Page 1

INSTRUCTION BOOK

HIGH POWER

SEMICONDUCTOR

CAL CART

Bird® Electronic Corporation

30303 Aurora Road

Cleveland (Solon), Ohio 44139

Sales & Technical Support: 440-248-1200

Sales email: sales@bird-technologies.com

Technical Support email: atechapp@bird-technologies.com

866-695-4569 toll free

©Copyright 2010 by Bird Electronic Corporation

Instruction Book Part Number 920-HPCC Rev. G

Thruline® and Termaline® are a Registered Trademarks

of Bird Electronic Corporation

Page 2

THIS PAGE INTENTIONALLY LEFT BLANK

Page 3

Safety Precautions

The following are general safety precautions that are not necessarily related to any

specific part or procedure, and do not necessarily appear elsewhere in this publication. These precautions must be thoroughly understood and apply to all phases of

operation and maintenance.

WARNING

Keep Away From Live Circuits

Operating Personnel must at all times observe general safety precautions. Do

not replace components or make adjustments to the inside of the test

equipment with the high voltage supply turned on. To avoid casualties, always

remove power.

WARNING

Shock Hazard

Do not attempt to remove the RF transmission line while RF power is present.

WARNING

Do Not Service Or Adjust Alone

Under no circumstances should any person reach into an enclosure for the

purpose of service or adjustment of equipment except in the presence of

someone who is capable of rendering aid.

WARNING

Safety Earth Ground

An uniterruptible earth safety ground must be supplied from the main power

source to test instruments. Grounding one conductor of a two conductor power

cable is not sufficient protection. Serious injury or death can occur if this

grounding is not properly supplied.

WARNING

Resuscitation

Personnel working with or near high voltages should be familiar with modern

methods of resuscitation.

WARNING

Remove Power

Observe general safety precautions. Do not open the instrument with the power on.

i

Page 4

Bird High Power Semiconductor Cal Cart

Safety Symbols

WARNING

Warning notes call attention to a procedure, which if not correctly performed,

could result in personal injury.

CAUTION

Caution notes call attention to a procedure, which if not correctly performed,

could result in damage to the instrument.

This symbol indicates that a shock hazard exists if the precautions in the instruction manual are not followed.

The caution symbol appears on the equipment indicating there is

important information in the instruction manual regarding that

particular area.

This symbol indicates that the unit radiates heat and should not

be touched while hot.

Note: Calls attention to supplemental information.

Warning Statements

The following safety warnings appear in the text where there is danger to operating and maintenance personnel and are repeated here for emphasis.

WARNING

Do not attempt to lift the cart by the handle.

On page 3.

WARNING

Ethylene glycol is toxic. Do not take internally. Avoid contact with eyes, skin,

and clothing. Avoid breathing vapor. Wash thoroughly after handling.

On page 4.

WARNING

Never attempt to connect or disconnect RF equipment from the transmission line

while RF power is being applied. Leaking RF energy is a potential health hazard.

On pages 6, 12, 16, 17 and 20.

WARNING

To avoid personal injury, disconnect the power cord from the AC line before

performing any maintenance, including fuse replacement.

On pages 11, 16, 17, 18, 20, 21 and 22.

On page 11.

ii

WARNING

The Bird 4421 contains no user-serviceable parts. Do not remove its cover.

Page 5

Caution Statements

The following equipment cautions appear in the text and are repeated here for

emphasis.

CAUTION

Check the electrical code for proper ac hookup prior to operation of the unit.

Make sure the neutral or return hookup is only used for that purpose.

On page 3.

CAUTION

Do not block air flow. The air intake vents on the side of the heat exchanger and

the exhaust on top must not be obstructed.

On page 3.

CAUTION

Use only distilled water or ethylene glycol as coolant. Do not use tap water,

automotive antifreeze, sealants, or leak stopping material. Use of these

materials will damage the instrument and void all warranties.

On pages 4 and 12.

CAUTION

Operation without sufficient coolant will damage the unit.

On pages 4, 7 and 12.

CAUTION

Due to the complexity of the Bird Power Sensor, field repairs beyond general

maintenance should not be attempted. Removal or disturbance of the power

sensor cover can result in cancellation of lifetime warranty.

On pages 13 and 17.

CAUTION

The Bird 4421 must be powered off when connecting or disconnecting the power

sensor from the power meter.

On page 17.

CAUTION

Failure to install a properly rated fuse may result in damage to equipment or

nuisance failure.

On page 18.

iii

Page 6

Bird High Power Semiconductor Cal Cart

Safety Statements

USAGE

ANY USE OF THIS INSTRUMENT IN A MANNER NOT SPECIFIED BY THE

MANUFACTURER MAY IMPAIR THE INSTRUMENT’S SAFETY

PROTECTION.

USO

EL USO DE ESTE INSTRUMENTO DE MANERA NO ESPECIFICADA POR EL

FABRICANTE, PUEDE ANULAR LA PROTECCIÓN DE SEGURIDAD DEL

INSTRUMENTO.

BENUTZUNG

WIRD DAS GERÄT AUF ANDERE WEISE VERWENDET ALS VOM

HERSTELLER BESCHRIEBEN, KANN DIE GERÄTESICHERHEIT

BEEINTRÄCHTIGT WERDEN.

UTILISATION

TOUTE UTILISATION DE CET INSTRUMENT QUI N’EST PAS

EXPLICITEMENT PRÉVUE PAR LE FABRICANT PEUT ENDOMMAGER LE

DISPOSITIF DE PROTECTION DE L’INSTRUMENT.

IMPIEGO

QUALORA QUESTO STRUMENTO VENISSE UTILIZZATO IN MODO

DIVERSO DA COME SPECIFICATO DAL PRODUTTORE LA PROZIONE DI

SICUREZZA POTREBBE VENIRNE COMPROMESSA.

iv

Page 7

SERVICE

SERVICING INSTRUCTIONS ARE FOR USE BY SERVICE - TRAINED

PERSONNEL ONLY. TO AVOID DANGEROUS ELECTRIC SHOCK, DO NOT

PERFORM ANY SERVICING UNLESS QUALIFIED TO DO SO.

SERVICIO

LAS INSTRUCCIONES DE SERVICIO SON PARA USO EXCLUSIVO DEL

PERSONAL DE SERVICIO CAPACITADO. PARA EVITAR EL PELIGRO DE

DESCARGAS ELÉCTRICAS, NO REALICE NINGÚN SERVICIO A MENOS

QUE ESTÉ CAPACITADO PARA HACERIO.

WARTUNG

ANWEISUNGEN FÜR DIE WARTUNG DES GERÄTES GELTEN NUR FÜR

GESCHULTES FACHPERSONAL.

ZUR VERMEIDUNG GEFÄHRLICHE, ELEKTRISCHE SCHOCKS, SIND

WARTUNGSARBEITEN AUSSCHLIEßLICH VON QUALIFIZIERTEM

SERVICEPERSONAL DURCHZUFÜHREN.

ENTRENTIEN

L’EMPLOI DES INSTRUCTIONS D’ENTRETIEN DOIT ÊTRE RÉSERVÉ AU

PERSONNEL FORMÉ AUX OPÉRATIONS D’ENTRETIEN. POUR PRÉVENIR

UN CHOC ÉLECTRIQUE DANGEREUX, NE PAS EFFECTUER D’ENTRETIEN

SI L’ON N’A PAS ÉTÉ QUALIFIÉ POUR CE FAIRE.

ASSISTENZA TECNICA

LE ISTRUZIONI RELATIVE ALL’ASSISTENZA SONO PREVISTE

ESCLUSIVAMENTE PER IL PERSONALE OPPORTUNAMENTE ADDESTRATO.

PER EVITARE PERICOLOSE SCOSSE ELETTRICHE NON EFFETTUARRE

ALCUNA RIPARAZIONE A MENO CHE QUALIFICATI A FARLA.

v

Page 8

Bird High Power Semiconductor Cal Cart

UNITS ARE EQUIPPED WITH RECHAREABLE BATTERIES.

