Page 1

BIO-TEK FL600

FLUORESCENCE

PLATE READER

HARDWARE GUIDE

29?D5;

9>CDBE=5>DC, 9>3

Page 2

29?D5;

HIGHLAND PARK, BOX 998, WINOOSKI, VT 05404-0998 USA.

(800) 451-5172 • (802) 655-4040 • FAX: (802) 655-7941

9>CDBE=5>DC, 9>3

Page 3

BIO-TEK FL600

FLUORESCENCE

PLATE READER

For Research & Development Use Only

HARDWARE GUIDE

™

Part No. 6001000

June, 1998

Revision D

Page 4

Notices

BIO-TEK INSTRUMENTS, INC.

Highland Park, Box 998

Winooski, Vermont, USA

05404-0998

Customer Service & Sales: 888-451-5171

Outside U.S.: 802-655-4040

Service: 800-24-BIOTK

Sales FAX: 802-655-7941

Service FAX: 802-655-3399

E-MAIL: sales@biotek.com

labtac@biotek.com

Internet: http://www.biotek.com

Lionheart Technologies, Europe N.V.

Sneeuwbeslaan 33

B-2610 Wilrijk

Belgium

TEL: (32) 3-8290455

FAX: (32) 3-8254749

Copyright

Copyright 1997, Bio-Tek Instruments, Incorporated. No part of this

publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language without the written permission of Bio-Tek

Instruments, Incorporated.

Trademarks

Bio-Tek® is a registered trademark, and FL600™ and KC4™ are trademarks of

Bio-Tek Instruments, Inc.. Windows® and Windows 95 are trademarks of the

Microsoft Corporation.

Restrictions and Liabilities

Information in this document is subject to change, and does not represent a

commitment by Bio-Tek Instruments, Inc. Changes made to the information in

this document will be incorporated in new editions of the publication. No

responsibility is assumed by Bio-Tek for the use or reliability of software or

equipment that is not supplied by Bio-Tek, or its affiliated dealers.

Bio-Tek Part No. 6001000

Bio-Tek FL600 iii

Page 5

Revision History

Revision Date Changes

A 4/97 Release to production

B 10/97 Added Stay Clear safety symbol. Corrected Electrical, Optical,

and Performance Specifications sections. Added CE Mark

information. Deleted Appendix A.

C3/98

D6/98

Preface: Added warranty. Page 2-1: Modified instructions for

Setting Up the FL600 Reader. Page 5-2: Changed electrical

specification for fuses. Page 5-11: Modified text and data on

serial communications to reflect parity differences between KC4

reader software and FL600 diagnostic software. Page 5-13: On

filter table, modified use of excitation filters and added two new

filter wavelengths.

Preface: Changed phone numbers and e-mail addresses.

Chapter 4: Changed air filter maintenance procedure. Added

lamp replacement procedure.

iv Bio-Tek FL600

Page 6

Warranty

This Warranty is limited and applies only to new products, except for computer-based

software which is covered under a separate Warranty Policy, manufactured by

Bio-Tek® Instruments, Inc. (“Bio-Tek”). Bio-Tek makes no warranty whatsoever

regarding the condition of used products.

Bio-Tek warrants the instrument (hereinafter collectively referred to as “Products” or

“Product”) for a period of one (1) year from the original purchase date against defective

materials or workmanship. This Warranty is limited to the original purchaser (the

“Purchaser”) and cannot be assigned or transferred. All claims under this Limited

Warranty must be made in writing to Bio-Tek, Attention: Service Department.

Purchaser must ship the Product to Bio-Tek, postage pre-paid. Bio-Tek shall either

repair or replace with new or like-new, at its option and without cost to the Purchaser,

any Product which in Bio-Tek’s sole judgment is defective by reason of defects in the

materials or workmanship.

This Warranty is VOID if the Product has been damaged by accident or misuse, or has

been damaged by abuse or negligence in the operation or maintenance of the Product,

including without limitation unsafe operation, operation by untrained personnel, and

failure to perform routine maintenance. This Warranty is VOID if the Product has been

repaired or altered by persons not authorized by Bio-Tek, or if the Product has had the

serial number altered, effaced, or removed. This Warranty is VOID if any of the

Products has not been connected, installed or adjusted strictly in accordance with

written directions furnished by Bio-Tek. Batteries, fuses, lightbulbs, and other

“consumable” items used in any of the Products are not covered by this Warranty.

Software utilized in conjunction with any of the Products is not covered by the terms of

this Warranty but may be covered under a separate Bio-Tek software warranty.

We will continue to stock parts for a maximum period of five (5) years after the

manufacturer of any equipment has been discontinued. Parts shall include all materials,

charts, instructions, diagrams, and accessories that were furnished with the standard

models.

THIS WARRANTY CONTAINS THE ENTIRE OBLIGATION OF BIO-TEK

INSTRUMENTS, INC., AND NO OTHER WARRANTIES, EXPRESSED, IMPLIED,

OR STATUTORY ARE GIVEN. PURCHASER AGREES TO ASSUME ALL

LIABILITY FOR ANY DAMAGES AND/OR BODILY INJURY OR DEATH

WHICH MAY RESULT FROM THE USE OR MISUSE OF ANY EQUIPMENT OR

INSTRUMENT BY THE PURCHASER, HIS EMPLOYEES, AGENTS, OR

CUSTOMERS, OTHER THAN THE EXPRESS WARRANTY CONTAINED

HEREIN. WE SHALL NOT BE RESPONSIBLE FOR ANY DIRECT OR

CONSEQUENTIAL DAMAGES OF ANY KIND. THIS WARRANTY SHALL NOT

BE CHANGED OR MODIFIED IN ANY WAY WITHOUT THE EXPRESS

WRITTEN PERMISSION OF AN OFFICER OF BIO-TEK INSTRUMENTS, INC.

Bio-Tek FL600 v

Page 7

Warnings and Precautions

When operated in a safe environment, according to the instructions in this manual,

there are no known hazards associated with the instrument. However, the

operator should be aware of certain situations which could result in serious injury.

Hazard Warnings

Warning! Power Rating. The instrument must be connected to a power

receptacle that provides voltage and current within the specified rating for the

system. Use of an incompatible power receptacle may produce electrical shock

and fire hazards.

Warning! Electrical Grounding. Never use a two-prong plug adapter to

connect primary power to the instrument. Use of a two-prong adapter disconnects

the utility ground, creating a severe shock hazard. Always connect the system

power cord directly to a three-prong receptacle with a functional ground.

Warning! Internal Voltage. Always turn off the power switch and unplug the

power cord before cleaning the outer surfaces of the instrument or changing

filters.

Warning! Liquids. Avoid spilling liquids on the instrument; fluid seepage into

internal components creates a potential shock hazard. Wipe up all spills

immediately. Do not operate the instrument if internal components have been

exposed to fluid. If the microplate appears to have been exposed to fluid, the

reading chamber may also have been exposed. To protect the incubator, remove

the top cover and clean the interior.

