Page 1

Page 2

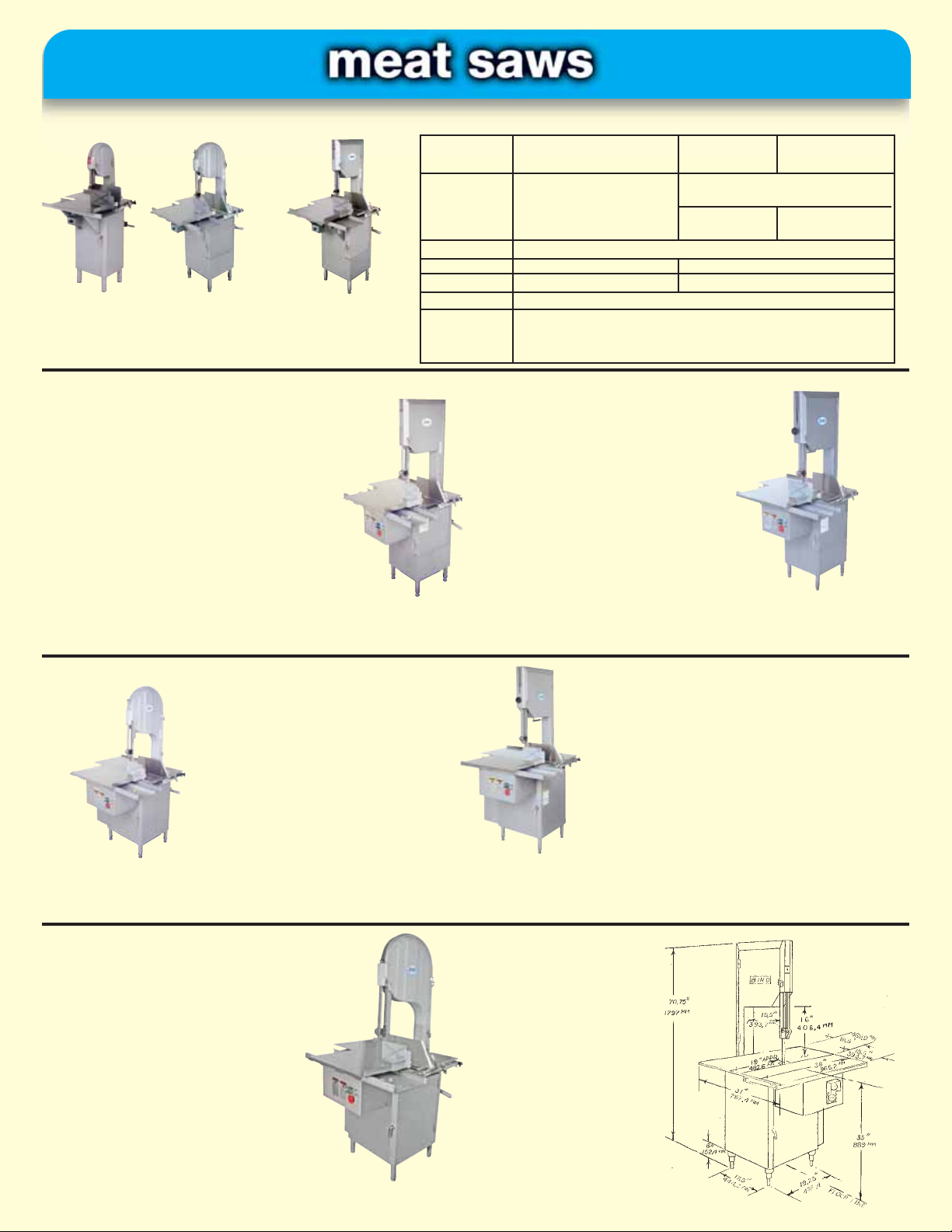

MODEL 22SS

MEAT SAW

12” (305mm)

MODEL 22SS MEAT SAW

W/SS HEAD STRUCTURE

12” (305mm)

Model 11 Model 22SS Model 22SS

SS Head

Finish: Powder Coating Stainless steel body

Nickel - Cast Nickel

Aluminum Cast Aluminum SS Head &

Head Door Structure

Motors: 1-1/2 HP (1.1kw), 1 or 3 phase, 50 or 60 Hz open high humidity

Blade: 5/8” (16mm) x 78” (1981mm)-4 TPI 5/8 (16mm) x 91” (2311mm)-4 TPI

Blade Speed: 3000 (914m) 3000 (914m)

Cutting Clearance: 9-1/4” (235mm) H x 9-1/4” (235mm) W 12-1/2” (317.5mm) H x 11” (279.4mm) W

Extra Cost Cord & plug, T.E.motors, watertight magnetic

Modifications: switches, 50 cycle 1 phase, front stationary

stainless steel table.

MODEL 1433 14” (355mm) MEAT SAW

Finish: Stainless steel, nickel.

Head structure: Stainless steel, movable, ratchet tension

Motor: 3 HP (2.2 kw), 50 or 60 Hz, 3 phase

totally enclosed, 1 phase available.

Switch: Watertight magnetic starter

with thermal overload and

under voltage protection.

Blade & Speed: 5/8” (16mm) x 108” (2743mm),

3550 fpm (1082M) ,higher speed at

no cost.

Cutting Clearance: 14-1/4” (362mm) H x 13” (330mm) W.

Meat Carriage: Stainless steel, EZ-Flow

System 23-1/2” (597mm) L x 15-1/2” (394mm) W.

Options: Stationary front table, optional motor voltages &

(Extra Cost) phases, cord and plug.

MODEL 3334SS-4003 16” (405mm) MEAT SAW

Finish: Stainless steel, nickel.

Head Structure: Cast aluminum, movable, ratchet tension.

Motor: 3 HP (2.2kw), 50 or 60 Hz, 3 phase

totally enclosed, 1 phase available.

Switch: Watertight magnetic starter with

thermal overload and under

voltage protection.

Blade & Speed: 5/8” (16mm) x 124” (3150mm),

4000 fpm (1219m), higher speed

at no cost.

Cutting Clearance: 15-1/2” (393.7mm) H x 15-1/2” (393.7mm) W.

Meat Carriage: Stainless steel, EZ-Flow

System 25-9/16” (649.3mm) L x 18” (457mm) W.

Extra Cost Modifications: Stainless steel head, cord and plug, water jet blade

cleaning system.

MODEL 3334SS-4003FH 16” (405mm) MEAT SAW

Finish: Stainless steel, nickel.

Head Structure: Fixed stainless steel.

