Page 1

NETWORK ENABLED

ANTENNA & CABLE MONITOR

SERIES ACMI

OPERATING INSTRUCTIONS

This is a preliminary manual. Specifications, limits, and text are subject to

change without notice. The information within this manual was as complete

as possible at the time of printing. Bird Electronic Corporation is not liable

for errors.

©Copyright 2014 by Bird Electronic Corporation

Instruction Book P/N 920-ACMI Rev. P1

Thruline® is a registered trademark of

Bird Electronic Corporation

Microsoft® and Windows® are registered

trademarks of the Microsoft Corporation

Page 2

This page is not blank

Page 3

Safety Precautions

The following are general safety precautions that are not necessarily related to

any specific part or procedure, and do not necessarily appear elsewhere in this

publication. These precautions must be thoroughly understood and apply to all

phases of operation and maintenance.

WARNING

Keep Away From Live Circuits

Oper

ating Personnel must at all times observe general safety precautions. Do

not replace components or make adjustments to the inside of the test

equipment with the high voltage supply turned on. To avoid casualties,

always remove power.

WARNING

Shock Hazard

Do not attempt to remove the RF transmission line while RF power is present.

WARNING

Do Not Service Or Adjust Alone

Under no circumstances should any person reach into an enclosure for the

purpose of service or adjustment of equipment except in the presence of

someone who is capable of rendering aid.

WARNING

Safety Earth Ground

An uniterruptible earth safety ground must be supplied from the main power

source to test instruments. Grounding one conductor of a two conductor

power cable is not sufficient protection. Serious injury or death can occur if

this grounding is not properly supplied.

WARNING

Resuscitation

Personnel working with or near high voltages should be familiar with modern

methods of resuscitation.

WARNING

Remove Power

Observe general safety precautions. Do not open the instrument with the

power on.

iii

Page 4

Safety Symbols

WARNING

Warning notes call attention to a procedure, which if not correctly

performed, could result in personal injury.

CAUTION

Caution notes call attention to a procedure, which if not correctly performed,

could result in damage to the instrument.

Note: Calls attention to supplemental information.

Warning Statements

The following safety warnings appear in the text where there is danger to operating and maintenance personnel, and are repeated here for emphasis.

WARNING

Leaking RF energy is a potential health hazard. Never attempt to connect or

disconnect equipment from the transmission line while RF power is being applied.

Severe burns, electrical shock, or death can occur.

See page 7.

WARNING

Do not touch the center conductor of the power monitor ports while RF

power is being applied.

See page 8.

WARNING

Disconnect the unit from the RF power source and the AC line before any

disassembly. The potential for electrical shock exists.

See page 11 and 21.

iv

Page 5

Caution Statements

The following equipment cautions appear in the text and are repeated here for

emphasis.

CAUTION

The input voltage must be clean and stable. Be sure that the input voltage

does not surge and does not contain spikes. Failure to comply may result in

permanent damage to the instrument.

See page 8.

CAUTION

The maximum input voltage differential is 72 V for High Voltage models, 36

V for Medium Voltage models, and 18 V for Low Voltage Models. Do not

apply an input voltage differential greater than the voltage limit for the

model. Failure to comply may result in permanent damage to the

instrument.

See page 8.

CAUTION

Do not use harsh or abrasive detergents for cleaning.

See page 21.

v

Page 6

Safety Statements

USAGE

ANY USE OF THIS INSTRUMENT IN A MANNER NOT

SPECIFIED BY THE MANUFACTURER MAY IMPAIR THE

INSTRUMENT’S SAFETY PROTECTION.

USO

EL USO DE ESTE INSTRUMENTO DE MANERA NO

ESPECIFICADA POR EL FABRICANTE, PUEDE ANULAR LA

PROTECCIÓN DE SEGURIDAD DEL INSTRUMENTO.

BENUTZUNG

WIRD DAS GERÄT AUF ANDERE WEISE VERWENDET ALS VOM

HERSTELLER BESCHRIEBEN, KANN DIE GERÄTESICHERHEIT

BEEINTRÄCHTIGT WERDEN.

UTILISATION

TOUTE UTILISATION DE CET INSTRUMENT QUI N’EST PAS

EXPLICITEMENT PRÉVUE PAR LE FABRICANT PEUT

ENDOMMAGER LE DISPOSITIF DE PROTECTION DE

L’INSTRUMENT.

IMPIEGO

QUALORA QUESTO STRUMENTO VENISSE UTILIZZATO IN

MODO DIVERSO DA COME SPECIFICATO DAL PRODUTTORE

LA PROZIONE DI SICUREZZA POTREBBE VENIRNE

COMPROMESSA.

vi

Page 7

SERVICE

SERVICING INSTRUCTIONS ARE FOR USE BY SERVICE TRAINED PERSONNEL ONLY. TO AVOID DANGEROUS

ELECTRIC SHOCK, DO NOT PERFORM ANY SERVICING

UNLESS QUALIFIED TO DO SO.

SERVICIO

LAS INSTRUCCIONES DE SERVICIO SON PARA USO

EXCLUSIVO DEL PERSONAL DE SERVICIO CAPACITADO. PARA

EVITAR EL PELIGRO DE DESCARGAS ELÉCTRICAS, NO

REALICE NINGÚN SERVICIO A MENOS QUE ESTÉ

CAPACITADO PARA HACERIO.

WARTUNG

ANWEISUNGEN FÜR DIE WARTUNG DES GERÄTES GELTEN

NUR FÜR GESCHULTES FACHPERSONAL.

ZUR VERMEIDUNG GEFÄHRLICHE, ELEKTRISCHE SCHOCKS,

SIND WARTUNGSARBEITEN AUSSCHLIEßLICH VON

QUALIFIZIERTEM SERVICEPERSONAL DURCHZUFÜHREN.

ENTRENTIEN

L’EMPLOI DES INSTRUCTIONS D’ENTRETIEN DOIT ÊTRE

RÉSERVÉ AU PERSONNEL FORMÉ AUX OPÉRATIONS

D’ENTRETIEN. POUR PRÉVENIR UN CHOC ÉLECTRIQUE

DANGEREUX, NE PAS EFFECTUER D’ENTRETIEN SI L’ON N’A

PAS ÉTÉ QUALIFIÉ POUR CE FAIRE.