THESE ARE TO BE REPLACED BY AUTHORIZED SERVICE PERSONNEL

ONLY!!!

LAS UNIDADES VIENEN EQUIPADAS CON BATERIAS RECARGABLES.

¡¡¡Y SOLAMENTE EL PERSONAL DE SERVICIO AUTORIZADO PUEDE

REEMPLAZARLAS!!!

GERÄTE SIND MIT WIEDER AUFLADBAREN BATTERIEN BESTÜCKT.

BATTERIEN SIND NUR VON QUALIFIZIERTEM SERICE PERSONAL

AUSZUWECHSELN!!!

CES DISPOSITIFS SONT ÉQUIPÉS DE BATTERIES RECHARGEABLES.

SEUL LE PERSONNEL D’ENTRETIEN AUTORISÉ EST HABILITÉ À LES

REMPLACER !

LE UNITÀ SONO DOTATE DI BATTERIE RICARICABILI,

CHE DEVONO DA COME SPECIFICATO DAL PRODUTTORE LA

PROTEZIONE DI SICUREZZA POTREBBE VENIRNE COMPROMESSA.

vi

Page 9

USE CORRECT VOLTAGE SETTING AND FUSE - SEE MANUAL.

UTILISER UNE TENSION ET UN FUSIBLE CORRECTS - CONSULTER LE MODE

D'EMPLOI.

USE LA INSTALACION Y FUSIBLE DE VOLTAJE CORRECTO - VEA EL MANUAL.

AUSSCHLIESSLICH VORSCHRIFTSMÄSSIGE WECHSELSPANNUNGSEINSTELLUNG UND SICHERUNG BENUTZEN - SIEHE DAZU HANDBUCH.

UTILLIZZARE TENSIONE E FUSIBLE ADATTI - FARE RIFERIMENTO AL

MANUALE.

vii

Page 10

Bird High Power Semiconductor Cal Cart

BE SURE THE 115/230V AC VOLTAGE SELECTOR IS SET TO THE PROPER LINE

VOLTAGE, AND THE CORRECT AC LINE FUSE IS INSTALLED BEFORE AC

POWER IS APPLIED.

S'ASSURER QUE LE SÉLECTEUR DE TENSION 115/230V C.A. EST BIEN RÉGLÉ

POUR LA TENSION DU RÉSEAU ET QUE LE FUSIBLE DE LIGNE C.A. CORRECT

EST EN PLACE AVANT DE METTRE SOUS TENSION C.A.

CERCIORESE QUE EL SELECTOR DE VOLTAJE DE 115/230V CA ESTE

COLOCADO A LA LINEA DE VOLTAJE APROPIADA Y QUE EL FUSIBLE ESTE

INSTALADO A LA LINEA CA ANTES DE APLICAR LA CORRIENTE ALTERNA.

VOR EINSCHALTEN DER WECHSELSTROMZUFUHR SICHERSTELLEN, DASS

DER 115/230V WECHSELSPANNUNGS-SELEKTOR AUF DIE

VORSCHRIFTSMÄSSIGE LEITUNGSSPANNUNG EINGESTELLT UND DIE

RICHTIGE WECHSELSTROM-HAUPTSICHERUNG EINGESETZT IST.

PRIMA DI EROGARE CORRENTE, ASSICURARSI CHE IL SELETTORE DI

VOLTAGGIO 115/230 V.C.A. SIA REGOLATO CORRETTAMENTE E CHE IL

FUSIBLE ADATTO ALLA LINEA DI ALIMENTAZIONE C.A. SIA INSTALLATO.

viii

Page 11

About This Manual

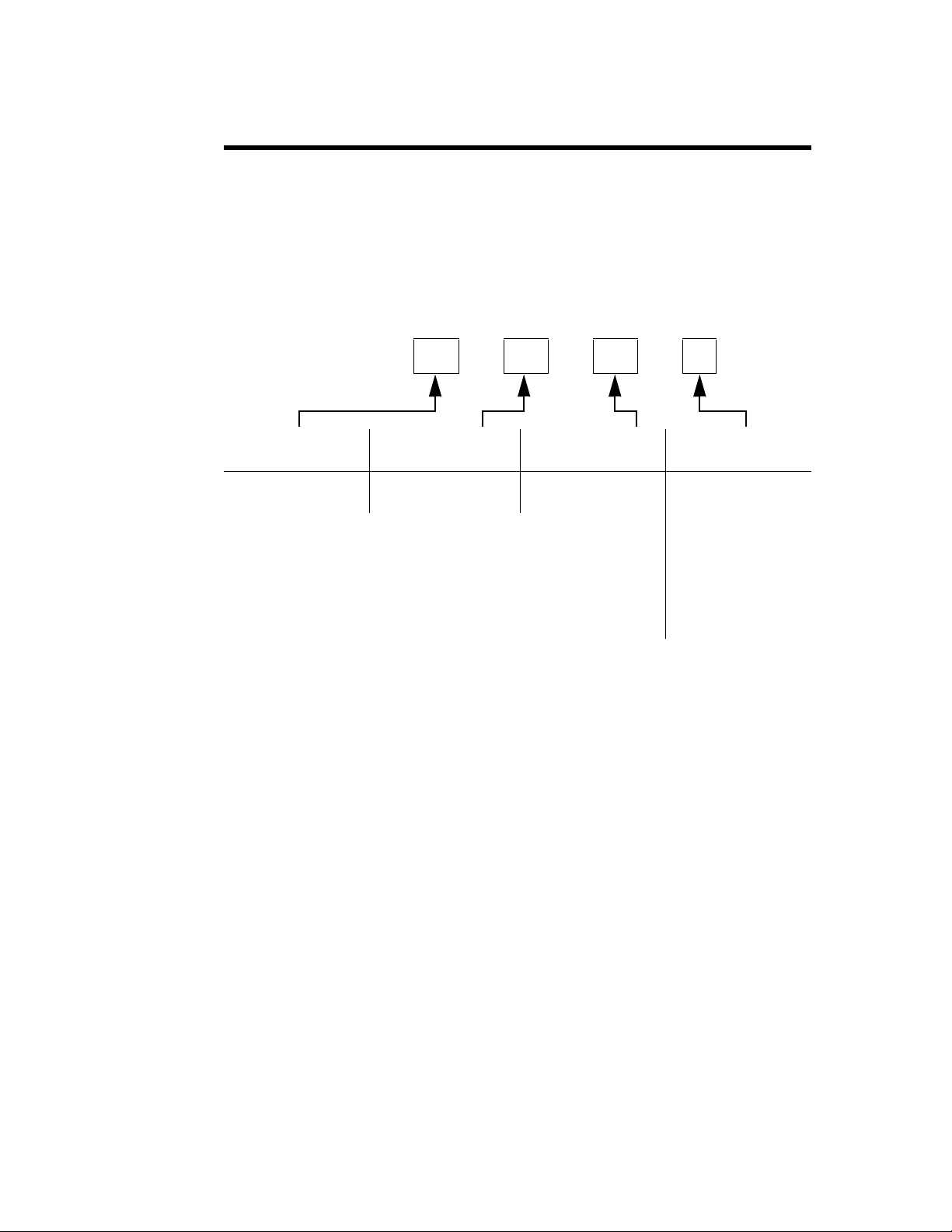

Numbering

This manual covers the operating and maintenance instructions for the following

models:

Cal Cart with 4421 meter, 4028B10M sensor,

8640 load, 1-5/8” flanged connector,

115Vac power supply and standard US plug

SCC81 01 01 01 1

Voltage and

Sensor Load RF Connector

01 4028B10M 01 8640 Series 01 1-5/8” EIA

Flanged

02 8640B Series 2 230V, 30A

Plug Style

1 115V, 15A

Nema 5-15P

Nema L6-30P

3 115V, 10A

International

4 230V, 10A

International

Changes to this Manual

We have made every effort to ensure this manual is accurate. If you discover any

errors, or if you have suggestions for improving this manual, please send your

comments to our Solon, Ohio factory. This manual may be periodically updated.

