Page 1

Virtual Power Meter

Operators Manual

Model VPM3

This is a preliminary manual. Specifications, limits, and text are subject to

change without notice. The information within this manual was as complete

as possible at the time of printing. Bird Electronic Corporation is not liable for

errors.

©Copyright 2013 by Bird Electronic Corporation

Instruction Book Part Number 920-VPM3 Rev. P1

Windows and Microsoft are registered trademarks

of the Microsoft Corporation

SeaLatch is a registered trademark of

Sealevel Systems, Inc.

Page 2

0

Page 3

About This Manual

This manual covers the operating and maintenance instructions for the following models:

VPM3

Changes to this Manual

We have made every effort to ensure this manual is accurate. If you discover

any errors, or if you have suggestions for improving this manual, please send

your comments to our Solon, Ohio factory. This manual may be periodically

updated. When inquiring about updates to this manual refer to the part number

and revision on the title page.

Literature Contents

Chapter Layout

Introduction — Describes the features of the VPM3, lists equipment supplied

and optional equipment, and provides power-up instructions.

Program Interfaces — Describes the features of VPM program and inter-

faces with the sensors.

Power Sensors — Descriptions, features, and procedures of all the 50XX

series sensors.

Specifications — Describes system requirements.

i

Page 4

ii

Page 5

Table of Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Changes to this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Literature Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i

Chapter Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Chapter 2 Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing the VPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Automatically connect to sensor on startup . . . . . . . . . . . . . . . . . . . . . 4

List sensors on startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Display menu bar icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing Language Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Clear Message Box State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

File Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Session Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Preset Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Measurement Data Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Advanced . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chart History (points) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Playback History (frames) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connecting a Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connecting the Directional Power Sensor (DPS) . . . . . . . . . . . . . . . . . . . . 8

Chapter 3 Average Power Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Display Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Bar Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Limit Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Sensor Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Sensor Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Meter Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sensor Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chart Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Show Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Show Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Show Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Best Fit Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Set Lower/Upper Delta Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Axis Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Manual Axis Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

xiii

Page 6

File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

New Sensor Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Close Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Save Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Save Session As... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Save Measurement Snapshot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Save Measurement Snapshot As... . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Save Preset As... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Recent Sessions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Recent Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preferences... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Statistical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Time Domain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Average Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Input Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Match Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Frequency Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Duty Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Start Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Stop Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Max Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Enable Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Logging Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Playback Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fullscreen Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Display Style . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Meter Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Playback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cascade Sessions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Tile Sessions Horizontally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Tile Sessions Vertically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

User Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

About Virtual Power Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

About Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Menu Label Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Configure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

For Wide Band Power Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

For Sensor 5015 and 5015-EF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

For Sensor 5014 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

xiv

Page 7

For Statistical Senors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Forward and Reflected Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Match . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Forward Peak Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Peak Average Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Burst Average Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Crest Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Complementary Cumulative

Distribution Function (CCDF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Save As . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Enable Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Open Preset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Analyzing Logged Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Opening .xml Files in Excel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Opening .csv Files in Excel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Zeroing a Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Chapter 4 Time Domain Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Configure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Input Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Frequency Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Duty Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Start Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Stop Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Enable Pulse Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Level... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Delay... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Holdoff... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Manual Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Zero Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

xv

Page 8

Chapter 5 Statistical Power Mode . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Statistical Power Measurement Methodology . . . . . . . . . . . . . . . . . . . . . . . 39

Complementary Cumulative Distribution Function (CCDF) . . . . . . . . . . 39

Example - 9 Channel CMA, One Signal . . . . . . . . . . . . . . . . . . . . . . . . . 39

Example - LTE vs Gaussian Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Interpreting Statistical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Configure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Confidence Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Start Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Stop Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Show/Hide Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 6 Power Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Sensor Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Mismatch Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Directional Power Sensor (DPS) Measurements . . . . . . . . . . . . . . . . . . . . . . 46

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

43 Type Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

APM/DPM Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Terminating Power Sensor (TPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Zeroing Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Correction Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Wideband Power Sensor (WPS) Measurements . . . . . . . . . . . . . . . . . . . . . . 48

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Zeroing Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Statistical Power Sensor (SPS) Measurements . . . . . . . . . . . . . . . . . . . . . . . 49

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Zeroing Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 7 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Minimum PC Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Appendix Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

xvi

Page 9

Chapter 1 Introduction

Power measurements verify and monitor the condition of a transmitter system.

To measure transmitter power, connect an external power sensor to the PC then

start the Virtual Power Meter program. Power sensors that are compatible with

the VPM are the Bird 5012B, 5014, 5015, 5015-EF, 5016B, 5017B, 5018B, 5019B,

7020, and STAT power sensors.

Note: ONLY sensors that have USB connections can be used with

VPM3 software.

The Power Meter mode has the following features:

Three display formats: numerical readout, analog dial, and chart

recording.

Display forward power, reflected power, match efficiency, peak power,

burst, and crest factor depending upon the capabilities of the sensor.

Display power measurements in Watts or dBm.

Display match units in either VSWR, Return Loss, Rho, or % Match effi-

ciency.

Adjust power and match readings for effects of attenuators, couplers,

and cable loss

Log data to a file and review

Save and recall sensor configuration setups

1

Page 10

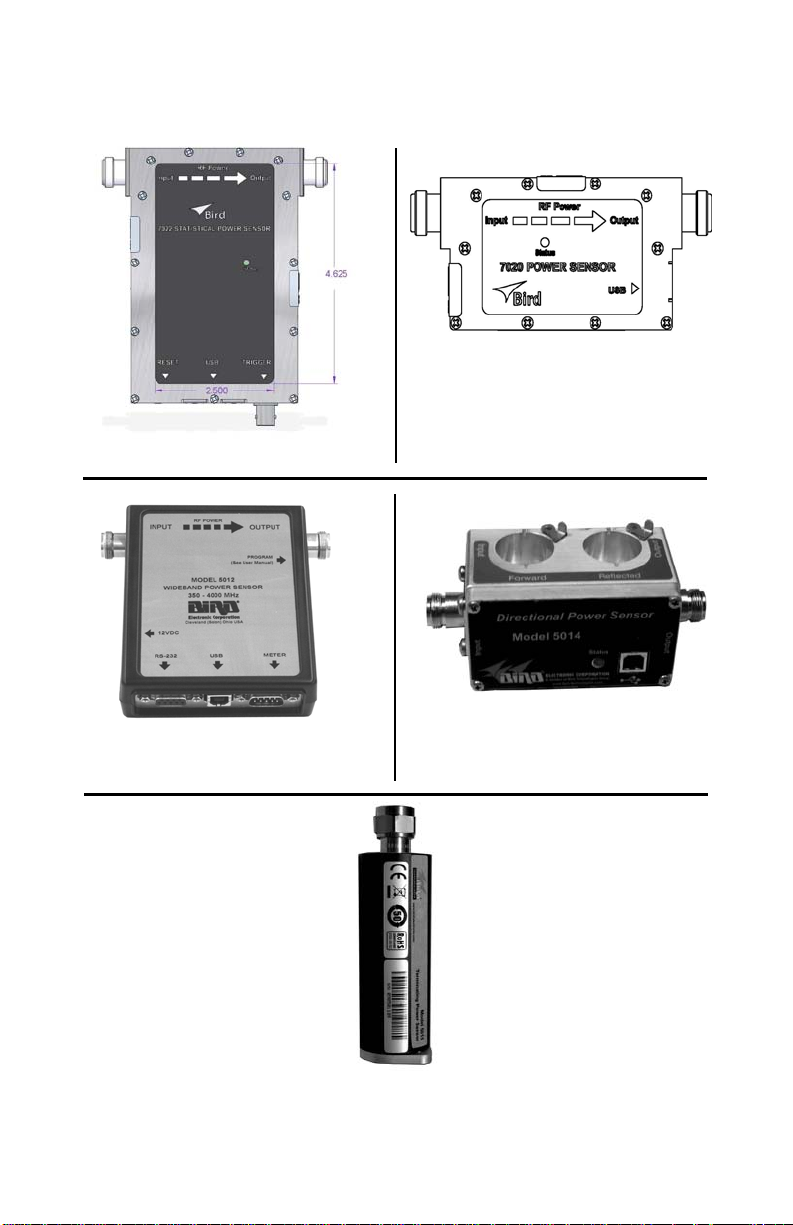

Figure 1 VPM Compatible Sensors

7022 Statistical Power Sensor (STAT)

7020 Power Sensor (WPS)

Directional Power Sensor

Wide Band Power Sensor

(WPS)

Terminating Power Sensor (TPS)

(DPS)

