Page 1

KNOWN FOR RELIABILITY

FOR OVER 87 YEARS

The industry standard 16” power cutters feature all stainless steel unitized welded

enclosed base structure with aluminum head structure. A stainless steel head is

available at extra cost.

The 3334SS is of proven design, durable, and reliable and is applicable to all small,

medium, and large supermarkets, and small and medium meat plants.

Unitized welded enclosed stainless steel base structure is standard. True blade

alignment allows excellent blade tracking, giving dependable straight cutting

year after year.

A broad range of right hand feed and true left hand feed machines are available.

There are numerous configurations and optional equipment to select from to meet

your requirements.

Model

3334SS-4003FH

Model

3334SS-4003

Model

3334SS Standard

End cut safety plate

not mounted

Page 2

MODELS

A=3334SS STD. (16”) B=3334SS-4003 (16”) C=3334SS-4003FH (16”)

CONSTRUCTION

UNITIZED STAINLESS STEEL BASE, TABLES, LEG BOLT LEVELERS, CARRIAGE CHANNEL & SUPPORTS

ALUMINUM HEAD AND DOOR REMOVABLE STAINLESS STEEL DOOR AND

FIXED HEAD

MOTORS

STANDARD EQUIPMENT

TWO SAW BLADES, OPERATION AND SAFETY MANUAL, SAFETY WALL POSTER, AND END CUT SAFETY PUSHER PLATE

SWITCH

GENERAL PURPOSE WATERTIGHT MAGNETIC, THERMAL OVERLOAD AND UNDER VOLTAGE PROTECTION

THERMAL OVERLOAD

HEAD AND DOOR

ALUMINUM STAINLESS STEEL FIXED

(RATCHET ARM BLADE TENSION) (SCREW HANDLE ASSEMBLY)

BASE STRUCTURE

STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL

BLADE STANDARD

124” (3150 MM) LENGTH X 5/8” (16 MM) WIDE X .022 (.5 MM) THICK, 3 TEETH PER INCH (8.5 MM BETWEEN TEETH, HARD TOOTH

(TWO SUPPLIED WITH EACH SAW)

BLADE SPEED

3200 (975 M) FEET PER MINUTE 4000 (1219 M) FEET PER MINUTE

BLADE GUIDE

UPPER AND LOWER BLADE BACKUP GUIDE ASSEMBLIES, REMOVABLE, WITH LONG LIFE CARBIDE BACKUP INSERTS

BLADE TENSION

RATCHET ARM AND CAM AGAINST POUND TESTED SPRING FACTORY PRESET SPRING SCREW

AND TENSION SPRING GAUGE HANDLE ASSEMBLY

BLADE WHEELS

16” (40.24 CM) CAST IRON CHROME NICKEL PLATING, UPPER ASSEMBLY LIFTS OUT

BEARINGS

HEAVY DUTY TAPERED ROLLER BEARINGS USED IN UPPER WHEEL AND LOWER BEARING HOUSING

CATCH PAN

POLY, EXTRA DEEP, ROUNDED CORNERS, PAN SEALED OFF FROM OTHER PARTS OF BASE, ACCESSIBLE THROUGH BASE

HINGED DOOR

CLEANING UNIT

STAINLESS STEEL BODY, LONG-LIFE CARBIDE GUIDES, STEEL SAW CLEANERS, REMOVABLE AS A UNIT FOR EASY CLEANING

(ASSEMBLY ALSO ADJUSTABLE AS A UNIT)

