Page 1

Compression sprayer

Profi Star 5 ITB

www.birchmeier.com

03/2019/11862210

Operating manual

Please read these

instructions carefully and

keep them in a safe place

Birchmeier Sprühtechnik AG

Im Stetterfeld 1

5608 Stetten

Schweiz

T +41 56 485 81 81

F +41 56 485 81 82

Page 2

Apparatus

Profi Star 5, ITB

Condition of fluid Air

Max allowable pressure

PS

4 bar

Max allowable temperature

TS

30°C

Min allowable temperature

TS

5°C

Volume V 7.5 l

Test-pressure

PT

concerning the control of series

Capacity of filling 5 l

Point of application

Sprayer

Peculiarity portable

Marked

CE

Safety control equipment

with pressure relief valve

EU Declaration of Conformity

over Manufacturing and Approval for Pressure Vessels in according to Directive 97/23 EG

Dwg for Manufact

Profi Star 5: 118 622 Rev. B Date 22.01.2015

Pressure vessel: Category I, according diagram 1, in the attachment 2 of Directive 97/23 EC

Fluid-Group 1 acc. Article 9

Fabricant: Birchmeier Sprühtechnik AG, CH-5608 Stetten

We hereby confirm, that the pressure vessel without equipment to which this declaration is refering to

is in compliance with the Directive 97/23 EC of European Parliament and of the Council of 29 May

1997.

The declaration based of EC-Certificate of conformity relating:

Birchmeier Sprühtechnik AG, CH-5608 Stetten

Advises for operators are in the operating manual.