2

Page 11

Chapter 2 Set Up

Installing the VPM

1. Insert installation CD.

2. Select Install Software when prompted.

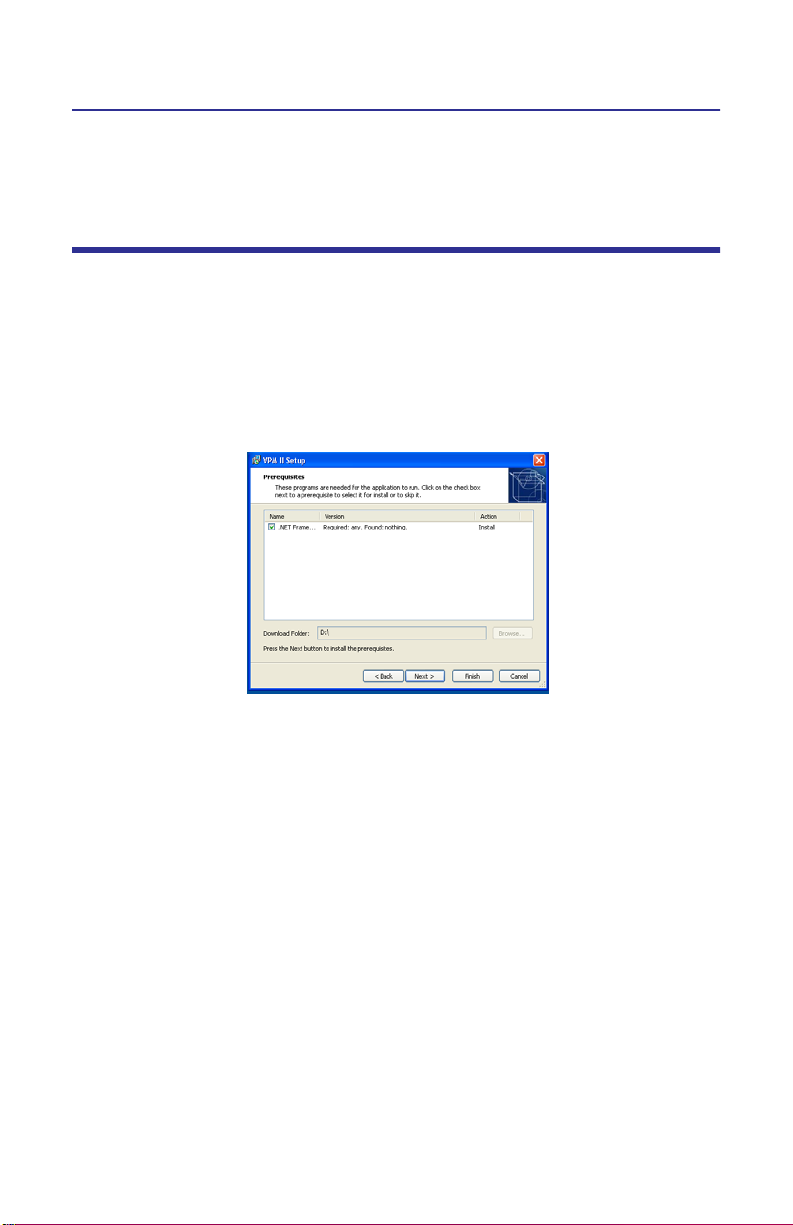

Note: Set-up will inspect the computer for any missing operating system prerequisites. If all are present, skip to step 6.

3. Select ‘Next ‘and the install utility begins the Prerequisites Installation process.

Figure 2 Install, Prerequisites Installation

4. Review the End-User License Agreement, check “I accept the terms of the

License Agreement” and select “Install.”

Note: The install Utility will install the prerequisites. This may take

several minutes

Note: When completed, check with Microsoft® support center for

any security updates. Typically, if “Automatic Updates” are configured

on the host PC, these will be automatically flagged and selected for

download and installation.

Note: The VPM3 installation utility will launch after the OS prerequisites are installed.

5. Do one of the following:

Accept the default installation location

Select a different folder:

6. Select ‘Next’ and the installer will complete.

7. Select “Finish” to launch the VPM3 program:

Note: When the VPM3 loads for the first time, the Preferences Dialog will prompt for a default log file save location. Perform the following to complete the process.

3

Page 12

8. Select the ‘Logging’ tab.

9. Enter a folder local to the PC to store log file data.

Note: This can be changed at any time in the Preferences. All active

sensor sessions must be closed before Preferences Dialog can be

opened.

10. Select the Advanced Tab.

11. Select the language in the drop down menu.

Note: For Mandarin Chinese, the East Asian languages files must be

installed. See “Language” on page 4.

Note: For any non-US English language setting, select ‘Windows’.

Any standard formats such as number and date formats from

"Regional and Language Options" found in the

Windows Control Panel will be mimicked in the VPM3 interface.

Preferences

The Preferences window will open automatically upon the first use of the VPM3.

If Preferences need to be changed at another time, it can be accessed from the

File drop down menu.

Default Settings may be restored when the Restore Default Settings button is

pressed.

General

Automatically connect to sensor on startup

When selected, the VPM3 will connect to the sensor upon the launching of the

program.

List sensors on startup

When selected, the VPM3 will list all available connectible sensors.

Display menu bar icons

When selected, the VPM3 will display the menu bar icons.

Language

Note: Default is English (US). For Chinese, the ‘East Asian languages’

files must be installed.

Installing Language Files

1. Open Control Panel>Regional>Language Options

2. Click on the Languages tab

3. Click on Supplemental language support.

4

Page 13

4. Click the ‘Install files for East Asian languages’ button.

5. Follow prompts.

Note: For any language change the application, must be restarted.

Note: All active sensor sessions must be closed before Preferences

Dialog can be opened.

Clear Message Box State

When this button is pressed, the Message will delete all store messages.

Figure 3 Preferences, General

File Locations

Note: Unless changed, the default directories are located in

Documents\VPM3 directory.

Session Directory

Sets the location of the session directory. See Save As on ......

Preset Directory

Sets the location of the preset directory. See Preset on ......

Measurement Data Directory

Sets the location of the data directory. See Measurements on .....

Figure 4 Preferences, File Locations

5

Page 14

Advanced

Chart History (points)

Sets the number of points to be collected in a session.

Playback History (frames)

Sets the number of frames created during a session.

Figure 5 Preferences, Advanced

6

Page 15

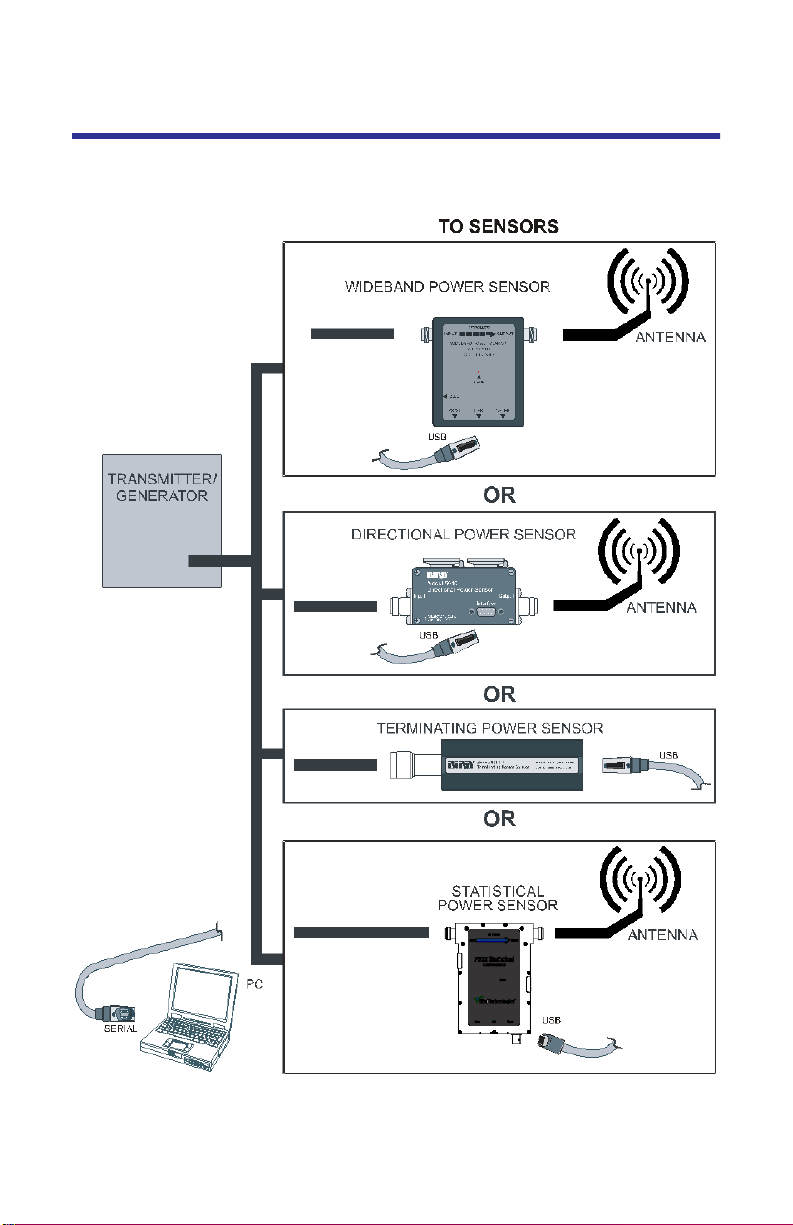

Connecting a Sensor

Note: Refer to the individual power sensor manual for specific infor-

mation regarding its sensor connections.

7

Page 16

1. Connect a power sensor to the computers USB port with a USB cable.

Note: Bird USB sensors are HID compliant devices and do not require

any driver installation. The only exception is the 7022 STAT power sensor which requires an installed driver.

Note: The 5014 and 5015 sensors LED will illuminate continually

when properly recognized by the host PC.

Note: The 5012B, 5016B, 5017B, 5018B, and 5019B sensors LED will

blink when properly recognized by the host PC.

2. Launch the VPM3.

3. Select the sensor from the sensor connection manager.

4. Press the Configure menu key, after VPM3 acquires the power sensor, See “Configure” on page 22.

Note: Multiple sensors can be connected and/or monitored simultaneously through multiple USB ports or via a powered USB hub. It can

take up to 30 seconds to detect a sensor.

