Page 1

Operator’s Manual

BioStack

™

Microplate Stacker

Page 2

Page 3

BioStack™ Microplate Stacker

Operator's Manual

© 2018

BioTek Instruments, Inc.

PN 7311000 Rev AH

Page 4

ii | BioStack Operator's Manual

Notices

BioTek® Instruments, Inc.

Highland Park, PO Box 998

Winooski, VT USA 05404-0998

© 2018, BioTek Instruments, Incorporated. No part of this publication may be

reproduced, transcribed, or transmitted in any form or by any means electronic or

mechanical, including photocopying and recording, for any purpose other than the

purchaser's use without the written permission of BioTek Instruments, Inc.

Trademarks

BioTek® is a registered trademark, and BioStack™, 405™ Microplate Washer,

EL406™, ELx405™, Eon™, Epoch™, Gen5™, Liquid Handling Control™,

MicroFill™, MultiFlo™, MultiFlo™ FX, PowerWave™, Precision™, Precision

Power™, Cytation™ and Synergy™ are trademarks of BioTek Instruments, Inc.

Microsoft® and Windows® are registered trademarks of Microsoft Corporation in

the United States and/or other countries.

All other trademarks are the property of their respective holders.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a

commitment by BioTek Instruments, Inc. Changes made to the information in this

document will be incorporated in new editions of the publication. No

responsibility is assumed by BioTek for the use or reliability of software or

equipment that is not supplied by BioTek or its affiliated dealers.

BioStack™ Microplate Stacker

Page 5

Notices| iii

Contents

Notices ii

Contact Information vi

Global Service and Support vi

Customer Service and Sales vi

Service/Technical Assistance Center (TAC) vi

European Coordination Center/Authorized European Representative vi

Revision History vii

Document Conventions xi

Intended Use Statement xi

Quality Control xii

Warranty and Product Registration xii

Warnings xii

Hazards xiii

Precautions xiv

CE Mark xvi

Directive 2014/30/EU: Electromagnetic Compatibility xvi

Directive 2014/35/EU Low Voltage (Safety) xvi

Directive 2012/19/EU: Waste Electrical and Electronic Equipment xvii

Directive 98/79/EC: In Vitro Diagnostics (if labeled for this use) xvii

Electromagnetic Interference and Susceptibility xvii

USA FCC CLASS A xvii

Canadian Department of Communications Class A xvii

User Safety xviii

Safety Symbols xix

BioStack 3 and BioStack 4: Secure Gripper Before Moving xx

Introduction 1

Introducing the BioStack 2

Product Description 3

BioStack 4: Notes about Handling Lidded Plates 4

Package Contents 6

Optional Accessories 6

Specifications 9

Stay-On Lid Mode (BioStack 4 Only) 10

Installation 13

Upgrade Scenarios 14

Unpack and Inspect the Instrument 15

Setting Up the BioStack 17

Remove the Shipping Hardware—BIOSTACK2WR 18

Remove the Shipping Hardware—BioStack 3 20

Remove the Shipping Hardware—BioStack 4 23

Wrist Angle Setting Requirements 26

0 Degree Orientation for Liquid Handlers 27

Dip Switch Settings 28

Change Setting for Wrist Angle 29

Change Setting for 50-Plate Stacks 30

BioTek Instruments, Inc.