Stetten, 23.01.2015

M. Zaugg

Head of Development & Design

Page 3

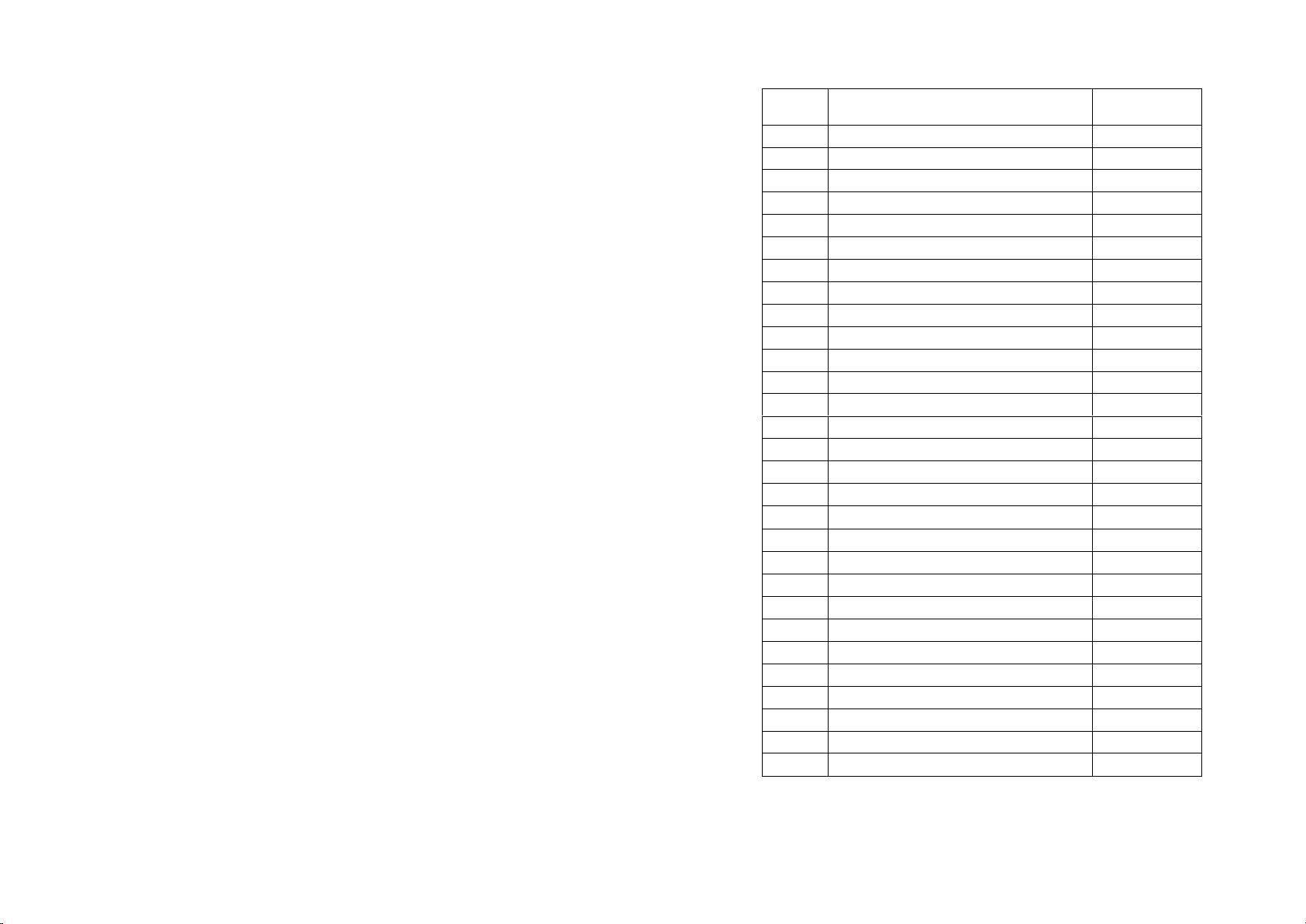

Guarantee

Pos.

Description

Parts number

1

Pressure relief valve 4 bar

116 179 02-SB

2 a

Flat gasket 21x15.4x2

3

Compressed air valve

501 375 31

4

Pump, black 1.4301 PP Viton

116 253 01-SB

5 a

O-Ring 50.16x5.34

6 a

Sleeve with guide (6 pcs.)

108 532 03

7 a

Sleeve

7

Sleeve PE-LD (6 pcs.)

116 427 01-SB

8 a

Pump gasket

9

Suction tube L = 435 mm

104 505 02

10 a

Flat gasket 15x5.5x2

11

Hose line 1.3 m

103 960 16

12

Trigger valve

120 475 01-SB

13

Handle plastic

103 922 01-SB

14 b

Filter

108 283 01

15 b

Gasket 24x16.2x2

16 b

Gasket 24x16.2x2

17 b

Valve rod

17 b

Shaped packing 11.8x4x4

17 b

Rim

18 b

Gland packing

19

Lever

120 465 01

20 b

Flat gasket 12.7x7x3

21 b

Flat gasket 17x11x1.5

22

Spray tube, 50 cm curved

113 707 04

23 a

Flat gasket 17x12.7x2

24

Adjustable nozzle 1.3 mm

285 025 98-SB

25 a

O-Ring 7.66x1.78

a

Gasket set

103 990 03-SB

b

Gasket set trigger valve

120 580 01-SB

We make a warranty of 24 months from the date of sale. During this warranty period we will repair

free of charge defects of the sprayer which are due to deficiencies in material and manufacturing,

either by repair of replacement of parts, or of the entire sprayer.

Prerequisite to the honoring of warranties is the appropriate storage and use of our equipment

strictly in accordance with the operating instructions which were valid on delivery (including the

instructions given on the appliances themselves). These instructions constitute an integral part of

our contract. Any and all damages which fall within our scope of responsibility must be reported to

us in writing immediately after they have been discovered.

Expressly excluded from the warranty and liability are damages and deficiencies:

Resulting from the non-adherence to our instructions and usage recommendations in the operating

manuals such as the improper use or inadequate maintenance of our equipment;

Resulting from chemical attack, or due to normal wear;

Due to damages, the causes of which are beyond the scope of our responsibility and influence, e.g.

mechanical damage, force majeure.

The warranty becomes null and void and any and all liabilities are disclaimed if the user or any third

party alters or makes inexpert repairs to the sprayer.

Excluded from the warranty and liability are all incidents which extend beyond the obligations set

forth above. Any and all liability is expressly excluded to the extent of the law. Expressly excluded is

in particular any and all liability for damages which are purely asset-related such as lost profit, loss

of use, operating outage etc.

Place of jurisdiction: Baden, Switzerland

Applicable law: Swiss law

For any further information concerning use or maintenance of the equipment please refer to your

dealer.

Technical data

Permissible operating pressure 4 bar max. (max. 58.02 psi)

Permissible operating temperature 5°C - 30°C (41°F - 86°F)

Tank volume 7.5 litres (1.98 US Gal)

Maximum tank contents 5 litres (1.32 US Gal)

Spraying-rate at 4 bar Mist, 0.53 litre/min (0.13 US Gal / min.)

Regulating nozzle Jet, 1.41 litre/min (0.36 US Gal / min.)

Spare parts list

Page 4

Important!

Before taking the sprayer into service for the first time, make sure to read the operating manual

thoroughly.

The user is liable for damages resulting from failure to observe these instructions.

Failure to observe the safety and warning alerts can result in injury to or death of persons!

Warning!

Do not use the sprayer while other persons are still in the working area.

Do not blow out a clogged nozzle or clogged valves with the mouth (danger of poisoning).

Clean the sprayer after each use, making sure not to cause pollution to water.

Do not fill chemicals into other containers (bottles, cans or the like). Store equipment and chemicals

such that they cannot be reached by children and household animals.