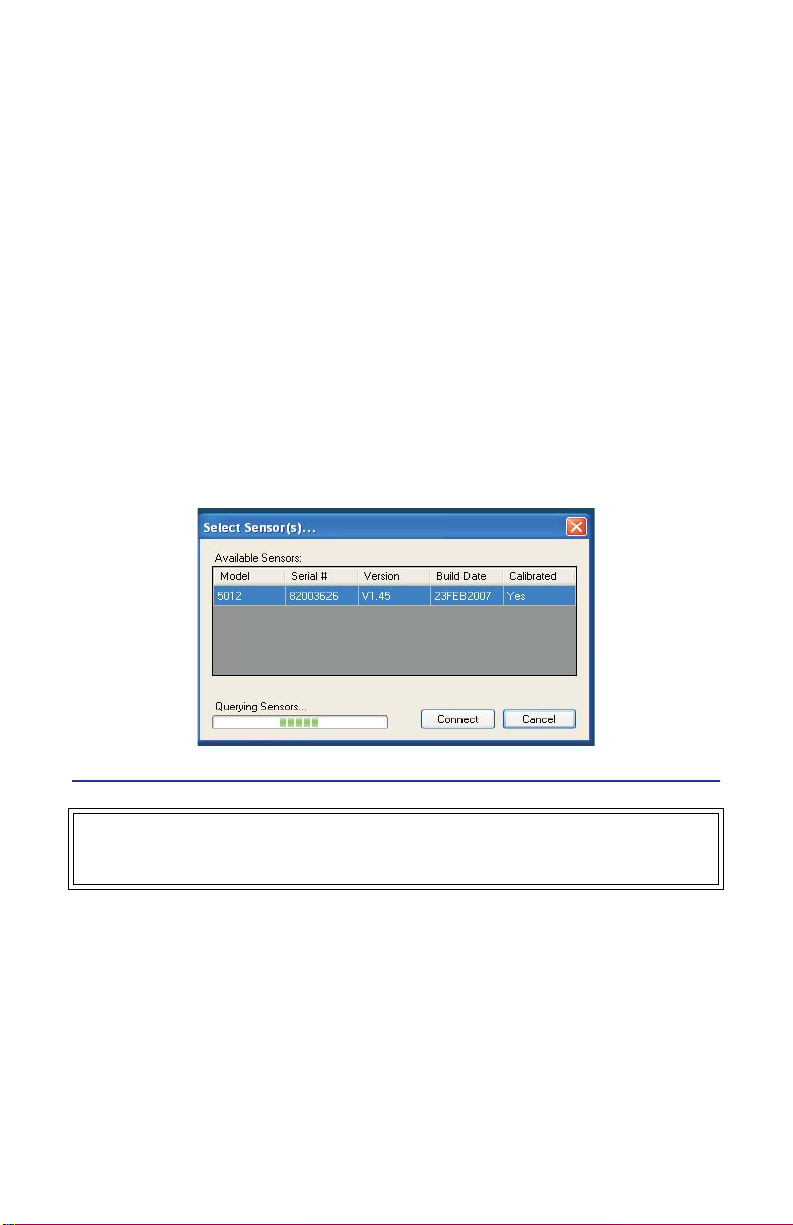

Figure 6 Sensor Connection Manager

Connecting the Directional Power Sensor (DPS)

WARNING

RF voltage may be present in RF element socket. Keep element in socket during

operation.

1. Connect the Bird DPS to the a USB port on the PC using the sensor cable

provided.

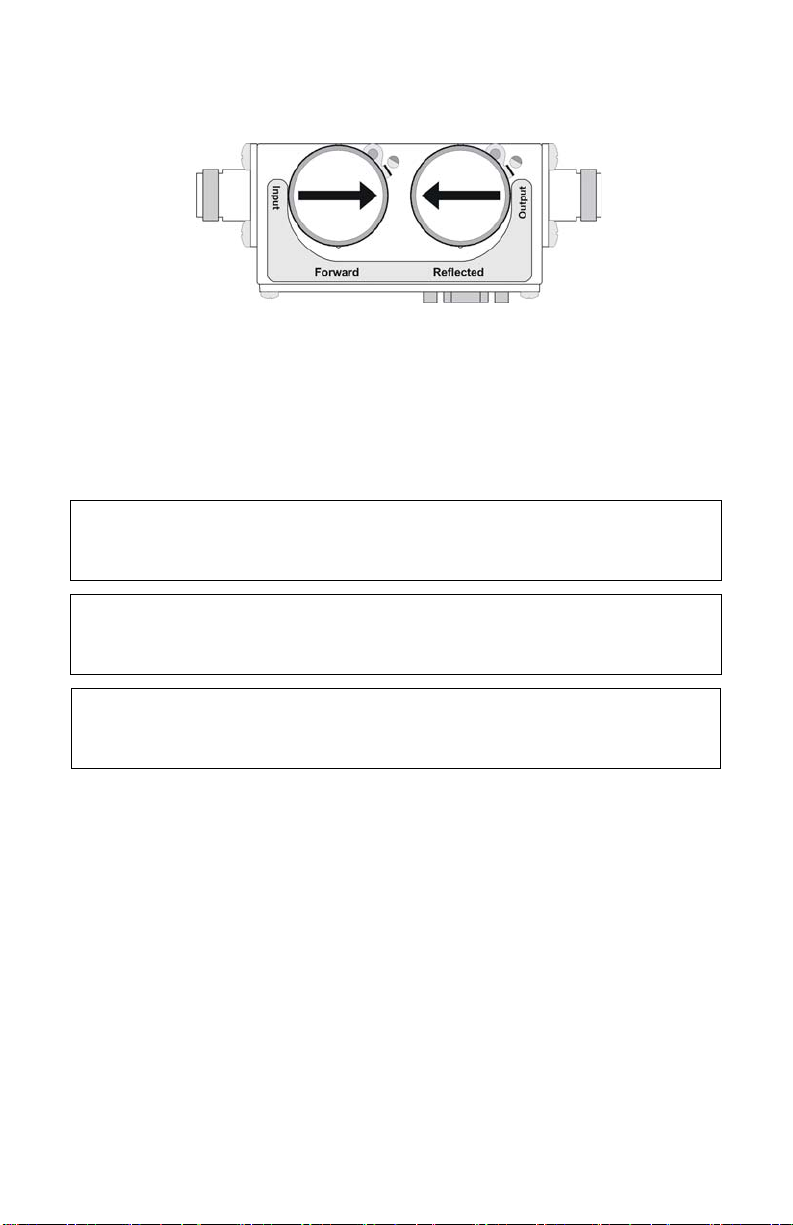

2. Connect the DPS to the RF line so that the arrow on the sensor points

towards the load.

Note: The arrow on the forward element should point towards the load.

Note: The arrow on the reflected element should point towards the

source.

Note: Both elements must be either APM/DPM or 43 types, do not

mix elements.

3. Set the power on the DPM to the forward element’s power rating.

8

Page 17

Figure 7 DPS Element Orientation

Connecting the Wideband Power Sensor (WPS)

1. Connect the Bird WPS to the a USB port on the PC using the sensor cable

provided.

2. Connect the WPS to the RF line so that the arrow on the sensor points

towards the load.

Connecting the Terminating Power Sensor (TPS)

CAUTION

Discharge all static potentials before connecting the TPS(-EF). Electrostatic

shock could damage the sensor.

CAUTION

When connecting the TPS or the TPS-EF, only turn the connector nut. Damage

may occur if torque is applied to the sensor body.

CAUTION

Do not exceed 2 W average or 125 W peak power for 5 μs when using the TPS

or the TPS-EF. Doing so will render the sensor inoperative.

Note: Connections are the same for the Bird 5011 and 5011-EF.

1. Connect the Bird TPS to the a USB port on the PC using the sensor cable

provided.

Note: An attenuator or directional coupler should be used with the

TPS in most applications.

Example - For an RF source with output between 0.1 and 50 W, use

a 40 dB, 50 W attenuator.

2. Connect the TPS RF input to the source (using an attenuator, if appropriate).

Note: Only connect the TPS directly to a source if the RF power will

be less than 10 mW.

Connecting the Statistical Power Sensor (SPS)

1. Connect the Bird WPS to the a USB port on the PC using the sensor cable

provided.

2. Connect the WPS to the RF line so that the arrow on the sensor points

towards the load.

9

Page 18

10

Page 19

Chapter 3 Average Power Mode

Display Types

Typical functions are selecting the type of measurement, type of element, units

of measure, measurement scales, offset values, and zeroing the sensor.

When a power sensor is properly connected (and detected), a status message,

located at the top of the Power Meter screen, will indicate the model number of

the power sensor (i.e., Bird model number). A popup with all decimals in the

reading will display when a mouse icon hovers over the specific reading.

Power Display

The selected measurement type is displayed in the main power display and

ancillary readings are displayed under the bar graph.

Bar Graph

The bar graph gives a visual indication of the main reading as well as displaying

the preset limits for the currently selected measurement. The scale of the graph

can be set to auto or full-scale.

Limit Indicators

'Virtual LEDs' indicate when pre-set limits have been exceeded.

Sensor Details

Provides a comprehensive display of all readings provided by the

sensor as well as all relevant configuration parameters

Sensor Status

Indicates the sensors connection status and zeroing progress.

11

Page 20

Figure 8 VPM Screen, Power Display

1

8

7

6

4

5

Item Description

1 Model of connected power sensor

2 Softkey Labels

3 Display Type

4 Menu Label Keys

5 Sensor Status

6 Sensor Readings

7 Power Meter

8 Limit Indicators

2

3

12

Page 21

Meter Display

Provides for a more traditional, analog-style view of main power display. The

selected measurement type is displayed in the analog meter as well as the preset limits for the currently selected measurement. The scale of the graph can be

set to auto or full-scale.

Sensor Readings

Numerical readout of selected measurement type and ancillary readings is displayed under the meter display.

Red indicates a questionable measurement. This means that the sensor has

determined that the measurement cannot be made or corrected reliably.

Figure 9 VPM Screen, Meter Display

Item Description

1 Model of connected power sensor

2 Softkey Labels

3 Display Type

4 Menu Label Keys

5 Sensor Status

6 Sensor Readings

7 Power Meter

8 Limit Indicators

13

Page 22

Chart Display

Used to display running time trace of all data collected by a sensor session or to

review data saved to a log file.

