Page 1

Bird Diagnostic System

7001B200-1

®

©Copyright 2012

Instruction Book P/N 920-7001B200-1 Rev. A

Bird Diagnostic System is trademark of Bird Electronic Corporation.

by Bird Electronic Corporation

Page 2

I am not blank

Page 3

Safety Precautions

The following are general safety precautions that are not necessarily related to any specific

part or procedure, and do not necessarily appear elsewhere in this publication. These precautions must be thoroughly understood and apply to all phases of operation and maintenance.

WARNING

Keep Away From Live Circuits

Operating Personnel must at all times observe general safety precautions. Do not

replace components or make adjustments to the inside of the test equipment with the

high voltage supply turned on. To avoid casualties, always remove power.

WARNING

Shock Hazard

Do not attempt to remove the RF transmission line while RF power is present.

Capacitors can store a dangerous electrical charge. Avoid contact with all system

capacitors. If it is necessary to perform work near a system capacitor, be sure to discharge

the capacitor through a low resistance.

WARNING

Do Not Service Or Adjust Alone

Under no circumstances should any person reach into an enclosure for the purpose of

service or adjustment of equipment except in the presence of someone who is capable

of rendering aid.

WARNING

Safety Earth Ground

An uniterruptible earth safety ground must be supplied from the main power source to

test instruments. Grounding one conductor of a two conductor power cable is not

sufficient protection. Serious injury or death can occur if this grounding is not properly

supplied.

WARNING

Resuscitation

Personnel working with or near high voltages should be familiar with modern methods

of resuscitation.

WARNING

Remove Power

Observe general safety precautions. Do not open the instrument with the power on.

iii

Page 4

Safety Symbols

WARNING

Warning notes call attention to a procedure, which if not correctly performed could

result in personal injury.

CAUTION

Caution notes call attention to a procedure, which if not correctly performed could

result in damage to the instrument.

The caution symbol appears on the equipment indicating there is

important information in the instruction manual regarding that particular area.

Note: Calls attention to supplemental information.

Warning Statements

The following safety warnings appear in the text where there is danger to operating and maintenance personnel and are repeated here for emphasis.

Caution Statements

The following equipment cautions appear in the text whenever the equipment is in danger of

damage and are repeated here for emphasis.

CAUTION

Bending RF cables can cause damage. When routing RF cables, the minimum

bend radius is 2 inches (25.4 mm). Do not bend the cables more than the

minimum bend radius. Failure to comply may result in permanent damage to

the cable and reduced equipment performance.

See page 6.

iv

Page 5

Safety Statements

USAGE

ANY USE OF THIS INSTRUMENT IN A MANNER NOT SPECIFIED BY THE

MANUFACTURER MAY IMPAIR THE INSTRUMENT’S SAFETY PROTECTION.

USO

EL USO DE ESTE INSTRUMENTO DE MANERA NO ESPECIFICADA POR EL

FABRICANTE, PUEDE ANULAR LA PROTECCIÓN DE SEGURIDAD DEL

INSTRUMENTO.

BENUTZUNG

WIRD DAS GERÄT AUF ANDERE WEISE VERWENDET ALS VOM HERSTELLER

BESCHRIEBEN, KANN DIE GERÄTESICHERHEIT BEEINTRÄCHTIGT WERDEN.

UTILISATION

TOUTE UTILISATION DE CET INSTRUMENT QUI N’EST PAS EXPLICITEMENT

PRÉVUE PAR LE FABRICANT PEUT ENDOMMAGER LE DISPOSITIF DE

PROTECTION DE L’INSTRUMENT.

IMPIEGO

QUALORA QUESTO STRUMENTO VENISSE UTILIZZATO IN MODO DIVERSO DA

COME SPECIFICATO DAL PRODUTTORE LA PROZIONE DI SICUREZZA

POTREBBE VENIRNE COMPROMESSA.

v

Page 6

SERVICE

SERVICING INSTRUCTIONS ARE FOR USE BY SERVICE - TRAINED

PERSONNEL ONLY. TO AVOID DANGEROUS ELECTRIC SHOCK, DO NOT

PERFORM ANY SERVICING UNLESS QUALIFIED TO DO SO.

SERVICIO

LAS INSTRUCCIONES DE SERVICIO SON PARA USO EXCLUSIVO DEL

PERSONAL DE SERVICIO CAPACITADO. PARA EVITAR EL PELIGRO DE

DESCARGAS ELÉCTRICAS, NO REALICE NINGÚN SERVICIO A MENOS QUE

ESTÉ CAPACITADO PARA HACERIO.

WARTUNG

ANWEISUNGEN FÜR DIE WARTUNG DES GERÄTES GELTEN NUR FÜR

GESCHULTES FACHPERSONAL.

ZUR VERMEIDUNG GEFÄHRLICHE, ELEKTRISCHE SCHOCKS, SIND

WARTUNGSARBEITEN AUSSCHLIEßLICH VON QUALIFIZIERTEM

SERVICEPERSONAL DURCHZUFÜHREN.

ENTRENTIEN

L’EMPLOI DES INSTRUCTIONS D’ENTRETIEN DOIT ÊTRE RÉSERVÉ AU

PERSONNEL FORMÉ AUX OPÉRATIONS D’ENTRETIEN. POUR PRÉVENIR UN

CHOC ÉLECTRIQUE DANGEREUX, NE PAS EFFECTUER D’ENTRETIEN SI L’ON

N’A PAS ÉTÉ QUALIFIÉ POUR CE FAIRE.

ASSISTENZA TECNICA

LE ISTRUZIONI RELATIVE ALL’ASSISTENZA SONO PREVISTE

ESCLUSIVAMENTE PER IL PERSONALE OPPORTUNAMENTE ADDESTRATO.

PER EVITARE PERICOLOSE SCOSSE ELETTRICHE NON EFFETTUARRE

ALCUNA RIPARAZIONE A MENO CHE QUALIFICATI A FARLA.

vi

Page 7

About This Manual

This manual covers the operating and maintenance instructions for the following models:

7001B200-1

Changes to this Manual

We have made every effort to ensure this manual is accurate. If you discover any errors, or if you

have suggestions for improving this manual, please send your comments to our Solon, Ohio factory. This manual may be periodically updated. When inquiring about updates to this manual

refer to the part number and revision on the title page.

Contents

Chapter Layout

Introduction - Introduces the external features and functions of the unit, equipment pro-

vided, and options available.

Installation - Provides information about connecting the instrument to your equipment.

Operating Instructions - All instructions necessary to operate the equipment are contained

in this chapter.

Maintenance - Parts lists and repair instructions are also in this chapter.

DeviceNet - Covers the operation and programming nuances of DeviceNet.

vii

Page 8

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Warning Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Caution Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Safety Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Changes to this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Chapter Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Chapter 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Bird Diagnostic System (BDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Standard Tracking Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Spectral Search (Sweep) Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Arc Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

BDS Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Items Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Communication Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connecting the Sensor and Receiver Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing the BDS Graphical User Interface Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 3 Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Setting Up the BDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Configuring Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Restoring PC Network Connection to Use DHCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Establishing a Connection to the BDS Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connection Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

BDS GUI Interface Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Toolbars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . 16

viii

Page 9

Status Bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting Up the BDS GUI Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Using Standard Tracking Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setting the Minimum Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Acquiring Fresh Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Stopping the Data Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Saving the Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Viewing the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table View\ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Time Plot View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Reconstructed Waveform View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Smith Chart View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Using Spectral Search (Sweep) Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setting the Minimum Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Acquiring Fresh Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Stopping Data Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Saving the Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Viewing the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Viewing Data in the Frequency Domain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Viewing Data in a Table of Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Viewing Captured Data Using MS Excel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

CSV File Format Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Scan Mode Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Standard Tracking Mode Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Frequency Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Analog I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

De-embedding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

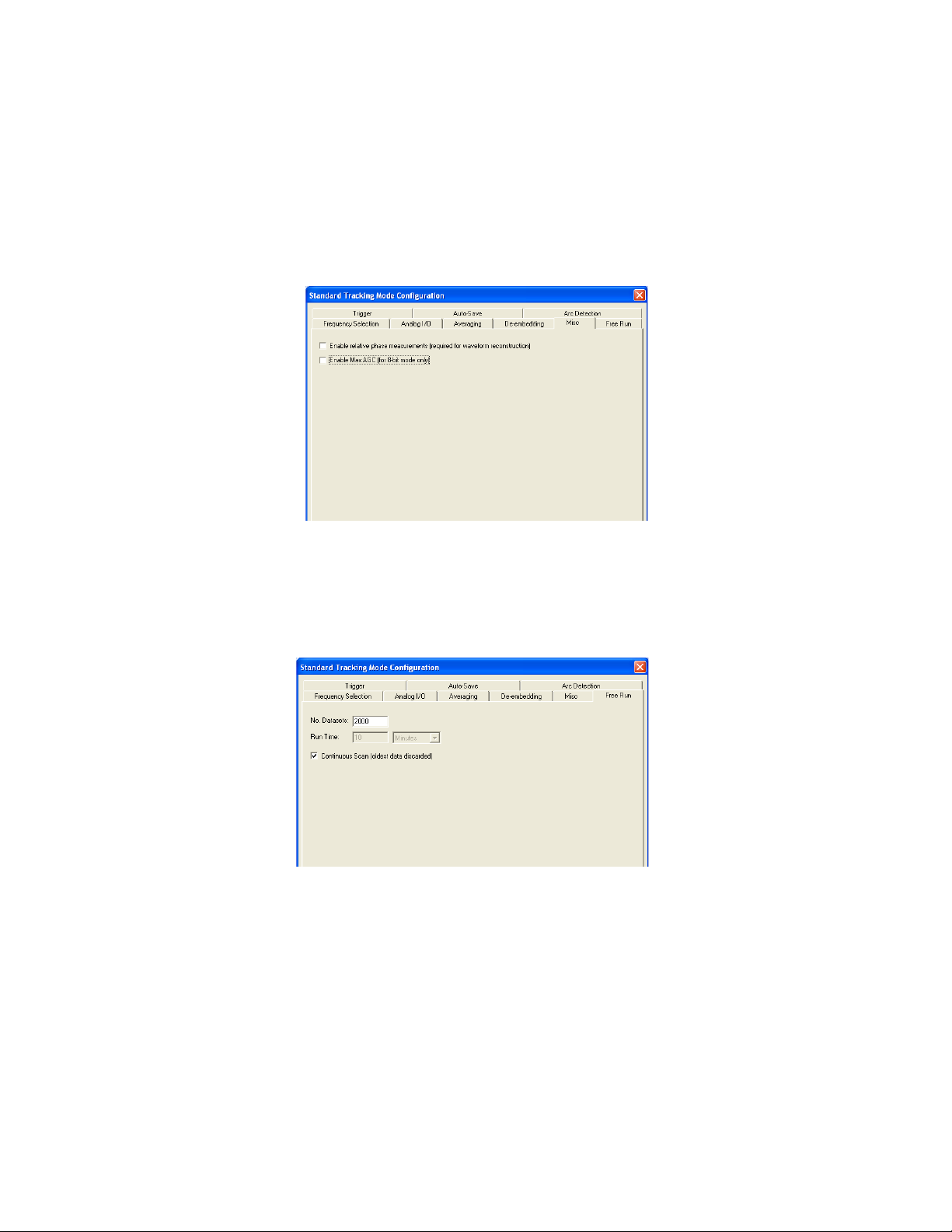

Misc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Free Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Auto-Save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Arc Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Spectral Search (Sweep) Mode Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Peak Locator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Graph Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Auto-Save & Arc Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Updating BDS Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Health LED Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Voltage, Current and Phase Measurement Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Physical and Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indicators and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Data Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Tabular Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Graphical Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

. . . . . . . 42

ix

Page 10

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

QC Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Specifications, DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Specification for DeviceNet "Custom Profile" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

DeviceNet Communication Interface Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 5 DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Reference Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Open DeviceNet Vendor Association, Inc. (ODVA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

DeviceNet System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

MAC ID & Baud Rate Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

LED Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

DeviceNet Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

DeviceNet Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Group 2 Only Slave Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

BDS Object Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Identity Object – Class Code: 1 (01HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Message Router Object – Class Code: 2 (02HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

DeviceNet Object – Class Code: 3 (03HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Assembly Object – Class Code: 4 (04HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Assembly Instance 100 (64HEX) – BDS Standard Mode Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Assembly Instance 100 (64HEX) Attributes (Input Assembly) . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Assembly 100 (64HEX) Instance Byte Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Assembly Sample Configuration and Byte Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Assembly Byte Mapping Spreadsheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Assembly Instance 101 (65HEX) – “Common Assembly Data” . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Connection Object – Class Code: 5 (05HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

S-Device Supervisor – Class Code: 48 (30HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Component Object – Class Code: 100 (64HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

S-Device Supervisor – Class Code: 48 (30HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Component Object – Class Code: 100 (64HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Application Object – Class Code: 101 (65HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Attenuation Control Object – Class Code: 104 (68HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Standard Mode Object – Class Code: 105 (69HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Standard Mode Data Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Fundamental – Search frequency selection parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

VIMeas – Single BDS V & I measurement result. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Constants And Data Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

