Page 1

+

IMPORTANT NOTICE

+

This Manual contains important

safety instructions which must

be strictly followed when using

this equipment.

AFMG-48

138-9-05-12

AFMG-48

138-4-08-13

Page 2

— NOTES —

Page 3

TABLE OF CONTENTS

Page

NOTICETOOWNERSANDOPERATORS......................................... 1

SAFETYTIPS............................................................... 2

INSTALLATION ............................................................. 3

UNCRATINGANDSETUP................................................ 3

MOTOR WIRING AND ELECTRICAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . 4

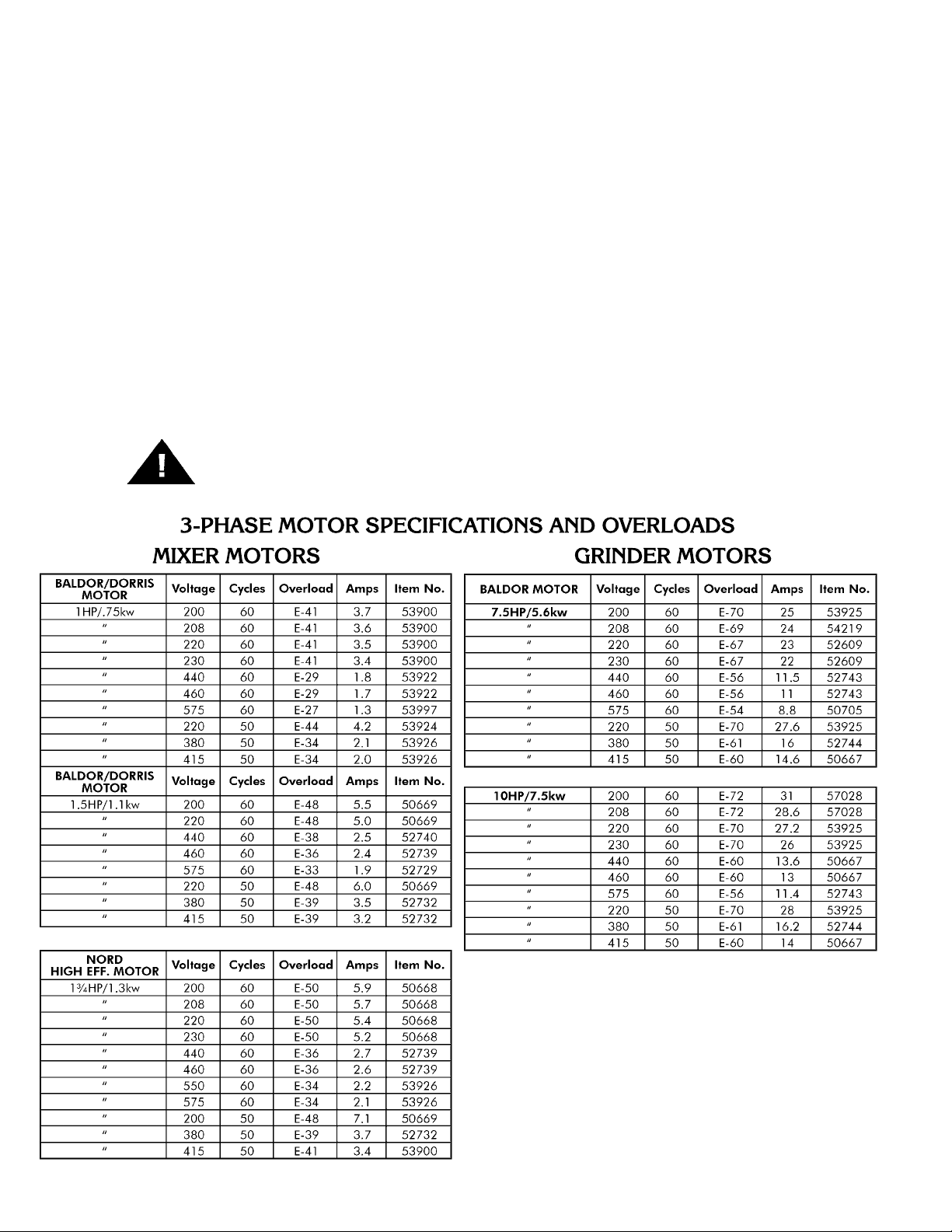

MOTORSPECIFICATIONS ............................................... 4

OPERATION................................................................ 6

TOPROCESSPRODUCT ................................................ 6

CLEANING................................................................. 7

MAINTENANCE ............................................................. 8

GRINDINGBOWLINSTALLATION ......................................... 8

MIXINGPADDLEINSTALLATION.......................................... 8

LUBRICATION.................................................... 8,9,10

NORD TRANSMISSION MAINTENANCE & LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . 9

DORRIS TRANSMISSION MAINTENANCE & LUBRICATION . . . . . . . . . . . . . . . . . . . . . . 10

MIXERDRIVEBELTTENSION.............................................10

MAIN DRIVE CHAIN AND SPROCKET LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . 10