Motor: 3 HP (2.2kw), 50 or 60 Hz, 3 phase

totally enclosed, 1 phase available.

Switch: Watertight magnetic starter

with thermal overload and

under voltage protection.

Blade & Speed: 5/8” (16mm) x 124” (3150mm),

4000 fpm (1219m), higher speed at no cost.

Cutting Clearance: 15-1/2” (393.7mm) H x 15-1/2” (393.7mm) W.

Meat Carriage: Stainless steel, EZ-Flow

System 25-9/16” (649.3mm) L x 18” (457mm) W.

Extra Cost Modifications: Cord and plug, water jet blade cleaning system.

MODEL 1433FH 14” (355mm) MEAT SAW

Finish: Stainless steel, nickel.

Head structure: Fixed stainless steel.

Motor: 3 HP (2.2kw), 50 or 60 Hz, 3 phase

totally enclosed, 1 phase available.

Switch: Watertight magnetic starter

with thermal overload and

under voltage protection.

Blade & Speed: 5/8” (16mm) x 108” (2743mm),

3550 fpm (1082m), higher speed

at no cost.

Cutting Clearance: 14-1/4” (362mm) H x 13” (330mm) W.

Meat Carriage: Stainless steel, EZ-Flow

System 23-1/2” (597mm) L x 15-1/2” (394mm) W.

Options: Stationary front table, optional motor voltages and

(Extra Cost) phases, cord and plug.

MODEL 11

MEAT SAW

10” (255mm)

MODEL 3334SS 16” (405mm) MEAT SAW

“ORIGINAL STANDARD”

Finish: Stainless steel, nickel.

Head Structure: Cast aluminum, movable, ratchet tension.

Motor: 2 HP (1.5kw), 50 or 60 Hz,

1 or 3 phase open.

Switch: General purpose,

thermal overload.

Blade & Speed: 5/8” (16mm) x 124” (3150mm),

3200 fpm (975m).

Cutting Clearance: 15-1/2” (393.7mm) H x 15-1/2”

(393.7mm) W.

Meat Carriage: Stainless steel.

15-1/2” (393.7mm) x 23-1/2” (597mm).

Options: Stainless steel head, watertight switch,

(Extra Cost) stationary front table, cord and plug.

Call factory for other designs.

MODEL 3334SS 16” (405mm)

TRIM CUTTER MEAT SAW

True left hand feed shown, right

hand feed available.

Stationary front table.

Less meat gauge plate assembly.

Stainless steel head and door structure.

3 HP (2.2kw), 50 or 60 Hz.

1 or 3 phase.

Page 3

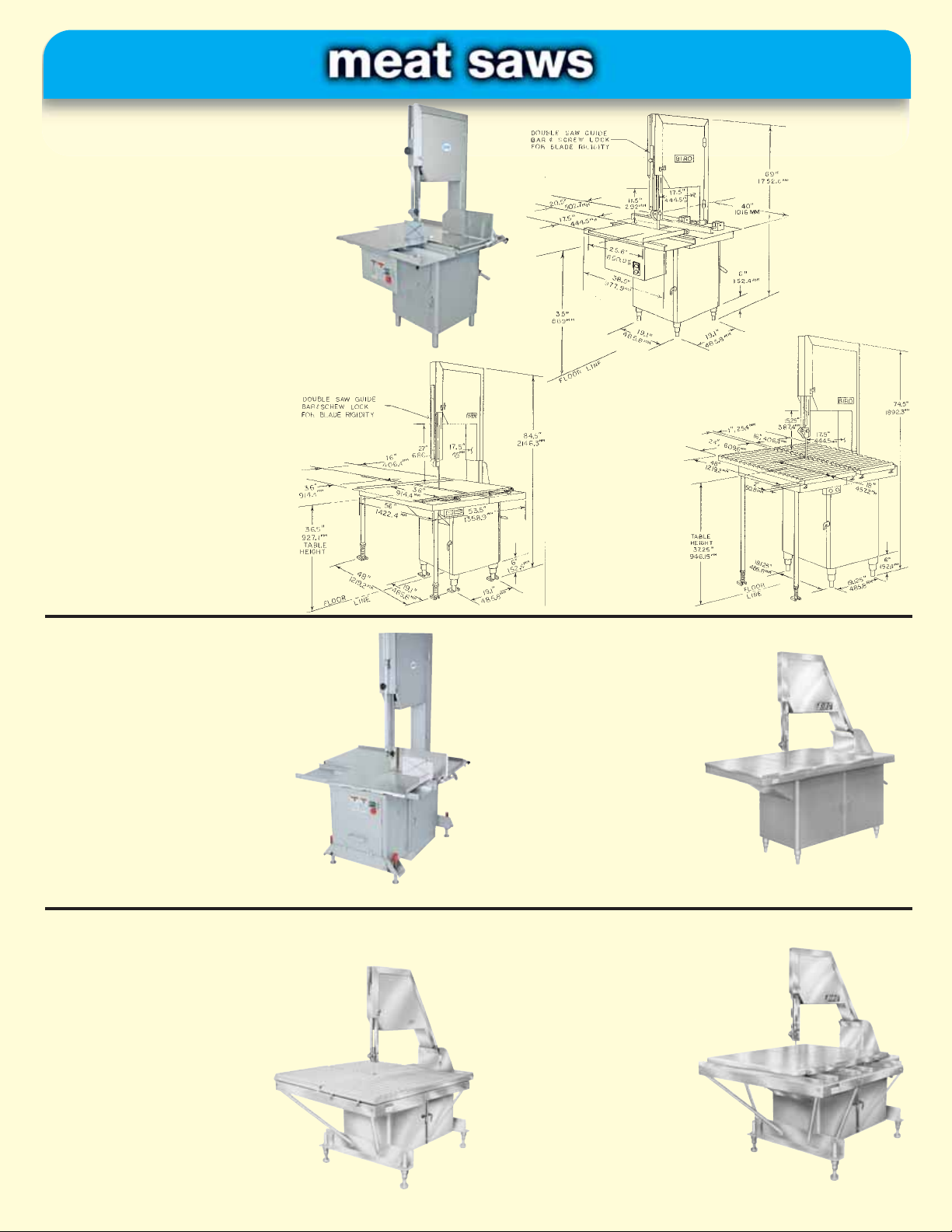

MODEL 4436 DESIGN 5E-3 BREAKING CUTTER

Finish: Base & head structure stainless steel. .

Motor: 5HP (3kw), 50 or 60 Hz, 3 phase.

Switch: Watertight magnetic remote with push button

start stop station.

Blade & Speed: 164-1/2” (4166mm) x 1” (25.4mm) x .035” (0.88mm)

@ 4000 fpm (1319m).