DRIVE SYSTEM

NON SLIP SILENT V-BELT, TENSION ADJUSTABLE DOUBLE V-BELT, TENSION

ADJUSTABLE

LEGS

STAINLESS STEEL LEG BOLT LEVELERS

MEAT CARRIAGE

STAINLESS STEEL, NYLON GUIDES, LARGER STAINLESS STEEL E-Z FLOW 8-BEARINGS CARRIAGE

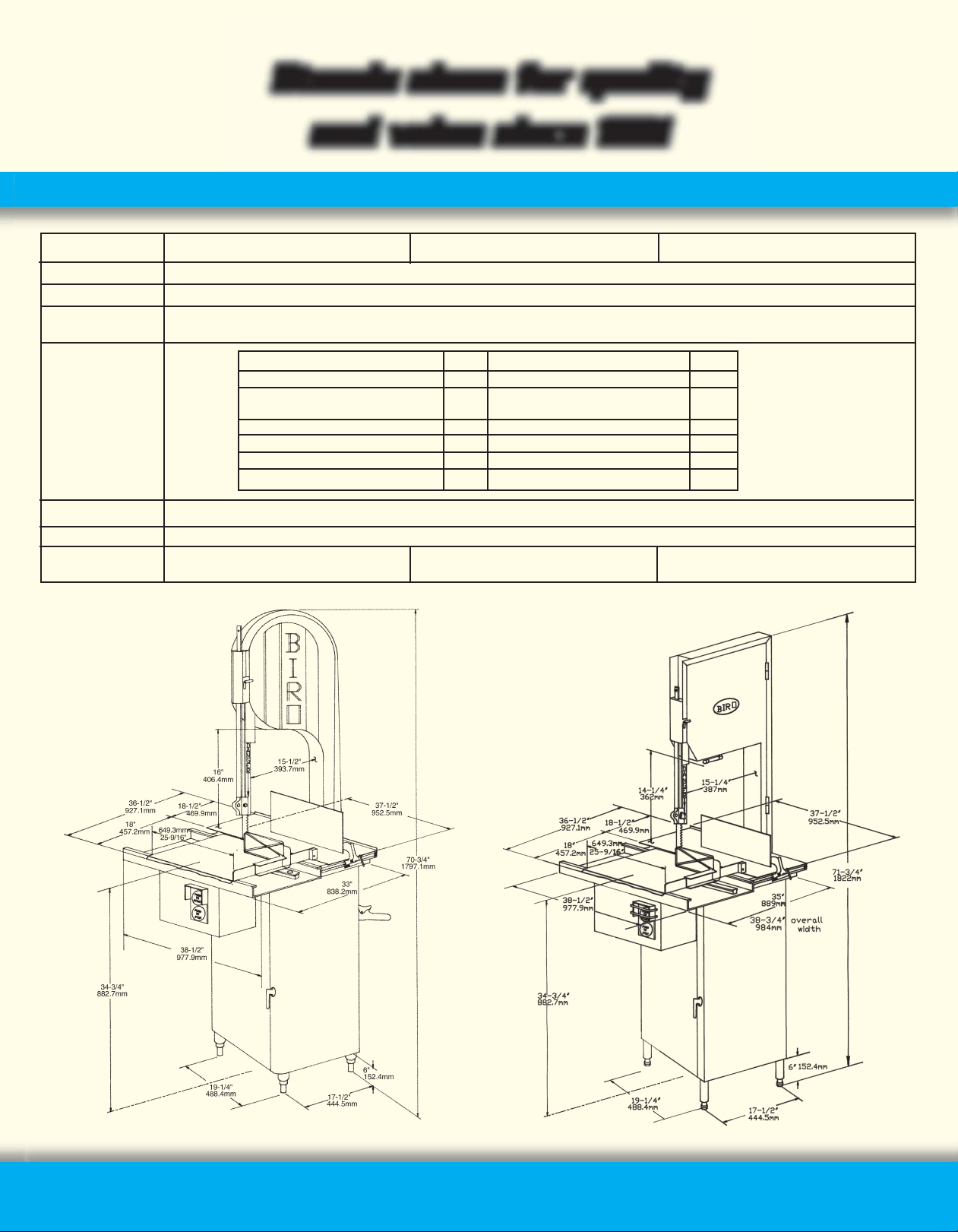

BEARINGS 15-1/2” (394 MM) X 18” (457-2 MM) WIDE X 25-9/16” (649.3 MM) LONG

23-1/2” (597 MM)

