Page 1

SITE ANALYZER™

CABLE AND ANTENNA TESTER

FOR WIRELESS SYSTEMS

OPERATING INSTRUCTIONS

FOR MODELS

SA-1700EX, SA-1700EXP

SA-2500EX, SA-6000EX

©Copyright 2008 by Bird Electronic Corporation

Instruction Book Part Number 920-7002A600S Rev. J

Site Analyzer is a trademark of Bird Electronic Corporation

Microsoft® and Windows® are registered trademarks

of the Microsoft Corporation

Page 2

.

ii

Page 3

Remove Power

Safety Precautions

Observe general safety precautions. Do

the power on.

Safety Earth Ground

An uninterruptible safety earth ground must be supplied from the

main power source to the instrument.

two conductor power cable is not sufficient protection. Serious injury

or death can occur if this grounding is not properly installed.

Safety Symbols

WARNING

ing notes call attention to a procedure, which if not correctly

Warn

performed, could result in personal injury.

CAUTION

Caution notes call attention to a procedure, which if not correctly

performed, could result in damage to the instrument.

The caution symbol appears on the

there is important information in the instruction manual

regarding that particular area

not open the instrument with

Grounding one conductor of a

equipment indicating

Note: Calls attention to supplemental information.

Warning Statements

The following safety warnings appear in

ger to operating and maintenance personnel, and

for emphasis.

WARNING

The SA-BATPAK is shipped charged. Be careful when removing the

safety cap, 12Vdc @ 2.0 AH/20 hour rate can be present inside the

receptacle. Do not touch the inside of the receptacle.

The possibility of an electric shock exists.

the text where there is dan-

are repeated here

iii

Page 4

Bird Technologies

WARNING

This equipment should not be connected to an antenna or operated

during a storm that has the potential to produce lightning.

The possibility exists for electrical shock.

WARNING

When using the AC adapter, only connect the plug to a properly

grounded receptacle. Serious injury or death can occur if grounding

is not properly installed.

Caution Statements

The following equipment cautions appear in the text and are repeated

here for emphasis.

CAUTION

Harsh or abrasive detergents, and some solvents, can damage the

display unit and information on the labels.

CAUTION

Always turn off the SA before connecting or disconnecting a sensor.

CAUTION

When using a Bird 5011 or 5011-EF, do not exceed 2 W average or

125 W peak power for 5 µs.

Doing so will render the sensor inoperative.

CAUTION

+22 dBm max. input

Do not apply RF power to Antenna Test Port. Exceeding the

maximum input will damage the Site Analyzer.

iv

Page 5

CAUTION

Long-term storage of the external battery pack can affect battery

performance and reduce battery life. Do not store the external

battery pack for long periods of time without proper storage

maintenance (refer to External Battery Pack (Optional), Long-term

Storage Maintenance, page 125). Failure to comply may result in

reduced battery charge and shortened battery life.

v

Page 6

Bird Technologies

Safety Statements

USAGE

ANY USE OF THIS INSTRUMENT IN A MANNER NOT

SPEC

IFIED BY THE MANUFACTURER MAY IMPAIR

THE INSTRUMENT’S SAFETY PROTECTION.

USO

EL USO DE ESTE INSTRUMENTO DE MANERA NO

E

SPECIFICADA POR EL FABRICANTE, PUEDE ANULAR LA

PROTECCIÓN DE SEGURIDAD DEL INSTRUMENTO.

BENUTZUNG

WIRD DAS GERÄT AUF ANDERE WEISE VERWENDET ALS VOM

HERSTEL

LER BESCHRIEBEN, KANN DIE GERÄTESICHERHEIT

BEEINTRÄCHTIGT WERDEN.

UTILISATION

TOUTE UTILISATION DE CET INSTRUMENT QUI N’EST PAS

EXPL

ICITEMENT PRÉVUE PAR LE FABRICANT PEUT

ENDOMMAGER LE DISPOSITIF DE PROTECTION DE

L’INSTRUMENT.

IMPIEGO

QUALORA QUESTO STRUMENTO VENISSE UTILIZZATO IN

MODO DIVERSO DA C

OME SPECIFICATO DAL PRODUTTORE

LA PROZIONE DI SICUREZZA POTREBBE VENIRNE

COMPROMESSA.

SERVICE

SERVICING INSTRUCTIONS ARE FOR USE BY

SERV

ICE - TRAINED PERSONNEL ONLY. TO AVOID

DANGEROUS ELECTRIC SHOCK, DO NOT PERFORM

ANY SERVICING UNLESS QUALIFIED TO DO SO.

SERVICIO

LAS INSTRUCCIONES DE SERVICIO SON PARA USO

EXC

LUSIVO DEL PERSONAL DE SERVICIO CAPACITADO. PARA

EVITAR EL PELIGRO DE DESCARGAS ELÉCTRICAS, NO

REALICE NINGÚN SERVICIO A MENOS QUE ESTÉ

CAPACITADO PARA HACERIO.

WARTUNG

ANWEISUNGEN FÜR DIE WARTUNG DES GERÄTES GELTEN

NUR

FÜR GESCHULTES FACHPERSONAL.

ZUR VERMEIDUNG GEFÄHRLICHE, ELEKTRISCHE SCHOCKS,

SIND

WARTUNGSARBEITEN AUSSCHLIEßLICH VON

QUALIFIZIERTEM SERVICEPERSONAL DURCHZUFÜHREN.

vi

Page 7

ENTRENTIEN

L’EMPLOI DES INSTRUCTIONS D’ENTRETIEN DOIT ÊTRE

RÉSERVÉ AU PERSONNEL FORMÉ AUX OPÉRATIONS

D’ENTRETIEN. POUR PRÉVENIR UN CHOC ÉLECTRIQUE

DANGEREUX, NE PAS EFFECTUER D’ENTRETIEN SI L’ON N’A

PAS ÉTÉ QUALIFIÉ POUR CE FAIRE.

ASSISTENZA TECNICA

LE ISTRUZIONI RELATIVE ALL’ASSISTENZA SONO PREVISTE

ESCLUSIVAMENTE PER IL PERSONALE OPPORTUNAMENTE

ADDESTRATO. PER EVITARE PERICOLOSE SCOSSE

ELETTRICHE NON EFFETTUARRE ALCUNA RIPARAZIONE A

MENO CHE QUALIFICATI A FARLA.

vii

Page 8

Bird Technologies

About This Manual

Changes to This Manual

We have made every effort to ensure this manual is accurate. If you

discover any errors, or if you have suggestions for improving this man

ual, please send your comments to our Solon, Ohio factory. This manual may be periodically updated. When inquiring about updates to

this manual refer to the part number and revision on the title page.

Reference Card

The Reference Card contains minimum operational steps and the

order they should be performed. Use this manual for reference or if

further explanation of any step is required.

Chapter Layout

Introduction — Describes the features of the Bird Site Analyzer and

provides power-up instructions.

Calibration — Lists the steps to calibrate the Site Analyzer, which

must be done before using Measure Match or Fault Location modes.

-

Measure Match Mode — Lists the steps to make match measurements, as well as providing instructions for all functions available in

Measure Match mode.

Fault Location Mode — Lists the steps to make distance to fault measurements, as well as providing instructions for all functions available

in Fault Location mode.

Save and Recall — Describes how to save and recall traces and setups

in Measure Match or Fault Location modes.

Measure Power Mode — Lists the steps to make power measurements, as well as providing instructions for all functions available in

Measure Power mode.

Utilities — Describes utilities to set up the Site Analyzer.

Computer Software — Provides installation instructions and lists the

features of the Bird Site Analyzer PC Software.

viii

Page 9

Maintenance — Lists routine maintenance tasks for the Site Analyzer, as well as troubleshooting for common problems. Specifications

and parts information are also included.

Step By Step Guide — Identifies buttons and connectors on the Site

Analyzer, and explains the display. Also provides step by step instruc

tions for making the most common measurements.