ASSISTENZA TECNICA

LE ISTRUZIONI RELATIVE ALL’ASSISTENZA SONO PREVISTE

ESCLUSIVAMENTE PER IL PERSONALE OPPORTUNAMENTE

ADDESTRATO. PER EVITARE PERICOLOSE SCOSSE

ELETTRICHE NON EFFETTUARRE ALCUNA RIPARAZIONE A

MENO CHE QUALIFICATI A FARLA.

vii

Page 8

About This Manual

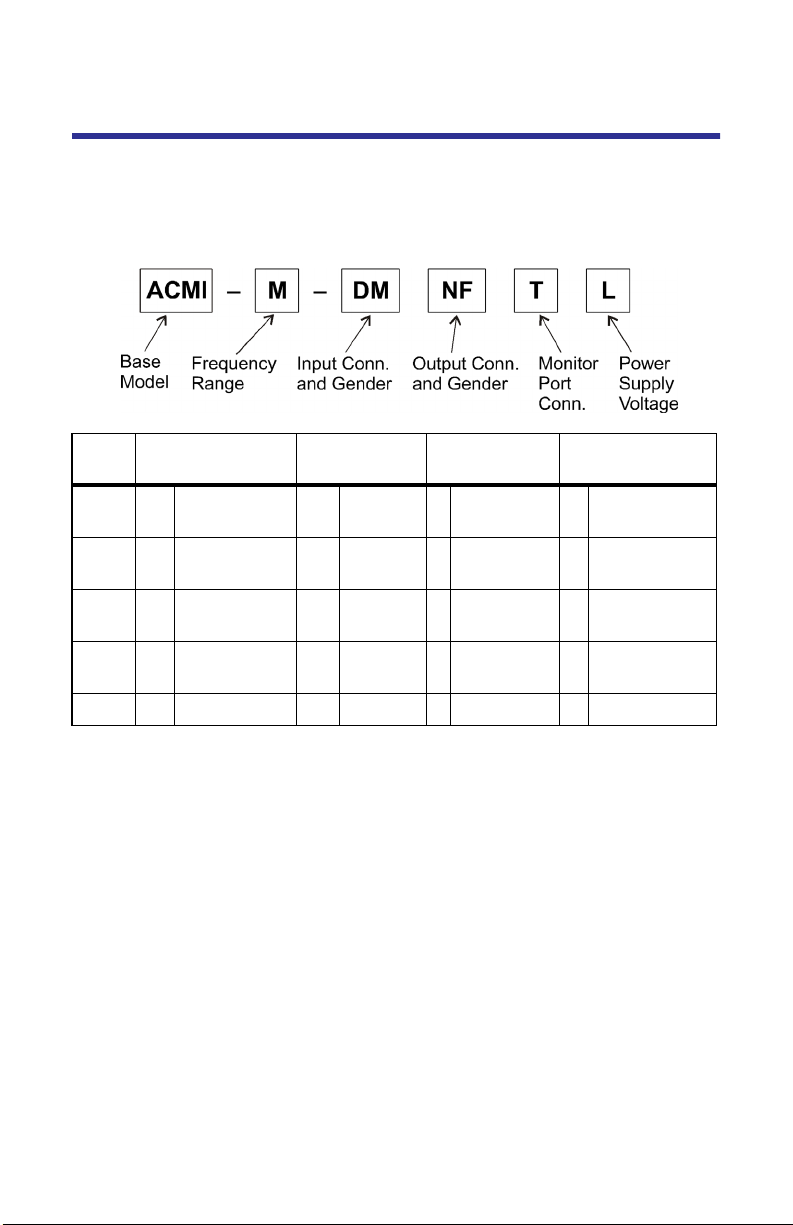

Sample Model ACM–M–DMNFTL

470 – 960 MHz ACM with male 7/16 input, female N output,

female TNC monitor ports, requiring a low voltage power supply

Base

Model

ACMI L0 108 – 138 NMMale N N Female N L +/- (9 to 18)

ACMI

500

Frequency Range

(MHz)

L1 136 – 225 NF Female NT Female

L2 225 – 520 DMMale 7/

M 470 – 960 DF Female

H 960 – 2400

RF

Connectors

16 DIN

7/16 DIN

Monitor Port

Connectors

TNC

B Female

BNC

Power Supply

Voltage

VDC)

H ± (36 to 72)

VDC

M +/- (18 to 36)

VDC

Note: Exception: Models in ACMI500 series do not support frequency

range L0 and H and any of its variations.

viii

Page 9

Changes to this Manual

We have made every effort to ensure this manual is accurate. If you discover

any errors, or if you have suggestions for improving this manual, please send

your comments to our Solon, Ohio factory. This manual may be periodically

updated. When inquiring about updates to this manual refer to the part number

and revision on the title page.

Chapter Layout

Introduction — Identifies the parts and functions of the ACMI.

Theory of Operation — Describes the ACMI’s alarm options.

Installation — Provides instructions for installing the ACMI at a site, as well as

detailed information on the cable connections.

Operating Instructions — Explains computer commands for controlling the

ACMI and describes operation of the PCTool software.

Maintenance — Lists routine maintenance tasks for the ACMI, as well as trou-

bleshooting information for common problems. Specifications and parts lists are

also included.

ix

Page 10

x

Page 11

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Warning Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Caution Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Changes to this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Items Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Component Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Alarm Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Alarm Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Alarm Latching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

VSWR Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Alarm on Zero Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

High Power Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Low Power Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Push-to-Talk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power/Alarm Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ethernet Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

WebTool Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Computer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

xi

Page 12

Bird Technologies

Chapter 4 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . .15

WebTool Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Stats Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Data Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Day Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Get Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Day Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Config Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Alarm Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Admin Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Network Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Email Alerts Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SNMP Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Password Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Help Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Push-to-Talk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting Push-to-Talk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Analog Output Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Frequency Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

RF Power Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Insertion Loss, Max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

VSWR, Max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

xii

Page 13

Chapter 1 Introduction

Designed for 50 ohm coaxial transmission lines, the Bird Antenna & Cable Monitor is

the solution for monitoring transmission antenna systems. Service providers and

end users can rely on it to keep their critical sites up and running. Designed to detect

antenna and cable faults that transmitter-internal VSWR monitors may not detect, it

also provides accurate in-line power measurement functionality.