Note: Displaying the running time trace does not automatically save

data to a file. The Logging function must be activated to save data. See

“Logging” on page 30.

Figure 10 VPM, Chart Display

Item Description

1 Model of connected power sensor

2 Softkey Labels

3 Display Type

4 Menu Label Keys

5 Sensor Status

6 Sensor Readings

7 Marker Readout

8 Time Chart Display

9 Scroll Buttons

Note: Only data stored in Extensive Markup Language format (.xml) can

be recalled using the VPM3. See “Logging” on page 30.

Both Type and Units may be changed at any time in chart display.

Right clicking in chart will change display options:

14

Page 23

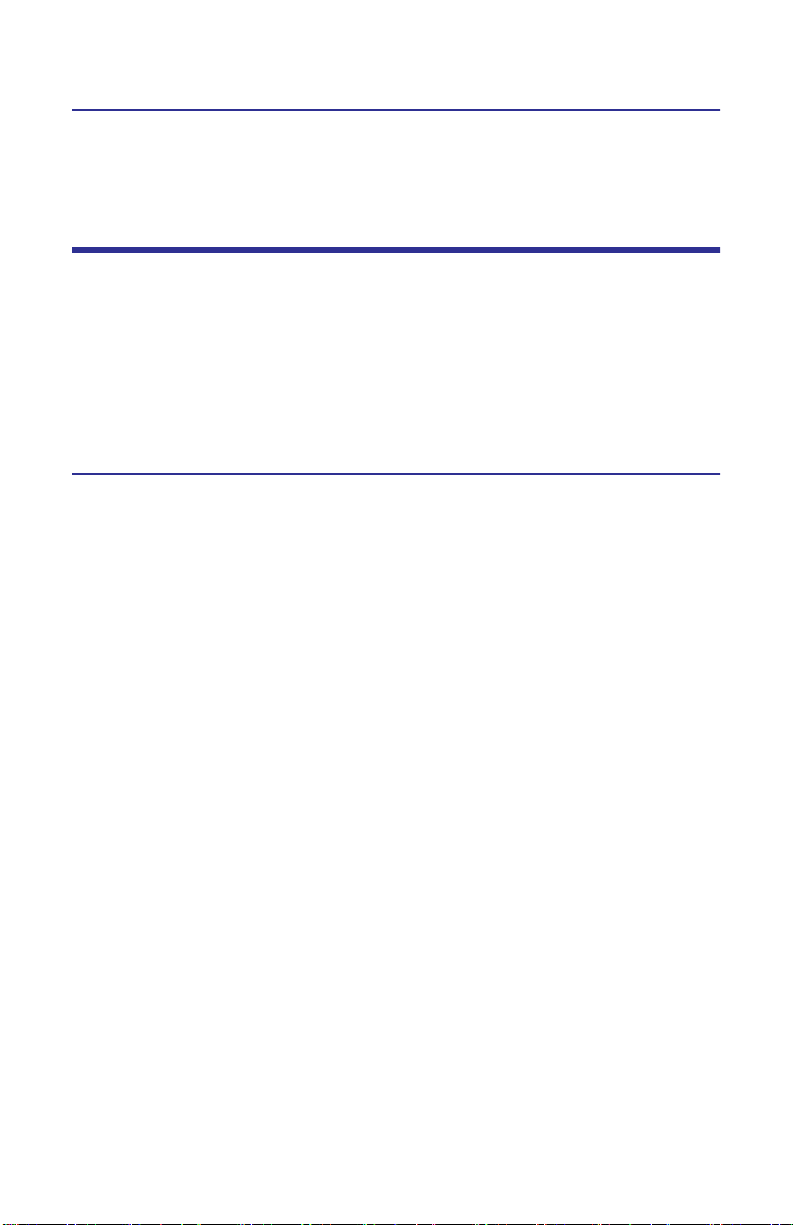

Show Markers

Toggles markers on & off. See “Markers” on page 15.

Show Grid

Turns major & minor grid on/off

Show Points

Toggles points on each data location

Best Fit Data

Adjust scales to show entire range of data

Set Lower/Upper Delta Marker

Moves the marker to the location of the mouse pointer & automatically sets the

position in time for the marker.

Figure 11 Chart Display, Options Menu

Options Menu

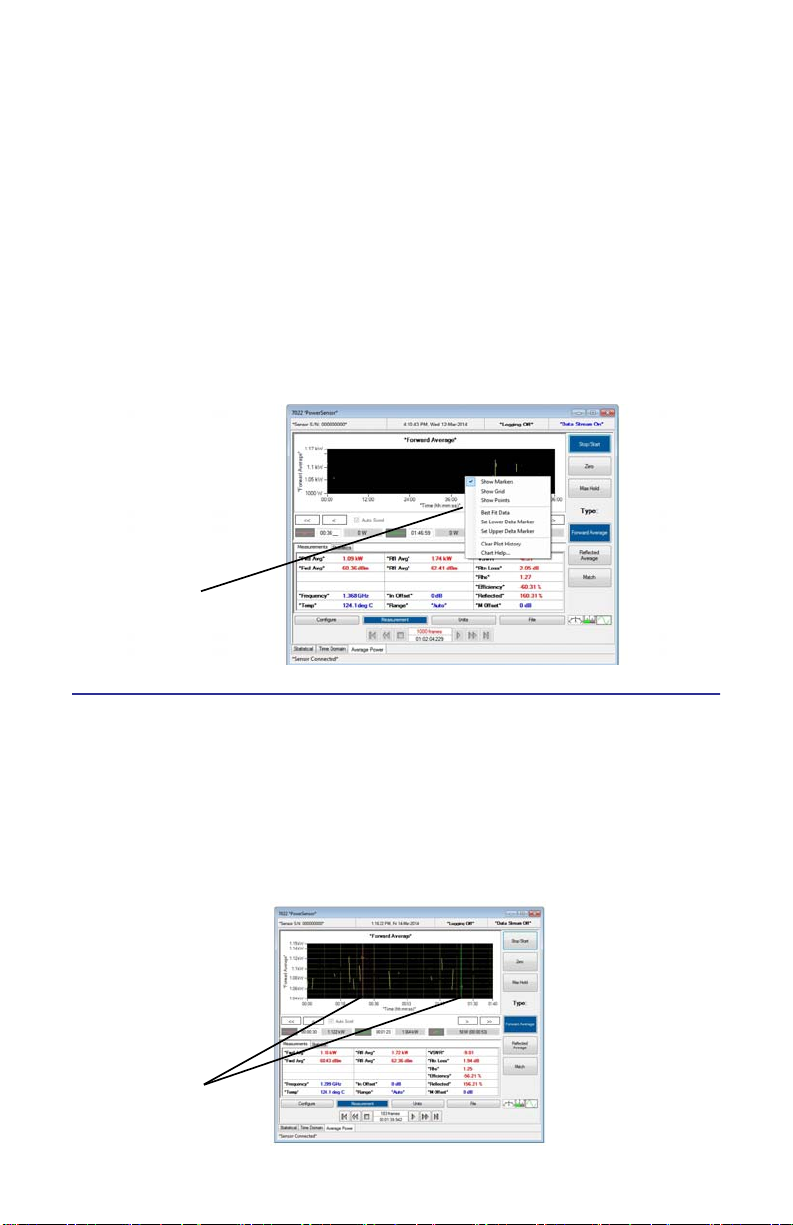

Markers

Click on marker & slide, also can type time in display to move markers to exact

time location.

Markers always stay in their current time reading.

Note: If the chart moves the markers off-screen, simply select ‘Set

Upper or Lower Delta Marker’ to return the markers to the current displayed time interval.

Figure 12 Chart Display, Markers

Markers

15

Page 24

Axis Scaling

Right click on Y or X axis to change scale from Auto to user-defined.

Figure 13 Chart Display, Changing Scale

Manual Axis Scaling

Change Time axis to ‘Manual’ allows scroll keys to be activated

<< , >> - Moves chart to start, end of log

< , > - Moves chart one span to the left or right

Auto Scroll - When checked, the chart will automatically advance

forward in time maintaining the same interval specified in the manual scale

entry.

Figure 14 Chart Display, Manual Axis Scaling

16

Page 25

Menu Bar

File

New Sensor Session

Displays sensor list and connection status dialog. Does not close the active sensor window/connection.

Open

Session - Displays the session open file dialog.

Preset - Displays the preset open file dialog.

Measurement - Displays the measurement open file dialog.

Reference Measurement - Displays the measurement open file dialog.

Close Session

Closes the active session window.

Save Session

Saves the active session without displaying the session file save dialog.

Save Session As...

Saves the selected session under a different name or file type.

Save Measurement Snapshot

Saves the most recent measurement frame to a file without displaying the measurement file save dialog.

Save Measurement Snapshot As...

Displays the measurement file save dialog.Recall/Review Log File...

Save Preset As...

Displays the preset file save dialog.

Recent Sessions

Displays the following submenu as a list of recent files

Recent Measurements

Displays the following submenu as a list of recent files

Preferences...

Sets the location of a saved files directory.

Exit

Closes the program and all open sessions.

17

Page 26

Mode

Note: The Mode menu is only displayed if the sensor supports more

than one measurement mode. For the 7022 sensor the following is displayed.

Statistical

Switch to Statistical mode. See “Statistical Power Mode” on page 37

Note: The mode tab will update to reflect this.

Time Domain

Switch to Time Domain mode. See “Time Domain Mode” on page 33.

Note: The mode tab will update to reflect this.

Average Power

Switch to Average Power mode. See “Average Power Mode” on page 11.

Note: The mode tab will update to reflect this.

Configure

Note: This menu will change depending on the sensor being displayed.