-

ix

Page 10

Bird Technologies

x

Page 11

Table of Contents

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Items Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Items Not Supplied. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Site Analyzer Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Antenna Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measure Match Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fault Location Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Transmitter Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measure Power Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Internal Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Adapters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

External Battery Pack (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 7

To charge the external battery pack: . . . . . . . . . . . . . . . . . . . . . . . 8

To use the external battery pack with a Site Analyzer: . . . . . . . . . 8

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Site Analyzer User Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Site Analyzer Display Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Display Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Calibration Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Calibrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 3 Measure Match Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Determine the Power of the Component Being Tested . . . . . . . . . . 17

Select the Measure Match Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setting the Measurement Frequency . . . . . . . . . . . . . . . . . . . . . . . . 18

Calibrate the Site Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Select the Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Set the Measurement Scale Limits . . . . . . . . . . . . . . . . . . . . . . . . . 23

xi

Page 12

Bird Technologies

Set the Measurement Data Points . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Set the Graph Display Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Set and Activate Acceptance Limits. . . . . . . . . . . . . . . . . . . . . . . . . 29

Measure the Match of the Component. . . . . . . . . . . . . . . . . . . . . . . 31

Interpreting the Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Measurement Hold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Activate Markers and Set Marker Style . . . . . . . . . . . . . . . . . . . . 34

Move Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Using Delta Markers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Using Markers with Recalled Traces . . . . . . . . . . . . . . . . . . . . . . 39

Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Cable Loss Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Interpreting the Cable Loss Measurement. . . . . . . . . . . . . . . . . . . . 45

Chapter 4 Fault Location Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Determine the Power of the Component Being Tested . . . . . . . . . . 47

Select Fault Location Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

What You Need to Know About

Setting the Frequency Span and Max Distance. . . . . . . . . . . . . . . . 49

Setting the Frequency Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setting the Maximum Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Calibrate the Site Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Setting the Cable Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Setting the Distance and Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Distance to Display on the Trace (start, stop) . . . . . . . . . . . . . . . 56

Setting the Scale & Unit of Measure . . . . . . . . . . . . . . . . . . . . . . . . 59

Set the Measurement Data Points . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Set the Graph Display Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Set and Activate Acceptance Limits. . . . . . . . . . . . . . . . . . . . . . . . . 66

Test for Fault Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Interpreting the Fault Location Measurement . . . . . . . . . . . . . . . . . 68

Measurement Hold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Activate Markers and Set Marker Style . . . . . . . . . . . . . . . . . . . . 70

Move Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Using Delta Markers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Using Markers with Recalled Traces . . . . . . . . . . . . . . . . . . . . . . 75

xii

Page 13

Smooth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Saving The Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Chapter 5 Save and Recall. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Save Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Label Text Shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Label Text Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Changing (editing) Label Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Quicktext for Trace Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

View Quicktext Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Create Quicktext . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Use Quicktext. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Delete Quicktext. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Recall a Saved Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Delete a Saved Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Save a Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Recall Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Delete Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Chapter 6 Measure Power Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Connecting a Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Display Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Setting the Full Scale Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Zeroing Bird Power Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Choosing the Displayed Measurement . . . . . . . . . . . . . . . . . . . . . 106

Setting Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Changing the mode for the 5010B . . . . . . . . . . . . . . . . . . . . . . . . . 107

The 43Peak Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Using the 5012 Wideband Power Sensor . . . . . . . . . . . . . . . . . . . 108

Changing the Measurement Type . . . . . . . . . . . . . . . . . . . . . . . 108

Choosing the Displayed Measurement . . . . . . . . . . . . . . . . . . 108

Function Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Average Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

VSWR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Video Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Peak Envelope Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Burst Average Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Crest Factor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

xiii

Page 14

Bird Technologies

Complementary Cumulative Distribution Function (CCDF) . . . 112

Setting the CCDF Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Setting the Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

5011-EF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Recall Setups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Chapter 7 Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Adjust Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Return to Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

FM Modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Chapter 8 Computer Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Computer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Chapter 9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

External Battery Pack (Optional),

Long-term Storage Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Upgrade to Model SA6000EX . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Service Facility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Sales Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

For EX Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

For Non EX Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Optional Equipment Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Hard Transit Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

External Battery Pack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Directional Power Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Terminating Power Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Wideband Power Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

xiv

Page 15

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Measure Match Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Fault Location Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Cable Loss Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

VSWR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Return Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Run / Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Fault Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Maximum Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Fault Location Distance Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Fault Location Distance - 238 Data Points . . . . . . . . . . . . . . . . . 141

Fault Location Distance - 475 Data Points . . . . . . . . . . . . . . . . . 142

Fault Location Distance - 949 Data Points . . . . . . . . . . . . . . . . . 143

xv

Page 16

Bird Technologies

xvi

Page 17

Chapter 1 Introduction

The Bird Site Analyzer is a multifunction test instrument for use in

installation and maintenance of wireless systems. Utilizing a univer

sal hardware and firmware concept, the same unit can be configured

into five model types that include both existing and new Bird Technol

ogy site analyzer models. The current product designation adds the

letters EX after the model number.

-

• SA-1700EX (25 MHz – 1700 MHz, no power measurement

capability)

• SA-1700EXP (25 MHz – 1700 MHz, with power measurement

capability)

• SA-2500EX (780 MHz – 2500 MHz, with power measurement

capability)

• SA-6000EX (25 MHz – 6000 MHz, with power measurement

capability)

Antenna systems are tested by using a Site Analyzer to measure

match conditions. Data points measured across a user-specified fre

quency band or distance range are graphed on a 238 pixel display

area. Transmitter systems are tested by using a Site Analyzer and a

Bird power sensor to measure RF power. Data is displayed as power or

match efficiency, depending upon the sensor.

-

-

Items Supplied

1. Site Analyzer (configured as one of the models described earlier)

2. Soft-Sided Carrying Case

3. PCTool Software

4. AC Power Adapter

5. Automobile Cigarette Lighter Adapter

6. 9-Pin Serial Communications Cable

7. Instruction Manual (Not Shown)

8. Reference Card (Not Shown)

1

Page 18

Bird Technologies

Items Not Supplied

• Calibration Combination (Cal Combo)

Site Analyzer Features

General

• Easy to operate and field ready for first-time, occasional, and

experienced users.

• Step by step guide shows how to make some of the most com-

mon immurements.

• High-resolution color display.

• Field replaceable Li-ion battery.

• Automatic power down conserves battery life.

• Operates in temperatures as low as 14°F (–10°C).

2

Page 19

Introduction

Antenna Test

• Rejects on-channel interfering signals to +13 dBm.

• Three user-selectable trace capture options: 238 data points

per sweep, 475 data points per sweep, 949 data points per

sweep.

• Three graphic display formats: envelope, maximum, mini-

mum.

• Sweep measurement progress bar: indicates status of mea-

surement being taken.

• Stores up to 15 setups.

• Adjustable pass/fail limit with visual indicator.

• Stores up to 500 sets of measurement data (traces) at the

default setting of 238 data points to facilitate conversion

between Measure Match (Sweep) and Fault Location (DTF).

• Measurement data can be transferred to the Anritsu Site Mas-

ter Software Tools.

• On-screen comparison between current measurement trace

and stored data traces – no PC required.

• Pop-up menus contain over 70 cable types and up to 80 fre-

quency band presets depending upon the instrument model

number.

• X and Y scales and units are user adjustable.

• Six markers for either direct or difference measurements. Can

also measure relative to limit line or recalled trace.

• Measurement hold to temporarily store a trace.

• Printing capability. The Site Analyzer is compatible with all

printers that use HP PCL Level 3, including most HP printers.

Measure Match Mode

• Fast swept measurement.

• Frequency can be set using either Start/Stop or Center/Span

frequencies.

• Measurement units can be Return Loss [dB], Cable Loss [dB],

or VSWR [ratio].

3

Page 20

Bird Technologies

Fault Location Mode

• Transform Algorithm - Fast Fourier Transform (FFT) with

three levels of smoothing.

• Distance units can be either feet or meters.

• Measurement units can be Return Loss [dB] or VSWR [ratio].

Transmitter Test

Measure Power Mode

• Numerical readout and analog dial.

• Can display either forward power, reflected power, or match

efficiency depending upon the sensor.

• Power measurement units can be either Watts or dBm. Match

units can be VSWR, return loss, or % match efficiency.

• Compatible with Bird Directional Power Sensors, Terminating

Power Sensors, VSWR Alarms, and Broadcast Power Monitors.