MAINDRIVECHAINTENSION.............................................11

CHAINREPLACEMENT..................................................11

WIRINGDIAGRAMS ..........................................................12

NOTES....................................................................13

PARTSDIAGRAMS.....................................................14,15,16

OPTIONAL STAINLESS STEEL BOWLS, AUGERS & END RINGS

(114mmUNGER&ENTERPRISE)..........................................15

PRODUCTMIXERSAFETYCOVERS&LIDLOCKS ............................17

DORRISMIXERTRANSMISSIONPARTSLIST.................................18

JOURNALBOX........................................................19

ELECTRICFOOTSWITCH................................................19

ITEMS REQUIRED FOR TANDEM OPERATION TO S/N 63591 . . . . . . . . . . . . . . . . . . . . . . 20,21

ITEMS REQUIRED FOR TANDEM OPERATION AFTER S/N 63592 . . . . . . . . . . . . . . . . . . . 22,23

CONNECTION INSTRUCTIONS FOR TANDEM OPERATION . . . . . . . . . . . . . . . . . . . . . . . 23,24

SAFETYLABELLOCATIONS...................................................25

OPERATOR'SSIGNATUREPAGE................................................26

NOTES....................................................................27

LIMITEDWARRANTY.........................................................28

PARTSDIAGRAMS.....................................................14,15,16

OPTIONAL STAINLESS STEEL BOWLS, AUGERS & END RINGS

(114mmUNGER&ENTERPRISE)..........................................15

PRODUCTMIXERSAFETYCOVERS&LIDLOCKS ............................17

DORRISMIXERTRANSMISSIONPARTSLIST.................................18

JOURNALBOX........................................................19

ELECTRICFOOTSWITCH................................................19

ITEMS REQUIRED FOR TANDEM OPERATION TO S/N 63591 . . . . . . . . . . . . . . . . . . . . . . 20,21

ITEMS REQUIRED FOR TANDEM OPERATION AFTER S/N 63592 . . . . . . . . . . . . . . . . . . . 22,23

CONNECTION INSTRUCTIONS FOR TANDEM OPERATION . . . . . . . . . . . . . . . . . . . . . . . 23,24

SAFETYLABELLOCATIONS...................................................25

OPERATOR'SSIGNATUREPAGE................................................26

NOTES....................................................................27

LIMITEDWARRANTY.........................................................28

PARTS DIAGRAMS ....................................................13, 14, 15

PRODUCT MIXER SAFETY COVERS & LID LOCKS

STANDARD & OPTIONAL STAINLESS STEEL BOWLS,

AUGERS & END

RINGS (114mm UNGER & ENTERPRISE..................17

........................ 16

Page 4

— NOTES —

Page 5

BIRO’s products are designed to process food products safely and efficiently. Unless the operator is properly trained and supervised, however, there is the possibility of a serious injury. It is the

responsibility of the owner to assure that this machine is used properly and safely, strictly following

the instructions contained in this Manual and any requirements of local law.

No one should use or service this machine without proper training and supervision. All operators should be thoroughly familiar with the procedures contained in this Manual. Even so, BIRO

cannot anticipate every circumstance or environment in which its products will be used. You, the

owner and operator, must remain alert to the hazards posed by the function of this equipment —

particularly the ROTATING GRINDING AUGER and the ROTATING MIXING PADDLE, which can

severely injure an inattentive operator amputating fingers and limbs. No one under eighteen (18)

years of age should operate this equipment. If you are uncertain about a particular task, ask your

supervisor.

This Manual contains a number of safe practices in the SAFETY TIPS section. Additional warnings are placed throughout the Manual. Warnings related to your personal safety are indicated by:

Warnings related to possible damage to the equipment are indicated by:

BIRO also has provided warning labels on the equipment. If any warning label or Manual becomes misplaced, damaged, or illegible, please contact your nearest Distributor or BIRO directly

for a replacement.

Remember, however, this Manual or the warning labels do not replace the need to be alert and

to use your common sense when using this equipment.

This Manual applies to machines with serial number 62001 and higher, to machines with tri-directional product mixer safety cover and 35 degree inlet, serial number 63592 and higher.

THE BIRO MANUFACTURING COMPANY

MARBLEHEAD, OHIO 43440-2099 U.S.A.

FAX (419) 798-9106

Phone (419) 798-4451

1

NOTICE TO OWNERS AND OPERATORS

OR

– NOTE –

A copy of this manual is included with each AFMG-48 MIXER GRINDER.

The descriptions and illustrations contained in this manual are not binding.

The manufacturer reserves the right to introduce any modification

without updating the manual.

Page 6

SAFETY TIPS

ROTATING GRINDING AUGER & ROTATING MIXING PADDLE

TO AVOID SERIOUS PERSONAL INJURY

· NEVER Touch This Machine without Training and Authorization by Your Supervisor.

· NEVER Place Hands into Machine Input or Output Openings.

· NEVER Open Machine During Operation.

· ONLY Use a Qualified Electrician to Install According to Local Building Codes: Machine MUST

Be Properly Grounded.

· ALWAYS Connect to Proper Voltage & Phase.

· ONLY Install on Level, Non-Skid Surface in a Clean, Well-Lighted Work Area Away from

Children and Visitors.

· ALWAYS Lock Machine Castors After Moving This Machine.

· NEVER Use This Machine For Non-Food Products.

· NEVER Operate Machine With Product Mixer Safety Cover Opened or Removed or Magnetic

Interlock Switch By-Passed.

· ALWAYS Turn Off, Unplug Machine From Power Source and Perform Lockout/Tagout

Procedure to this Machine BEFORE Attempting to Unjam or Unclog, Cleaning or Servicing

· NEVER Leave Machine Unattended While Operating.

· NEVER Alter This Machine From its Original Form as Shipped From Factory. DO NOT

Operate Machine With Missing Parts.

· PROMPTLY REPLACE Any Worn or Illegible Warning Labels.

· ALWAYS Read Operation and Service Manual BEFORE Operating, Cleaning, or Servicing.

· USE ONLY BIRO Parts and Accessories Properly Installed.

2

Page 7

INSTALLATION

TO AVOID SERIOUS PERSONAL INJURY, PROPERLY INSTALL

EQUIPMENT IN ADEQUATE WORK AREA

· ALWAYS Use Qualified Technician and Electrician for Installation.

· ALWAYS Connect to Proper Voltage & Phase.

· ALWAYS Install Equipment in Work Area with Adequate Light and Space Away From Children

and Visitors.

· ONLY Operate on a Solid, Level, Non-Skid Surface.

· ALWAYS Lock Machine Castors After Moving Machine to Operating Location.

· NEVER Bypass, Alter, or Modify This Equipment in Any Way From Its Original Condition.

· NEVER Operate With Product Mixer Safety Cover Opened or Removed or Magnetic Interlock

Switch by-Passed.

· NEVER Operate Without all Warning Labels Attached and Owner/Operator Manual Available to

the Operator.

UNCRATING AND SET UP

1. Read this Manual thoroughly before installation and operation. Do not proceed with installation and operation if

you have any questions or do not understand anything in this Manual. Contact your local Distributor, or BIRO

first.

2. Remove all banding, shipping carton, and all equipment from inside the tub. Then take machine off shipping

pallet.

3. This machine is shipped with the adjustable legs fully retracted. The legs allow for a height adjustment from the

floor to centerline of bowl 24

1

16

“ minimum to 33

9

16

” maximum.

4. This machine weighs approximately 700 pounds. To avoid accidents block up machine after raising to desired

operating height.

5. The adjustable legs can now be unbolted and lowered to the floor using the following steps.

a. Unbolt leg and while holding leg turn leg adjusting stud (Item No. 53985) clockwise until caster rests on floor.

b. Be sure bolt holes line up. Replace bolts and tighten securely.

6. Install machine on a level, solid, non-skid surface in a well-lighted work area away from children and visitors.

7. This machine is complete except for knife and plate. There is a bowl shipping plug (stamped steel) placed in the

output end of the grinding bowl to retain the grinding auger during shipment. REMOVE THE BOWL SHIPPING

PLUG AND THE GRINDING AUGER.