. .83

Page 11

xi

Page 12

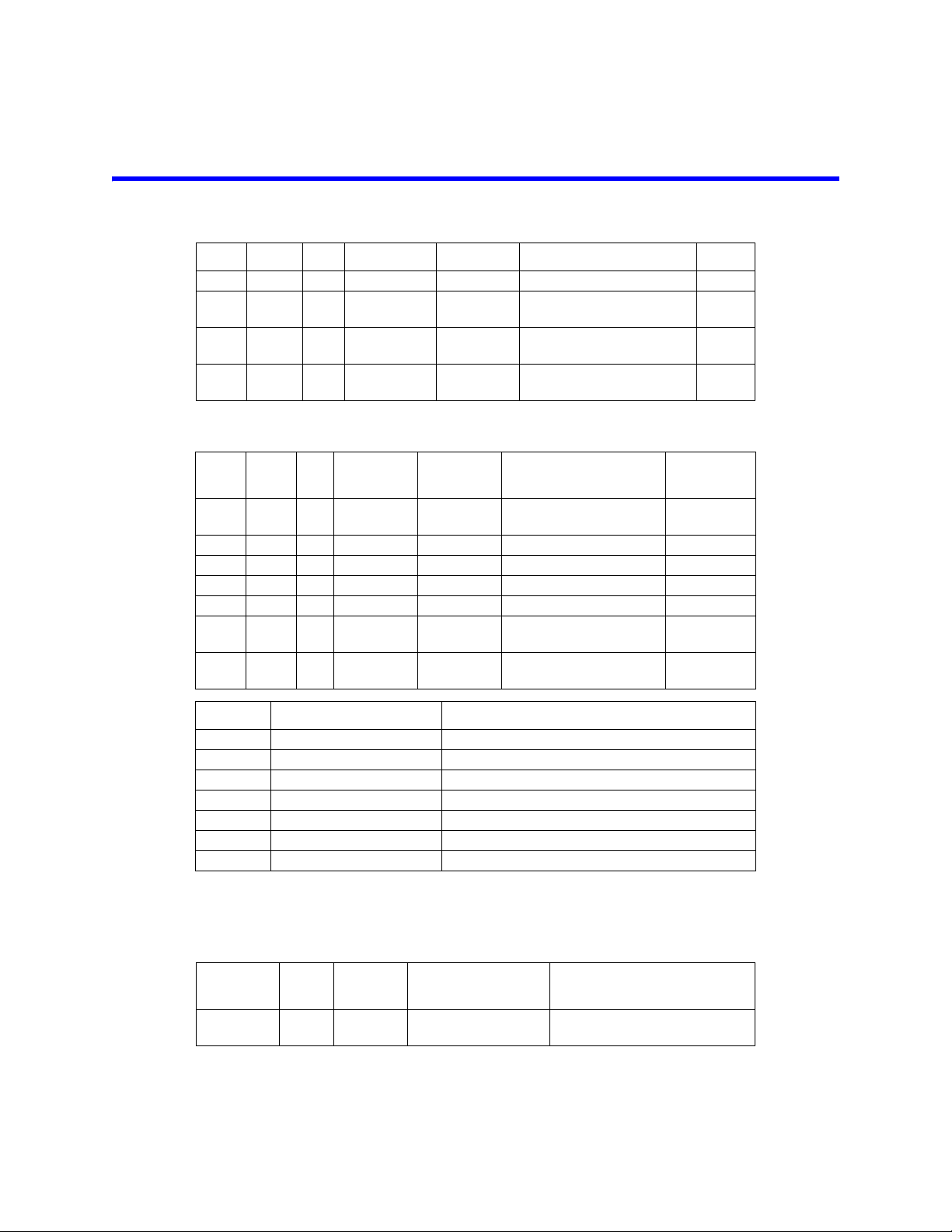

List of Tables

Table 3-1 Standard Tracking Mode CSV Format Description . . . . . . . . . . . . . . . . . . 25

Table 3-2 Spectral Search Mode CSV Format Description . . . . . . . . . . . . . . . . . . . . 26

Table 3-3 Arc Detect CSV Format Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 5-1 Network Status LED Operation (NET) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 5-2 Module Status LED Operation (MOD) –

Corresponds to the Status attribute of the Identity Object . . . . . . . . . . . 53

Table 5-3 Group 2 Only Slave Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 5-4 Identity Class Attributes (Instance 0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 5-5 Identity Instance Attributes (Instance 1) . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 5-6 Identity Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 5-7 Identity Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Table 5-8 Identity Object Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 5-9 Message Router Class Attributes (Instance 0) . . . . . . . . . . . . . . . . . . . . . . 56

Table 5-10 Message Router Instance Attributes (Instance 1) . . . . . . . . . . . . . . . . . . 56

Table 5-11 Message Router Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 5-12 Message Router Object Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 5-13 DeviceNet Class Attributes (Instance 0) . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 5-14 DeviceNet Instance Attributes (Instance 1) . . . . . . . . . . . . . . . . . . . . . . . 57

Table 5-15 DeviceNet Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 5-16 DeviceNet Object Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 5-17 Assembly Class Attributes (Instance 0) . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 5-18 Assembly Instance 100 (64HEX) Data Attribute Mapping . . . . . . . . . . . 61

Table 5-19 Assembly Instance 101 (65HEX) Instance Attributes . . . . . . . . . . . . . . . 63

Table 5-20 Assembly Instance 101 (65HEX) Instance Component Mapping . . . . . . 64

Table 5-21 Assembly Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 5-22 Assembly Object Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Table 5-23 Connection Class Attributes (Instance 0) . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 5-24 Connection Instance Attributes (Instance 1) . . . . . . . . . . . . . . . . . . . . . . 65

Table 5-25 Connection Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table 5-26 Connection Object Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table 5-27 Device Supervisor Class Attributes (Instance 0) . . . . . . . . . . . . . . . . . . . 66

Table 5-28 S-Device Supervisor Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table 5-29 S-Device Supervisor Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 5-30 S-Device Supervisor Object Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

xii

Page 13

Table 5-31 Component Object Class Attributes (Instance 0) . . . . . . . . . . . . . . . . . . 67

Table 5-32 Component Object Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 5-33 Component Object Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 5-34 Component Object Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 5-35 S-Device Supervisor Class Attributes (Instance 0) . . . . . . . . . . . . . . . . . 68

Table 5-36 S-Device Supervisor Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 5-37 S-Device Supervisor Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 5-38 S-Device Supervisor Object Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 5-39 Component Object Class Attributes (Instance 0) . . . . . . . . . . . . . . . . . . 69

Table 5-40 Component Object Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 5-41 Component Object Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 5-42 Component Object Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 5-43 Application Object Class Attributes (Instance 0) . . . . . . . . . . . . . . . . . . 70

Table 5-44 Application Object Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 5-45 Application Object Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 5-46 Application Object Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 5-47 Attenuation Control Class Attributes (Instance 0) . . . . . . . . . . . . . . . . . 71

Table 5-48 Attenuation Control Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 5-49 Attenuation Control Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 5-50 Attenuation Control Object Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 5-51 Standard Mode Class Attributes (Instance 0) . . . . . . . . . . . . . . . . . . . . . 72

Table 5-52 Standard Mode Instance Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 5-53 Standard Mode Common Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 5-54 Standard Mode Object Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 5-55 HarmSel – Harmonic Component

Selection Bitfield (16-bit WORD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table 5-56 DACSel – DAC Selection Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 5-57 DeeSegment – Transmission Line Segment

De-embedding Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table 5-58 DeeOpts - De-embedding Options Bitfield (8-bit BYTE) . . . . . . . . . . . . . 78

Table 5-59 CIP™ Elementary Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 5-60 DATE_AND_TIME Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 5-61 SHORT_STRING Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 5-62 SHORT_STRING Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 5-63 BDS System Status Bitfield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table 5-64 Output Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

xiii

Page 14

xiv

Page 15

Chapter 1 Introduction

Bird Diagnostic System (BDS)

The Bird Diagnostic System (BDS) is a broadband (1 MHz to 500 MHz) RF monitoring and diagnostic system designed

to be used in a 50 or non-50 ohm environment. It is comprised of three components:

• In-line RF sensor

• A receiver that processes the real-time sensor data

• A cable that connects the sensor to the receiver

The sensor, which consists of passive, temperature stable components, is inserted into an RF delivery system where

it couples voltage and current signals and sends that data to the receiver through the cable assembly. The receiver

converts the incoming analog signal to digital data and then processes the data and makes it available to the communication port. The user’s system communicates with the receiver through the communication port.

There are two modes of operation:

• Standard Tracking Mode

• Spectral Search (Sweep) Mode

In both operating modes, there are two data monitoring modes:

• Low resolution data monitoring (8 bit ADC)

• High resolution data monitoring (12 bit ADC)

The BDS also has the capability to locate arc transients. These operating modes are explained in the following sections.

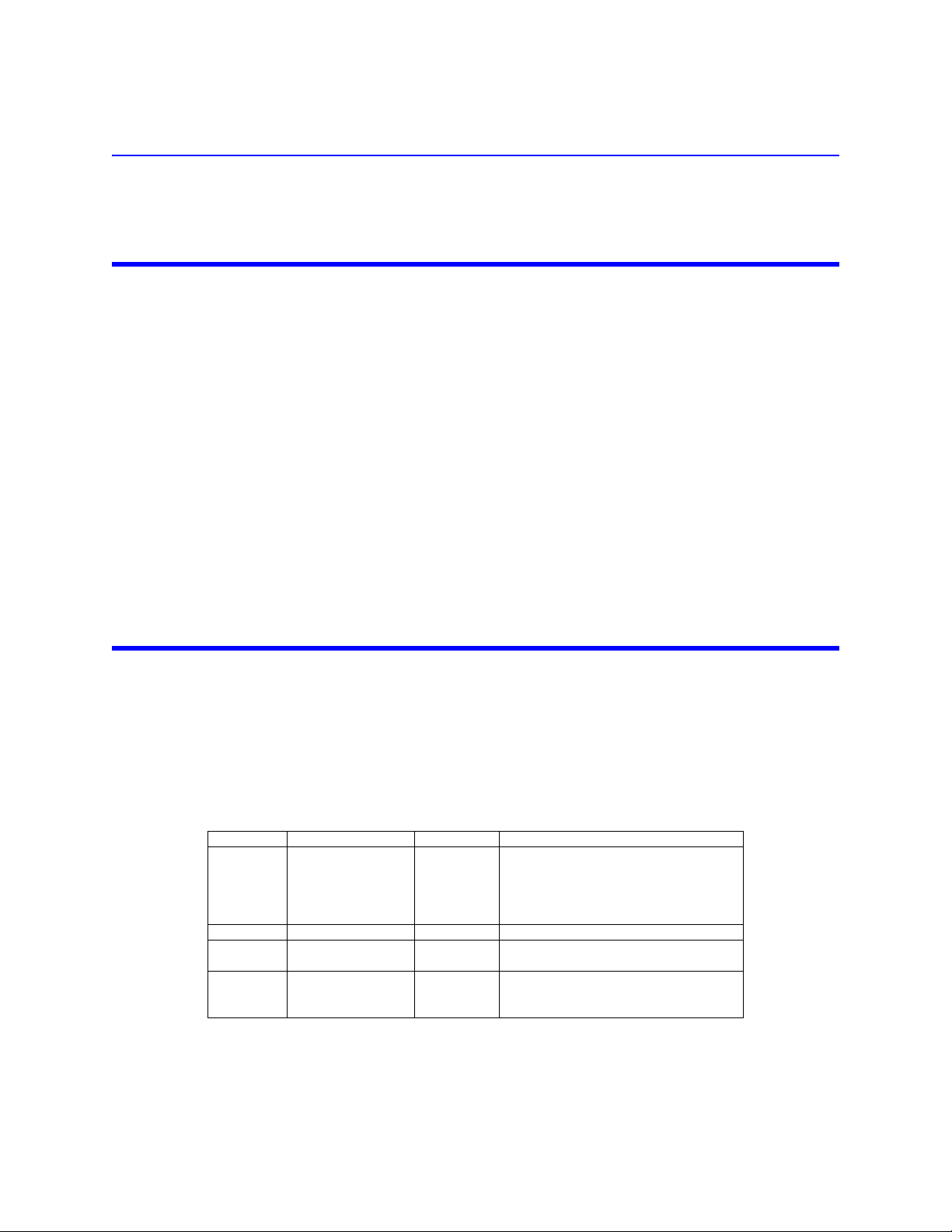

Standard Tracking Mode

In the Standard Tracking mode, the BDS collects voltage and current information for user specified fundamental frequencies. Up to five fundamental frequencies can be specified to monitor. For each fundamental frequency, up to 15

harmonic frequencies can also be monitored (in addition to the fundamental) and a subset of up to 6 mixing products can also be monitored. The BDS reports voltage amplitude, current amplitude, and phase information as a data

set for each specified fundamental frequency.