MEAT GAUGE PLATE

STAINLESS STEEL FACED, ADJUSTABLE FROM 1/16” (1.6 MM) TO 6-1/2” (106.1 MM), LOCKS IN POSITION, EASY TO ADJUST, ENTIRE

ASSEMBLY REMOVABLE FOR CLEANING

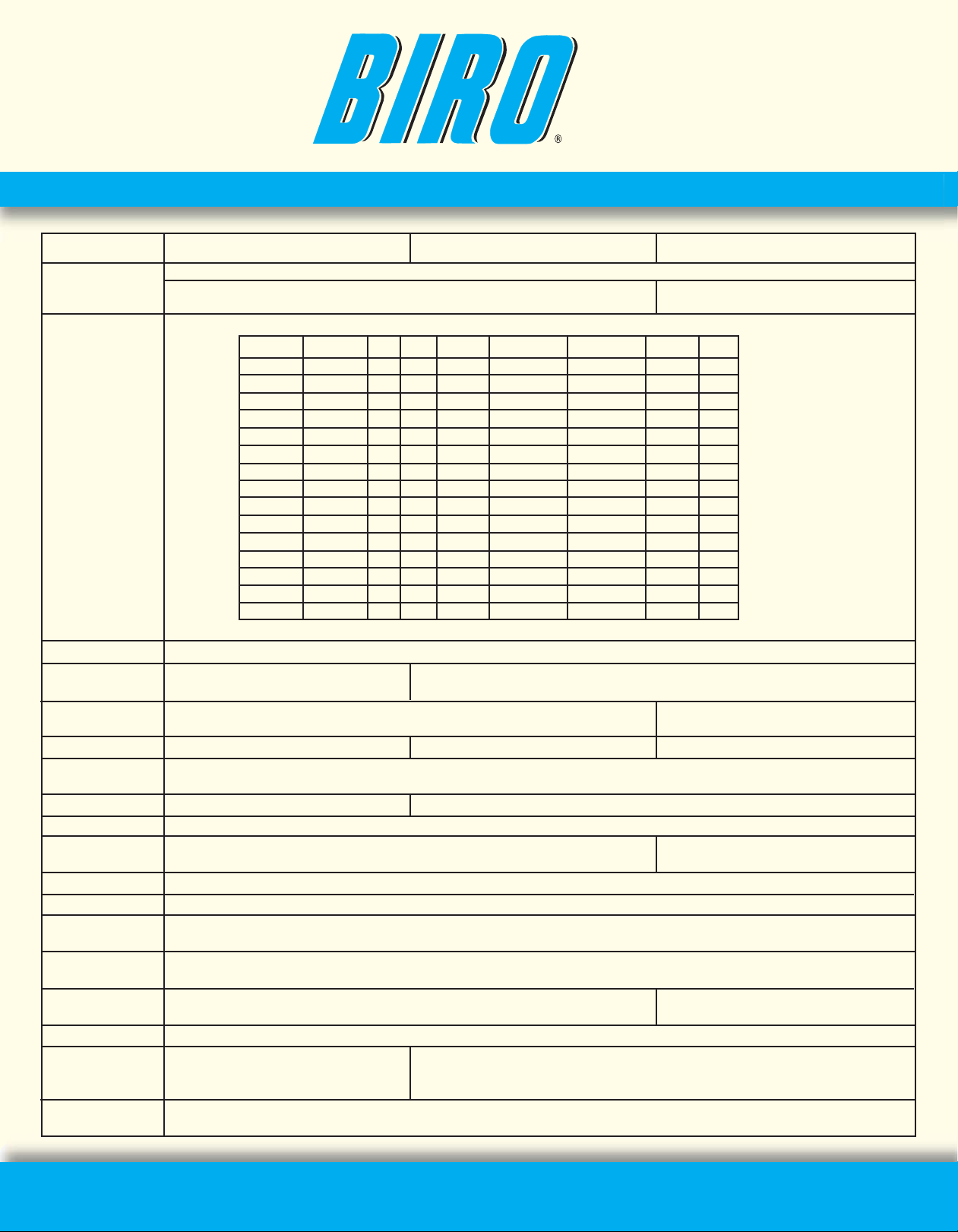

MODEL STATUS HP KW TYPE VOLTS AMPS CYCLE PH

A STD 2 1.5 HH 115/208-230 21/11.6-10.5 60 1

A STD 2 1.5 HH 208-220/440 5.9-5.6/2.8 50/60 3

A EC 2 1.5 TE 115/208-230 21/11.6-10.5 60 1

A EC 2 1.5 TE 208-220/440 6.3-5.8/2.9 50/60 3

A EC 2 1.5 TE 550 2.2 60 3

A EC 2 1.5 HH 115/208-230 28/15-14 50 1

A EC 3 2.2 TE 208-220/440 9.1-8.6/4.3 60 3

B-C STD 3 2.2 TE 208-220/440 9.1-8.6/4.3 60 3

A EC 3 2.2 TE 208/380-415 8.1/5.8-4.3 50 3

B-C STD 3 2.2 TE 220/380-415 8.1/5.8-4.3 50 3

A-B-C EC 3 2.2 TE 208-230 15.5-14 60 1

A-B-C EC 3 2.2 TE 220-440 12.5-11.5 50 1

A-B-C EC 3 2.2 TE 550 3.6 60 3

A-B-C EC 5 3.7 TE WP 208-220/440 14.4-13.6/6.8 50/60 3

A-B-C EC 5 3.7 TE WP 380-415 7.9-72 50 3

STD=Standard EC=Extra Cost TEFC=Totally Enclosed Fan Cooled WP=Water Proof HH=High Humidity

A=3334SS STD B=3334SS-4003 C=3334SS-4003FH

Page 3

Stands alone for quality

and value since 1921

Service is available from over 245 locations worldwide

MOTOR COMPARTMENT

SEALED OFF FROM MEAT CONTACT AREAS, EASILY ACCESSIBLE THROUGH REMOVABLE PANEL DOOR

PLATTER

ALL STAINLESS STEEL, HELD IN PLACE WITH TWO PUSH PULL HOLD DOWN STAINLESS STEEL RODS

SAFETY END CUT

STANDARD, REMOVABLE

PUSHER PLATE

OPTIONS (EC)

OPTIONS (NC)

HIGHER FEET PER MINUTE SPEED (CALL FACTORY)

CERTIFICATION

U.L., N.S.F., U.S.D.A., C.S.A., C.F.I.A.

WEIGHT

UNCRATED: 464 LBS. (210 KG) UNCRATED: 510 LBS. (231 KG) UNCRATED: 522 LBS. (237 KG)

