Page 1

Operator’s Manual

Microplate Dispenser

MultiFlo™ FX Microplate

Dispenser

Page 2

Page 3

MultiFlo™ FX Multi-Mode Dispenser

Operator's Manual

BioTek Instruments, Inc.

May 2014

© May 2014

Part Number 1261000

Revision B

Page 4

ii | MultiFlo FX Operator's Manual

Notices

BioTekInstruments, Inc.

Highland Park, P.O. Box 998

Winooski, Vermont 05404-0998 USA

All Rights Reserved

© 2014, BioTek®Instruments, Incorporated. No part of this publication may be

reproduced, transcribed, or transmitted in any form, or by any means electronic

or mechanical, including photocopying and recording, for any purpose other

than the purchaser’s use without written permission of BioTek Instruments, Inc.

Trademarks

BioTek®is a registered trademark and MultiFlo™ FX Multi-Mode Dispenseris a

trademark of BioTek Instruments, Inc.

Microsoft®, Internet Explorer®, Windows®, Windows 7, Windows 8, Windows

Vista®, Windows XP, and Excel®are either registered trademarks or trademarks

of Microsoft Corporation in the United States and/or other countries.

All other trademarks are the property of their respective holders.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a

commitment by BioTek Instruments, Inc. Changes made to the information in

this document will be incorporated in new editions of the publication. No

responsibility is assumed by BioTek for the use or reliability of software or

equipment that is not supplied by BioTek or its affiliated dealers.

MultiFlo™ FX Multi-Mode Dispenser

Page 5

Notices|iii

Contents

Notices ii

All Rights Reserved ii

Trademarks ii

Restrictions and Liabilities ii

Global Service and Support ix

Revision History x

Document Conventions xi

Intended Use Statement xi

Quality Control xi

Warranty and Product Registration xii

Dispense Cassette Warranty xii

Repackaging and Shipping xii

Warnings xii

Hazards and Precautions xiii

Hazards xiii

Precautions xiv

CE Mark xvi

Directive 2004/108/EC: Electromagnetic Compatibility xvi

Directive 2006/95/EC Low Voltage (Safety) xvi

Directive 2002/96/EC: Waste Electrical and Electronic Equipment xvii

Directive 98/79/EC: In Vitro Diagnostics (if labeled for this use) xvii

Electromagnetic Interference and Susceptibility xvii

USA FCC CLASS A xvii

Canadian Department of Communications Class A xviii

User Safety xviii

Safety Symbols xix

Introduction 1

Introducing the MultiFlo™ FX Dispenser 2

Features of the MultiFlo FX 3

Washer 3

Peri-pump Dispenser 4

Syringe Dispensers 4

Liquid Handling Control™ (LHC) Software 5

RAD™ Technology Features 5

MultiFlo FXModels 6

MultiFlo FX Dispenser Comparison 7

Plate Types Table 9

BioStack Compatibility 10

Package Contents 12

Optional Accessories 13

Peri-pump Optional Accessories 13

Syringe Dispenser Optional Accessories 14

BioTek Instruments, Inc.

Page 6

iv | MultiFlo FX Operator's Manual

Strip Washer Optional Accessories 15

Physical Specifications 18

Performance Specifications 21

Peri-Pump Dispenser 21

Syringe Dispensers 22

Strip Washer 23

Space Requirements 25

BioTek's Customer Resource Center 26

Installation 27

Unpack and Inspect the Instrument 28

Install the Waste Tubing 29

Remove the Shipping Hardware 31

Set up the Strip Washer 34

Strip Washer accessories 34

Attach washer module and connect its cable 35

Install the tubing bracket 37

Install the Fluid Supply 38

Install the Waste Bottle 39

Install the muffler 41

Install Washer Manifolds 41

Set Up the Peri-pump Dispenser 44

Attach the Peri-pump Cover Panel 44

Install the Secondary Peri-Pump 46

Install RAD Technology Components 51

Install the Tubing Bracket and RADModule 51

Install the tubing bracket 52

Attach the RADModule to the Tubing Bracket 52

Install RAD Dispense Head 53

Dispense Cassette Diagram 54

Install the Dispense Cassette 56

Install RAD Technology Cassette 58

Prime Trough Inserts 59

Peri-pump Reservoir Holder 60

Shorten the Dispense Cassette Tubing 61

Install the Syringe Dispenser Component 62

Syringe Dispenser Placement Options 63

Install the Syringe Dispenser on Back Shelf 64

Install the Syringe Dispenser on Top 65

Install Tubing and Manifolds for Syringe Dispenser 68

Syringe Dispenser Check Valves 70

Install Inline Filter for 32-Tube Dispensers 71

Install Software/Connect to Computer 71

Connect to Host Computer 72

Connect Power Cable 72

Define Instrument Settings 73

LHC Users Only 73

Enable Waste Sensor 73

MultiFlo™ FX Multi-Mode Dispenser

Page 7

Notices|v

Update the Instrument to use the Syringe Dispenser 74

Change the Syringe Dispenser Manifold 75

Change the cassette type setting 76

Setting the Time and Date 77

Define Startup Preferences (LHC users only) 77

Verify Performance 79

Verify the Peri-Pump Dispenser 80

Verify the Syringe Dispensers 80

Verify the Washer Component 81

Repacking the MultiFlo FX 82

Install the Shipping Hardware 83

Repacking the Secondary Peri-pump 85

MultiFlo FX Repacking 86

Repacking the Syringe Dispenser 89

Repacking the Strip Washer 90

Operation 91

Touch Screen Basics 92

Quick Prime 93

Quick Dispense 94

Quick Wash 95

Add protocols to the Home screen 95

Remove protocols from the Home screen 95

Get protocols from a memory stick - USB drive 96

Hardware Change Detected 96

Optimize Performance 98

Recommended prime volumes for the Strip Washer 99

Recommended prime volumes for the Peri-pump 99

Recommended prime volumes for the Syringe dispensers 101

Optimize protocols to improve evacuation 101

Add a secondary aspiration to a wash cycle 101

Create or Modify a Protocol 102

Protocol Parameters Tables 103

Wash Parameters Table 108

Washer Flow Rates 111

Pre-Dispense 113

Minimum Prime Volumes for the Strip Washer 114

Bottom Wash 114

Change the Plate Type 115

Rename a protocol 115

Shake/Soak Step Parameters 116

Repeat steps in a Loop 116

Delay the Protocol 117

Timer Activated Delay 118

RUN: Running Predefined Protocols 120

LHC Users Only: Customize the Predefined Protocols 120

Predefined Protocols Listing 121

Predefined Sample Protocols 122

Operating with the BioStack 124

BioTek Instruments, Inc.

Page 8

vi | MultiFlo FX Operator's Manual

Use the BioStack 125

Re-stack plates in the BioStack 127

Nth Plate to perform special process 127

About the Nth Plate Step 128

Advanced Plate Sequencing with the BioStack 129

Plate Types and Processing Patterns 133

Handling Special Plates and Mini-tubes 134

1536F - 1536-well Flanged Plates 134

Peri-pump Special Plate Handling 134

Special Plate Carrier for Mini-tubes 136

Mini-Tube Racks 137

Dispensing to Mini-Tubes 137

Dispense Processing Patterns 138

8-Channel Dispenser Dispense Pattern 139

Dispense Pattern with Both Syringes 140

Washer Operation 141

About the MultiFlo FX Wash Step 141

Cell Wash 142

Define a Cell Wash Protocol 142

Cell Wash Strategies 143

Biomagnetic Separation - Magnetic Bead Assays 145

Perform Magnetic Bead Assays 146

Optimize Magnetic Bead Protocols 147

Flat Magnets 147

Ring Magnets 148

How to determine the Magnet Adapter Height Offset 149

Magnet Height Offset 150

Special Procedure for Magnetic Bead Assays 151

Peri-pump Peristaltic Dispenser 152

Peri-pump: How it works 153

Release the tension on the dispense cassette 154

Peri-pump Dispense Step 155

RADTip Tracking 156

RAD Well Map 157

Require a Specific Peri-pump Cassette 158

Peri-pump Advanced Settings 159

Settings for 0.5 µL Dispense 159

8-to-1 Tube RAD Cassette 159

Dual Syringe Dispenser 160

How to Prime the Syringe dispenser 160

Syringe Prime Step 161

Syringe Dispense Step 163

Change the Syringe Dispenser Manifold 165

Syringe Dispenser Settings 166

Syringe Dispenser- Autoclavable vs. Non-autoclavable 167

Changing the Instrument's Settings 168

Dispense Pattern 168

MultiFlo™ FX Multi-Mode Dispenser

Page 9

Notices|vii

Change the Plate Carrier Setting (Touch screen) 169

Change the Plate Clearance Setting (Touch screen) 169

Plate Carrier Speed 170

Upload-Download Protocols (LHC Only) 170

Transfer Protocols (Touch Screen Only) 170

Transfer Plate Lid Definitions 171

Maintenance 173

Overview 174

Recommended Maintenance Schedule 176

Daily Maintenance 178

Overnight/Multi-Day Maintenance 179

AutoPrime 179

Turn on AutoPrime for the Peri-pump Dispenser 180

Turn on AutoPrime for the Syringe Dispenser 182

Turn on AutoPrime for the Washer 183

Soak the manifold tubes in cleaning fluid 185

Removing Protein Residuals and Fungi Growth 187

Periodic Maintenance 189

Autoclavable Components 190

Clean the Bottles 190

Clean the Plate Carrier 191

Clean the exterior surfaces 191

Peri-pump Dispenser Maintenance 192

Flush the Dispense Cassette 192

Unclog the Dispense Tips 194

RADSingle-tube Cassette - Unclog the Tip 196

RAD8-to-1 Cassette - Unclog the Tips 197

Record the Number of Plates Processed 199

RAD8-to-1 Cassette - Replace Chute 200

Syringe Dispenser and Strip Washer Maintenance 201

Clean the Manifolds 201

Clean the Dispense/Aspirate Tubes 202

Clean or Replace the Check Valves 204

Autoclave the Syringe Head 204

Decontamination 205

Tools and Supplies 206

Decontaminate Exterior Surfaces 207

Decontaminate Tubing and Manifold 208

Long Shutdown (Prepare for Storage or Shipment) 208

Storing the Instrument 210

Replace Components 210

Calibrate the Backlash for Syringe Dispenser 212

Qualification 215

Qualification Overview 216

Washer 216

Peri-pump and Syringe Dispensers 216

Qualification Schedule 217

BioTek Instruments, Inc.

Page 10

viii | MultiFlo FX Operator's Manual

Index..........................................................................................

System Self-Test, Verify Information 218

Record Onboard Software 218

Liquid Testing the MultiFlo™ FX Multi-Mode Dispenser 219

Which Tests to Perform? 219

Important Recommendations for All Liquid Tests 220

Peri-pump Dispense Precision and Accuracy Tests 221

Peri-pump Dispenser Test Materials 223

Peri-pump Dispenser Precision and Accuracy Test Solutions 223

Perform the Peri-Pump Precision and Accuracy Tests 224

Syringe Dispenser Liquid Tests 235

Syringe Dispenser Test Materials 236

Syringe Dispenser Test Solutions 236

Perform the Syringe Dispense Precision & Accuracy Test 236

Washer Qualification Liquid Tests 250

Dispense Precision and Accuracy Test 250

Evacuation Efficiency Test 250

Washer Qualification Test Materials 251

Create Washer Qualification Protocols 252

Dispense Precision and Accuracy Test 253

Evacuation Efficiency Test 254

Evacuation Diagnostic Test 256

Troubleshooting 271

Troubleshooting 272

Syringe Dispenser Troubleshooting 273

Dispense Manifold Movement 273

Fluid Delivery 274

Fluid Leakage 276

Microplate Carrier Movement 276

Syringe Movement 277

Peri-pump Troubleshooting 277

Washer Troubleshooting 278

Fluid Aspiration 278

Fluid Delivery 280

Fluid Leakage 282

Error Codes 283

System Error Codes 284

MultiFlo FX Software Error Codes 294

Chemical Compatibility 306

301

MultiFlo™ FX Multi-Mode Dispenser

Page 11

Global Service and Support| ix

Global Service and Support

BioTek instrument service and repair is available worldwide at several of BioTek’s

International Service Centers and in the field at your location. Contact the office

nearest you to arrange service or to get answers to your technical questions, call the

Technical Assistance Center (TAC) at 802-655-4740 in the US.