Precautions

The following precautions are provided to help you avoid damaging the system:

Caution: Service. The system should be serviced by Bio-Tek-authorized service

personnel. Only qualified technical personnel should perform troubleshooting and

service procedures on internal components.

Caution: Replacement Fuses. Use replacement fuses with the required current

rating and specification. Improper fuses or short-circuiting the fuse holders may

cause fire or damage the instrument.

vi Bio-Tek FL600

Page 8

Caution: Environmental Conditions. Do not expose the system to temperature

extremes. System performance may be adversely affected.

Caution: Filter Settings. The software filter settings must match the actual

filters used in the reader, in order to prevent possible damage to the

photomultiplier and/or degradation of data.

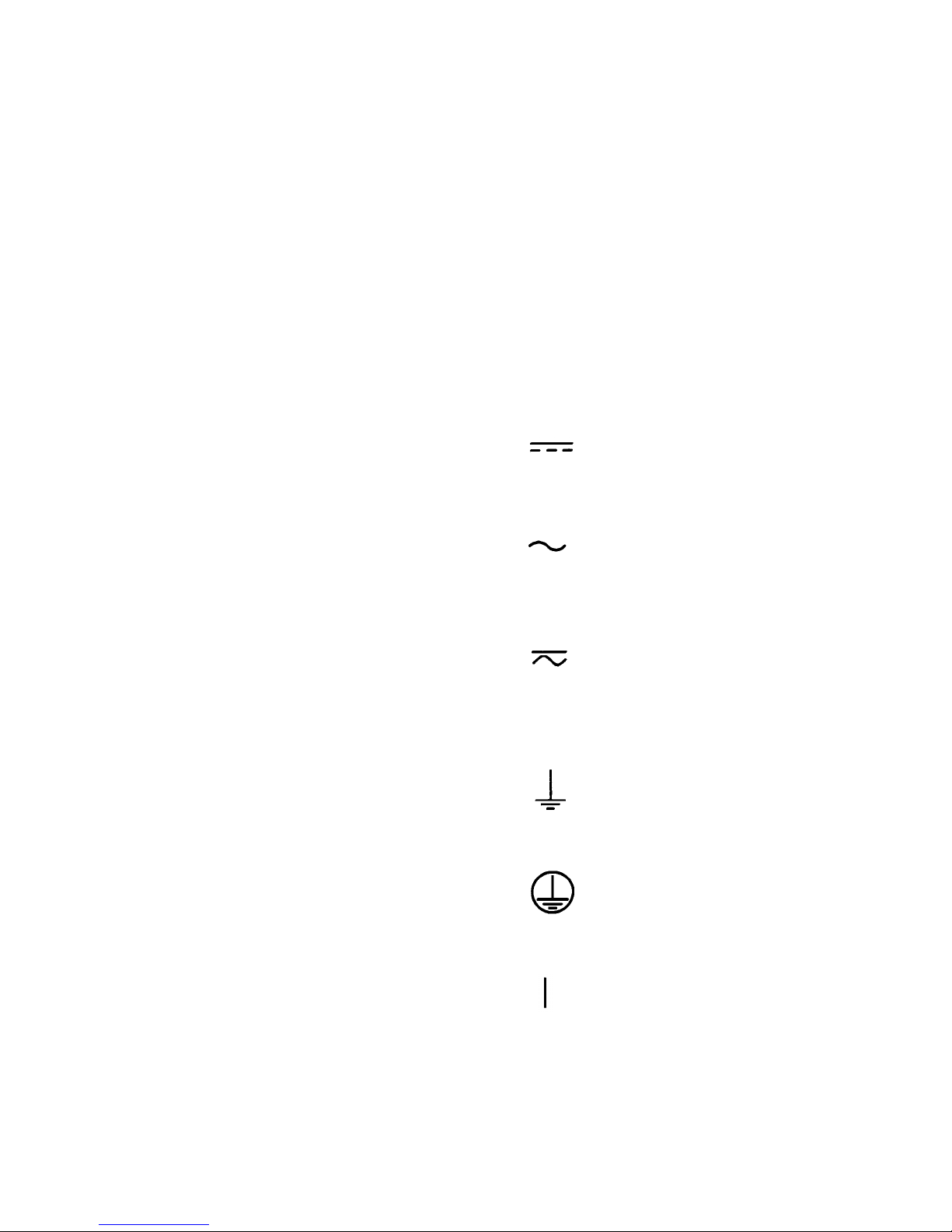

Safety Symbols

The following warning and informational symbols may be found in various

locations on the instrument. Only qualified personnel who recognize shock

hazards and are familiar with the safety precautions should use this instrument.

Read the manual carefully before operating this instrument.

Direct current

Courant continue

Gleichstrom

Corriente continua

Corrente continua

Alternating current

Courant alternatif

Dreiphasen-Wechselstrom

Corriente Atterna

Corrente alternata

Both direct and alternating current

Courant continu et courant alternatif

Allstrom (Gleich - und Wechselstrom

Corriente continua y corriente alterna

Corrente continua e corrente alternata

Earth ground terminal

Borne de terre

Erde (Bettriebserde)

Borne de Tierra

Terra (di funzionamento)

Protective conductor terminal

Borne de terre de protection

Schutzleiteranscluss

Borne de Tierra de Protección

Terra di protezione

On (Supply)

Marche (alimentation)

Ein (Verbindung mit dem Netz)

Connectado

Chiuso

Bio-Tek FL600 vii

Page 9

Off (Supply)

Arrest (alimentation)

Aus (Trennung vom Netz)

Desconectado

Aperto (sconnessione dalla rete di alimentazione)

Caution (Refer to accompanying documents)

Attention (voir documents d'accompanement)

Achtung siehe Begleitpapiere

Atención (vease los documentos incluidos)

Attenzione, consultare la doc annessa

Caution, risk of electric shock

Attention, risque de choc electrique

Gefährliche elektrische Spannung

Atención, riesgo de sacudida eléctrica

Alta tensione (in questo documento

Alta tensione non significa "te nsione pericolosa"

come definito in IEC 417)

Stay clear

Ne pas toucher svp .