Cutting Clearance: 15” (381mm).

Cutting Width: 31” (787mm) throat.

Standard Equipment: Right hand feed, two way

roller conveyor tops

54” (1348mm) x 48” (1219mm),

stabilizing support system.

Options: 5/8” (16mm) x .022” (0.56mm) wheels,

(Extra Cost) left hand operation, various roller

configurations, 7-1/2 HP (5.6kw).

MODEL 55 20” (510mm) MEAT SAW

Finish: Stainless steel, nickel.

Head Structure: Fixed, stainless steel.

Motor: 5 HP (3kw), 50 or 60 Hz, 3 phase totally enclosed.

Switch: Watertight magnetic star ter with ther mal overload

and under voltage protection.

Blade & Speed: 3/4”(19mm) x 164-1/2” (4178.3mm),

3880 fpm (1180m), higher

speed at no cost.

Cutting Clearance: 20” (508mm) H x 21” (533mm) W.

Meat Carriage: Stainless Steel, EZ-Flow System

28-3/8”(720mm) L x 19 -3/8” (492mm) W.

Options: Various table designs, optional

(Extra Cost)

voltages, left hand feed, cord & plug,

numerous other options (contact factory

for more information).

MODEL 4436 DESIGN 5 BREAKING CUTTER

Finish: Base & head structure stainless steel. .

Motor: 5 HP (3kw), 50 or 60 Hz, 3 phase.

Switch: Watertight magnetic remote with push

button start stop station.

Blade & Speed: 164-1/2” (4178.3mm) x 1” (25.4mm) x .035”

(0.88mm) @ 4000 fpm (1219m).

Cutting Clearance: 17-1/4” (435mm)

Cutting Width: 31” (787mm) throat.

Tables: Right hand feed,

Standard Equipment: Stationary front table

34-1/8” (867mm) x 20” (508mm),

stationary rear table 34-1/8” (867mm)

x 30” (762mm).

Options: Outriggers, 5/8” (16mm) x .022” (0.56mm)

(Extra Cost) wheels, left hand operation, 7-1/2 HP (5.6kw).

Call factory for other designs.

MODEL 44SS-HH

27” (685mm)

MEAT SAW

Right hand feed

Double moving carriage

Heavy duty carriage channel

Extended head structure

Floor chocks

SS legs with discs

Blade length - 156” (3962mm)

MODEL 44SS

18” (455mm)

MEAT SAW

Right hand feed

Low profile head and

door structure

Split platter for

blade change

Precision gauging fence

Blade length - 124”

(3150mm).

MODEL 44SS

18” (455mm)

MEAT SAW

Right hand feed

Roller conveyor top

MODEL 44SS 18” (455mm) MEAT SAW

Finish: Stainless steel, nickel.

Head Structure: Stainless steel.

Motor: 3 HP (2.2kw), 50 or 60 Hz, 3 phase open.

Switch: Watertight magnetic starter with

thermal overload and under

voltage protection.

Blade & Speed: 5/8” (16mm) x 135” (3429mm),

4000 fpm (1219m), higher speed

at no cost.

Cutting Clearance: 17” (430mm) H x 17-1/2” (444.5mm) W.

Meat Carriage: Stainless steel, EZ Flow

System 25-9/16” (646mm) L x 18” (457mm) W.

Options: Various table designs, 5 HP (3kw) motor and voltages,

(Extra Cost) left hand feed, cord and plug, numerous other

options (contact factory for more information).

MODEL 4436 DESIGN 13B BREAKING CUTTER

Finish: Base & head structure stainless steel.

Motor: 5 HP (3kw), 50 or 60 Hz, 3 phase.

Switch: Watertight magnetic remote push button

start stop station.

Blade & Speed: 178-1/2” (4534mm) x 1” (25.4mm) x .035”

(0.88mm) @ 4000 fpm (1219m).

Cutting Clearance: 19-3/4” (502mm).

Cutting Width: 31” (787mm) throat

Meat Carriage: Right hand feed,heavy

duty, inside & outside

moving tables 48” (1219mm) x

40” (1016mm).

Standard Equipment: Stabilizing support system.

Options: 5/8” (16mm) x .022” (0.56mm) wheels,

(Extra Cost) left hand operation, 7-1/2 HP (5.6kw).

Page 4

Finish: Stainless steel hopper, frame, lid, and

paddle.Tinned bowl, ring, and auger.

Motors: Auger-3 HP (2.2kw), 208V, 60 Hz, 3 phase.

50 Hz available;60Hz, 1 Phase.

Drive System: Auger-single reduction chain drive,

Mixer-double reduction gear drive.

Bowl Type: Size 32, uses size 32 plate and knives.

Hopper Capacity: Up to 50 lbs. (23kg).

Output Capacity: Up to 68 lbs.(31kg)/minute.

Standard

Equipment: Splash guard, ring wrench, 10’ cord

and plug. Safety interlock on lid and tub.

Options: Size 32 plate and knife, stainless steel

(Extra Cost) grinder stand with 5” DIA. total-lock

swivel casters with preventz additive,

pneumatic footswitch 3 HP (2.2kw),

1 phase.

Finish: Stainless steel hopper, frame, legs, lid,

and paddle.Tinned bowl, ring, and auger.

Motors: Standard: 5 HP (3.7kw), 208V, 60 Hz, 3 phase

Optional: 7-1/2 HP (5.6kw), 208V, 60 Hz, 3 phase

(Extra Cost) 7-1/2 HP (5.6kw), 220/380V, 50 Hz, 3 phase

5 HP (3.7kw), 220V, 50 Hz, 3 phase

5 HP (3.7kw), 220V, 60 Hz, 1 phase.

Drive System: Tandem single reduction oil bath

speed reducers with heavy duty

mechanical clutch.

Bowl Type: Size 32, uses size 32 plate and knives.

Hopper Capacity: Up to 140 lbs. (64kg).

Output Capacity: Up to 68 lbs. (31kg)/minute.

Standard

Equipment: Splash guard, ring wrench, 8’(2.4m) cord

and plug on 3 phase only.

Options: Size 32 plate and knife, stainless steel

(Extra Cost) bowl, ring, and auger, adjustable legs and

casters with preventz additive, pneumatic

or electric footswitch, meat lug holder,

right or left feed inlet.

MODEL EMG-32

ERGONOMIC MIXER GRINDER

Finish: Stainless steel hopper, frame, legs, lid,

and auger.Tinned bowl, and ring.