Features

Measures forward and reflected power as well as VSWR and Return Loss.

Measures true average power of pulses with high peak-to-average

ratios - works with any modulation.

When monitoring transmitter output power, alarms available for low

or high power.

Accurately monitors antenna and cable system VSWR. Alarm triggered

if antenna or cable fails.

Integral coupler measures small changes in VSWR through high feeder

and interface losses.

Note: High directivity maximizes measurement accuracy.

Sampling ports allow signal measurements without requiring system

downtime.

Excellent passive intermod allows the unit to be inserted into multi-

channel systems with a single Tx/Rx antenna with no desensing or deg-

radation of receiver performance.

Can be rack mounted at the output of transmitter combiner or linear

power amplifier.

Setup and operation via built-in PCTool software.

Items Supplied

ACMI Unit

Instruction Manual

Optional Accessories

Note: See “Replacement Parts” on page 33 for part numbers of

accessories.

PCTool Software - PC software for locating ACMI units on a network.

DB-15 Power/Alarm Cables - Connects the Antenna Monitor to a power

supply and to external controllers. 50 feet long with male/female connectors.

Note: Refer to Figure 3 and Figure 4 on page 8 for pin layout.

DB-15 Interface Connector - Allows easy custom data cable connections to

the ACM.

1

Page 14

Component Description

Figure 1 Antenna & Cable Monitor Outline

1 RF Input Connects to the amplifier or combiner

2 Forward Monitor Port Samples the forward travelling wave

3 Reflected Monitor Port Samples the reflected wave

4 RF Output Connects to the antenna or feeder

5 Reset Switch Resets the alarm. If an alarm trigger is still present,

the alarm will reactivate

6 Operation/Test LED Green LED indicates when the unit is powered

7 Alarm LED Red LED indicates when an alarm is triggered

8 Ethernet Port RJ-45 connector. Interface to a PC using a Cat5

Ethernet cable

9 Power/Alarm Parallel

Port

15 pin female connector. Connects to the power

supply using a male 15 pin cable.

remote operation.

Also used for

2

Page 15

Chapter 2 Theory of Operation

Alarm Response

When an alarm is triggered, the Bird Antenna & Cable Monitor turns on the

alarm LED and and de-asserts a TTL logic line (pulls low). In addition, depending

on configuration settings, one Form C dry contact relay changes state (i.e. activates or de-acitvates) as a result of the VSWR alarm activating. A second Form

C dry contact relay changes state as a result of either the low power or high

power alarms activating. Refer to the Power/Alarm Connector pins for proper

connection and Alarm configuration for set-up.

The LED activates the TTL logic line de-asserts as a result any of the three alarm

conditions (VSWR, low or high power).

If power to the unit is lost, both relays default to their de-energized condition.

The PCTool software can configure whether the relays energize or de-energize

during initialization or in response to an alarm when the unit is operating. Refer

to the section on Alarms for instructions on setting alarm response behavior.

Alarm Reset

Alarms can be reset locally with the reset switch.

Alarms are reset when the reset pin on the Power/Alarm port is acti-

vated by a TTL compatible logic low signal (0 to 0.8 VDC).

The PCTool can reset the unit through the Ethernet port by sending a

“Reset Alarm” command.

Reset events clear all three alarms (VSWR, High Power, Low Power)

and reset both relays.

Alarm Latching

The alarm defaults to latching operation. In this mode, the alarm will stay active

until reset. In non-latching mode, the VSWR alarm will reset automatically about

forty seconds after the trigger condition is corrected, power alarms will reset in

about one-and-half seconds after the power condition is corrected.

VSWR Alarm

The ACM continuously monitors forward and reflected power. From the power

measurements, the VSWR is calculated and compared to the allowed maximum

(default of 1.5 to 1). Based on the results of the comparison, possible actions

include:

3

Page 16

No alarm is activated if the VSWR is less than the maximum, or if the

VSWR alarm is disabled.

If the VSWR is equal to or slightly greater than the maximum, additional

measurements are accumulated to determine a trend. If reverse power is

increasing, an alarm is triggered. If the reverse power is stable, measurements continue until a trend is established. An alarm will be triggered if the

VSWR exceeds the maximum for more than thirty seconds.

If the VSWR is much greater than the maximum then an alarm condi-

tion is triggered immediately.

Alarm on Zero Power

When the forward power is very small (< 2.5% of full scale), the measured VSWR

becomes large due to the noise floor of the sensor. Under these conditions, the

VSWR level is meaningless. When the zero power alarm is disabled, the VSWR will

not be monitored at these low powers.

High Power Alarm

When the high power alarm is enabled, the forward power is continuously monitored. The alarm trigger is a percentage of the Monitor’s full scale power, from 0 –

125%. If the forward power is greater than the trigger level, an alarm is triggered.

Low Power Alarm

When the low power alarm is enabled, the forward power is continuously monitored. The alarm trigger is a percentage of the Monitor’s full scale power, from

0 – 125%. If the forward power is less than the trigger level, an alarm is triggered.

Push-to-Talk

The low power alarm and the VSWR alarm can falsely trigger when the transmitter is not keyed. The Push-to-Talk feature disables alarm checking for a predetermined period after the Push-to-Talk logic line is asserted. In order to prevent false

alarms while monitoring for low power and high VSWR, the Push-to-Talk feature

must be enabled.

4

Page 17

Chapter 3 Installation

This chapter provides information for preparing the Bird Antenna & Cable Monitor for use.

Unpacking and Inspection

1. Carefully inspect the shipping container for signs of damage.

Note: If damage is noticed, do not unpack the unit. Immediately

notify the shipping carrier and Bird Electronic Corporation.

2. If the shipping container is not damaged, unpack the unit.

Note: Save the packing material in case the unit needs to be shipped

again.

3. Inspect all of the components for visible signs of damage.

Note: Immediately notify the shipping carrier and Bird Electronic

Corporation of equipment damage or missing parts.