Example - Select 2 MHz as the first fundamental frequency (F1) and 13.56 MHz as the second fundamental frequency (F2), and specify two harmonics for F1 (H1 and H2) and one harmonic for F2 (H1), the results

would be grouped as a set for each fundamental frequency as shown in the following table (note that H0 is

the same as the fundamental frequency and that N represents the N

Dataset Fundamental Harmonic Data

1 F1 (2MHz) H0 (F1) 2.0MHz, V,I,phase

F1 (2MHz) H1 (2F1) 4.0MHz, V,I,phase

F1 (2MHz) H2 (3F1) 6.0MHz, V,I,phase

F2 (13.56MHz) H0 (F2) 13.56MHz, V,I,phase

F2 (13.56MHz) H2 (3F2) 40.68MHz, V,I,phase

…… … …

N F1 (2MHz) H0 (F1) 2.0MHz, V,I,phase

F1 (2MHz) H1 (2F1) 4.0MHz, V,I,phase

F1 (2MHz) H2 (3F1) 6.0MHz, V,I,phase

F2 (13.56MHz) H0 (F2) 13.56MHz, V,I,phase

F2 (13.56MHz) H2 (3F2) 40.68MHz, V,I,phase

:

th

data set).

1

Page 16

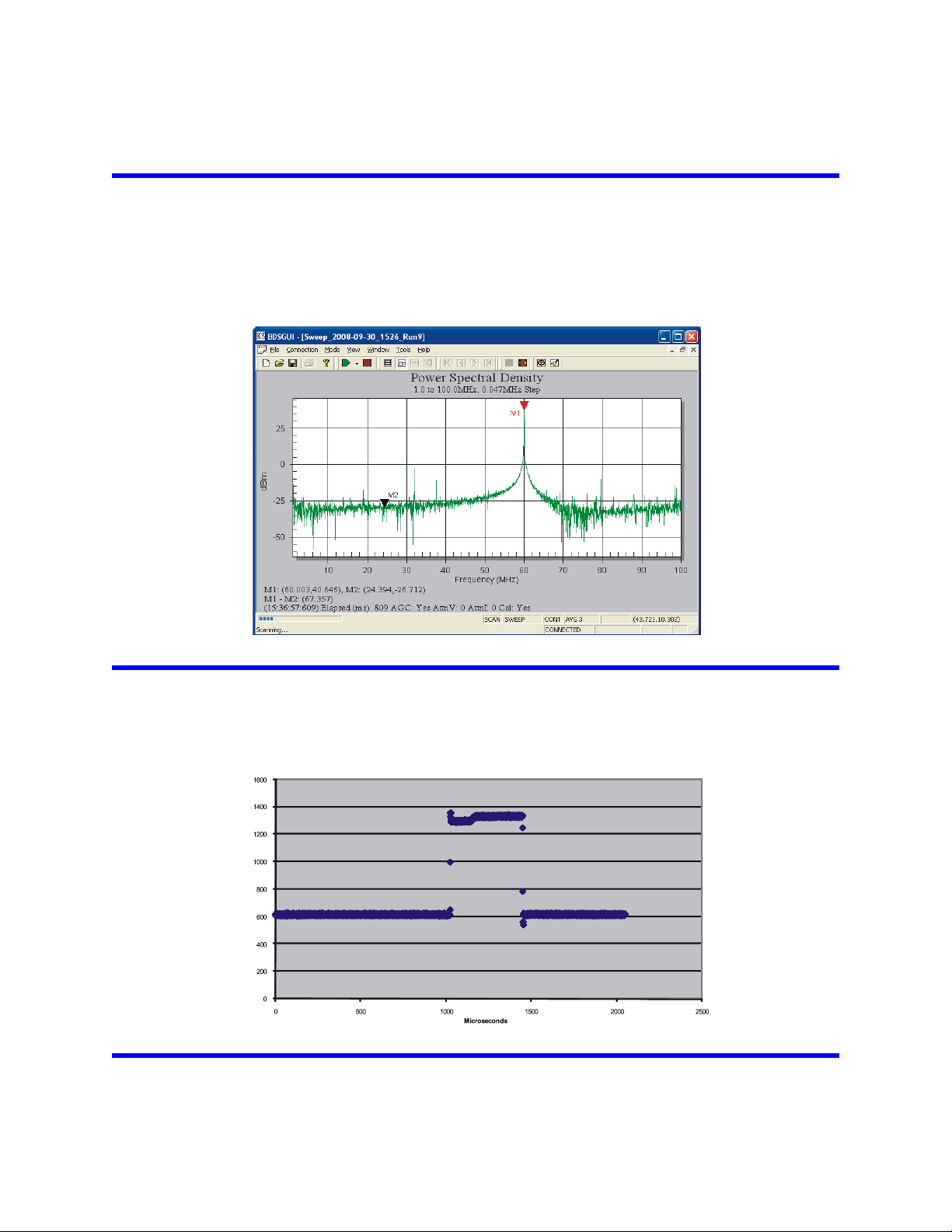

Spectral Search (Sweep) Operating Mode

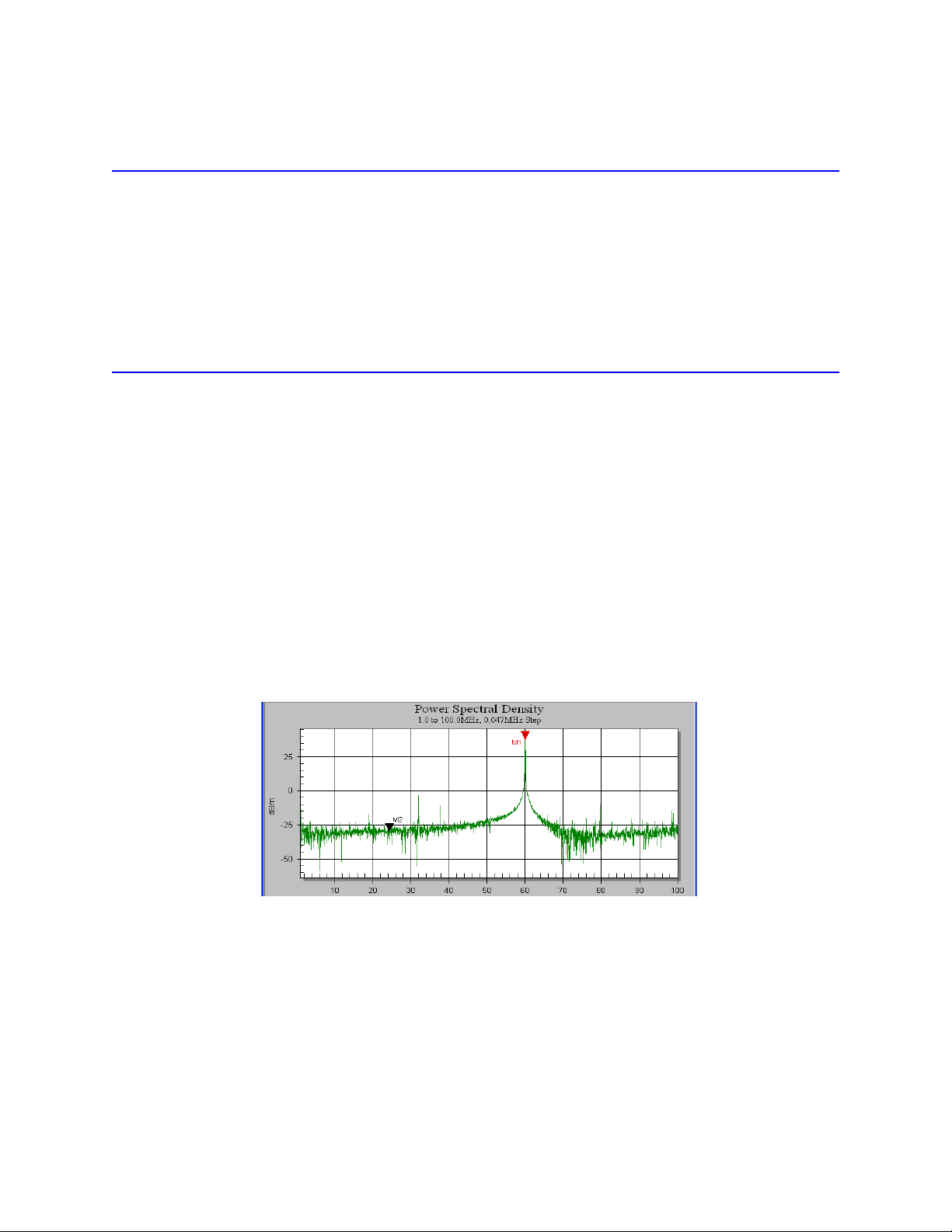

The Spectral Search (Sweep) Mode is used to get an overall view of the spectral components in a given frequency band. It

sweeps across a frequency band, from start to stop frequency, displaying the amplitude at each frequency step.

The user defines the frequency band by entering a start frequency, a stop frequency, and a step increment. The BDS

produces power spectral density information for each detected frequency in the band in accordance with the step

increment value (Fig. 1).

Figure 1 Spectral Search (Sweep) Operating Mode

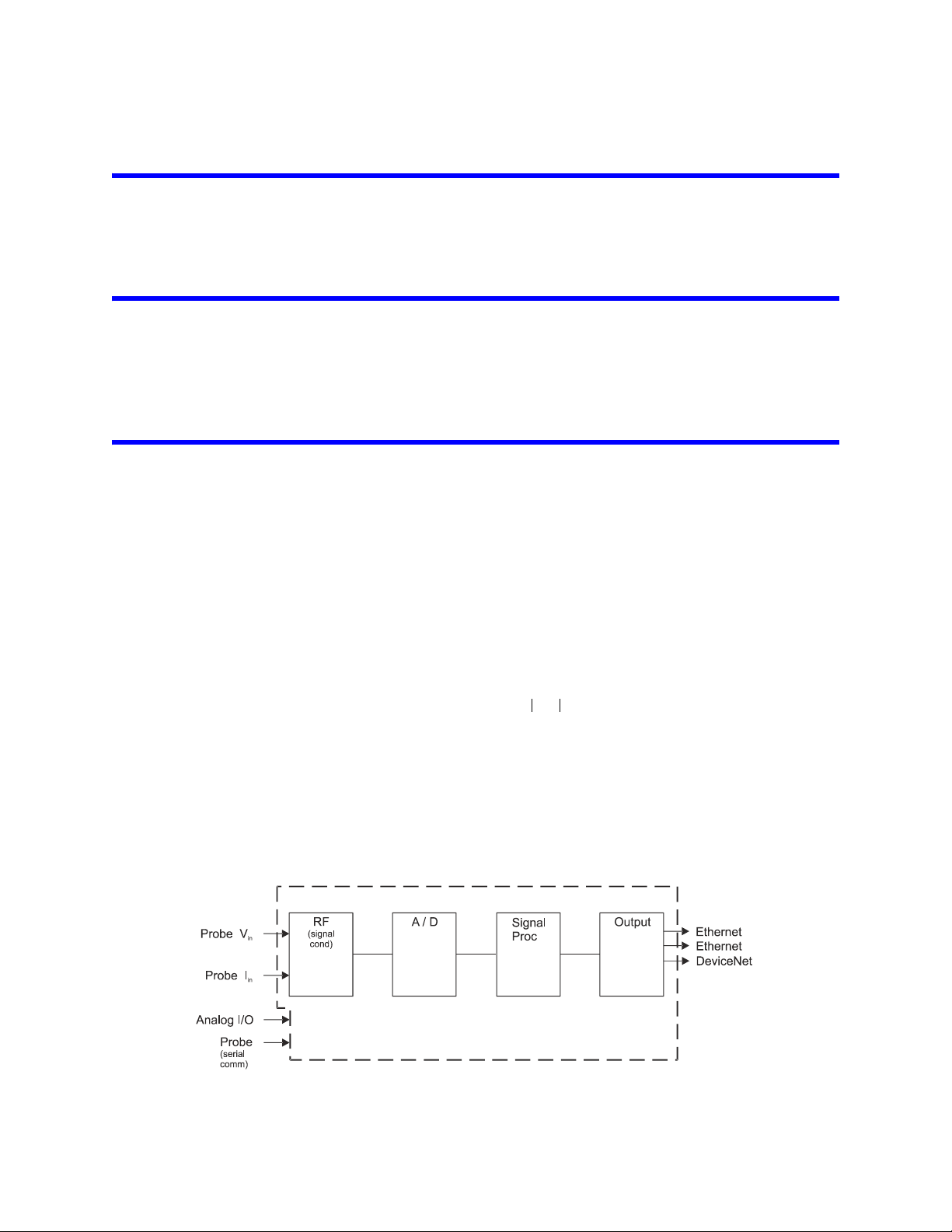

Arc Detection

The BDS has the ability to locate and report arc/transient events. The user can define the parameters of what a transient

may look like in their system, specifying arc length, and impulse change in dB. This feature is available in both Standard

Tracking and Spectral Search modes and in both 12-bit and 8-bit resolution.

Figure 2 Typical Arc Detection Image

.

BDS Sensors

The BDS requires a non-intrusive passive RF sensor. The sensor is purchased separately based upon the specifications of the end user’s requirements.