BioTek World Headquarters US BioTek China

Mailing Address:

PO Box 998, Highland Park

Winsooki, VT 05404-0998 United States

Service Shipping Address:

15 Tigan Street

Winooski, VT 05404 United States

Phone: (800) 242-4685

Fax: (802) 654-0638

Email: TAC@biotek.com

Website: www.biotek.com

BioTek Germany Service Center

& European Coordination Center

Kocherwaldstrasse 34 D-74177

Bad Friedrichshall

Germany

Phone: +49 (0) 71369680

Fax: +49 (0) 7136968111

Room 304, Tower D

Ocean International Center

62 Middle 4th East Ring Road

Chaoyang District

Beijing 100024

P.R. China

Phone: +86 (10) 85865569

Fax: +86 (10) 85861829

Email: infochina@biotek.com

Website: www.biotekchina.com.cn

BioTek Instruments SAS

Bureau de liaison France

50 avenue d’Alsace

68025 Colmar Cedex

France

Phone: +33 (3) 89206329

Fax: +33 (3) 89204379

Email: info@biotek.de

Website: www.biotek.de

Email: info@biotek.fr

Website: www.biotek.fr

BioTek India BioTek Singapore

Unit 223, Linkway Estate

New Link Road, Malad West

Mumbai 400064

India

Phone: +91 (22) 28789966

Fax: +91 (22) 28759944

Email: biotek@biotek.in Email: singapore@biotek.in

20 Science Park Road #01-08A

Teletech Park

Singapore 117674

Phone: +65 65922100

Fax: +65 67772611

BioTek Instruments, Inc.

Page 12

x | MultiFlo FX Operator's Manual

BioTek India BioTek Singapore

Website: www.biotek.in Website: www.biotek.com

BioTek South Korea BioTek Switzerland

3F, Gyungnam building, 830-48

Yeoksam-dong, Gangnam-gu

Seoul, South Korea (135-936)

Phone: +82 (0) 2-562-4740

Fax: +82 (0) 2-562-4750

Email: korea@biotek.com

Website: www.biotekinstruments.co.kr

Zentrum FanhÖfli 8

6014 Luzern

Switzerland

Phone: +41 (41) 2504060

Fax: +41 (41) 2505064

Email: info@biotek.ch

Website: www.biotek.ch

BioTek United Kingdom (UK) BioTek Japan

6 Bull Street

Potton, Bedfordshire SG19 2NR

United Kingdom

Phone: +44 (1767) 262000

Fax: +44 (1767) 262330

Email: info@biotek.uk.com

Website: www.biotek.uk.com

8F Andoh Building

2-7-1 Taito, Taito-ku

Tokyo 110-0016 Japan

Phone: +81 (0)3 5812 8109

Fax: +81 (0)3 5812 8115

Email: infojapan@biotek.com Website:

www.biotek.com/ja

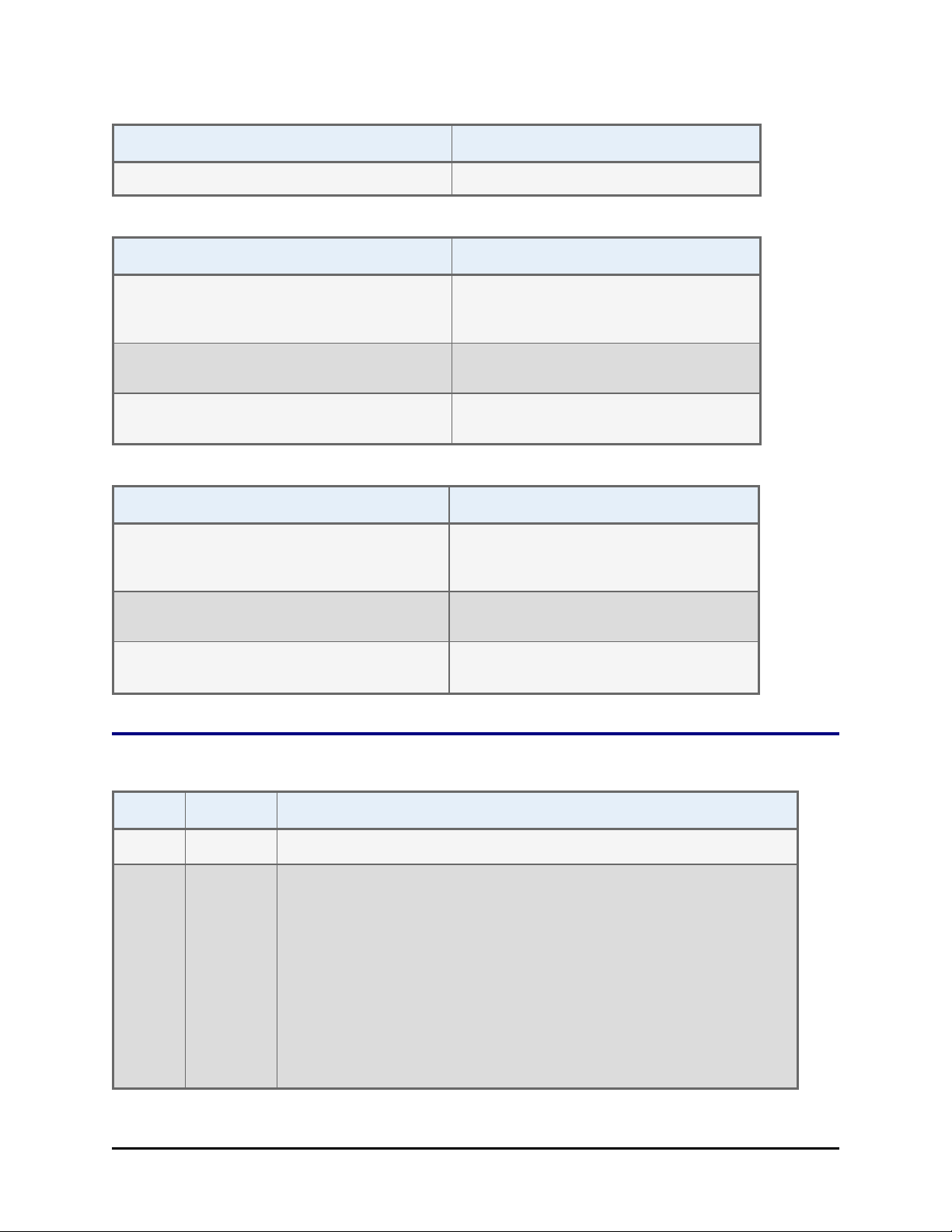

Revision History

Rev Date Changes

A 10/2013 First Issue

B 5/2014 The manual was updated to add RAD Technology content

throughout. Syringe dispenser installation steps were updated to

add the "Import from USB" calibration data feature. Added

references to new Peri-pump cassette types and new Syringe

dispenser manifolds. Added references to and some instructions

for running the BioStack 4 to process microplates with lids.

Updated the contents of the Cassette Calibration folder to match

improvements made to its separately purchased accessory kit:

PN7170017. Refined the procedure to remove proteins from the

tubing by emphasizing the need to flush first with buffer.

MultiFlo™ FX Multi-Mode Dispenser

Page 13

Document Conventions

This manual uses the following typographic conventions:

n This note format calls attention to important information.

Warnings are presented in this style to call attention to potential hazards and

other safety concerns.

This icon calls attention to important safety information.

Document Conventions| xi

Tips and suggestions for improving performance are formatted this way.

Navigation instructions: how to get to the function being described

Intended Use Statement

l The MultiFlo™ FX Multi-Mode Dispenser provides microplate priming and dispensing, and

when equipped, washing, for ELISA™, fluorescence and chemiluminescence

immunoassays, cellular and agglutination assays.

l If the instrument has an "IVD" label it may be used for clinical and non-clinical purposes,

including research and development. If there is no such label the instrument may only be

used for research and development and non-clinical purposes.

Quality Control

It is considered good laboratory practice to run laboratory samples according to

instructions and specific recommendations included in the assay package insert for

the test to be conducted. Failure to conduct Quality Control checks could result in

erroneous test data.

BioTek Instruments, Inc.

Page 14

xii | MultiFlo FX Operator's Manual

Warranty and Product Registration

Please take a moment to review the Warranty information that shipped with your

product. Please also register your product with BioTek to ensure that you receive

important information and updates about the product(s) you have purchased.

You can register online through BioTek’s Customer Resource Center (CRC) at

www.biotek.com or by calling 888/451-5171 or 802/655-4740.

Dispense Cassette Warranty

The Peri-pump dispense cassettes are backed by BioTek's Confidence-Plus lifetime

warranty. For the lifetime of the cassette, BioTek guarantees the cassette

components (Tip Holder, Center Holder, Tube Tensioner, and Tube Organizer) will

withstand steam autoclave conditions of 121°C and 1 bar (750 mmHg) without

adversely affecting dispense performance. In the event of a failure of any cassette

component previously listed, BioTek will replace the cassette components free of

charge.

Repackaging and Shipping

If you need to ship the instrument to BioTek for service or repair, contact BioTek

for a Return Materials Authorization (RMA) number and use the original packing

materials. Other forms of commercially available packaging are not recommended

and can void the warranty. If the original packing materials have been damaged or

lost, contact BioTek for replacement packing.

Warnings

Operate the instrument on a level, stable surface away from excessive

humidity.

When operated in a safe environment, according to the instructions in this

document, there are no known hazards associated with the MultiFlo FX.

However, the operator should be aware of certain situations that could result in

serious injury; these vary depending on the instrument type. See Hazards and

Precautions.

Strict adherence to instrument maintenance and qualification procedures is

required to ensure accurate dispense volumes and risk-free operation.

MultiFlo™ FX Multi-Mode Dispenser

Page 15

Hazards and Precautions

Hazards

The following hazards are provided to help avoid injury:

Warning! Power Rating. The instrument’s power supply or power cord must

be connected to a power receptacle that provides voltage and current within the

specified rating for the system. Use of an incompatible power receptacle may

produce electrical shock and fire hazards.

Warning! Electrical Grounding. Never use a plug adapter to connect primary

power to the external power supply. Use of an adapter disconnects the utility

ground, creating a severe shock hazard. Always connect the power cord directly

to an appropriate receptacle with a functional ground.

Warning! Service. Only qualified technical personnel should perform service

procedures on internal components.

Hazards and Precautions| xiii

Warning! Accessories. Only accessories which meet the manufacturer’s

specifications shall be used with the instrument.

Warning! Lubricants. Do not apply lubricants to the microplate carrier or

carrier track. Lubricant on the carrier mechanism will attract dust and other

particles, which may obstruct the carrier path and cause the instrument to

produce an error.

Warning! Liquids. Avoid spilling liquids on the instrument; fluid seepage into

internal components creates a potential for shock hazard or instrument

damage. If a spill occurs while a program is running, abort the program and

turn the instrument off. Wipe up all spills immediately. Do not operate the

instrument if internal components have been exposed to fluid.

Warning! Unspecified Use. Failure to operate this equipment according to

the guidelines and safeguards specified in this manual could result in a

hazardous condition.

Warning! Software Quality Control. The operator must follow the

manufacturer’s assay package insert when modifying software parameters and

establishing washing or dispensing methods. Failure to conduct quality

control checks could result in erroneous test data.

Warning! Internal Voltage. Always turn off the power switch and unplug the

power supply before cleaning the outer surface of the instrument.

BioTek Instruments, Inc.

Page 16

xiv | MultiFlo FX Operator's Manual

Warning! Potential Biohazards. Some assays or specimens may pose a

biohazard. Adequate safety precautions should be taken as outlined in the

assay’s package insert. This hazard is noted by the symbol shown here. Always

wear safety glasses and appropriate protective equipment, such as chemically

resistant rubber gloves and apron.