The Bird ACM is shipped complete and ready for use upon receipt. After unpacking and inspecting the unit, it is ready to be installed.

WARNING

Leaking RF energy is a potential health hazard. Never attempt to connect or

disconnect equipment from the transmission line while RF power is being

applied. Severe burns, electrical shock, or death can occur.

Mounting

Mount the ACMI in the feeder line between the combiner and the antenna.

Make sure that the alarm LED and reset button are accessible, and that the connecting cables have proper clearance.

Cable Connections

Note: Refer to Figure 2 on page 6 for cable connections.

When connecting the Bird ACM to RF power, use 50 ohm coaxial cable suitable

for the frequency and power level of operation. The cable connector should

mate with the connector on the unit.

5

Page 18

Connect the amplifier or combiner to the Monitor’s input. Connect the antenna

or feeder to the output.

WARNING

Do not touch the center conductor of the power monitor ports while RF

power is being applied.

To monitor the RF waveform, connect the forward and reflected power monitor

ports to an appropriate power sensor or meter.

Note: If a power monitor port is not being used, terminate it with a

50 load.

Figure 2 Cable Connections

6

Page 19

Power/Alarm Connector

Note: The power cable must be <50m in length.

Connect the external power supply here. Pin numbers and descriptions are given

in Figure 3.

CAUTION

The input voltage must be clean and stable. Ensure that the input voltage

does not surge and does not contain spikes. Failure to comply may result in

permanent damage to the instrument.

CAUTION

The maximum input voltage differential is 72 V for High Voltage models, 36

V for Medium Voltage models, and 18 V for Low Voltage Models. Do not

apply an input voltage differential greater than the voltage limit for the

model. Failure to comply may result in permanent damage to the

instrument.

High voltage models (ACMI-x-xxxxxH and ACMI500-x-xxxxxH) require 36 to 72

VDC (48 V nominal) @ 2 W. Either terminal (10 or 11) may be connected to DC

input ground, as dictated by the power supply requirements.

Medium voltage models (ACMI-x-xxxxxM and ACMI500-x-xxxxxM) require 18 to

36 VDC (24V nominal) at 2 W. Either terminal (10 or 11) may be connected to DC

input ground, as dictated by the power supply requirements.

Low voltage models (ACMI-x-xxxxxL and ACMI500-x-xxxxxL) require 9 to 18 VDC

(12 V nominal) @ 2 W. Either terminal (10 or 11) may be connected to DC input

ground, as dictated by the power supply requirements.

7

Page 20

Figure 3 High Voltage DB-15 Power/Alarm Connector, Female

Pin Description

1 Relay 1, VSWR alarm contact

2 Relay 1, VSWR alarm common contact

3 Alarm output, TTL compatible

4 PTT input, +5V to +24V to activate,

5 Reset input, TTL compatible

6 Relay 2, Power Alarm contact

7 Relay 2, Power Alarm common contact

8 Relay 2, Power Alarm contact

9 Relay 1, VSWR Alarm contact

10 DC input, + terminal. See Figure 4.

11 DC input, – terminal. See Figure 4.

12 Analog FWD, 0 to 5 VDC linearly proportional to forward

13 Analog RFL, 0 to 5 VDC linearly proportional to reflected

14 - 15 Ground

(closed when relay is not energized or loss of power to unit)

(open when the relay is engaged)

TTL High ( 4.3 VDC with a 10k load) = no alarm

TTL Low (<0.2 VDC) = alarm (VSWR, Low, or High Power)

0V or open to deactivate

TTL Low (<0.5 VDC) resets all active alarms

(closed when relay is not energized or loss of power to unit)

(open when relay is energized)

(open when relay is not energized or loss of power to unit)

(closed when the relay is energized)

(open when relay is not energized or loss of power to unit)

(closed when the relay is energized)

, 200 ohm output impedance

power

, 200 ohm output impedance

power

Figure 4 Power/Alarm Connector Wiring, Female

8

Page 21

Ethernet Connector

Note: Max. Ethernet cable length must be <50m.

The Ethernet connector carries data between the Antenna Monitor and a PC.

When connecting to the ACMI using the Ethernet port, you use the WebTool

software to setup the ACMI. You do not need to install the WebTool software

because it is part of the ACMI firmware.

In order to determine the IP address of the ACMI, the BMPE Finder utility will

need to be installed.

Note: You must have Java runtime installed before you can use the

WebTool software.

Network connections require specific address and protocol information. Have a

qualified IT or network professional perform the ACMI ethernet setup. Failure to

comply may result in loss of network communication or the inability to

communicate with the ACMI.

The setup in this section should be performed only by a person who thoroughly

understands IP and network setup protocols.

Note: If you are connecting to a network, before you begin, do the

following:

CAUTION

Contact your IT professional to get the subnet mask values for

your network and to determine whether or not your network

has a DHCP server.

Inform your network administrator that the ACMI will use port

10001. The network administrator might need to open this

port before you can set up the ACMI.

1. Install the Java runtime environment.

Note: Perform this step if it is not already done.

Note: To use the WebTool software, your PC must have the Java run-

time environment (java virtual machine v1.4.2 or later) installed prior to

connecting the ACMI to an ethernet device. If you do not have the runtime environment, you can download it from the web at www.java.com

or from the Bird Technology web site (www.bird-electronic.com). For

information about downloading the Java 2 Runtime Environment, refer

to the readme.txt file that was provided with your unit.

Dangerous RF voltage. Do not connect or apply an RF signal to the ACMI during

WARNING

equipment setup. Failure to comply may result in severe burns, loss of use of

limbs, or death.

WARNING

Do not connect RF power to the unit.

2. Apply operating power to the ACMI.

3. Follow the ethernet setup flowchart (Figure 5, page 10) to complete the

installation.

9

Page 22

Figure 5 Ethernet Connection Flowchart

10

Note: The name you enter (at the left of the @ symbol) is also used in

the ACMI Finder utility. If you use the email option to notify someone

that an alarm has occurred, the name of this ACMI will help identify

where the alarm came from.

Page 23

11

Page 24

12

Note: To use the features of the WebTool software, refer to

Chapter 4 Operating Instructions on page 15.