Bird 5010B

Directional

Power

Sensor

Bird 5011 or

5011-EF

Terminating

Power

Sensor

4

Page 21

Bird 5012

Wideband

Power

Sensor

Introduction

5

Page 22

Bird Technologies

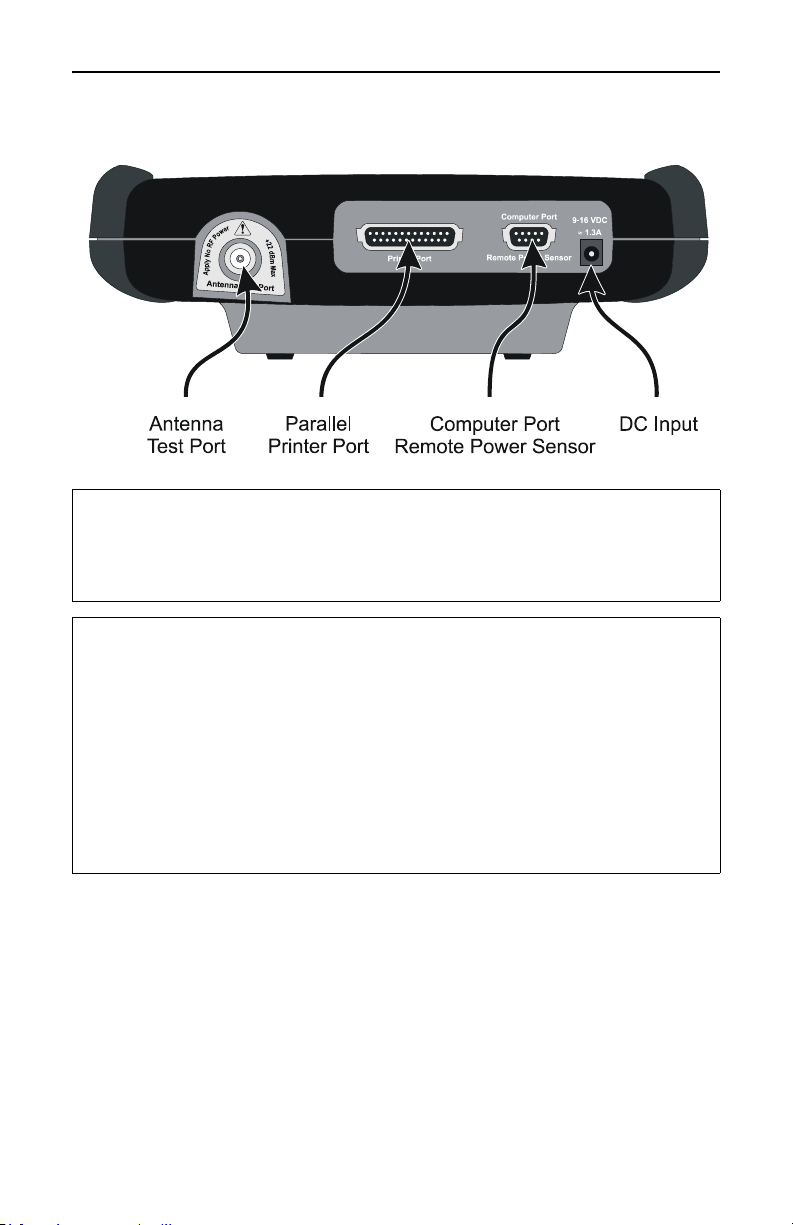

Connectors

CAUTION

+22 dBm max. input

Do not apply RF power to Antenna Test Port. Exceeding the

maximum input will damage the Site Analyzer.

Antenna Test Port Female N connector for connecting to the antenna.

Use a phase-stable cable for best results.

Parallel Printer Port 25-pin (DB25) parallel connector for connecting to

HP-type inkjet printers. Pinter cable not included.

Computer/Power

Sensor Port

9-pin RS-232 (DB9) serial connector for connecting

to a PC or to Bird power sensors.

DC Input Input for external power supplies. Plug either the

ac power supply or the cigarette lighter adapter

into the dc input. The external supplies operate the

unit and charge the internal battery.

Power Supply

Internal Battery

The Bird Site Analyzer has an internal, rechargeable, lithium-ion battery pack. This will operate the unit for a minimum of 3 hours of continuous usage. Recharging time, from a full discharge, is

approximately 4 hours.

Note: When the unit is received the battery may not be

fully charged. An ac adapter should be used when operating

the unit for the first time.

6

Page 23

Introduction

The battery symbol gauge indicates the approximate battery life remaining. At ¼ charge the gauge also displays “LO”. When using an external

power source, a power cord symbol replaces the battery symbol gauge.

Adapters

WARNING

When using the AC adapter, connect the AC plug

only to a properly grounded receptacle. Serious

injury or death can occur if not properly grounded.

The Bird Site Analyzer can be operated using an ac adapter or a 12V

automobile cigarette lighter adapter. Using these adapters will also

charge the internal battery.

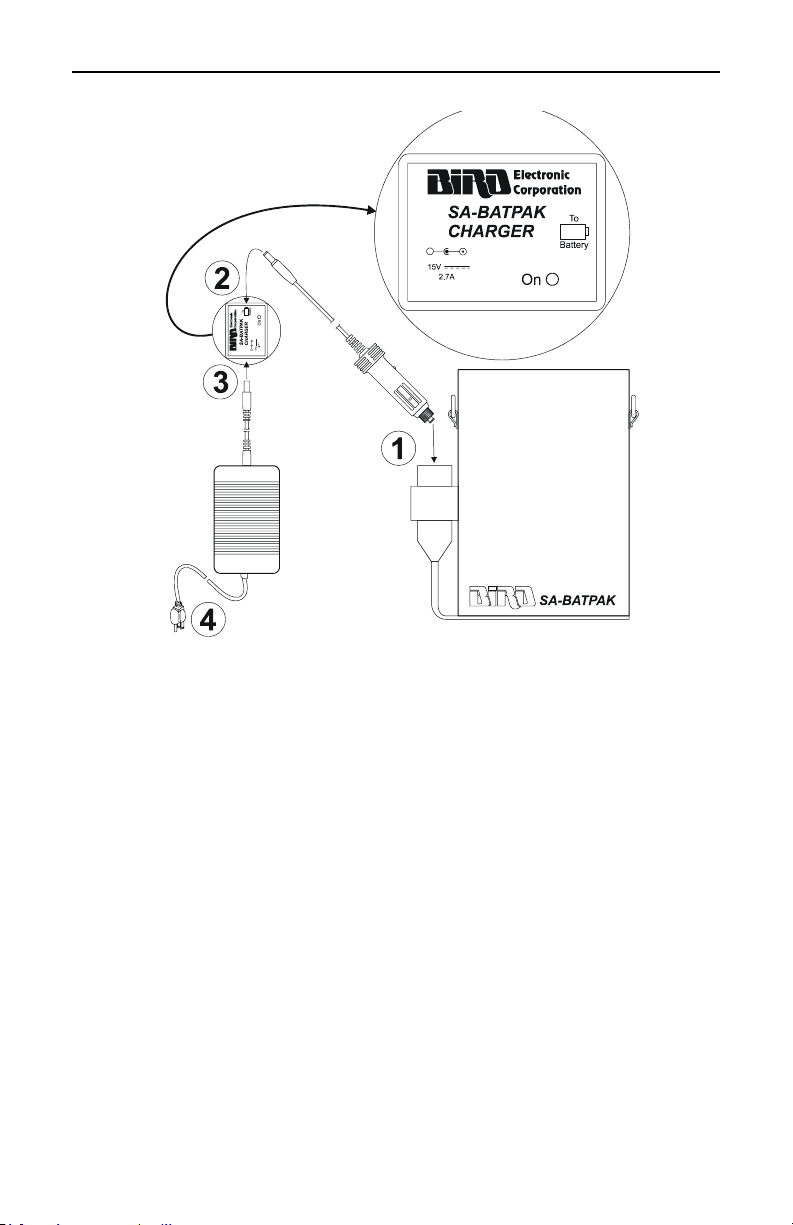

External Battery Pack (Optional)

WARNING

The SA-BATPAK is shipped charged. Be careful

when removing the safety cap, 12VDC @ 2.0 AH/20

hour rate can be present inside the receptacle. Do

not touch the inside of the receptacle. The possibility

of an electric shock exists.

CAUTION

Long-term storage of the external battery pack can

affect battery performance and reduce battery life.

Do not store the external battery pack for long

periods of time without proper storage maintenance

(refer to External Battery Pack (Optional), Longterm Storage Maintenance, page 125). Failure to

comply may result in reduced battery charge and

shortened battery life.

The SA-BATPAK is an optional external battery pack. This will operate the unit for approximately 1 to 2 hours. The liquid acid gel battery

will fully charge, from a full discharge, in about 6-8 hours.

7

Page 24

Bird Technologies

To charge the external battery pack:

1. Plug the automobile cigarette lighter adapter into the external

battery pack on the side that says “To Battery”. Refer to the figure

above.

2. Plug the other end of the cigarette lighter adapter into the charger

adapter.

3. Plug the ac adapter into the charger adapter.

4. Plug the ac adapter into a properly grounded outlet. The charger’s

“On” LED comes on and stays on until the charger is disconnected.

To use the external battery pack with a Site Analyzer:

1. Plug the automobile cigarette lighter adapter into the charged

external battery pack.