Bitte nicht berühren

No tocario por favor

Si prega di non toccare

viii Bio-Tek FL600

Page 10

Contents

1. Introducing the Bio-Tek FL600

Hardware Requirements 1-3

Software Requirements 1-4

2. Getting Started

Setting Up the FL600 Reader 2-1

Installing KC4™ and FL600 Diagnostic Software 2-2

Installing KC4 2-2

Installing the Hardware Key 2-2

Installing the FL600 Diagnostic Software (Diagnostics Use)2-2

Checking the FL600 System 2-4

Using the FL600 Diagnostic Software 2-4

Filter Wavelength Locations 2-5

Checking the COM Port 2-5

Running System Diagnostics 2-7

What to Do if the Tests Fail 2-8

Exiting the FL600 Diagnostic Software 2-9

3. Replacing Filters and Adjusting Probe Height

Adding and Replacing Filters 3-1

Changing the Filters Inside the Reader 3-2

Setting the Filter Positions in KC4 Software 3-6

Utilizing the Filter Adapter System 3-7

Removing the Filter from the Adapter 3-7

Inserting the Replacement Filter into the Adapter 3-8

Adjusting Top Optical Probe Height 3-8

FL600 Interior Configuration Diagrams 3-10

4. Bio-Tek FL600 Maintenance

Maintaining the Reader 4-1

How to Maintain the Exterior 4-1

How to Replace the Air Filter 4-1

How to Replace the Lamp 4-3

Bio-Tek FL600 ix

Page 11

5. Technical Information

Bio-Tek FL600 Fluorescence/Absorbance Plate Reader 5-1

Physical Dimensions 5-1

Operating Conditions 5-1

Electrical Specifications 5-2

Optical Specifications 5-2

Scanning Mechanism 5-3

Temperature Control 5-4

Performance Specifications 5-4

CE Mark Approval 5-8

Computer Specifications for FL600 Diagnostic Software 5-10

FL600 Serial Communications 5-11

Ordering Filters 5-12

Fluorescence Filters 5-12

Absorbance Filters 5-14

x Bio-Tek FL600

Page 12

&KDSWHU

,QWURGXFWLRQ WR WKH

This chapter introduces the Bio-Tek FL600 Fluorescence

Plate Reader. You'll find information on hardware and

,QWURGXFLQJ7KH)/

Thank you for selecting the Bio-Tek FL600. The FL600 is a powerful

fluorescence and absorbance measurement system which measures

through the use of a photomultiplier tube housed inside of a light-

impermeable detection compartment. The FL600 is capable of quantifying

both soluble and cell-associated fluorescence. The system consists of:

%LR7HN

software requirements and optional equipment

)/

suggestions.

• Accessories Kit

Both software packages are for Windows-based PCs and provides the user

with full command of the operation of the X-Y scanner. FL600’s precision

X-Y mechanism scans a microplate with a sensitive optical detection

system to quantify the fluorescence or absorbance in each well.

• The Bio-Tek FL600 Fluorescence Plate Reader

• KC4™ reader control and data reduction software

• FL600 System Software for diagnostics

• Serial Communications Cable (P/N 75034)

Page 13

Virtually any microplate type from 6 to 384 wells can be used with the

FL600. Users can select any microplate from the FL600’s built-in list of

industry-standard plates, or they can define their own unique plate

format(s).

The FL600 is designed to meet international radio frequency emission

standards, EMC immunity standards, and user safety standards.

The Bio-Tek FL600 should be installed in a well-ventilated area, free from

dust and fumes. Keep the system away from direct sunlight and local heat

sources.

1-2

Introduction to the Bio-Tek FL600

Page 14

+DUGZDUH5HTXLUHPHQWV

0LQLPXP&RPSXWHU5HTXLUHPHQWVIRU)/6\VWHP6RIWZDUH

DQG.&6RIWZDUHIRU:LQGRZVDQG

• IBM™ 486 PC or clone 33 MHz clock

• 640 KB base memory, extended to 8 MB

• Color graphics monitor (VGA)

• Color graphics adapter (VGA)

• 120 MB hard drive

• High-density floppy disk drive 3½"

• 1 serial (COM) and 1 parallel (LPT) port

• Mouse and keyboard ports

• Microsoft or compatible mouse

5HFRPPHQGHG&RPSXWHU5HTXLUHPHQWVIRU)/6\VWHP

6RIWZDUHDQG.&6RIWZDUHIRU:LQGRZVDQG

• IBM 486 PC or clone 100 MHz clock

• 640 KB base memory, extended to 8 MB

• Color graphics monitor (VGA)

• Color graphics adapter (VGA)

• 120 MB hard drive

• High-density floppy disk drive 3½"

• 1 serial (COM) and 1 parallel (LPT) port

• Mouse and keyboard ports

• Microsoft or compatible mouse

• Surge/spike protector

Introduction to the Bio-Tek FL600

1-3

Page 15

5HFRPPHQGHG&RPSXWHU5HTXLUHPHQWV)RU:LQGRZV

• IBM 486 / 100 MHz PC or better compatible

• Memory: 640 KB base, extended to 16 MB minimum

• 250 MB hard drive

3ULQWHU

• Microsoft Windows compatible printer

6RIWZDUH5HTXLUHPHQWV

• FL600 System Software, version 2 or higher

• KC4™ reader control and data reduction software

• MS-DOS version 5.0 or later

• Microsoft Windows version 3.1 or later, or Microsoft

Windows 95 (with 16 MB memory)

1-4

Introduction to the Bio-Tek FL600

Page 16

&KDSWHU

*HWWLQJ6WDUWHG

This chapter discusses how to set up the Bio-Tek FL600

hardware, check the communication port and run the

diagnostic tests, install and configure the FL600 software,

6HWWLQJ8S7KH)/5HDGHU

and exit the FL600 system software.

CAUTION: It is recommended that two people lift the FL600, which weighs about 23

kg (50.6 lb.). Care must be taken when moving the device or removing it from the

packaging. Hold the device firmly from the bottom of the case when lifting it.

Setting up the Bio-Tek FL600 Fluorescence Plate Reader is simply a matter of

connecting the system to the computer via the computer’s serial port, installing

the software, and setting up communications parameters. One of the serial ports

most likely already has a mouse connected to it (the FL600 software, since it

operates under Windows, requires a mouse).

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

110V for 100-120V˜ operation,

220V for 200-240V˜ operation

Set the incubator power switch to the appropriate voltage as

follows:

Turn off the PC.

To connect the FL600, first attach the 9-pin D-type cable into the

computer’s serial port (COM1, COM2, COM3, or COM4).

Plug the other end of the cable into the Serial Data Port located at

the rear of the FL600 Fluorescence Plate Reader.

Connect the power cable to the back of the Plate Reader.

Step 6:

Plug all power cords into grounded, electrical outlets (use of a surge

protector is strongly recommended).

Page 17

The FL600 and all computer hardware must be electrically grounded and

connected to a viable surge protector to avoid dangerous shocks and to

avoid destroying the electronic components through electrical spikes and

surges.

,QVWDOOLQJ.&DQG)/'LDJQRVWLF6RIWZDUH

The FL600 is supplied with two Windows™ software packages, KC4™

and FL600 Diagnostic Software.

KC4 controls the reader, reduces the fluorescence and absorbance data,

and furnishes the reports.

The FL600 Diagnostic software provides diagnostics to test the reader.

Although it contains other functions, these are undocumented and

unsupported.

,QVWDOOLQJ.&

Please consult your KC4™ User’s Guide. Place disk 1 into the floppy

drive. Run Setup.exe by choosing the Run option from the File Menu of

your Windows program. This routine will guide you through the

installation of KC4 onto your hard disk.

,QVWDOOLQJWKH+DUGZDUH.H\

To use KC4 to control the reader and print data, the hardware key needs to

be installed on the parallel port of your computer. Please consult your

KC4 Operations manual for further instruction.

,QVWDOOLQJWKH)/'LDJQRVWLF6RIWZDUH

'LDJQRVWLFV8VH

To install the FL600 software, follow these steps:

Step 1:

Step 2:

Step 3:

Step 4:

Turn on your computer, start Windows, and activate Windows’

Program Manager, if necessary.