Warning! Pinch Hazard. Some areas of the instrument or its components can

present pinch hazards when the instrument is operating. Depending on the

instrument or component, these areas are marked with the symbol shown here.

Keep hands/fingers clear of these areas when the instrument is operating.

Precautions

The following precautions are provided to help avoid damage to the instrument:

Caution: Service. The instrument should be serviced by BioTek authorized

service personnel. Only qualified technical personnel should perform

troubleshooting and service procedures on internal components.

Caution: Spare Parts. Only approved spare parts should be used for

maintenance. The use of unapproved spare parts and accessories may result in

a loss of warranty and potentially impair instrument performance or cause

damage to the instrument.

Caution: Environmental Conditions. Do not expose the instrument to

temperature extremes. For proper operation, ambient temperatures should

remain within the range listed in the Specifications section. Performance may

be adversely affected if temperatures fluctuate above or below this range.

Storage temperature limits are broader.

Caution: Sodium Hypochlorite. Do not expose any part of the instrument to

the recommended diluted sodium hypochlorite solution (bleach) for more than

20 minutes. Prolonged contact may damage the instrument surfaces. Be certain

to rinse and thoroughly wipe all surfaces.

Caution: Buffer Solution. Although many precautions have been taken to

ensure that the instrument is as corrosion-proof as possible, the instrument is

not sealed and liquids can seep into sensitive components. Make sure that any

spilled buffer solution is wiped off the instrument. Prolonged exposure to salt

solution may corrode parts of the microplate carrier, movement rail, springs,

and other hardware.

Caution: Chemical Compatibility. Some chemicals may cause irreparable

damage to the instrument. The following chemicals have been deemed safe for

use in the instrument: buffer solutions (such as PBS), saline, surfactants,

deionized water, 70% ethyl, isopropyl, or methyl alcohol, 40% formaldehyde,

and 20% sodium hydroxide. Never use acetic acid, DMSO, or other organic

solvents. These chemicals may cause severe damage to the instrument.

MultiFlo™ FX Multi-Mode Dispenser

Page 17

Hazards and Precautions| xv

Contact BioTek for more information and prior to using other questionable

chemicals.

Caution: Bovine Serum Albumin. Solutions containing proteins, such as

bovine serum albumin (BSA), will compromise the instrument’s performance

over time unless a strict maintenance protocol is adhered to. See

Maintenance procedures regarding BSA.

Caution: Power Supply. Only use the power supply shipped with the

instrument. Operate this power supply within the range of line voltages listed

on it.

Caution: Disposal. This instrument contains printed circuit boards and wiring

with lead solder. Dispose of the instrument according to Directive 2002/96/EC,

“on waste electrical and electronic equipment (WEEE),” or local ordinances.

Caution: Warranty. Failure to follow preventive maintenance protocols may

void the warranty.

Caution: Shipping Hardware. All shipping hardware (e.g., shipping bracket

etc.) must be removed before operating the instrument and reinstalled before

repackaging the instrument for shipment.

Caution: Do not run the Peri-pump without a cassette installed on the pump.

Caution: Electromagnetic Environment. Per IEC 61326-2-6 it is the user’s

responsibility to ensure that a compatible electromagnetic environment for this

instrument is provided and maintained in order that the device will perform as

intended.

Caution: Electromagnetic Compatibility. Do not use this device in close

proximity to sources of strong electromagnetic radiation (e.g., unshielded

intentional RF sources), because these may interfere with the proper operation.

BioTek Instruments, Inc.

Page 18

xvi | MultiFlo FX Operator's Manual

CE Mark

Based on the testing described below and information contained

herein, this instrument bears the CE mark.

n Note: See the Declaration of Conformity for specific information.

Directive 2004/108/EC: Electromagnetic Compatibility

Emissions—Class A

The system has been type-tested by an independent, accredited testing

laboratory and found to meet the requirements of EN 61326-1: Class A for

Radiated Emissions and Line Conducted Emissions.

Verification of compliance was conducted to the limits and methods of EN 55011

(CISPR 11) Class A. In a domestic environment it may cause radio interference,

in which case, you may need to mitigate the interference.

Immunity

The system has been type-tested by an independent, accredited testing

laboratory and found to meet the requirements of EN 61326-1 and EN 61326-2-6

for Immunity. Verification of compliance was conducted to the limits and

methods of the following:

EN 61000-4-2, Electrostatic Discharge

EN 61000-4-3, Radiated EM Fields

EN 61000-4-4, Electrical Fast Transient/Burst

EN 61000-4-5, Surge Immunity

EN 61000-4-6, Conducted Disturbances from RFI

EN 61000-4-11, Voltage Dips, Short Interruptions and Variations

Directive 2006/95/EC Low Voltage (Safety)

The system has been type-tested by an independent testing laboratory and was

found to meet the requirements of this Directive. Verification of compliance was

conducted to the limits and methods of the following:

MultiFlo™ FX Multi-Mode Dispenser

Page 19

Electromagnetic Interference and Susceptibility| xvii

EN 61010-1, “Safety requirement for electrical equipment for measurement,

control and laboratory use. Part 1, General requirements.”

EN 61010-2-081, “Particular requirements for automatic and semi-automatic

laboratory equipment for analysis and other purposes.”

Directive 2002/96/EC: Waste Electrical and Electronic Equipment

Disposal Notice: This instrument contains printed circuit boards and wiring with

lead solder. Dispose of the instrument according to Directive 2002/96/EC, “on

waste electrical and electronic equipment (WEEE)” or local ordinances.

Directive 98/79/EC: In Vitro Diagnostics (if labeled for this use)

l Product registration with competent authorities.

l Traceability to the U.S. National Institute of Standards and Technology (NIST).

EN 61010-2-101 Particular requirements for in vitro diagnostic (IVD) medical

equipment.

Electromagnetic Interference and Susceptibility

USA FCC CLASS A

RADIO AND TELEVISION INTERFERENCE

NOTE: This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user

will be required to correct the interference at their own expense.

In order to maintain compliance with FCC regulations shielded cables must be

used with this equipment. Operation with non-approved equipment or

unshielded cables is likely to result in interference to radio and television

reception.

BioTek Instruments, Inc.

Page 20

xviii | MultiFlo FX Operator's Manual

Canadian Department of Communications Class A

This digital apparatus does not exceed Class A limits for radio emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Le present appareil numerique n'émet pas de bruits radioelectriques depassant

les limites applicables aux appareils numerique de la Class A prescrites dans

le Reglement sur le brouillage radioelectrique edicte par le ministere des

Communications du Canada.

User Safety

This device has been type-tested by an independent laboratory and found to meet

the requirements of the following:

l Underwriters Laboratories UL 61010-1 “Safety requirements for electrical

equipment for measurement, control and laboratory use; Part 1: general

requirements.”

l Canadian Standards Association CAN/CSA C22.2 No. 61010-1 “Safety

requirements for electrical equipment for measurement, control and

laboratory use; Part 1: general requirements.”

l EN 61010 Standards, see CE Mark on page xvi.

MultiFlo™ FX Multi-Mode Dispenser

Page 21

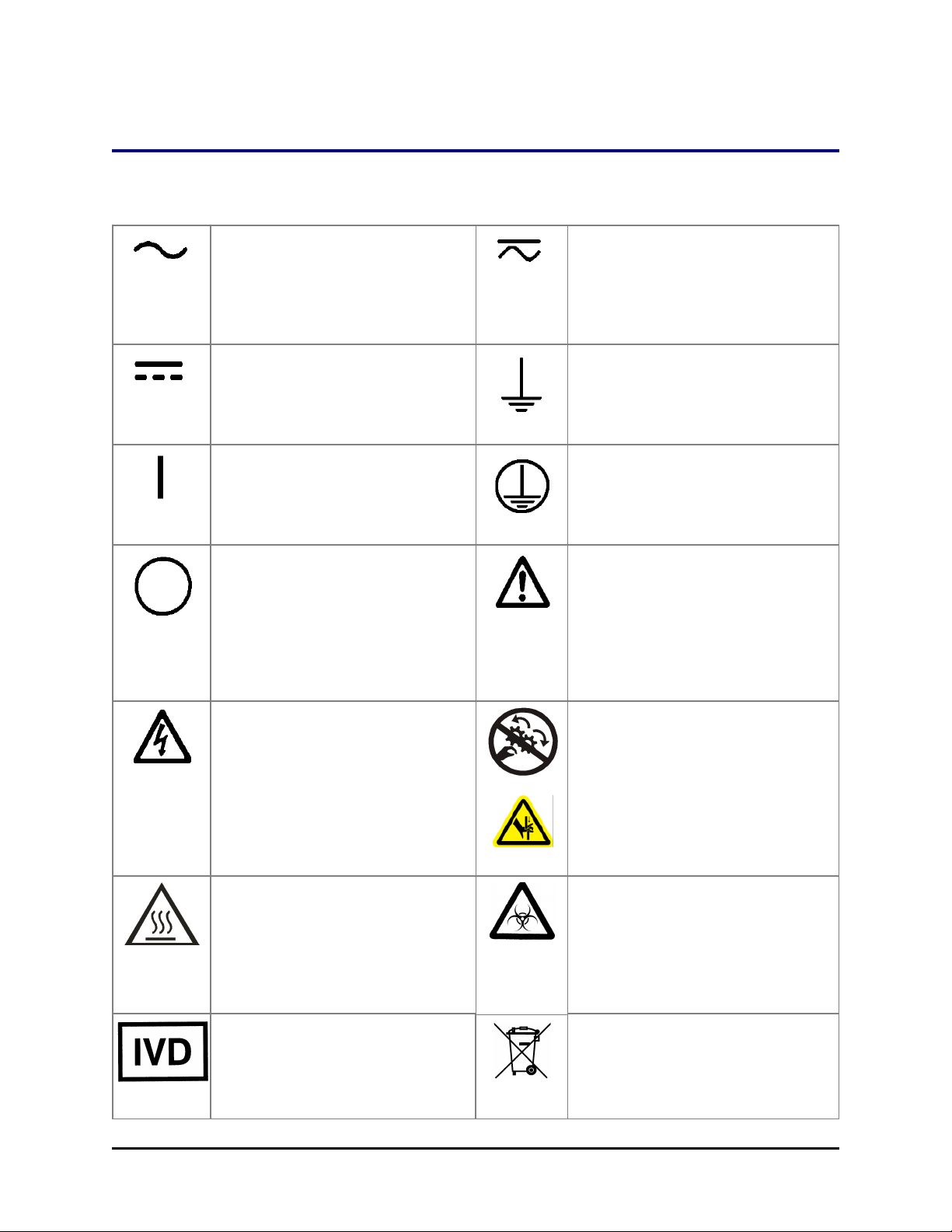

Safety Symbols

Some of these symbols appear on the instrument or accessories:

Alternating current

Courant alternatif

Wechselstrom

Corrientealterna

Correntealternata

Safety Symbols| xix

Both direct and alternating current

Courant continu et courant alternatif

Gleich - und Wechselstrom

Corriente continua y corrientealterna

Corrente continua e

correntealternata

Direct current

Courant continu

Gleichstrom

Corriente continua

Corrente continua

On (Supply)

Marche (alimentation)

Ein (VerbindungmitdemNetz)

Conectado

Chiuso

Off (Supply)

Arrêt (alimentation)

Aus (TrennungvomNetz)

Desconectado

Aperto

(sconnessionedallaretedialimentazio

ne)

Warning, risk of electric shock

Attention, risque de choc électrique

Gefährlicheelektrischeschlag

Precaución, riesgo de

sacudidaeléctrica

Attenzione, rischiodiscossaelettrica

Earth ground terminal

Borne de terre

Erde (Betriebserde)

Borne de tierra

Terra (difunzionamento)

Protective conductor terminal

Borne de terre de protection

Schutzleiteranschluss

Borne de tierra de protección

Terra diprotezione

Caution (refer to accompanying

documents)

Attention (voir documents

d’accompanement)

AchtungsieheBegleitpapiere

Atención (vease los

documentosincluidos)

Attenzione, consultare la doc annessa

Warning, risk of crushing or pinching

Attention, risqued’écrasement et

pincement

Warnen, Gefahr des Zerquetschens

und Klemmen

Precaución, riesgo del

machacamiento y sejeción

Attenzione,

rischiodischiacciareedintrappolarsi

Warning, hot surface

Attention, surface chaude

Warnen, heißeOberfläche

Precaución, superficiecaliente

Attenzione, superficiecalda

In vitro diagnostic medical device

Dispositif médical de diagnostic in

vitro

Medizinisches In-Vitro-Diagnostikum

Dispositivo médico de diagnóstico in

Warning, potential biohazards

Attention,

risquesbiologiquespotentiels

Warnung!