Motors: Auger-7-1/2 HP (5.6kw), 208V, 60 Hz, 3 phase

Mixer-3/4 HP (.56kw), 208V, 60 Hz, 3 phase

(Other voltages call factory). 50 Hz available.

Drive System: Auger-single reduction chain drive

Mixer-double reduction chain drive.

Bowl Type: Size 32, uses size 32 plate and knives.

Hopper Capacity: Up to 150 lbs. (68kg).

Output Capacity: Up to 80 lbs. (36.3kg)/minute first grind.

Up to 56 lbs. (25.4kg)/minute second grind.

Standard

Equipment: Stainless steel auger and paddles (2),

splash guard, ring wrench, pneumatic

footswitch, 11’cord and plug, reversible

paddles, meat cart less lugs, locking swivel

casters with preventz additive.

Options: Size 32 plate and knife, electric

(Extra Cost) footswitch.

MODEL AFMG-48 MIXER GRINDER

Finish: Stainless steel hopper, frame, legs, lid

and paddle.Tinned bowl, ring, and auger.

Motors: Auger-7-1/2 HP (5.6kw), 208V, 60 Hz, 3 phase

Mixer-1-3/4 HP (1.3kw), 208V, 60 Hz, 3 phase

(Other voltages call factory). 50 Hz available.

Drive System: Auger-single reduction chain drive

Mixer-Direct Drive.

Bowl Type: Size 48, uses size 32 plate and knives.

Hopper Capacity: Up to 200 lbs. (91kg).

Output Capacity: Up to 65 lbs. (30kg)/minute.

Standard

Equipment: Splash guard, ring wrench, 12’cord and

plug for U.S. 220V, locking swivel casters with

preventz additive, right side or no inlet hopper.

Options: 10 HP (7.5kw) auger motor, electric or

(Extra Cost) pneumatic footswitch, stainless steel ring,

auger, and bowl, size 32 plate and knife.

Accessory cleaning and storage rack, extra long

stainless steel legs, connecting horn and seal for

tandem operations. Left side inlet hopper.

MODEL MINI-32 MIXER GRINDER MODEL AFMG-24 MIXER GRINDER

MODEL AFMG-52 MIXER GRINDER

Finish: Stainless steel hopper, frame, lid and paddle.

Tinned bowl, ring, and auger.

Motors: Auger-7-1/2 HP (5.6kw), 208V, 60 Hz, 3 phase

Mixer-1-3/4 HP (1.3kw), 208V, 60 Hz, 3 phase

(Other voltages call factory). 50 Hz available.

Switch: Watertight magnetic switch system with thermal

overload protection. Magnetic safety interlocks on

hopper lid.

Drive System: Auger-single reduction chain drive.

Mixer-Direct Drive.

Bowl Type: Size 52, uses size 52 plate and knives.

Hopper Capacity: Up to 200 lbs. (91kg).

Output Capacity: Up to 100 lbs. (45.5kg)/minute.

Standard

Equipment: Splash guard, ring wrench, 12’cord and plug for

U.S.220V, locking swivel casters with preventz additive,

right side or no inlet hopper.

Options: 10 HP (7.5kw) auger motor, electric or pneumatic

(Extra Cost) footswitch, stainless steel ring, auger, and bowl,

size 52 plate and knife.Accessory cleaning and

storage rack, extra long stainless steel legs,

connecting horn and seal for tandem operations.

Finish: Stainless steel hopper, frame, legs, lid and paddle.

Tinned bowl, ring, and auger.

Motors: Auger 10 HP (7.5kw) totally enclosed motor.Mixer

5HP (3.7kw) totally enclosed motor.(Other

voltages call factory). 50 Hz available.

Switch: Watertight magnetic switch system with thermal

overload protection. Magnetic safety interlocks on

hopper lid, includes 12’ 6-4 power cord.

Drive System: Auger-single reduction (35 pitch - 4 row) roller

drive chain with tapered roller bearings; Mixer-

double reduction gear box and open face gear drive

Bowl Type: Size 52, uses size 52 plate and knives.

Hopper Capacity: Up to 400 lbs.(182kg)

Output Capacity: Up to 100 lbs. (45.5kg)/minute.

Standard

Equipment: 35 degree right hand inlet, stainless steel 2nd grind

paddle with center arm, adjustable legs with

casters, spurt guard and ring wrench, 12’ 6-4 cord.

Options: Stainless steel bowl, ring and auger, bolt on

(Extra Cost) hinged step, electric or pneumatic footswitch,

connecting horn and seal for tandem operations

550 volt.

MODEL AFMG-52-4 MIXER GRINDER

Shown mounted

on optional extra

cost stand.

Shown with optional

extra cost casters.

Page 5

Finish: Stainless steel hopper, legs, frame,

bowl, ring, auger, and paddles.

Motors: Auger-20 HP (14.9kw), 208V, 60 Hz, 3 phase.

Mixer-5 HP (3.7kw), 208V, 60 Hz, 3 phase.

(Other voltages call factory).

50 Hz available.

Drive System: Auger-single reduction chain drive.

Mixer-double reduction chain drive.

Bowl Type: Size 56, uses size 56 plate and

knives.

Hopper Capacity: Up to 800 lbs. (362.9kg)

Output Capacity: Up to 250 lbs.(113.7kg)/minute.

Standard

Equipment: Splash guard, ring wrench,

pneumatic lid lift. 9’ cord no plug.

Options: Wire grate style lid, right side inlet

(Extra Cost) feed tube, size 56 plate and knife,

locking swivel casters.

Finish: Stainless steel hopper, legs, frame, bowl,

ring, auger, and paddles.

Motors: Auger-15 HP (11.2kw), 208V, 60 Hz, 3 phase.

Mixer-5 HP (3.7kw), 208V, 60 Hz, 3 phase.

(Other voltages call factory). 50 Hz available.

Drive System: Auger-single reduction synchronous

drive belt.

Mixer-double reduction synchronous

drive belt.

Bowl Type: Size 56, uses size 56 plate and knives.

Hopper Capacity: Up to 400 lbs. (182kg)

Output Capacity: Up to 200 lbs. (91kg)/minute.

Standard

Equipment: Splash guard, ring wrench, 9’cord no plug.

Options: Wire grate style lid, right side inlet feed

(Extra Cost) tube, size 56 plate and knife. Locking

swivel casters, footswitch available

(electric or pneumatic).

MODEL AFMG-56-4 MIXER GRINDER

MODEL AFMG-56 MK III MIXER GRINDER

Stew/Strip Cutter

Fajitas, chicken fingers, etc.

Finish: Stainless steel case and top.