When inquiring about updates to this manual refer to the part number and revision on the title page.

Terminology

There are some unique terms used throughout this literature. They are defined

here clarify any misunderstanding.

Cal Cart - The entire unit.

Sensor - The power sensor

Meter- The power meter and display

Load - The entire load (water-cooled RF termination).

Resistor Assembly - The load component which connects directly to the RF line.

It is inside the HEAT EXCHANGER, connected by two hoses.

Heat Exchanger - The parts of the Moduload left when the LOAD is removed. It

contains the pump, fans, coolant reservoir, and controls.

Resistor - A subcomponent of the RESISTOR ASSEMBLY. This is the ceramic

resistor which actually absorbs the RF power.

ix

Page 12

Bird High Power Semiconductor Cal Cart

Chapter Layout

Introduction — Describes the features of the Cal Cart, lists equipment supplied

and optional equipment, and provides power-up instructions.

Setup — Describes the power supply and connection instructions.

Operating Instructions — Describes the base level operation instructions.

4421 Instructions — All instructions necessary to operate the 4421 Power Meter

in conjunction with the Bird Semiconductor Cal Cart.

Maintenance — Lists routine maintenance tasks as well as troubleshooting for

common problems. Specifications and parts information are also included.

x

Page 13

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Warning Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Caution Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Changes to this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Items Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

RF Power Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Power Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Chapter 1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Adding Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Connecting RF Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 3 4421 Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Audible Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

DC Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Changing the Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Flushing the Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power Meter and Sensor Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Functional Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Push Button Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Load Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Removing the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Replacing the Cord Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Replacing the Power Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Replacing Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Load Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

xi

Page 14

Replacing Resistor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Removing the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Resistor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Removing the Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Inspecting the Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replacing a Fractured Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Replacing the Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Replacing the Conductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Storage and Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Storing the Load Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Shipping the Load Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Max. Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Bird High Power Cal Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Bird 4421 RF Power Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Bird 4028B Series RF Power Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Bird 8640S Series Moduloads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Cal Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Resistor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

xii

Page 15

Chapter 1 Introduction

This instruction book is intended for use by operators of the Bird High Power

Cal Cart (HPCC). This chapter contains introductory information including

component descriptions and items supplied.

The HPCC is designed for immediate, effortless use. It has three primary components. The Bird 4421 RF Power Meter displays RF power measurements.

Bird 4028 Series Power Sensors are highly accurate sensors that measure RF

power without requiring calibration or external couplers or attenuators. Bird

Moduloads are low reflection 50 Ω terminations that can dissipate 25 kW.

These components are installed on a cart for easy transportation. The cart is

suitable for use in a cleanroom environment, and is equipped with four swivel

casters for maximum maneuverability. The only setup required is adding coolant and connecting AC and RF power.

Items Supplied

Stainless Steel Cart with the following items installed:

z Bird 4421 RF Power Meter

z Bird 4028 Series Sensor

z Bird 8640 or 8640B Series Moduload

z Cabling

z Instruction Manual

RF Power Meter

Power Sensor

Load

The Bird 4421 RF Power Meter measures forward and reflected RF power

when used with a Bird power sensor. Measurement units can be either Watts

or dBm. Because of the quality of the attached load, reflected power will be

negligible and can usually be ignored.

Note: The 4421 is equipped with rechargeable batteries. These are

shipped uncharged. Connect the unit to AC power the first time you use

it to charge the batteries.

Bird 4028 Series Power Sensors are designed for use in semiconductor processing and calibration applications. 4028 Sensors are accurate to ±2%(2σ) at

specified calibration frequencies and power levels. Sensors are controlled by

the Power Meter.

Bird Moduloads are self-cooling, nonradiating, low reflection terminations for

high power RF lines. They dissipate up to 25 kW with a VSWR of less than

1.1:1 from 1 kHz to 900 MHz.

1

Page 16

Introduction

40"

(1016 mm)

Drain

Plug

Coolant

Gauge

Coolant

Filler Cap

Power

Meter

22"

(559 mm)

39"

(991 mm)

ON/OFF

Switch

Front

Panel

Power Sensor

RF Connector

Handle

Coolant

Reservoir

Pump

Load

Resistor

RF

Input

Fan

To Other Heat

Exchanger Assemblies

Heat Exchanger

Heat Exchanger

Assembly

From Other Heat

Exchanger Assemblies

Features

Indicators

z Useable with CW, AM, FM, SSB, and TV modulation, and certain

pulse types.

Note: Contact Bird Electronic Corporation for information on

using Moduloads with pulsed signals.

z Self-contained water-based cooling system

z Coolant Level Gauge

Figure 1 Cal Cart Outline

2

Figure 2 Load Cooling System Block Diagram

Page 17

Chapter 2 Setup

This chapter provides information for on-site requirements, unpacking,

inspection, and preparing the Bird High Power Cal Cart for use.

Unpacking and Inspection

1. Carefully inspect shipping container for signs of damage.

2. Do one of the following:

z If the shipping container is damaged, do not unpack the unit. Immedi-

ately notify the shipping carrier and Bird Electronic Corporation.

z If the shipping container is not damaged, unpack the unit. Save ship-

ping materials for repackaging.

3. Inspect unit for visual signs of damage.

Note: If there is damage, immediately notify the shipping carrier

and Bird Electronic Corporation.

Setup

Setup consists of three basic steps: moving the unit into position, adding coolant, and connecting AC power and the RF line. These steps are explained in

more detail below.

WARNING

Do not attempt to lift the cart by the handle.

CAUTION

Check the electrical code for proper AC hookup prior to operation of the

unit. Make sure the neutral or return hookup is only used for that purpose.

CAUTION

Do not block air flow. The air intake vents on the side of the heat exchanger

and the exhaust on top must not be obstructed.

z Use the HPCC in a dry, dust-free and vibration-free environment.

Note: Do not use outdoors or in areas of condensing humidity.

z Allow a minimum of one foot clearance along the sides and three feet

over the top to allow unobstructed air intake and exhaust.

z Surrounding air must be free of contaminants or particles that could

be drawn into the air intakes.

z The AC power supply required is 115/230 V @ 50/60 Hz, 1φ.

Note: The unit is equipped with an unterminated, reractable

power cord. Connect a power plug to this cord, appropriate to local

power source.

3

Page 18

Setup

Coolant

WARNING

Ethylene glycol is toxic. Do not take internally.

Avoid contact with eyes, skin, and clothing. Avoid breathing vapor. Wash

thoroughly after handling.

CAUTION

Use only distilled water or a distilled water/ethylene glycol mixture (with a

maximum of 35% ethylene glycol) as coolant. Do not use tap water,

automotive antifreeze, sealants, or leak stopping material. Use of these

materials will damage the instrument and void all warranties.

Distilled water is the primary coolant for the unit. Ethylene glycol can be

added to prevent bacterial growth and freezing; 10% to 35% ethylene glycol is

recommended. Using at least 10% will prevent bacterial growth and at least

35% will prevent freezing to –20°C.

Note: When using both ethylene glycol and distilled water, add the

water first, then the ethylene glycol, to ensure proper mixing.

Adding Coolant

Figure 3 on page 5 shows the coolant’s freezing point for a given percentage of

ethylene glycol in the mix. The following example shows the weights to make a

65% distilled water to 35% ethylene glycol mixture in 5 and 55 gallon quantities.

5 Gal. (18.9 L) 55 Gal. (208.2 L)

Distilled Water 28.0 lb (12.7 kg) 310 lb (140.6 kg)

Ethylene Glycol 15.2 lb (6.9 kg) 167 lb (75.7 kg)

CAUTION

Operation without sufficient coolant will damage the unit.

