Page 1

+

IMPORTANT NOTICE

+

This Manual contains important

safety instructions which must

be strictly followed when using

this equipment.

Page 2

TABLE OF CONTENTS

Page

NOTICETOOWNERANDOPERATORS.......................................... 1

SAFETYTIPS............................................................... 2

INSTALLATION ............................................................. 3

WARNINGLABELS............................................................5

OPERATION................................................................ 6

TOPROCESSPRODUCT.................................................... 6

CLEANING................................................................. 8

MAINTENANCE ............................................................. 9

GENERAL................................................................ 9

LUBRICATION ............................................................10

CHANGINGTHESAWBLADE ................................................10

WARNINGLABELLOCATIONSONMACHINE......................................11

PARTSDIAGRAMS...........................................................12

OPERATOR'SNOTES.........................................................17

WIRINGDIAGRAM ...........................................................23

OPTIONAL DOUBLE ROLLING TABLES PARTS LIST & DIAGRAMS . . . . . . . . . . . . . . . . . . . . . 24

OPTIONAL FIXED FRONT TABLE PARTS LIST & DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . 25

PARTSLIST/ORDERING.......................................................26

PARTSASSEMBLIESLIST/ORDERING ...........................................27

WEARABLESAWPARTS ......................................................28

OPERATOR'SSIGNATUREPAGE................................................29

LIMITEDWARRANTY.........................................................30

Page 3

NOTICE TO OWNERS AND OPERATORS

BIRO’s products are designed to process food products safely and efficiently. Unless the operator is properly trained and supervised, however, there is the possibility of a serious injury. It is the

responsibility of the owner to assure that this machine is used properly and safely, strictly following

the instructions contained in this Manual and any requirements of local law.

No one should use or service this machine without proper training and supervision. All operators should be thoroughly familiar with the procedures contained in this Manual. Even so BIRO

cannot anticipate every circumstance or environment in which its products will be used. You, the

owner and operator, must remain alert to the hazards posed by the function of this equipment –

particularly the SHARP MOVING BAND TYPE SAW BLADE. No one under eighteen (18) years of

age should operate this equipment. If you are uncertain about a particular task, ask your

supervisor.

This Manual contains a number of safe practices in the SAFETY TIP section. Additional warnings are placed throughout the Manual. Warnings related to your personal safety are indicated by:

Warnings related to possible damage are indicated by:

BIRO also has provided a wall chart to be posted near the equipment. If any warning label, wall

chart, or Manual becomes misplaced, damaged, or illegible, please contact your nearest Distributor or BIRO directly for a replacement.

Remember, however, this Manual or the warning labels do not replace the need to be alert and

to use your common sense when using this equipment.

This Manual applies to all Model 55 Power Saws.

1

OR

– NOTE –

“A copy of this manual is included with each Model 55 Saw.”

“The descriptions and illustrations contained in this manual are not binding.

The manufacturer reserves the right to introduce any modification without

replacing the manual.”

Page 4

SAFETY TIPS

SHARP MOVING BAND TYPE SAW BLADE

TO AVOID SERIOUS PERSONAL INJURY

NEVER Touch This Machine Without Training and Authorization By Your Supervisor.

ALWAYS Read Operating and Service Manual BEFORE Operating, Servicing or Cleaning.

ALWAYS Keep Hands Clear of Band Type Saw Blade and Other Moving Parts.

ONLY Use a Qualified Electrician to Install According to Local Building Codes: Machine MUST

Be Properly Grounded.

ONLY Install on a Level, Non-Skid Surface in a Clean, Well-Lighted Work Area Away From

Children and Visitors.

DO NOT Attempt to Operate This Machine Until it has Been Inspected and Demonstrated by the

Seller – Recognized BIRO Representative.

DO NOT Alter or Modify This Machine in any Way From its Original Form. This Machine in its

Original Form Meets the Intent of O.S.H.A. Applicable Standards.

NEVER Operate With Saw Guide Bar with Saw Guard in the Raised Position or the Saw Guard

Removed from the Saw Guide Bar.

ALWAYS Adjust Saw Guide Bar with Saw Guard to Within

1

2

" of Product to be Cut.

ALWAYS Use Safety End Cut Pusher Plate for Smaller Products or The Last Cuts of Product.

DO NOT Use This Machine for Non-Food Products.

DO NOT Use This Machine to Cut Pigs Feet.

DO NOT Wear Gloves While Operating.

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Removing Shrouds, Removable Guards, Covers, Doors, Fences or Panels

for Cleaning, Servicing or Any Other Reason.

NEVER Leave Machine Unattended While Operating.

PROMPTLY REPLACE Any Worn or Illegible Warning Labels.

USE ONLY Genuine BIRO Parts and Accessories Properly Installed.

2

Page 5

INSTALLATION

TO AVOID SERIOUS PERSONAL INJURY,

PROPERLY INSTALL EQUIPMENT IN ADEQUATE WORK AREA

ALWAYS Read Operating and Service Manual BEFORE Operating, Servicing or Cleaning.

ALWAYS Use Qualified Technician and Electrician for Installation.

ONLY Install on a Level, Non-Skid Surface in a Clean, Well-Lighted Work Area Away From

Children and Visitors.

DO NOT Attempt to Operate This Machine Until it has Been Inspected and Demonstrated by the

Seller – Recognized BIRO Representative.

DO NOT Alter or Modify This Machine in any Way From its Original Form. This Machine in its

Original Form Meets the Intent of O.S.H.A. Applicable Standards.

NEVER Operate With Saw Guide Bar with Saw Guard in the Raised Position or the Saw Guard

Removed from the Saw Guide Bar.

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Removing Shrouds, Removable Guards, Covers, Doors, Fences or Panels

for Cleaning, Servicing or Any Other Reason.

NEVER Operate Without all Warning Labels Attached and Wall Chart Posted.

USE ONLY Genuine BIRO Parts and Accessories Properly Installed.

1. Read this Manual thoroughly before installation and operation. Do not proceed with installation and operation if

you have any questions or do not understand anything in this Manual. Contact your local Distributor, or BIRO

first.

2. Install machine on a level, solid, non-skid surface in a well-lighted work area away from children and visitors.

3. After installing machine in operational area, it is imperative that the four adjustable legs be adjusted to level the

machine to eliminate rocking. Remove all wood supports.

4. Machine MUST be properly grounded. Use qualified electrician to install according to building codes.

3

ALWAYS LEVEL MACHINE BEFORE USING

NOTE TO OWNER AND ELECTRICIAN: IF THIS MACHINE IS NOT CORD

AND PLUG CONNECTED TO THE ELECTRICAL POWER SUPPLY, THEN IT

SHOULD BE EQUIPPED WITH, OR CONNECTED TO, A LOCKABLE,

MANUALLY OPERATED DISCONNECT SWITCH (OSHA 1010.47).

Page 6

WIRING MOTOR

(A) All power saws are wired at the factory for 220 volts or 440 volts as specified on original order. Be sure motor

specificaitons (voltage, cycle, phase) match power supply line. Be sure line voltage is up to specification.

(B) Connect leads to machine in a manner that will be approved by local electrical inspectors.

(C) We recommend not less than No. 12 wire. If leads are too light, machine may not have sufficient cutting

power and/or speed.

(D) The V-belt is packed loose in machine to prevent deformation, and must be installed on pulleys at time of

installation.

(E) Motors are dual voltage and can be changed according to wiring diagram on motor nameplate. Be sure the

correct AEG contactor and overload is installed to match the selected volts and amps.

(F) FAILURE TO USE THE PROPER CONTACTOR AND OVERLOAD FOR MOTOR VOLTAGE WILL CAUSE

IRREPARABLE DAMAGE TO THE CONTACTOR.

(G) The BIRO Manufacturing Company is not responsible for permanent wiring, connection or installation.