Lexan Hopper Cover

Motors: 1/2 (.38kw) or 3/4 (.56kw) HP, 115-60-1

or 230-60-1 open type. 50 Hz available.

Switch: On/Off toggle type with cover safety switch.

Transmission: Oil bath gear box with Polyflex double-V belt.

Cutting groups: Stainless steel with stainless

steel spacers and combs.

No Cost Options: 140 RPM roller speed (HD units

only, upon request).

Standard Equipment: Tenderizing / knitting assembly 5’ cord and

3 prong molded grounded plug, 115 volt.

Options: Cutlet cradle, scoring rollers, star

(Extra Cost) rollers, stir fry/stew cutter assemblies

in the following widths: 1/4” (6.3mm) (HD

only), 3/8” (9mm) (HD only), 9/16” (14mm)

(HD only), 3/4” (19mm), 7/8” (22mm), 1” (25mm),

1-1/4” (32mm), 1-9/16” (40mm), 2” (51mm),

stainless steel cover, 50 Hz motor.

MODEL PRO-9 SERIES TENDERIZERS

TANDEM SYSTEMS

Model AFMG-52 to AFMG-52

Tandem System (Right to Left)

Model AFMG-56 MK III to AFMG-56 MK III

Tandem System (Right to Left)

(Call factory for various configurations)

Page 6

MODEL 812SS/822SS (shown)

MEAT GRINDER

Finish: High polish stainless steel case,

tinned bowl, ring, and worm.

Motors: 1 HP (.75kw), 115/230V, 60 Hz

1 or 3 phase open standard; 50 Hz

available.

Switch: Toggle activator with magnetic contactor.

Feed Pan: Stainless steel standard,

20” (508mm) L x 13” (330mm) W x 2-1/2” (64mm) D.

Transmission: High torque drive, 95% efficient.

Bowl Type: Size 12 (Model 812) size 22 (Model 822),

straight side.

Capacity: 812 6-10 lbs. (2.7-4.5kg) per minute.

822 10-16 lbs. (4.5-7.3kg) per minute.

Standard Equipment: Meat stomper, 6’ cord and plug, 115 volt.

Options: 812 - size 12 plate and knife.

(Extra Cost) 822 - size 22 plate and knife.

MODEL 722 MEAT GRINDER

Finish: Cast aluminum body,

tinned bowl, ring, and worm.

Motors: 1 HP (.75kw), 115/230V, 60 Hz,

1 or 3 phase totally enclosed

standard, 50 Hz available.

Switch: Toggle

Feed Pan: Stainless steel standard

20” (508mm) L x 13” (330mm) W

x 2-1/2” (64mm) D.

Transmission: High torque drive, 95% efficient.

Bowl Type: Size 22 straight side.

Capacity: 10 - 16 Ibs.(4.5-7.3kg) per minute.

Standard Equipment: Meat stomper,

6’ cord and plug, 115 volt.

Options: Size 22 plate and knife.

(Extra Cost)

MODEL 6642 MEAT GRINDER

Finish: High polish stainless steel case,

tinned bowl, ring, and worm.

Motors: 2 HP (1.5kw), 115/230V, 60 Hz, 1 or 3 phase

standard; 50 Hz available.

Switch: Waterproof push button with

magnetic contactor.

Feed Pan: Stainless steel standard,

removable, 39”(991mm) L x

20” (508mm) W x 4-3/4” (121mm) D.

Transmission: Double reduction steel gear type,

oil bath.

Bowl Type: Size 42, flared, uses size 32

knife and plate.

Capacity: Up to 41 lbs. (19kg) per minute.

Legs: 4” (102mm) standard, 22” (559mm) available

at extra cost.

Standard Equipment: Splash guard, bowl guard, meat

stomper, ring wrench.

Options: Size 32 plate and knife, longer legs.

(Extra Cost) Power cord, plug.

MODEL 922SS MEAT GRINDER

Finish: High polish stainless steel case,

tinned bowl, ring, and worm.

Motors: 1 HP (.75kw), 115/230V, 60 Hz, 1 or 3

phase standard.

50 Hz available.

Switch: Magnetic contactor with front

mounted push button station

and tray safety interlock.

Feed Pan: Stainless steel standard, removable,

26-3/4” (679mm) L x 15-1/2” (394mm) W

x 2-3/4” (70mm) D

Transmission: High torque drive, 95% efficient.

Bowl Type: Size 22, flared.

Capacity: 12-20 lbs. (5.4-9.1kg) per minute.

Standard Equipment: Bowl guard, meat stomper,

6’ cord and plug, 115 volt.

Options: Size 22 plate and knife.

(Extra Cost)

MODEL 346SS MEAT GRINDER

Finish: Stainless steel case, tray and

guard, tinned bowl, ring, and worm.

Motors: 3 HP (2.25kw), various voltages, 50/60 Hz,

1 phase or 3 phase.

Switch: Magnetic type with thermal

overload and under voltage

protection.

Feed Pan: Left hand feed, removable,

45” (1143mm) L x 24” (611mm) W

x 7-1/4” (184mm) D.

Transmission: Heavy duty roller chain drive.

Bowl Type: Size 46, straight chute type,

uses size 32 knife and plate.

Capacity: 25 - 40 lbs. (11-18kg)/minute.

Standard

Equipment: Splash guard, bowl guard,

ring wrench, meat stomper.

Options: Size 32 plate and knife, SS bowl,

(Extra Cost) ring, and wor m, leg extensions,

right hand feed.

MODELS 548SS, 7548SS,

552SS, 7552SS HHP MEAT GRINDERS

Finish: Stainless steel case, tray, and guard,

tinned bowl, ring, and worm.

Motors: 5 (3.7kw), or 7-1/2 (5.6kw) HP, various

voltages, 50/60Hz, 1 phase (5 HP only) or 3 phase.

Switch: Magnetic type with thermal overload

and under voltage protection.

Feed Pan: Left hand feed, removable,

52” (1321mm) L x 29” (737mm) W x

9” (229mm) D.

Transmission: Heavy duty roller chain drive.

Bowl Type: Size 48 or 52 flared, uses size 32 or 52

knife and plate.

Capacity: 25 - 100 Ibs. (11-45kg)/minute.

Standard Equipment: Splash guard, bowl guard, ring wrench,

meat stomper.

Options: Plate and knife, 550 volt motor,

(Extra Cost) leg extensions, right hand feed,

5 HP (3.7kw), 1 phase motor.

Page 7

MODELS 1056SS, 1556SS HHP MEAT GRINDERS

Finish: Stainless steel case, tray, and guard,

tinned bowl, ring, and worm.