2. Plug the other end of the cigarette lighter adapter into the dc

input of the Site Analyzer.

8

Page 25

Introduction

n

Power Up

For the first power-up and after a failure, reset the unit (refer to

Return to Defaults, page 119).

Self Test

The unit performs an automatic self test at power up. If the self test

fails, refer to

tive action. If the problem persists, return the unit for service.

The self test screen also displays the software revision information as

shown below.

Troubleshooting, page 126 for possible causes and correc-

Model SA-6000EX, 25 - 6000 MHz

SN: 00000000

Feb 2005

22

Copyright © 1998 - 2005 by Bird Electronic Corporatio

System Information

Before you use the Site Analyzer, record the following system information:

• Frequency Span — ex: 824-894 MHz (cellular band)

• Cable Type — ex: LDF 7 - 50A

• Approximate Cable Length — ex: 300 feet

• Transmitter Power — ex: 50 W

WARNING

This equipment should not be connected to an

antenna or operated during a storm that has the

potential to produce lightning.

The possibility exists for electrical shock.

9

Page 26

Bird Technologies

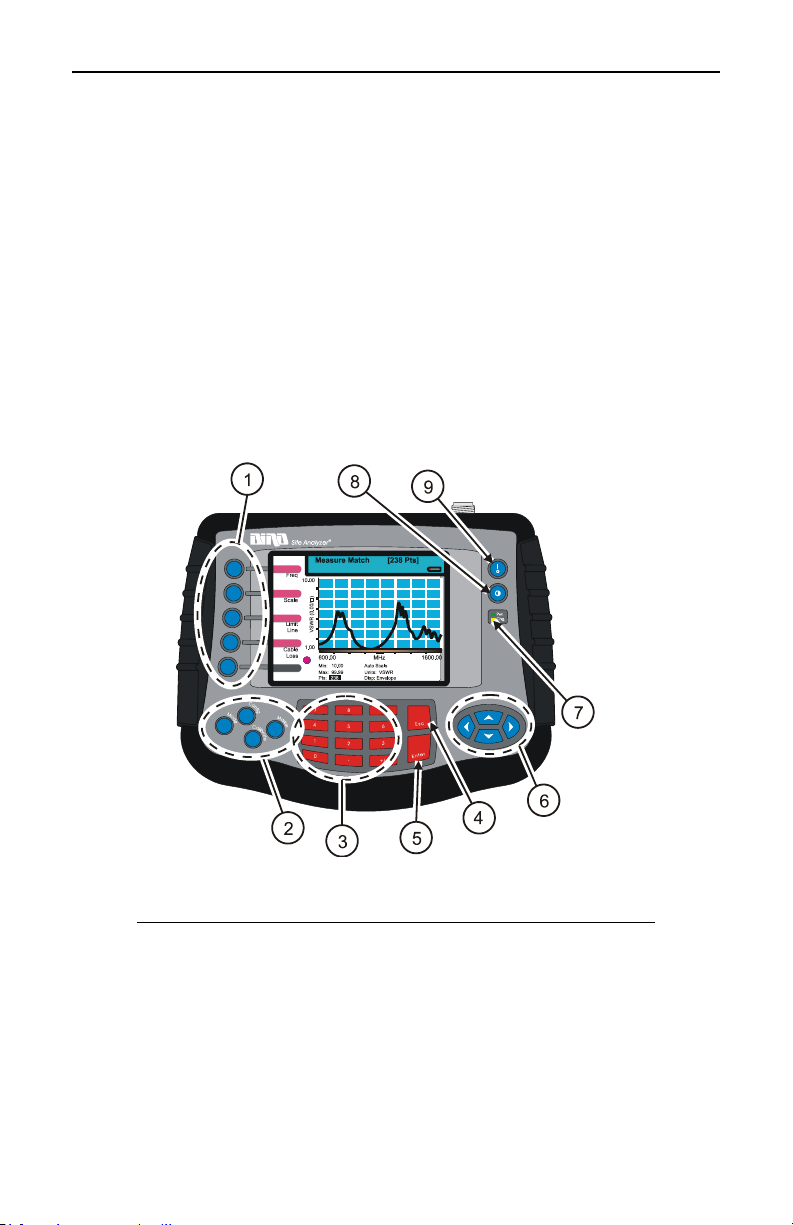

Site Analyzer User Keys

There are two types of keys on the Site Analyzer. The first type,

referred to as a hard key, always has a particular function. The func

tion of the key does not change and is printed on the unit surface or on

the key itself.

The second type is referred to as a softkey. The five keys at the left of

the display are softkeys. Each softkey has a function which can vary

depending upon the operational mode. The function of the key will be

identified at the left of the display, next to the key.

See Figure 1 and its accompanying table for a description of user keys.

Figure 1 User Key Identification

-

10

1. Softkeys Activates the function described

directly to the right of the key.

2. Hard Keys

Mode Activates the mode menu. Use this

to select Measure Match, Fault

Location, Measure Power, or

Utilities mode.

Config Activates the configuration menu for

the current mode. Use this to set

variable parameters (e.g. frequency

band, distance, and units).

Page 27

Introduction

Calibrate Activates the calibration menu.

Marker Activates the marker menu. Use this

to turn markers on or off and to

move the active marker.

3. Numeric Keys Enters numeric data into the

selected item, or as defined by the

function description.

4. Escape Key

During:

Menu Use Backs up one menu level.

Data Entry Exits data entry without changing

the value.

5. Enter Key

During

List Selection Selects the highlighted item in the

list.

Data Entry Exits data entry, changing the

value.

6. Cursor Keys

Left Arrow

During:

Data Entry Deletes previously entered data one

character at a time.

Marker Use Moves active marker left one point

at a time.

All other times As defined by the function

description.

Right Arrow

During:

Marker Use Moves active marker right one point

at a time.

All other times As defined by the function

description.

Up Arrow

During:

Data Entry Increases the numeric value.

Marker Use Moves the marker to the maximum

trace value.

11

Page 28

Bird Technologies

While pressing

Increases the display contrast.

the Contrast

key

All other times As defined by the function

description.

Down Arrow

During:

Data Entry Decreases the numeric value.

Marker Use Moves the marker to the minimum

trace value.

While pressing

Decreases the display contrast.

the Contrast

key

All other times As defined by the function

description.

7. Battery LED The yellow LED lights when the unit

is powered from an external dc

power source. It blinks while

charging the internal battery. Once

the battery is fully charged the

yellow LED stops blinking.

The green LED lights whenever the

unit is on.

8. Contrast Key Hold while pressing the up/down

arrow keys to adjust the contrast of

the display.

12

9. l/0 (On/Off) Turns the instrument on and off.

The key must be pressed for at least

one-half (½) second.