1. Make sure that the drain plug is in place.

2. Remove the filler cap on the top and at the rear of the unit.

3. Add about 3 quarts (2.9 L) of coolant.

4. Turn the unit on for a few seconds to draw coolant into the system.

5. Repeat steps 3 and 4 twice more, until the coolant remains steady at or

just below the high mark on the level gauge.

6. Replace the filler cap.

7. Turn the unit on

8. Run the unit for five minutes to remove any air trapped in the system.

4

Page 19

Figure 3 Freezing Point of Ethylene Glycol / Distilled Water Mixture

-60

-50

-40

-30

-20

-10

0

Temperature, Degrees Celsius

10 20 30 40 50 60

% Ethylene Glycol

Specifications for ethylene glycol

having: specific gravity 1.125 @

32°F; specific heat .575 @ 68°F

-80

-60

-40

-20

0

20

40

Temperature, Degrees Fahrenheit

10 20 30 40 50 60

% Ethylene Glycol

Specifications for ethylene glycol

having: specific gravity 1.125 @

32°F; specific heat .575 @ 68°F

Setup

5

Page 20

Setup

BOLT BULLET LOADRF COAXIAL LINE

Connecting RF Power

After installing the Bird High Power Cal Cart, the RF transmission line can

be attached using standard coaxial line coupling kits.

To couple the swivel flange with a flanged RF transmission line refer to

Figure 4 while following the instructions below:

Figure 4 Swivel Flanged Coupling

WARNING

Never attempt to connect or disconnect RF equipment from the

transmission line while RF power is being applied.

Leaking RF energy is a potential health hazard.

1. Insert the center bullet and push it in until it is fully seated.

2. Connect the coaxial input in a straight line and push carefully on the center conductor to close.

Note: The swivel flange on the load makes connection independent

of the orientation of the fixed flange on the coaxial input outer conductor.

3. Insert the bolt sets and tighten evenly all around to transmission line

manufacturer’s recommended torque. Use all of the bolts.

6

Page 21

Chapter 3 Operating Instructions

WARNING

Never attempt to connect or disconnect RF equipment from the

transmission line while RF power is being applied.

Leaking RF energy is a potential health hazard.

CAUTION

Operation without sufficient coolant will damage the unit.

Normal Operation

Note: After setting up the Bird High Power Cal Cart:

1. Check that the coolant level is above the minimum mark on the rear coolant gauge.

2. Connect the unit to the AC line.

3. Check that the fans are running properly.

4. Turn on the Bird 4421 power meter.

5. Wait about 10 seconds for proper coolant flow.

6. Apply RF power.

7. Make measurements.

Note: See "Operating Instructions" on page 7 for specific instruc-

tions on controlling the meter.

Shutdown

1. Turn off RF power at the source.

2. Turn off the 4421 power the meter off.

3. Wait approximately 5 minutes for the load to cool to room temperature to

prevent heat stress.

4. Disconnect the AC line.

7

Page 22

Operating Instructions

8

Page 23

Chapter 4 4421 Instructions

LIST EN TALK L OCAL LO CKOUT

FWD

AUTO

LO BAT

REMOTE

MODEL 4421 RF POWER METER

AUTO

RANGE

UP

DOWN

SWRRFLFWD MIN MAX dBm LIGHT ON / OFF

MW nW

KW µW

W mW

dBm

FWD

RFL

SWR

Push Button Functions

Figure 5 Push Buttons

Push Button Description

FWD, RFL

SWR

Press to measure forward (reflected) RF power. FWD (RFL)

indicator and current unit of measure turn on.

Press to measure standing wave ratio. SWR indicator turns on.

Value displayed will be between 1.0 and 199.9

Used after pressing FWD, RFL, SWR, or dBm. Displays the

MIN, MAX

minimum (maximum) measured value of the previous function as

long as MIN (MAX) is held down.

Used after pressing FWD or RFL. dBm indicator turns on. Power is

dBm

displayed in dBm units.

Used after pressing SWR. Return loss is displayed.

LIGHT

Press to turn on or turn off the display’s backlight. If left on, the light

automatically shuts off after 30 minutes.

AUTO Press to automatically set the scale. AUTO turns on.

Press to select the next higher (lower) scale. If the scale is too high

UP, DOWN

for the power sensor, an error will be displayed.

Used while AUTO indicator is on. Stops automatic scaling. AUTO

indicator turns off.

ON/OFF Press to turn the power meter on or off.

9

Page 24

4421 Instructions

Error Codes

The Bird 4421 displays error codes when the RF power is either below the

selected range (underrange) or above the selected range (overrange). Figure 6

displays the error codes and Figure 7 lists the function limits.

Figure 6 Error Codes

Symbol Explanation

Value greater than overrange limit of function

Value less than underrange limit of function

Figure 7 Function Limits

Function Limit Error

Audible Warning

FWD, RFL

FWD dBm, RFL dBm

SWR

Return Loss

Power > 199.9% of full scale or 120 % of top

range

Power > 120% of full scale

Power < 3% of low range

FWD < 20% of low range

FWD – RFL = 0

FWD < 20% of low range

RFL < 20% of low range

Return Loss > 40 dB

Overrange

Overrange

Underrange

Underrange

Overrange

Underrange

Underrange

Underrange

If the RF power level exceeds 120% of the sensor’s power range, the meter will

sound a warning buzzer.

10

Page 25

Chapter 5 Maintenance

This chapter describes routine maintenance, along with troubleshooting

instructions for the power meter and power sensor. Disassembly instructions

for the Bird High Power Cal Cart are also provided. For service beyond this

level, return the unit to a qualified service center.

WARNING

To avoid personal injury, disconnect the power cord from the AC line before

performing any maintenance, including fuse replacement.

WARNING

Never attempt to connect or disconnect RF equipment from the

transmission line while RF power is being applied.

Leaking RF energy is a potential health hazard.

WARNING

The Bird 4421 contains no user-serviceable parts.

Do not remove its cover.

This manual cannot list all malfunctions that may occur, or corrective actions.

If a malfunction is not listed or is not corrected by the listed corrective actions,

contact a qualified service center.

Routine Maintenance

Inspection

The HPCC requires only simple, routine maintenance.

z Wipe off dust and dirt regularly.

z Check the connectors and cables for damage.

z Clean the connector contacts with alcohol or dry cleaning solvent.

z If dust has collected on the radiator coils, remove the screws around

the edge of the top panel, remove the panel, and vacuum the coils.

z The coolant level should be checked once a week, more often if the Cal

Cart is used continuously or in high ambient temperatures.

Note: The coolant level should be above the minimum mark on the

gauge even when the unit is on. To add coolant, See “Changing the

Coolant” on page 13.

11

Page 26

Maintenance

DC Resistance

Measuring the DC resistance between the inner and outer conductors of the

RF connector shows changes in the load over time, a good check of the resistor’s condition. Under normal operating conditions, the resistor should provide

at least 5,000 hours of operation before requiring any additional service. DC

resistance tracking must start before the load is put into service, and should

be measured annually.

Perform the following steps and record the value for future comparison. Make

sure that you have an ohmmeter with an accuracy of ±1% at 50 ohms and that

the load temperature is between 20 and 25 °C (68 to 77 °F) before starting.

Figure 8 Measuring Resistance

WARNING

Never attempt to connect or disconnect RF equipment from the

transmission line while RF power is being applied.

Leaking RF energy is a potential health hazard.

1. Turn off the RF power.

2. Disconnect the RF cables from the RF connectors on the load.

3. Check the load’s center and outer conductors for visible damage or excessive wear.

4. Connect the multimeter test leads to the center and outer conductors.

Refer to Figure 8.

5. Compare the measured value with the previous measurement and with

the baseline resistance, measured when the load was put into service.

Note: If the new value differs from either of these by more than 2

ohms this could indicate a failing resistor.