Motors: 10 (7.5kw) or 15 (11.2kw) HP, various

voltages, 50/60Hz, 3 phase.

Switch: Magnetic type with thermal

overload and under voltage

protection.

Feed Pan: Left hand feed, removable,

52” (1321mm) L x 29” (737mm) W

x 9” (229mm) D.

Transmission: Heavy duty roller chain drive.

Bowl Type: Size 56 flared,

uses size 56 knife

and plate.

Capacity: Up to 125 Ibs. (56.7kg)/minute.

Standard Equipment: Splash guard, bowl guard,

ring wrench, meat stomper.

Options: Plate and knife, 550 volt motor,

(Extra Cost) leg extensions, right hand feed.

MODEL BCC-100 POULTRY CUTTER

MODEL BCC-100 POULTRY CUTTER

Finish: Stainless steel, cast aluminum.

Motor: 3/4 HP (.56kw), 1 phase, totally enclosed; 3 phase and 50 Hz motors available

at extra cost.

Switch: Enclosed, water proof tilt type with red (ON) safety light.

Knife Blade: 9” (229mm) diameter, stainless steel knife type blade.

Standard

Equipment: 5’ cord and plug, 115 volt. Knife Blade Sharpener.

Options: 9” (229mm) diameter, serrated blade, stainless steel.

(Extra Cost)

MODEL FBC-4800SS CHIPPER

Finish: Stainless steel construction.

Motors: 5 HP (3.7kw), 208/220, 440-60-3, 575-60-3, 220/380-415-50-3.

Switch: Magnetic type with low voltage and overload protection.

Transmission: Oil bath with heavy duty bronze gear fitted directly to motor.

Standard Equipment: Polyethylene product receptacle, product receptacle dolly, floor bolt down locator

chocks, operating and safety manual.

Operation: Maximum block size 8” (203mm) x 16-1/2” (419mm)x 19-1/2” (495mm)., recommended block temperature

is 15° to 25° F or -10° to -4° C, can reduce block into chips approximate 3-1/2” (89mm) x 3-1/2” (89mm) x

1/4” (6mm) in less than 60 seconds.

Cleaning: Entire lid opens for easy access, knife shuttle assembly removable as a unit for cleaning.

Options: Stainless steel discharge chute.

(Extra Cost)

TANDEM SYSTEM

Model HHP to AFMG-48

Tandem System

Page 8

MODELS VTS-41 AND

VTS-42 V A CUUM (shown)

MARINA TING TUMBLERS

Finish: Stainless steel frame, except

wheels and lid gasket.

Drum Motor: 1/25 HP (.03kw), 115V, 60 Hz, 1 phase.

Vacuum Pump: 1/8 HP (.09kw), 115V, 60 Hz, 1 phase.

Portable pump (VTS-41).

Enclosed pump (VTS-42).

Capacity: 40 lb. (18kg) capacity stainless

steel drum.

Standard

Features: Tumbling timer, 6’ cord and plug.

Options: 50 Hz motor for 42, variable

(Extra Cost) speed motor available.

Finish: Stainless steel frame, except wheels

and lid gasket.

Drum Motor: 1/25 HP (.03kw), 115V, 60 Hz, 1 phase.

Vacuum Pump: 1/8 HP (.09kw), 115V, 60 Hz, 1 phase.

Portable pump (VTS-43).

Enclosed pump (VTS-44).

Capacity: Twin 20 lb. (9.1kg) capacity stainless

steel drums.

Standard

Features: Tumbling timer, 6’ cord and plug.

Options: 50 Hz motor for 44, variable speed

(Extra Cost) motor, 40 lb. (18kg) stainless steel drum.

MODEL VTS-43 (shown)

AND VTS-44 V A CUUM

MARINA TING TUMBLERS

Finish: Stainless steel frame, drum

and case.

Drum Motor: 3/4 HP (.56kw) Variable Speed,

115V, 60 Hz, 1 phase

Vacuum Pump: 3/4 HP (.56kw), 115V, 60 Hz, 1 phase.

External trap with filter.

Drum Capacity: 100 lb. (45.4kg) approximate.

Standard

Features: 0-50 minute interval mode

timer, vacuum in-line filter,

OFF/RUN/JOG switch, lock

swivel casters, 8’ cord and

plug 115 volts, photo eye for

safety shutdown.

Options: 50 cycle, reverse switch

(Extra Cost) (momentary), extension legs.

MODEL VTS-100

V ACUUM TUMBLER

MODEL VTS-500

V ACUUM TUMBLER

Finish: Stainless steel frame,

drum and case.

Drum Motor: 3/4 HP (.56kw) Variable Speed,

115V, 60 Hz, 1 phase,

Vacuum Pump: 3/4 HP (.56kw), 115V, 60 Hz,

1 phase. External trap with filter.

Drum Capacity: 500 lb. (227kg) approximate.

Standard

Features: 0-99 minute timer, repeat cycle

run-stop-run, external moisture

trap, vacuum in-line filter,

OFF/RUN/JOG switch, locking

swivel casters, 8’ cord and plug

115 volts, photo eye for safety

shutdown.

Options: 50 cycle, reverse switch

(Extra Cost) (momentary), extension legs.

Finish: Stainless steel except the wheels

& lid gaskets.

Drum Motor: 1/25 HP (.03kw).

Vacuum Pump: 1/8 HP (.09kw) with filter VTS-45.

1/8 HP (.09kw) with external filter

on case VTS-46.

Capacity: 20 pound (9.1kg) drum, maximum,

15 lbs (7 KG) optimum.

Standard

Features: 6’ cord, 3 prong plug, 115-60-1.

6’ cord, no plug, 220-6-1 and 220-50-1.

Operating and safety manual.

Options:

(Extra Cost) Variable speed (0-14), tumbler cart,

wood box.

MODEL VTS-45 AND

VTS-46 (shown) VACUUM

MARINA TING TUMBLERS

VTCRT1S STAINLESS STEEL CART

(shown) AND

VTCRT1 GRAY PLASTIC (not shown)

32” (813mm) W x 20” (508mm) D x 30” (762mm) H.

For VTS-41, 42, 43, 44, 45 or 46 Vacuum Tumblers

and Food Formers. (Not for slicer).

REMOTE PUMP

For Models VTS-41/43/45.

VT63077C CART

Metal frame w/bottom

shelf only.

(756mm)

(152mm)

(391mm)

(762mm)

Page 9

MODEL B300M GRAVITY FEED MANUAL SLICER

Finish: Body – Anodized polished aluminum cast with non-corrosive metal frame.

Motor: IP 65 – 1/2 HP (.35 KW) 115V 60 HZ 1 ph inter nally cooled, water resistant.