Page 29

Introduction

Site Analyzer Display Screen

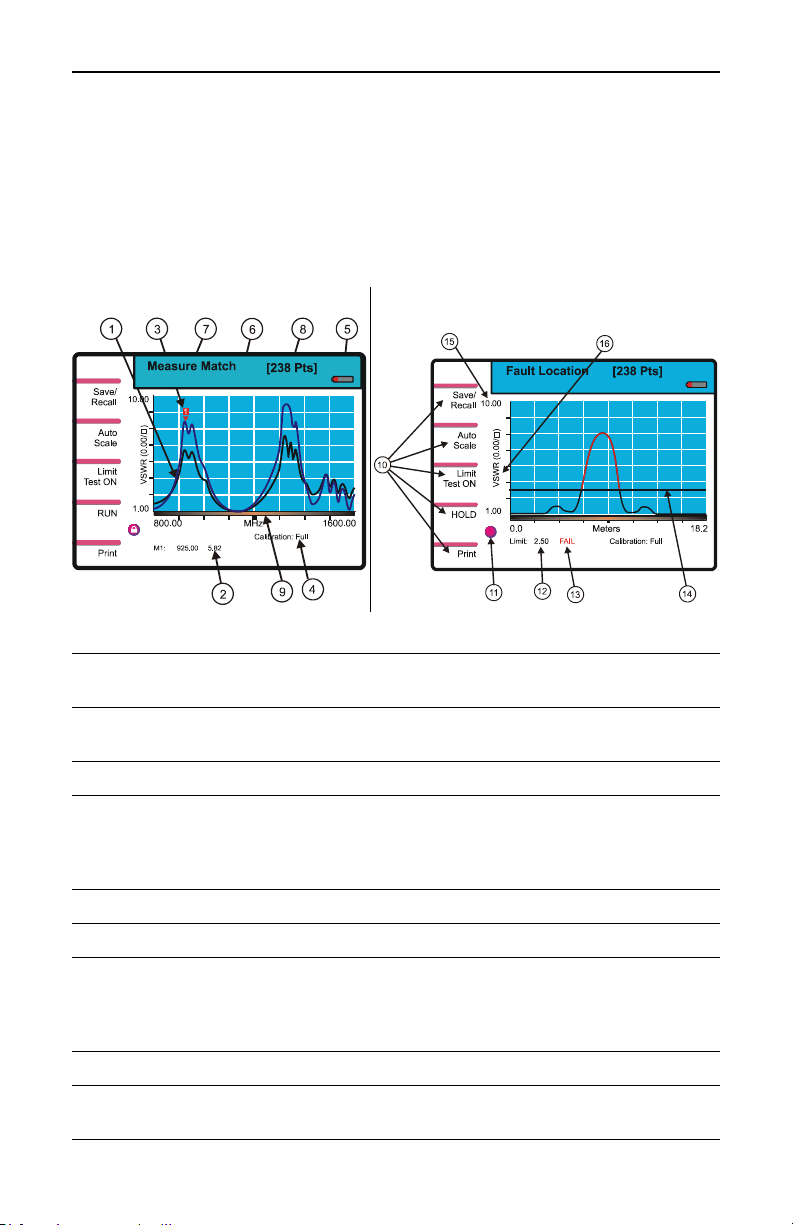

See the following two figures and the accompanying table for a

description of the display screen components for Measure Match mode

and for Fault Location mode.

Display Description

Measure Match Sample Display

1. Trace Graphic display of the measurement.

2. Marker Value Indicates the position and value of a trace

3. Marker Cursor Identifies the trace point displayed in the

4. Calibration Indicator Indicates the calibration status.

5. Battery Gauge Indicates whether the Site Analyzer is

6. Recalled Trace Name Indicates the name of a recalled trace.

Fault Location Sample Display

point.

marker value.

using the internal battery or an external

power supply, and indicates the amount

of battery life remaining.

7. Mode Indicator Name of the current mode.

8. Measurement Data Points Indicates the number of datapoints

collected for each trace. 238 = standard, 475

= twice as many data points as 238, 949 =

four times as many data points as 238.

9. Progress Bar Indicates data collection progress

10. Softkey Description Describes the function of the softkey to

the left of the description.

13

Page 30

Bird Technologies

11. Indicator Ball Indicates if the trace is sweeping.

12. Limit Line Value Indicates the limit value.

13. Limit Test Indicator Displays FAIL if any part of the trace

exceeds the limit value.

14. Limit Line A horizontal line that graphically

displays the limit value.

15. Scale Indicates the minimum and maximum

values displayed on that axis.

16. Units Indicates the measurement units for that

axis.

14

Page 31

Chapter 2 Calibration

Calibration Accessories

• Calibration Combination (Cal Combo) which contains:

One 50 ohm load

One Open standard

One Short standard

• Test Cable (optional) – A phase-stable cable will provide con-

sistent, reliable results.

Note: When using a test cable connected to the Site Ana-

lyzer, attach the Cal Combo to the end of the cable during calibration.

Calibrating

For best results, set the frequency and calibrate the Bird Site Analyzer immediately before taking measurements.

Follow the numbered steps in Figure 2, page 16 to calibrate the Site

Analyzer.

Note: When calibrated, the Site Analyzer’s main screen

will display “Calibration: FULL”. When uncalibrated, the Site

Analyzer’s main screen will display “Calibration: OFF”.

Note: Calibration is performed at the highest number of

data points (949 points) and the calibration graphs are displayed using the currently selected display method (envelope,

maximum, or minimum).

15

Page 32

Bird Technologies

Figure 2 Calibrating the Site Analyzer

Step Action

16

1 Press the Calibrate key

2 Connect the Cal Combo “Open” connector to

the unit antenna port

3 Press the Open softkey then wait for the

unit to beep and display Done

4 Connect the Cal Combo “Short” connector to

the unit antenna port

5 Press the Short softkey then wait for the

unit to beep and display Done

6 Connect the Cal Combo “Load” connector to

the unit antenna port

7 Press the Load softkey then wait for the

unit to beep and display Done

8 Remove the Cal Combo from the unit

Page 33

Chapter 3 Measure Match Mode

Match measurement verifies and monitors the match conditions in the

antenna system at various frequencies. The results are shown on an xy graph. Frequency is shown on the x-axis and return loss, cable loss,

or VSWR is shown on the y-axis.

Before you make a match measurement, be sure that you have a Bird

Calibration Combination (Cal Combo) and all necessary cables and

adapters of the correct size and connector type.

This chapter describes how to make a match measurement and provides step by step instructions. In addition, this chapter describes how

to set and move markers. For information and instructions to save and

recall traces, refer to

To make a match measurement, follow the procedures in this chapter

in the order they are presented.

Determine the Power of the Component Being Tested

Use a service monitor, power meter, or spectrum analyzer to check that

the component being tested does not have power greater than +22 dBm.

Save and Recall, page 79.

CAUTION

+22 dBm max. input

Do not apply RF power to Antenna Test Port.

Exceeding the maximum input will damage the

Site Analyzer.

17

Page 34

Bird Technologies

Select the Measure Match Mode

Follow the numbered steps in Figure 3 to turn ON the Site Analyzer

and select the Measure Match mode.

Figure 3 Selecting the Measure Match Mode

Step Action

1 Turn On the Site Analyzer. Press ON/

OFF key for ½ second.

2 Press the MODE key

3 Press the Measure Match key

Setting the Measurement Frequency

You must be in the Measure Match mode to set a frequency.

Frequencies can be set manually or chosen from a list of presets (band

list). If the start, stop, center, or span frequency is manually set, the

band list will indicate “Custom”. Be sure to set the frequency to a

value that is well beyond the normal range of the antenna. For exam

ple, for a 450 MHz antenna, set the start frequency at 400 and the

stop frequency at 500 MHz, for an 800 MHz antenna, set the start fre

quency at 700 and the stop frequency at 1,100 MHz.

Note: Changing the frequency settings will automatically

turn calibration off. Always set the frequency before calibrating

the unit.

18

-

-

Page 35

Measure Match Mode

Note: If you enter a frequency that is outside of the range

of the Site Analyzer, the Site Analyzer will override your entry

and set the minimum or maximum frequency of the model.

1. Make sure that the unit is turned on and in the Measure Match

mode (refer to

2. Follow the numbered steps in Figure 4 on page 19 to set a custom

frequency or follow the steps in Figure 5 on page 20 to select from

a preset band list.

Figure 4 Setting a Custom Sweep Frequency

Select the Measure Match Mode, page 18).

Step Action

1Press the Config key

2Press the Freq softkey

3 Use the left or right scroll keys to select

Start, Stop, Center, or Span

4 Use the keypad keys to enter a value

and press Enter when finished.

5Press the Esc key to exit the configura-

tion screen

19

Page 36

Bird Technologies

Figure 5 Selecting a Sweep Frequency from a Band List

Step Action

1 Press the Config key

2 Press the Freq softkey

20

3 Use the left or right scroll keys to select

Start, Stop, Center, or Span

4 Use the up or down scroll keys to open the

band list menu

5 Use the up or down scroll keys to select the

desired band

6 Press the Enter key to accept the selection

7 Press the Esc key to exit the configure

screen

Page 37

Measure Match Mode

Calibrate the Site Analyzer

If you need to use an extension cable to connect the Site Analyzer to

the system, connect the extension cable to the antenna test port on the

Site Analyzer and then connect the Bird Cal Combo to the end of the

extension cable. Follow the calibration procedure in

Chapter 2, Calibration, page 15.

Note: When using an extension cable, you should use a

phase stable cable to ensure performance and accuracy. Bird

offers optional phase stable cables that will not degrade the performance of your Site Analyzer. Using a non-Bird phase stable

cable may decrease and degrade the accuracy of the system.

Select the Measurement Units

You can select units before or after making a measurement. When

making a match measurement, you can select one of three units for

the Y (vertical) scale,

• VSWR (ratio)

• Rtn Loss (dB)

• Cbl Loss (dB)

1. Make sure that the instrument is turned on and in the Measure

Match mode (refer to

2. Select Frequency (refer to Setting the Measurement Frequency,

page 18)

3. Make sure that the instrument is calibrated (refer to Calibration,

page 15).

4. Follow the numbered steps in Figure 6, page 22 to set

measurement units.