WARNING

Ethylene glycol is toxic. Do not take internally. Avoid contact with eyes, skin,

and clothing. Avoid breathing vapor. Wash thoroughly after handling.

CAUTION

Use only distilled water or the supplied mixture of distilled water and

ethylene glycol (with a maximum of 35% ethylene glycol) as coolant. Do not

use tap water, automotive antifreeze, sealants, or leak stopping material.

Use of these materials will damage the instrument and void all warranties.

12

CAUTION

Operation without sufficient coolant can damage the unit.

Page 27

Changing the Coolant

Maintenance

Note: To just add coolant, go to step 5. To just drain the coolant,

follow steps 1 – 4.

1. Get a clean container, with a capacity of 3 gal. (11 L), to hold the old coolant.

2. Remove the filler cap on the top and at the rear of the unit.

Note: This will allow the coolant to drain faster.

3. Unscrew and remove the drain plug at the bottom rear.

4. Drain the coolant into the container.

Note: If the coolant has no contaminants it may be reused.

5. Replace the drain plug and screw it tightly into place.

6. Add about 3 quarts (2.9 L) of coolant.

7. Turn the unit on for a few seconds to draw coolant into the system.

8. Repeat steps 6 and 7 twice more, until the coolant remains steady at or

just below the high mark on the level gauge.

9. Replace the filler cap.

10. Turn the unit on and run it for five minutes to remove any air trapped in

the system.

Flushing the Coolant

Note: If the coolant is contaminated, for example by pipe sealant

or a broken resistor, the system should be thoroughly flushed.

1. Fill the unit with clean, potable water.

2. Run the unit for five minutes with no RF power applied.

3. Drain the coolant and discard it.

4. Repeat steps 1 – 3 until the drained liquid is clear.

5. Refill the system with proper coolant (distilled water or a distilled water/

ethylene glycol mixture) as described above.

Power Meter and Sensor Troubleshooting

Since the power meter and power sensor can only work together, the first step

is to determine which is malfunctioning. Connect the power sensor to the

meter and perform the functional test on page 14. If the power meter is malfunctioning, refer to the troubleshooting table below. If the power sensor is

malfunctioning, return it for service.

Due to the complexity of the Bird Power Sensor, field repairs beyond

general maintenance should not be attempted. Removal or disturbance of

the power sensor cover can result in cancellation of lifetime warranty.

CAUTION

13

Page 28

Maintenance

Meter’s

Model

Number

Meter’s

Software

Rev. Date

Sensor’s

Model

Number

Sensor’s

Software

Rev. Date

–..4421..–07.01.02–..4021..–07.01.02–

PROBLEM POSSIBLE CAUSE CORRECTION

Power meter has no

power

Dash moves across

the display

Display blank or not

updating

Power meter turns off

while on battery power

Push buttons do not

respond

Every segment on the

display is lit

Have the batteries been

Recharge the batteries.

charged?

Is the power meter’s AC power

Connect the power cord.

cord connected to the terminal

strip?

Is the Cal Cart’s AC power cord

Connect AC power.

connected to the AC line?

Is the ON/OFF rocker switch on

Set the switch to ON.

the rear panel set to OFF?

Unplug the Cal Cart. Has the

power meter fuse blown?

Replace fuse (See “Replacing

Fuses” on page 18).

Is the AC power cord defective? Replace AC power cord.

Is the sensor cable connected

Connect sensor cable.

to both the power meter and

power sensor?

Is the sensor cable defective? Replace sensor cable.

Have the batteries been

charged?

NO: Recharge battery

YES: Return meter for service.

Is “LO BAT” displayed? YES: Recharge battery

NO: Return meter for service.

Test the push buttons (See

Return meter for service.

“Push Button Test” on page 15).

Are they defective?

Return meter for service.

Functional Test

1. Disconnect the AC power cable and turn the power meter off.

Note: The On/Off switch on the rear panel of the meter should be On.

2. Connect the AC power cable.

3. Press the On/Off button on the front panel of the power meter whileholding down the FWD and SWR push buttons, .

4. Immediately release all three.

5. Ensure that both of following happen:

z The power meter’s model number and revision date should scroll

across the display.

Note: If a dash “–” is displayed instead, then the meter is malfunc-

tioning.

z The power sensor’s model number and revision date should scroll

across the display.

Note: If a dash “–” is displayed after the power meter data, then

the power sensor is malfunctioning.

Figure 9 Test Display, No Malfunction

14

Page 29

Push Button Test

Maintenance

Note: This test checks that the push buttons and display are function-

ing properly. If a push button is malfunctioning, return the power meter.

1. Disconnect the power sensor.

2. Turn the power meter On.

Note: After the power up display disappears, three dashes “– – –”

should scroll across the display.

3. “AUTO” and “FWD” should be displayed, and a reading of “.000 W”.

4. Press RFL. “FWD” should change to “RFL” on the display.

Note: The reading should remain the same.

5. Press SWR.

Note: “RFL” should change to “SWR”. “.000 W” should change to

“ ” (underrange error).

6. Hold down MIN.

Note: “ ” should change to “ ” (overrange error).

7. Release MIN.

Note: “ ” should change to “ ”.

8. Hold down MAX.

Note: “ ” should change to “.000”.

9. Release MAX.

Note: “.000” should change to “ ”.

10. Press dBm.

Note: “SWR” should change to “dBm”.

11. Press dBm.

Note: “dBm” should change to “SWR”.

12. Press FWD.

Note: “SWR” should change to “FWD”. “ ” should change

to “.000 W”.

13. Press LIGHT.

Note: The back-light should turn on.

14. Press LIGHT.

Note: The back-light should turn off.

15. Press s (up).

Note: The power meter should change ranges each time it is

pressed until it reaches “.000 KW”.

16. Press t (down).

Note: The power meter should change ranges each time it is

pressed until it reaches “.000 W”.

17. Turn the power meter OFF.

15

Page 30

Maintenance

40"

(1016 mm)

Drain

Plug

Coolant

Gauge

Coolant

Filler Cap

Power

Meter

22"

(559 mm)

39"

(991 mm)

ON/OFF

Switch

Front

Panel

Power Sensor

RF Connector

Handle

Load Troubleshooting

PROBLEM POSSIBLE CAUSE CORRECTION

Repair

Blower not

operating

Is the load’s AC power cord

connected to the terminal strip?

Is the Cal Cart’s AC power cord

Connect the power cord.

Connect AC power.

connected to the AC line?

Unit turned off. Set the line switch to ON.

Fuse burnout. Replace fuse (See "Replacing

Fuses" on page 18).

Coolant leaking Loose connections. Tighten drain plug and all

connections.

Worn or cracked tubing. Replace defective tubing.

Excessive

reflected power

Resistor’s DC resistance has

changed.

Check DC resistance. See "DC

Resistance" on page 12).

Figure 10 Cal Cart Outline

16

WARNING

To avoid personal injury, disconnect the power cord from the AC line before

performing any maintenance, including fuse replacement.

WARNING

Never attempt to connect or disconnect RF equipment from the

transmission line while RF power is being applied.

Leaking RF energy is a potential health hazard.

Page 31

Removing the Front Panel

1. Remove the screws on the front panel.

2. Pull on the handle set into the base of the front panel to remove it.

3. When making AC connections, refer to the wiring diagram below.

Figure 11 Cal Cart Wiring Schematic

Replacing the Cord Reel

Maintenance

Note: To access the power sensor or the AC connections, it will be

necessary to remove the cart’s front panel.

1. Disconnect the cord reel from the terminal strip.

2. Unscrew the AC connector.

3. Unscrew and remove the cord reel.

4. Screw the replacement cord reel into place.

5. Replace the ring terminal and quick disconnects on the cord reel.

6. Thread the AC connector through the grommet, and connect the wires on

the other end to the terminal strip (See Figure 11).