Page 25

WebTool Software

Computer Requirements

The WebTool software does not need to be installed because it is part of the

ACMI firmware. The WebTool will run on any computer with Windows 98 or

greater using a supported web browser with Java runtime installed. In order to

locate the IP address of an ACMI, the BPME Finder Utility is used. This is a separate program that is installed on a host machine and is not part of the WebTool

software.

To install and run the program, your computer system must meet or exceed the

requirements listed below:

486 or better CPU (66 MHz or better recommended)

1 MB of free memory

Hard Disk Drive

CD-ROM Drive

Note: Follow the instructions on the CD provided to install the software.

Web browser that supports Java Virtual Machine v1.4.2 or later such as

Microsoft Internet Explorer or Google Chrome Browser

The BPME Finder tool may also be downloaded from the Bird Technologies

Group website at:

www.bird-technologies.com/acm_pc-tool

13

Page 26

14

Page 27

Chapter 4 Operating Instructions

WebTool Software

The ACMI WebTool software is used to monitor the measurement outputs from

the ACMI and to set and change alarm and network configurations. This software runs in a web browser (such as Microsoft’s Internet Explorer). To use the

tool, open a web browser then in the address field, type the address of the

BPM-E you wish to access. The software has five buttons at the left side that

open the following screens: Main, Stats, Config, Admin, and Help. You can

access information about the WebTool software by click on the Help button.

Main Screen

The Main screen is the default screen you see when you open the WebTool software (Figure 6, page 16). The Main screen identifies the ACMI at the top of the

window. The center of the screen displays measurement data that is being

received from the ACMI. You can set the refresh rate from 1 second to 60 seconds (how frequently the software updates the data from the ACMI). At the bottom of the window, the status bar displays various information about the

software and uses three alert colors, red - a fatal error (cannot establish connection, connection lost), yellow - a warning (cannot complete a user request, user

does not have access permission), gray - normal operation.

For more information about the Main screen features, refer to the help section

in the software (click on the Help button).

The alarm condition area (Figure 7, page 16) will display three conditions

No alarm (green text) - no alarm condition exists

Latched (red text) - an alarm condition did occur but its cause has been

fixed or the cause no longer exists.

Alarm (red text) - an alarm condition that has occurred and has not

gone away or been reset is identified by text (VSWR, High Pwr, Low

Pwr, or any combination of these if more than one alarm exists).

You can reset the alarm at the ACMI by pressing the reset button or by clicking

on the Reset Alarm button on the Web Tool Main screen. If the cause of the

alarm is still present, the message cannot be reset.

15

Page 28

Figure 6 ACMI WebTool Software, Main Screen

Figure 7 Alarm Active Message

Stats Screen

The Stats screen (Figure 12 on page 20) can chart and display historical data

stored in the ACMI memory. You can chart forward and reflected power readings and alarm conditions (low power, high power, and VSWR alarm). You can

display the data in either a line graph or a bar chart.

The ACMI keeps data for a 365 day period. You select the starting day (in the

Begin field) and the number of days to view. Day 0 is today, day 1 is yesterday,

and so on to day 364. Click the Add >> button to add the days to the list to view.

When you click the Chart It button, the WebTool retrieves the data and generates a new chart. Click the Clear button to clear your day selection.

The Stats View is not password protected. It is used to retrieve and plot historical data stored on the BPME. You can use the controls provided on this view to

generate charts and save the data for your records.

16

Page 29

Data Log

The BPME maintains a 365 day log (data log) of forward and reflected power

readings and alarm conditions (low power, high power, and VSWR alarm). For

each new day, the BPME will automatically take a power reading every minute

and average it with the previous minute. This averaged value is temporarily

stored every hour and then a new average is started. If an alarm occurred over

the course of an hour, then a value of '1' is logged for the specific condition that

triggered the alarm: low power, high power, and/or VSWR. At the end of a 24

hour period, the hourly power reading data is averaged and the percentage of

time that a specific alarm was on is written to non-volatile storage. Each individual hour’s data (both powers and alarms) is also written to non-volatile storage

at the end of the day. If the power is lost, you will loose only historical data

obtained for the current day after the log started and before the power went

out. All other data will remain intact.

Figure 8 Data Log

Day Selection

The steps to create and display information from the data log are: select the

days to view, choose to include or exclude alarm data, select chart type, chart

the data.

1. Select Days

a. Decide which days to view.

Note: Day 0 is today, day 1 is yesterday, and so on up to day 364.

b. Enter the day number of the log you wish to view in the Begin field

under Day Selection.

c. Click the Add >> button to add it to the list of days to view.

To add a range of days,

a. Enter the start day in Begin.

b. Enter the number of days in the No. Days field.

c. Click the Add >> button.

Note: The day numbers can be added in any order and any range.

17

Page 30

Example - Comparing data from days 3-6 to days 203-206 on the

same chart. You can view the days you've selected by scrolling the

list to the right of the Add >> button under Day Selection.

Note: The more days you view, the longer it will take to chart them.

2. Include Alarm Data

a. Check the Include Alarm Data check box.

Note: This will retrieve alarm data for each selected day and generate a new alarm chart. The chart will be shown under the "Alarms"

tab. See the figure below for an example of an alarms bar chart.

3. Choose Chart Type

a. Select the chart type: Line or Bar.

Note: A line chart will plot the data as a simple connected line graph

with data values on the y-axis and the time units (days or hours) on the

x-axis. The line chart has no day limit and can also be used to plot

hourly data.

Note: A bar chart will plot the data as vertical bars - one for each day

- with the days on the x-axis and the data values on the y-axis. You can

use the bar chart to plot up to only 12 days at once.

Note: Hourly data is logged with hour 0 as the first hour of the day

and hour 23 as the last hour of the day.

4. Chart the Selection

a. Click the Chart It button to retrieve the data and generate a new

chart.

b. Click Clear to clear your day selections.

Note: Once the chart has been displayed you can browse the various

graphs for each power scale and alarms by clicking on the appropriate

tab at the top of the chart. Each chart is plotted in a similar fashion from the least-recent to the most-recent data value aquired - when

reading from left to right along the x-axis.