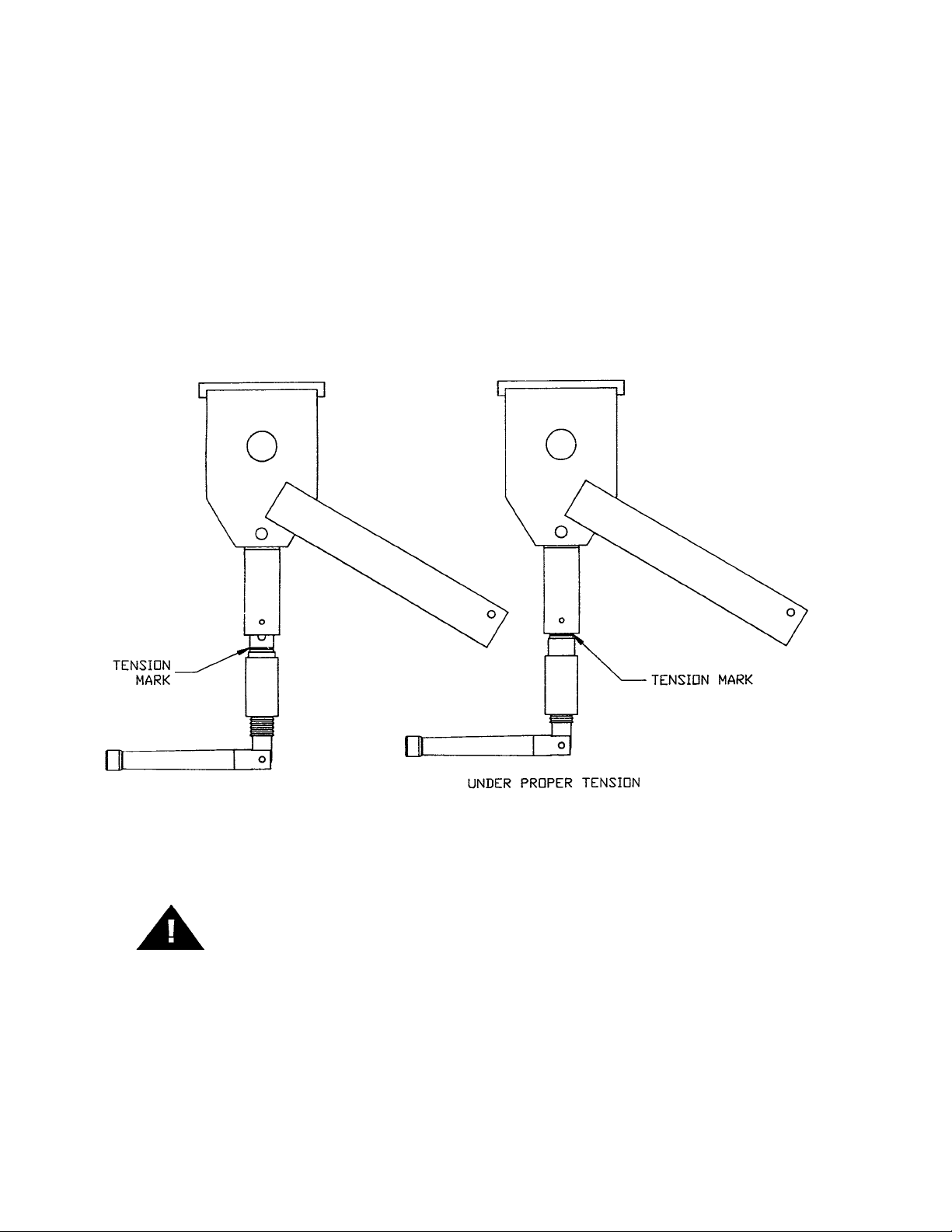

5. Be sure saw blade is properly installed on the saw wheels and set at proper tension. Turn the blade tensioning

handle clockwise until the tension mark is even with the bottom of the upper wheel hinge plate as shown.

6. Make sure the saw guide bar is in its lowest position. Close head and base doors and latch.

7. Push the start button and check for proper phasing of the motor. Blade should be traveling down through the

saw guide.

8. Watch for proper tracking of the saw blade. Back of blade should be centered in the hole in saw guide in

stationary bar (Item No. 119A). Push the stop button to stop machine.

9. Check placement of all warning labels, wall chart and Manual. Machine is ready for trained operators to process

product.

10. Contact your local Distributor or BIRO directly if you have any questions or problems with installation or

operation of this machine.

4

KEEP HANDS CLEAR OF SHARP MOVING BAND TYPE SAW

BLADE

Page 7

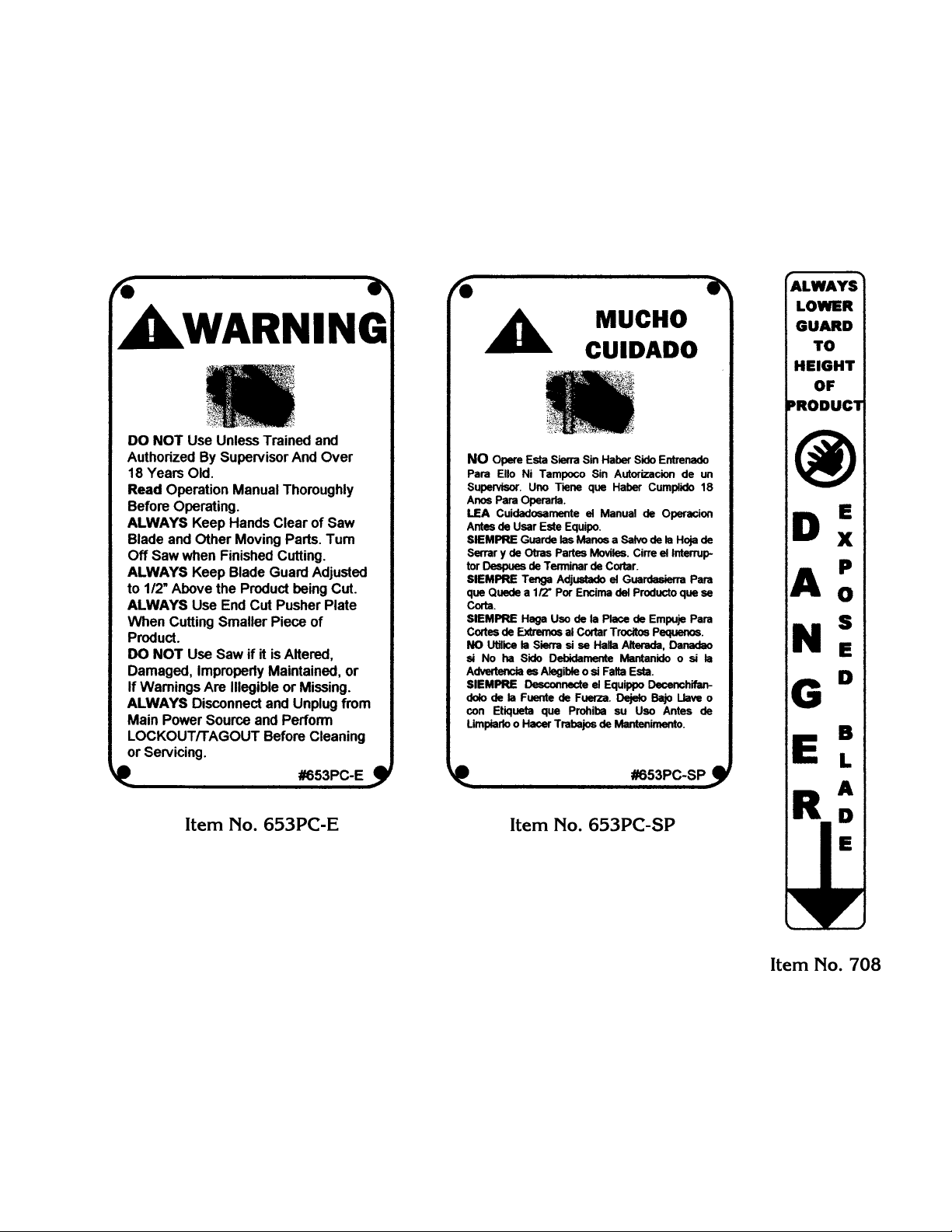

WARNING LABELS

FOR BIRO POWER SAWS

SEE PAGE 11 FOR LOCATIONS ON MACHINE

5

Page 8

OPERATION

SHARP MOVING BAND TYPE SAW BLADE

TO AVOID SERIOUS PERSONAL INJURY

NEVER Touch This Machine Without Training and Authorization By Your Supervisor.

ALWAYS Read Operating and Service Manual BEFORE Operating, Servicing or Cleaning.

ALWAYS Keep Hands Clear of Band Type Saw Blade and Other Moving Parts.

DO NOT Tamper With, Bypass, Alter, or Modify this Equipment in Any Way or Form.

DO NOT Alter or Modify This Machine in any Way From its Original Form. This Machine in its

Original Form Meets the Intent of O.S.H.A. Applicable Standards.

NEVER Operate With Saw Guide Bar with Saw Guard in the Raised Position or the Saw Guard

Removed from the Saw Guide Bar.

ALWAYS Adjust Saw Guide Bar with Saw Guard to Within

1

2

" of Product to be Cut.

ALWAYS Use Safety End Cut Pusher Plate for Smaller Products or The Last Cuts of Product.

DO NOT Use This Machine for Non-Food Products.

DO NOT Use This Machine to Cut Pigs Feet.

DO NOT Wear Gloves While Operating.

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Removing Shrouds, Removable Guards, Covers, Doors, Fences or Panels

for Cleaning, Servicing or Any Other Reason.

NEVER Leave Machine Unattended While Operating.

NEVER Operate Without All Warnings Attached and Wall Chart Posted.

A. TO PROCESS PRODUCT

1. Before starting power cutter, adjust saw guide bar with saw guard down to within

1

2

" (13mm) of product to be

cut.