Replacing the Power Sensor

To avoid personal injury, disconnect the power cord from the AC line before

The Bird 4421 must be powered off when connecting or disconnecting the

WARNING

performing any maintenance, including fuse replacement.

WARNING

Never attempt to connect or disconnect RF equipment from the

transmission line while RF power is being applied.

Leaking RF energy is a potential health hazard.

CAUTION

power sensor from the power meter.

CAUTION

Due to the complexity of the Bird Power Sensor, field repairs beyond

general maintenance should not be attempted.

Removal or disturbance of the power sensor cover can result in cancellation

of lifetime warranty.

17

Page 32

Maintenance

Fuse 1

Fuse 2

Fuse

Drawer

AC Module

Replacing Fuses

1. Disconnect the RF line from the HPCC.

2. Remove the unit’s front panel (see "Removing the Front Panel" on

page 17).

3. Disconnect the sensor cable from the power sensor.

4. Disconnect the RF cable from the sensor output port.

5. Remove the screws on the sensor mounting bracket and remove the sensor

from the mounting bracket.

6. Put the new sensor in the bracket and screw it into place.

Note: Make sure the arrow on the side of the sensor points towards

the load, and that the end labeled “SOURCE” points towards the front

of the Cal Cart.

7. Connect the RF cable to the sensor end labeled “LOAD”.

8. Connect the sensor cable.

9. Replace the unit’s front panel.

WARNING

To avoid personal injury, disconnect the power cord from the AC line before

performing any maintenance, including fuse replacement.

CAUTION

Failure to install the properly rated fuse may result in equipment damage

or nuisance failures.

1. Gently pry the fuse drawer out of the AC module.

Note: The fuse holder does not detach from the AC module.

2. Install the replacement fuses then close and secure the fuse holder.

Fuse 1 is a spare fuse and fuse 2 is the active fuse.

AC Line Voltage Fuse Rating

115 Vac T630 mA, 5x20 mm Time Lag Fuse

230 Vac T315 mA, 5x20 mm Time Lag Fuse

Figure 12 AC Line Fuse

18

Page 33

Replacing Batteries

X4

X4

Maintenance

WARNING

Exposed AC line voltage (115 VAC or 230 VAC). Disconnect the power cord

from the AC line before replacing the batteries. Failure to comply may

result in severe electrical shock or death.

1. Disconnect the AC power cord from the AC mains supply.

2. Remove the four screws that secure the top cover.

3. Lift the top cover to access the attached ground wire then disconnect the

ground wire and remove the cover.

4. Unfasten the battery retaining belts then remove the battery tubes (Figure 13).

Note: Be sure to note the polarity and orientation of the battery

tubes before removing them.

5. Remove the batteries from each tube and insert replacement batteries.

Note: Be sure to note the polarity (positive and negative) arrange-

ment of the batteries.

6. Install the battery tubes into the unit and secure with the retaining belts.

Note: Be sure to position the retaining belts as they were before

removal and tighten them securely.

7. Connect the ground wire to the top cover.

8. Install the top cover.

9. Secure the top cover with the four screws removed earlier.

Figure 13 Batteries

Item Description

1 Battery retaining belt

2 Battery tube (batteries inside)

19

Page 34

Maintenance

Load Servicing

Replacing Resistor Assembly

To avoid personal injury, disconnect the power cord from the AC line before

1. Disconnect the RF line from the Cal Cart

2. Disconnect the Sensor from the Load.

3. Remove the Cal Cart front panel (see "Removing the Front Panel" on page 17).

4. Disconnect the load’s AC line from the terminal strip.

5. Drain the coolant (See “Changing the Coolant” on page 13).

6. Remove the screws around the edge of the top panel

7. Raise the top panel only high enough to gain access to the fan supply plug.

8. Disconnect the fan-supply plug on top of the radiator block by pressing the

latch in the center of the plug while pulling away from the mating connector.

9. Unscrew the hose clamps on both water connections to the resistor assembly.

10. Remove the nuts, on the inside of the front panel, holding the assembly to

the front panel.

11. Unscrew the mounting clamp holding the resistor assembly to the rest of

the unit.

12. Remove the top half of the clamp.

13. Carefully push the assembly forward a few inches to access the wires and

water connection fittings.

14. Note the position and direction of the output elbow then unscrew it from

the load.

15. The resistor assembly can now be removed.

WARNING

performing any maintenance, including fuse replacement.

WARNING

Never attempt to connect or disconnect RF equipment from the

transmission line while RF power is being applied.

Leaking RF energy is a potential health hazard.

Note: Remove the nuts only. Do not disturb the screws. The screws

also secure the outer conductor assembly to the resistor. Hold this

assembly to keep it from falling and being damaged.

20

Page 35

Removing the Pump

Maintenance

WARNING

To avoid personal injury, disconnect the power cord from the AC line before

performing any maintenance, including fuse replacement.

1. Drain the coolant (See “Changing the Coolant” on page 13).

2. Remove the load (See “Replacing Resistor Assembly” on page 20).

3. Disconnect the pump wire leads from the terminal block on the inside of

the front panel.

4. Loosen the hose clamps on the input and output hoses to the pump, and

remove the hoses.

5. Unscrew the hex nut on the drain tube at the base of the pump. Remove

the drain tube.

6. Unscrew the bolts securing the base of the pump to the unit.

7. Remove the pump, carefully, from the unit.

8. Note the position and direction of the fittings, then twist them off counterclockwise.

9. To replace the pump, reverse the above steps.

Note: When replacing the threaded fittings, carefully coat the

external threads, ONLY, with a pipe sealing compound. Coating only

the external threads reduces the chances of contaminating the coolant.

21

Page 36

Maintenance

Resistor

Outer Flow Tube

1

9A

Resistor Sleeve

7

Load Housing

O-Ring

8

Inner Flow Tube

9

Ground Cap Assembly

10

Hose Fitting 90°

5

Hose Fitting 90°

5

Inner O-Ring

17

Outer O-Ring

2

Water Chamber With

O-Ring Inner Seal

3

and

4

1/4-20 x 2-1/2

Socket Head Cap Screw (6)

6

Load Housing

Resistor

Center Conductor

Assembly

1/4-20 x 1-1/2

Socket Head Cap Screw (6)

Outer Conductor

Assembly

Resistor Fitting Seal O-Ring

12

16

11

1

15

Resistor Assembly

The load is designed to be quickly and easily repaired in the field. If a significant change in the DC resistance is noted or if the resistor should fail, inexpensive replacement resistors are available.

WARNING

To avoid personal injury, disconnect the power cord from the AC line before

performing any maintenance, including fuse replacement.

Figure 14 Load Exploded View

Removing the Resistor

22

Note: Numbers in brackets [ ] refer to the labeled parts in Figure 14.

1. Remove the resistor assembly. (see "Replacing Resistor Assembly" on

page 20).

2. Turn the assembly on end with the hose fitting up.

Note: Use a

approximately

3. Pull the water chamber assembly out.

Note: It may be necessary to rock the chamber gently while pulling.

3

⁄16 hex socket wrench to tighten the cap screws [6]

1

⁄2 inch-lbs.

Page 37

Inspecting the Resistor

Maintenance

4. Remove the following parts and set them aside for reassembly:

z Inner flow tube [9]

z Resistor sleeve [7]

z Cushioning O-ring [8]

5. Remove the ground cap assembly by gently prying it upward using the flat

blade of a screw driver and working around the circumference of the part

until is is free.

Note: The ground cap assembly [10] should now be exposed on the

resistor at the end of the load housing.

6. Pull the resistor [1] straight out using a gentle rocking motion.

Note: Do this only if the resistor [1] is intact.

Note: The resistor sleeve [7] has a small escape hole at the side and

an access counter bore leading to it. If the sleeve is removed, be sure

this counterbore faces the O-Ring and the resistor [1] during reassembly. This is essential for internal water venting. The base of the inner

flow tube has water outlet holes and a small shoulder. At reassembly,

these must fit into mating recesses in the input fitting.