2

Page 17

Items Supplied

p vi θcos××=

Z vi÷θ∠=

• Receiver unit

• Instruction Manual

• BDS GUI Software

Communication Options

The Bird Diagnostic System offers the following methods of communication:

• BDS GUI

• DeviceNet

• Customer defined

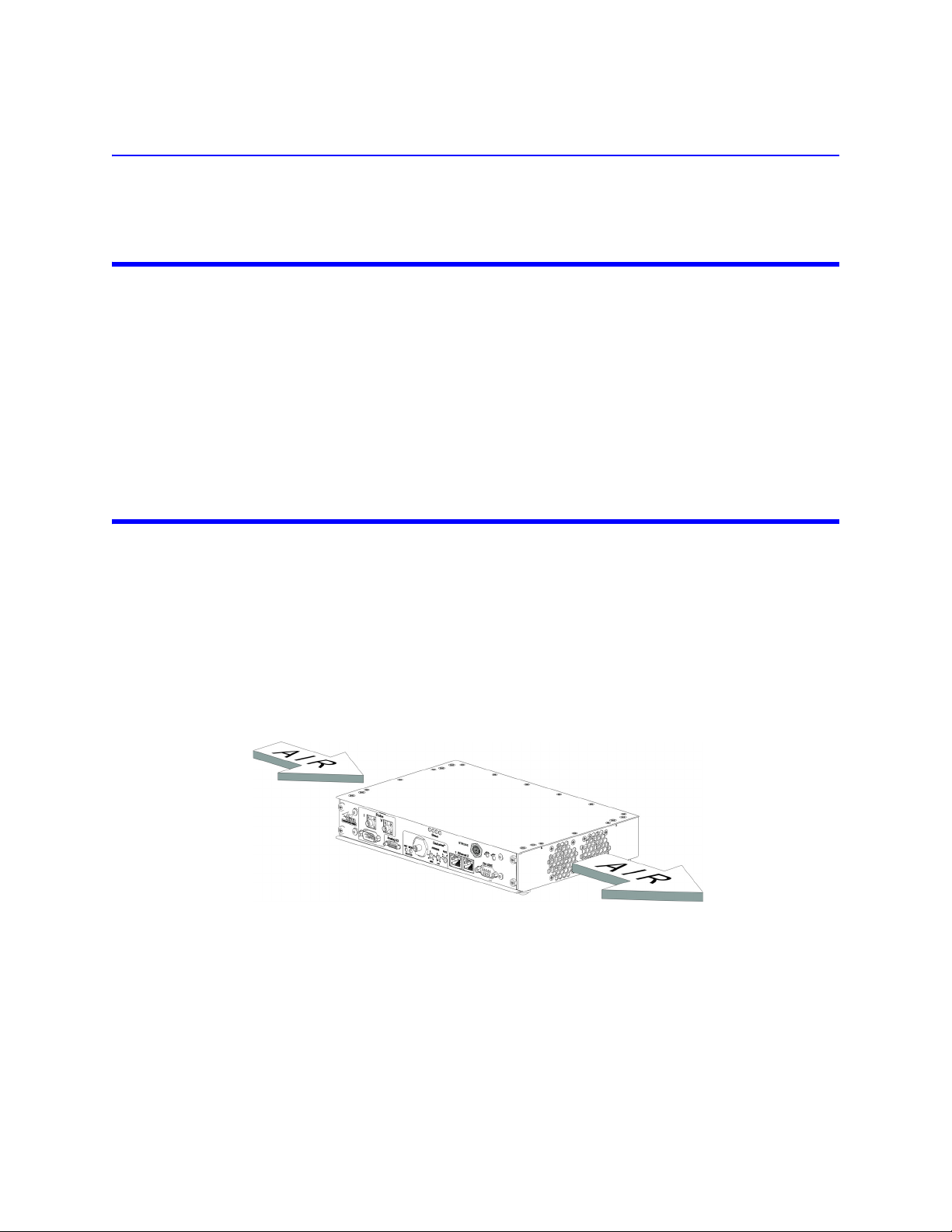

Theory of Operation

The Bird Diagnostic System (BDS) is a real-time RF measurement system that consists of a sensor, a sensor cable, and a

receiver. The sensor is mounted in the host system’s RF delivery system where it simultaneously measures voltage and

current (both magnitude and phase of each) and sends the data to the receiver. Each component of the BDS (sensor,

sensor cable, receiver) is calibrated separately and contains its own calibration constants which permits interchangeability without recalibration. A sensor, sensor cable, or receiver can be replaced with minimal loss of accuracy.

The receiver processes the sensor data and makes it available to the communication ports. The receiver consists of RF input

conditioning circuits, A/D converters, a high-speed signal processor, and input / output connectors (Figure 3, page 3).

The A/D converters convert the analog RF signal to digital information for processing; the high-speed signal processor converts the signal from the time domain to the frequency domain while maintaining the correct phase relationship of each harmonic to its fundamental frequency.

The output of the BDS contains information about the RF including up to five fundamental frequencies (amplitude of

both voltage and current and their phase for each fundamental frequency) and up to 15 overtones for each fundamental frequency (amplitude of both voltage and current and their phase for each harmonic, and also the phase relationship of each harmonic to the voltage component of its specific fundamental frequency). With this data set (voltage,

current, and phase), power ( ) and impedance ( ) can be determined for each fundamental and harmonic frequency.

Users can choose number of fundamental frequencies (up to five) and associated harmonics (up to 15 for each fundamental frequency) that are acquired and processed. Choosing a small number of fundamental and harmonic frequencies reduces the computing time and, therefore, provides output data faster than choosing a larger number of

fundamental and harmonic frequencies. See “Frequency Tracking” on page 40.

The host system can communicate with the BDS receiver through any of the methods outlined in Communication

Options, page 3.

Figure 3 Bird Diagnostic System Block Diagram

3

Page 18

4

Page 19

Chapter 2 Installation

Unpacking and Inspection

1. Carefully inspect shipping container for signs of damage.

2. Do one of the following:

• If the shipping container is damaged, do not unpack the unit. Immediately notify

the shipping carrier and Bird Electronic Corporation.

• If the shipping container is not damaged, unpack the unit. Save shipping materi-

als for repackaging.

3. Inspect unit for visual signs of damage.

Note: If there is damage, immediately notify the shipping carrier and Bird Electronic Corporation.

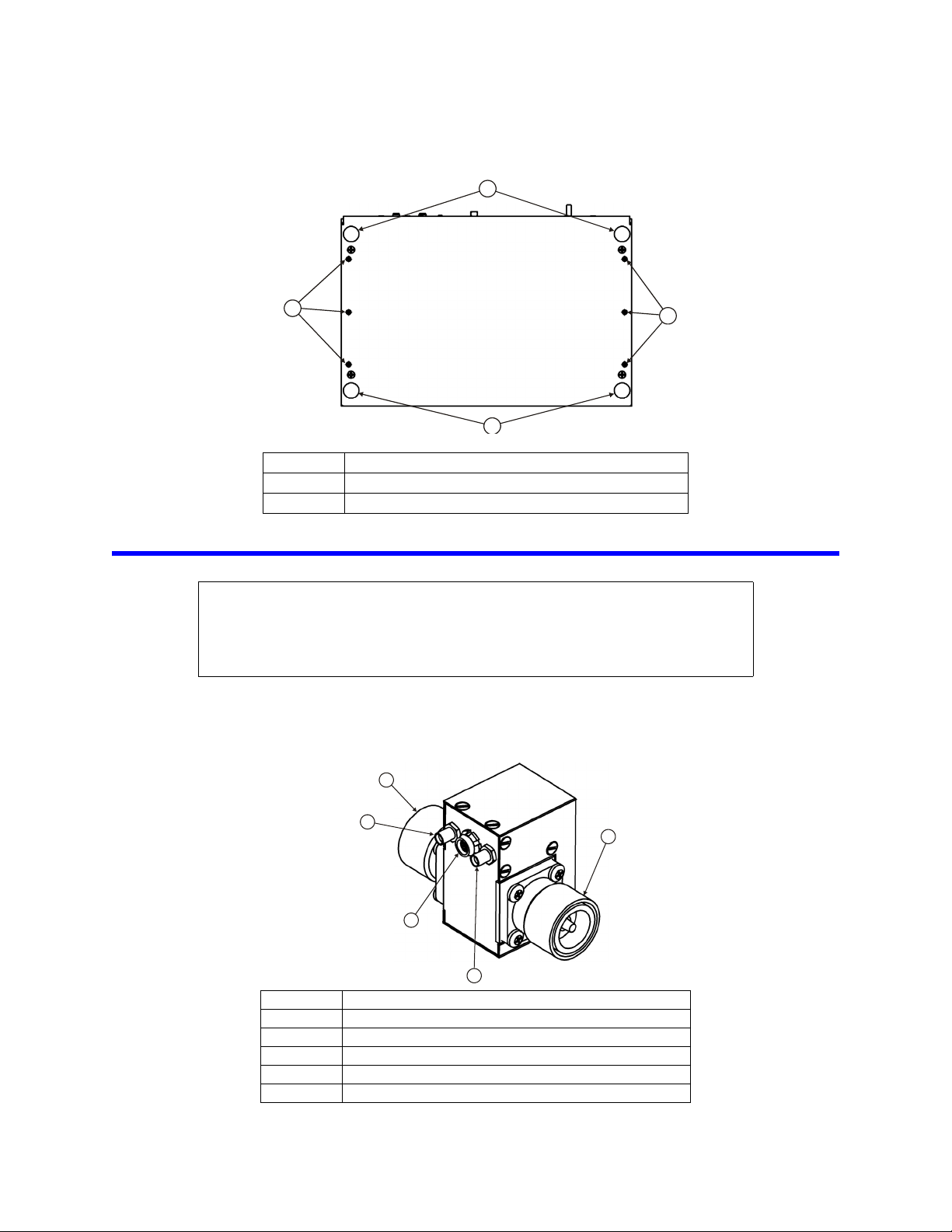

Installing the Receiver

The receiver has cooling fans inside and air vents on both ends of the case. For proper operation, be sure to install

the receiver in a location that permits free air flow around and through the unit (Figure 1).

Place the receiver in a suitable location within the length of the cables from the sensor. The receiver can be installed

free standing or secured in place using the six mounting holes in the bottom of the case. To secure the receiver in

place, first remove the four rubber feet then secure the unit using 6-32 screws that will not extend inside the

receiver case more than one inch (1.0 in or 25.4 mm). (Figure 2).

The BDS receiver requires an external +24 V DC power source for operation. The operating voltage is supplied

through the Power In +24V connector located on the reat side of the reciever.

Figure 1 Receiver Air Flow Path

5

Page 20

Figure 2 BDS Receiver Mounting Holes

1

1

2

2

1

2

5

3

4

Note: Standard BDS

sensor shown.

Item Description

1 Mounting feet, rubber

2 Mounting holes, 6-32 threaded

Installing the Sensor

Bending RF cables can cause damage. When routing RF cables, the minimum

bend radius is 2 inches (25.4 mm). Do not bend the cables more than the

minimum bend radius. Failure to comply may result in permanent damage to the

CAUTION

cable and reduced equipment performance.

1. Connect the sensor RF In connector to the feed side of the host RF source cable.

2. Connect the sensor RF Out connector the load side of the host RF source cable.

Figure 3 Sensor Cable Connections

Item Description

1 RF output connector

2 RF input connector

3 Current connector, SMA standard polarity

4 Temperature / data connector, 7 pin

5 Voltage connector, SMA reverse polarity

6

Page 21

Connecting the Sensor and Receiver Cables

1. Connect the current and voltage cables to the sensor (Figure ).

2. Torque the SMA connectors to 1.55 Nm (±0.15 Nm).

Note: The SMA connector on the current sensor cable has a standard center

conductor and the SMA connector on the voltage sensor cable has a reverse

polarity center conductor.

3. Connect the temperature/data cable to the sensor.

4. Connect the current and voltage data cables to the receiver (Figure on page 7).

Torque the SMA connectors to 1.55 Nm (±0.15 Nm).

5. Connect the temperature / data cable to the receiver.

6. Connect the external power supply (24 VDC) to the Power connector on the rear of

the receiver. Refer to Appendix 8 for pinout data for the DeviceNet connector.

7. Apply power to the power supply and verify that the Power On LED on the receiver

lights.

8. Verify communication with the host computer.

Figure 4 Receiver Cable Connections from Sensor

Item Description

1 Current sensor connector

2 Voltage sensor connector

3 Sensor temperature / data connector (DB-9)

Installing the BDS Graphical User Interface Application

1. Run “7001A242-X_BDSGUI_setup-X.exe”.

Note: This will create a short under the start menu folder “Start Bird->Bird

Technologies Group->BDS GUI.”

2. Copy the shortcut onto the PC’s desktop (optional).

7

Page 22

8

Page 23

Chapter 3 Operating Instructions

Overview

The BDS GUI is used to configure the BDS receiver and obtain measurement data from the system. There are two

modes of operation: Standard Tracking and Spectral Search. In addition, the BDS provides arc/transient detection

capability that is available in both operating modes.

There are two sampling resolutions for all modes: 8-bit, 1G sample/second, and 12-bit, 200M sample/second.