6

Page 9

2. Make sure all doors are closed and latched.

3. Adjust meat gauge assembly forward to desired thickness of cut.

4. Push start button and watch blade for proper tracking.

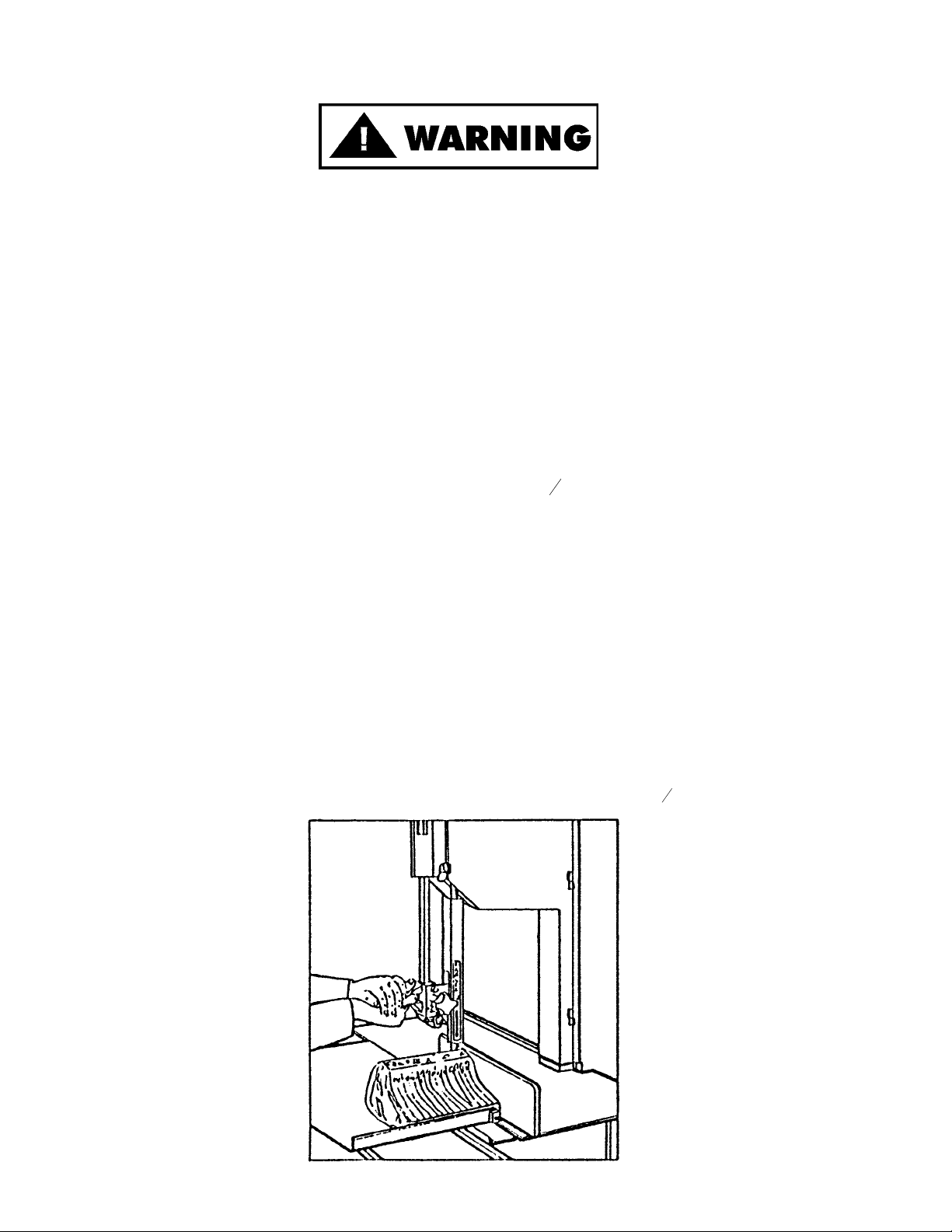

5. Standing in front of the power cutter, place product on the meat carriage. Pay attention to position of your

hands. Keep hands clear of moving band type saw blade. Leaning lightly against the scalloped front edge of

meat carriage, hold the product firmly in right hand with product face flush against meat gauge plate. Move

the meat carriage from right to left at a steady rate until fully past the saw blade. Use left hand to remove and

stack cut product, NEVER REACH IN FRONT OF BAND TYPE SAW BLADE. On the return stroke, pull

the product toward you, away from saw blade.

6. ALWAYS use the Safety End Cut Pusher Plate (Part No. 256P) for smaller products or the last cuts of product.

The pusher plate is supplied as standard equipment on all BIRO power saws.

7. When finished cutting, push stop button. Perform lockout/tagout procedure.

7

DO NOT WEAR GLOVES WHILE OPERATING

NEVER REACH OR GRAB FOR PRODUCT IN FRONT OF

MOVING BAND TYPE SAW BLADE

Page 10

CLEANING

SHARP MOVING BAND TYPE SAW BLADE

TO AVOID SERIOUS PERSONAL INJURY

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedures to This

Machine BEFORE Removing Shrouds, Removable Guards, Covers, Doors, Fences or Panels

for Cleaning, Servicing or Any Other Reason.

ALWAYS Read Operating and Service Manual BEFORE Operating, Servicing or Cleaning.

DO NOT Alter or Modify This Machine in any Way From its Original Form. This Machine in its

Original Form Meets the Intent of O.S.H.A. Applicable Standards.

ONLY Use Recommended Cleaning Equipment, Materials and Procedures.

NEVER Spray Water or Other Liquid Substances Directly at Motor, Power Switch or any Other

Electrical Components.

ALWAYS Thoroughly Clean Equipment Daily.

CLEANING THE BIRO POWER CUTTER:

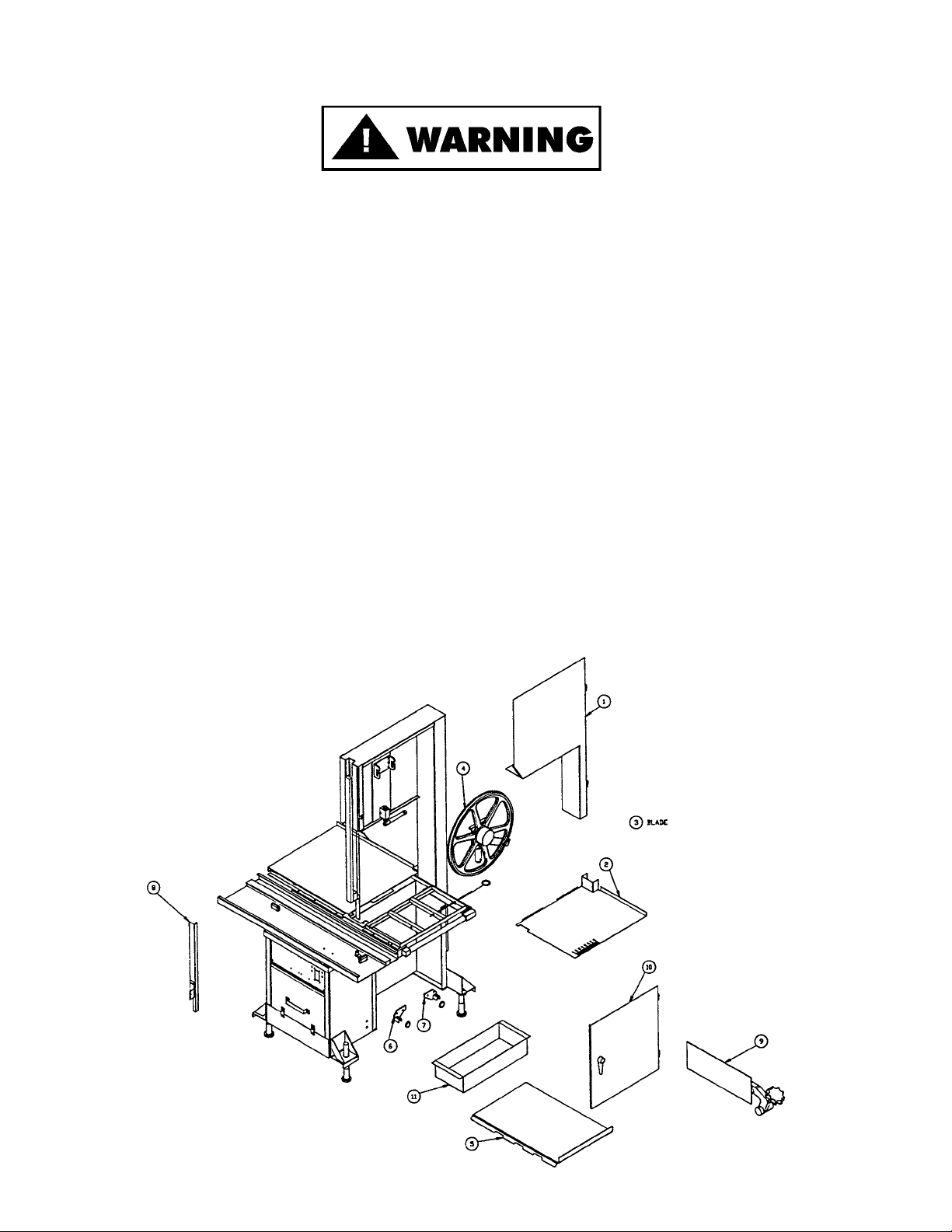

Disconnect the electrical power from the machine before cleaning. Parts to be removed have been made accessible

and can be removed without tools. Notice the drawing below that all parts are numbered. Each part should be removed for cleaning in the numbered sequence shown. To ensure cleaner cuts, keep the cleaning system in good

condition. Parts on the cleaning system which should be checked weekly, and changed as required. See Maintenance

on pages 9 & 10.

8

Page 11

MAINTENANCE

SHARP MOVING BAND TYPE SAW BLADE

TO AVOID SERIOUS PERSONAL INJURY

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Removing Shrouds, Removable Guards, Covers, Doors, Fences or Panels

for Cleaning, Servicing or Any Other Reason.