Insert the FL600 Setup diskette into the floppy drive.

Select

Run

from the Windows’

File

menu.

Type drive: setup, (i.e., b: setup).

2-2

Getting Started

Page 18

Setup will indicate to you that all FL600 diagnostic software files will be

installed into the drive and directory C:\FL600. You will be given the

opportunity to change either the drive or the directory (or both). Setup

creates a new group called Bio-Tek FL600. Note that this is different from

the KC4™ group created by the KC4™ software.

NOTE: Be sure that TrueType Fonts are enabled in the Fonts Section of the

Windows Control Panel. FL600 requires certain TrueType fonts when

printing reports. For more information on activating TrueType Fonts,

please check your Windows User’s Guide.

Getting Started

2-3

Page 19

&KHFNLQJWKH)/6\VWHP

Before you begin to use the FL600 software, you should first check that

the FL600 settings are correct.

8VLQJWKH)/'LDJQRVWLF 6RIWZDUH

Step 1:

To start the FL600 diagnostic software:

From within Windows, double-click on the FL600 icon.

Depending on your computer speed, the FL600 diagnostic

software should boot up from within 15 to 60 seconds.

Longer than that might indicate that your computer system

needs more RAM or clock speed.

The FL600 Plate Layout screen will appear:

2-4

Figure 2-1: FL600 Plate Layout Screen

Getting Started

Page 20

)LOWHU:DYHOHQJWK/RFDWLRQV

Refer to Chapter 3 for instructions on determining filter locations. Record

the filter locations to be entered into KC4.

&KHFNLQJWKH&203RUW

Next, turn on the FL600 Reader using the switch located on the right side

of the front panel and check the COM Port Setting.

NOTE: When the Reader has been switched on, a green light next the switch

lights up and the plate transport moves out, ready to load a plate.

Step 1:

Pull down the

Instrument

menu and select

Communications

. A

dialog box appears showing you the currently selected

communications port, through which the software is attempting to

communicate with the FL600 Reader:

Figure 2-3: Communications Port Settings Screen

Getting Started

2-5

Page 21

Step 2:

Check to ensure that the correct com port is selected.

You can test the COM port to see if it is connected and

communicating correctly by clicking on

Test.

If the FL600

is switched on and connected correctly, you will see the

following dialog box appear:

Figure 2-4: Plate Model Information Window

NOTE: You will see an error message if any of the following conditions exist: the

FL600 is not correctly connected; it is not switched on; the incorrect

communications port is selected; there is a cable problem. Check that

the reader is switched on and correctly connected to the computer, that

you have selected the correct communications port, and that the cable is

operational. Then close the message window and try the

Click on OK to close the dialog box. You will return to the

test

again.

communications port information dialog box.

Click on OK to save the selected communications port, if

you’ve changed it.

NOTE: If you select

Cancel

, the communications window will close without

recording any changes.

2-6

Getting Started

Page 22

5XQQLQJ6\VWHP'LDJQRVWLFV

The FL600 diagnostic software will automatically test the functionality of

the Plate Reader, using the diagnostic tests.

Step 1:

Step 2:

Pull down the

Instrument

menu and select

Diagnostics

. You will

see the following window.

Figure 2-5: Initial FL600 Diagnostics Screen

To start diagnostic tests, click on the

Start

button. Information

detailing the status of the reader appears in the window as each test

is completed. (To close the window without starting the diagnostic

tests, click on

Close or Cancel

.)

Getting Started

2-7

Page 23

Once the FL600 has completed its self-diagnostic tests,

your screen should look similar to the one that follows:

Figure 2-6: FL600 Diagnostics Screen After Testing

:KDW7R'R,IWKH7HVWV)DLO

If any of the diagnostic tests should fail, click on the

below

the computer and the reader was will display on the screen.

Cancel

. A log showing exactly what the communications between

Print the log by selecting the

Enter the requested details on the fax cover sheet (which

prints automatically with the log) and fax both sheets to

Bio-Tek’s Technical Assistance Center at (802) 655-3399

in the USA or +32-3-825-47-49 in Europe. Technical

Assistance personnel will review the problem and instruct

you on what to do next.

To close the log, select the

Then, to close the diagnostics window and return to the

main screen, click on the

window.

File

menu and choosing

File

menu and choose

Cancel

button on the Diagnostics

Log...

button just

Close

Print

.

.

2-8

Getting Started

Page 24

([LWLQJ7KH)/'LDJQRVWLF6RIWZDUH

Step 1:

Step 2:

Select

unsaved work. Click on

exit without saving changes, or

You will be prompted as to whether or not you want to close the

Exit

from the File menu. You will be prompted to save any

Yes

to save the changes and exit, No to

Cancel

to forget all about exiting.

reader door, thus parking the plate transport inside the reader.

Figure 3-11: The Exit Window

To exit the software and have the door automatically closed, click in the

Close reader door

close the door (make sure you have removed your plate). Click

check box and click on OK to exit the software and

Cancel

continue without exiting.

to

NOTE: You should always opt to close the reader door when you are shutting

down the system to protect the optics from dust. Alternatively, the

carrier can be withdrawn and the reader door closed by pressing the

button located in the recess under the plate carrier.

NOTE: You can remove this software from your system (save the diskettes)

and reload it if you suspect that you are having any problems with the

instrument.

Getting Started

2-9

Page 25

2-10

Getting Started

Page 26

&KDSWHU

5HSODFLQJ)LOWHUVDQG

$GMXVWLQJ3UREH+HLJKW

This chapter discusses how to add and replace filters and

$GGLQJDQG5HSODFLQJ)LOWHUV

adjust probe height for the FL600.

Adding new filters or replacing existing filter sets is a two-step process:

• Changing the excitation and emission or absorption filters in

the filter wheels inside the reader.

• Changing the settings to reflect the filter change in the KC4™.

The settings in the system software must correspond exactly to the

physical location and specification of the filters on the filter wheels. An

error in the system software specification for the filter could damage the

instrument and affect the FL600 warranty.

Page 27

&KDQJLQJ)LOWHUV ,QVLGHWKH5HDGHU

Step 1:

Ensure that the plate carrier is parked inside the reader.

Press the red button located in a recess under the plate

carrier so that the plate carrier moves inside the reader and

stops.

Park Button

Figure 3-1: Parking the Plate Transport Mechanism

(Plate Carrier)

Step 2:

Step 3:

Power down the FL600, and disconnect the reader’s power cord.

Never operate the instrument with the cover off. Operating the reader

without a cover poses a serious shock hazard and may damage the

detection circuit.

Exposing the inside measurement chamber to ambient light for more

than 30 minutes may cause saturation of the measurement device.

Should this occur, please wait 24 hours before reading.

Remove the reader’s cover.

Using a 4 mm Allen wrench (supplied in the Accessories

Kit), remove the five screws (Figure 3-2) that secure the

reader’s cover to the base.

Remove the top cover and set it aside.