MoeglichebiologischeGiftstoffe

Atención, riesgosbiológicos

Attenzione, rischiobiologico

Separate collection for electrical and

electronic equipment

Les équipements électriques et

électroniques font l’objet d’une

collecte sélective

BioTek Instruments, Inc.

Page 22

xx | MultiFlo FX Operator's Manual

vitro

Dispositivo medico diagnostico in

vitro

Consult instructions for use

Consulter la notice d’emploi

Gebrauchsanweisung beachten

Consultar las instrucciones de uso

Consultare le istruzioni per uso

Getrennte Sammlung von Elektround Elektronikgeräten

Recogida selectiva de aparatos

eléctricos y electrónicos

Raccolta separata delle

apparecchiature elettriche ed

elettroniche

MultiFlo™ FX Multi-Mode Dispenser

Page 23

Chapter 1

Introduction

Thank you for purchasing the MultiFlo™ FX Multi-Mode

Dispenser. This chapter describes the instrument's features

and specifications and includes important contact information.

Introducing the MultiFlo™ FX Dispenser 2

Features of the MultiFlo FX 3

MultiFlo FX Dispenser Comparison 7

BioStack Compatibility 10

Package Contents 12

Optional Accessories 13

Physical Specifications 18

Performance Specifications 21

Space Requirements 25

BioTek's Customer Resource Center 26

Page 24

2 | Chapter 1: Introduction

Introducing the MultiFlo™ FX Dispenser

The MultiFlo FX offers several devices in one instrument: one or two peristaltic

pump dispensers called the Peri-pump, a dual Syringe pump dispenser, and either

a strip Washer or a single-channel Random Access Dispenser (RAD) module. The

MutliFlo FX is available in multiple configurations to support numerous

microplate geometries.

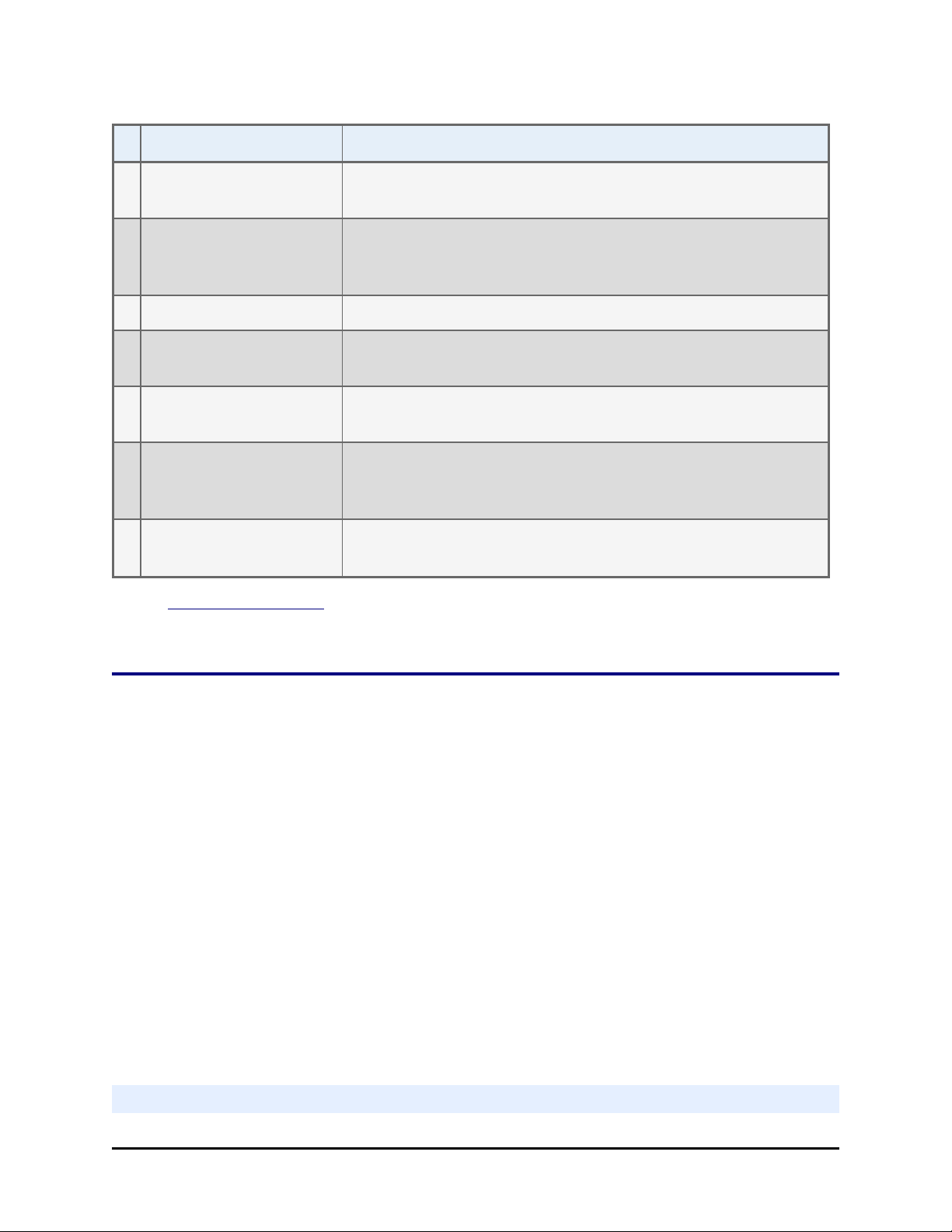

Device/Component Description

1 Peri-pump Dispenser Peristaltic, 8-channel dispenser with entirely visible fluid

path.

2 Dispense arm Holds the Peri-pump Tip Holder(s), the Syringe dispenser

manifolds and the washer dispense manifold, when

applicable.

MultiFlo™ FX Multi-Mode Dispenser

Page 25

Features of the MultiFlo FX | 3

Device/Component Description

3 Aspirate/RAD arm Washer and RAD models only: holds the strip washer's

aspirate manifold or the RAD cassette's tip holder.

4 Priming trough Waste reservoir for collecting or disposing of priming fluid.

Priming trough inserts, for collecting fluid, are shown in this

image.

5 Plate Carrier Holds standard microplates for processing.

6 Touch screen One of two ways to control the MultiFlo FX; the other way is

LHC.

7 Strip Washer An external module containing a syringe-pump dispenser

and vacuum aspiration pump.

8 Syringe Dispenser Another external module with two distinct syringe-pump

dispensers that support a variety of manifold types to

process standard and low-density microplates.

9 Peri-pump Dispenser Secondary or external Peri-pump dispenser (required for

RAD models).

See Plate Types Table on page 9 to review the plate types supported by each

device.

Features of the MultiFlo FX

l Supports all microplate-based assays, including ELISA, fluorescence,

chemiluminescence, RIA, DNA probes, and cellular assays.

l A variety of solutions, including buffered saline and reagents can be dispensed.

l The intuitive onboard software allows you to create and store wash and dispense

protocols. BioTek provides numerous predefined protocols for maintenance and

instrument qualification purposes.

l Two USB flash drive ports facilitate file transfer and storage.

l A low-maintenance design, the result of BioTek’s long history with liquid-handling

instruments.

l Compatible with BioTek’s BioStack™ Microplate Stacker for automated plate processing.

l A robot-accessible carrier that can be interfaced into some robotic systems.

l Computer control using BioTek’s Liquid Handling Control™software (“LHC”).

Washer

BioTek Instruments, Inc.

Page 26

4 | Chapter 1: Introduction

l Programmable dispense volumes, and a wide range of wash options, from gentle

washing for cellular assays to vigorous washing for ELISA.

l A “bottom washing” routine to lower the background absorbance and “crosswise” or

secondary aspiration to reduce residual volumes.

l Supports Wash, Prime, Dispense, and Aspirate steps.

l Several predefined protocols are provided to simplify preventative maintenance, which

should be performed regularly to ensure optimum washer performance.

Peri-pump Dispenser

l A peristaltic pump with eight individual tubes transfers fluid from a supply bottle, or up

to eight different supply bottles, to various vessels. The pump has four rollers over which

the tubing is stretched.

l The tubing is contained in an easy to load and unload cassette that is attached to the

pump head. The pump’s protective cover must be in place to run a dispense routine.

l Three tubing sizes are available: 1 µL, 5 µL, and 10 µL for the most precise dispensing of

volumes from 1 to 30,000 µL and 0.5 µL dispenses when using a 1 µL cassette.

l RAD™ Technology models support "random access dispensing" with several single-

channel cassette options, including a bulk dispensing cassette (8 tubes to one chute) with

flow tracking to minimize turbulence in the wells.

l Autoclavable tubing (steam temperatures and pressures of 121° C and 1 bar

(750 mmHg)) is compatible with 70% ethyl or isopropyl alcohol and 0.5% sodium

hypochlorite (bleach) solution for easy maintenance.

Syringe Dispensers

l The Syringe dispenser has a long-lasting seal that ensures precise and accurate fluid

delivery, as well as reproducibility for repeated dispenses.

l Two syringe pumps support distinct fluid sources and dispense manifolds:

o

16-channel: one tube per well for 384-well plates and two tubes per well for 96well plates.

o

32-channel: one tube per well for 1536-well plates.

o

8-channel (two manifolds in one block): one tube per well for both 96- and 384well plates.

l Autoclavable components can be used with organic solvents and provide easy

maintenance.

l Does not require recalibration

Low-density Microplate-specific Syringe Manifolds

Plate-specific dispense manifolds with angled dispensing for cellular assays:

MultiFlo™ FX Multi-Mode Dispenser

Page 27

Features of the MultiFlo FX | 5

l 6-well plate: 8-channel dispense manifold (4 tubes/well).

l 12-well plate: 9-channel dispense manifold (3 tubes/well).

l 24-well plate: 8-channel dispense manifold (2 tubes/well).

l 48-well plate: 12-channel dispense manifold (2 tubes/well).

Liquid Handling Control™ (LHC) Software

BioTek’s Liquid Handling Control (LHC) software lets you control the instrument

from your computer. You’ll enjoy the convenience of programming assay-specific

wash and dispense protocols in a familiar Windows environment (Microsoft

Windows®7, Windows 8, and Windows XP).

For high-throughput applications, the LHC supports BioStack™ integration.