8. After checking and making sure the power supply is correct, plug in your machine. NEVER OPERATE THIS

MACHINE WITH PRODUCT MIXER SAFETY COVER OPEN. (Machine will not run with cover open.)

9. Machine must be properly grounded. Use qualified electrician to install according to local building codes.

3

Page 8

MOTOR WIRING AND ELECTRICAL REQUIREMENTS

1. Interchange of current is made in motor outlet box. Leads are properly marked. Changing instructions are on

the motor plate or motor outlet box.

2. All grinders are wired 220 volts unless otherwise specified. Be sure motor specifications (voltage, cycle, phase)

match power supply line. Be sure line voltage is up to specification.

3. Electrical connections to be in accordance with safety codes and National Electrical Code.

4. Rated voltage of the unit shall be identical with full supply voltage.

5. Voltage drop on the supply line shall not exceed 10% of full supply voltage.

6. The feederline conductor size in the raceway from the branch circuit to the unit must be correct to assure

adequate voltage under heavy starting and short overload conditions.

7. The feederline conductor shall only be used for the supply of one unit of the relevant horsepower. For

connections of more than one unit on the same feederline, a local electrician will have to be consulted to

determine the proper conductor size.

8. The size of the electrical wiring required from the power source to the mixer grinder with 7½HP grind motor is a

MINIMUM of No. 10 Wire. With 10HP grind motor MINIMUM of No. 8 WIRE to be used.

9. The BIRO Manufacturing Company is not responsible for permanent wiring, connection or installation.

4

NOTE TO OWNER AND ELECTRICIAN: IF THIS MACHINE IS NOT CORD

AND PLUG CONNECTED TO THE ELECTRICAL SUPPLY SOURCE, THEN IT

SHOULD BE EQUIPPED WITH, OR CONNECTED TO, A LOCKABLE,

MANUALLY-OPERATED DISCONNECT SWITCH (OSHA 1010.147).

Page 9

10. Two sets of green and red pushbuttons are located on the front of the machine that activate the magnetic

contactors that control the mix and grind motors. The magnetic interlock switch is mounted in the pushbutton

box. It lines up with the magnet attached to the product mixer safety cover. When the safety cover is raised the

machine will stop operation.

11. Push the green start button for grind. CHECK THE ROTATION OF THE AUGER DRIVE SHAFT; ROTATION

MUST BE COUNTER-CLOCKWISE as indicated by the rotation decal affixed to the grinding bowl. ROTATION

MUST ONLY BE CHECKED WITH THE GRINDING AUGER REMOVED, otherwise serious irreparable damage

may occur to grinding components.

12. Push the green start button for mix. CHECK ROTATION OF THE MIXING PADDLE; ROTATION MUST BE

COUNTER-CLOCKWISE as indicated by the rotation decal located on the paddle front mounting hub.

Backwards operation will not allow mixing paddle to feed product to the grinding auger.

13. If machine runs clockwise (backwards), it must be rewired to correct rotation, otherwise serious irreparable

damage may occur to grinding components. Both the auger and the mixing paddle must operate in the same

direction.

14. Check operation of optional footswitch if equipped. Plug footswitch cord into fitting at the bottom of the

pushbutton control box. Move toggle selector to foot. The machine will operate with pressure on the footswitch

treadle. Releasing the treadle stops the machine. The footswitch operates the mix and grind together.

15. Insert auger assembly into grinding bowl, place knife (sharp edges out) onto the square end of the auger

assembly. The breaker plate slides over the worm knife drive pin, and is held from rotating by pins in the grinding

bowl. Install the retaining ring.

ONLY HAND TIGHTEN RETAINING RING

For best results, use knife and plate as a set. Do not operate machine for any period of time without product

in the grinding bowl. This will cause heating and dulling of the knife and plate.

16. Check placement of all warning labels and Manual. Machine is now ready for trained operators to process

product.

17. Use meat deflector attached to grinding bowl to eliminate meat splatter.

18. Contact your local Distributor or BIRO directly if you have any questions or problems with the installation or

operation of this machine.

5

Page 10

OPERATION

ROTATING GRINDING AUGER & ROTATING MIXING PADDLE

TO AVOID SERIOUS PERSONAL INJURY

· ONLY Properly Trained Personnel Should Use This Equipment.

· NEVER Place Hands Into Machine Input or Output Openings.

· NEVER Open Machine During Operation.

· DO NOT Wear Gloves While Operating.

· DO NOT Tamper With, Bypass, Alter, or Modify This Equipment in Any Way From Its Original

Condition.

· NEVER Operate Machine With Product Mixer Safety Cover Opened or Removed or Magnetic

Interlock Switch By-Passed.

· ALWAYS Turn Off, Unplug Machine from Power Source and Perform Lockout/Tagout

Procedure to This Machine Before Unjamming, Unclogging, Cleaning or Servicing.

· NEVER Leave Unattended While Operating.

· NEVER Operate Without All Warning Labels Attached and Owner/Operator Manual Available to

the Operator.

A. TO PROCESS PRODUCT

1. Before starting mixer grinder, have a container for receiving ground product at the output end of the grinding

bowl.

2. FIRST GRIND

a. Fill Product Hopper (Maximum 200 Pounds), close Product Mixer Safety Cover.

b. Push both grind and mix green start buttons to feed first grind. It is recommended to use a breaker plate

with

3

8

" diameter or larger holes.

c. Push both grind and mix red stop buttons when all product has been ground out.

3. SECOND GRIND

a. Fill Product Hopper (Maximum 200 Pounds), close Product Mixer Safety Cover.

b. Push the mix green start button only. During this mix operation seasonings may be added through the

sight holes in the Product Mixer Safety Cover.

c. After the desired mix, push the green grind start button to operate grinding auger and grind out product.

d. Push both grind and mix red stop buttons when all product has been ground out.

4. Unplug from power source and perform lockout/tagout procedures.

6

Page 11

CLEANING

ROTATING GRINDING AUGER & ROTATING MIXING PADDLE

TO AVOID SERIOUS PERSONAL INJURY

· ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedures to

This Machine Before Cleaning or Servicing.

· ONLY Use Recommended Cleaning Equipment, Materials, and Procedures.

· NEVER Spray Water or Other Liquid Substances Directly at Motor, Power Switch or any Other

Electrical Components.

· ALWAYS Thoroughly Clean Equipment at Least Daily.

CLEANING THE BIRO MIXER GRINDER

1. Disconnect mixer grinder from power source and perform lockout/tagout procedures.

2. Remove grinding bowl end ring, breaker plate, knife and grinding auger.

3. Remove mixing paddle. Be sure front most paddle arm is pointing up. Loosen the thumb screw on the mixer

paddle lock arm (Item No. 53853). While supporting the mixing paddle, remove the lock arm. Turn the mixing

paddle counterclockwise, slide forward to disengage from drive shaft and lift from product hopper.