3-2

Bio-Tek FL600

Page 28

Figure 3-2: Removing the cover screws

Step 4:

Remove the covers on both filter wheels.

Excitation Filter

Wheel Cover

Locate the two filter assemblies at the rear of the reader,

adjacent to the printed circuit board (Figure 3-3).

Emission Filter

Wheel Cover

Bio-Tek FL600

Figure 3-3: Filter wheel locations

Remove the filter wheel covers by pulling up on the heads

of the plastic snap catches. (Figure 3-4)

3-3

Page 29

Figure 3-4: Removing the cover on the emission filter wheel

Step 5:

Step 6:

Step 7:

Remove the filters you wish to change, being careful not to touch

the filter’s glass surface, or other optical components. Use extreme

care to avoid dropping the filter into the interior of the instrument.

Rotate the filter wheel until you reach the filter you want to

change.

Using filter forceps (available in the Accessory Kit),

remove the filter cell by pulling it straight up and out of the

wheel.

If removing absorbance filters, remove the holder

containing the filter, not the filter itself.

Ensure that the glass surfaces of the filters are free of dust and

smudges.

Insert the new filter, and note its wavelength and position on the

filter wheel.

Fluorescence Filters:

3-4

Align the new filter with the filter wheel, using the

illustration below (Figure 3-5). The arrow on the filter cell

should point away from the center of the filter wheel.

Insert the new fluorescence filter, and seat the filter by

applying gentle, equal pressure on the edges of the filter

housing.

Helpful hint: If the filter is marked 485/20X:

• 485 is the center wavelength;

• 20 is the bandwidth at one-half maximum transmission

(BWHM) of the excitation (X) filter.

Bio-Tek FL600

Page 30

An emission filter has an “M” designation.

y

• A dual-function Excitation/Emission filter has an

“X/M“ designation.

Absorbance Filters:

Insert the filter into the filter holder, and insert this

assembly into the filter wheel.

Absorbance filters do not need to be aligned.

Step 8: Note the filter’s position on the wheel (the molded letters A, B, C

are to the right of each filter), and the wavelength that is printed on

the top or side of each filter cell.

1

1\Y

\YW^

W^]U

]U^

^d

d

1

1b

bb_g

b_g

Figure 3-5: Aligning the filter with the filter wheel

Step 9: Replace the covers on the filter wheels. Put any unused filters in a

secure place.

Secure the filter wheel covers by gently placing the cover

over the access hole and then pressing down on the plastic

snap covers.

Fit the instrument cover, and secure it using the five screws.

Seal the unused filters in a plastic container, and store them

in a cool, dry location.

Step 10: Re-connect the power cable, and power up the reader.

The plate carrier will move to the plate load position.

Bio-Tek FL600

3-5

Page 31

6HWWLQJWKH)LO WHU3RVLWLRQVLQ.&6RIWZDUH

The second and most important step in changing or adding filters to the

reader is changing the KC4 software filter settings to accurately reflect the

new filters and their position on the wheel. The values for filters in the

KC4 software must match the values of the filters in the reader to avoid

damaging the reader and invalidating data.

NOTE 1: Settings are stored on the PC, not the FL600. Remember to reprogram

the filter settings if you move the unit to another PC.

3-6

Bio-Tek FL600

Page 32

8WLOL]LQJWKH)LOWHU$GDSWHU6\VWHP

The FL600 comes equipped with a set of “500 series” fluorescence filters,

which fit directly into the filter wheel. Should your application require

absorbance filters of different wavelengths than those originally supplied

with your instrument, you may order them from Bio-Tek.

Absorbance wavelengths are available only in the smaller “287 series.”

These filters must be fitted into a filter adapter before insertion into the

filter wheel. The following instructions explain how to change the filter in

the adapter.

The “287 series” filter system involves the filter, the filter adapter, a

retaining ring, and a removal-insertion tool. The tool is a cylindrical object

about two inches tall, with nodes protruding from the top and bottom.

5HPRYLQJWKH)LOWHUI URPWKH$GDSWHU

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

Step 6:

Step 7:

Step 8:

Remove the filter adapter from the filter wheel, as described in the

section entitled Changing Filters Inside the Reader.

Place the adapter on a clean table. Be careful not to work too close

to the edge of the table, and give yourself plenty of space. (The

filter is very small and easy to misplace when it pops out.)

Place the adapter with the wide end face-down against the table.

Insert the longer node of the tool into the top of the adapter.

Place your thumbs on top of the tool and your other fingers along

the edges underneath the adapter.

Lift both objects as a unit, to approximately one inch off the table.

Make sure that you keep the adapter parallel to the table.

Firmly press the tool down into the adapter, until the filter and

retaining ring pop out onto the table.

Put the filter in a safe, clean place for future use.

Bio-Tek FL600

3-7

Page 33

,QVHUWLQJWKH5HSODFHPHQW)L OWHULQWRWKH$GDSWHU

Step 1:

Ensure that the replacement filter is free of dust and smudges. If

not, carefully clean the filter with a cotton swab soaked in alcohol.

Step 2:

Center the replacement filter on top of the retaining ring, and then

place the adapter onto the filter, wide end down. If possible, align

the window on the side of the adapter with the last four digits of

the filter number, so that the four digits will appear in the window.

Step 3:

Place both thumbs on either side of the top edge of the adapter, and

press down very firmly with equal pressure, until the assembly

snaps together.

Step 4:

Insert the shorter node of the tool into the adapter, and press down

firmly to seat the filter.

Step 5:

Install the filter adapter into the filter wheel, as described in the

section entitled Changing Filters Inside the Reader.

$GMXVWLQJ7RS2SWLFDO3UREH+HLJKW

Each FL600 model has been factory-configured with a top probe height

that will provide maximum sensitivity for the specified plate thickness.

Should you wish to change plate types, it may be necessary to reset the

probe height to prevent the probe from hitting the plate, or to maximize

sensitivity.

To achieve maximal sensitivity when using the top optical probe it is

necessary to adjust the probe height as low as possible, while still allowing

free movement of the microplate underneath. Follow the directions below

to adjust the top probe height, referring to the diagrams in Figure 3-6.

Step 1:

To withdraw the plate carrier into the instrument, press the plate

carrier retrieval button located on the front underside of the

instrument. Shut off the instrument, and unplug the power cord.

Step 2:

Using the 4 mm hex screw driver provided in the accessories box,

remove the five machine screws holding down the top cover.

These screws are located in the recessed pockets on the underside

edge of the bottom shroud. (See Figure 3-2.)

NOTE 1: Never operate the instrument with the cover off. Operating

the reader without a cover poses a serious shock hazard and may

damage the detection circuit.

3-8

Bio-Tek FL600

Page 34

NOTE 2: Exposing the inside measurement chamber to ambient light

for more than 30 minutes may cause saturation of the measurement

device. Should this occur, please wait 24 hours before reading.

Step 3:

Step 4:

Step 5:

Step 6:

Step 7:

Step 8:

Reaching into the inside of the instrument, place a microplate on

the plate carrier, ensuring that it is the same type you usually use.