Select the Measure Match Mode, page 18)

21

Page 38

Bird Technologies

Figure 6 Setting Match Mode Measurement Units

Step Action

1 Press the Config key

2 Press the Scale softkey

3 Press the left or right scroll keys to select

Units

22

4 Press the up or down scroll keys to open the

units list menu

5 Press the up or down scroll keys to select

the desired units

6 Press the Enter key to accept the selection.

7 Press the Esc key to exit the configure

screen

Page 39

Measure Match Mode

Set the Measurement Scale Limits

You can manually set the minimum and maximum values on the Y

(vertical) scale or you can choose Auto Scale and let the instrument

select values that will display the entire trace. You cannot enter val

ues that are outside of the limits of the instrument (-60 and 0). If you

are unsure of the expected results, set the minimum to –60 dB and

maximum to 0 dB or choose Auto Scale. Auto Scale is available on the

main screen as well as on the mode configure screens. The table below

lists typical worst case values for selected measurements.

Component Return Loss Limits

Antenna at Resonance –14 dB

Connector –25 dB

Jumper –35 dB

Lightning Protector –25 dB

Transmission Line –30 dB

1. Turn on the instrument and enter the Measure Match mode (refer

to

Select the Measure Match Mode, page 18).

2. Select Frequency (Setting the Measurement Frequency, page 18)

3. Make sure that the instrument is calibrated (refer to Calibration,

page 15).

4. Follow the numbered steps in Fig. 7 to set the scale limits.

-

23

Page 40

Bird Technologies

Figure 7 Setting Match Mode Scale Limits

Step Action

1 Press the Config key

2 Press the Scale softkey

3 To enter a manual value, skip this step.

Use the left or right scroll keys to select

Auto Scale then press Enter

24

4 If you selected Auto Scale, skip this step.

Use the left or right scroll keys to select

Min then enter your value or enter –60 and

press Enter

5 If you selected Auto Scale, skip this step.

Use the left or right scroll keys to select

Max then enter your value or enter 0 and

press Enter

6 Press the Esc key to exit the configure

screen.

Page 41

Measure Match Mode

Set the Measurement Data Points

You can select the number of data points to take during a measurement. There are three data point options, 238 points, 475 points, and

949 points. Increasing the number of data points increases the mea

surable distance in distance-to-fault measurements and increases the

detail in Measure Match mode measurements. When you save a trace,

the number of data points collected (238, 475, or 949) are saved.

The default number of data points is 238. Selecting 475 data points

provides twice as many measurement points as 238, but it takes

approximately twice as long for the trace to sweep and display. Select

ing 949 data points provides four times as many measurement points

as 238, but it takes approximately four times as long for the trace to

sweep and display.

A progress bar, just below the x-axis, moves from left to right indicating the progress of the sweep. When the progress bar reaches the right

side of the screen, the sweep is finished.

When you change the number of measurement data points, the current trace is erased and the Save softkey is disabled until the sweep

finishes and the screen displays the first new trace. If you press the

Save softkey before the first sweep has completed, the Save softkey

icon (the red bar) will blink until the sweep finishes and then the dis

play will change to the Save and Recall screen (in response to you

pressing the Save softkey).

1. Turn on the instrument and enter the Measure Match mode (refer

to

Select the Measure Match Mode, page 18).

2. Select Frequency (refer to Setting the Measurement Frequency,

page 18)

3. Make sure that the instrument is calibrated (refer to Calibration,

page 15).

4. Follow the numbered steps in Figure 8, page 26 to set the number

of measurement data points.

-

-

-

25

Page 42

Bird Technologies

Figure 8 Setting the Number of Measurement Data Points

Step Action

1 Press the Config key

2 Press the Scale softkey

3 Press the left or right scroll key to select

Pts

26

4 Press the up scroll key to open the selec-

tion list

5 Press the up or down scroll key to select a

data point option (238, 475, 949)

6 Press the Enter key to accept the selection

and return to the configuration screen

Page 43

Measure Match Mode

Set the Graph Display Type

When the Site Analyzer collects data during a sweep, you can specify

that it measure 238 data points, 475 data points, or 949 data points.

Selecting 475 data points takes twice as much time to sweep as 238

points, and 949 points takes four times as much time to sweep as 238

points.

The Site Analyzer display screen graph area can display only 238

points because of its physical pixel limitations. However, if the trace

contains 475 points or 949 points, all points are represented on the

display. There are three modes available to display the data points for

the trace: envelope, maximum, and minimum. For 238 data points,

there is no difference in the display for each of the three modes

because each data point occupies a separate pixel. For 475 data points

and 949 data points, the envelope mode displays all data points, the

maximum mode displays only the highest (peak) magnitude data

point for each pixel, and the minimum mode displays only the lowest

(minimum) magnitude data point for each pixel.

Note: When you save (or download) a trace, all measured

data points (238, 475, 949) are saved (or downloaded). The display modes (envelope, maximum, minimum) are for the Site

Analyzer display only and are not saved (or downloaded) with

your trace.

1. Turn on the instrument and enter the Measure Match mode (refer

to

Select the Measure Match Mode, page 18).

2. Select Frequency (refer to Setting the Measurement Frequency,

page 18)

3. Calibrate the instrument (refer to Calibration, page 15).

4. Follow the numbered steps in Figure 9, page 28 to set the graph

display.

27

Page 44

Bird Technologies

Figure 9 Setting the Graph Display

Step Action

1 Press the Config key

28

2 Press the Scale softkey

3 Press the left or right scroll key to select

Disp

4 Press the up scroll key to open the selec-

tion list

5 Press the up or down scroll key to select a

display type (envelope, maximum, minimum)

6 Press the Enter key to accept the selection

and return to the configuration screen

Page 45

Measure Match Mode

Set and Activate Acceptance Limits

The limit line helps you see failures. It appears as a horizontal line at

the value you select.

You can set an acceptance limit line to help visualize what part of the

measurement trace is not acceptable. The part of the trace that is not

acceptable will display in red. To view the limit line, you must have

the limit test ON. This feature is available only in the Measure Match

mode and the Fault Location mode.

1. Turn on the instrument and enter the Measure Match mode (refer

to

Select the Measure Match Mode, page 18).

2. Select the frequency (refer to Setting the Measurement

Frequency, page 18).

3. Calibrate the unit (refer to Calibrate the Site Analyzer, page 21).

4. Follow the numbered steps in Figure 10, page 30 to turn ON the

limit test and set the limit line value.

Note: You can set a limit line value with the limit test

turned OFF, but you will not see a line displayed on the screen.

29

Page 46

Bird Technologies

Figure 10 Setting a Limit Line

Step Action

1 While in the Measure Match mode or the

Fault Location mode, press the Limit Test

key:

First press - Test ON Aud (line and sound)

Second press - Test ON (line only)

Third press - Test OFF

30

2 Press the Config key

3 Press the Limit Line softkey

4 Use the keyboard to enter a limit value of

your choice or use the suggested limits

listed below (use the +/- key to enter a negative value) then press the Enter key.

Antenna at resonance -14 dB

Connectors -25 dB

Jumpers -35 dB

Lightning protector -25 dB

Transmission lines -30 dB

5 Press the Esc key to exit the configure

screen

Page 47

Measure Match Mode

Measure the Match of the Component

1. Connect the Site Analyzer to the component being tested as follows:

• ANTENNA – (if used) Connect the Phase Stable Cable directly

to the coaxial connector of the antenna. There should be no

other transmission lines or jumpers connected.

• OTHER COMPONENTS – (Including Jumpers, Transmission

Lines, Lightning Protectors, and RF Filters) Connect the

Phase Stable Cable to one end of the component. Connect the

Calibration Combination Load to the other end of the component.

2. Wait at least 10 seconds for the sweep to update.

3. When you have a trace on the screen, you can do any of the

following:

• Hold the trace (refer to Measurement Hold, page 33)

• Add markers to the trace (refer to Markers, page 70)

• Save the trace (refer to Save Trace, page 80)

• Print the trace (refer to Printing, page 77)

31

Page 48

Bird Technologies

Interpreting the Measurement

The graph below shows a typical Match Measurement for an antenna

system.

1. Parts of the sweep below the limit line are better than the limit.

2. Antennas and filters should be below the limit line for the entire

band, and above the limit line outside the band.

3. Other components should be flat and below the limit line across

the entire band.

32

Page 49

Measure Match Mode

Measurement Hold

You must be in either Measure Match mode or Fault Location mode to

hold a trace.

The hold feature stops updating the display at the end of the current

sweep. Press the Hold softkey to hold the displayed trace and press

the Run softkey (the same key) to resume taking measurements. A

measurement is being held when there is a lock icon in the indicator

ball and the Hold softkey changes its name to Run.