DO NOT POWER SPRAY DIRECTLY AT ELECTRICAL COMPONENTS

4. Machine is now ready to be cleaned using warm soapy water and rinsed with clean water. Machine may be

cleaned by power spray washing, taking care to not spray directly at any electrical controls.

5. The grinding head can be removed for cleaning if desired. This is accomplished by removing the three nuts on

the back flange of the grinding head.

6. After machine has been cleaned and allowed to dry, all exposed metal surfaces should be coated with a good

food grade light oil or grease.

7

CLEANING THE BOWL - RING AND WORM

CARE OF TIN COATED PRODUCTS

(DO’S AND DON’TS)

1. Do not use abrasive cleaning materials, such as Brillo pads or metal scrapers. Tin is a soft metal and should be cleaned

with a soft cloth and dried.

2. Do not use a cleaning agent containing a high percentage of free alkali or acid.

3. Do not use detergent containing a high percentage of tri-sodium phosphate or meta-silicate. Tin is reactive to both.

4. Rinse well and dry thoroughly after washing to remove agents that may be reactive to tin.

5. If sterilizing agent containing chlorine is used, the tinned surface must be thoroughly rinsed. Chlorine is corrosive to tin.

6. Dry thoroughly after rinsing and store in a dry environment.

7. If water is exceptionally hard, drying will be necessary to prevent spotting.

Page 12

MAINTENANCE

ROTATING GRINDING AUGER & ROTATING MIXING PADDLE

TO AVOID SERIOUS PERSONAL INJURY

· ALWAYS Turn Off, Unplug from Power Source and Perform Lockout/Tagout Procedures to

This Machine BEFORE Servicing.

· NEVER Touch This Machine Without Training and Authorization By Your Supervisor

· NEVER Place Hands Into Machine Input or Output Openings.

· NEVER Bypass, Alter or Modify This Equipment in Any Way From Its Original Condition.

· PROMPTLY REPLACE Any Worn or Illegible Warning Labels.

· USE ONLY GENUINE BIRO Parts and Accessories Properly Installed.

A. GRINDING BOWL INSTALLATION

1. Mount the grinding bowl on the three threaded studs on the front of the machine. Tighten in position with

provided nuts.

2. Place the grinding auger in the grinding bowl and fully seat rear drive tang into auger drive shaft.

3. Install knife, breaker plate and end retaining ring.

ONLY HAND TIGHTEN RETAINING RING

4. When the bowl assembly is mounted and tight, there should be approximately

1

8

" gap between the back

inside wall of the grinding trough and the back of the auger. The bowl ring wrench which is provided with

each mixer grinder is used only for REMOVAL of the end retaining ring for cleaning purposes or for changing

knife and breaker plate.

B. MIXING PADDLE INSTALLATION

1. Check that mixer paddle drive pin (Item No. 53516) in the mixer paddle drive shaft (Item No. 53955-N) is

positioned vertically.

2. Holding the mixing paddle by the center shaft and with the front blade up carefully fit drive receiving collar

onto the end of the drive shaft. Insert paddle lock arm assembly (Item No. 53852) into the front of the mixing

tub and onto the front of the mixing paddle.

3. When fully seated, turn the lock arm counterclockwise so the protruding arm is behind the lock set screw

bracket. Tighten the mixer paddle lock set screw (Item No. 53568).

C. LUBRICATION

1. MOTORS: The mix and grind motors have pre-lubricated bearings. These bearings should be re-lubricated

annually with a good grade of bearing grease. Do not over-grease.

2. BEARING HOUSING: The main bearings are housed in an enclosed and sealed journal box. Re-lubricate

semi-annually with a good grade of bearing grease. Do not over-grease.

8

Page 13

OPERATING AND MAINTENANCE INSTRUCTIONS

3. FOR NORD HELICAL – WORM GEAR AND MOTOR REDUCER

ELECTRICAL CONNECTIONS

Check the motor nameplate to verify the phase, hertz and

voltage agrees with the available power supply. Connection

should conform to local codes. A connection diagram for

the motor is located inside the conduit box and on the

motor nameplate. The motor starter has overload

protector.

START-UP

All units are lubricated before shipment. The lubricant level should be

checked with the unit mounted in its correct operating position. Lubricant

should be added or removed to bring it to the correct level.

MAINTENANCE

A. MOTOR

During maintenance, inspect the fan guard and remove any accumulated debris from under or around the

gear reducer. Motor bearings are greased and sealed for life. Motor requires no periodic maintenance.

B. GEAR REDUCER

All units are filled from factory with ISO VG680as. This is a Polyglycol (PG) type synthetic lubricant. Units

should be checked periodically for increase noise, surface temperature, vibration, shaft movement, and

amperage draw. Gear reducer should have the lubricant changed every 20,000 hours or four years,

whichever occurs first. For adverse operating conditions the interval should be shorter. DO NOT MIX

SYNTHETIC & MINERAL BASE OILS. After the unit is drained of the used lubricant, it should be filled

with approximately 1.48 Qts. of a compatible lubricant to the above specification. Once the unit is filled,

the lubricant level should be verified at the Oil Level Plug.

Please note the chart below for oil compatibility:

The listing below offers suggestions on the

manufacturers of recommended lubricants. Use

synthetic oil (Polyglycol-Base) between 14 – 175°

with an ISO Viscosity Class of ISO VG 680.

Aral Degol GS 680 Klober Klubersynth GH 6-680

BP Enersyn SG-XP 680 Mobile Glycgoyle HE 680

Texaco Pinnacle 680 Tribol 800/680

9

Item No. Description

1773-1 Lock Ring ½²

35220 Motor cord SO 14/4´41²

53511 Cord connector 14/4 AL.

53516 Mixer paddle drive pin

53769-35 Mixer drive shaft key

53769-47 Mixer shaft washer retainer

53953 Mixer drive shaft seal

53955-N Mixer drive shaft

57211 Mounting plate

57212 Motor & reducer only – Nord

1¾HP, 208/460V-50/60-3Ph.