ALWAYS Read Operating and Service Manual BEFORE Operating, Servicing or Cleaning.

NEVER Touch This Machine Without Training and Authorization By Your Supervisor.

NEVER Bypass, Alter or Modify This Machine in any Way From its Original Form. This

Machine in its Original Form Meets the Intent of O.S.H.A. Applicable Standards.

ALWAYS Keep Hands Clear of Band Type Saw Blade and Other Moving Parts.

PROMPTLY REPLACE Any Worn or Illegible Labels.

USE ONLY GENUINE BIRO Parts and Accessories Properly Installed.

A. GENERAL

1. Machine should be generally inspected every time it is cleaned (at least daily) to ensure that it is in good

condition and has not been damaged or tampered with.

a. SAW WHEELS: Clean outer diameter grooves daily. Check for cracks, gouges or wear on flange and

grooves.

DO NOT IMMERSE UPPER WHEEL ASSEMBLY IN WATER

b. WHEEL CLEANER ASSEMBLIES: Check condition of fiber cleaner, change every four (4) weeks.

c. REMOVABLE FINGER LIFT ASSEMBLY: Check condition of saw guard, make sure mounting bolts are

tight and “DANGER EXPOSED BLADE” decal is attached and legible. Check condition of upper saw

guide (Part No. 602B), replace every six (6) months. Check adjustment of upper saw guide. Should be

1

32

" between back of blade and saw guide carbide.

d. SAW GUIDE BAR: Check condition of inner and outer saw guide bar, replace as necessary. Check saw

guide bar spring for proper tension. The spring should hold the bars in any desired position in its travel.

Replace saw guide bar spring (Part No. 193) as necessary using instructions on following page.

9

NEVER USE THIS MACHINE WITHOUT PROPERLY INSTALLED

AND FUNCTIONING SAW GUIDE BAR WITH SAW GUARD

Page 12

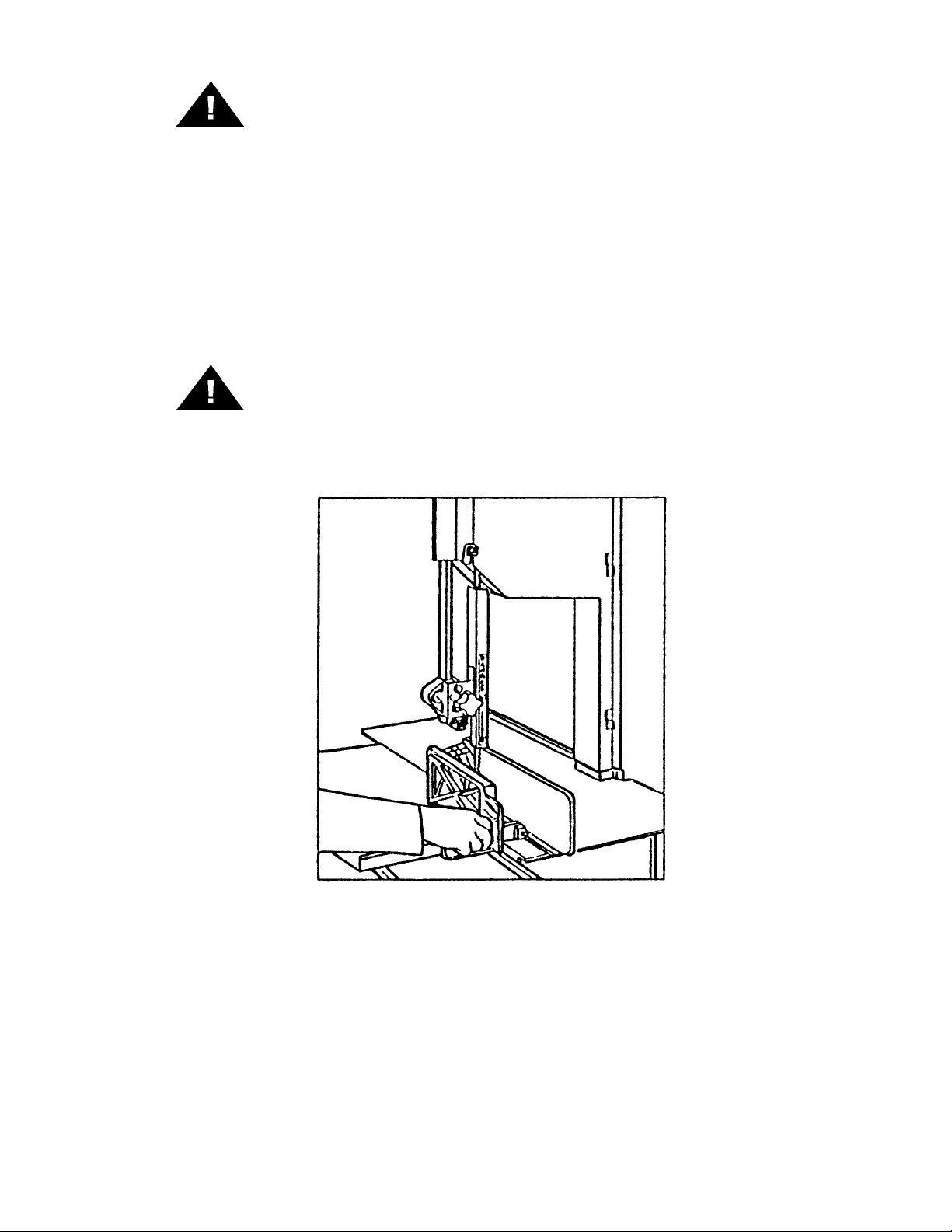

1. Remove the finger lift fastener knob (Item No. 211A-291Q) and the finger

lift assembly (Item No. 55234).

2. Remove the finger lift fastener stud (Item No. 211D).

3. Unbolt and remove the outer saw guide bar (Item No. 55190) and the

guide bar spacer blocks (Item No. 116RS).

4. Push the inner saw guide bar (Item No. 55189) up and out of the top of the

head structure.

5. Remove the saw guide bar spring (Item No. 193).

6. Lower the new saw guide bar spring through the top of the babbitt pocket

area and guide the spring into its seating position with a standard

screwdriver. (NOTE: Drawing)

7. While holding the saw guide bar spring in position, re-enter the inner saw

guide bar from the top. Compress the saw guide bar spring slightly with

the screwdriver tip until the saw guide bar slides past the spring.

8. Replace the outer saw guide bar and spacer blocks, the finger lift fastener

stud, the fingerlift assembly and the fingerlift fastener knob.

9. Test by placing saw guide bar in several positions. Verify that it stays in

desired position.

e. STATIONARY BAR ASSEMBLY: Check condition of nylon filler (Part No. 177), change every four (4)

weeks. Check condition of saw guide (Item No. 119A), check tracking of blade through guide, back of

blade should be centered in hole, replace every six (6) months. Check condition and adjustment of lower

blade back-up guide (Part No. S608), should have

1

32

" gap between back of blade and saw guide carbide.

Replace every six (6) months.

f. SAW CLEANERS: Check condition of blade cleaners (Item No. 131), replace every four (4) weeks.

g. MEAT GAUGE ASSEMBLY: Check free movement of meat gauge arm on gear rack. Gear rack to be

kept lubricated at all times with light food grade oil. Check operation of release handle. Check that worm

gear engages properly with gear rack.

h. MEAT CARRIAGE ASSEMBLY: Check free movement through full range of travel. Check for side to

side tolerance, adjust as necessary. Check condition of and grease bearings, replace as necessary.

Check condition of thumb guard, replace as necessary.

i. SAFETY ITEMS: Check for safety end cut pusher plate is with machine and accessible. All warning

labels present, properly affixed and legible. Model and Serial Number plate properly affixed and legible.

Wall poster within operators view from machine. Operating and Service Manual accessible to operator.

B. LUBRICATION

1. UPPER WHEEL BEARINGS: Grease every four (4) months. Change grease every twelve (12) months.

2. MEAT CARRIAGE BEARINGS: Grease every four (4) weeks.

3. SAW GUIDE BAR: Oil daily with food machine oil.

4. INNER MEAT GAUGE GEAR RACK: Oil daily with food machine oil.

5. MOTOR BEARINGS: Bearing grease will lose its lubricating ability over time, not suddenly. The lubricating

ability of a grease (over time) depends primarily on the type of grease, the size of the bearing, the speed at

which the bearing operates and the severity of the operating conditions. Good results can be obtained if the

following recommendations are used in your maintenance program.

A high grade ball or roller bearing grease should be used. Recommended grease for standard service

conditions is Polyrex EM (Exxon Mobil).

Equivalent and compatible greases include: Texaco Polystar, Rykon Premium #2, Pennzoil Pen 2 Lube, and

Chevron SRI.

Recommended lubrications intervals is every 9 months with the equivalent of two (2) teaspoons of grease.

10

Page 13

C. CHANGING THE SAW BLADE

Disconnect electrical power to the machine. Move meat gauge plate to rear of machine on gear rack and turn away

from head out of the way. Open the head door fully. Pull out platter hold down rod. Remove right side platter half.

Release tension on blade, turn tensioning handle counter-clockwise. Lift nylon filler. Remove blade. Install new blade

by reversing procedure. Be sure tension mark is even with the bottom of the hinge plate for proper blade tension.