Place the probe height adjustment shim (provided in the

accessories box) on the top of the plate, taking care to center it over

the plate. The end that contains the notch matching the top probe

size must be oriented toward the optical probe.

Using the 2.5 mm hex wrench provided, loosen the two set screws

holding the top probe in place. These two set screws are located on

the front surface of the top probe.

Carefully raise the probe so that the bottom of the top probe is

above the top edge of the plate and shim on the plate carrier.

Turn the X-axis and the Y-axis drive screws so that the appropriate

notch in the shim is located underneath the top probe.

Carefully lower the top probe into the notch of the shim, taking

care not to damage the probe. Make sure that the probe is straight

and vertical, and then tighten the set screws.

Step 9:

Step 10:

Step 11:

Step 12:

Step 13:

Turn the X-axis drive screw so that the plate is no longer located

under the probe. Make sure that the plate carrier has not traveled

so far as to open the door. If it has done so, back the plate up by

turning the X-axis screw.

Remove the microplate and shim from the plate carrier.

Replace the top cover. Carefully align the five 4 mm screws

holding the top shroud in place, and then tighten them.

Check the door for ease of movement. If the door movement is

impeded, try readjusting top shroud, making sure that it is on

properly and that the screws are tightened sufficiently.

Attach the power cord, and turn on the power switch. The plate

carrier should eject.

Bio-Tek FL600

3-9

Page 35

FL 600 IN TER IO R CO N FIG U R ATION

Y-AXIS SCREW

BOTTOM

PROBE

PROBE

MICROPLATE

TOP

INC U BATO R

EMISSION

FILTER

WHEEL

EXCITATION

FILTER

WHEEL

LAMP

PMT

POWER

SUPPLY

SET SCREW S

DOOR

X-AXIS SCREW

TOP PR O BE A DJU STMEN T JIG

(top view )

5 mm probe

1-3 m m probe

Figure 3-6: FL600 interior configuration

FA N

FL600 TO P PRO BE POSITION

(side v iew )

SET SCRE W

TOP PRO BE

PROBE HEIGHT ADJUSTMENT JIG

0,&523/$7(

3-10

Bio-Tek FL600

Page 36

&KDSWHU

%LR7HN)/0DLQWHQDQFH

0DLQWDLQLQJ7KH5HDGHU

The FL600 requires regular, systematic maintenance to guarantee that it

will run in top form. This includes regularly cleaning the reader’s exterior,

changing its air filter, and replacing its lamp.

This chapter explains the preventative maintenance

procedures for the FL600, including how to

replace the air filter and the lamp.

+RZWR&OHDQWKH([WHULRU

Exterior maintenance consists of simply wiping the reader with a damp

cloth and mild detergent.

+RZWR&OHDQDQG 5HSODFHWKH$L U)LOWHU

Dust can affect flourescence values. The FL600 air filter should be

cleaned or replaced once every six months, more often if your site is

especially dusty.

Step 1: To access the air filter, snap the fan cover away from the right hand

underside of the reader (on the same side as the plate transport), by

grabbing it between your thumb and forefinger and pulling

downward. (See

Figure 4-1

Figure 4-2

and

.)

Page 37

DLU ILOWHU

U

Figure 4-1

Step 2: Remove the air filter, a thin, grey piece of material.

DLU ILOWH

IDQ FRYHU

Step 3:

Clean the filter by blowing the dust out with an air blower, and/or

rinsing by hand with sudsy water and then clean water. Be sure to

dry the filter thoroughly before reinserting it into the fan cover.

Step 4:

If the filter is damaged or difficult to clean, or if the fan cover is

damaged, replace the entire fan cover and filter with Bio-Tek P/N

49840.

Step 5:

Return the fan cover to its original position at the underside of the

reader, and snap it back into place.

4-2

Figure 4-2

Bio-Tek FL600

Page 38

Never use the FL600 without an air filter.

+RZWR5HSODFHWKH/DPS

NOTE: Full instructions for lamp replacement are provided with the lamp

replacement kit.

CAUTION! Never touch the surface of the lamp, as any residue could

hamper illumination. We recommend that you wear gloves when

touching a new lamp.

Step 1:

Step 2:

Make sure the plate transport mechanism is “parked.” To do so,

press the red button in the recess under the plate carrier, so that the

plate carrier moves inside the reader and stops.

park button

Shut off the FL600, and then unplug both the power and computer

Figure 4-3

cables from the rear of the device.

Bio-Tek FL600

4-3

Page 39

CAUTION! It is very dangerous to operate the FL600 with the cover

off, as there is a probability of electrical shock.

Step 3:

Step 4:

Using the 4 mm Allen wrench provided in the accessories kit,

unscrew the five screws holding the reader cover to the base.

Remove the top cover, and set it aside.

Figure 4-4

Step 5:

Step 6:

At the back of the FL600, on the left side, you will find the

lamp assembly (as shown below).

Excitation Filter Wheel

Lamp

Assembly

Remove the two PMT wires from the cable harnesses on the lamp

Emission Filter Wheel

Figure 4-5

cover, and disconnect the solenoid cable. (See Figure 4-6.)

Unscrew the two thumb screws that hold the lamp cover onto the

lamp assembly, and lift up the lamp cover. (See Figure 4-7.)

4-4

Bio-Tek FL600

Page 40

Step 7:

Using the 3mm Allen wrench provided in the accessories kit,

unscrew the three screws mounting the lamp assembly to the lamp

housing.

CAUTION! Fingerprints can ruin the FL600 quartz halogen

lamp and render it unusable.

Step 8:

Disconnect the lamp wires, and slide the lamp assembly away from

the PMT base and toward the fan.

VROHQRLG

FDEOH

FDEOH KDUQHVV

ZLUHV

307 EDVH

Step 9:

Step 10:

Step 11:

Step 12:

Step 13:

Step 14:

FDEOH KDUQHVV

Carefully remove the lamp assembly from the lamp housing.

Remove the lamp from the lamp assembly by removing the three

Figure 4-6

3mm hex screws.

Insert the new lamp (P/N 6000556S) into the lamp assembly, and

then replace the three screws.

Remount the lamp assembly to the lamp housing, and screw down

the three 3mm hex screws. Be careful not to over-tighten them.

Reconnect the two lamp wires in any configuration. Polarity is not

an issue.

Replace the lamp cover, making sure that cable attached to the

solenoid is routed through the center hole of the lamp cover.

Bio-Tek FL600

4-5

Page 41

Step 15:

Attach the lamp cover to the lamp assembly, using the two thumb

screws. Be careful not to over-tighten them.

Step 16:

Step 17:

Step 18:

Step 19:

ODPS FRYHU

Reconnect the solenoid cable, and re-route the cables through the

cable harness.

Replace the reader cover, and attach it by screwing in the five

screws.

Plug in the power cable and the computer cable.

Turn on the FL600. The plate transport mechanism will

automatically move into the load position.