Input Offset

To read the true power when using a coupler or attenuator, enter (in dB) the

attenuation or coupling factor. To convert percentages to dB, use the equation:

Attenuation dB 10 Log10 Attenuation percent100=

Note: The Bird 5015-EF uses frequency-dependent correction factors

to provide more accurate measurements that are entered here. For

more information, refer to the owners manual for the 5015-EF.

Match Offset

The masking effect of cable loss can cause significant error when measuring

antenna VSWR or return loss levels. This masking can make an antenna to

“appear” to perform more efficiently than is actually the case. The offset error

may be corrected with the following equation:

RL at Antenna = RL at Transmitter - (2 x CL)

RL = Return Loss

CL = Cable Loss or Match Offset.

In the Match Offset dialog, enter the total insertion loss of the cable connected

between the power sensor and antenna, in dB. The VPM3 will correct the displayed match values according this equation.

18

Page 27

Smoothing

Note: The smoothing in this menu item is available only with the

7022 and is performed in the sensor itself. It only effects the average

power measurement in the forward direction and is used for very low

rep rate signals (<200Hz).

Selects smoothing that is performed by the sensor for average forward and

reflected power.

None - No smoothing is performed.

Low - Uses a moving average of 8 samples.

Medium - Uses a moving average of 16 samples.

High - Uses a modified moving average (exponential average with alpha = 1/N).

Frequency Setpoint

Note: 7022 Only.

Auto - The frequency will be determined by the sensor.

Full - The specified frequency will be used in correcting the power measurement.

Note: Use this when the sensor is unable to measure the frequency

of a signal.

Duty Cycle

Note: 7022 Only.

Sets the duty of a measurement for determining the Burst Average power. If sensor is capable, the duty cycle will be inferred by the sensor hardware and

reported. A user-defined duty cycle can be entered to override the sensor provided value.

Note: If zero is entered, the duty cycle automatically sets to Auto.

Note: For best duty cycle measurement with the 7022, have at least

10 pulses on the time domain screen.

Auto - The duty cycle will be determined by the sensor.

Specify Duty Cycle - The specified duty cycle will be used to determine the

Burst Average power.

Note: Use this for best accuracy when the duty cycle is known.

See “Specifications” on page 51 for more information on how duty cycle is calculated and used for each sensor that has the feature.

Measurement

Type

Selects the parameter that is displayed in the bar graph, meter or chart.

19

Page 28

Units

Power - Toggles the power measurement between Watts and Decibels.

Match - Allows selection of match measurement units.

Note: This is dependent on the sensor attached.

Start Acquisition

Starts a trace for the selected session.

Stop Acquisition

Holds a trace until a started again.

Max Hold

Holds and displays the highest trace data points.

Zero

Performs a zero calibraion on the selected sensor. See “Zeroing a Sensor” on

page 32.

Log

Enable Data Logging

Starts monitoring the selected Measurement type. See “Logging” on page 30.

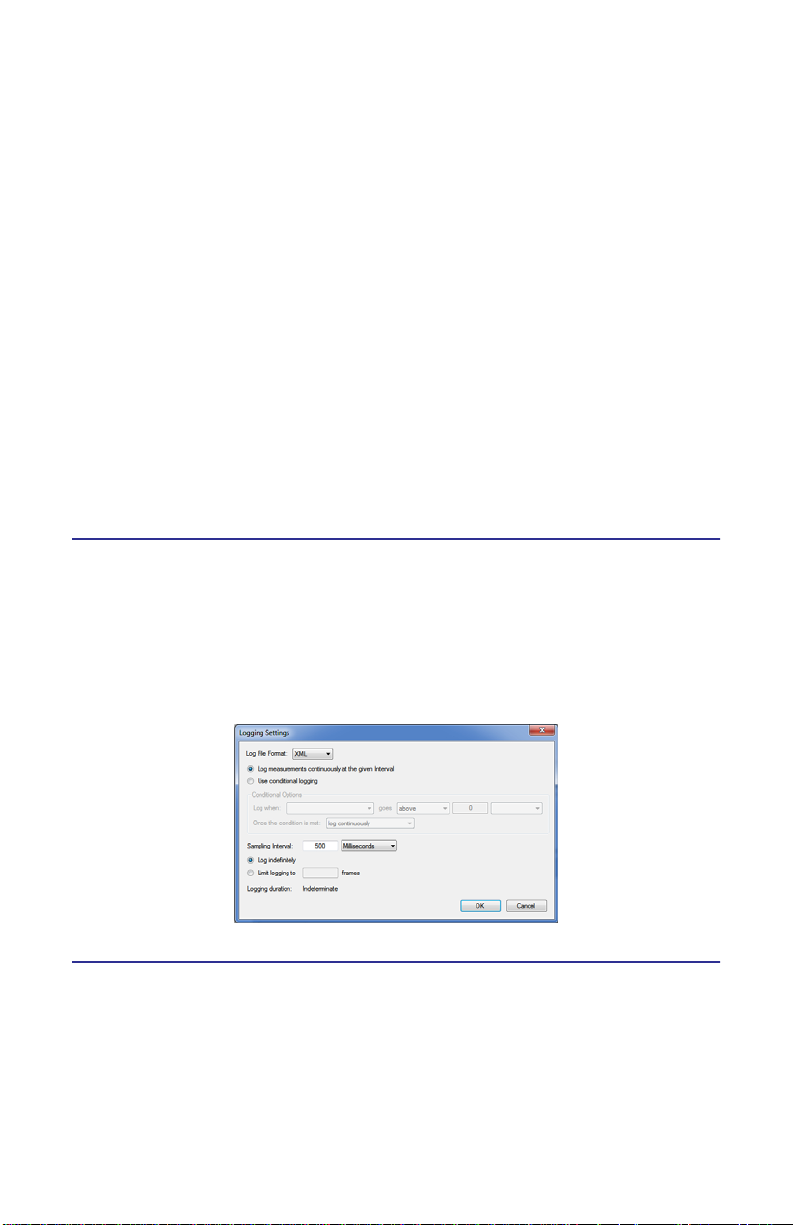

Logging Settings

See “Logging” on page 30.

Figure 15 VPM, Logging Settings

View

Control Panel

When selected, it will display the control buttons.

Playback Controls

When selected, it will display the playback controls.

20

Page 29

Details

When selected, it will display the details of the measurement.

Fullscreen Mode

Toggles the display to full screen on and off.

Display Style

Choose between three:

Digital

Analog

Chart

Meter Range

Choose between two:

Auto

Full

Smoothing

Choose between two:

Enabled

Specify Number of Readings

Playback

Choose between six:

Clear Buffer

No Delay

1 sec

2 sec

4 sec

8 sec

Window

Cascade Sessions

Organizes the sessions in a cascading, offset display.

Tile Sessions Horizontally

Organizes the sessions horizontally.

Tile Sessions Vertically

Organizes the sessions vertically.

21

Page 30

Help

User Manual

Opens a html version of the user manual.

About Virtual Power Meter

Displays version info about the VPM and any attached sensors.

About Sensor

Displays model information of the selected sensor.

Menu Label Keys

Configure

Note: Specific configuration features depend upon the power sensor

being used.

When the Configure menu key is pressed, the soft key functions that specify the

setup information about the sensor and the measurements are enabled. What

type of element in the power sensor, offsets for input and match, duty cycle,

and the scale for forward and reflected power is displayed at this time.

Note: For DPS sensors, element scales have pre-defined values and

an “Other” category for arbitrary values.

Note: The 5015-EF offset factors are used for frequencies above 4

GHz.

For Wide Band Power Sensors

Video Filter - Except for average power and VSWR measurements, all WPS

measurements rely on a variable video filter to improve accuracy. This filter can

be set to either 4.5 kHz, 400 kHz, or full bandwidth. It should be as narrow as

possible while still being larger than the demodulated signal bandwidth (video

bandwidth). Narrowing the filter limits the noise contribution caused by interfering signals. Listed below are some common modulation schemes and the

appropriate video filter.

Video Filter Modulation Type

4.5 kHz CW Burst (Burst width > 150 μs), Voice Band AM, FM, Phase

Modulation, Tetra

400 kHz CW Burst (b.w. > 3 μs), GSM, 50 kHz AM, DQPSK

Full Bandwidth CW Burst (b.w. > 200 ns), CDMA, WCDMA, DQPSK, DAB/DVB-T

Note: 7022 has 5KHz, 500KHz, and 5MHz VBW filter and only effects

the time domain data, not average power.

Figure 16 Video Filter Settings, 300 kHz Signal

22

Page 31

1. Press the Input Offset soft key and use the key pad to enter the amount of

attenuation then press the Enter key.

2. Press the soft key to select Auto Duty Cycle.

3. Press the soft key to select Auto Range.

Figure 17 VPM, Configure, WPS

For Sensor 5015 and 5015-EF

1. Press the Power: Watts soft key.

2. Press the Input Offset soft key and use the key pad to enter the amount of

attenuation then press the Enter key.

23

Page 32

Figure 18 VPM, Configure, TPS

For Sensor 5014

43 Peak - Refer to the 5014 owner’s manual.

DPM - Refer to the 5014 owner’s manual.

1. Press the soft key to select the type of element.

2. Press the Forward Scale to enter the watt rating of the forward element.

3. Press the F/R Scale 10:1 Ratio soft key to select ON.

4. Press the Input Offset soft key and use the key pad to enter the amount of

attenuation then press the Enter key.

Figure 19 VPM, Configure, DPS

For Statistical Senors

Input Offset - See “Input Offset” on page 18.

Match Offset - See “Match Offset” on page 18.

Meter Range - .

Smoothing - See “Smoothing” on page 19.

Freq Setpoint - See “Frequency Setpoint” on page 19.

Duty Cycle - See “Duty Cycle” on page 19.

24

Page 33

Measurement

Note: Specific measurement types depend upon the power sensor

being used.