WARNING LABELS LOCATIONS

ON MODEL 55 POWER SAWS

Item No. 653PC-E Warning label,

English

1 ea. attached to head below

Model & S/N plate.

11

Item No. 653PC-E Warning label,

English

1 ea. attached to channel bracket

Item No. 653PC-SP Warning label,

Spanish

1 ea. attached to channel bracket

Item No. 708; DANGER

Exposed Blade

Attached to saw guard on

saw guide bar

Page 14

121314

Page 15

Page 16

Item No. Description

A16112 Head door latch assembly

HHS058S Hex head screw,

5

16

-18

´

7

8

,SS

HHS060S Hex head screw,

5

16

-18´1, SS

LW15S Lock washer,

5

16

,SS

SSS15 Set screw,

5

16

-18

´

5

16

,SS

112-212 Waved washer

14TH Head door hinge welded

14TP Head door hinge pin, 1

1

2

"

14TP-1 Head door hinge pin, 1

1

4

"

Item No. Description

55135 Right support angle

55136 Left support angle

55138 Hinge bracket, upper wheel

55153 Head assembly, weldment, SS

55154 Head door, SS

55191 Head & door assembly, SS

55193 Hinge bracket assembly, upper wheel

55233 Head door assembly, SS

w/VTS7181

Page 17

15

Item No. Description

AN15S Acorn nut,

1

4

-20, SS

HHS0481S Hex head screw,

1

4

-20´1

1

2

,SS

HHS124S Hex head screw,

1

2

-13

´

7

8

,SS

HN40S Hex nut,

1

2

-13 light jam, SS

LW30S Lock washer,

1

2

,SS

S18005-15 Position mount – ½ thick

S18005-16 Position mount –

11

16

thick

S18253 Upper wheel aligning screw, SS

193 Saw guide bar spring

194KS-1 Lock knob 1

1

8

196 Saw tension spring

360A1 Grease fitting

Item No. Description

55170 Blade tension cap gauge

55171-1 Blade tension adjustment housing

55172 Blade tension screw

55173 Blade tension adjustment handle

55174 Upper wheel hinge plate

55184 O-ring, blade tension screw

55192 Blade tension assembly

55194 Upper wheel assembly w/hinge plate

55312 O-ring for tension cap gauge

55313 Plastic washer – tension screw

55314 O-ring, plastic washer

Page 18

Blade Tension Screw

INSTALLATION INSTRUCTIONS

Disconnect the machine from the main power supply.

Loosen tension on the saw blade and remove the upper wheel assembly.

Unbolt the (A) tensioning handle from the (B) blade tension screw.

At the bottom handle mount turn the (B) blade tension screw clockwise until it can be lifted out of the

(C) housing.

Apply a good food grade grease to the replacement (D) tension screw and install into the (C) housing

turning counterclockwise until it bottoms out.

Replace the (A) tensioning handle. Be sure the (E) spring and (F) plunger pin are still present in the

end of the (A) handle.

Replace the upper wheel assembly and the blade.

Tension the blade.

16

(A) 55173 Tension handle

(B) 55172 Blade tension screw

(C) 55171-1 Adjustment housing

(D) 55172K Blade tension screw kit

(E) 14554 Compression spring

(F) 55178 Plunger pin

55184 O-ring, large

55313 Plastic washer

55314 O-ring, small

AN15S acorn nut, ¼-20

HHS048S Hex head screw ¼-20´1¼

Page 19

— NOTES —

17

Page 20

18

Item No. Description

A18227 Bearing cup-cone assembly

A18360 Lower bearing housing assembly w/o wheel

CB94S Carriage bolt,

3

8

-16´1

1

2

,SS

HN25S Hex nut,

3

8

-16, SS

LW25S Lock washer,

3

8

,SS

SSS05S Set screw, 10-24

´

3

8

,SS

SSS20 Set screw,

3

8

-16

´

3

8

, knurled, cup pt.

18231DL Lower shaft seal, double lip

18251AL Upper V-belt pulley, 12.8´1

1

8

, ali.

Item No. Description

18300 Lower shaft woodruff key

18360 Lower bearing housing

18361 Lower shaft

22003-6 Lower wheel, 22", 6 spoke

252X Shaft lock nut

277 Lower shaft pulley key

360A1 Grease fitting

360B-2 Adj. set screw, lwr brg hsg,

1

2

-13

´

3

4

flat pt.

362 Lower bearing housing adj. cap

Item No. Description

A18227 Bearing cup/cone assembly

A18247 Upper shaft & brg. assembly w/o wheel

A295 Wheel cleanqer assembly

HHS005S Hex head screw, 8-32

´

1

2

,SS

HHS010S Hex head screw, 10-32

´

3

8

,SS

HN05S Hex nut, 8-32, SS

HN40S Hex nut,

1

2

-13 light jam, SS

S18253 Upper wheel aligning screw, SS

S229 Wheel cleaner arm spring, SS

S244 Wheel cleaner arm stud, SS

S295 Wheel cleaner arm, SS

S325 Wheel cleaner washer, SS

Item No. Description

179 Wheel cleaner

18230DL Upper shaft seal, double lip

18247 Upper shaft

18248 Upper wheel hub cap

18252 Upper shaft lock nut

22003U-6 Upper wheel, 22", 6 spoke

234 Grease fitting

237 Upper shaft castellated lock nut

238 Upper shaft castellated lock washer

247A Upper shaft bearing back-up washer

512 Upper wheel hub cap gasket

531 Retaining ring

55174 Upper wheel hinge plate

55194 Upper wheel assembly with hinge plate

55196 Upper wheel assembly w/o hinge plate

55197 Upper wheel hinge plate assembly

Page 21

19

Item No. Description

A602 Saw guide assembly upper

FW05S Flat washer,

1

4

SS

HHS015S Hex head screw, 10-32

´

7

8

SS

HHS020S Hex head screw,

1

4

-20

´

3

8

SS

HHS085S Hex head screw,

3

8

-18´2SS

HN10S Hex nut, 10-32 SS

LW05S Lock washer, #10 SS

LW10S Lock washer,

1

4

,SS

LW15S Lock washer,

5

16

,SS

RHS10S Round head screw, 10-32

´

3

4

SS

RHS30S Round head screw,

1

4

-20

´

7

8

SS

116RS Spacer, double saw guide bar

17211-22 Shim, .022

17211-35 Shim, .035

193 Saw guide bar spring

211 Finger lift

211A-291Q Finger lift fastener knob, 4 point

211D Finger lift fastener bolt

55140 Saw guard w/708 DANGER decal

55189-1 Saw guide bar, inner, 32"

55190-1 Reinforcement bar, outer, 30"

55234 Finger lift assembly, removable

55235 Saw guide bar assembly, double

601 Upper saw guide bracket

602B Upper saw guide

708 Decal, “DANGER EXPOSED BLADE”

Item No. Description

A18275 Meat gauge plate assembly

A262 Release handle assembly

FW10S Flat washer,

5

16

,SS

HHS040S Hex head screw,

1

4

-20

´

3

4

,SS

HHS060S Hex head screw,

5

16

-18´1, SS

HN20S Hex nut,

5

16

-18, SS

LW10S Lock washer,

1

4

,SS

LW15S Lock washer,

5

16

,SS

S235 Taper pin, 4

´

3

4

,SS

S262 Release handle, SS

S265 Meat gauge release spring, SS

18275 Meat gauge arm

18275-2 Meat gauge plate, SS

264G Meat gauge hand wheel groove pin

264-1 Meat gauge release hand wheel

Item No. Description

267 Meat gauge release cotter key

270 Meat gauge release pin

271 Meat gauge worm gear

272-7-1 Lock knob,

5

16

-18, 3 point

272-8 Cap nut,

5

16

-18, SS

272-9 Hex head screw,

5

16

-18´2, SS

272-12 Brass ball,

7

32

dia.