CRATED: 531 LBS. (240 KG) CRATED: 564 LBS. (256 KG) CRATED: 575 LBS. (261 KG)

MODELS

A=3334SS STD. (16”) B=3334SS-4003 (16”) C=3334SS-4003FH (16”)

WATERTIGHT MAGNETIC SWITCH A POWER CORD AND PLUG A,B,C

LOWER REMOVABLE SAW WHEEL A,B,C DOUBLE FLANGE BLADE WHEELS A,B,C

STAINLESS STEEL HEAD AND A,B DOUBLE FLANGE BLADE WHEELS A,B,C

DOOR (MOVABLE) (LOWER REMOVABLE)

DOUBLE SAW GUIDE BAR A,B,C NARROW GUIDES (CHECK FACTORY) A,B,C

LEFT HAND FEED WITH S.S. HEAD A,B STATIONARY FRONT TABLE A,B,C

LOW PROFILE S.S. HEAD STRUCTURE A,B STAINLESS STEEL WHEELS A,B,C

WATER JET B,C SPLIT PLATTER, FAST BLADE CHANGE A,B,C

Model 3334SS-4003

Model 3334SS-4003FH

Page 4

THE BIRO MANUFACTURING COMPANY

1114 WEST MAIN STREET

MARBLEHEAD, OH 43440-2099 U.S.A.

Phone: (419) 798-4451

Fax: (419) 798-9106

http://www.birosaw.com

sales@birosaw.com

ITEM NO.: LIT 3334 SERIES-334

FORM NO.: Md 3334SS-339-9-08-2-MARK

ALL SPECIFICATIONS CONTAINED HEREIN ARE

SUBJECT TO CHANGE WITHOUT NOTIFICATION.

Model 3334SS

Right Hand Feed

Stainless Steel Head and Door Structure

Portion Control Gauge Plate Full Length of Platter

Meat Gauge Stabilizers

Model 3334SS

Right Hand Feed

Stainless Steel Head and Door Structure

Split Platter

Precision Gauging Fence – Full Length

Model 3334SS Trim Cutter

True Left Hand Feed

Stationary Front Table

Less Meat Gauge Plate Assembly

Stainless Steel Head and Door Structure

Model 3334SS Trim Cutter

Right Hand Feed

Stationary Front Table 15-1/2” x 38”

Meat Gauge Plate Assembly Available

Loading...

Loading...