When the sprayer is passed on to third parties, definitely make sure that it is accompanied by the

operating manual.

The user is responsible versus third parties, and in particular domestic animals and children, that

when taking the sprayer into service any escaping media as a result of the opening of the safety

relief valve, as well as the spray jet during spraying operations, are not directed at said third parties.

When spraying the agent avoid contact with the spraying liquid. During this work make sure to wear

protective clothing, a protective mask and safety glasses and to protect the hands.

Do not spray against the wind, as well as during strong winds. Do not spray any more of the agent

than necessary for the surface to be treated.

Safety Instructions

Before each use check to ensure that the sprayer has been correctly assembled, and that it is in a

functional and undamaged condition. Special attention must be given to the tightness of the hose

connections, as well as to the correct functioning/freedom of movement of the safety relief valve (1).

The sprayer is equipped with a pressure relief valve (1) which discharges excessive pressure. The

pressure relief valve is adjusted to 4 bar / 58.02 psi. It is noted expressly that any and all

manipulation of the pressure relief valve is prohibited. In this case, any and all warranties of

BIRCHMEIER Sprühtechnik AG become null and void, and all liabilities are disclaimed by

BIRCHMEIER Sprühtechnik AG.

Make sure that the desired agent is suitable for this sprayer. The safety and handling instructions of

the chemical manufacturer are to be observed and adhered to. The use of any and all chemicals is

at your own responsibility and risk. If you should have any doubts in this respect, please consult our

after-sales service.

The sprayer must not be filled with caustic substances (e.g. disinfectants and impregnating liquids

which attack the skin or materials), corrosive substances (acids) or highly inflammable or

combustible substances.

The sprayer must not be filled with liquids at a temperature greater than 30°C / 86°F. Do not leave

the appliance standing in the sun under pressure. The effects of frost can damage the equipment.

Before unscrewing the pump (4) always first release the pressure via the pressure relief valve (1),

holding the sprayer away from the body at an angle.

Applications

The equipment can be used to spray the recognized pesticides, weed-killers and liquid fertilizers, as

used in the home, in the garden, on the farm, or in vineyards.

Preparing the equipment for use

Fit the spray pipe according the spare parts diagram. Screw the stop valve (11) on to the hose (10)

and then insert the spray tube (13) with nozzle (15) in the stop valve and screw up tight. Finally, make

sure all joints are tight.

Operation

Filling the tank:

On each occasion first fully release the pressure in the tank by lifting the pressure relief valve (1).

Unscrew the pump (4) and fill the tank; the maximum permissible volume of liquid must not be

exceeded (see level-mark on the tank), so that sufficient space remains for the air-cushion. The

maximum permissible operating temperature is 30°C / 86°F.

Pressurizing the tank:

Screw in the pump (4) and tighten the connection firmly. Release the pump handle from the locked

position by pressing down on it slightly and turning it to the left. Pump up until the red mark appears on

the pressure relief valve (1). Operating pressure has then been reached. Fasten the pump handle in

the locked position again.

Compressed air: In order to pump up the appliance using an external pressure source a pressurereducing valve must be used, set to a maximum pressure of 4 bar / 58.02 psi. When a pressure of 4

bar / 58.02 psi has been reached the pressure source must be removed.

Spraying:

The liquid is sprayed by operating the spray-gun. The spray-pattern can be matched to the particular

requirement by turning the milled part of the adjustable regulating nozzle.

Releasing the pressure:

When spraying is completed or before unscrewing the pump in order to re-fill or empty the tank the

pressure must be fully released by lifting the pressure relief valve (1). When doing this, hold the

appliance at an angle, away from the body.

Care and maintenance

After use the appliance must be emptied; never store the spray-liquid in the sprayer.

Unscrew the pump and empty the tank.

The appliance must be washed out using a suitable agent and then rinsed with clean water; do not

use hot water (max. 30°C / 86°F).

Store the equipment away from the effects of frost. For storage the spray-tube may be hooked onto

the pump handle.

Particular attention must be given to parts which are subject to wear, such as the nozzle and

gaskets. The nozzle (15) must be cleaned periodically. These parts are easily replaceable.

Periodically apply a little oil to the piston-rod, the thread of the pump-tube and the O-ring (5) (see ->

oil). Screw in the pump only loosely when the appliance is not in use.

Do not clean the nozzle with hard objects, nor blow through it using the mouth. The most suitable

cleaning device is a nail-brush or tooth-brush.

To dry the sprayer, place it upside down, without the pump (4), and leave it standing open to the air.

Spare parts and repairs

If any part shows signs of damage or wear, replace it immediately. Use only BIRCHMEIER original

parts (see spare parts list).

Loading...

Loading...