272-13 Hex head screw,

5

16

-18´1

1

4

,SS

272-14 Castle nut,

5

16

-18, SS

275THS Truss head screw,

1

4

-20

´

3

8

275THS-1 Truss head screw,

1

4

-20´1

55182 Meat gauge bracket

55185 Meat gauge gear rack

55236 Meat gauge assembly

55237 Meat gauge bracket assembly

Page 22

20

Item No. Description

AS415D Stationary bar assembly

HHS025S Hex head screw,

1

4

-20

´

1

2

,SS

LW10S Lock washer,

1

4

SS

S268 Stationary bar headless screw

119A Saw guide in stationary bar

177 Nylon filler

S415D Stationary bar

Item No. Description

AS12132 Rear cleaning unit assembly

HHS003S Hex head screw, 8-32

´

1

4

SS

HHS055S Hex head screw,

5

16

-18

´

3

4

SS

LW15S Lock washer,

5

16

,SS

S12132 Rear blade cleaning unit

S235 Taper pin, 4

´

3

4

,SS

131 Saw cleaner, SS

211Q Fastener knob,

5

16

-18, 4 point

Item No. Description

A295 Wheel cleaner assembly

HHS003S Hex head screw, 8-32

´

1

4

SS

HHS005S Hex head screw, 8-32

´

1

2

,SS

HHS009S Hex head screw, 10-24´¼SS

HHS055S Hex head screw,

5

16

-18

´

3

4

SS

HN05S Hex nut, 8-32, SS

LW15S Lock washer,

5

16

,SS

S229 Wheel cleaner arm spring, SS

S235 Taper pin, 4

´

3

4

,SS

S244 Wheel cleaner arm shoulder bolt, SS

S295 Wheel cleaner arm, SS

S325 Wheel cleaner arm washer, SS

S608 Back-up guide, carbide

131 Saw cleaner, SS

14640 Wheel cleaner, Rulon

179 Wheel cleaner

211Q Fastener knob,

5

16

-18, 4 point

55114-1 Lower front cleaning unit, weldment

55241-1 Lower front cleaning unit assembly

Item No. Description

AS415D-2 Stationary bar assembly

HHS025S Hex head screw,

1

4

-20

´

1

2

,SS

LW10S Lock washer,

1

4

SS

S268 Stationary bar headless screw

119A Saw guide in stationary bar

177 Nylon filler

S415D-2 Stationary bar, SS

S608 Back-up guide, carbide

SSS04S Set screw, cup point 10-24

´

1

4

SS

Page 23

21

Item No. Description

A16200 Channel stop assembly, movable

A16220-1 Channel stop assembly, fixed

FW08S Flat washer,

3

8

,SS

FW15S Flat washer,

1

2

,SS

HHS055S Hex head screw,

5

16

-18

´

3

4

,SS

HHS075S Hex head screw,

3

8

-16´1

1

4

,SS

HN25S Hex nut,

3

8

-16, SS

LW15S Lock washer,

5

16

,SS

LW25S Lock washer,

3

8

heavy, SS

S200B1 Carriage stop stud, SS

Item No. Description

CB94S-1 Carriage bolt, flat head

3

8

-16´1½, SS

16200 Carriage stop, movable

16220-1 Carriage stop, fixed

18120EZ-B3 Guide bar, EZ flow

310 Waved washer

311 Rubber bumper for stops

311-1 Rubber bumper for movable stop

376 Drive screw, #10

´

1

2

,SS

55126 Channel, EZ flow

55186 Channel assembly, EZ flow

Item No. Description

A175S Thumb guard assembly, NSS

AN15S Acorn nut,

1

4

-20, SS

FW05S Flat washer,

1

4

,SS

HN25S Hex nut,

3

8

-16, SS

LW20S Lock washer,

3

8

,SS

S155EZ-1 Weld stud,

1

4

-20

´

3

8

,SS

S155EZ-2 Weld stud,

3

8

-16

´

1

2

,SS

S155EZ-3 Hex stand-off

S155-11 Meat carriage stop thumb screw, SS

Item No. Description

16155-13 Carriage stop angle, SS

16159 Meat carriage bearing, SS

175S Thumb guard

175-1-S Thumb guard nut, SS

175-2-S Thumb screw, SS

55127 Meat carriage angle, EZ flow

55128 Meat carriage top only

55180 Carriage stop

55216 Meat carriage assembly

Page 24

22

Item No. Description

HHS070S Hex head screw,

3

8

-16´1, SS

HHS125S Hex head screw,

1

2

-13´1, SS

HN31S Hex nut,

3

8

-16, SS

HN43S Hex nut,

1

2

-13, SS

LW20S Lock washer,

3

8

,SS

LW30S Lock washer,

1

2

,SS

SSS20 Set screw,

3

8

-16

´

3

8

, knurled pt.

221-68 V-belt, 68"

221-70 V-belt, 70"

4-401AL Motor pulley, 5´1

1

8

, ali.

55107 Channel bracket, right side

55108 Channel bracket, left side

55109 Channel bracket, top

55111 Front panel – channel bracket

55121 Bottom support weldment, DNS

55123 Motor mount weldment

55125 Pivot block, motor mount

55134 Motor, Baldor 5HP,

208-230/460-60-3

55134-WEG Motor, WEG 5HP,

208-230/460-60-3/TE

55134-575 Motor, Baldor 5HP, 575-60-3/TE

55137 Adjustment stud, motor mount

55179 Support, channel brkt. front panel

55187 Channel brkt. & motor comp.

assembly

Item No. Description

AS415D Stationary bar assembly

HHS025S Hex head screw,

1

4

-20

´

1

2

,SS

LW10S Lock washer,

1

4

,SS

MC-10E Cotter key,

1

8

´

1

S268 Stationary bar headless screw, SS

Item No. Description

S415D Stationary bar, SS

119A Saw guide in stationary bar

177 Nylon filler

55291 Platter, right top

55309 Platter, left top

18212W Platter rod

Item No. Description

HHS070S Hex head screw,

3

8

-16´1, SS

HHS125S Hex head screw,

1

2

-13´1, SS

HN31S Hex nut,

3

8

-16, SS

HN43S Hex nut,

1

2

-13, SS

LW20S Lock washer,

3

8

,SS

LW30S Lock washer,

1

2

,SS

SSS20 Set screw,

3

8

-16

´

3

8

, knurled pt.

221-68 V-belt, 68"

221-70 V-belt, 70"

4-401AL Motor pulley, 5´1

1

8

, ali.

55107 Channel bracket, right side

55108 Channel bracket, left side

55109 Channel bracket, top

55111 Front panel – channel bracket

55121 Bottom support weldment, DNS

55123 Motor mount weldment

55125 Pivot block, motor mount

55134 Motor, Baldor 5HP,

208-230/460-60-3

55134-WEG Motor, WEG 5HP,

208-230/460-60-3/TE

55134-575 Motor, Baldor 5HP, 575-60-3/TE

55137 Adjustment stud, motor mount

55179 Support, channel brkt. front panel

55187 Channel brkt. & motor comp.

assembly

55115

HHS080S

HHS080S Hex head screw, 3⁄8 -16 x 1 1⁄2 SS

55115 Front spacer

Page 25

23

Item No. Description

A16226A-SG GR/RD palm button assembly

HHS041S Hex head screw,

1

4

-28

´

1

2

,SS

HHS070S Hex head screw,

3

8

-16´1, SS

HN05S Hex nut, 8-32, SS

HN20S Hex nut,

5

16

-18, SS

H462 Switch guard

H462-1 Switch guard ferrule

LW03S Lock washer, #8, SS

LW15S Lock washer,

5

16

,SS

LW20S Lock washer,

3

8

,SS

RHS075S Roundhead screw, 8-32

´

3

4

,SS

151 Watertight conduit´15½"

16226A-6 Palm button speed nut

224-1 Conduit connector, straight, WT

225-1 Conduit connector, 90 deg., WT

226-28 Connector washer

226EE-540 Switch assembly, 5HP, 208/220-60-3

226EE-544 Switch assembly, 5HP, 440-60-3

226EE-548 Switch assembly, 5HP, 575-60-3

241GR Green #12 wire´33½"

241WH White #12 wire´33½"

375 Rivet

653PC-E Warning label, English

653PC-SP Warning label, Spanish

55107 Channel bracket, right side

55110 Control panel, channel bracket

55133 Switch bracket before SR No. 55059

55188 Switch mounting bracket assembly

55327 Switch bracket starting with

Serial No. 55059

NOT SHOWN

226EE-C011K Contactor, LS11K.10-C0, 208/220V

226EE-E0 Contactor, LS05.10-E0, 440V

226EE-F0 Contactor, LS05.10-F0, 575V

226EE-OL08L Overload, B17S-M, (5.5-8)

226EE-OL18O Overload, B17S-O, (14.5-18)

Page 26

OPTIONAL DOUBLE ROLLING TABLES

24

Item No. Description

A36-2001 Carriage stop assembly, movable

A36-2002 Carriage stop assembly, fixed

FW08S Flat washer,

3

8

,SS

FW15S Flat washer,

1

2

,SS

HHS025S Hex head screw,

1

4

-20

´

1

2

,SS

HHS041S Hex head screw,

1

4

-28

´

1

2

,SS

HHS055S Hex head screw,

5

16

-18

´

3

4

,SS

HHS070S Hex head screw,

3

8

-16´1, SS

HN15S Hex nut,

1

4

-20, SS

HN20S Hex nut,

5

16

-18, SS

HN25S Hex nut,

3

8

-16, SS

HN30S Hex nut,

3

8

-16 light jam, SS

HN35S Hex nut,

3

8

-16, heavy jam, SS

LW10S Lock washer,

1

4

,SS

LW15S Lock washer,

5

16

,SS

LW20S Lock washer,

3

8

,SS

LW25S Lock washer,

3

8

heavy, SS

S155EZ-2 Weld stud,

3

8

-16

´

1

2

S155EZ-3 Hex stand-off

S235 Taper pin, 4

´

3

4

,SS

S360CB-1 Carriage bolt,

3

8

-16´1

1

4

,SS

16015-3 Motor base plate wing nut

16159 Meat carriage bearing, SS

18120EZ-B3 Guide bar, EZ flow

18D9239-4 Left rear bearing angle

18D9239-5 Left front bearing angle

296-800H Switch bracket

375 Drive screw

Item No. Description

376 Drive screw, #10

´

1

2

,SS

50655-1 Pushbutton switch guard

55121 Bottom support weldment, DNS

55198 Bearing angle, right rear

55199 Bearing angle, right front

55200 Rear meat carriage, dbl rolling tables

55203 Front meat carriage, dbl rolling tables

55204 Rim extension, right

55205 Front box channel, dbl rolling tables

55206 Channel bracket, right side, dbl rolling tables

55207 Channel bracket, left side, dbl rolling tables

55208 Pan angle, front meat carriage

55210 Tie bar, left

55211 Tie bar, right

55212 Top front panel, channel bracket

55213 Filler plate with neck guard,

dbl rolling tables

55304 Saw guard w/708 Danger decal for double

rolling tables

653PC-E Warning label, English

653PC-SP Warning label, Spanish

800H-2HA4 Watertight start/stop station, SS enclosure

NOT SHOWN

226EE-605 Switch assembly 5HP, 208/230-60-3

226EE-C011K Contactor, LS11K.10-C0, 208/230

226EE-0L18O Overload, B18K-O (14.5-18)