1. Carefully check the resistor [1] for fractures.

2. Check the inside of the housing for damage to the internal parts.

3. Do one of the following:

z If the resistor is broken, other internal parts are damaged, or if the

z If no damage has been found, proceed to "Replacing the Resistor" on

Replacing a Fractured Resistor

1. Turn the assembly on end with the RF input connector up to allow any

loose pieces of the resistor to fall out of the housing.

2. Use a

3. Remove the outer conductor assembly [12].

4. Pull out the center conductor assembly [11].

5. Remove, carefully, any remaining pieces of the resistor.

6. Check the inside of the housing for damage.

7. Remove the inner flow tube [9] and ground cap assembly [10].

8. Check inner flow tube and ground cap assembly for broken pieces.

9. Wash, thoroughly, the inside of the conductor assemblies, housing and

water chamber under clear running water.

10. Replace the ground cap assembly and the inner flow tube.

Note: Even in the event of failure the resistor substrate will usu-

ally remain intact.

parts do not fit together properly, proceed to "Replacing a Fractured

Resistor" on page 23.

page 24.

3

⁄16 hex socket wrench to remove the cap screws [16].

Note: Normally the outer flow tube will remain with the housing.

If it comes out, return it after inspection and cleaning.

23

Page 38

Maintenance

Replacing the Resistor

1. Insert the new resistor [1] into the resistor fitting of the center conductor

assembly [15] to test its tightness.

Note: The resistor should be snug but should not have to be forced

into the fitting. If the resistor is too loose:

a. Press the fitting fingers together slightly

b. Insert the resistor again.

c. Continue closing the ends of the resistor fitting until a snug fit

is obtained.

2. Bottom the resistor in the fitting.

3. Insert the resistor and center conductor assembly into the housing.

4. Replace the outer conductor assembly [12] and screw it into place.

5. Stand the load on its end with the RF connector down.

6. Replace the ground cap assembly onto the exposed end of the resistor.

Note: Make sue that it seats on the load housing.

7. Do one of the following:

z If the inner flow tube [9] is separated from the water chamber assembly [3]:

a. Place it inside the resistor

b. Lower until it reaches the resistor fitting.

c. Twist, gently, the flow tube until it seats in the bottom of the resis-

tor fitting.

z If the inner flow tube [9] is not separated from the water chamber

assembly [3], procedd to Step 4.

4. Check that the O-Ring [8] is on the inner flow tube next to the resistor and

the resistor sleeve [7] is right behind it.

Note: Make sure the counterbore faces the O-Ring and the resistor.

5. Replace the water chamber [3], gently rocking and twisting the chamber

to achieve a flat seat on the outer housing.

Note: If the water chamber does not fit properly make sure that the

inner flow tube is properly placed.

6. Tighten the water chamber screws [6].

7. Check the DC resistance between the inner and outer conductors; it

should be about 50 ohms.

Note: Record this measurement as the new baseline reading.

8. Install the resistor assembly on the heat exchanger.

9. Connect the hoses and fill with coolant.

10. Run the pump for five minutes and check for leaks before applying RF

power.

24

Page 39

Replacing the Conductor

1. Remove the cap screws [16] from the RF connector, using a

2. Remove the outer conductor assembly [12].

3. Remove the center conductor assembly [11] by pulling it carefully out of

4. Insert the new center conductor assembly into load housing.

5. Replace the outer conductor and screw it into place.

Storage and Shipment

Storing the Load Resistor

1. Cover Bird HPCC Loads before storing to keep out dust and dirt.

2. It is not necessary to install the shipping plug.

3. Store in a dry, dust-free environment where the ambient temperature will

Maintenance

3

⁄16 allen wrench.

Note: If only the outer conductor needs replaced, install it now and

screw it into place.

the load housing.

Note: Make sure the resistor [1] and inner flow tube [9] do not

come out with the center conductor.

Note: Make sure the resistor fitting makes a snug fit with the resistor.

remain between –40 and +45 °C (–40 to +113 °F).

Shipping the Load Resistor

1. Remove the vent plug.

2. Install the shipping plug.

3. Wrap the vent plug with padding and tape it to the side of the load for pro-

4. Wrap the connector in padding.

5. Pack and brace the load in a sturdy wooden crate for shipment.

tection.

Note: With the shipping plug installed, it is not necessary to empty

out the coolant.

25

Page 40

Maintenance

Customer Service

Any maintenance or service procedure beyond the scope of those in this chapter should be referred to a qualified service center.

If you need to return the unit for any reason, request an RMA through the

Bird Technologies website (link shown below). All instruments returned must

be shipped prepaid and to the attention of the RMA number.

Bird Service Center

30303 Aurora Road

Cleveland (Solon), Ohio 44139-2794

Fax: (440) 248-5426

E-mail: bsc@bird-technologies.com

For the location of the Sales Office nearest you, visit our website at:

http://www.bird-technologies.com

26

Page 41

Specifications

Max. Power

Maintenance

To determine the model numbers of the Cal Cart components, see “Numbering”

on page ix.

Note: Certain sensors or connectors may be incompatible with some

models. See “Numbering” on page ix for a list of available components,

or contact Customer Service.

The Cal Cart’s maximum power is the MINIMUM of the max. power of the

sensor and the max. power of the load, under normal conditions.

Bird High Power Cal Cart

Frequency Range Sensor dependent

Power Range Dependent on sensor, sensor connectors, and load

Connectors 1-5/8” Flanged

Dimensions 40”L x 22”W x 39”H (1005 x 550 x 991 mm)

Weight, Nominal 240 lbs. (109 kg)

Tempe rature Load coolant dependent

Calibration Cycle 1 year

Bird 4421 RF Power Meter

VSWR Display 1.0 – 199.9 max

Return Loss Display 0 to 40 dB max

Display Accuracy ± 1 on least significant digit

AC Power 115/230 Vac @ 50/ 60 Hz

Batteries 8 Nickel Metal Hydride rechargeable 1.2 volt cells

Battery Life Approximately 8 hours continuous usage

Battery Charger Built-in battery charger. Drained batteries require

approximately 28 hours to recharge.

Display LCD, 4½ digit display. Indicates mode, measurement units,

battery condition, remote status, and signal increase /

decrease. Self contained backlight.

Fuse Rating

115 Vac

230 Vac

Dimensions, Nominal 15.5”L x 12.25”W x 4.25”H (393 x 311 x 108 mm)

Weight, Nominal 9.5 lbs. (4.3 kg)

IEC (5 x 20 mm) Time Lag Type T

T630 ma

T315 ma

27

Page 42

Maintenance

RFL Accuracy FWD Accuracy

FWD Power

10

Directivity 10/

---------------------------------+=

VSWR 1

P

R

P

F

------+

⎝⎠

⎜⎟

⎛⎞

1

P

R

P

F

------–

⎝⎠

⎜⎟

⎛⎞

⁄=

Bird 4028B Series RF Power Sensors

Frequency Range

4028B10M 10 – 15 MHz

RF Power Range 1 kW – 25 kW

Accuracy, Fwd, Best Case

*

Accuracy, Reflected Calculated from FWD accuracy and FWD power

Accuracy, VSWR Calculated from FWD and RFL power

± 2.0% (2σ)

Calibration Frequencies,

Typical (MHz)

4028B10M

†

10.0, 13.56, 15.0

Calibration Power, Typical 3.5 kW

VSWR, Max. 1.05:1

Insertion Loss, Max. 0.05 dB

Directivity, Min. 28 dB

Impedance, Nominal 50 ohms

VSWR Range 1.00 to 2.00 (40.0 to 9.5 dB Return Loss)

Max. Allowable Terminating

2.00:1

VSWR

Calibration Technique Calibration vs. frequency curve stored in nonvolatile

memory in each sensor. Sensor output corrected at

frequency of measurement within rated range.