Figure 9 Alarms Screen

18

Page 31

Get Data

1. Click the Get Data button.

Note: This will display the data for the current chart in a new window

ab-delimited text format.

in a t

2. Copy the text and paste it into a file on your computer or directly into a

Micr

osoft Excel workbook.

Note: In MS Windows, hold the Ctrl button and press A to select all

the data, hold Ctrl and press C to copy, select your destination (e.g.

Excel), and hold Ctrl and press V to paste. See the figure below for an

example.

Figure 10 Get Data Screen

Day Detail

1. Select a day under Day Detail (at the right of the chart).

2. Click the View Day button to retrieve and generate a new chart of hourly

data for the selected day.

Note: This new chart will appear in a new window. The window can

be resized to stretch the chart's dimensions (by dragging the lowerright corner of the window).

3. Click the Get Data button on this window to display the hourly data for the

selected day in a new window.

Note: It works just like the Get Data button explained in the above

paragraph.

Figure 11 Day Detail

19

Page 32

Figure 12 Web Tool Stats Screen

Config Screen

The Config (Configure) screen has sets alarm configuration and analog output

gain. The administrator of the WebTool can set an optional password requirement to control who can make changes to the Config screen (refer to Admin

Screen for password control).

Alarm Tab

In the Alarms tab (Figure 13, page 22), you specify ACMI alarm settings. To

return to the factory default alarm settings, click on the Factory Default button.

After you have set the alarm preferences, click the Apply Changes button to

record your settings in memory.

You can select or deselect the following alarm conditions:

Latch Alarms - Sets whether the alarm will reset automatically in the absence

of an alarm condition. When this checkbox is unchecked, if an alarm trigger is

corrected, the VSWR alarm will reset after a forty-five second delay and the

power alarms after a one and a half second delay. When the box is checked, the

alarms must be manually reset.

Alarm at Power (Pwr) Up - At power up, before the instrument is ready to

take measurements, the unit performs initialization tasks. During this period,

the units alarm indicators (LED & TTL output) will activate for ~2ms and the

alarm relays will toggle to there alarm-active state for ~2ms (i.e. change from

activated to deactivated or visa-versa depending on the Relay Energized on

Alarm configuration)

20

Page 33

Checking the Alarm at Pwr Up box will cause the units alarm indicators and

alarm relays to remain in an alarm condition from the time power is applied

until the unit begins making measurements. At that time, the relays and indicators will return to their no-alarm condition until an event activates them.

VSWR Alarm Enable - Check the VSWR Alarm Enable box to monitor the

VSWR reading and activate the alarm if the VSWR exceeds the Trip Point for

more than thirty seconds, is equal to or slightly greater than the Trip Point and

reverse power is increasing or immediatly if the VSWR is much greater than the

Trip Point.

VSWR Relay Energized on Alarm - Checking this box will cause the VSWR

alarm relay to energize if the VSWR alarm is active and de-energize when the

alarm is not active. Un-checking this box will cause the VSWR alarm relay to deenergize when the alarm is active and energize when it is not active. Unchecking

this box ensures a fail-safe alarm configuration.

This setting will determine which relay contact will be open and which will be

closed in the event of an alarm condition and influence the hard-wiring of the

VSWR relay contacts. Refer to the power/alarm connection instructions.

VSWR trip point - Specify the VSWR value that will cause a VSWR alarm

(select values from the drop-down list). This value is adjustable from 1.3 to 2.5

by increments of 0.1. Check the VSWR Alarm Enabled on Zero Power checkbox

to allow the VSWR alarm to trigger at very low forward power (< 2.5% of full

scale power).

High Power Alarm (forward power only) - Check the Enable box and spec-

ify the percentage of full scale at which an alarm will occur. The high power

value must be greater than the low power value. The maximum value is 125% of

full scale power. The alarm setpoint is entered as a percent of full scale. For

example, if you have a 500W full scale unit and would like an alarm when the

forward power exceeds 375 W, the alarm setpoint would be 375 / 500 x 100 or

75%. Enter 75 in the field and check the Enable High Power Alarm checkbox.

Low Power Alarm (forward power only) - Check the Enable box and spec-

ify the percentage of full scale at which an alarm will occur. The low power value

must be less than the high power value. The minimum is 0%.

Power Relay Energized on Alarm - Checking this box will cause the Power

alarm relay to energize if the Power alarm is active and de-energize when the

alarm is not active. Un-checking this box will cause the Power alarm relay to

de-energize when the alarm is active and energize when it is not active.

Unchecking this box ensures a fail-safe alarm configuration.

This setting will determine which relay contact will be open and which will be

closed in the event of an alarm condition and influence the hard-wiring of the

Power relay contacts. Refer to the power/alarm connection instructions.

Trigger Alarm Button - After you have set or made changes to alarm settings,

you can use the Trigger Alarm button to test the alarms (messages, relay, TTL outputs). If the Config password is enabled, you will be required to enter the password

before you can test the alarm settings.

21

Page 34

Factory Defaults - Use the Factory Defaults button to clear all alarm settings

and return the alarm configuration to factory default conditions (Latch Alarms

and VSWR Alarm Enable checked, VSWR Trip Point =1.8).

Figure 13 WebTool Config Screen, Alarms

Admin Screen

The Admin screen has four tabs, Network, Email Alerts, SNMP, and Passwords.

After making changes in one or all of the tabs, click the Apply All Changes button

to record your settings in memory.

For more information about the Admin screen, refer to the help in the software

(click on the Help button).

Network Tab

In the Networking tab (Figure 14 on page 23), you can specify the following information about the address of the ACMI: IP address, subnet mask, gateway IP,

DHCP host name, and whether or not DHCP is used.

An IP address is required even if you connect the BPM-E directly to a computer

that is not on a network. Contact your IT professional for assistance in determining the IP address, subnet mask, and information about DHCP use and name.

22

Page 35

Figure 14 WebTool Admin Screen, Network Setup

Email Alerts Tab

In the Email Alerts tab (Figure 15 on page 23), you can specify the following information: the SMTP server IP, the SMTP port, whether or not to use the email alerts,

the email address of the ACMI, and the email addresses of two people to notify

when an alarm occurs (optional).