Please refer to the LHC Installation Guide and Help system to learn about:

o

Installing the LHC software on the controlling computer

o

Running Maintenance protocols

®

o

Running Qualification protocols

o

Special considerations when operating with the BioStack Microplate Stacker

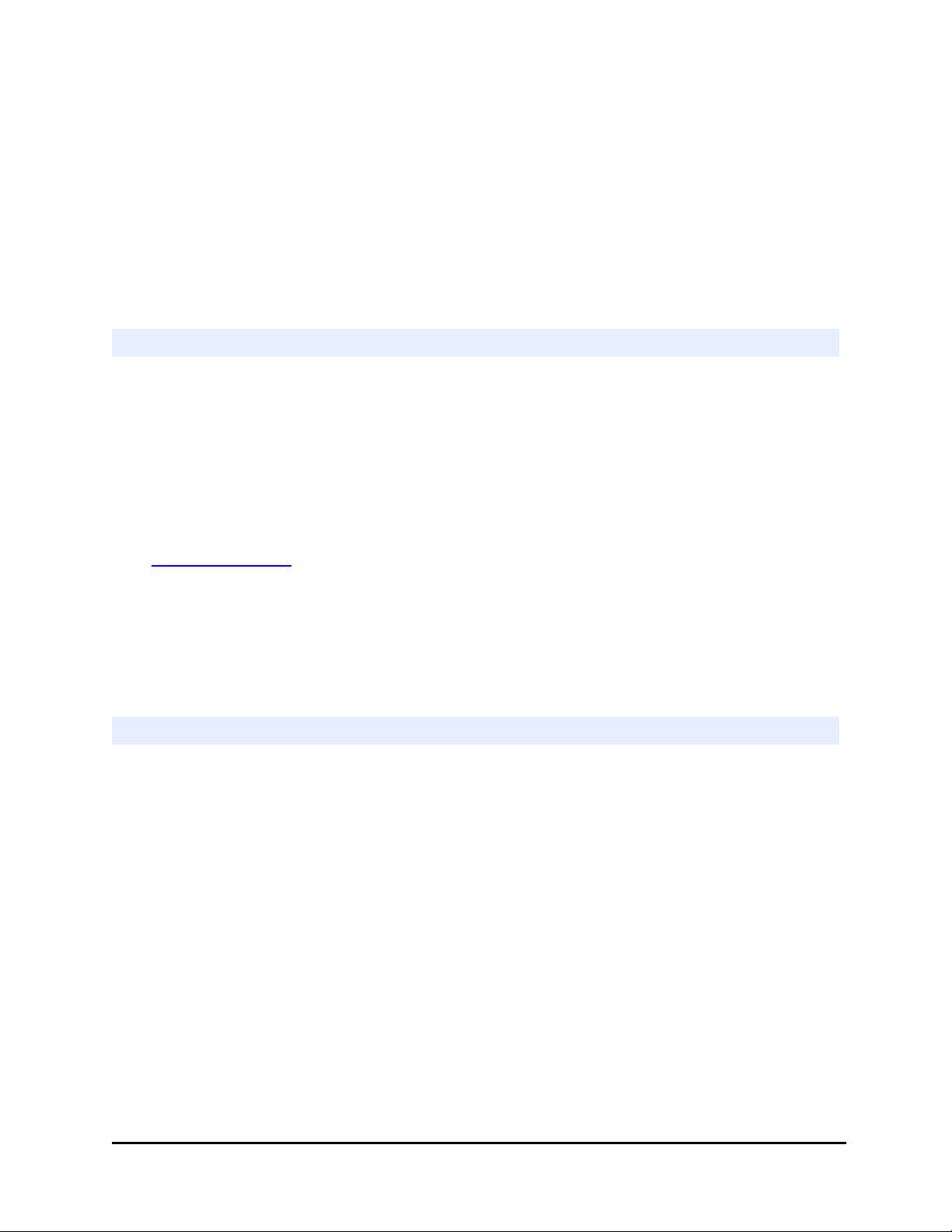

RAD™ Technology Features

Random Access Dispensing or RAD models offer the most gentle dispensing

possible to support sensitive cellular assays. The single-tube cassettes are ideal for

reagent preservation, hit-picking or partial plate filling. The 8-to-1 channel bulk dispensing cassettes are designed to preserve cell monolayers in low-density

plates. An external Peri-pump powers the RAD cassettes, which are not compatible

with the internal Peri-pump.

At a glance:

Features Single-tube 8-to-1 tube

Plate

Types

Cassette

tubing

6- to 384-well 6-, 12-, 24-well

1 µL, 5 µL, or 10 µL 5 µL only

Primary

Uses

Example

Application

Random dispensing in 48-,

96-, and 384-well plates

Dispensing costly reagent lowest dead volume

Fast but gentle dispensing with "Tip Tracking"

Media addition to cells in low-density plates

BioTek Instruments, Inc.

Page 28

6 | Chapter 1: Introduction

Features Single-tube 8-to-1 tube

Other Hit picking: fast, intuitive

selection of individual

wells, rows, or columns;

Access and preserve more

reagent: single tube can

handle minute quantities of

reagent.

MultiFlo FXModels

Tip Tracking: gradually raises the tip chute as

fluid is dispensed to the well to ensure the least

disturbance possible. See RADTip Tracking on

page 156.

cell monolayer is preserved

Model Internal Peri-pump Strip Washer RAD Technology

MFX

MFXW X

MFXP X

MFXPW X X

MFXR X

MFXPR X X

The Syringe and secondary Peri-pump dispensers are ordered separately. Except

RAD models include the external Peri-pump.

MultiFlo™ FX Multi-Mode Dispenser

Page 29

MultiFlo FX Dispenser Comparison | 7

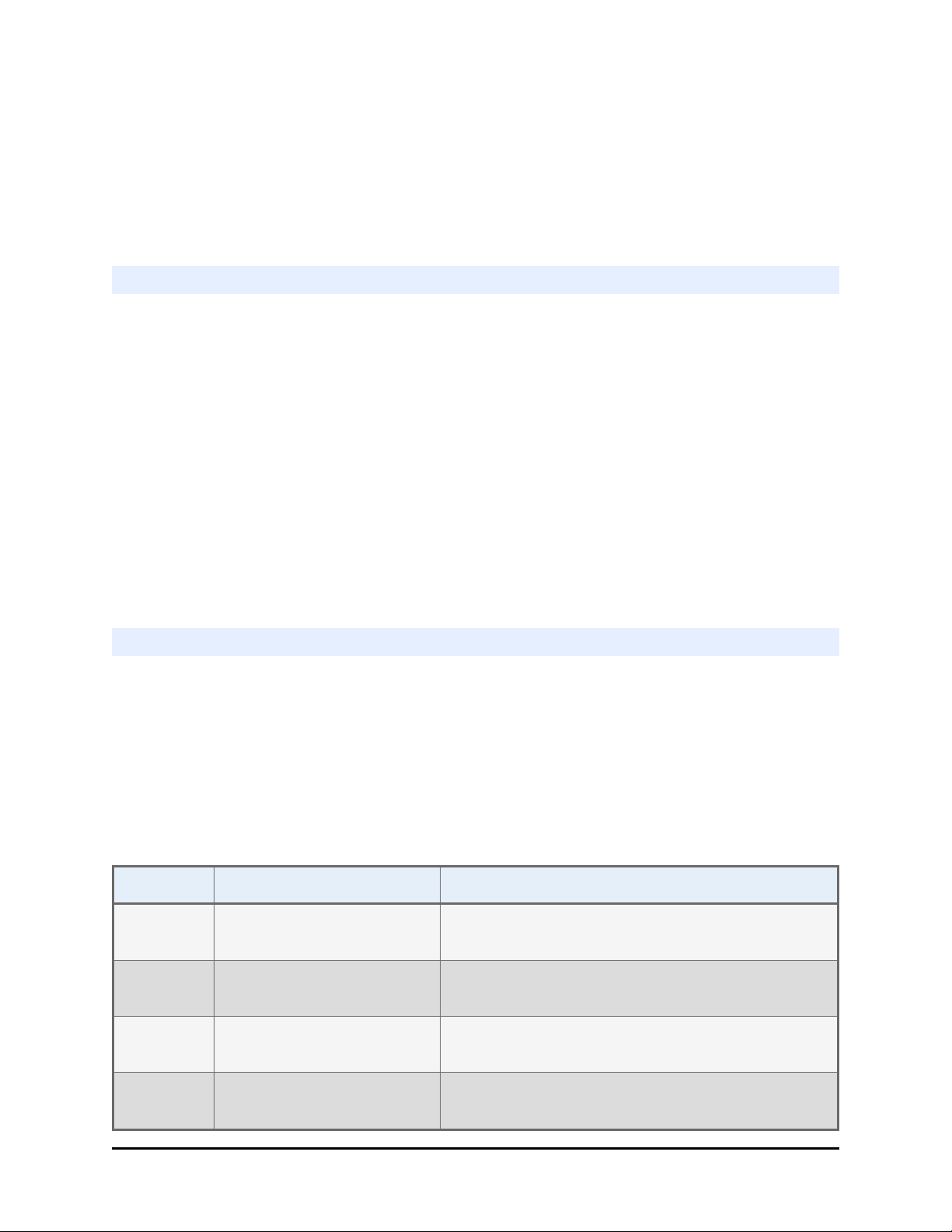

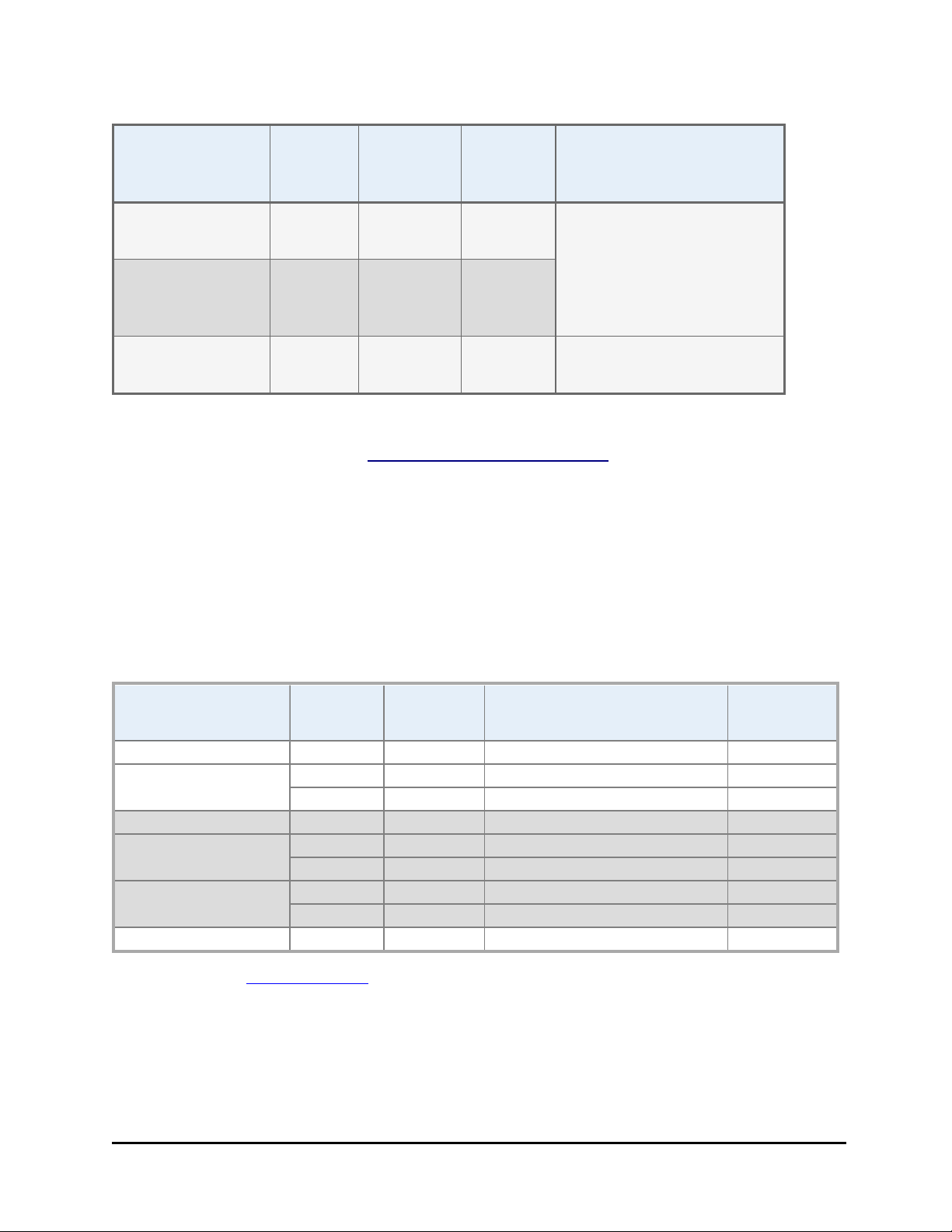

MultiFlo FX Dispenser Comparison

Counting the washer as a potential dispenser, the MultiFlo FX offers three distinct

dispensers. Here is a comparison of the devices:

n For precious reagents use the Peri-pump to preserve unused fluids. It has

the shortest, most visible fluid path, and a Purge capability to reverse the fluid

flow to recover fluid from the tubing. Another advantage is the ability to

dedicate a dispense cassette to use with one reagent only, reducing the

amount of priming required prior to use. And, you can shorten the tubing to

further reduce the dead volume: See Shorten the Dispense Cassette

Tubing on page 61.

n RAD Technologyoffers the best tools for preserving cells and reagents.

n All MultiFlo FX devices are capable of dispensing up to 30,000 µL. BioTek's

recommended maximum dispense volumes are cited here.