Sampling Rate, Nominal 2 readings / second

Operating Power Supplied by power meter via sensor cable

Dimensions, Nominal 6.75”L x 3.5”W x 4.75”H (175 x 89 x 121 mm)

Weight, Nominal 5 lb. 2 oz. (2.33 kg)

* For rated accuracy, no more than 1% AM; Harmonics –50 dBc or less

Derate accuracy by 2% (2σ) outside cal. power or cal. frequency

Derate accuracy by 2% (2

σ) below 15 °C and above 35 °C

† Other calibration frequencies available upon request

28

Page 43

Maintenance

Bird 8640S Series Moduloads

Frequency Range 1 kHz – 900 MHz

Power Rating 25 kW continuous duty

Mode CW, AM, FM, SSB, TV and certain pulse types

Impedance, Nominal 50 ohms

VSWR, Max 1.10:1

Cooling Method Water dielectric and forced air convection

Coolant

Coolant Capacity 9 qts. (8.5 L) nominal

AC Power 115/230 Vac @ 50/ 60 Hz

Fuse Rating

Operating Temperature

*

115 Vac

230 Vac

Water only

35% Ethylene Glycol

Distilled water or distilled water/ethylene glycol

mixture

15 A (3AB time delay)

8 A (5x20 mm time delay)

†

†

5 to 45

0 to 35

°C (41 to 113 °F)

†

°C (32 to 95 °F)

Replacement Parts

Cal Cart

Storage Temperature

Water only

35% E.G.

* Below 5°C, ONLY use 35% E.G. and 65% Dist. H2O mixture

† Above 30°C (86 °F) with water only, or 25°C (77 °F) with a 35% ethylene gly-

col mixture, derate power to 20 kW max.

+5 to +50 °C (41 to 122 °F)

–20 to +50 °C (–4 to +122 °F)

Description Qty Part Number

Power Meter Fuse,

IEC (5 x 20 mm) Type T

115 Vac, T630 mA

230 Vac, T315 mA

Cord, AC Power, Power Meter

115 Va c

230 Vac Harmonized

Plug, 115 Vac 1 5A2626

Cable, Sensor 1 4421-038

Grommet 1 SA2617-20

Cordreel 1 4421A383-2

Handle 1 4421A385

1

5A2257-14

5A2257-11

1

5-1286

5A2416

29

Page 44

Maintenance

Resistor Assembly

Exploded views are used to illustrate the parts below and indicate their relation to each other. Each part in the exploded view has an item number referencing this list.

Item No. Description Qty Part Number

1 Resistor 1 8755-027

2 Outer O-Ring 1 8410-009

3 Water Chamber 1 8755-014

4 Water Chamber Inner O-Ring 1 5-099

5 Fitting, 90° 2 8640-089

6 Screw

1

⁄

-20 x 2-

4

7 Resistor Sleeve 1 8755-026

8 Sleeve O-Ring 1 8110-059

9 Inner Flow Tube 1 8755-025

1

⁄

” 6 1121-2508-00

2

Heat Exchanger

9A Outer Flow Tube 1 8755-024

10 Resistor Ground Cap 1 8755-005

15 Center Conductor O-Ring 1 5-1127

16 Screw

1

⁄

4

-20 x 1

1

⁄

” 6 1121-1808-00

2

17 Inner O-Ring 1 5-567

Description Qty Part Number

Cord, AC Power

115 Vac

230 Vac

Fuse

115 Vac, 15 A (3AB time delay)

230 Vac, 8 A (5x20 mm time delay

Coolant Gauge Kit 1 5-1200

Ethylene Glycol 1 Gal. 5-1134-3

1

5-1836

5-1837

2

5-1828-36

5A2257-25

30

Page 45

Figure 15 Resistor Assembly Exploded View

Resistor

Outer Flow Tube

1

9A

Resistor Sleeve

7

Load Housing

O-Ring

8

Inner Flow Tube

9

Ground Cap Assembly

10

Hose Fitting 90°

5

Hose Fitting 90°

5

Inner O-Ring

17

Outer O-Ring

2

Water Chamber With

O-Ring Inner Seal

3

and

4

1/4-20 x 2-1/2

Socket Head Cap Screw (6)

6

Load Housing

Resistor

Center Conductor

Assembly

1/4-20 x 1-1/2

Socket Head Cap Screw (6)

Outer Conductor

Assembly

Resistor Fitting Seal O-Ring

12

16

11

1

15

Maintenance

31

Page 46

Maintenance

Replacement Parts

Casters 4 4421A384

Battery, size C, NiMH 8 5A1230

Cable, IEEE-488

2 m

1 m

Description Qty Part Number

1

5-1317-2

5-1317-1

Cable, RS-232

10 ft.

5 ft.

Null Modem Kit (RS-232 only) 1 4380-250

Panel Mount Kit 1 4421-250

1

5-1662-2

5-1662-1

32

Page 47

Limited Warranty

All products manufactured by Seller are warranted to be free from defects in material and workmanship for a

period of one year, unless otherwise specified, from date of shipment and to conform to applicable specifications,

drawings, blueprints and/or samples. Seller’s sole obligation under these warranties shall be to issue credit, repair

or replace any item or part thereof which is proved to be other than as warranted; no allowance shall be made for

any labor charges of Buyer for replacement of parts, adjustment or repairs, or any other work, unless such

charges are authorized in advance by Seller.

If Seller’s products are claimed to be defective in material or workmanship or not to conform to specifications, drawings, blueprints and/or samples, Seller shall, upon prompt notice thereof, either examine the products where they are located or issue shipping instructions for return to Seller

(transportation charges prepaid by Buyer). In the event any of our products are proved to be other

than as warranted, transportation costs (cheapest way) to and from Seller’s plant, will be borne by

Seller and reimbursement or credit will be made for amounts so expended by Buyer. Every such claim

for breach of these warranties shall be deemed to be waived by Buyer unless made in writing within

ten days from the date of discovery of the defect.

The above warranties shall not extend to any products or parts thereof which have been subjected to

any misuse or neglect, damaged by accident, rendered defective by reason of improper installation or

by the performance of repairs or alterations outside of our plant, and shall not apply to any goods or

parts thereof furnished by Buyer or acquired from others at Buyer’s request and/or to Buyer’s specifications. Routine (regularly required) calibration is not covered under this limited warranty. In addition, Seller’s warranties do not extend to the failure of tubes, transistors, fuses and batteries, or to

other equipment and parts manufactured by others except to the extent of the original manufacturer’s

warranty to Seller.

The obligations under the foregoing warranties are limited to the precise terms thereof. These warranties

provide exclusive remedies, expressly in lieu of all other remedies including claims for special or consequential damages. SELLER NEITHER MAKES NOR ASSUMES ANY OTHER WARRANTY WHATSOEVER,

WHETHER EXPRESS, STATUTORY, OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS, AND NO PERSON IS AUTHORIZED TO ASSUME FOR SELLER ANY OBLIGATION OR LIABILITY NOT STRICTLY IN ACCORDANCE WITH THE FOREGOING.

Special Lifetime Warranty - Series 4020, Series 4027A,

Series 4027F, and Series 4028 Power Sensor Head

In addition to its standard warranty, the Bird Electronic Corporation warrants its Series 4020, Series

4027A, Series 4027F, and Series 4028 Thruline® Power Sensor Heads for lifetime to original purchaser. This extended warranty is against burnout. For the warranty to apply, the Sensor Head must

be used with the correct Bird Electronic Corporation Display Unit, the maximum power rating of the

Sensor must not be exceeded, the Sensor RF circuit must be properly terminated and the Sensor not

subjected to physical abuse.

Bird Electronic Corporation, at its option, will repair or replace the defective Sensor at its world

Headquarters at 30303 Aurora Road, Solon, Ohio 44139.

The customer is responsible to pay transportation charges to return the defective sensor to Bird.

Loading...

Loading...