You can have the WebTool software contact two specified recipients via email if

an alarm occurs. The ACMI needs to be connected to a computer or server that

has email capabilities. Contact your IT professional for assistance in determining

the SMTP server IP and port. The text you enter at the left of the @ symbol in

the From email address will uniquely identify this ACMI in all sent emails. Use

text that will identify the ACMI and its location. The text at the right of the @

symbol is the email domain information for your server.

Figure 15 WebTool Admin Screen, Email Alerts

23

Page 36

SNMP Tab

In the SNMP tab (Figure 16 on page 24), you can specify setup for the SNMP feature if you have chosen to use it. Contact your IT professional for assistance. You

can obtain the latest MIB file from the Bird Technologies web site.

Figure 16 WebTool Admin Screen, Set SNMP Email Address

Password Tab

In the Password tab (Figure 17 on page 25), you can set the administrator password and the optional configuration access password. When you set or change a

password, you must type the password a second time in the appropriate “confirm” field before it will be accepted.

You must have a password to view and edit the Admin screen. The default password is “bird” (lower case without the quotes). After you make changes, click on

the Apply All button.

If a configuration access password is set, users can view the Config screen but

not edit it. A password must have at least 3 and no more than 49 characters.

24

Page 37

Figure 17 Web Tool Admin Screen, Passwords

Help Screen

While you are using the WebTool software, you can get on-line help about the

screens and features by clicking on the Help button at the left side of the screen.

25

Page 38

Push-to-Talk

When enabled, the Push-to-Talk (PTT) feature monitors the PTT logic input on

the DB-15 connector. When the PPT input is not asserted (low or open), the lowpower and VSWR alarms will not be monitored. When the PTT logic input is

asserted (i.e. when the transmitter is keyed) the PTT delay timer will begin to

countdown. During this PTT Delay, the low-power and VSWR alarms will continue not to be monitored. The alarms will be monitored only when the end of

the PPT Delay is reached and the PTT logic input is still asserted. This prevents

false alarms while monitoring for low power and high VSWR.

Note: The VSWR Alarm Enable and/or Low Power Alarm Enable

must be enabled (checked) in order for these alarms to activate after a

PTT logic event and delay.

Setting Push-to-Talk

1. Open the Power Monitor Options dialog.

2. Do one of the following:

Check the Enable checkbox to turn the Push-to-Talk feature on.

Uncheck the Enable checkbox to turn the Push-to-Talk feature off.

3. Enter any value for the time up to 14 sec.

Note: The time actually programmed on the ACM will be a multiple

of 156.25 ms. For this reason, the time displayed will be slightly different from the time set. The actual delay from the PTT signal is uncertain

because the PTT signal is asynchronous to the internal measurement

samples. The uncertainty is +/- 156.25 ms.

Figure 18 Push-to-Talk

26

Page 39

Analog Output Gain

This setting controls the sensitivity of the two analog outputs on the ACMI. The

output level for the two channels are proportional to the measured power in

the forward and reflected directions. The output range is 0 to 5.0 V with 10 bits

of resolution. The gain settings allow the adjustment of the range at the cost of

resolution.

Example - At a gain of 1, the resolution is approximately 0.12% of

full scale. At a gain of 8 it is approx 0.015% of full scale.

The tables below show the forward and reflected range and resolution for the

100 W and 500 W ACMs for the various gain settings:

Table 1-1 100 W ACMI

Gain Max (W) Resolution (mW) Max (W) Resolution (mW)

1 125.00 122.0703 12.50 12.2070

2 62.50 61.0352 6.25 6.1035

4 31.25 30.5176 3.13 3.0518

8 15.63 15.2588 1.56 1.5259

Table 1-2 500 W ACMI

Gain Max (W) Resolution (mW) Max (W) Resolution (mW)

1 625.00 610.3516 62.50 61.0352

2 312.50 305.1758 31.25 30.5176

4 156.25 152.5879 15.63 15.2588

8 78.13 76.2939 7.81 7.6294

27

Page 40

28

Page 41

Chapter 5 Maintenance

This chapter contains troubleshooting instructions, part information, and specifications for the Bird Antenna & Cable Monitor.

Inspection and Cleaning

This unit requires only simple and routine maintenance.

CAUTION

Do not use harsh or abrasive detergents for cleaning.

WARNING

Disconnect the unit from the RF power source and the AC line before any

disassembly. The potential for electrical shock exists.

1. Wipe off dust and dirt regularly.

Note: Use a soft, clean cloth dampened with mild detergent.

2. Check connectors, connector pins, and cables for damage.

Note: If needed, clean the connectors using a self-drying contact

cleaner that leaves no residue.

Troubleshooting

The Bird Antenna Monitor has no operator serviceable parts. Any required service must be performed at an authorized service facility.

The table below contains troubleshooting information for problems which can

occur during normal operation. This manual cannot list all malfunctions that

may occur, or their corrective actions. If a problem is not listed or is not corrected by the listed actions, notify a qualified service center.

Problem Possible Cause Correction

Operation/Test LED

does not illuminate

Alarm LED does not

illuminate

High VSWR Dirty connectors Clean connectors.

No DC power Check power source.

Defective LED Return the unit to an

authorized service center

Defective LED Return the unit to an

authorized service center

Defective connectors Replace connectors.

Shorted or open

transmission line

Have the line serviced.

.

.

29

Page 42

Customer Service

Any maintenance or service procedure beyond the scope of those in this chapter should be referred to a qualified service center.

If you need to return the unit for any reason, request an RMA through the Bird

Technologies website (link shown below). All instruments returned must be

shipped prepaid and to the attention of the RMA number.

Bird Service Center

30303 Aurora Road

Cleveland (Solon), Ohio 44139-2794

Fax: (440) 248-5426

E-mail: bsc@bird-technologies.com

For the location of the Sales Office nearest you, visit our website at:

http://www.bird-technologies.com

30

Page 43

Specifications

General

Directivity, Min.

108 – 960 MHz

960 – 2400 MHz

VSWR Alarm Setpoint 1.3:1.0 to 2.5:1.0 by 0.1:1.0 steps.