Figure 20 VPM, Type, WPS

Figure 21 VPM, Type, DPS

Forward and Reflected Power

Average power is a measure of the equivalent “heating” power of a signal, as

measured with a calorimeter. It measures the total RF power in the system, and

does not depend on number of carriers or modulation scheme.

Average power is the most important measurement of any transmission system

since the average power is normally specified on the operating license. It is also

valuable as a maintenance tool, showing overall system health, and for calibration.

25

Page 34

Match

p

Match measures the relation between forward and reflected average power.

The health of the feedline and antenna systems can be monitored using Match,

or VSWR, measurement under full power operating conditions. High VSWR is an

indicator of feed line damage, overtightened cable or feed line clamps, or

antenna changes/damage due to weather conditions, icing, or structural damage to the tower.

Rho and Return Loss are also the same measurement, but in different units:

Rho -

VSWR -

Return Loss (dB) -

Rho PRPF=

VSWR

1 p+

------------ -=

1

–

ReturnLoss dB20 log=

Figure 22 Average and Peak Envelope Power, Square Wave Signal

Forward Peak Power

Peak power measurements detect amplitude changes as a signal modulates the

carrier envelope.

Transmitter overdrive can be detected with peak measurements. Common

problems are overshoot at the beginning of burst packets, amplitude modulation, and excessive transients. These damage system components with excessive peak power and also cause data degradation, increasing the Bit Error Rate.

For TDMA applications, Peak and Burst Power measurements are used to detect

overshoot in single timeslots. Other timeslots must be turned off for this test.

Peak Average Power

This displays the average of the positive and negative peak power readings.

Burst Average Power

Burst width (BW) is the duration of a pulse. Period (P) is the time from the start

of one pulse to the start of the next pulse. Duty cycle (D) is the percentage of

time that the transmitter is on. To calculate the duty cycle simply divide the

burst width by the period (D = BW / P). Low duty cycles mean that the burst

width is much less than the period; a large amount of dead time surrounds each

burst. For low duty cycles, the burst average power will be much larger than the

average power.

After peak power is measured, a threshold of ½ the peak is set. The sampled

power crosses that threshold at the beginning and end of each burst. The time

between crossings is used to calculate the duty cycle. Burst Average Power is

calculated by dividing the Average Power by the Duty Cycle.

26

Page 35

Burst average power is calculated in the 7022 automatically using the average

detector and the duty cycle.

Burst average power can also be calculated in the time domain mode using the

average power between markers function.

Burst power measurements provide accurate, stable measurements in bursting

applications such as TDMA and radar. Accurately measuring the output signal

strength is essential for optimizing radar coverage patterns. Actual transmitted

power in a single timeslot can be deter-mined in TDMA. The other timeslots

must be off during this test.

Figure 23 Burst Average Power

Crest Factor

Crest factor (CF) is the ratio of the peak and average powers, in dB. The WPS calculates the Crest Factor from the Forward Peak and Average Power measurements.

Crest factor is becoming one of the most important measurements as communication systems move into the digital age. For CDMA and similar modulation

types the CF may reach 10 dB. If the crest factor is too large, the transmitter will

not be able to handle the peak powers and amplitude distortion will occur. Crest

factor can also detect overdrive and overshoot problems. Knowing the CF allows

end-users to more accurately set base station power and lower operating costs.

Figure 24 Crest Factor, 10 dB CDMA Signal, 100 W Peak, 10 W Ave

Complementary Cumulative Distribution Function (CCDF)

CCDF measures the amount of time the power is above a threshold. This threshold is set in the Configure, CCDF Factor menu. Equivalently, it is the probability

that any single measurement will be above the threshold. The WPS samples the

power over a 300 ms window and compares it to a user-specified threshold, in

Watts. The time above the threshold relative to the total time is the CCDF.

27

Page 36

CCDF measurements are most useful for pseudo-random signals, such as

WCDMA, where a high CCDF means that the transmitter is being overdriven.

CCDF can also detect amplitude distortion within an envelope caused by

unwanted modulating signals. In TDMA systems, CCDF indicates the health of

power amplifier stages and their ability to sustain rated power over an appropriate timeframe. As a trouble-shooting aid, CCDF allows tracking of trends such as

amplifier overdrive (which can cause dropped calls and high bit error rates).

Figure 25 CCDF, 100 W Signal, 80 W Threshold, 20% CCDF

Units

When the Units menu key is pressed, the soft key functions that select the units

of measure are enabled. For power measurements, Watts or dBm can be

selected. For match measurements, VSWR, dB, rho, and percent (%) can be

selected.

Figure 26 VPM, Units, WPS

28

Page 37

Figure 27 VPM, Units, TPS

Figure 28 VPM, Units, DPS

File

Note: Save and Save As captures the most recent measurement

readings. It will not store the time-chart information. To store time

chart display, ensure logging is enabled. See “Logging” on page 30.

Save

Press this soft key to create a snapshot of the readings displayed on the screen.

That snapshot is saved in the log file folder “Setup” in the Preferences under the

File menu item. Each quick save is stored in a separate file that is named using

the date-time file naming format:

MMMM_NNNNNNNN_YYYYMMDD_HHMMSS.xml

Model

Serial Number

Year

Month

Day

Hour

Seconds

Minute

29

Page 38

Save As

Same as Quick Save, only the program will request a title to save the trace under.

Figure 29 VPM, File

Enable

Enable Logging

See “Logging” on page 30.

Logging Settings

See “Logging” on page 30.

Open Preset

Applies a preset to the measurement.

Logging

Measurement logging is a powerful tool for monitoring and tracking system performance. Storing the readings enables the ability to graph the output over time, know

the exact time of a failure, or compare systems.

The VPM3 can be set up to take many readings over a short test period, to take

a few readings a day for long-term monitoring, to log only while the transmitter

is on, or to log when power spikes or drops below a critical value, depending on

specific needs. To begin logging:

1. Configure the logging options.

2. Begin logging by selecting Enable Logging.

Note: When logging is active, in the upper right of the sensor session

will display “Logging On.”

3. Stop logging by selecting Enable Logging.

After logging is complete, the data can be reviewed in the a VPM3 logfile recall/

review session or imported into Microsoft Excel or another spreadsheet program for analysis.

Note: Log files are stored in the default log file directory under

:Documents/VPM3/Measurements.

30

Page 39

Analyzing Logged Data

The simplest way to view logged data is to recall in VPM3. See “Chart Display”

on page 14.

Note: Only log files saved as .xml can be opened and viewed in the

VPM3. Files saved in comma-separated format (CSV) can be read by

most common spreadsheet programs.

Since logged data is stored in a text file in an .xml or comma-separated text file

where each line is one data record. Fields are separated by commas format, it is

also readable by most spreadsheet programs.

Each log file is stored in a separate file that is named using the same date-time

file naming format as for quick-save.

Opening .xml Files in Excel

1. Open the file in Microsoft Excel.

Note: The file will appear in Microsoft Excel with each field in its own

column.

2. Filter the data, since the Extensive Markup Language format is a hierarchical format.

a. In the Measurement column, select the drop-down and check only

the Forward Average label.

b. In the Limit Type column, select the drop-down and check only the

Lower label.

Note: This will now show data in a time vs. power format. Additional

filtering and sorting can be applied using the options in the column

headers.

Opening .csv Files in Excel

1. Open the file in Microsoft Excel.

Note: The file will appear in Microsoft Excel with each field in its own

column. If all the data is in a single column, follow these steps to convert it:

a.Click on the column name, to select the entire column.

b.Select Text To Columns, under the Data tab.

Note: A conversion wizard should open.

c.Select Delimited, under Original Data Type.

d.Click Next.

e.Check Comma, under Delimiters.

Note: All other delimiters should be unchecked. Treat Consecutive

Delimiters as One should be unchecked.

f.Click Next.

g.Click Finish.

31

Page 40

2. Create a graph of the forward and reflected average power as a function of

time:

a. Select row 1 by clicking on the row name.

b. Select Delete, under the Edit tab.

Note: The first line of header information will be deleted.

c. Click on cell B1.

d. While holding down the Ctrl key, select columns B (Time), H (Avg

Fwd W), and J (Avg Rfl W).

e. Select Chart, under the Insert tab.

Note: The chart wizard should open.

f. Select XY (Scatter).

g. Select the Line subtype.

h. Click Next.

i. Click Next in the data range, which should already be set.

j. Enter a title and names for the X and Y axes.

k. Click Finish.

Note: Other data can be graphed by selecting the appropriate columns in step d.

Zeroing a Sensor

1. Check that no RF is in the system.

Note: The sensor will read “~0.”

2. Do one of the following:

Press the Measurement menu button.

Go to the Measurement menu and select the Zero menu item.

Note: Calibration will take about 40 seconds. Do not interrupt the

calibration. A progress bar for the calibration will be displayed on the

screen.

Note: Some soft key features will not be available for certain power

sensors.

3. Press “Run” to resume data collection with the new Zero offset.

Figure 30 Zeroing Sensor

32

Page 41

Chapter 4 Time Domain Mode

Display

Figure 31 Screen Features, Time Domain

Item Description

1 Model of connected power sensor

2 Lower Delta Marker

3 Upper Delta Marker

4 Menu Label Keys

5 Sensor Status

6 Modes

7 Hard Key Menu

8 Limit Indicators/Statistic Indicators

9 Marker Indicators

10 Time Domain Plot

33

Page 42

Menu Bar

File

See “File” on page 17.

Mode

See “Mode” on page 18.

Configure

Note: This menu will change depending on the sensor being displayed.

Input Offset

To read the true power when using a coupler or attenuator, enter (in dB) the

attenuation or coupling factor. To convert percentages to dB, use the equation:

Attenuation dB 10 Log10 Attenuation percent100=

Note: The Bird 5015-EF uses frequency-dependent correction factors

to provide more accurate measurements that are entered here. For

more information, refer to the owners manual for the 5015-EF.