IP 65 – 1/2 HP (.35 KW) 220V 50 Hz 1 ph internally cooled, water resistant.

Blade Size: 12” (300 mm) hollow ground alloy steel.

Slice Thickness: 9/16” (15 mm).

Max. Round Cut: 7.5” (190 mm).

Max. Rect. Cut: 10” x 5.5” (254 mm x 139 mm).

Standard Features: Removable product table, blade protective ring guard, product table lockout,

automatic spring loaded belt tensioning, polygroove belt drive, thermal overload/no volt

release, green pushbutton on-off control with red e-stop button, water resistant IP65 motor,

wiring harness, electronic controls, and connectors, detachable sharpener assembly, product fence.

MODEL B350M GRAVITY FEED MANUAL SLICER

Finish: Body – Anodized polished aluminum cast with non-corrosive metal frame.

Motor: IP 65 – 1/2 HP (.35 KW) 115V 60 HZ 1 ph inter nally cooled, water resistant.

IP 65 – 1/2 HP (.35 KW) 220V 50 Hz 1 ph internally cooled, water resistant.

Blade Size: 13-3/4” (350 mm) hollow ground alloy steel.

Slice Thickness: 1” (25 mm).

Max. Round Cut: 10” (254 mm).

Max. Rect. Cut: 12-1/2” x 9” (317 mm x 228 mm).

Standard Features: Oversized product table, blade protective ring guard, tilt-away product table lockout,

automatic spring loaded belt tensioning, polygroove belt drive, thermal overload/no volt

release, green pushbutton on-off control with red e-stop button, water resistant IP65 motor,

wiring harness, electronic controls, and connectors, detachable sharpener assembly,

product fence.

MODEL B350MV HORIZONTAL FEED MANUAL SLICER

Finish: Body – Anodized polished aluminum cast with non-corrosive metal frame.

Motor: IP 65 –1/2 HP (.35 KW) 115V 60 HZ 1 ph inter nally cooled, water resistant.

IP 65 – 1/2 HP (.35 KW) 220V 50 Hz 1 ph internally cooled, water resistant.

Blade Size: 13-3/4” (350 mm) hollow ground alloy steel.

Slice Thickness: 1” (25 mm).

Max. Round Cut: 10-1/2” (266 mm).

Max. Rect. Cut: 12” x 10” (304 mm x 254 mm).

Standard Features: Oversized product table, blade protective ring guard, tilt-away product table lockout,

automatic spring loaded belt tensioning, polygroove belt drive, thermal overload/no volt

release, green pushbutton on-off control with red e-stop button, water resistant IP65 motor,

wiring harness, electronic controls, and connectors, detachable sharpener assembly,

product fence.

MODEL B350A AUTOMATIC FEED SLICER

Finish: Body – Anodized polished aluminum cast with non-corrosive metal frame.

Motor: IP 65 – 1/2 HP (.35 KW) 115V 60 HZ 1 ph inter nally cooled, water resistant.

IP 65 – 1/2 HP (.35 KW) 220V 50 Hz 1 ph internally cooled, water resistant.

Blade Size: 13-3/4” (350 mm) hollow ground alloy steel.

Slice Thickness: 7/8” (23 mm).

Max. Round Cut: 9-1/2” (241 mm).

Max. Rect. Cut: 11-3/4” x 6” (298 mm x 152 mm).

Standard Features: Oversized product table, blade protective ring guard, tilt-away product table lockout,

automatic spring loaded belt tensioning, polygroove belt drive, thermal overload/no volt

release, green pushbutton on-off control with red e-stop button, water resistant IP65 motor,

wiring harness, electronic controls, and connectors, detachable sharpener assembly,

product fence.

Three Automatic Speed Selections w/Three Table Strokes in each Speed:

Automatic Speed #1 – 48 strokes per/min.w/short stroke, 40 strokes per/min. w/medium stroke,

38 strokes per/min. w/long stroke

Automatic Speed #2 – 56 strokes per/min.w/short stroke, 45 strokes per/min. w/medium stroke,

45 strokes per/min. w/long stroke

Automatic Speed #3 – 60 strokes per/min.w/short stroke, 50 strokes per/min. w/medium stroke,

50 strokes per/min. w/long stroke

Model B300M (Detachable

sharpener not shown)

Model B350M with

detachable sharpener

Model B350MV with

detachable sharpener

Model B350A (Detachable

sharpener not shown)

Page 10

MODEL 109PCM HORIZONTAL SLICER

(WITH MECHANICAL THICKNESS ADJUSTMENT)

Electrical: 2 HP (1.5kw), 208/220/440 volts, 60 Hz, 3 phase, 220/380/415 volts, 50 Hz,

3 phase, 10’ cord no plug. Specify voltage prior to ordering.

Finish: Stainless steel frame and skin. Lexan chamber lids.

Chamber Size: 9” (228 mm) high x 10” (254 mm) wide x 30” (762 mm).

Safety: Magnetic interlocks on all doors, brake motor, locking casters, OSHA lockout

power switch.

Blades: Stainless steel curved sickle type. Two blades supplied with each machine, one

smooth or serrated blade on the machine and whichever one you want extra.

Blade Speed: Up to 170 cuts per minute.

Controller: Main on off, run or jog, push button start, emergency “E” stop.

Cut Thickness: 1/16” plus (2.0 mm) minimum or 1-1/8” (28.6 mm).

Standard: 5” Dia. total-lock swivel casters with prevenz, operating manual, 15’cord no plug.

Options: Serrated blade.

(Extra Cost)

Conveyor: Not available.

MODEL 109PC HORIZONTAL SLICER (ELECTRONIC PROGRAM)

Electrical: 3 HP (2.2kw), 208/220/440 volts, 60 Hz, 3 phase, 220/380/415 volts, 50 Hz,

3 phase, 10’ cord no plug. Must specify exact voltage prior to ordering.

Finish: Stainless steel frame and skin. Lexan chamber lids.

Chamber Size: 9” (228 mm) high x 10” (254 mm) wide x 30” (762 mm).

Safety: Magnetic interlocks on all doors, brake motor, locking casters, OSHA lockout

power switch.

Blades: Stainless steel curved sickle type. Two blades supplied with each machine, one

smooth or serrated blade on the machine and whichever one you want extra.

Blade Speed: Up to 180 cuts per minute.

Controller: Electronic, splash proof, user friendly keypad in English or metric (tactile and

audible), programmable up to 7 programs, automatic transport retur n.

Cut Thickness: 1/16” plus (2.0 mm) minimum or 30” (762 mm) maximum.