Page 27

OPTIONAL FIXED FRONT FULL LENGTH TABLE

25

Item No. Description

AS415D Stationary bar assembly

A16220-1 Carriage stop assembly, fixed

FW08S Flat washer,

3

8

,SS

HHS025S Hex head screw,

1

4

-20

´

1

2

,SS

HHS055S Hex head screw,

5

16

-18

´

3

4

,SS

HHS070S Hex head screw,

3

8

-16´1, SS

HN25S Hex nut,

3

8

-16, SS

LW10S Lock washer,

1

4

,SS

LW15S Lock washer,

5

16

,SS

LW25S Lock washer,

3

8

heavy, SS

MC-10E Cotter key,

1

8

´

1

S268 Stationary bar headless screw

Item No. Description

CB94S-1 Carriage bolt, flat head

3

8

-16´1½, SS

S415D Stationary bar, SS

119A Saw guide in stationary bar

16220-1 Carriage stop, fixed

177 Nylon filler

311 Rubber bumper

376 Drive screw, #10

´

1

2

,SS

55126-FT Channel, for fixed front table

55309 Left top platter assembly

18212W Platter rod

55177 Front stationary table assembly

55317 Right top fixed table, platter

Page 28

MODEL 55 ITEM NUMBERS AND DESCRIPTIONS

ALWAYS ADVISE MODEL & SERIAL NUMBER WHEN ORDERING

26

Item No. Description

AN15S Acorn nut,

1

4

-20, SS

CB64S Carriage bolt,

1

4

-20´1

1

2

,SS

FW05S Flat washer,

1

4

,SS

FW08S Flat washer,

3

8

,SS

FW10S Flat washer,

5

16

,SS

FW15S Flat washer,

1

2

,SS

HHS003S Hex head screw, 8-32

´

1

4

,SS

HHS005S Hex head screw, 8-32

´

5

8

,SS

HHS009S Hex head screw, 10-24´¼SS

HHS010S Hex head screw, 10-32

´

3

8

,SS

HHS015S Hex head screw, 10-32

´

7

8

,SS

HHS020S Hex head screw,

1

4

-20

´

3

8

,SS

HHS025S Hex head screw,

1

4

-20

´

1

2

, SS

HHS040S Hex head screw,

1

4

-20

´

3

4

,SS

HHS041S Hex head screw,

1

4

-28

´

1

2

,SS

HHS0481S Hex head screw,

1

4

-20´1

1

2

,SS

HHS055S Hex head screw,

5

16

-18

´

3

4

,SS

HHS058S Hex head screw,

5

16

-18

´

7

8

,SS

HHS060S Hex head screw,

5

16

-18´1, SS

HHS070S Hex head screw,

3

8

-16´1, SS

HHS075S Hex head screw,

3

8

-16´1

1

4

,SS

HHS085S Hex head screw,

3

8

-16´2, SS

HHS110S Hex head screw,

1

2

-20´1, SS

HHS125S Hex head screw,

1

2

-13´1, SS

HN05S Hex nut, 8-32, SS

HN10S Hex nut, 10-32, SS

HN15S Hex nut,

1

4

-20, SS

HN20S Hex nut,

5

16

-18, SS

HN25S Hex nut,

3

8

-16, SS

HN30S Hex nut,

3

8

-16 light jam, SS

HN31S Hex nut,

3

8

-16, SS

HN35S Hex nut,

3

8

-16 heavy jam, SS

HN40S Hex nut,

1

2

-13 light jam, SS

HN43S Hex nut, ½-13, SS

HN45S Hex nut,

1

2

-20, SS

HN49 Hex nut,

5

8

-11, plated

HN55S Hex nut,

5

8

-18 jam, SS

H462 Switch guard

H642-1 Switch guard ferrule

LW05S Lock washer, #10, SS

LW10S Lock washer,

1

4

,SS

LW15S Lock washer,

5

16

,SS

LW20S Lock washer,

3

8

,SS

LW25S Lock washer,

3

8

heavy, SS

LW30S Lock washer,

1

2

,SS

LW35S Lock washer,

5

8

,SS

MC-10E Cotter pin,

1

8

´

1, SS

RHS075S Round head screw, 8-32

´

3

4

,SS

RHS10S Round head screw, 10-32

´

3

4

,SS

RHS30S Round head screw,

1

4

-20

´

7

8

,SS

SSS04S Set screw, 10-24

´

1

4

, cone point, SS

SSS05S Set screw, 10-24

´

3

8

, cup point, SS

SSS20 Set screw,

3

8

-16

´

3

8

, knurled cup point, SS

S12132 Rear blade cleaning unit

S155EZ-1 Weld stud,

1

4

-20

´

3

8

,SS

S155EZ-2 Weld stud,

3

8

-16

´

1

2

,SS

S155EZ-3 Hex stand-off

S18253 Upper wheel aligning screw, SS

S200B1 Stop stud, SS

S229 Wheel cleaner arm spring, SS

S235 Taper pin, 4

´

3

4

,SS

S244 Wheel cleaner arm shoulder bolt, SS

S262 Meat gauge release handle, SS

S265 Meat gauge release spring, SS

S268 Stationary bar headless screw, SS

S295 Wheel cleaner arm, SS

S325 Wheel cleaner washer, SS

CB94S-1 Carriage bolt, flat head

3

8

-16´1½, SS

S415D Stationary bar, SS

S608 Back up guide, carbide

TP4S Taper pin, 4

´

3

4

,SS

TP6S Taper pin, 6

´

3

4

,SS

VT460S Model & S/N plate

112-212 Waved washer

116RS Saw guide bar spacer block

119A Saw guide in stationary bar

131 Saw cleaner, SS

14TH Head door hinge, welded

14TP Head door hinge pin, long

Item No. Description

14TP-1 Head door hinge pin, short

14640 Wheel cleaner, rulon

151 WT conduit

16015-3 Motor base plate wing nut

16155-13 Carriage stop angle, SS

16159 Meat carriage bearing, SS

16200 Movable carriage stop

16220-1 Fixed carriage stop

16226A-6 Palm button speed nut

17211-22 Fingerlift shim, .022

17211-35 Fingerlift shim, .035

175S Thumb guard

175-1-S Thumb guard nut, SS

175-2-S Thumb screw

177 Nylon filler

179 Wheel cleaner

18D9239-4 Left rear bearing angle

18D9239-5 Left front bearing angle

18120EZ-B3 Guide bar, EZ flow

18212W Platter rod

18230DL Upper shaft seal, double lip

18231DL Lower shaft seal, double lip

18247 Upper shaft

18251AL Upper v-belt pulley, 12.8´1

1

8

, ali.

18252 Upper shaft lock nut

18275 Meat gauge arm

18275-2 Meat gauge plate only, SS

18300 Lower shaft woodruff key

18360 Lower bearing housing

18361 Lower shaft

193 Saw guide bar spring

194KS-1 Lock knob – 1

1

8

"

196 Tension spring

211 Finger lift

211A-291Q Fastener knob,

3

8

-16, 4 point

211D Finger lift fastener stud

211Q Fastener knob,

5

16

-18, 4 point

22003-6 Lower wheel, 22", 6 spoke

22003U-6 Upper wheel, 22", 6 spoke

221-68 V-belt, 68"

221-70 V-belt, 70"

224-1 Conduit connector, straight, WT

225-1 Conduit connector, 90 deg., WT

226-28 Connector washer

226EE-C011K Contactor, LS11K.10-C0, 208/220V

226EE-E0 Contactor, LS05.10-E0, 440V

226EE-OL08L Overload, B17S-M, (5.5-8)

226EE-OL18O Overload, B17S-O, (14.5-18)

226EE-540 Magnetic starter, 5HP, 208/220-60-3

226EE-544 Magnetic starter, 5HP, 440-60-3

226EE-548 Switch assembly, 5HP, 575-60-3

226EE-605 Switch assembly 5HP, 208/230-60-3

for double rolling tables

234 Grease fitting

237 Upper shaft castellated lock nut

238 Upper shaft castellated lock washer

241GR Green wire, 12 ga.

241WH White wire, 12 ga.