Scale

There are three settings for the measurement plot.

Time (Horizontal)

Power (Vertical)

Reference Level

Bandwidth

There are four settings to choose from:

No Filter

5 kHz

5 MHz

20 MHz

34

Page 43

Frequency Setpoint

See “Frequency Setpoint” on page 19.

Duty Cycle

See “Duty Cycle” on page 19.

Measurement

Start Acquisition

Starts a trace for the selected session.

Stop Acquisition

Holds a trace until a started again.

Enable Pulse Measurement

Starts a pulse trace for the selected session.

Zero

See “Zeroing a Sensor” on page 32.

Trigger

Source

Choose between three:

Internal - Triggered when the signal crosses the specified trigger level.

External - Triggered by a signal applied to the external trigger connector.

Manual - Triggered by selecting the manual trigger menu selection or

button.

Mode

The mode affects operation only when the selected source is Internal or External.

Choose between three:

Single - Once the trigger occurs the signal is displayed. No further trig-

ger events are acted upon until you stop and restart the measurement

Auto - The measurement is triggered automatically if the specified trig-

ger event does not occur within the greater of 10ms or the acquisition

interval of the last measurement.

Normal - The measurement is not triggered until the specified trigger

event occurs.

35

Page 44

Edge

When the selected source is Internal, this selects the direction that the signal

crosses the specified trigger level to cause a trigger event.

Choose between two:

Rising

Falling

Level...

Note: Auto level was added that sets the trigger level automatically

half way between the max and min values of the previous time

domain data set.

Sets a specific the trigger power level when the source is internal.

Delay...

Specifies the delay between the trigger event and the start of the signal acquisition.

0 - the trigger event occurs at the mid-point of the time axis.

Positive values - Trigger event shifts to the left on the display.

Negative values - Trigger event shifts to the right on the display.

Note: Values are limited by the sensor. If a value exceeding a limit is

specified, the sensor will change that value to the limit.

Holdoff...

Specifies the minimum amount of time from the end of one measurement to

the next trigger event.

Manual Trigger

Triggers a single measurement.

Zero Delay

Resets any Trigger delay to zero.

Log

See “Logging” on page 30.

View

See “View” on page 20.

Window

See “Window” on page 21.

Help

See “Help” on page 22.

36

Page 45

Chapter 5 Statistical Power Mode

Most modern wireless communication systems employ complex modulation

and channel access methods like orthogonal frequency division multiplexing

(OFDM), or code division multiple access (CDMA). These methods use a combination of amplitude and phase modulation to create symbol based multichannel

or multicarrier systems that result in pseudorandom or noise-like power envelopes. The consequence is that modulation parameters such as AM depth or FM

modulation index are not useful. Indeed, the peak-to-average power ratio of

the modulated carrier is a complex function of the data stream content rather

than just amplitude, and as such is not constant with time. Since digitally modulated signals often appear noise-like it makes sense to use statistical analysis in

order to characterize them.

RF Power meters that provide measurements based upon statistical methods

have been available for use in laboratory environments for more than ten years.

The most significant advantage is that they are capable of making meaningful

power measurements of signals incorporating complex modulation methods. In

essence, provide meaningful measurements independent of the modulation

method used in the system.

The Bird Statistical Power Meter is a rugged, portable power sensor that is well

suited for use in the field by less sophisticated users than those that would typically be found in a laboratory setting.

37

Page 46

Display

Figure 32 Screen Features, Statistical Mode

Item Description

1 Model of connected power sensor

2 Lower Delta Marker

3 Upper Delta Marker

4 Menu Label Keys

5 Sensor Status

6 Modes

7 Hard Key Menu

8 Limit Indicators/Statistic Indicators

9 Marker Indicators

10 Time Domain Plot

38

Page 47

Statistical Power Measurement Methodology

Complementary Cumulative Distribution Function (CCDF)

The most commonly used parameter is that of the Complementary Cumulative

Distribution Function (CCDF), which provides an indication as to the probability

that the measured power level is greater than a specific power value. This technique has become extremely useful with modern communications systems,

where power levels appear to be noise-like, and do not follow a traditional

power envelope. With regard to CCDF, it is important to understand that CCDF

measurements require no time synchronization with the waveform to be measured, and no specific test signal is required. This type of power analysis may be

performed using live, “on-air” signals.

Example - 9 Channel CMA, One Signal

This figure illustrates a time record for a nine channel CDMA One Signal. Note the

noise-like nature of the signal, and the lack of any defined waveform envelope.

This figure illustrates the same signal using statistical methods (CCDF), where

the Y axis represents the percentage of time that the signal is at or above a level

specified by the X axis, and the X axis represents the level (dB) of the signal

above the average power of the waveform.

In this case, the signal of interest is being compared to band limited Gaussian

noise, as this signal has a defined characteristic, dependent upon the signal

bandwidth.

Example - LTE vs Gaussian Noise

This example illustrates another view of this concept, comparing the statistical

performance of a live LTE envelope compared to Gaussian noise.

Figure 41 presents another view of this data in numeric format, as a means of

illustrating a few of the data points on the CCDF curves. This table shows that

10% of the time, this particular LTE waveform demonstrates a peak to average

ratio of 4.46 dB. At the same time, the table also reveals that the same waveform demonstrates a peak to average ratio of 10.56 dB 0.0001% of the time.

Interpreting Statistical Data

There are many factors that influence the performance of modern communications systems. Some examples:

The presence of interfering signals within the operating bandwidth of

the system.

Transmission line discontinuities resulting in multiple reflections within

the transmission system.

39

Page 48

Poor amplifier linearity caused by amplifier compression. This results in

signal distortion and poor fidelity of transmitted waveforms.

Antenna damage or degradation resulting in high transmission system

reflections.

Issues with transmitter modulator performance resulting in high error

vector magnitude (EVM).

Many of the above transmission system issues may be identified through the

use of the statistical techniques mentioned above. For example, if a particular

LTE radio system was known to be dropping calls at a higher rate than expected,

a service technician will need to know whether the problem is with the radio

itself, or with some element of the transmission system, or with the air interface. Measuring the CCDF statistics of the base station radio, while terminated

with a high quality 50 ohm termination, and then again with the radio connected to the transmission and antenna system will provide clues as to where

the issues may be.

Another useful technique is to compare live data from the system with a known

“reference” transmission, as is demonstrated above using Gaussian waveforms.

40

Page 49

Menu Bar

File

See “File” on page 17.

Mode

See “Mode” on page 18.

Configure

Note: This menu will change depending on the sensor being displayed.

Scale

Specifies the maximum of the Upper Range.

Run Mode

There are two settings to choose from:

Normal - Takes one measurement and stops.

Clear Restart - Once a measurement has been completed and dis-

played another is started automatically.

Bandwidth

There are four settings to choose from:

No Filter

5 kHz

5 MHz

20 MHz

Confidence Factor

Sets the duration of the measurement.

Percentage - Acquires sufficient samples to achieve an error tolerance of +/-

0.1% with the specified confidence factor.

Number of Samples - Acquires at least the specified number of samples.

Time Duration - Acquires samples for at least the specified amount of time.

41

Page 50

Figure 33 Confidence Factor

Measurement

Start Acquisition

Starts a trace for the selected session.

Stop Acquisition

Holds a trace until a started again.

Show/Hide Reference

Sets the reference display.

Log

See “Logging” on page 30.

View

See “View” on page 20.

Window

See “Window” on page 21.

Help

See “Help” on page 22.

42

Page 51

Chapter 6 Power Sensors

Accuracy

The Bird power sensors are highly accurate. Accuracy is specified for each sensor

type is typically given as a percent of reading or of full-scale.

Example - If a sensor has a specified accuracy of 5% of reading +

1.0 uW, then for a 10 mW signal the uncertainty is ± 0.501 mW. For

a 1 mW signal the measurement uncertainty is ± 0.051 mW.