57212-2 Motor & reducer only – Nord

1¾HP, 550-575V-50/60-3Ph

57212K Conversion kit & plate – Nord

1¾HP, 200-230V-50/60-3Ph

57212K-1 Conversion kit & plate – Nord

1¾HP, 380-415V-50/60-3Ph

57212K-2 Conversion kit & plate – Nord

1¾HP, 440-460V-50/60-3Ph

57212K-3 Conversion kit & plate – Nord

1¾HP, 550-575V-50/60-3Ph

Item No. Description

57212K-208 Motor & reducer & shaft

replacement w/o plate – Nord

57212K-380 Motor & reducer & shaft

replacement w/o plate – Nord

57212K-440 Motor & reducer & shaft

replacement w/o plate – Nord

57212K-575 Motor & reducer & shaft

replacment w/o plate – Nord

C776 Terminal ring #10

HHS125S Hex head screw, ½-13´1SS

Item No. Description

HHS127S Hex head screw, ½-13

´

1½SS

HHSM059S Hex head screw,

M8´1.25´20mm

HN42S Hex nut, ½-13 SS

LW15S Lock washer,

5

16

SS

LW30S Lock washer, ½ SS

SSS10Z Set screw, ¼-20´¼SS

NORD GEAR CORP.

800 Nord Drive

P.O. Box 376

Waunakee, WI 53597-0367

Page 14

4. FOR DORRIS MIXER TRANSMISSION

DORRIS MIXER TRANSMISSION: Oil in the mixer

transmission should be changed after the first four (4)

weeks of operation. This is to remove the "run-in" oil

and also any small metal shavings that may have been

generated during the initial mating of the gears. After

the first oil change, subsequent changes should be

performed every six (6) months. After draining the oil,

refill the unit to the "level" plug (1 qt.) at the center of

the transmission with a petroleum based rust and

oxidation (R&O) inhibited gear oil. Viscosity Range for

15-75 degrees F (-9 – 24 degrees C) is AGMA Lube No.

3 or ISO Grade 100.

TO CHANGE OIL:

a. Unplug mixer/grinder from power source and

perform lockout/tagout procedures.

b. Remove rear drive cover.

c. Remove breather plug from top of transmission and

oil level plug from side of transmission

d. With a container in place to catch old oil, remove the

magnetic drain plug from the bottom of the

transmission.

e. When all oil has drained, clean the drain plug and

replace into the transmission.

f. Refill transmission with approx. one (1) quart of the

recommended gear oils or equivalent. Or until oil

appears at bottom of oil level sight hole.

g. Replace breather and oil level plugs.

h. Carefully turn mixer transmission pulley by hand to

lubricate internal gears.

i. Reinstall rear drive cover.

D. MIXER DRIVE BELT TENSION

1. Unplug mixer/grinder from power source and perform lockout/tagout procedures.

2. Remove rear drive cover.

3. Loosen the four bolts holding the 1HP motor to its mounting plate.

4. Slide 1HP motor away from mixer transmission.

5. When approximately

1

2

" total belt flex has been attained, retighten motor bolts.

6. Reinstall rear drive cover.

E. MAIN DRIVE CHAIN AND SPROCKET LUBRICATION:

The main drive chain has been pre-lubricated at the factory to protect it against dirt and moisture. Chain life

will vary appreciably depending upon its lubrication. The better the lubrication, the longer the chain life.

Lubrication effectiveness will vary with the amount of lubricant and frequency of application. Ideally, a

lubricant film should always be present between the working parts. Manually lubricate the chain as often as

is needed (possibly once a week). NEVER exceed three months without lubricating.

Lubricating just the outside of the chain does little good. Apply lubrication on the inside of the chain span so

that it will work through the moving parts and joints by centrifugal force as the chain rotates and reach the

area where one surface “scrubs” another.

10

Page 15

MAIN DRIVE CHAIN AND SPROCKETS LUBRICATION (continued):

Recommended types of chain lubricant are those with Molybdenum Disulphide or Graphite added. Also

bonded lubricants such as Dow Corning Molykote 321R or equivalent are excellent for open chains. The

lubricant should be of a viscosity whereby it will “flow” somewhat and penetrate the internal working surfaces.

Thick stiff greases are of little value because they cannot work into moving parts of the chain.

a. Unplug mixer/grinder from power source and perform lockout/tagout procedures.

b. Remove rear drive cover.

c. Spray or brush lubricant on inside of chain, slowly and carefully turning large sprocket by hand.

d. Reinstall rear drive cover.

F. MAIN DRIVE CHAIN TENSION (See Diagram Below)

1. Unplug mixer/grinder from power source and perform lockout/tagout procedures.

2. Remove rear drive cover.

3. Remove right and left side skirts.

4. Loosen the four bolts that hold the motor to the frame of the machine.

5. Loosen the lock nuts on the motor adjusting stud.

6. To Loosen Chain Tension. Turn motor adjusting studs counterclockwise. Grasp motor and pull toward

adjusting stud. Be sure to turn both adjusting studs the same amount and evenly. Total chain flex should be

1

8

"to

3

8

". Be sure to keep motor shaft parallel with auger drive shaft.

To Tighten Chain Tension. Turn motor adjusting studs clockwise. Be sure to turn both adjusting studs the

same amount and evenly. Total chain flex should be

1

8

"to

3

8

". Do not overtighten chain as this will put

excessive and damaging pressure on the motor bearings. Be sure to keep motor shaft parallel with auger

drive shaft.

7. Retighten motor mounting bolts.

8. Retighten motor adjusting stud lock nuts.

9. Reinstall the right and left side skirts.

10. Reinstall the rear drive cover.

G. CHAIN REPLACEMENT

1. Part No. H384-CL Service Replacement Chain is provided with a

"Connecting Link" (Part No. H384-LINK) so that is can be separated to

facilitate installation over the sprockets

Upon assembly, be sure the connecting link is installed so the spring

clip is orientated with its opening facing "opposite" the direction of the

chain travel (See Diagram). â

11

AFTER INSTALLATION

THE CHAIN SHOULD BE

TENSIONED TO

APPROXIMATELY

1

8

to

3

8

FLEX

Page 16

12

Page 17

— NOTES —

13

Page 18

AFMG-48 SIDE VIEW PARTS DIAGRAM

14

Page 19

Fig. Item No. Description

1 57154 Product mixer safety cover, tri directional,

#63592 on

1A 53547 Lid with chute opening

1B 53543 Conveyor chute

2 56072 Safety cover latch

3 56073 Safety cover latch mounting bracket, L.H.

4 56074 Safety cover latch mounting bracket, R.H.

5 AN20S Acorn nut,

3

8

-16 (2 req.)

6 RHS24S Round head screw,

1

4

-20

´

1

2

(2 req.)

HNNL15S Hex nut, nylok,

1

4

-20 (2 req.)