• The 12-bit sampling mode allows for a 1-100 MHz tracking range with a wider dynamic range, higher accu-

racy, and better repeatability than the 8-bit mode.

• The 8-bit mode allows for a wider tracking range of 1-500MHz at the expense of narrower dynamic range

and less repeatability as compared to 12-bit mode.

The BDS accurately measures voltage (V), current (I) and phase (P) in both Standard Tracking and Spectral Search operating

modes. The BDS GUI uses these three basic parameters to derive other quantities such as power and impedance.

Setting Up the BDS

Configuring Network Settings

Note: These instructions apply to a Windows XP PC.

1. Connect an Ethernet cable to Port 1 on the BDS receiver front panel.

2. Select “Start->Control Panel->Network Connections” from Windows XP

3. Double-click your local area connection and click the "Properties" button.

4. Scroll down and double-click "Internet Protocol (TCP/IP)".

5. Select "Use the following IP address".

6. Enter the following settings:

• IP address: 192.168.0.100

• Subnet mask: 255.255.255.0

• (Gateway is ignored)

7. Click the "OK" button for the "Internet Protocol (TCP/IP) Properties" dialog.

8. Click the "OK" button to apply the connection properties.

Note: The BDS Web UI can reconfigure its network settings, such as reassigning IP addresses, defining a domain name, and enabling DHCP. Refer to the BDS

“Quick Start Guide” for instructions on the BDS Web UI.

Restoring PC Network Connection to Use DHCP

1. Follow steps 1-3 above.

2. Select "Obtain an IP Address Automatically".

3. Click the "OK" button for the "Internet Protocol (TCP/IP) Properties" dialog.

4. Click the "OK" button to apply the connection properties.

9

Page 24

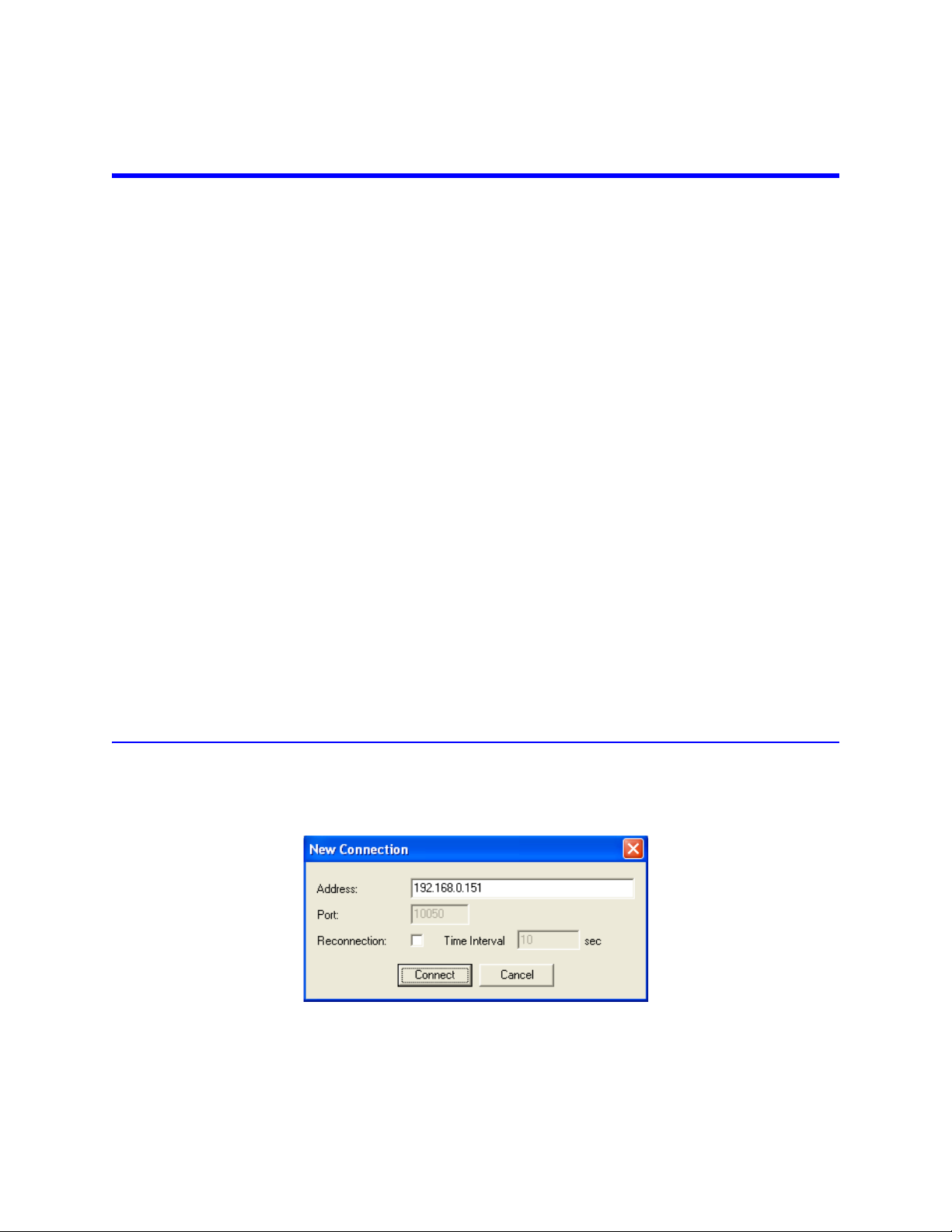

Establishing a Connection to the BDS Receiver

These instructions cover connecting to the receiver using a direct PC-to-receiver Ethernet connection on port 1 (left port).

1. Connect an Ethernet cable connected from the PC to port 1 on receiver.

Note: It does not have to be a crossover cable, the BDS will auto-negotiate the

hardware.

2. Apply power to the BDS receiver.

3. Confirm that the yellow LED (the one on right) of port 1 is illuminated.

4. Wait for the BDS to finish booting.

Note: The four status LED’s on the front panel will all turn green when the BDS

is ready (GGGG).

Note: If there is not a probe connected, the following pattern will be displayed:

GGGY. Any other pattern indicates a possible system failure. See “Status LEDs”

on page 13 for more information.

5. Using the BDS GUI, Select “Connection->New…” from the main menu.

6. Enter the following IP address of port 1 in the “Address:” field: 192.168.0.151

7. Click the “Connect” button.

Note: “CONNECTED” should be displayed in the left-most indicator field of the

main status bar at the bottom of the application window.

Note: The BDS GUI will save your connection settings as defaults. If disconnected from the receiver, a connection can be reestablished by either clicking the

“Connection” icon, using “Connection->Open”, or simply by starting a data

acquisition. This also works on subsequent launches of the BDS GUI application.

For more information see the "Connection Options" on page 10.

There are two modes of operation with the Bird GUI: Standard Tracking and Spectral Search (Sweep). In addition, the

BDS also has arc detection capability that is available in both operating modes. In all modes data is captured in 12-bit

hi-resolution (Hi-res) or in 8-bit low-resolution (Low-res).

Connection Options

The BDS GUI communicates with the receiver over Ethernet. In order to establish a connection to the BDS receiver you

first need to make sure that the receiver must be on the subnet (it has an IP address that is addressable by the PC).

Figure 1 Connection Dialog

Address - The IP address or host name of the BDS receiver.

Note: Default IP addresses:

•Ethernet Port 1 (left): 192.168.0.151

•Ethernet Port 2 (right): 10.10.0.29

10

Page 25

Port - The TCP/IP socket port (always 10050).

Reconnection - Mark this checkbox to have the BDS GUI automatically reconnect when it loses connection with

the receiver or if a connection fails.

Timer Interval - The time in seconds to wait before the next reconnection attempt is made.

Connect button – Establishes a connection with the receiver at the given address. Closes the dialog and saves the

settings to the system registry.

Cancel button – Exits the dialog without applying the connection.

Applying Power

The Bird Diagnostic System receiver requires an external customer supplied 24 VDC power source capable of delivering 1 amp. DC power is delivered through the Power In connector.