WKXPE VFUHZV

ODPS 31 6

IDQ

ODPS DVVHPEO\

ODPS ZLUHV

ODPS KRXVLQJ

Figure 4-7

4-6

Bio-Tek FL600

Page 42

&KDSWHU

7HFKQLFDO,QIRUPDWLRQ

This chapter contains a variety of technical information, including

hardware specifications for the Bio-Tek FL600 Fluorescence Plate

Reader.

%LR7HN)/)OXRUHVFHQFH$EVRUEDQFH3ODWH

5HDGHU

3K\VLFDO'L PHQVLRQV

Height 247 mm (97 in.)

Width 707 mm (278 in.)

Depth 426 mm (168 in.)

Weight 23 kg (50.6 lb.)

Shipping Weight 30 kg (66 lb.)

2SHUDWLQJ&RQGLWLRQV

Temperature +4°C to +35°C

Relative Humidity 20% to 80%, non-condensing

Page 43

(OHFWULFDO6SHFLIL FDWLRQV

Fuse 5.0 amp, time-delay T, glass, 5 mm x 20 mm, 250 volt-type

(Part Number 46055)

Input Voltage 90-132 volts AC

180-240 volts AC

47-63 Hz, 525 VA max

The power supply has a auto ranging power input.

Internal Voltages ±15 volt DC, +24 volt DC, +5 volt DC,

-950 volt DC

2SWLFDO6SHFLILFDWL RQV

Lamp Type M32-Type, Tungsten-Halogen, 75 watt

optically stabilized lamp in fan-cooled assembly

Lamp Life 2000 hours minimum

Excitation Range 300 nm - 650 nm filters

fitted in a motor driven wheel assembly

Emission Range 350 nm - 750 nm filters

fitted in a motor driven wheel assembly (complete

with photomultiplier)

Absorbance Range 340 nm - 750 nm filters

Filter Wheel 6 positions

Detector Photomultiplier Tube

Probe Diameter The fully randomized Quartz fiber bundles are

available in four sizes to meet user needs. Different

probes can be fitted to the upper and lower positions

at the factory.

5.0 mm general purpose probe for all media up to

96 wells.

3.0 mm general-purpose probe suitable for media up

to 96 wells

5-2

Technical Information

Page 44

1.5 mm special probe for 384-well plates with

minimum crosstalk, reduced sensitivity on other

plates

1.0 mm special probe for high-density media.

Probe Selector Probe diameters can be different in the top read and

bottom read positions.

Selection of top or bottom read position is under software

control.

The height of the top reading probe may need to be set by

the user for different plate heights. See the section

entitled Adjusting Top Optical Probe Height in Chapter

3.

6FDQQLQJ0HFKDQLVP

Speed 65 mm/second maximum

Resolution 5 microns

Repeatability within ±25 microns

X Drive 10.0 mm leadscrew

Y Drives 10.0 mm leadscrew

There are two (Y axis) Probe scanning mechanisms fitted for top and bottom

read configurations

Probe Configurations Selection of top or bottom reader or optical density mode

under computer control

Technical Information

5-3

Page 45

7HPSHUDWXUH&RQWURO

The FL600 is fitted with a heater block which can be programmed to heat the

plate to a temperature above ambient.

Temperature Range Ambient +6° Celsius to 50° Celsius

Uniformity Within ±0.5° Celsius across a 96 well Dynatech black plate

measured with thermal probes in the center and four corner

wells and 150 µl of Johnsons Baby Oil per well.

Time to Stabilize Within 30 minutes after switching on

Time to Cool Approx. 2.5 hours from 37° Celsius to 6° Celsius

above the on-board ambient temperature reference

sensor.

3HUIRUPDQFH6SHFLILFDWLRQV

Standard Plate Types All 96-well microplates and most 48- to 6-well

tissue culture plates

High-Density Plate Types 384-well microplates.

Note: Reader performance will be optimized by factory-

fitting of a smaller fibre optic probe 1.0mm or 1.5mm

diameter).

60, 72 and 96 well Terasaki plates

Note: Optimum probe size is 1.0mm or 1.5mm diameter.

A custom plate adapter is required.

Plate Sizes Minimum 126 mm × 84 mm

Maximum 133 mm × 90 mm

5-4

Technical Information

Page 46

Sensitivity (Specified)

Bottom Reading 5.0mm Probe

Top Reading 5.0mm Probe

10 pg/ml solution of Sodium Fluoroscein, in PBS,

150 µl per well Signal to Noise Ratio of 2 or greater.

Excitation 485/20, Emission 530/25

Hellma 96-well quartz plate.

125 ng/ml solution of Propidium Iodide, in PBS,

150 µl per well Signal to Noise Ratio of 2 or greater.

Excitation 485/20, Emission 645/40

Cestar 3603 96-well plate.

20 pg/ml solution of Sodium Fluoroscein, in PBS,

300 µl per well Signal to Noise Ratio of 2 or greater.

Sensitivity (Typical)

Excitation 485/20, Emission 530/25

Dynatech 96-well black plate.

160 pg/ml solution of Methylumbelliferone, in CBB,

300 µl per well Signal to Noise Ratio of 2 or greater.

Excitation 360/40, Emission 460/40

Dynatech 96-well black plate.

125 ng/ml solution of Propidium Iodide, in PBS,

300 µl per well Signal to Noise Ratio of 2 or greater.

Excitation 485/20, Emission 645/40

Dynatech 96-well black plate.

Typical sensitivities can be two to three times

more sensitive than specified

Technical Information

5-5

Page 47

Data Capture

Up to 6 different filter sets and sensitivities per

scan; maximum of 300 scans (1800 repeat reads

of the plate); wait time of up to 9999 seconds

between each read of a plate

Kinetic Speed

End Point Speed

Static Mode

30 seconds/plate, using Rapid Mode

4-6 seconds/column (depending on computer

speed), using Rapid Mode

5-10 reads/second/filter set, using Fast Kinetic

mode

1 read/3 seconds/2 filter sets, using Fast Kinetic

mode

48 seconds/plate including in and out time using

rapid mode, in fluorescence.

The probe will remain stationary under a well 0.1,

0.35, 0.5, or 2 seconds before taking a reading. A

single sample can be taken or 2, 3, 4, 5, 10, 20, 50,

or 100 readings that are averaged. Time between

samples can range from 10 ms to 2550 ms.

Plate Shaker

5-6

Technical Information

The plate may be shaken at three settings for a

period of 1 to 255 seconds. The settings are:

High 25 Hz 0.6 mm travel

Medium 17 Hz 0.9 mm travel

Low 12.5 Hz 1.2 mm travel

Page 48

Fixed References

The instrument contains 4 embedded references

which are optionally read at the start of each scan.

The references are:

1. Black Acetal Reference Disk used for Optical

Density 0% transmission and fluorescence

background

2. Green Reference Disk for fluorescence with

Excitation 485 and Emission 530nm.

3. Brown Reference Disk for fluorescence with

Excitation 590 and Emission 645nm.