Standard: 5” Dia. total-lock swivel casters with prevenz, operating manual, 15’cord no plug.

Optional

Conveyor: 10” (254mm) wide take away conveyor variable speed from 0-55 ft. (0-5.1m) per minute,

(Extra Cost) independent on-off switch, white food grade removable belt, all doors have safety interlocks.

Sickle type smooth edge blade.

Sickle type smooth edge blade.

Thickness adjuster right side.

Shown with conveyor.

Enlarged

TEMPERED / FRESH BONELESS WHOLE MEAT SLICER

Page 11

MODEL F2000

Finish: Anodized polished aluminum body with stainless steel enclosures.

Motor: 1HP (.75kw), 115V 60 Hz 1ph.

Production: 2000 Single shapes per hour.

Shape Size: 1” to 4-3/4” / 25mm to 120mm.

Hopper Size: 6.6 gallons / 25 lt.

MODEL F3000

Finish: Anodized polished aluminum body with stainless steel enclosures.

Motor: 1HP (.75kw), 115V 60 Hz 1ph.

Production: 3000 Single shapes per hour.

Shape Size: 1” to 4-3/4” / 25mm to 120mm.

Hopper Size: 6.6 gallons / 25 lt.

MODEL F4000

Finish: Anodized polished aluminum body with stainless steel enclosures.

Motor: 1HP (.75kw), 115V 60 Hz 1ph.

Production: 4000 Single shapes per hour.

Shape Size: 1” to 4-3/4” / 25mm to 120mm.

Hopper Size: 6.6 gallons / 25 lt.

MODEL B1200 BISCUIT/COOKIE MACHINE

Finish: Anodized polished aluminum body with stainless steel enclosures.

Motor: 1HP (.75kw), 115V 60 Hz 1ph.

Production: 1200 Single shapes per hour.

Shape Size: 1” to 4-1/2” / 25mm to 115mm.

Hopper Size: 6.6 gallons / 25 lt.

MODEL HD3000 PNEUMATIC

Finish: Anodized polished aluminum body with stainless steel enclosures.

Motor: 1HP (.75kw), 115V 60 Hz 1ph.

Production: 3000 Single shapes per hour.

Shape Size: 1” to 4-3/4” / 25mm to 120mm.

Hopper Size: 11 gallons / 40 lt.

Std. Features: Flight Conveyor w/built in Machine Stand.

Built-in Pneumatic wire drum scraper.

FOOD FORMER DRUMS

(call factory for additional shapes)

Paper Holder

Manual Wire Cleaner

Assembly for Drum

NSF Approved

(Standard on machine)

Page 12

Service is available from over 260 locations worldwide

Since 1921 the

BIRO

®

Manufacturing Company has dev eloped and manufactured safe and reliable f ood

processing equipment to meet the various requirements of the food processing industry.

BIRO

also

designs and builds special food processing machines according to customer specifications. A wide

variety of models are available from which to select as well as a number of electrical motor and

controller options. It is important that electrical specifications for your particular application be specified

when inquiring. If additional assistance is needed regardless whether the equipment is standard or

special, contact your authorized distributor covering your locality or the Sales Department of the BIRO

Manufacturing Company, Marblehead, Ohio 43440 U.S.A.

BIRO

®

is the registered trademark of the Biro Manufacturing Company, Marblehead, Ohio 43440 as

applied to power driven meat, fish, and bone cutting machines, meat grinders, tenderizers, chippers,

slicers and cutters; automatic feed mixer-grinders, vacuum tumblers, patty/food formers, blades and

parts thereof of its manufacture or design for use in the food processing industry.

THE INFORMATION AND FINDINGS CONTAINED HEREIN REPRESENT

OUR BEST JUDGEMENT BASED ON WORK DONE AND TESTS

PERFORMED. THE BIRO MANUFACTURING COMPANY ASSUMES NO

LIABILITY WHATSOEVER EXPRESSED OR IMPLIED IN CONNECTION

WITH ITS USE. AS GOVERNMENTAL REGULATIONS AND CONDITIONS

MAY CHANGE, IT IS THE BUYER’S RESPONSIBILITY TO DETERMINE THE

APPROPRIATENESS OF SELLER’S PRODUCT FOR BUYER’S

SPECIFIC END USE. ALL SPECIFICATIONS CONTAINED HEREIN ARE

SUBJECT TO CHANGE WITHOUT NOTIFICATION.

Food Processing Machine Manufacturers

THE BIRO MANUFACTURING COMPANY, 1114 W. MAIN ST., MARBLEHEAD, OHIO 43440-2099 U.S.A.

Phone:+1 (419) 798-4451 FAX:+1 (419) 798-9106 http://www.birosaw.com email: sales@birosaw.com

Item No: Lit-Stuffer-300

Form No: Stuffer-300-2-11-17-MARK

COMPANY PROFILE STATEMENT

THE BIRO®MANUFACTURING COMPANY established in 1921, is an Ohio, USA corporation, with three manufacturing/assembly plants.

BIRO designs, manufactures, and markets safe, durable, and reliable power operated, stainless steel, food and meat processing machinery.

BIRO is committed to satisfy specific needs of all segments of the food and meat industry: the food retail stores, the food service, and the

food processing, including portion control and the seafood processing operations.

BIRO’s product line includes a broad selection of models and variations of Power Saws, Tender izers/Knitters, Cubers, Strip Cutters, Poultry

Cutters, Horizontal High Speed Meat Slicers, Deli/Meat Slicers, Grinders, Mix er/Grinders, Marinating Vacuum Meat Tumblers, and Food/Patty

Formers.

BIRO PHILOSOPHY

BIRO ENGINEERING & DESIGN: Our concept is for optimum performance and efficiency with safety and sanitation as our priority in

the design process. We specialize in being able to modify our machines to meet your requirements.

BIRO MACHINES: Our concept of a “better buy” for the customer is not only based on initial acquisition cost but more importantly…

machines built to last longer. There’s increased productivity throughout the machine’s life because of less down time.

BIRO PARTS: The customer will realiz e low er maintenance costs with reasonab ly priced parts, less frequent replacement requirements,

thus less labor needed. The quality of BIRO par ts in relation to cost is the most competitive in the industry.

BIRO TECHNICAL SERVICE: The end users will benefit from over 220 highly motivated, independently owned, authorized sales and

service distributors worldwide. These distributors have the benefit of factory training and technical staff support.

BIRO CUSTOMER SERVICE: With the cooperation of all our employees, we will continue to strive to build long standing relationships

with our valued customers by providing responsive customer service.

Loading...

Loading...