11

Page 26

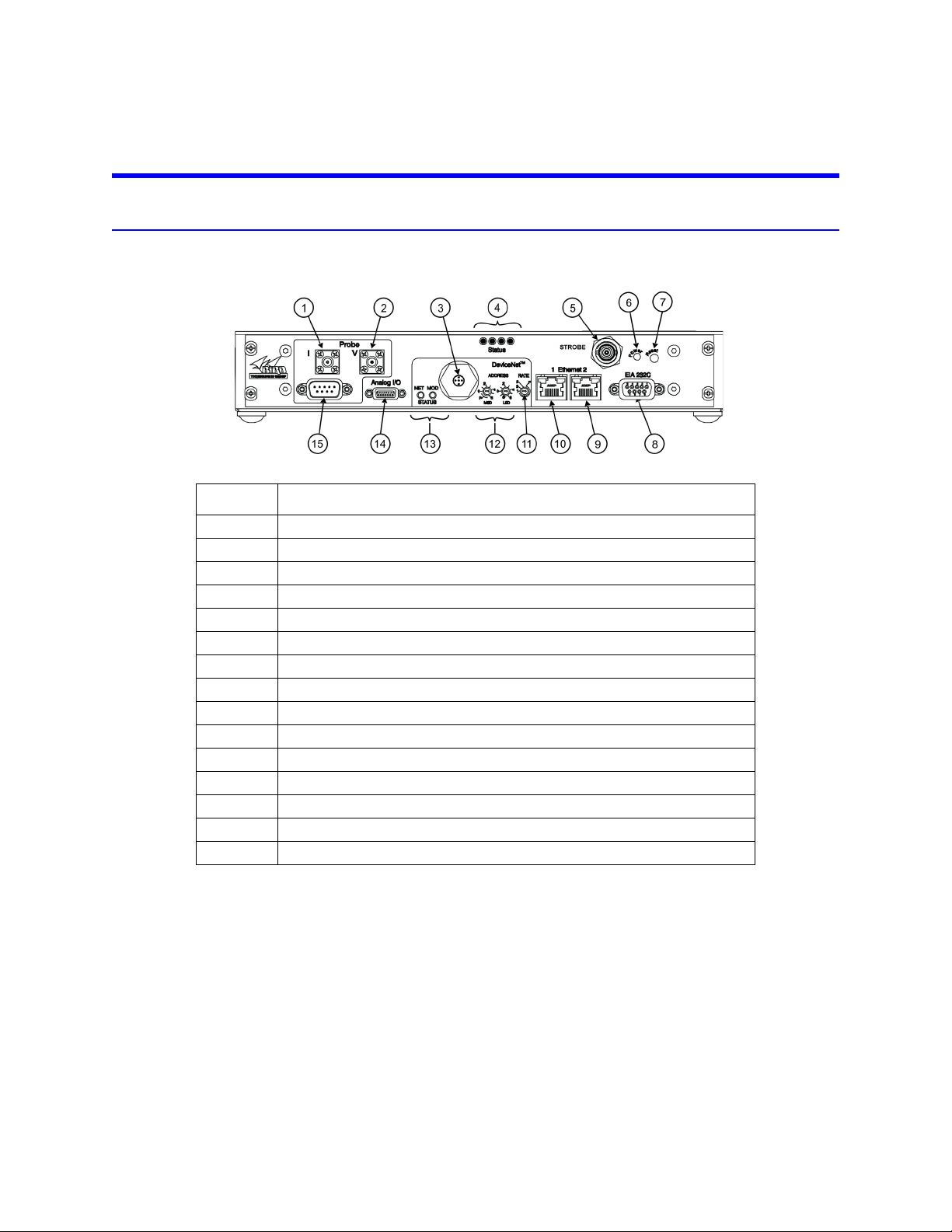

Controls and Indicators

Connector Panel

Figure 2 Connector Panel

Item Description

1 Current sensor connector

2 Voltage sensor connector

3 DeviceNet connector

4Status LEDs

5 Strobe Connection

6 Power LED

7 Reset Button

8 RS-232 connector (DB-9)

9 Ethernet Connection (Port 2)

10 Ethernet Connection (Port 1)

11 Devicenet buad rate switch (not available on all models)

12 Devicenet address switches (not available on all models)

13 Devicenet status LEDs (not available on all models)

14 Analog I/O connector (DB-15)

15 Sensor temperature / data connector (DB-9)

12

Page 27

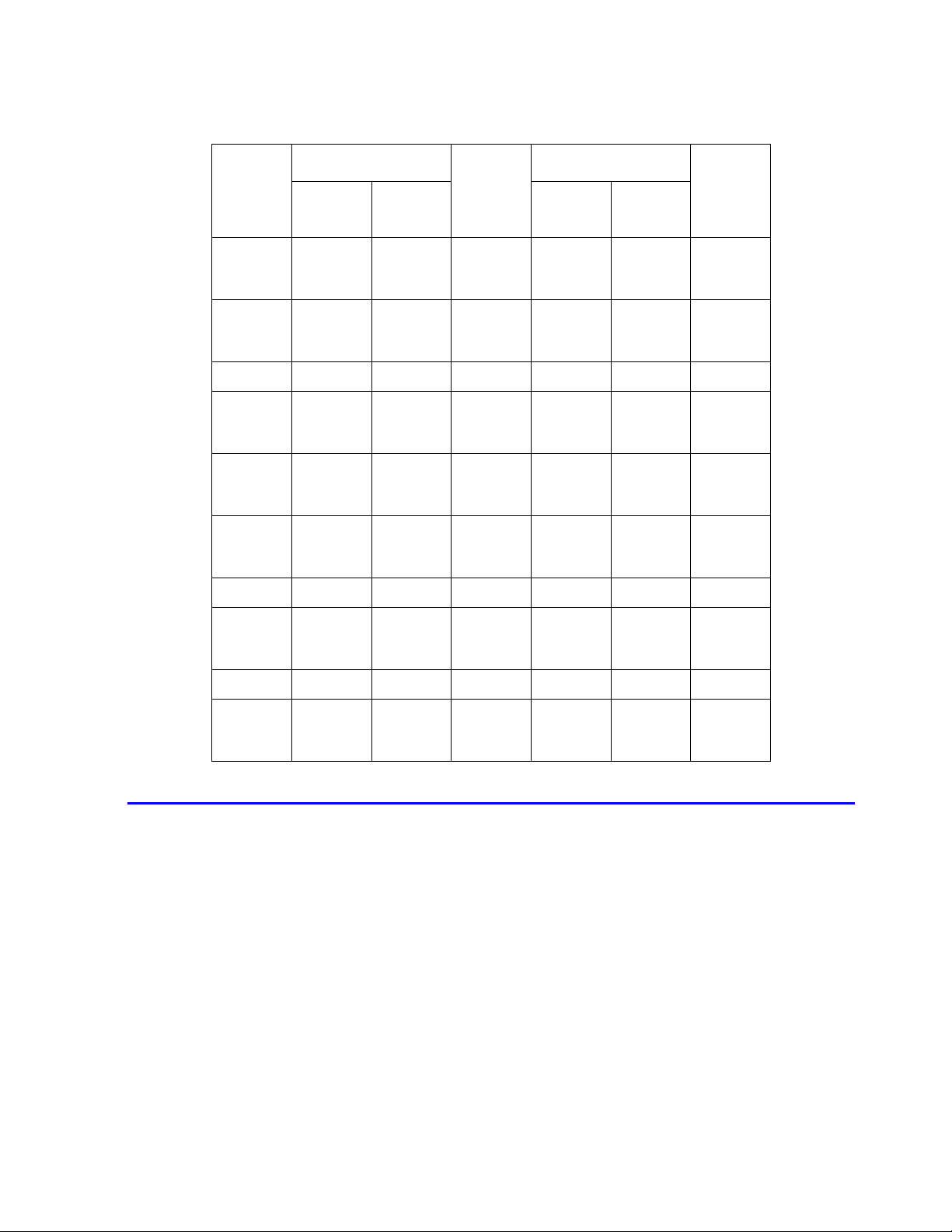

Status LEDs

The receiver has four status LEDs. Each LED can have four conditions, off (O), on green (G), on yellow (Y), and on red

(R). The four letters in the LED code column are arranged left-to-right as viewed on the instrument. The letters indicate the condition of each LED. The meaning of the code is in the description column.

Code Description

OOOO No power applied

RRRR CPU Exception to unknown vector

OROR RAM Failure

ORRO Bootloader checksum failure

ORRR Kernel Failure

OOOR CPU Fault - Illegal instruction

OORO CPU Fault - Address error

OORR CPU Fault - Unimplemented A-line

OROO CPU Fault - Unimplemented F-line

YYOO Bootloader RAM test pass

YYYO Bootloader loaded

YYYY Bootloader running

GYYY Operating system loaded

GGYY Operating system running

GGGY Main applications running, but calibration data has not

been loaded (the probe is disconnected).

GGGG System is ready with all components connected and

all calibration data loaded.

YGGY Loading FPGA image.

RYYY DSP Error – general or initialization failure.

YRYY DSP error – DCM lock failure.

YYRY DSP error – PLL lock failure.

YRRY DSP error – heartbeat flat-line. DSP stopped

producing data.

YYYR Fatal application software error – unrecoverable

exception caught.

RYRY Fatal application software error – assertion failure.

YRYR Fatal application software error – segmentation fault.

YYRR Fatal application software error – bus error.

13

Page 28

BDS GUI Interface Detail

Menu Bar

File

Provides standard file operations for opening and saving BDS Documents.

New – Creates a new BDS document.

Note: The new document will inherit the properties of the previous document, including measurement and

scan options.

Open… - Opens a BDS document from a file.

Note: This will currently open “BDS Capture Files” and not CSV files.

Close – Closes the active document.

Note: This will stop data acquisition (if running).

Save – Saves the active BDS document in the previously selected format (BDS or CSV).

Note: This will stop data acquisition (if running).

Save As… Saves the active BDS document in a number of formats. See Figure 3.

Note: This will stop data acquisition (if running).

Recent Document List - List of recently opened documents.

Exit – Closes the BDSGUI application.

Note: Automatically stops data acquisition and disconnects from the BDS receiver.

Figure 3 Save As Menu Option

Connection

New… - Displays the “Connection Options” dialog (see Connection Options).

Close – Closes the current connection to the BDS receiver.

Mode

Offers menu items for configuring and operating a Mode. This menu is context-sensitive to the currently active

mode (Tracking or Spectral Search).

Start Free Run / Start Sweep – Starts an acquisition.

Start Trigger – Starts an acquisition based on an event trigger (Tracking Mode only).

14

Page 29

Stop – Stops data acquisition.

Halt Mode – Stops the BDS measurement process for the active mode.

Switch To->Tracking Mode – Changes the active mode to Standard Tracking Mode.

Switch To->Spectral Search Mode – Changes the active mode to Spectral Search (Sweep) Mode.

Gain Ctrl… - Displays the “Gain Control” dialog (see Gain Control Options).

Options… - Displays the options dialog for the active mode.

View

Offers menu items for selecting a new view of a BDS document, configuring a view, or showing toolbars. The menu is

context-sensitive to the currently active mode (Tracking or Spectral Search).

Standard Tracking Mode View Menu Items:

Table – Display the document data in tabular format.

Time Plot – Display the document data plotted on a graph over time.

Waveform – Show the most recent dataset as a reconstructed waveform.

Note: Relative phase information must be requested to display data in this view. Relative phase is

requested by selecting the “Enable relative phase measurements” option in the Standard Tracking Mode

options.

Dataset… - Display the “Dataset Number” dialog, allowing the user to show data for a single measurement.

Spectral Search Mode View Menu Items:

Peaks – Display a table of peaks that have been located in the sweep data.

Sweep – Display amplitude over frequency.

Markers… - Display the “Markers” dialog, allowing the user to enable/disable markers and set their positions on

the graph.

View Menu Items Shared between both Operating Modes:

Toolbars – Display or hide the various toolbars.

Status Bar – Display or hide the main status bar.

Options… - Launch the “Display Options” dialog (see Display Options).

Window

Presents standard window menu options.

New Window – Creates a new View window from the active window.

Cascade – Aligns windows on top of one another.

Tile – Aligns windows in a tile pattern so that no windows overlap.

Arrange Icons

Active Window

Tools

Provides some supplemental applets.

Arc Data Viewer… - Displays the “Arc Detect Data Archive” dialog, allowing the user to download Arc Detect cap-

ture files that are stored on the receiver.

Help

Show Help – Shows this help document.

About - Displays the “About” dialog, showing the application version and date information.

15

Page 30

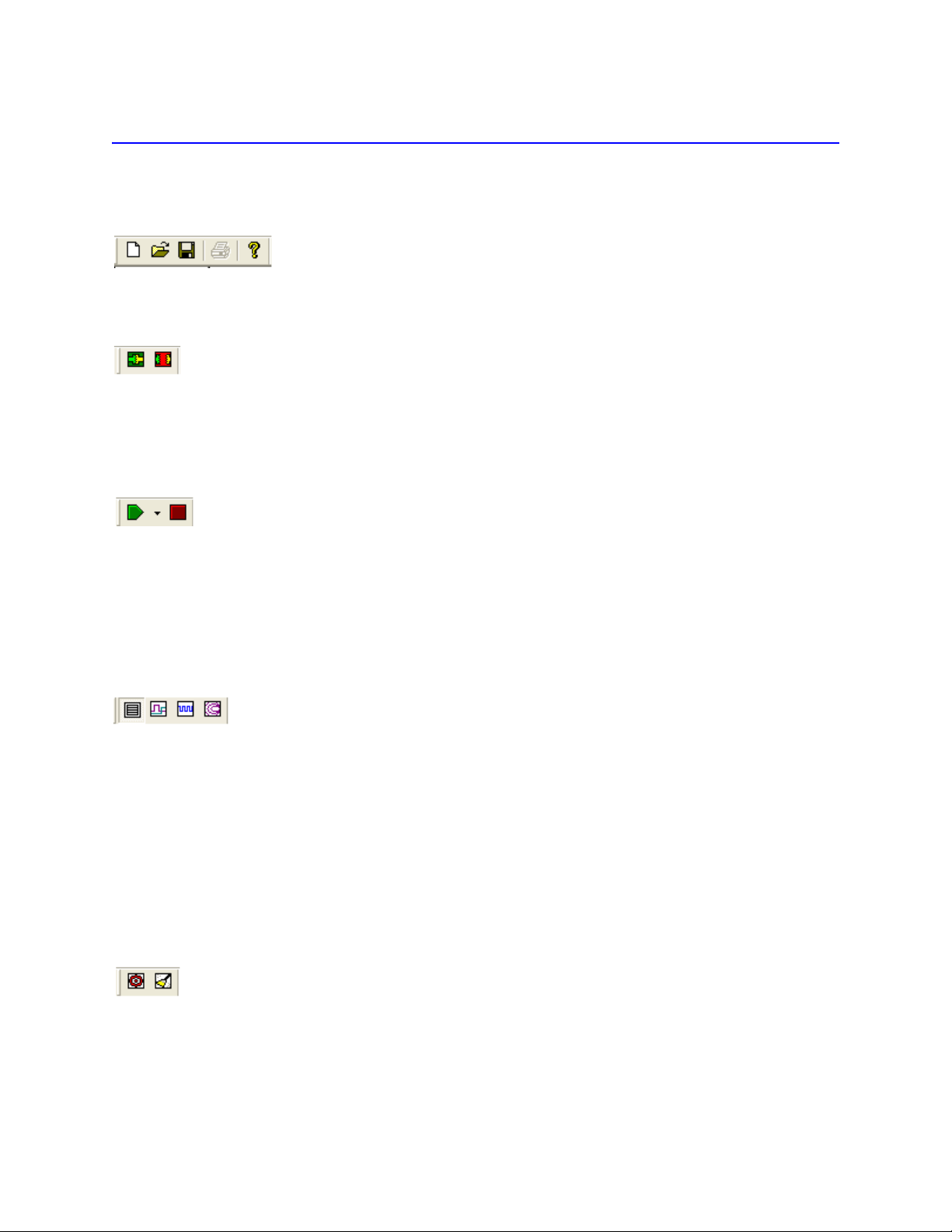

Toolbars

Toolbar icons are described from left to right.

Standard

Standard Windows file save and load buttons.

Connection

Connect – Click the green button on the left to connect to the BDS receiver using the IP Address of the receiver

saved in the system registry.

Disconnect – Click the red button on the right to close your connection to the BDS receiver.

Scan

Start Button – Starts a new data acquisition (Free Run, Trigger, or Sweep). Pressing the green button will start the

data acquisition, or selecting from the drop-down arrow will start a specific scan mode.

Note: This has the same functionality as the “Mode->Start” menu items.

Stop Button – Pressing the red button will stop data acquisition.

Note: This has the same functionality as the “Mode->Start” menu items.

Graph

Table – Press the left button to show the document data in tabular format.

Time Plot – Press the middle-left button to show the document data plotted on a graph over time.

Note: That this will display a “Sweep View” if in Spectral Search mode.

Waveform – Press the middle-right button to show the most recent dataset as a reconstructed waveform.

Note: This view does not apply while in Spectral Search mode.

Smith Chart – Press the right button to show collected data as a Smith chart. Smith chart data is plotted normal-

ized to 50 Ohms.

Note: This view does not apply while in Spectral Search mode.

Options

Standard Tracking Mode Options –Press the red reticule icon the left to display the Standard Tracking Mode

options dialog.

Spectral Search Mode Options –Press the broom icon on the right to display the Spectral Search (Sweep)

Mode options dialog.