4. Clear Optical path used for Optical Density

100% transmission

Technical Information

5-7

Page 49

%DVHG RQ WKH WHVWLQJ EHORZ WKH GHYLFH EHDUV WKH &( PDUN

(OHFWURPDJQHWLF,QWHUIHUHQFHDQG6XVFHSWLELOLW\

EC EMC DIRECTIVE 89/336/EEC

EN 50081-1, CLASS A-EMISSIONS

The device has been type tested by an independent testing laboratory and found

to meet the requirements of EC Directive 89/336/EEC for Radiated Emissions

and Line Conducted Emissions. Verification was to the limits and methods of

EN 55022:1995. The device is classified as EN 55022, Class A.

EN 50082-1 IMMUNITY

The device was also tested and found to meet requirements for Electrostatic

Discharge Susceptibility, Radiated Susceptibility, and Electrical Fast

Transient/Burst Susceptibility. Verification of compliance was conducted to

the limits and methods of EN 50082-1:1992, IEC 1000-4-2:1995, EN 61000-43:1996, and IEC 1000-4-4:1995.

USA FCC CLASS A

Warning: Changes or modifications to this unit not expressly approved by the

manufacturer could void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

Like all similar equipment, this equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area could cause interference, in

which case the user will be required to correct the interference at his own

expense.

5-8

Technical Information

Page 50

CANADIAN DEPARTMENT OF COMMUNICATIONS CLASS A

6DIHW\

This digital apparatus does not exceed Class A limits for radio emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Le present appareil numerique n'met pas du bruits radioelectriques depassant

les limites applicables aux appareils numerique de la Class A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le ministere des

Communications du Canada.

This device has been type tested by an independent laboratory and found to

meet the requirements of:

EC DIRECTIVE 73/23/EEC, LOW-VOLTAGE DIRECTIVE

EN 61010-1: “Safety requirement for electrical equipment for measurement,

control and laboratory use. Part 1 General requirements.”

Technical Information

5-9

Page 51

&RPSXWHU6SHFLILFDWLRQV)RU)/'LDJQRVWLF6RIWZDUH

0LQLPXP&RPSXWHU 5HTXLUHPHQWV

)RU:LQGRZV DQG

Base Unit IBM 486 PC or clone 33 MHz clock

640 KB base memory, extended to 8 MB

Color graphics monitor (VGA)

Color graphics adapter (VGA)

120 MB hard drive

High-density floppy disk drive 3½"

1 serial and 1 parallel port

Microsoft Windows compatible mouse and keyboard ports

Printer Microsoft Windows compatible printer

5HFRPPHQGHG&RPSXWHU5HTXLUHPHQWV

)RU:LQGRZV DQG

Base Unit IBM 486 DX PC or clone 100 MHz clock or better

640 KB base memory, extended to 8 MB

Color graphics monitor (VGA)

Color graphics adapter (VGA)

120 MB hard drive

High-density floppy disk drive 3½"

1 serial and 1 parallel port

Microsoft Windows compatible mouse and keyboard ports

Surge/spike protector

Printer Microsoft Windows compatible printer

5HFRPPHQGHG&RPSXWHU5HTXLUHPHQWV

IRU:LQGRZV

Base Unit IBM 486 DX PC or clone 100 MHz clock or better

6RIWZDUH5HTXLUHPHQWV

Bio-Tek FL600 System software is compatible with Windows 95 (16 MB of RAM

is recommended)

5-10

Technical Information

640K base memory, extended to 16 MB minimum

250 MB hard drive

MSDOS version 5.0 or higher

Bio-Tek FL600 System software version 2

Bio-Tek KC4 reader control and data reduction software

Microsoft Windows version 3.1 or higher

Page 52

)/6HULDO&RPPXQLFDWLRQV

The reader communicates with the computer via a 9-pin D-type male-female

connector (P/N 75034).

The connector is wired as follows.

PIN Computer FL600

1 DCD Not used

2 RX TX data to computer

3 TX RX data from

4 DTR Not used

5 GND Signal ground

6 DSR Not used

computer

7 RTS Linked to pin 8

8 CTS Linked to pin 7

9 RI Not used

Serial Port

Parameter

KC4 Reader

Control and Data

Reduction

FL600

Diagnostic

Software

Software

Baud rate 9600 9600

Data bits 8 8

Parity Even None

Stop bit 1 1

Note: The FL600 Diagnostic Software settings can not be changed- through

either software or hardware tools.

Technical Information

5-11

Page 53

2UGHULQJ)LOWHUV

The following list reflects standard and custom filters for use with the FL600. For the

latest additions to this list, please contact Bio-Tek’s Customer Service Department.

)OXRUHVFHQFH)LOWHUV

These are high-quality interference filters fitted in 22 mm diameter cells.

NOTE: The positions of each filter in the excitation and emission wheels can be user-

configured for minimum switch time of pairs, in kinetics applications using twocolor fluorescence.

FL500 AND FL600 EXCITATION/EMISSION FILTERS

FL500 use

Wavelength/

Bandwidth

360/40 5002020 Excitation only Standard Filter

380/20 5002028 Excitation only

Part

Number

(std 420-

700+nm

versions)

Comments

400/30 5002005 Excitation only

420/50 5002006 Both

440/30 5002027 Both

440/40 5002007 Both

450/50 5002008 Both

460/40 5002022 Both Standard Filter.

485/20 5002021 Both Standard Filter

485/40 5002009 Both

508/20 5002018 Both

530/25 5002023 Both

tandard Filter, used in both wheels

545/40 5002010 Both

5-12

Technical Information

Page 54

Wavelength/

Part

FL500 use

Comments

Bandwidth

Number

(std 420-700+nm

versions)

560/15 5002015 Both Alamar Blue™ Excitation Filter

560/20 5002011 Both

560/40 5002012 Both

590/20 5002025 Both Standard Filter

590/35 5002024 Both Standard Filter

620/40 5002013 Both

630/32 5002014 Both

633/10 5002017 Both

635/10 5002019 Both

645/40 5002026 Both Standard Filter

680/30 5002029 Both

Excitation Filters

340/30 5002030 Excitation only

410/10 5002001 Excitation only 400/30 filter is preferred in most

cases

540/25 5002004 Excitation only

310/20 5002039 N/A

340/11 5002043 Excitation only

Technical Information

5-13

Page 55

$EVRUEDQFH)LOWHUV

All absorbance filters are placed in the emission filter wheel and require an adapter

(part #6002000). See the section entitled Utilizing the Filter Adapter System in

Chapter 3, for further information. For the latest additions, please contact BioTek’s Customer Service Department.

FL600 ABSORBANCE FILTERS

Wavelength Part Number (2874 plus

340 2874340

380 2874380

405 2874405

410 2874410

415 2874415

wavelength)

440 2874440

450 2874450

465 2874465

470 2874470

490 2874490

515 2874515

530 2874530

540 2874540

550 2874550

562 2874562

570 2874570

5-14

Technical Information

Page 56

Wavelength Part Number (2874 plus

Wavelength)

580 2874580

590 2874590

600 2874600

610 2874610

620 2874620

630 2874630

640 2874640

650 2874650

660 2874660

720 2874720

750 2874750

Technical Information

5-15

Page 57

5-16

Technical Information

Loading...

Loading...