If you press the Hold softkey while the unit is in the process of acquiring

data (sweeping), it will not hold the trace until the sweep has finished.

Follow the numbered steps in Figure 11, page 33 to activate or deactivate measurement hold.

Figure 11 Measurement Hold

Step Action

1 Press Hold key to hold the measurement;

press Run key to resume sweeping

2 Lock symbol indicates measurement is

held

33

Page 50

Bird Technologies

Markers

You must be in either Measure Match mode or Fault Location mode to

use markers.

You can activate and use up to six markers to visually indicate the trace

value at specific frequency points. All markers follow the current trace

only. The site analyzer displays the frequency and signal value for each

marker at the bottom of the screen. You can display each marker as a

triangle pointer or a vertical line through the trace. You can also display

the difference (delta) in frequency between two markers. Markers indi

cate VSWR to 0.01, and Return Loss or Cable Loss to 0.1 dB.

When you display both a recalled trace and the current measurement

trace at the same time, there is an additional marker option, single

mode and dual mode. In single mode, the markers function normally

(indicating the frequency and value at the marker). In dual marker

mode, you select a marker using the Mark softkey and, at the bottom

of the screen, the site analyzer displays the marker number, the fre

quency and value of the current trace at the marker, and the difference in frequency and value between the current trace and the

recalled trace. The difference in frequency is always 0.00 (zero). Only

the first three markers (M1, M2, M3) are available in dual mode.

-

-

Activate Markers and Set Marker Style

1. Be sure that you are in either Measure Match mode or Fault

Location mode.

2. Follow the numbered steps in Figure 12, page 35 to activate

markers and set their style.

34

Page 51

Figure 12 Activate Marker and Set Style

Step Action

Measure Match Mode

1 Press the Marker key to enter marker

setup

2 Press the Mark softkey to select a marker

(1-6)

3 Press the Active / Off softkey to turn ON

the selected marker (active) or turn OFF

the selected marker (off)

4 Press the Type softkey to select triangle

marker (4 in figure) or line marker (1 in

figure)

Repeat Step 2 through Step 4 to select and

activate up to six markers and set the

mark style

5 Press the Esc key to return to the test

screen

35

Page 52

Bird Technologies

Move Markers

You can move the active marker along the trace (frequency axis) by

using the left and right scroll keys or by entering a frequency with the

numeric key pad. All markers follow the current trace only.

If you have recalled a trace and you want to use markers to compare it

to the current trace, you need to select the dual mode (refer to

Using

Markers with Recalled Traces, page 39). The marker will move along

the current trace (as described in the following paragraph) and compare each data point at the marker frequency (on the current trace) to

the first saved data point in the recalled trace (other data points in the

recalled trace are not compared). For more information about compar

ing data points, refer to Using Markers with Recalled Traces, page 39.

Since traces can be created using different numbers of data points

(238, 475, 949), moving a marker along a 475 data point or 949 data

point trace will appear different from how the marker moves along a

238 data point trace. In a 238 data point trace, when you press the

right or left scroll keys, the marker moves with each key press. In a

trace with 475 data points, there are two data points at each pixel.

When you first move to a new pixel, the screen displays the value of

the first data point that was saved and when you press the right scroll

key the marker does not “move” but the screen displays the value of

the second data point. Pressing the right scroll key a third time moves

to the next frequency. Similarly in a trace with 949 data points, there

are four data points at each marker pixel. When you first move to a

new frequency, the screen displays the value of the first data point

that was saved and each time you press the right scroll key the

marker does not “move” but the screen displays the value of the next

data point (in the order saved). Pressing the right scroll key a fourth

time moves to the next frequency.

1. Be sure that you are in either Measure Match mode or Fault

Location mode.

2. Follow the numbered steps in Figure 13, page 37 to select and

move markers.

-

36

Page 53

Figure 13 Moving Markers

Measure Match Mode

Step Action

1 Press the Marker key to enter marker

setup

2 Press the Mark softkey to select a marker

(1-6)

3 Press the right or left arrow keys to move

the marker right or left, or enter a frequency value on the keypad and press

Enter

4 Press the up arrow keys to move the

marker to the highest point on the trace

5 Press the down arrow key to move the

marker to the lowest point on the trace

6 Press Esc to return to the test screen

37

Page 54

Bird Technologies

Using Delta Markers

In the delta marker mode, only active markers will be visible. The

delta marker feature displays the difference (delta) in both frequency

and value between the selected marker and each of the other active

marker. If the limit line is active, you will also see the difference

between the selected marker and the limit line. The frequency differ

ence between the selected marker and the limit line will always be the

frequency at the marker. All markers follow the current trace only.

-

Note: The delta marker feature compares points only on

one trace, and you must have at least two active markers for the

delta option to work.

To select and use delta markers, follow the numbered steps in

Figure 14 on page 38.

Figure 14 Delta Markers

38

Step Action

1 Press the Marker key to enter marker

setup

2 Press the Mark softkey to select an active

marker (1-6)

3 Press the Delta softkey to cycle through

the active markers and limit line (if active)

4 Press Esc to return to the test screen

Page 55

Measure Match Mode

Using Markers with Recalled Traces

When a trace is recalled, the screen displays both the current trace

and the recalled trace and there is an additional marker option, Single

Mode / Dual Mode. In single mode, the markers function normally; the

site analyzer displays the frequency and trace value at each marker.

In dual mode, the markers show the actual value of both traces and

the difference in value between the recalled trace and the current

trace. All markers follow the current trace only, and only three mark

ers are available in dual mode, M1, M2, and M3. When you select dual

mode, the markers move as described in

Move Markers, page 36. Each

time you press the right scroll key, the screen displays the next saved

data point of the current trace and compares it to the first data point

of the recalled trace (other data points of the recalled trace are

ignored).

Figure 15 on page 40 shows the data comparison graphically.

1. Be sure that you are in either Measure Match mode or Fault

Location mode.

2. Recall a trace (refer to Recall a Saved Trace, page 91).

3. Follow the numbered steps in Figure 16 on page 41 to set markers

on a recalled trace.

-

39

Page 56

Bird Technologies

Figure 15 Comparing Data Points in Dual Mode

40

Page 57

Figure 16 Using Markers with Recalled Traces

Step Action

1 Press the Marker key

Measure Match Mode

2 Select single mode or dual mode

3 Select a marker

4 Press the left or right scroll key to move the

marker

5 Press Esc to return to the test screen

41

Page 58

Bird Technologies

Printing

The Bird Site Analyzer can print the information displayed on the

screen to any HP Deskjet printer that supports the PCL Level 3 proto

col. To print the screen image, first hold the image (Measurement

Hold, page 33) then press the Print key (Figure 17, item 1).

Note: If you press the Print softkey when there is no

printer connected, the unit will try to print and then display

the word ERROR beside the softkey. To clear the error, select

Mode>Utility>Printer, then press the Printer softkey a second

time to reset the system.

Figure 17 Print the Screen Image

-

42

Page 59

Measure Match Mode

Cable Loss Measurement

To measure cable loss, make sure that the cable being tested is unterminated (not connected to anything at the far end).

Note: Cable loss is a measurement choice that is available

in Measure Match (Configuration). It can also can be selected

by choosing Cbl Loss from Units when you are setting the Scale

in Measure Match (Configure).

1. Check the power of cable to be tested (refer to Determine the

Power of the Component Being Tested, page 17). Make sure that

the cable does not have power greater than +22 dBm.

2. Make sure that you have the correct adaptors and connectors and

a Bird Calibration Combination (cal combo). Also make sure that

you know the frequency band of the system

3. Turn on the Site Analyzer and enter the Measure Match mode

(refer to

4. Follow the numbered steps in Figure 18 on page 44 to set up the

Site Analyzer to measure cable loss.

Select the Measure Match Mode, page 18).

43

Page 60

Bird Technologies

Figure 18 Set Up for Cable Loss Measurement

Step Action

1Press the Config key

2Press the Scale softkey

3 Press the right or left scroll keys to select Units

4 Press the up key to open the units list

5 Press the up or down keys to select Cbl Loss

and press Enter

5. Select the Freq softkey and set the frequency start and stop to a

range that is well beyond the normal range of the antenna (refer

to

Setting the Measurement Frequency, page 18).

Note: For example, for a 450 MHz antenna, set the start

frequency at 400 and the stop frequency at 500 MHz, for an 800

MHz antenna, set the start frequency at 700 and the stop frequency at 1,100 MHz.