7 RHS31S Round head screw,

1

4

-20´1

HNNL15S Hex nut, nylok,

1

4

-20

8A 53456 Mixer paddle assembly, 1st grind, optional

8B 53918 Mixer paddle assembly, 2nd grind,

standard

9 53953 Mixer drive shaft seal

10 53516 Mixer paddle drive pin

11 SSS10Z Drive pin set screw

12 53594 Bearing for 53520 assembly

13 53517-1 Thrust bearing

14 53852 Lock arm assembly w/brgs.

15 53568 Mixer paddle lock set screw

16 57047 Wireway cover, #63401 on

17 1116 Acorn nut, 10-32 (3 req.)

18 SSS45S Meatguard mounting stud

19 WN20S Wing nut

20 52392 Meat guard splash shield

21 HK48 Knife drive pin

22 HP48 Bowl plate pin (3 req.)

23 HR42/48 Bowl ring

24 52106-CTN Bowl w/plate pins

25 54278-CTN Auger assembly

25B 54278B Square drive auger adapter

25C 54278C Auger shear pin

25D FHS33S Shear pin flat head screw,

1

4

-20´½

26 53413 Bowl mounting stud – short (1 req.)

HNF42S Hex flange nut,

1

2

-13, (2 req.)

26A 53413-2 Bowl mounting stud – long (2 req.)

26B HNF42S Flange hex nut ½-13 bowl mounting nut

(3 req.)

27 57159K Auger drive shaft seal kit

27A 57160 Seal retainer, SS

27B 57159 Auger drive shaft seal, double lip

27C FHS26S Flat head screw 10-32

´

3

4

,SS

28 53475-200 Motor, 7½HP, 200/400-60-3

53475 Motor, 7

1

2

HP, 208/460-60-3

53475-50 Motor, 7½HP, 208/380-50-3

53941 Motor, 7

1

2

HP, 575-60-3

53475-1 Baldor 7½HP, bearing both ends –

206KDD

53475-2 Doerr 7½HP, bearing, opp. shaft –

206KDD

53475-3 Doerr 7½HP, bearing, shaft end –

207KDD

57025-200 Motor, 10HP, 200/400-60-3

57025 Motor, 10HP, 208/460-50/60-3

57025-5 Motor, 10HP, 575-60-3

57092 Motor, 10HP, 220/380-50-3

29 53886 Journal box assembly

30 H384-CL Roller chain

31 54310 Adjusting stud

32 55092 Rear drive cover w/handles

55092-COSK Rear drive cover COS kit

55092-COS Rear drive cover w/handles & magnet

14688 4-point knob, AL

14688-COS Locking knob, AL

57219 Screw – COS rear drive cover

FW05S Flat washer ¼, SS

FW16S Flat washer

5

16

,SS

HHS025S Hex head screw ¼-20

´

½, SS

HHS049S Hex head screw

5

16

-18´½, SS

HHS050S Hex head screw

5

16

-18

´

5

8

,SS

Fig. Item No. Description

HHS055S Hex head screw

5

16

-18´¾, SS

HN07S Hex nut 10-24, SS

HN15S Hex nut ¼-20, SS

HN20S Hex nut

5

16

-18, SS

LW10S Lock washer ¼, SS

LWE10P Lock washer #10 ext tooth, SS

33 53478 Starter w/110V coil, Furnas size 1,

14DP32AF81, 7

1

2

HP

55046 Starter w/24V coil, Furnas size 1,

14DP32AJ71, 7½HP

75DF14 Contact kit, Furnas 1 pole only (size 1)

7½HP

57027 Starter w/110V coil, Furnas size 1

3

4

,

14EP32AF81, 10HP

57027CE Starter w/24V coil, Furnas size 1¾,

14EP32AJ71, 10HP

75EF14 Contact kit, Furnas 1 pole only (size 1¾)

10HP

33A 34478 Holding coil – 120V/240V

55047 Holding coil – 24V

34 53851 Fuse, FNM-1 AMP, 250V timedelay

35 53914 Transformer, 230/460 to 115V

53731 Transformer, 575 to 115V

PC141-1 Transformer replacement,

200/208/220/240/277/380 to 24V

36 See electrical diagram, page 4

37 53477 Starter w/110V coil, Furnas size 00,

14BP32AF81, 1¾HP

55045 Starter w/24V coil, Furnas size 00,

14BG32AJ71, 1HP

75BF14 Contact kit, Furnas 1 pole only (size 00)

1HP

37A 34478 Holding coil – 120V/240V

55047 Holding coil – 24V

38 53633 Starter box cover

39 53860 Starter box

40 52181-1 Magnetic switch bracket for magnet

41 52181-1 Magnet w/mounting brkt. (110 volt)

PC166 Magnetic safety switch (24 volt) old style

units only (not CE)

42 42MC-Y73 Green start button

43 H442-1 Magni switch, 3 amp

53872 Safety switch mounting bracket

44 42MC-Y74 Red stop button

45 50655-1 Switch guard

H462-1 Switch guard ferrule

HN20S Hex nut

5

16

-18 SS

LW15S Lock washer

5

16

SS

46 54320K Toggle switch,hand/foot, w/boot

47 54321 Toggle switch waterproof half boot

48 53869CEK Legend plate, w/int’l. symbols, int'l kit

49 53870 Legend plate gasket

50 52655 Female receptacle, 5 pole, for footswitch

51 52662 Protective cap assembly

52 53872 Safety switch bracket

53 35376 End anchor

54 35241 Mounting channel

55 35375 End barrier

56 35374 Terminal block

57 53783 Decal, rotation

58 57156 Front splash shield

HHS025S Hex head screw ¼-20

´

½, SS

HN15S Hex nut ¼-20, SS

LW10S Lock washer ¼, SS

NOT SHOWN

57073 Power cord, 10’, 8-4

54268 Power cord, 10’, 10-4

2563 Legend plate hex screw

10-32

´

1

2

,SS

53965 Optional leg ext. kit with brace

BIRO MODEL AFMG-48-II MIXER GRINDER PARTS LIST

15

Page 20

16

Fig. Item No. Description

1 56221 Safety cover torsion spring, R.H.,

#63401 on

56222 Safety cover torsion spring, LH.,

#63401 on

2 57050 Safety cover hinge rod, #63401 on

2A 57153 Tri directional hinge rod, for front

opening, #63440 on

2B 56045 Hinge rod spacer (2 req'd)

2C AN20S Acorn nut

3

8

-16, SS (2 req'd)

3 53755 Motor, 1HP, 208/460-60-3

53755-50 Motor, 1½HP, 220/380/50-3

53942 Motor, 1HP, 575-60-3

57210 Motor, 1½HP, 200-60-3

4 53771 Transmission & motor mounting

bracket, #62001 on

5 53769 Transmission (Dorris), #62001 on

6 53955 Mixer drive shaft

7 53773 Transmission mounting angle,

#62001 on

8 54303 Outer disc, double rod, #62001 on

9 14688 Lock knob, (2 req.)