247A Upper shaft bearing spacer washer

249 Door lock handle

252X Shaft lock nut

256P Safety end cut pusher plate

264G Meat gauge hand wheel groove pin

264-1 Meat gauge release hand wheel

267 Meat gauge release cotter pin

270 Meat gauge release pin

271 Meat gauge worm gear

272-7-1 Lock knob,

5

16

-18, 3 point

272-8 Cap nut,

5

16

-18, SS

272-9 Hex head screw,

5

16

-18´2, SS

272-12 Brass ball,

7

32

272-13 Hex head bolt,

5

16

-18´1

1

4

,SS

272-14 Castle nut,

5

16

-18, SS

275THS Truss head screw,

1

4

-20

´

3

8

275THS-1 Truss head screw,

1

4

-20´1

296-800H Pushbutton switch bracket

310 Waved washer

311 Rubber bumper

311-1 Rubber bumper

Page 29

MODEL 55 ITEM NUMBERS AND DESCRIPTIONS (Cont.)

27

ASSEMBLIES FOR MODEL 55

Item No. Description

AS12132 Rear cleaning unit assembly

AS415D Stationary bar assembly

A16112 Head door latch assembly

A16200 Carriage stop assembly, movable

A16220-1 Carriage stop assembly, fixed

A16226A-SG Palm button assembly

A175S Thumb guard assembly

A18227 Bearing cup/cone assembly

A18247 Upper shaft & bearing assembly

A18275 Meat gauge plate assembly

A262 Meat gauge release assembly

A295 Wheel cleaner assembly

A36-2001 Carriage stop assembly, dbl rolling tables

A36-2002 Carriage stop assembly, dbl rolling tables

A602 Upper guide assembly

55164 Left top platter assembly

55186 Channel assembly, EZ flow

Item No. Description

55187 Channel brkt & motor comp. assembly

55191 Head & door assemlby

55192 Blade tension assembly

55193 Hinge bracket assembly, upper wheel

55194 Upper wheel assembly w/hinge plate

55196 Upper wheel assembly w/o hinge plate

55197 Upper hinge plate assembly

55216 Meat carriage assembly, EZ flow

55233 Head door assembly

55234 Finger lift assembly, removable

55235 Saw guide bar assembly, double

55236 Meat gauge assembly

55237 Meat gauge bracket assembly

55238 Platter assembly

55241-1 Front cleaning unit assembly

55242 Lower bearing housing assembly w/o wheel

55243 Opt. fixed table assembly

Item No. Description

36A1 Grease fitting

360B-2 Set screw,

1

2

-13

´

3

4

, flat point

362 Bearing adjusting cap

36-239LN Locknut, 1

1

4

-12, SS

36-239L-10A Solid leg, 10", SS

36-242R Base door lock

375 Drive screw

376 Drive screw, #10

´

1

2

,SS

4-401AL Motor pulley, 5´1

1

8

, ali

50655 Switch guard

512 Upper wheel hub gasket

531 Retaining ring

55100-1 Base frame assembly

55102 Basefoot outrigger angle, rear, 30"

55104 Base door, right hinged

55105 Left panel w/handle

55106 Scrap bucket

55107 Channel bracket, right side

55108 Channel bracket, left side

55109 Channel bracket, top

55110 Control panel, channel bracket

55111 Front panel – channel bracket

55114-1 Lower cleaning unit weldment

55121 Bottom support weldment, DNS

55123 Motor mount weldment

55125 Pivot block, motor mount

55126 Channel, EZ flow

55126-FT Channel, fixed front table

55127 Meat cariage angle, EZ flow

55128 Meat carriage top only

55131 Platter, right top

55133 Switch bracket before SR No. 55059

55134 Motor, Baldor 5HP, 208-220/440-60-3

55134-WEG Motor, WEG 5HP, 208-230/460-60-3/TE

55134-575 Motor, Baldor 5HP, 575-60-3/TE

55137 Adjustment stud, motor mount

55138 Upper wheel hinge bracket

55140 Saw guard on saw guide bar w/708 decal

55153 Head weldment

55154 Head door

55165 Platter rod, RH platter top

55168 Thread, head column

55170 Blade tension cap gauge

55171 Blade tension adjustment housing

Item No. Description

55172 Blade tension screw

55173 Blade tension adjustment handle

55174 Upper wheel plate

55177 Front stationary table assembly

55179 Support, channel bracket front panel

55180 Carriage stop

55181 Base foot outrigger, front

55182 Meat gauge bracket

55184 O-Ring, blade tension screw

55185 Meat gauge gear rack

55189 Saw guide bar, 32"

55190 Reinforcement bar, 30"

55195 Right top fixed table, platter

55198 Bearing angle, right rear

55199

Bearing angle, right front

55200 Rear meat carriage, dbl rolling tables

55203 Front meat carriage, dbl rolling tables

55204 Rim extension, right

55205 Front box channel, dbl rolling tables

55206 Channel bracket, right side, dbl rolling tables

55207 Channel bracket, left side, dbl rolling tables

55208 Pan angle, front meat carriage

55210 Tie bar, left

55211 tie bar, right

55212 Top front panel, channel bracket

55213 Filler plate, dbl rolling tables

55220 Motor mount support, LH

55290 Platter bracket

55302HT Saw blade, 164-

123

4

´

X .022 HT, 3TPI

55291 Platter – right top

55309 Platter – left top

55312 O-ring for tension cap gauge

55313 Plastic washer – tension screw

55314 O-ring – plastic washer

55317 Platter – right top fixed table

55327 Switch bracket starting with Serial No. 55059

601 Upper saw guide bracket

602B Upper blade back-up guide, carbide

653PC-E Warning label, English

653PC-F Warning label, French

653PC-SP Warning label, Spanish

671 Wall poster

708 Decal “DANGER EXPOSED BLADE”

800H-2HA4 WT start/stop station, SS

Page 30

WEARABLE SAW PARTS THAT WILL FIT BIRO POWER CUTTERS

MODELS

11-22-1433-33-34-3334-44-4436-55

— EXCEPT WHERE NOTED OTHERWISE —

CONTACT YOUR NEAREST BIRO AUTHORIZED DISTRIBUTOR

OR CONTACT BIRO MANUFACTURING

Ph. 419-798-4451 E-Mail: service@birosaw.com

28

Page 31

OPERATOR'S SIGNATURE PAGE

MY SIGNATURE ATTESTS THAT I HAVE COMPLETELY READ AND UNDERSTAND THIS

MANUAL. I REALIZE THAT THIS MACHINE, IF OPERATED CARELESSLY, CAN CAUSE SERIOUS INJURY TO MYSELF AND OTHERS.

NAME (PRINT) SIGNATURE

SUPERVISOR’S

INITIALS

DATE

29

Page 32

LIMITED WARRANTY:

WARRANTY: The BIRO Manufacturing Company warrants that Model 55 Power Meat Saw will be free

from defects in material and workmanship under normal use and with recommended service. BIRO

will replace defective parts, which are covered by this limited warranty, provided that the defective parts

are authorized for return, shipping charges prepaid, to a designated factory for inspection and/or testing.

DURATION OF WARRANTY: The warranty period for all parts covered by this limited warranty is

eighteen (18) months from Inspection/Demonstration as advised on the returned Warranty Registration

card, or two (2) years from original factory ship date, whichever occurs first, except as noted.

PARTS NOT COVERED BY WARRANTY: The following are not covered by this limited warranty:

steel cleaners, item number 131; wheel cleaners, item number 179; steel guide, item number 119A;

upper saw guide, item number 602B; lower back guide, item number S608; nylon filler, item number

177. This limited warranty does not apply to machines sold as used, rebuilt, modified,or altered from

the original construction in which the machine was shipped from the factory. (WATER CONTAMINATED ELECTRICAL SYSTEMS ARE NOT COVERED UNDER THIS LIMITED WARRANTY.) BIRO is

not responsible for electrical connection of equipment, adjustments to switch controls or any other

electrical requirements, which must be performed only by a certified electrician. BIRO is not responsible for service charges or labor required to replace any part covered by this limited warranty or for any

damages resulting from misuse, abuse, lack of proper or recommended service.

EXCLUSION OF WARRANTIES AND LIMITATION OF REMEDIES: BIRO gives no warranties other

than those expressly stated in this limited warranty. THE IMPLIED WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR PROCESSING OF FOOD PRODUCTS, AND ALL

OTHER IMPLIED WARRANTIES ARE SPECIFICALLY EXCLUDED. BIRO IS NOT LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, EXPENSES, OR LOSSES. THE REMEDIES PROVIDED

IN THIS BIRO LIMITED WARRANTY ARE PURCHASER’S SOLE AND EXCLUSIVE REMEDIES

AGAINST BIRO.

REGISTRATION CARDS: You must sign, date and complete the warranty registration card supplied

with each machine. The warranty card must be returned to The Biro Manufacturing Company for

proper registration. If no warranty card is returned to BIRO, the warranty period will begin from the

date the machine was originally shipped from the factory.

HOW TO GET SERVICE:

1. Contact the agency from whom you purchased the machine.

2. Consult the yellow pages of the phone directory for the nearest authorized dealer.

3. Contact BIRO Mfg. Co. for the authorized service entity (250 plus worldwide) in your area.

THE BIRO MANUFACTURING COMPANY

1114 Main Street

Marblehead, Ohio 43440-2099

Ph. 419-798-4451

Fax 419-798-9106

E-mail: service@birosaw.com

Web: http://www.birosaw.com

30

ITEM No.: 55221-284

PTCT Md 55-284-11-06-4 COMM

ITEM No.: 55221-284

PTCT Md 55-284-4-08-5 PPD

Loading...

Loading...