16

Page 31

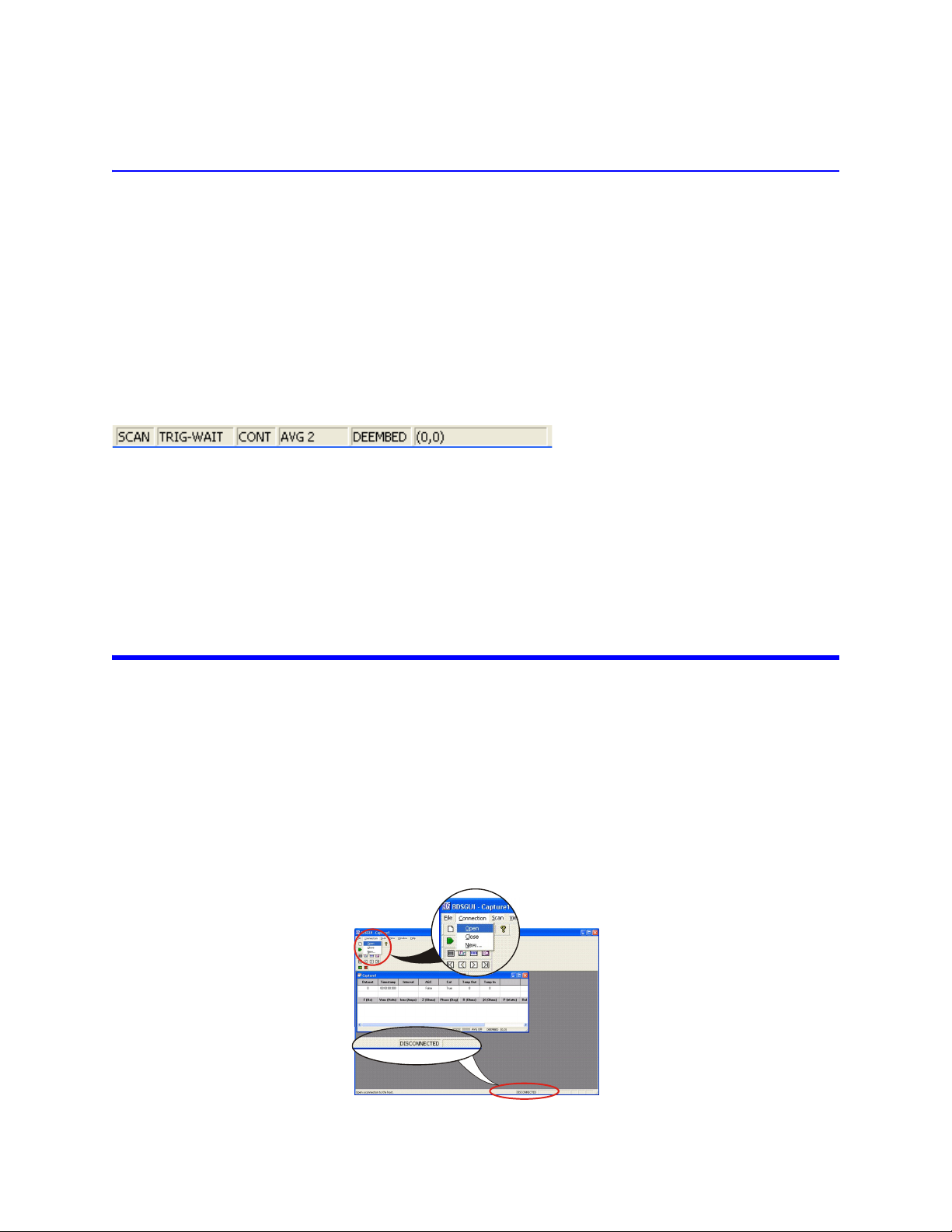

Status Bars

Main

The main status bar is a standard window status bar displaying a status message (to the left) and keyboard indicator

fields (CAP, INS, NUM).

In addition to the standard keyboard indicators, this status bar also displays the connection status and input overload conditions.

• If the BDSGUI is connected, then “CONNECTED” is displayed in the left-most indicator field,

• If the BDSGUI is not connected, then “DISCONNECTED” is displayed.

• When an overload condition is detected on the voltage and/or current channel, then “OVERLOAD” is dis-

played in the indicator field to the right of the connection indicator.

View

Each view window has it’s own status bar. The view status bar has five indicator fields (from left to right):

Scan – Displays “SCAN” if the document is collecting data from the BDS. Empty if not collecting.

Scan Mode – Displays the current scan mode for the document – “FREE”, “TRIGGER”, or “SWEEP”.

Continuous – Displays “CONT” while collecting data in “Continuous Scan” mode.

Cal Requested – Displays “CAL” if corrected readings are requested for this document. Empty if non-corrected

readings are requested.

De-embedding – Displays “DEEMBED” if impedance de-embedding is enabled for this view. Empty if impedance

de-embedding is disabled.

Setting Up the BDS GUI Application

The BDS GUI application obtains data from the host application. To do this perform the following:

1. Ensure the all hardware is connected.

2. Ensure network connections are correct. See “Configuring Network Settings” on

page 9.

3. Select and configure an operating mode (Standard Tracking or Spectral Search

(Sweep)).

4. Select Connection>Open from the main menu.

5. Verify that CONNECTED is displayed in the main status bar at the bottom of the window.

Note: The BDS GUI will automatically connect to the host on the start of a new scan if you skip this step.

Figure 4 Connecting the BDS GUI to a Receiver

17

Page 32

Using Standard Tracking Mode

To collect data in the Standard Tracking Mode, the minimum configuration you need is to specify at least one fundamental frequency, the number of data sets to acquire, and then start a Free Run scan.

There are many settings and options available in the Standard Mode of operation.

For more information about Standard Tracking Mode options, refer to "Spectral Search (Sweep) Mode Options" on

page 34.

Setting the Minimum Configuration

Note: The minimum configuration is one fundamental frequency and no harmonics or IMD.

1. At the Main menu, select “Mode->Options…” or click the red reticule icon in the

“Options” toolbar. The Standard Tracking Mode Configuration dialog box opens.

2. Click on the “Frequency Selection” tab to bring it to the foreground.

Figure 5 Frequency Selection

18

3. Enter a frequency of choice (custom frequency) into the “Fundamental” field or

select a frequency from the list of fundamental frequencies then click the “Add>>”

button to add your selection to the Selected Frequencies list at the right.

Note: If harmonics are desired for this fundamental frequency, click on each

“H” button that represents the harmonics you desire (e.g. H1, H2, H3, H7, H12).

Note: To remove a frequency or harmonic from the Selected Frequency list,

select it then click the “<<Remove” button.

4. Add more fundamental frequencies and harmonics as desired. When you are finished adding frequencies and harmonics, click the “Apply” button.

5. Click the “Free Run” tab to bring it to the foreground.

6. In the “No. Datasets” field, enter the number of datasets to capture.

7. Do one of the following:

Page 33

• Select the “Continuous Scan” check box for the data acquisition to continue

uninterrupted.

Note: In Continuous Scan, when the specified number of data sets has been

captured, the system will discard the oldest data set and store the newest data

set (first-in-first-out method) so that you will always have the specified number

of data sets.

• Do not select Continuous Scan for the data acquisition to stop only after the speci-

fied number of data sets or after the specified Run Time expires.

8. Click the Apply button to apply the values and keep the dialog box open or click the

“OK” button to apply the values and close the dialog box.

Acquiring Fresh Data

Select "Mode->Start Free Run" from the main menu to start the data acquisition.

Note: Clicking the green Run button on the “Scan” toolbar will also start an acquisition.

Stopping the Data Acquisition

The data acquisition can be stopped by doing one of the following at any time:

• Select the "Mode->Stop" from the main menu.

• Press the red Stop button from the "Scan" tool bar.

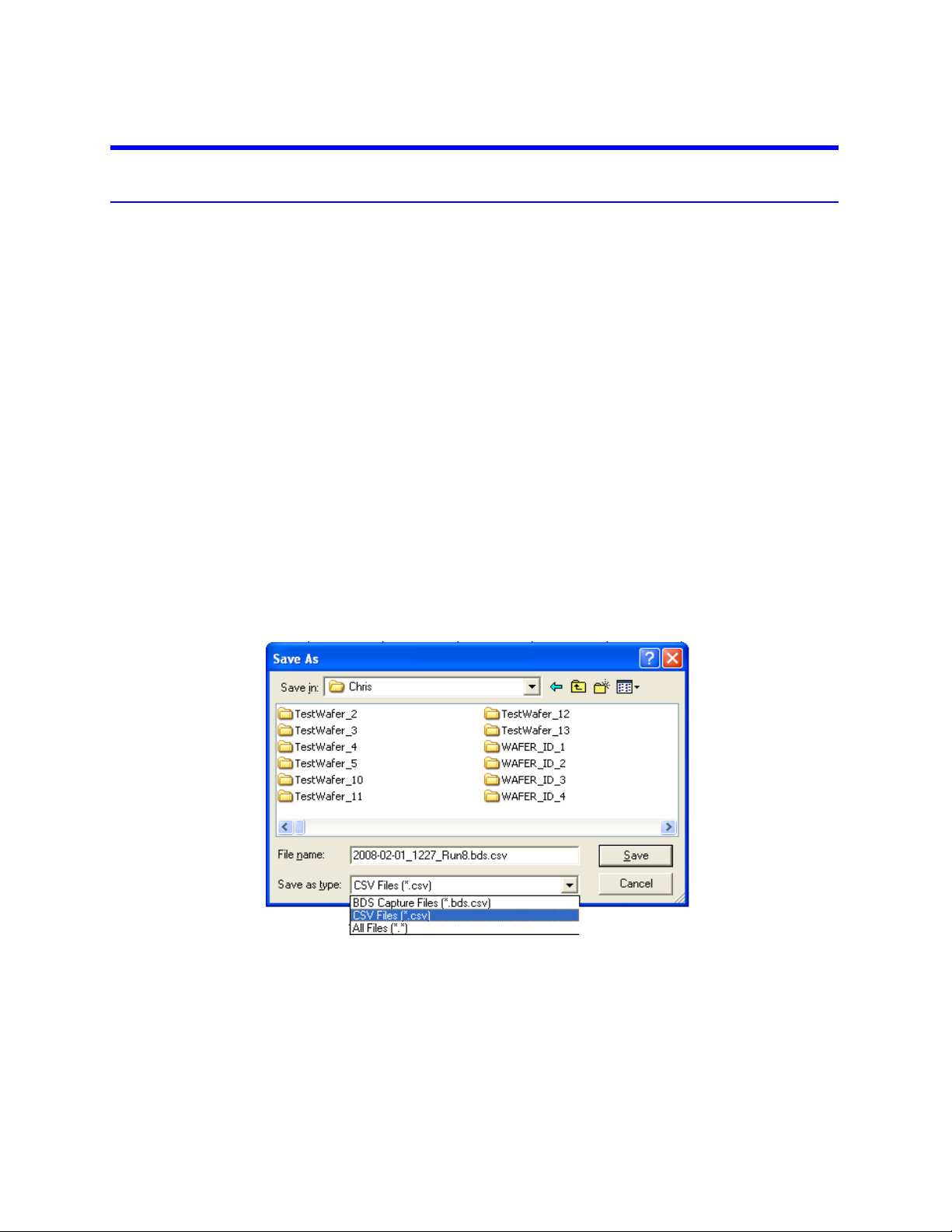

Saving the Document

Select "File->Save As…" from the main menu.

Note: If the data will be analyzed using another application such as MS Excel or MATHCAD, it’s recommended that the document is saved in the “true” CSV file format. The “true” CSV format saves the data in a

format that is more easily interpreted than the “BDS Capture Files” format.

• Select “CSV Files (*.csv)” from the “Save as type:” drop-down list.

Note: The file format can also be selected in the auto save options. Auto save options can be set up by

selecting “Mode->Options…” from the main menu.

Figure 6 Saving the Document in Standard Trackng Mode

19

Page 34

Viewing the Data

Data can be viewed while it’s being collected or after a data acquisition completes. The data is displayed in the following formats:

• Table

• Time plot

• Reconstructed waveform

• Smith chart

These views can be accessed and switched at any time by:

• Selecting a different view using the buttons on the View tool bar (Figure ).

• Right-clicking anywhere on a view and choosing from the pop-up menu.

• Selecting View and your choice from the main menu.

Note: View options are available by selecting “View->Options…” from the main menu or by right clicking

anywhere on a view and selecting “Options…” from the pop-up menu.

Tab l e Vie w \

Figure 7 Data in Tabular Format and View Selection Buttons

The table view displays the most recently collected dataset in tabular form. The fields are described in detail below:

• Dataset - The dataset number - a count of how many datasets have been received for the document.

• Timestamp - The time the dataset was captured from the BDS receiver.

• Elapsed (ms) - The time (in milliseconds) between measurement datasets, giving an indication of data

update rate.

• AGC - Automatic gain control indicator.

Note: Displays “Yes” if automatic gain control is used or “No” if manual gain control is used.

• Cal – Measurement calibration indicator.

Note: Displays “Yes” if the displayed measurement dataset has been calibrated or “No” if it has not been

calibrated.

Note: Check the probe connection to the receiver if the BDS GUI is indicating that the measurements are

not being calibrated.

• Arc - Arc detected during the displayed measurement cycle.

Note: This will display “No” if no transient event has been detected or “Yes” with a red background if a

transient has been detected during the measurement cycle.

The data table displays the following information for each harmonic component returned in the dataset:

• F (Hz) - The estimated frequency in Hz. This is the frequency reported by the BDS receiver.

20

Page 35

• Vrms (Volts) - RMS voltage reading.