Volume

Device

range

µL/well

Peri-pump 0.5‡, and

1-3000*

RAD

Technology

0.5‡, and

130,000*

Syringe 8-

10-3000 <5% CV @

tube/6-well

Precision Accuracy

<10% CV

@ 1

µL/well

(typical

+/-10%

(typical

+/-3%) @

1 µL/well

<3% CV)

<10% CV

@ 1

µL/well

(typical

+/-10%

(typical

+/-3%) @

1 µL/well

<3% CV)

±2 µL @

20 µL/well

10

µL/well

Approximate Dead

volume

Cassette Type:

1 µL 1.20 mL

5 µL 4.23 mL

10 µL 7.36 mL

Type Dead Vol.

1 µL 150 µL

5 µL 530 µL

10 µL 920 µL

For all manifold types:

12 mL

Syringe 16-tube 5-3000 <10% CV

@ 5

µL/well

±2 µL @

10

µL/well

Syringe 12-/24- 5-30,000 <3% CV @ ±2 µL @

BioTek Instruments, Inc.

Page 30

8 | Chapter 1: Introduction

Volume

Device

/48-well certain

Syringe 32-tube 3-3000 <12% CV

Strip Washer 20 –

*1 µL cassettes' maximum recommended dispense volume is 50 µL/well.

‡ 0.5 µL dispensing is supported when using a 1 µL cassette.

¥Depending on wash manifold, See Performance Specifications on page 21.

range

µL/well

30,000

Precision Accuracy

any

µL/well

@ 6

µL/well

≤3.0 - 5.0

¥

% CV

µL/well

±5% @ 6

µL/well

≤±3.0% 12 mL

Approximate Dead

volume

BioTek recommends priming a dispenser with three times its dead volume to

prepare it for accurate dispensing.

Processing Time

§

Protocols were optimized for speed to obtain the following processing times,

including the fastest flow and travel rates. Some of these parameters are listed in

the Parameters column of the table. Only standard, non-RAD Peri-pump

cassettes are referenced here.

Device Plate

Type

Peri-pump - 5 µL 96 10 High flow rate 3

Peri-pump - 1 µL 384 1 High flow rate 6

1536 1 High flow rate 21

Syringe 8-tube 96 20 Flow rate 1 6.5

Syringe 16-tube 96 20 Flow rate 1 5.25

384 20 Flow rate 1 14

Syringe 32-tube 1536 3 One SB manifold 16.5

1536 14 One LB manifold 27

Strip Washer 96 300 3 cycles <105

Volume

(µL/well)

Parameters Time in

seconds

§ Review the Specifications for more details.

¥ Excluding plate carrier and manifold homing movements.

SB = small bore Syringe manifold; LB = large bore manifold.

¥

MultiFlo™ FX Multi-Mode Dispenser

Page 31

MultiFlo FX Dispenser Comparison | 9

Plate Types Table

Only the Peri-pump can process all plate types. Washer manifolds are named for

plate types they process. Only the 32-tube Syringe dispenser manifolds and the

Peri-pump can dispense to 1536-well plates.

Plate

Height

Columns x

Plate Type

96 Well 12x8 14.35 84 336

96 Deep Well 12x8 41.50 N/A 929

96 Half Well^ 12x8 14.20 84 332

96 Mini Tubes 12x8 49.53 N/A 1105

384 Well 24x16 14.22 64 333

384 Deep Well 24x16 44.08 N/A 986

384 PCR 24x16 9.50 6 230

1536 Well 48x32 10.41 N/A 250

1536 Flanged‡ 48x32 10.26 N/A 196

N/A = Plate washing not supported for this plate type.

Rows

mm Washer Dispensers

Default Aspirate &

Dispense Heights

Low-Density Plates: Peri-pump (non-RAD), Strip Washer, Syringe

Plate

Type

6 Well 3x2 20.20 465 4* 4

12

Well

24

Well

48

Well

Aspirate Ht. default setting = 51 steps (2.07 mm) for all these plate types.

^ Syringe dispenser requires standard 8-channel manifold; washer manifold must be 96/384-well.

‡ Only 1536 Flanged (153F) plates have a "flange height" greater than zero. These plates require

columns

x rows

4x3 20.20 460 2* 3

6x4 20.50 452 2 2

8x6 20.10 460 1* 2

Plate Ht.

(mm)

Dispense Ht.

(steps)

PP tubes/

well

Washer/Syringe

BioTek Instruments, Inc.

tubes/well

¥

Page 32

10 | Chapter 1: Introduction

special handling.

¥

Plate-type specific manifolds: The correct volume-per-tube to meet the specified per-well volume is

dispensed. (Does not apply to non-RAD Peri-pump cassettes!)

*Important: when dispensing to 6-, 12-, 24- and 48-well plates (with a non-RAD cassette) some

dispense tubes must be removed from the Peri-pump's fluid supply vessel. See Handling Special

Plates and Mini-tubes on page 134.

Plate Geometry Diagram

l Plate height = physical measurement

l Default Dispense Height = (plate height - flange height + 1.0 mm)

l Travel Height = (plate height - flange height + Plate Clearance)

n If the Dispense Height is greater than Travel Height, the travel height is

changed to match the dispense height.

BioStack Compatibility

The MultiFlo FX is compatible with BioTek’s BioStack Microplate Stacker. The

BioStack can rapidly transfer microplates one-at-a-time to and from the instrument,

and includes:

l Removable stacks (one input and one output).

l Optional restacking of plates to maintain correct sequencing.

l The ability to continue processing plates following the aborting/failure of

one plate.

l The ability to pause processing to allow the user to add more plates to the

MultiFlo™ FX Multi-Mode Dispenser

Page 33

BioStack Compatibility | 11

input stack or to remove some from the output stack.

l De-lidding and re-lidding capability with BioStack 4.

If you have purchased the BioStack to operate with the MultiFlo FX, refer to the

BioStack Operator’s Manual for instructions on configuring the MultiFlo FX to run

with the BioStack. To help you get started: See Operating with the BioStack on

page 124.

If you are interested in purchasing the BioStack, contact your local BioTek dealer

for more information or visit our website at www.biotek.com.

BioTek Instruments, Inc.

Page 34

12 | Chapter 1: Introduction

Package Contents

n Part numbers and package contents are subject to change and vary according

to instrument model. Please contact BioTek Customer Care if you have any

questions.

Description PN

Power cord (part numbers vary by country of use) Varies

Power supply 76077

RS-232 serial cable 75034

USB cable (USB Virtual COM Port Driver Software & instructions) 75108

Microplate carrier 7170501

Priming trough insert (1 or 2) for Peri-pump 7182043

Priming trough insert for Syringe dispensers (2) and Strip washer

7182044

or RAD dispenser

Strip plate (12x1) 98265

Screwdriver, Phillips 98268

Accessory kit 1260004

Stylus: for cleaning washer and Syringe manifold dispense tubes 2872304

10 cc syringe and tubing for Peri-pump cassette maintenance 7210021

Shipping brackets (2) - model dependent 1262010

1262011

1262115

Hex wrench: 7/64" for removing shipping brackets 48169

Peri-pump Reservoir Holder (2 holders + 4 straps) 7212034

7212035

MultiFlo™ FX Getting Started Guide (and operator’s manual on USB

1261006

- PN 1261000)

n Some components are model specific, they ship only with certain instrument

models.

MultiFlo™ FX Multi-Mode Dispenser

Page 35

Optional Accessories

n Part numbers and package contents are subject to change and vary according

to instrument model. Please contact BioTek Customer Care if you have any

questions.

General Instrument Accessories

Description PN

Optional Accessories | 13

BioTek liquid testing solutions for

instrument qualification tests

Special plate carrier for mini-tubes 7212042

Liquid Handling Control™ Software LHC2

BioStack™ Microplate Stacker and integration kit Biostack

Installation-Operational-Performance Qualification (IQOQ-PQ) package

Wetting

Agent

Blue Test

Dye

7773002

7773001

1260521

Peri-pump Optional Accessories

Secondary Peri-pump assembly: PN 7210010

Dispense cassettes and accessories:

Cassette Type Cassette Tips

Replacement

tubing kit*

Tubing

extension

kit

1 µL plastic tips 7170012 7172150

1 µL 1536-well, plastic tips 7170018 7172150

1 µL sapphire jeweled

stainless steel tips*

1 µL 1536-well, sapphire

jeweled stainless steel tips*

7170015 48692

7170016 48692

7170009 7170022

BioTek Instruments, Inc.

Page 36

14 | Chapter 1: Introduction

Cassette Type Cassette Tips

5 µL plastic tips 7170011 7172059

5 µL stainless steel tips 7170014 7172128

5 µL plastic, large bore tips 7170024 7172039

10 µL plastic tips 7170010 7172059

10 µL stainless steel tips 7170013 7172128

10 µL plastic, large bore tips 7170024 7172039

*Save your stainless steel tips for reuse with a replacement kit, they ship with plastic tips.

RAD‡ Technology Cassettes PN

10 µL Single molded tip 1260015

5 µL Single molded tip 1260016

1 µL Single molded tip 1260017

10 µL Single steel tip 1260018

Replacement

tubing kit*

7170008 7170021

7170007 7170020

extension

Tubing

kit

5 µL Single steel tip 1260019

1 µL Single steel tip 1260021

10 µL Large-bore single molded tip 1260020

Bulk dispenser: 8 tube to 1 chute (5 µL

tubing, molded tips)

1260022

‡Random Access Dispenser (RAD)

Accessory PN

Cassette Calibration Kit 7170017

Peri-pump Reservoir Holder 7210509

40 mL Priming Trough Insert 7182109

Syringe Dispenser Optional Accessories

Accessory PN

Autoclavable Syringe Dispenser Module: 16-Tube Manifold (2) 7180006S

MultiFlo™ FX Multi-Mode Dispenser

Page 37

Optional Accessories | 15

Accessory PN

Non-Autoclavable Syringe Dispenser Module 7210009

Autoclavable Syringe Dispenser Module 7210008

8-Tube (2 x 8 channel) Manifold (1) 7180548S

16-Tube Manifolds (2) 7180543S

32-Tube Small Bore (SB) Manifolds (2) 7180533S

32-Tube Large Bore (LB) Manifolds (2) 7180534S

6-Well-Plate Manifold: 8-tubes (4 tubes/well) 1260537S

12-Well-Plate Manifold: 9-tubes (3 tubes/well) 1260536S

24-Well-Plate Manifold: 8-tubes (2 tubes/well) 1260535S

48-Well-Plate Manifold: 12-tubes (2 tubes/well) 1260534S

Stylus – for cleaning 8-/16-tube dispense manifold tubes 2872304

Stylus – for cleaning 32-tube LB dispense manifold tubes 7182095

Stylus – for cleaning 32-tube SB dispense manifold tubes 7182102

Inline Filters (2) 48705

Hex wrench: 3/32” for removing syringe pumps 48570

Hex wrench: 1/16” for removing magnets from dispense manifolds 48713

Spare tubing sets (2 - 1/dispenser), autoclavable 7183006

DMSO- & Acetonitrile-safe tubing sets (2 - 1/dispenser) 7183002

Special large-bore 8-tube manifold for 96-well plates 7180549S

Strip Washer Optional Accessories

Accessory PN

Fluid Supply Kit 1263007

Waste Bottle and Tubing Kit 1263001

Waste Bottle with Sensor 4070545

BioTek Instruments, Inc.