10 57133 Side entrance seal, double rod, 35°

inlet, #63592 on

10A 54302 Side entrance seal, double rod, 90°

inlet, #62001 to #63591

11 53891 Auger drive shaft key

12 53894 Auger drive shaft lockwasher

13 53715 Ring wrench hanger

HN15S13A Hex nut ¼-20, SS

14 52357 Ring wrench (order H340)

15 55093 Right side skirt, 35° inlet, #63592 on

15A 55094 Right side skirt – no hole

15B 55095 Right side skirt, 90° inlet, #52001 to

#52344

16 53580 Sprocket, 22 tooth (order H382-1)

H382 Sprocket – 19 tooth (replacement

only)

17 PC175-1 Swivel caster w/total lock (4 req.) –

new style

53952 Swivel caster w/lock (4 req.) – old

style

18 53944-1 Standard leg, 9

1

2

" adjusting – new

caster pad style

53944-5K Foot leg pad bumper kit (4 ea.)

53944 Standard leg, 9

1

2

" adjusting – old

caster pad style

19 55096 Left side skirt – 35° inlet

19A 55097 Left side skirt – no hole

19B 55098 Left side skirt, 90° inlet

20 53727 Main sprocket #62001 on

21 53895 Auger drive shaft locknut #62001 on

22 16251-90X78AL

Pulley, (driven) 9

´

7

8

I.D.

23 15063 V-belt 5L350

24 53469 Pulley, (driving), 3.15

´

7

8

I.D.

25 57201K Motor bracket support bar kit

26 C617 Motor shaft key ¼´¼´2²

Page 21

OPTIONAL STAINLESS STEEL BOWLS, AUGERS & RINGS

17

Fig. Item No. Description

1 53446 Lid assembly to #63400

2 HN30S Hex nut,

3

8

-16, SS (2 ea.)

3 51563 Lid hinge pin to #63400 (2 ea.)

4 53530 Lid lock arm to #63400

5 53533 Lid lock spacers to #63400 (2 ea.)

6 AN15S Acorn nut,

1

4

-20, SS (2 ea.)

7 HHS035S Hex head screw,

1

4

-20

´

5

8

,SS

(2 ea.)

Fig. Item No. Description

8 FW05S Flat washer,

1

4

, SS (2 ea.)

9 56072 Safety cover latch

10 56073 Latch mounting bracket, LH

11 56074 Latch mounting bracket, RH

12 RHS24S Round head screw,

1

4

-20

´

1

2

,SS

(2 ea.)

13 HNNL15S Hex nut,

1

4

-20 nylok (3 ea.)

14 RHS31S Round head screw,

1

4

-20´1, SS (1

ea.)

Fig. Item No. Description

55081 Lid lock retrofit kit

S/N 63401 to 63696

1 55059 Lid lock

2 55061 Lever arm assembly

3 2503 Nylon washer, .125 thick (2 ea.)

4 2504 Nylon washer, .060 thick (4 ea.)

5 AN17S Acorn nut,

5

16

-18, SS (2 ea.)

6 FHS33S Flat head screw,

1

4

-20

´

1

2

,SS

(2 ea.)

7 HN15S Hex nut,

1

4

-20, SS (2 ea.)

114mm UNGER

Item No. Description

FHS33S Shear pin fastener ¼-20´½SS

HHS012S Hex head screw, 10-32

´

1

2

SS

HK114 Knife drive pin, 114mm Unger

HR42/48S-114 End ring, SS, 114mm Unger

LW05S Lock washer, #10, SS

52106S-114 Bowl, SS, 114mm Unger

54278-CTNS-114

Auger assembly, SS, 114mm

Unger

54278C Auger shear pin

56049SK-114 Key, 114mm Unger

ENTERPRISE

HR42/48S End ring, SS

52106S Bowl, SS

54278-CTNS Auger assembly, SS

Page 22

DORRIS MIXER TRANSMISSION PARTS LIST

18

H369 Hex head screw

5

16

-18´¾

LW30S Lockwasher, SS

1

2

"

0850 Setscrew

1

4

-20

´

1

4

" long

1084 Hex head cap screw

1

2

-13´1

1

4

long

1103 Set screw

1

4

-20

´

3

8

" long

SSS30 Set screw

3

8

-24

´

3

4

" long

53516 Mixer drive pin

53769 Mixer paddle transmission

53769-01 Transmission housing

53769-03 Cover plate

53769-05 Low speed open cap

53769-06 High speed closed cap

53769-07 High speed open cap

53769-08 Low speed shaft

53769-09 Intermediate pinion gear

53769-10 High speed pinion gear

53769-11 Intermediate gear

53769-12 Low speed gear

53769-20 Intermediate closed cap

53769-31 High speed shaft key

53769-32 Intermediate gear key

53769-33 Low speed gear key

53769-35 Low speed shaft key

53769-36 Low speed Timken cup

53769-37 Low speed Timken cone

53769-38 High speed Timken cup (closed end)

53769-39 High speed Timken cone (closed end)

53769-40 High speed Timken cup (open end)

53769-41 High speed Timken cone (open end)

53769-42 Intermediate Timken cup

53769-43 Intermediate Timken cone

53769-44 Intermediate spacer ring

53769-45 Low speed spacer ring

53769-46 High speed spacer ring

53769-47 Puller shaft seal

53769-57 Intermediate shims

53769-58 High speed shims

53769-59 Low speed shims

53769-60 Cover plate gasket

53769-61 High speed oil seal

53769-62 Low speed oil seal

53769-63 Hex screw (intermediate cap)

53769-64 Hex screw (high speed cap)

53769-69 Hex screw (low speed cap)

53769-71 Hex screw (cover)

53769-74 Breather plug

53769-75 Magnetic drain plug

53769-96 Grease fitting

53953 Mixer drive shaft seal

53955 Mixer drive shaft

Page 23

NO. 53886 JOURNAL BOX ASSEMBLY

19

FOOTSWITCH PARTS LIST

224-2 Cord connector, wt, straight,

3

4

"

52654 Male plug w/6’ cord, 5 wire

52655 Female receptacle, 5 pole

52661 Male plug w/12’ cord, 5 wire

52668 Footswitch w/12’ cord and plug

53693 Footswitch

53693-A Cover guard

53693-C Cover gasket

53693-D Cover screw – short

53693-E Cover screw – long

53693-F Ground screw

53693-G Treadle spring

53693-H Internal assembly complete

53693-I Actuator

53693-M Micro switch BA-2R62-A4

53693-O Washer

53693-T Treadle w/actuator & return spring

53693-U Auxiliary treadle return spring

53693-W Treadle

53693-X One actuator & actuator spring assembly

54213 Foot switch w/6’ cord & plug

Item No. Description

53609 Journal box, #62001 on

53724 Auger drive shaft, #62001 on

53785 Journal box seal (2 ea.)

53886 Journal box assembly complete

53888, 53940 Front bearing cup/cone assembly

Order H310A

53889, 53939 Rear bearing cup/cone assembly

Order H311A

53993 Vented grease fitting

53979-1 Cord 8’ w/o foot switch

54213 Foot switch w/6’ cord & plug

Page 24

20

TANDEM OPERATION

PARTS LIST

272-7-1

5

16

-18 plastic knob – 3 pt.