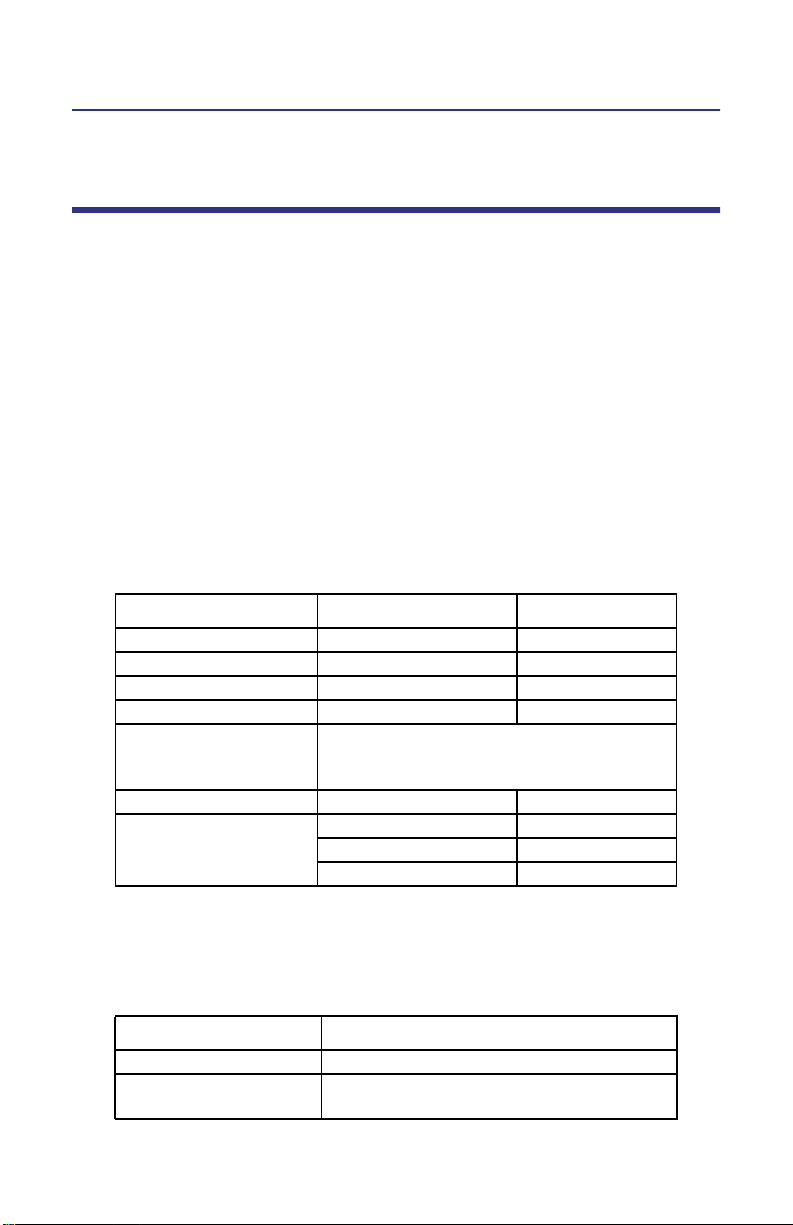

Sensor Uncertainty

While this value is a good estimate, the sensor is actually more accurate. The

sensor’s accuracy also depends on the temperature, and the power and frequency of the source; Table 1 lists some examples of uncertainty factors. If an

uncertainty is given as a power, divide this value by the measured RF power and

convert to a percentage. For example, an uncertainty of ± 0.25 μW with a RF

power of 10 μW is a 2.5% uncertainty. Table 2 lists external factors, such as

using attenuators or using a cable to connect a sensor to the transmitter, which

could affect the measurement uncertainty.

Table 1 - Example Uncertainty Factors

Error Source Conditions Uncertainty

Calibration Uncertainty ± 1.13%

Frequency Response 40 MHz to 4 GHz ± 3.42%

Temperature Linearity –10 to +50 °C ± 3.43%

*

Other

Resolution ± ½ smallest displayed digit

Zero Set

Noise

†

± 0.125 μW

†

*. Above 40 °C, when making measurements at frequencies

between 40 and 100 MHz, add 1.1%.

†. After a 5 minute warm-up, measured over a 5 minute

interval and 2 standard deviations

Table 2 - External Factors

< 40 °C or > 100 MHz ± 0.50%

(e.g. for a mW scale, three decimal places

are displayed. ½ the smallest is 0.5 μW)

above 1.05 mW ± 0.7 μW

105 μW to 1.05 mW ± 0.4 μW

below 105 μW ± 0.2 μW

Error Source Conditions

Attenuator Uncertainty Frequency dependent

Cable Uncertainty Frequency and length dependent (± 5% at

1 GHz for a ‘reasonable’ 1.5 m cable)

43

Page 52

The root sum square (RSS) uncertainty is the industry standard method for combining independent uncertainties. To determine the TPS's RSS uncertainty:

1. Square each uncertainty factor.

2. Add these values together.

3. Take the square root of this sum.

Table 3 has two examples of uncertainty calculations. The first is a 10 mW signal

at room temperature. The second is a 10 μW, 40 MHz signal at 50°C. Since this

measurement is at both low frequency and high temperature, the uncertainty

will be increased. Note that the RSS uncertainties are smaller than the values

from the rough estimate. This will always be the case.

Table 3 - Uncertainty Examples

Example 1

(10 mW, Room Temp)

Error

Source

Cal. Uncert. 1.13 % 1.28 1.13 % 1.28

Freq. Resp. 3.42 % 11.70 3.42 % 11.70

Temp. Lin. 3.43 % 11.76 3.43 % 11.76

Other 0.5 % 0.25 1.6 % 2.56

Res. 0.005 % 0.00 0.5 % 0.25

Zero Set 0.00125 % 0.00 1.25 % 1.56

Noise 0.007 % 0.00 2 % 4.00

Sum Uncert. 24.99 33.11

RSS Uncert. 5.00 % 5.75 %

Quick Uncert. 5.01 % 16 %

Percent

Uncert.

RSS

Term

Example 2

(10 μW, 40 MHz, 50°C)

Percent

Uncert.

RSS

Term

Mismatch Uncertainty

Another factor of measurement accuracy is mismatch uncertainty. When a source

and a load have different impedances, some signal will be reflected back to the

source. This uncertainty depends on both the VSWR of the TPS and the VSWR of the

rest of the system. For a system VSWR of 1.0, the mismatch uncertainty would be 0.

For a VSWR of 5.0, the mismatch uncertainty would be 12.5%. Given the VSWR of

the TPS and the source, the mismatch uncertainty can be calculated as follows.

Mismatch uncertainty (MU) is related to the reflection coefficient ( by the formula:

MU percent1

+21–100=

s1

Note: where s = reflection coefficient of the source,

and l = reflection coefficient of the load (the TPS)

The reflection coefficients can be calculated from the VSWR by the formula:

VSWR 1–VSWR 1+=

44

Page 53

Example - If a source with a 1.50:1 VSWR with the Terminating

Power Sensor was used, which has a max VSWR of 1.20:1, the mismatch uncertainty would be calculated as follows:

1.50 1–1.50 1+ 0.200==

s

1.20 1–1.20 1+ 0.091==

1

MU 1

0.200 0.091+

2

1–100 3.67==

If a source with a 1.30:1 VSWR was used instead, the mismatch uncertainty

would be:

1.30 1–1.30 1+ 0.130==

s

1.20 1–1.20 1+ 0.091==

1

MU 1 0.130 0.091+

2

1–100 2.39==

Using a lower VSWR source can drastically reduce the mismatch uncertainty.

Keep in mind that the typical VSWR of the Model 5011 is 1.03:1, which gives a

much lower mismatch uncertainty.

Example - With the 1.50:1 source, the mismatch uncertainty would

be:

1.50 1–1.50 1+ 0.200==

s

1.03 1–1.03 1+ 0.015==

1

MU 1

0.200 0.015+

2

1–100 0.59==

To determine the total uncertainty of the measurement, combine the RSS

uncertainty with the mismatch uncertainty using the RSS method. Square the

RSS uncertainty, add it to the square of the mismatch uncertainty, and take the

square root.

Using Example 1 in Table 3 with a source VSWR of 1.50 and a TPS VSWR of 1.20,

the total uncertainty would be:

5.0023.67

2

+ 6.20 percent=

For example 2, the total uncertainty would be 6.82 %.

45

Page 54

Directional Power Sensor (DPS) Measurements

Description

The DPS series sensors utilize elements in order to make power measurements.

Each element has an arrow on it that represents the direction in which it measures power. The elements ignore power in the opposite direction with a directivity of at least 25 dB. The DPS series can make power measurements using

either 43 type or APM/DPM elements, and the readings available vary, based on

which elements are being used.

Since the DPS uses two elements, it can measure the quality of the system by

comparing the forward and the reflected power. This is usually presented in the

form of VSWR (voltage standing wave ratio) or Return Loss.

43 Type Elements

The 43 type elements are normally used to measure peak power. These elements can measure the peak power of a system with an accuracy of +/-8% of full

scale as long as the signal meets the following requirements:

At least 15 pps (pulses per second)

Minimum pulse width of 15 μs

(800 ns if frequency is greater than 100 MHz)

Minimum Duty Cycle of 0.01%

In addition, 43 type elements can be used to measure average power in signals

with a peak-to-average ratio close to 1, like a CW or FM signals. In these cases,

the average power is measured with an accuracy of +/- 5% of full scale.

APM/DPM Elements

The APM/DPM elements are used to measure true average power. True average

power means the sensor provides equivalent heating power of the signal,

regardless of modulation or number of carriers. These elements can measure

average power with an accuracy of +/-5% of reading from full scale down to

2.5% of full scale.

Note: The equivalent heating power is dependent on the duty cycle

of a signal. If a system puts out 50 watts with a 50% duty cycle, the

APM/DPM elements will measure 25 watts.

46

Page 55

Terminating Power Sensor (TPS)

Description

The Bird Terminating Power Sensor (TPS) and 5015-EF extended frequency TPS

are a diode-based power sensors that measures true average power.

For best results, wait 5 minutes after applying power to the sensor before taking

readings.

Zeroing Sensor

Over time, the sensor’s “zero value” (reading with no applied RF power) can

drift, making all readings inaccurate by this value. For example, if the zero value

is –0.02 W, measuring a 50 W signal will give a reading of 49.98 W, a 0.04%

error. Measuring a 1 W signal will give a reading of 0.98 W, a 2% error. If the

drift would be a significant error, rezero the sensor:

1. Ensure the sensor has reached a stable operating temperature.

2. Ensure no RF power is applied to the sensor.

3. Press “Zero” to begin Calibration.

Note: Calibration will take about 40 seconds. Do not interrupt the

calibration! A bar on the screen will display calibration progress.

Correction Factors

The Bird TPS-EF uses frequency-dependent correction factors to improve its

accuracy. To use the correction factors:

1. Look at the Correction Factor Table on the side of the TPS and find the correction factor corresponding to the frequency under test.

2. Add the correction factor to all other necessary offsets (for example, the

coupling factor of a directional coupler).

3. Enter the total offset into the power meter.

4. Input the Offset on the VPM3. See “Input Offset” on page 18.

Note: Correction factors are only required above 4 GHz. Below

4 GHz, the TPS-EF can be used as a normal TPS. See “Terminating

Power Sensor (TPS)” on page 47.

47

Page 56