Page 38

16 | Chapter 1: Introduction

Accessory PN

Spacer Block (substitute for Syringe manifolds) 1262038

Muffler 4073009

Thumb screws 01262

Vacuum Line Filter 48146

Tubing Bracket 1262066

Washer Manifold Kits

Manifold Type Accessory PN

Accessory Kit 1260013

96/384-Well

Dispense Manifold 1262028

Aspirate Manifold 1262029

6-Well Accessory Kit 1260009

Dispense Manifold 1262052

Aspirate Manifold 1262053

12-Well Accessory Kit 1260010

Dispense Manifold 1262050

Aspirate Manifold 1262051

24-Well Accessory Kit 1260011

Dispense Manifold 1262048

Aspirate Manifold 1262049

48-Well Accessory Kit 1260012

Dispense Manifold 1262046

Aspirate Manifold 1262047

Magnetic Bead Assay Accessories

Accessory PN

Magnet Adapter (to support the magnet on the plate carrier) 1262063

Magnets:

MultiFlo™ FX Multi-Mode Dispenser

Page 39

Optional Accessories | 17

Accessory PN

384-well Flat Magnet 7103017

384-well Ring Magnet 7102215

96-well Flat Magnet 7103016

96-well Ring Magnet 7102216

BioTek Instruments, Inc.

Page 40

18 | Chapter 1: Introduction

Physical Specifications

Labware

Microplates 96-well, 384-well, and 1536-well that comply with ANSI/SLAS

microplate standards 1-2004, 2-2004, 3-2004, and 4-2004. 96-well

standard, half-height, deep; 384-well standard, deep, PCR; 1536well standard and flanged. The Peri-pump and plate-type specific

washer and syringe manifolds also support 6- (Corning® 3516), 12(Corning 3513), 24- (Corning 3524), and 48- (Corning 3548) well

plates when special handling instructions are followed. Corning 96Well Cluster Tubes (PN: 4410, 4411), called Mini-tubes in this

application, are supported using a special plate carrier.

Microstrips 1 x 8, 1 x 12

Microwells Flat, round, "V” bottom

Hardware& Environmental

User Interface 5.7" touch screen

Power Supply The instrument uses two internal power supplies: 24-volt 60 watt and

48-volt 60 watt. These supplies are compatible with 100-240 V~; 5060 Hz.

Dimensions

(W x D x H)

Weight (≤) 19.5 lb (8.8 kg)

Operating

Conditions

Relative Humidity The instrument should be operated in a non-condensing humid

Approximately 17.19 x 11.75 x 8.0 inches (44 cm x 29 cm x 20 cm)

base model (without strip washer, external Peri-pump, or Syringe

dispenser).

10° - 40°C (50° - 104°F)

environment having a maximum relative humidity of 80% at

temperatures up to 31°C decreasing linearly to 50% relative humidity

at 40°C.

Peri-Pump

Peristaltic pump: Positive-displacement peristaltic pump with 4 rollers that stretch

the 8 tubes (one per channel) to deliver fluid.

MultiFlo™ FX Multi-Mode Dispenser

Page 41

Physical Specifications | 19

Cassette

Types

1 µL 0.5, 1 - 30,000µL1000 384-well plates @ 5

5 µL 5 - 30,000 µL 1000 96-well plates @ 50

10 µL 10 - 30,000 µL 1000 96-well plates @ 100

Dispense

range

Cassette Life Dead Volume

µL/well

µL/well

µL/well

RAD ™ technology cassettes

Single-tube

(any µL)

8-to-1 tubes

(5 µL)

0.5*, 1 - 30,000µL1 µL: 16,000 wells @ 5 µL

5 µL: 12,000 wells @ 50 µL

10 µL: 12,000 wells @ 100 µL

5 - 30,000 µL N/A 4.2 mL

1.2 mL

4.2 mL

7.4 mL

Type Dead Vol.

1 µL 150 µL

5 µL 530 µL

10 µL 920 µL

* Requires 1 µL tubing

Syringe Dispenser

Two external positive-displacement syringe pump dispensers which support

various manifold types.

Manifold Type

8-Tube 2 x 8-channel non-autoclavable manifold with replaceable stainless

steel tubes to process 96- and 384-well plates.

16-Tube 1 x 16-channel autoclavable manifold with replaceable stainless steel

tubes to process 96- and 384-well plates.

32-Tube 1 x 32-channel manifold cannot be autoclaved, and does not support

non-factory tube replacement. An inline 90-micron filter is included

to minimize clogs. For 1536-well plates only. Two models: large bore

(LB) and small bore (SB).

Plate-Type-Specific Manifolds:

6-Well 1 x 8-channel autoclavable manifold (4 tubes/well) with replaceable

stainless steel tubes to process 6-well plates. Tubes are angled 7

degrees to minimize turbulence in the wells.

12-Well 1 x 9-channel autoclavable manifold (3 tubes/well) with replaceable

BioTek Instruments, Inc.

Page 42

20 | Chapter 1: Introduction

Manifold Type

stainless steel tubes to process 12-well plates. Tubes are angled 7

degrees to minimize turbulence in the wells.

24-Well 1 x 8-channel autoclavable manifold (2 tubes/well) with replaceable

stainless steel tubes to process 24-well plates. Tubes are angled 7

degrees to minimize turbulence in the wells.

48-Well 1 x 12-channel autoclavable manifold (2 tubes/well) with replaceable

stainless steel tubes to process 48-well plates. Tubes are angled 7

degrees to minimize turbulence in the wells.

Supply bottle volume Two 1L bottles: glass for autoclavable models or plastic for

non-autoclavable.

Strip Washer

The external strip washer module uses a non-autoclavable positive-displacement

syringe pump to dispense fluid and a vacuum pump to aspirate fluid. Its dualaction design uses separate, plate-type-specific manifolds for aspirating and

dispensing.

Manifold Type

96/384-Well 1 x 8-channel dispense and aspirate manifolds to process 96- and

384-well plates.

48-Well 1 x 12-channel dispense manifold (2 tubes/well) and 1 x 6-channel

aspirate manifold to process 48-well plates.

24-Well 1 x 8-channel dispense manifold (2 tubes/well) and 1 x 4-channel

aspirate manifold to process 24-well plates.

12-Well 1 x 9-channel dispense manifold (3 tubes/well) and 1 x 3-channel

aspirate manifold to process 12-well plates.

6-Well 1 x 8-channel dispense manifold (4 tubes/well) and 1 x 2-channel

aspirate manifold to process 6-well plates.

Waste bottle volume One 2L vessel; optional accessory includes a waste sensor.

Supply bottle volume Two 2L plastic bottles (non-autoclavable).

MultiFlo™ FX Multi-Mode Dispenser

Page 43

Performance Specifications | 21

Performance Specifications

Peri-Pump Dispenser

Precision is measured for a whole 96-well or 384-well plate (12- or 24-well plate for RAD

technology) using room-temperature deionized or distilled water with 0.1% Tween 20 with

FD&C #1 blue dye. Precision is measured for 1536-well plates by dispensing to 384 wells, 12

columns with a 15% isopropyl alcohol solution. The absorbance of the solution is read at 630

nm and 450 nm reference. Specifications apply to volumes that are full unit increments for the

cassette to which they apply, except the 1 µL cassette also supports 0.5 µL increments when

dispensing this volume. For example: the precision specification for a 10 μL cassette is valid

at 10, 20, 30, ..., 3000 μL; the 1 µL cassette precision specification is valid at 0.5, 1, 2, 3, ...,

30,000 µL.

Accuracy is measured gravimetrically when dispensing room-temperature deionized water.

Specifications apply to volumes that are full unit increments for the cassette to which they

apply. For example: the accuracy specification for a 10 µL cassette is valid at 10, 20, 30, ...

30,000 µL.

Cassette

Precision

Accuracy

1 µL 10%CV @ 1 µL per well ± 10% @ 1 µL per well

5%CV @ 2 µL per well* ± 5% @ 2 µL per well*

10%CV @ 0.5 µL per well n/a

5 µL 5%CV @ 5 µL per well ± 4% @ 5 µL per well

2.5%CV @ 10 µL per well* ± 2% @ 10 µL per well*

10 µL 4%CV @ 10 µL per well ± 4% @ 10 µL per well

2%CV @ 20 µL per well* ± 2% @ 20 µL per well*

* These specifications are for these dispense volumes and higher.

Exception: the accuracy specs above apply to the RAD technology bulk-dispensing cassette, 8

tubes-to-1 (chute) with 5 µL tubing for volumes that are 8 times the full unit increments for

the cassette, e.g. valid at 40, 80, 160, ... 30,000 µL:

l ± 4% when volume is 40 µL/well

l ± 2% when volume is ≥80 µL/well.

BioTek Instruments, Inc.

Page 44

22 | Chapter 1: Introduction

Cassette Expected Lifetime

Cassette Types

1 µL 1000 384-well plates @ 5 µL/well 2,000 mL

5 µL 1000 96-well plates @ 50 µL/well 5,000 mL

10 µL 1000 96-well plates @ 100 µL/well 10,000 mL

Cassette Life

Total Volume

With strict adherence to best practices and maintenance recommendations, this is

the typical longevity of the dispense cassettes.

Syringe Dispensers

Precision is measured for a whole 96-well or 384-well plate using room-temperature

deionized or distilled water with 0.1% Tween 20 with FD&C #1 blue dye. Precision is

measured for 1536-well plates by dispensing to 384 wells, 12 columns with a 15% isopropyl

alcohol solution. The absorbance of the solution shall be read at 630 nm and 450 nm

reference.

Accuracy is measured gravimetrically when dispensing room-temperature deionized water.

Dispense Precision

8-Tube ≤ 2% CV when dispensing 100 µL/well

≤ 5% CV precision at 20 µL/well

≤ 5% CV precision at 40 µL/well **

** Tested in-house to <4.0% CV.

16-Tube ≤ 2% CV when dispensing 100 µL/well

≤ 2.5% CV precision at 80 µL/well***

≤ 5% CV precision at 20 µL/well

≤ 10% CV precision at 5 µL/well*

*unspecified for non-autoclavable syringe pumps.

*** Tested in-house to <1.6% CV.

32-Tube < 12% CV when dispensing 6 µL per tube

Dispense Accuracy

8-Tube Forallvolumes2 µL or 1%, whichever is greater, at flow rate 2.

16-Tube Forallvolumes 2 µL or 1%, whichever is greater, at flow rate 2.

32-Tube ± 5% when dispensing 6 µL/well at flow rate 3.

MultiFlo™ FX Multi-Mode Dispenser

Page 45

Performance Specifications | 23

Low-Density-Plate-Specific Manifolds

Dispense Precision

Refer to the values below for dispense precision when measured in full plates with the

specified volume of deionized water with 0.1% Tween 20 and FD&C#1 blue dye solution

and read at 630 nm/405 nm.

Plate Type Performance Volume (µL/well)

6-Well ≤5.0% CV 5560

12-Well ≤3.0% CV 2240

24-Well ≤3.0% CV 1120

48-Well ≤3.0% CV 560

Dispense Accuracy is measured gravimetrically when dispensing any volume of roomtemperature deionized water using Flow Rate 2. For all plate-specific manifolds, dispense

accuracy shall be 2 µL or 1%, whichever is greater.

Strip Washer

Residual Volume (Evacuation Efficiency)

96Well

6-, 12-,

24-,

48Well

Washer Manifold Volume (µL/well) Travel Rate Residual Volume (µL/well)

Average residual of ≤2.0 µL per well after a 3-cycle wash when dispensing 300

µL per well using a bottom-touching well aspiration and a solution of deionized

water with 0.1% Tween® 20 or equivalent buffer solution. (The aspirate height

adjustment should be optimized for the plate prior to testing.)

Refer to the table below to determine the average residual volume per well after

dispensing the specified µL-per-well using a bottom-touching well aspiration and

a solution of deionized water without Tween in flat-bottomed plates. (The

aspirate height adjustment should be optimized for the plate prior to testing.)

6-well 5560 0 CW 600

12-well 2240 0 CW 150

24-well 1120 0 CW 50

48-well 560 0 CW 25

BioTek Instruments, Inc.