53489 Dscg. Horn 24/42/46/48 to 24/48/52

inlet less seal

57044 Connec. brkt. AFMG52 to AFMG48

57044 Connec. brkt. AFMG52 to AFMG52

53552-1A Connecting brkt. assem. man/auto

53604 Dscg. horn 52 to 24/48/52 inlet

53667 Dscg. horn 56 to 24/48/52 inlet

53671 Seal only 24/42/46/48 to 24/48/52

inlet

53673 Disc. horn 48-52 w/seal

53933 Seal only 52/56 to 24/48/52 inlet

Page 25

TANDEM OPERATION ILLUSTRATION FOR 90° INLET

FROM S/N 62001 TO S/N 63591

21

Page 26

22

Page 27

CONNECTION INSTRUCTIONS

TANDEM OPERATIONS

AFMG-48 or ARFMG-52 INTO AFMG-48 or AFMG-52

Heavy Horsepower Grinder INTO AFMG-48 or AFMG-52

23

Remove Side Entrance Seal, Item No. 57133; Outer Disc, Item No. 54303 and

Lock Knobs, Item No. 14688 from the inlet tube of the Second Grind Machine.

Clean out the tube if necessary.

Install the Inlet Tube Seal Item No. 53671 or 57145

into the inlet tube of the Second Grind Machine until

fully seated.

Remove the Ring from the First Grind Machine, Item No. HR42/48 or HR52. Insert the Discharge Horn, Item No. 57144-7 or 57143-7 into the ring. (DO NOT

reinstall the ring on the First Grind Machine at this time.) Slide the Clamp Assembly, Item No. 57144-11 or 57143-11 onto the Discharge Horn.

Insert the Discharge Horn with Ring and Clamp Assembly

into the Seal, pushing it fully against the inlet tube internal

fins. Attach the lock latches to the tabs on the side of the

inlet tube and lock down. Tighten the lock knob on the

Clamp Assembly.

Move the Discharge Horn of the Second Grind Machine up to the Bowl of the First

Grind Machine. With the Auger, Knife and Grinding Plate installed in the First

Grind Machine, thread the Ring onto the First Grind Machine Bowl. RING

SHOULD BE HAND TIGHTENED ONLY: USE NO TOOLS.

Page 28

TANDEM OPERATION ILLUSTRATION FOR 35° INLET

S/N 63592 ON

24

Page 29

Page 30

OPERATOR’S SIGNATURE PAGE

MY SIGNATURE ATTESTS THAT I HAVE COMPLETELY READ AND UNDERSTAND THIS

MANUAL. I REALIZE THAT THIS MACHINE, IF OPERATED CARELESSLY, CAN CAUSE SERIOUS INJURY TO MYSELF AND OTHERS.

NAME (PRINT) SIGNATURE

SUPERVISOR’S

INITIALS

DATE

26

Page 31

— NOTES —

27

Page 32

LIMITED WARRANTY

WARRANTY: The Biro Manufacturing Company warrants that the BIRO AFMG-48-II Mixer

Grinder/Chopper will be free from defects in material and workmanship under normal use and with

recommended service. BIRO will replace defective parts, which are covered by this limited warranty, provided that the defective parts are authorized for return, shipping charges prepaid, to a

designated factory for inspection and/or testing.

DURATION OF WARRANTY: The warranty period for all parts covered by this limited warranty is

one (1) year from date of inspection/demonstration as advised on the returned Warranty registration card, or eighteen (18) months from original factory shipping date, whichever date occurs first,

except as noted below.

PARTS NOT COVERED BY WARRANTY: The following are not covered by this limited warranty:

wearable parts in the grinding system such as bowl, ring, worm, drive shaft, and knife drive pin.

This limited warranty does not apply to machines sold as used, rebuilt, modified, or altered from

the original construction in which the machine was shipped from the factory. Water contaminated

electrical systems are not covered under this limited warranty. BIRO is not responsible for electri cal connection of equipment, adjustments to the switch controls or any other electrical requirements, which must be performed only by a certified electrician. BIRO is not responsible for service

charges or labor required to replace any part covered by this limited warranty or for any damages

resulting from misuse, abuse, lack of proper or recommended service.

EXCLUSION OF WARRANTIES AND LIMITATION OF REMEDIES: BIRO gives no warranties

other than those expressly stated in this limited warranty. THE IMPLIED WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR PROCESSING OF FOOD PRODUCTS, AND ALL OTHER IMPLIED WARRANTIES ARE SPECIFICALLY EXCLUDED. BIRO IS NOT

LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, EXPENSES, OR LOSSES. THE

REMEDIES PROVIDED IN THIS BIRO LIMITED WARRANTY ARE PURCHASER’S SOLE AND EXCLUSIVE REMEDIES AGAINST BIRO.

REGISTRATION CARDS: You must sign, date and complete warranty registration card supplied

with each machine. The warranty card must be returned to The Biro Manufacturing Company for

proper registration. If no warranty card is returned to BIRO, the warranty period will begin from

the date the machine was originally shipped from the factory.

HOW TO GET SERVICE:

1. Contact the entity from whom you purchased the machine; or

2. Consult the yellow pages of the phone directory for the nearest authorized dealer; or

3. Contact BIRO Mfg. Company for the authorized service entity (250 plus worldwide) in your area.

THE BIRO MANUFACTURING COMPANY

1114 Main Street

Marblehead, Ohio

Ph. 419-798-4451

Fax 419-798-9106

E-mail: service@biro saw.com

Web: http://www.birosaw.com

28

ITEM NO: 53913

PTCT AFMG 48-138-9-05-12 COMM

ITEM NO: 53913

PTCT AFMG 48-138-4-08-13 PPD

Loading...

Loading...