PV

rmsIrms

×()Phase()cos=

• Irms (Amp) - RMS current reading.

• Z (Ohms) - Impedance magnitude in Ohms. Note: Z=V/I.

• Phase (Deg) - The phase in degrees.

• R (Ohms) – Resistance in Ohms - the real part of impedance (in rectangular coordinates).

• jX (Ohms) – Reactance in Ohms - the imaginary part of impedance (in rectangular coordinates).

• P (Watts) - Power in Watts.

Note:

• Rel P (dBc) - Power relative to the carrier in dBc.

• Rel Ph – Phase relative to the fundamental in degrees.

Note: This is only reported if relative phase is enabled. See “Enable relative phase measurements” in Standard Tracking Mode Options.

• Attn V (dB) - The attenuation applied (in dB) to the voltage channel during this frequency measurement.

• Attn I (dB) - The attenuation applied (in dB) to the current channel during this frequency measurement.

Time Plot View

Figure 8 Data Viewed in Time Plot Format

Note: The Time Plot view displays each dataset over time. The dataset number is displayed on the X-axis.

Reconstructed Waveform View

Figure 9 Data Viewed As a Waveform

Note: The Waveform view displays a single waveform of a fundamental tone constructed from the harmonic components captured. Waveform reconstruction is only possible if relative phase is enabled. See

“Enable relative phase measurements” in Standard Tracking Mode Options.

21

Page 36

Smith Chart View

Figure 10 Data Viewed in a Smith Chart

Note: The Smith Chart view displays data normalized to 50 Ohms (a value of 1 on the horizontal axis represents 50 Ohms).

Using Spectral Search (Sweep) Mode

To collect data in the Spectral Search Mode you can simply use the default sweep configuration and then start a Sweep.

There are many settings and options available in the Spectral Search Mode of operation.

For more information about Spectral Search Mode options, refer to Spectral Search Mode Options.

Setting the Minimum Configuration

Note: The minimum Spectral Search Mode configuration is a 12-bit Uniform sweep of 1-100MHz.

1. At the main menu, select “Mode->Switch To->Spectral Search Mode”.

2. Select “Mode->Options…” from the main menu or click the broom icon in the

“Options” toolbar. The Sweep Mode Configuration dialog box opens.

3. Click on the “Sweep” tab to bring it to the foreground.

4. Click the “More Options >>” button.

5. Click the “Default Settings” button.

6. Click the “OK” button to apply the settings and close the dialog.

Acquiring Fresh Data

Select "Mode->Start Sweep" from the main menu to start the data acquisition.

Note: Clicking the green Run button on the “Scan” toolbar will also start an acquisition.

Stopping Data Acquisition

The data acquisition can be stopped at any time by performing one of the following:

• Select "Mode->Stop" from the main menu

• Use the red Stop button from the "Scan" tool bar.

22

Page 37

Saving the Document

1. Select "File->Save As…" from the main menu.

Note: If the data will be analyzed using another application such as MS Excel

or MATHCAD, it’s recommended that the document is saved in the “true” CSV

file format. The “true” CSV format saves the data in a format that is more easily

interpreted than the “BDS Capture Files” format.

2. Select “CSV Files (*.csv)” from the “Save as type:” drop-down list.

Note: The file format can also be selected in the auto save options. Auto save

options can be set up by selecting “Mode->Options…” from the main menu.

Viewing the Data

Data can be viewed while it’s being collected or after a data acquisition completes. The data is displayed in the following formats:

• Frequency-Domain View

• Table o f Peaks

These views can be accessed and switched at any time by:

• Selecting a different view using the buttons on the View tool bar.

• Right-clicking anywhere on a view and choosing from the pop-up menu.

• Selecting View and your choice from the main menu.

Note: View options are available by selecting “View->Options…” from the main menu or by right clicking

anywhere on a view and selecting “Options…” from the pop-up menu.

Viewing Data in the Frequency Domain

Figure 11 Viewing Data in the Frequency Domain

Note: Each data point is displayed as amplitude over frequency, with frequency on the x-axis.

Amplitude display formats can switched by right-clicking on the graph and selecting one of the format types from

the pop-up window:

• Voltage

• Current

• Impedance

• Watts

• dBm.

Note: Format type can also be selected from the Spectral Search Options.

23

Page 38

Marker Usage - Up to 2 markers can be used to view data point details or deltas between 2 data points on the

graph. The active marker, the one with user input focus, is in red and the inactive marker is in black.

Marker Keys:

• Up Arrow – Place the active marker at the maximum value (the highest peak).

• Left Arrow – Move the active marker to the previous point. Tap to move one point at a time or hold to

incrementally skip points.

• Right Arrow – Move the active marker to the next point. Tap to move one point at a time or hold to incre-

mentally skip points.

• E – On/Off – Enable or disable the active marker.

• P – Cycle through peaks, placing the active marker at the next peak.

• 1 – Activate (and enable) marker number 1.

• 2 – Activate (and enable) marker number 2.

Viewing Data in a Table of Peaks

The peak table view displays the peak values most recently located in the sweep in a tabular form. The fields are:

• Sweep - The sweep number - a count of how many sweep have been made since the acquisition was

started.

• Timestamp - The time the sweep dataset was captured from the BDS receiver.

• Elapsed (ms) - The time (in milliseconds) between sweeps, giving an indication of data update rate.

• AGC - Automatic gain control indicator.

Note: Displays “Yes” if automatic gain control is used or “No” if manual gain control is used.

• Cal – Measurement calibration indicator.

Note: Displays “Yes” if the sweep data has been calibrated or “No” if it has not been calibrated.

Note: Check the probe connection to the receiver if the BDS GUI is indicating that the measurements are

not being calibrated.

• Arc – Arc detected during the displayed measurement cycle.

Note: This will display “No” if no transient event has been detected or “Yes” with a red background if a

transient has been detected during the measurement cycle.

• Peak – The peak number. Peaks are listed in ascending order (highest to lowest).

• F (Hz) – The frequency of the peak in Hz.

Selected amplitude. One of the following:

• Vrms (Volts) – RMS voltage.

• Irms (Amps) – RMS current.

• Z (Ohms) – Impedance in Ohms.

• P (Watts) – Power in Watts.

• P (dBm) – Power in dBm.

24

Page 39

Viewing Captured Data Using MS Excel

It is recommended that the data being viewed is saved in the “true” CSV file format. The “true” CSV format saves the

data in a format that is more easily interpreted than the “BDS Capture Files” format. See “Saving the Document” on

page 19 in Using Standard Tracking Mode or see “Saving the Document” on page 23 in Using Spectral Search (Sweep)

Mode for more information.

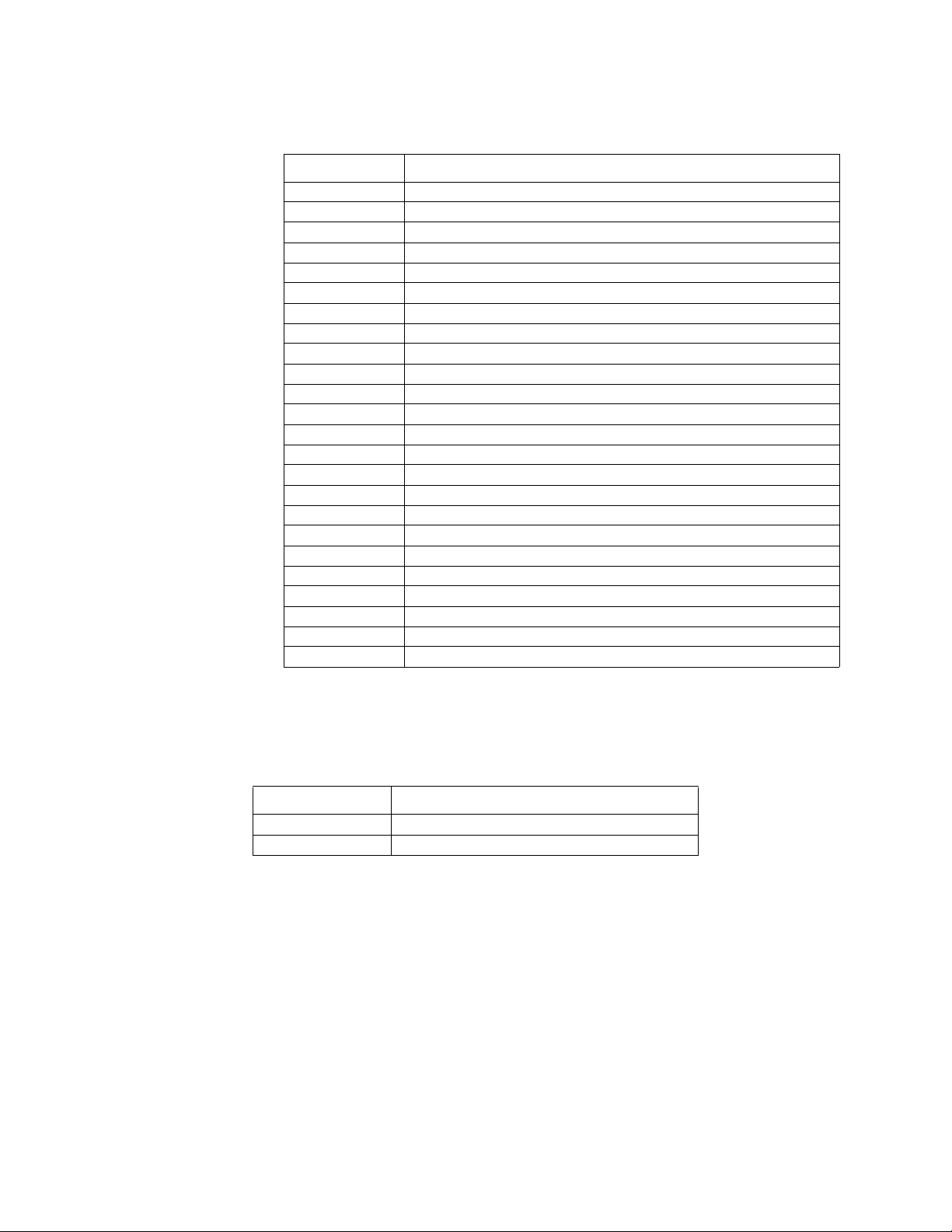

CSV File Format Description

Header fields are listed in the first row in the file. Measurement data is listed in all subsequent rows. A comma separates each field or data point.

Table 3-1 Standard Tracking Mode CSV Format Description

Column Header Description

1 Step Internal Bird use.

2 Time(ms) The time in milliseconds from the beginning of the file.

3 Arc Arc detection status. 0 if no transient was detected during

the measurement cycle or 1 if a transient was detected.

4 F1_Freq_0 Frequency in MHz for the 1

5 F1_V_0 RMS Voltage for the 1

6 F1_I_0 RMS Current for the 1

7 F1_Ph_0 Phase in radians for the 1st fundamental (overtone H0).

8 F1_PhRel_0 Relative phase in radians for the 1

Note: Relative phase is only saved in this column if it is enabled.

9 F1_Freq_1 Frequency in MHz for the 1

fundamental (overtone H1).

10 F1_V_1 RMS Voltage for the 1

(overtone H1).

11 F1_I_1 RMS Current for the 1

(overtone H1).

12 F1_Ph_1 Phase in radians for the 1

(overtone H1).

13 F1_PhRel_1 Relative phase in radians for the 1

fundamental (overtone H1). Note: Relative phase is only

saved in this column if it is enabled.

…

N Fn_V_m RMS Voltage for the m

(overtone Hm).

N+1 Fn_I_m RMS Current for the m

(overtone Hm).

N+2 Fn_Ph_m Phase in radians for the m

fundamental (overtone Hm).

N+3 Fn_PhRel_m Relative phase in radians for the m

fundamental (overtone Hm). Note: Relative phase is only

saved in this column if it is enabled.

N+4 to

IMD All intermods are listed after the harmonics.

end-of-row

st

fundamental (overtone H0).

st

fundamental (overtone H0).

st

fundamental (overtone H0).

st

fundamental (overtone H0).

st

harmonic of the 1st

st

harmonic of the 1st fundamental

st

harmonic of the 1st fundamental

st

harmonic of the 1st fundamental

st

harmonic of the 1st

th

harmonic of the Nth fundamental

th

harmonic of the Nth fundamental

th

harmonic of the Nth

th

harmonic of the Nth

25

Page 40

Table 3-2 Spectral Search Mode CSV Format Description

Column Header Description

1 Frequency (Hz) Frequency reported for the step point in Hz.

2 RMS Voltage RMS Voltage reported for the step point.

3 RMS Current RMS Current reported for the step point.

4 Phase (R) Phase in radians for the step point.

5 AttnV Attenuation applied to the voltage channel while measuring

6 AttnI Attenuation applied to the current channel while measuring

the point.

the point.

Table 3-3 Arc Detect CSV Format Description

Column Header Description

1 Voltage ADC Voltage ADC counts. Range: 0-127 for 8-bit, 0-2047 for 12-bit

mode.

2 Current ADC Current ADC counts. Range: 0-127 for 8-bit, 0-2047 for 12-bit