6. Connect a phase stable cable to the Site Analyzer antenna test

port and connect a Cal Combo to the other end of the cable.

7. Calibrate the Site Analyzer (See Calibrate the Site Analyzer, page 21).

Note: After calibration, with the load still connected, the

output must below -25 dB. If it is not, there is a problem.

8. Remove the Cal Combo unit from the cable. Do not disconnect the

phase stable cable from the Site Analyzer.

44

Page 61

Measure Match Mode

9. Connect the phase stable cable to one end of the cable under test.

10. Connect the Short connection on the Cal Combo unit to the other

end of the cable being tested.

11. Wait at least 10 seconds to allow the trace to update.

12. Hold the trace on the screen (See Measurement Hold, page 33).

13. Place a triangle-style marker (mark 1) at the minimum loss point

within the frequency band on the trace (refer to

14. Place a triangle-style marker (mark 2) at the maximum loss point

within the frequency band on the trace.

15. If appropriate, save and label the trace (refer to Save Trace, page 80).

Markers, page 34).

Interpreting the Cable Loss Measurement

The graph below shows a typical cable loss measurement. Note that the

scale is greatly reduced to show the cable’s variation across frequency.

1. Take the average of M1 and M2. This is the average cable loss

across the frequency band.

2. Compare the loss with the manufacturer’s specified loss for a cable

of this length. If they do not correspond, retake the measurement,

then check the cable for problems.

3. The Cable Loss for a good cable should be flat across the frequency

band.

45

Page 62

Bird Technologies

46

Page 63

Chapter 4 Fault Location Mode

Fault location identifies the position of impedance discontinuities

(reflections) within the antenna/feeder system. The measurement

results are displayed on an x-y graph. Distance from the Site Analyzer

is shown on the x-axis, while relative magnitude of the discontinuity is

shown on the y-axis.

Before you make a fault location measurement, be sure that you have

the following items and information:

• A Bird Calibration Combination (Cal Combo) calibration unit

• All necessary cables and adapters of the correct size and con-

nector type.

• The velocity of propagation for the cable type you will measure

(obtain from the cable manufacturer)

• Number of data points to use in making the distance to fault

measurement (user choice)

This chapter describes how to make a fault location measurement and

provides step by step instructions. In addition, this chapter also

describes how to set and move markers. For information and instruc

tions to save and recall traces, refer to Save and Recall, page 79.

-

To make a fault location measurement, follow the procedures in this

chapter in the order they are presented.

Determine the Power of the Component Being Tested

Use a service monitor, power meter, or spectrum analyzer to check that

the component being tested does not have power greater than +22 dBm.

CAUTION

+22 dBm max. input

Do not apply RF power to the Antenna Test Port.

Exceeding the maximum input will damage the Site

Analyzer.

47

Page 64

Bird Technologies

Note: Changing the frequency settings will automatically

turn calibration off. Always set the frequency before calibrating

the unit.

Note: If you enter a frequency that is outside of the range

of the Site Analyzer, the Site Analyzer will override your entry

and set the minimum or maximum frequency of the model.

Select Fault Location Mode

1. Apply power to the Site Analyzer. Press and hold the ON/OFF key

for at least 1/2 second then wait for the unit to go through its

power-on initialization.

2. To select the Fault Location mode, follow the numbered steps in

Figure 19 on page 48.

Figure 19 Select Fault Location Mode

48

Step Action

1 Press the Mode key

2 Press the Fault Location softkey

Page 65

Fault Location Mode

What You Need to Know About Setting the Frequency Span and Max Distance

Note: Changing the frequency span or the max distance

will automatically turn calibration off. Always set the frequency span or max distance before calibrating the unit.

The maximum distance you can measure is determined by the frequency span, the velocity of propagation of the cable (Vp), and the

number of data points to measure (238, 475, or 949). These factors are

discussed in the following paragraphs.

Max DistanceWhen you specify a frequency span, the Site Analyzer

calculates the maximum measurable distance. If you know the maxi

mum distance you want to measure, you can enter it instead of the frequency span; the Site Analyzer calculates the frequency span for you.

If you manually enter a maximum distance, be sure to select the data

points before entering the max distance

-

Note: If you select a maximum distance less than the total

length of the cable system, the trace might show a spike that is

not really a fault, but rather an echo from the portion of the

cable that is beyond the length you chose. Such a spike is

known as an alias. To avoid aliasing, always set the maximum

distance to a value that is a few feet or meters greater than the

entire length of your cable system.

Data Points

the measurable distance (475 points results in twice the distance of

238 points, and 949 points results in four times the distance of 238

points) (refer to

data points measured, the software automatically recomputes the new

maximum measurable distance. If you manually enter a maximum

distance, be sure to select the data points before entering the max dis

tance. Changing data points does not turn calibration off.

Frequency SpanIf you narrow the frequency span you will increase

the measurable distance (refer to the

page 140).

Velocity of PropagationThe velocity of propagation is a characteristic

of the cable and is expressed as a percentage. Contact the cable manu

facturer to get the velocity of propagation value for the cable you are

using.

If you increase the number of data points you will increase

Equations, page 140). When you change the number of

Fault Location Distance Tables,

-

-

49

Page 66

Bird Technologies

Setting the Frequency Span

For a given number of data points (238, 475, 949), entering a frequency span causes the Site Analyzer to calculate and enter the maximum measurable distance and, conversely, ent

distance causes the Site Analyzer to calculate and enter the required

frequency span.

There are two methods you can use to determine the

(for both methods, you need to know the maximum distance, velocity

of propagation, and number of data points). Instructions for both

methods are in Step 2 below:

ering a maximum

frequency span

• Use the Fault Location Distance Tables, page 140.

• Calculate the frequency span.

1. Select Measure Match Mode (refer to Select the Measure Match

Mode, page 18).

2. Determine the frequency span. Choose how many data points you

want to measure

Distance and Resolution

propagation percentage that is closest to the cable in your system.

Read down the

frequency span or the maximum distance. When choosing a

distance, choose one that is approximately 25% more than your

tower height (or length of the cable system to be tested).

For example, for a cable with a dielectric constant of 2.296, the

v

elocity percentage is 66%. If the cable system is 100 feet long, and

you choose 238 data points, then the Site Analyzer should be set to

a frequency span of 700 MHz. The resolution of the graph will be

5.6 inches.

then, from the

table (page 140), choose a velocity

Vel Prop percentage column to determine the

appropriate Fault Location

Note: To avoid potential false “spikes” (aliases) on the

trace, be sure to select a distance that is at least 25% greater

than the length of your cable system.

If you know your cable’s velocity of propagation and its length but

the

y are not on one of the tables, you can either enter the max distance into the Site Analyzer or y

frequency span required by using the following equation:

Freq Span =

where (# points - 1) is 237, 474, or 948

If you enter a span greater than the current settings permit

span will be set to the maximum allowable value.

50

150()relative velocity (%) # points 1–()××

------------------------------------------------------------------------------------------------------------

ou can determine the approximate

test length (m)

, the

Page 67

Fault Location Mode

3. Enter the frequency span. Follow the numbered steps in Figure 20

on page 51 to enter the values you determined in Step 2.

4. Enter the center frequency. The center frequency is the center of

the antenna’s frequency range.

To set the max distance, follow the numbered steps in Figure 20 on

page 51.

Figure 20 Setting the Frequency Span and the Center Frequency

Step Action

1 Press the Config key

2 Press the Freq softkey

3 For both Span and Center, scroll to select

the item (Span or Center)

4 Enter the Span value determined from the

table earlier. Enter the value for the center

frequency as determined in instruction

Step 3.

5 After you enter the Span value, press Enter

After you enter the Center value, press

Enter

6 Press the Mode key

7 Press the Fault Location softkey

51

Page 68

Bird Technologies

Setting the Maximum Distance

Note: Changing the frequency span or the max distance

will automatically turn calibration off. Always set the

frequency span or max distance before calibrating the unit.

1. Select the Fault Location mode (Figure 19 on page 48).

2. Follow the numbered steps in Figure 21 on page 52 to enter the

maximum distance value.

3. At the warning message (Figure 22, page 53) press Enter to accept

your entry or Esc to cancel your entry. When you press Enter, the

Site Analyzer will display the Calibration screen so you can begin

the calibration process.

Figure 21 Setting the Maximum Distance

Step Action

1Press the Config key

2Press the Distance softkey

3 Press the right or left arrow keys to scroll to Max

4 Numeric key pad - enter a maximum distance value

5Press the Enter key after entering a value

6Press the Esc key to exit the configuration screen

52

Page 69

Fault Location Mode