Alarm Relays Dry, form C. Common, normally

Relay Contact Rating 100 VDC @ 0.5 A

Visual Alarm Red LED will light to indicate

Alarm Stimulus VSWR setpoint exceeded,

Alarm Reset Local mechanical reset switch

RF Connectors Male or Female, N or 7/16 DIN

Monitor Port Connectors Female N, TNC, or BNC

Monitor Port Coupling –63 dB nominal

Passive Intermodulation

Products

Ethernet Port

Connector

Protocol

Power/Alarm Parallel Port Female DB-15 connector

Power Requirements

ACMI-x-xxxxxL

ACMI500-x-xxxxxL

ACMI-x-xxxxxM

ACMI500-x-xxxxxM

ACMI-x-xxxxxH

ACMI500-x-xxxxxH

Analog Outputs 0 to 5 V full scale, 200 ohm

Temperature

Operating

Storage

Altitude, Max. 3000 m (10,000 ft.)

Humidity, Max. 95% non-condensing

Dimensions, Nominal,

without connectors

Weight, Max. 2 lbs. (0.9 kg)

30 dB

26 dB

Refer to "Power/Alarm Connector"

on page 7 for information about

power limitations.

open, & normally closed contacts.

an alarm

response time proportional to

overload

Remote input (Reset if VDC =

0 to +0.8 V)

< –130 dBc

RJ-45

10/100 IEEE802.3

+/- (8 to 18) VDC @ 2.65 W

+/- (8 to 18) VDC @ 2.65 W

+/- (18 to 36) VDC @ 2.65 W

+/- (18 to 36) VDC @ 2.65 W

+/- (36 to 72) VDC @ 2.65 W

+/- (36 to 72) VDC @ 2.65 W

output impedance

0 to 50 °C (32 to 122 °F)

–20 to +80 °C (–4 to +176 °F)

4.75” L x 6.44” W x 1.22” H

(121 x 164 x 31 mm)

31

Page 44

Frequency Range

ACM500I

--L1

L2

M

---

RF Power Range

ACMI-xx-xxxxxx

ACMI500-xx-xxxxxx

Accuracy

ACMI500

--L1

L2

M

----

Insertion Loss, Max.

108 - 960 MHz

960 - 2400 MHz

VSWR, Max.

N Connectors

108 - 960 MHz

960 - 2400 MHz

7/16 DIN Connectors

108 - 960 MHz

960 - 2000 MHz

2000 - 2400 MHz

ACMI

ACMI

L0-xxxxxx

L1-xxxxxx

L2-xxxxxx

M-xxxxxx

H-xxxxxx

L0

L1

L2

M

H

108 – 138 MHz

136 – 225 MHz

225 – 520 MHz

470 – 960 MHz

960 – 2400 MHz

2.5 – 100 W

12.5 – 500 W

+/- 8%

± 10%

± 8%

± 5%

± 5%

0.1 dB

0.15 dB

1.07:1

1.1:1

1.07:1

1.1:1

1.2:1

32

Page 45

Safety

EMC Directive 2004/108/EC relating to

Safety European Standard EN 61010-

Replacement Parts

electromagnetic compatibility

EN 61326-1 - Electrical equipment

for measurement, control and

laboratory use - EMC requirements

- Part 1: General requirements

(IEC

61326-1):

Radiated Immunity (EN 61000-4-3)

Radiated Emissions (EN 55011)

ESD Immunity (EN 61000-4-2)

EFT Immunity (EN 61000-4-4)

Surge Immunity (EN 61000-4-5)

Conducted Immunity (EN 61000-4-

6)

1:2001 – Safety Requirements for

Electrical

Equipment for Measurement,

Control, and Laboratory Use.

Description Part Number

Instruction Manual 920-ACMI

PCTool Software 7005A970

DB-15 Interface Cable,

50 ft., male/female

DB-15 Interface Connector SUBCON-15/M-SH

5A2264-15-MF-50

33

Page 46

34

Page 47

Limited Warranty

All products manufactured by Seller are warranted to be free from defects in

material and workmanship for a period of one (1) year, unless otherwise speci

fied, from date of shipment and to conform to applicable specifications, drawings, blueprints and/or samples. Seller’s sole obligation under these warranties

shall be to issue credit, repair or replace any item or part thereof which is

proved to be other than as warranted; no allowance shall be made for any labor

charges of Buyer for replacement of parts, adjustment or repairs, or any other

work, unless such charges are authorized in advance by Seller.

If Seller’s products are claimed to be defective in material or workmanship or

not to conform to specifications, drawings, blueprints and/or samples, Seller

shall, upon prompt notice thereof, either examine the products where they are

located or issue shipping instructions for return to Seller (transportationcharges prepaid by Buyer). In the event any of our products are proved to be

other than as warranted, transportation costs (cheapest way) to and from

Seller’s plant, will be borne by Seller and reimbursement or credit will be made

for amounts so expended by Buyer. Every such claim for breach of these warranties shall be deemed to be waived by Buyer unless made in writing within ten

(10) days from the date of discovery of the defect.

The above warranties shall not extend to any products or parts thereof which

have been subjected to any misuse or neglect, damaged by accident, rendered

defective by reason of improper installation or by the performance of repairs or

alterations outside of our plant, and shall not apply to any goods or parts

thereof furnished by Buyer or acquired from others at Buyer’s request and/or to

Buyer’s specifications. Routine (regularly required) calibration is not covered

under this limited warranty. In addition, Seller’s warranties do not extend to the

failure of tubes, transistors, fuses and batteries, or to other equipment and

parts manufactured by others except to the extent of the original manufacturer’s warranty to Seller.

The obligations under the foregoing warranties are limited to the precise terms

thereof. These warranties provide exclusive remedies, expressly in lieu of all other

remedies including claims for special or consequential damages. SELLER NEITHER

MAKES NOR ASSUMES ANY OTHER WARRANTY WHATSOEVER, WHETHER

EXPRESS, STATUTORY, OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS, AND NO PERSON IS AUTHORIZED TO ASSUME FOR SELLER ANY

OBLIGATION OR LIABILITY NOT STRICTLY IN ACCORDANCE WITH THE FOREGOING.

-

35

Page 48

Bird Technologies

36

Loading...

Loading...