Q.TY

A62GM

G106 PULLEY B 350 M 1

G108 SHAFT - KNIFE 25 x 97 1

G109 SPACER 1

G5CIN BELT 2350/2370 G TB2 11 x 400 1

M9310 PIN 10 x 22 1

M9313 SPRING PIN 5 x 25 1

M9314 BEARING TENS. SPRING 1

M9315 BEARING PIN 1

M9372 MOTOR - IP 65 115 VOLT 60 Hz 1

W2CUS SS TRANSMISSION BEARING 2

W6CUS SS BEARING 6000 ZZ 10 x 20 X 6 2

X0060 CAP SCREW 1

X0070 LOCKWASHER 1

MOTOR ASSEMBLY IP 65

06

Page 36

ABM COMPANY

UNI 350 G AUTO

Automatic Slicer

Complete Assembly

CODE DESCRIPTION Q.TY

GRSTA

W3CON CAPACITOR 20 Mf 1

X0710 ELECTRIC BOX - BASE 1

X0720 PLASTIC COVER 1

Z9PLA START SWITCH - IP 69 1

Z9PLH STOP SWITCH - IP 69 RED 1

Z9KAP SWITCH PROTECTION 2

Z9TCA CARD 115/60Hz - 1

COMPLETE CONTROL BOX

Page 37

AF01US

ABM COMPANY

UNI 350 G AUTO

Automatic Slicer

AF008

Z9MSB

AF006

AF033

Complete Assembly

AF038

AF039

AF011

Z9MAF

AF008

AF023

AF022

ZZVOL

AF006

AF0020

AF022

AF034

AF035

AF036

AF040

AF039

AF022

AF038

CODE DESCRIPTION DESCRIZIONE Q.TY

AF006 SHAFT - SHARP + CLEANING STONE ALBERO MOLA 2

AF008 NUT - SPECIAL DADO 2

AF011 SPRING - CLEANING STONE MOLLA ALBERO MOLA 1

AF01US

AF020 SPRING - SHARPENING STONE MOLLA ALBERO MOLA 1

AF022 SCREW - PLAST IC VITE 3

AF023 SCREW - MAIN GUIDE - PLASTIC VITE PLASTICA 1

AF033 ARM AGGANCIO 1

AF034 HOUSING - CORPO AFFILATOIO 1

AF035 SHARPENER CAM CAMMA 1

AF036 KNOB - SHARPENER MANOPOLA 1

AF038 WASHER - PLASTIC RONDELLA 2

AF039 RING - RETAINER - UNI 7434 ANELLO 2

AF040 SCREW - TC 5 x 10 VITE 2

Z9MAF STONE - SHARPENING MOLA 1

Z9MSB CLEANING STONE MOLA 1

ZZVOL KNOB - BLADE G. + SHARPENER VOLANTINO 1

SHARPENER - COMPLETE ASSEMBLY AFFILATOIO COMPLETO

08

Page 38

M9373

MONO-PHASE

ABM COMPANY

UNI 350 G AUTO

Automatic Slicer

Motor Assembly

A63GM

Z9SCH

MONO-PHASE

Mono-Phase

Complete Assembly

Z3CON

GRSTS

MONO-PHASE

220V-50Hz

CODE DESCRIPTION Q.TY

A63GM

GRSTS

M9373 MOTOR - IP 65 - 220/50 Hz IP 65 1

Z9SCH CARD 220/50 Hz 1

Z3CON CAPACITOR 10 Mf 1

MOTOR ASSEMBLY IP 65 220 - 50Hz

COMPLETE CONTROL BOX 220/50 Hz

09

Page 39

Factory:

WWW.BIROSAW.COM

THE BIRO MANUFACTURING COMPANY, 1114 W. MAIN ST., MARBLEHEAD,

OH 43440-2099 U.S.A.

Loading...

Loading...