Page 46

24 | Chapter 1: Introduction

Dispense Precision

Refer to the values below for washer dispense precision when measured in full plates with

the specified volume of deionized water with 0.1% Tween 20 and FD&C#1 blue dye

solution and read at 630 nm/405 nm.

Plate Type Performance Volume (µL/well)

96-Well ≤3.0% CV 300

6-Well ≤5.0% CV 5560

12-Well ≤3.0% CV 2240

24-Well ≤3.0% CV 1120

48-Well ≤3.0% CV 560

384-Well ≤3.0% CV 80

Dispense Accuracy

Washer dispense accuracy shall be ≤±3.0% when deionized water with 0.1% Tween 20

(and FD&C#1 blue dye) solution. The weight of the fluid dispensed shall be measured

gravimetrically.

Plate Type Volume (µL/well)

96-Well 300

6-Well 1120

12-Well 2240

24-Well 1120

48-Well 560

384-Well 80

MultiFlo™ FX Multi-Mode Dispenser

Page 47

Space Requirements | 25

Space Requirements

The Physical Specifications on page 18 describe the width (W), depth (D) and height

(H) of the base unit of the MultiFlo FX without an external Peri-pump, Syringe

dispenser, or Washer installed. Likewise, the space required for the bottles, tubing

and power cables is omitted.

Beginning with the base unit dimensions, add space for accessory devices and vessels:

l Expect a depth of 20" (51 cm) when installing a Strip washer and/or Syringe dispenser to

the back. Similarly, expect to add 8" (20 cm) to the depth when installing the RAD

technology dispenser.

l Add 4"-5" to the depth or width for fluid supply and waste bottles, depending on

placement.

l Plan on a height of approximately 12" (31 cm) when installing the washer: the waste

bottle is the tallest accessory, or (if the waste bottle resides elsewhere) at least 10" to

accommodate the washer tubing bracket.

l When an external Peri-pump or Syringe dispenser is installed on top, the height

increases to about 10", which is required for RAD™ technology.

BioTek Instruments, Inc.

Page 48

26 | Chapter 1: Introduction

l Increase the width requirement to include the side tubing bracket and/or supply vessels.

l BioStack integration requires a width of at least 34" in the standard 90° interface. Find

more details in the BioStack Operator's Manual.

BioTek's Customer Resource Center

BioTek's Customer Resource Center (CRC) continues our tradition of superior

service and support. After an easy registration process, you can access lots of

useful information about your BioTek microplate instrumentation and software. On

the secure CRC website, you can:

l Track orders

l Access warranty information, user manuals and software updates

l Download technical and application information

l Maintain equipment inventory (product registration)

l Request service and technical support

l View service history

l And much more!

Register at https://customer.biotek.com

n Dispense cassette data sheets are available for download at the CRC.

MultiFlo™ FX Multi-Mode Dispenser

Page 49

Chapter 2

Installation

This chapter provides detailed installation instructions.

Unpack and Inspect the Instrument 28

Install the Waste Tubing 29

Remove the Shipping Hardware 31

Set up the Strip Washer 34

Set Up the Peri-pump Dispenser 44

Install the Secondary Peri-Pump 46

Install RAD Technology Components 51

Install the Syringe Dispenser Component 62

Install Software/Connect to Computer 71

Connect Power Cable 72

Define Instrument Settings 73

Verify Performance 79

Repacking the MultiFlo FX 82

Install the Shipping Hardware 83

Repacking the Secondary Peri-pump 85

MultiFlo FX Repacking 86

Repacking the Syringe Dispenser 89

Repacking the Strip Washer 90

Page 50

28 | Chapter 2: Installation

Unpack and Inspect the Instrument

Important: Save all packaging materials. If you need to ship the instrument or

accessories to BioTek for repair or replacement, you must use the original packaging.

Using other forms of commercially available packaging is not recommended and can void

the warranty. Improper packaging that results in damage to the instrument may lead to

additional charges. Refer to the operator's manual for repacking instructions.

Inspect the shipping box, packaging, instrument, and accessories for signs of

damage.

If the MultiFlo™ FX Multi-Mode Dispenser is damaged, notify the carrier and your

BioTek representative. Keep the shipping cartons and packing material for the

carrier’s inspection. BioTek will arrange for repair or replacement of your

instrument immediately, before the shipping-related claim is settled.

1. Unpack the boxes containing the instrument and other equipment:

l MultiFlo™ FX Multi-Mode Dispenser and accessories

l Strip Washer and accessories

l Dual Syringe Dispenser and accessories

l Additional Peri-pump Dispenser and accessories, including RAD™

technology components, if applicable.

2. Place all packing materials back into the shipping boxes for reuse if necessary.

3. Syringe Dispenser models: when the Syringe dispenser is a component of your

instrument, review the placement options for it (as described on page 63) and decide

which one best suits your lab before proceeding with the installation.

Refer to the Package Contents on page 12 to make sure you have all expected

equipment.

MultiFlo™ FX Multi-Mode Dispenser

Page 51

Install the Waste Tubing | 29

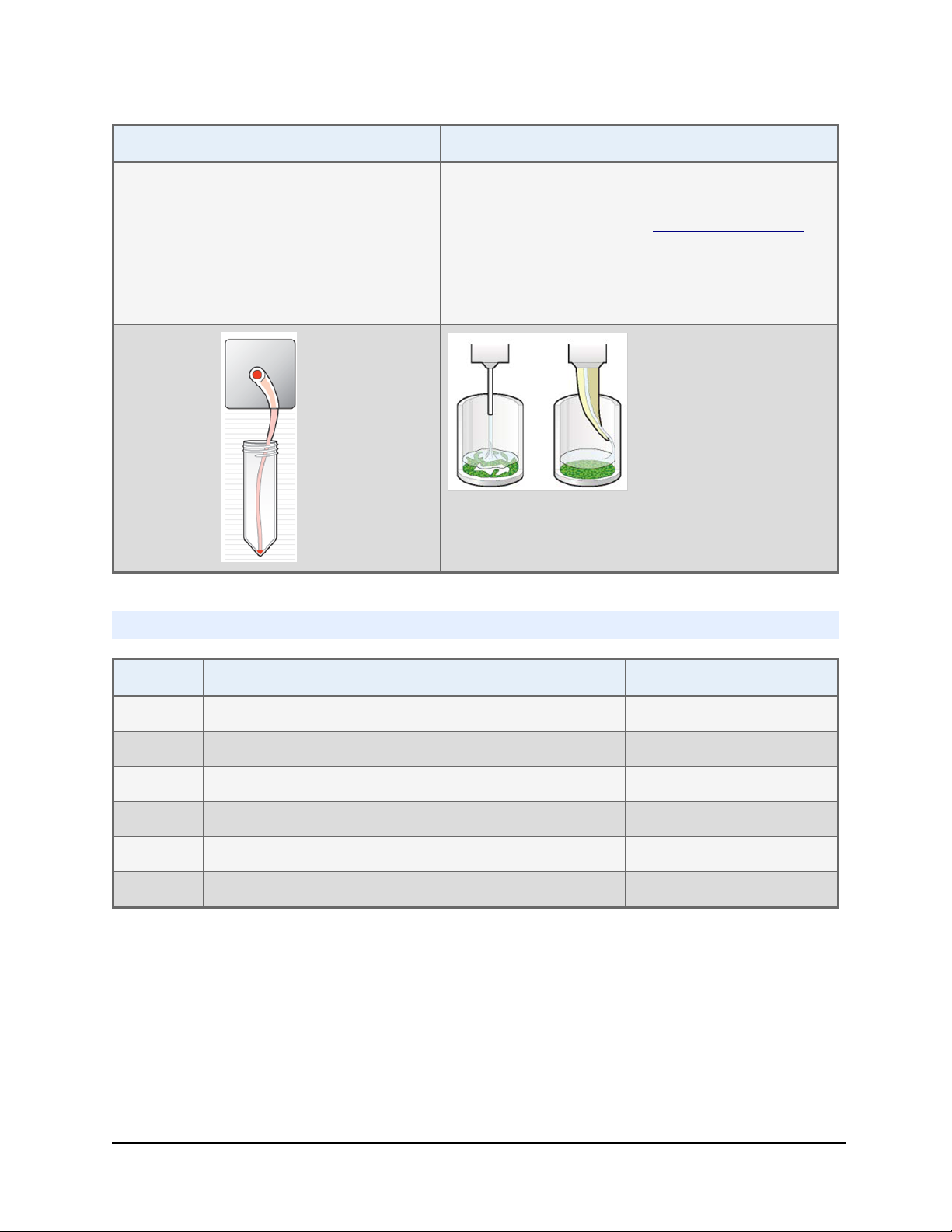

Install the Waste Tubing

A length of tubing and a bracket to hold it is provided to drain the priming trough

into a waste container. It's safer to perform this task before removing the shipping

hardware.

Underside of MultiFlo showing priming trough waste tubing

Important note: The waste

tubing must lay flat to

properly drain the priming

trough. The side bracket

provided with the instrument

supports this goal, but it may

not be needed in your lab,

depending on where you

position the dispenser and its

waste receptacle.

You will need:

l Philips head screwdriver (small)

l Waste tubing: 4' provided (PN 7213010)

l Possibly scissors or knife to cut tubing to desired length

l Side bracket provided

l Waste vessel: to capture discarded fluid

To install the tubing:

Install Side Bracket for Waste Tubing

BioTek Instruments, Inc.

Page 52

30 | Chapter 2: Installation

1. Turn instrument onto its back to access its

underside.

2. Remove the two screws in the lower left

corner. You will use them to install the

bracket.

3. Align the side bracket with the screw holes

so its hook opens towards you and use the

screws to install the bracket.

You may or may not use the side bracket, depending on where you place the waste

vessel.

Attach the Tubing to the Priming Trough

1. Thread the waste tubing under the

bracket and onto the priming trough's

spout.

Remove the bracket and/or use water or

alcohol to help the tube slide onto the spout.

2. Snake the tubing around the

instrument to the side bracket.

3. Return the instrument to normal

position.

Position Waste Container and Tubing

When all the installation steps are completed:

1. Place the waste container under the instrument's work surface.

2. Position the waste tubing to drain into the waste container, cutting it to the

optimal length, if necessary.

Next, remove the shipping hardware.

MultiFlo™ FX Multi-Mode Dispenser

Page 53

Remove the Shipping Hardware | 31

Remove the Shipping Hardware

Two shipping brackets (and a rubber band when a Peri-pump is included) protect

the MultiFlo FX during shipping. After installing the waste tubing for the priming

trough, place it upright on a level work surface to remove the shipping hardware.

(Store the shipping brackets on the back of the instrument in slots provided for this

purpose.)

You will need:

l Allen (or hex) wrench taped to plate carrier.

The shipping hardware is slightly different than shown above for MultiFlo FX

BioTek Instruments, Inc.

Page 54

32 | Chapter 2: Installation

without a washer or RAD technology:

For these

MultiFlo FX

models:

l MFX

l MFXP

First remove the

plate carrier

shipping bracket

and then remove

the dispense arm

bracket.

Reverse this

order when

reinstalling the

brackets (before

shipping): put the

dispense arm

bracket on the

post first.

Remove shipping brackets:

1. Remove the plate carrier shipping bracket: use the Allen wrench to remove the

two screws that hold it to the plate carrier. Tilt the bracket downwards slightly,

and release it from the post.

2. Remove the dispense arm shipping bracket: use the Allen wrench to remove the

two screws that hold the bracket to the instrument.

3. Attach the shipping brackets to the back of the instrument for storage. They will

be needed if the dispenser must be shipped in the future.

MultiFlo™ FX Multi-Mode Dispenser

Page 55

Remove the Shipping Hardware | 33

Dispense-arm bracket for

MultiFlo FX without a washer or

RAD technology

4. Insert the brackets into their respective slots on the back of the instrument, in

lower right corner. Slide the plate-carrier bracket's longest arm into the slot and

use the Allen wrench to screw it in place. (Exception: The dispense-arm bracket

for MFX and MFXP models does not fit into a slot. Attach it with one screw so

the short end projects out from the instrument. You must first remove the large

support bracket attached to the back panel that is used for an external Peripump. Insert the second screw next to the bracket.)