Page 6

iv | BioStack Operator's Manual

Test Plates for Compatibility—BioStack 4 Only 30

Connect to Power 31

Connect to Computer 32

Connect to Liquid Handler 33

Where to Go Next 35

Repacking the BioStack 36

Install the Shipping Hardware—BioStack2WR 37

Install the Shipping Hardware—BioStack 3 37

Install the Shipping Hardware—BioStack 4 38

Repacking—Install Shipping Panel 39

Operation 41

Before You Start 42

Load Plates into Input Stack 43

Load Plates Using the Pedestal 44

Supported Microplate Types and Dimensions 45

Processing Microplates 46

Controlling the BioStack: 46

Stopping Plate Processing 47

Restack the Plates 49

Processing Plates with Lids 49

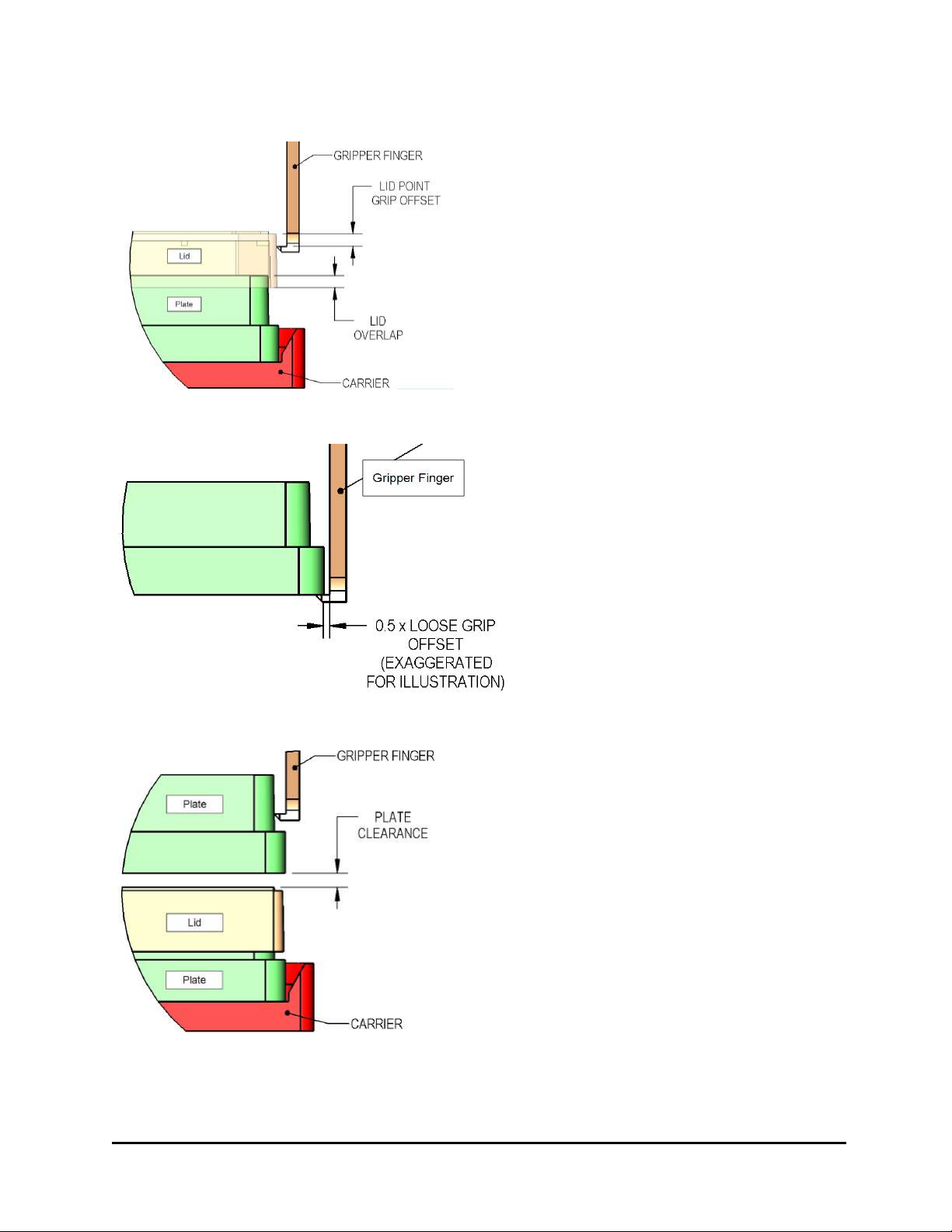

Plate De-Lidding: How It Works 50

Prevent Condensation on Plate Lids 51

Plate Lid Definition Files 52

Microplate and Lid Dimensions 53

Plate Lid Advanced Dimensions 54

Start Up the BioStack 57

Maintenance 59

Overview 60

Recommended Maintenance Schedule 60

Warnings and Precautions 61

Required Materials 61

Routine Cleaning Procedure 63

Decontamination 64

Tools and Supplies 65

Decontaminate the BioStack 65

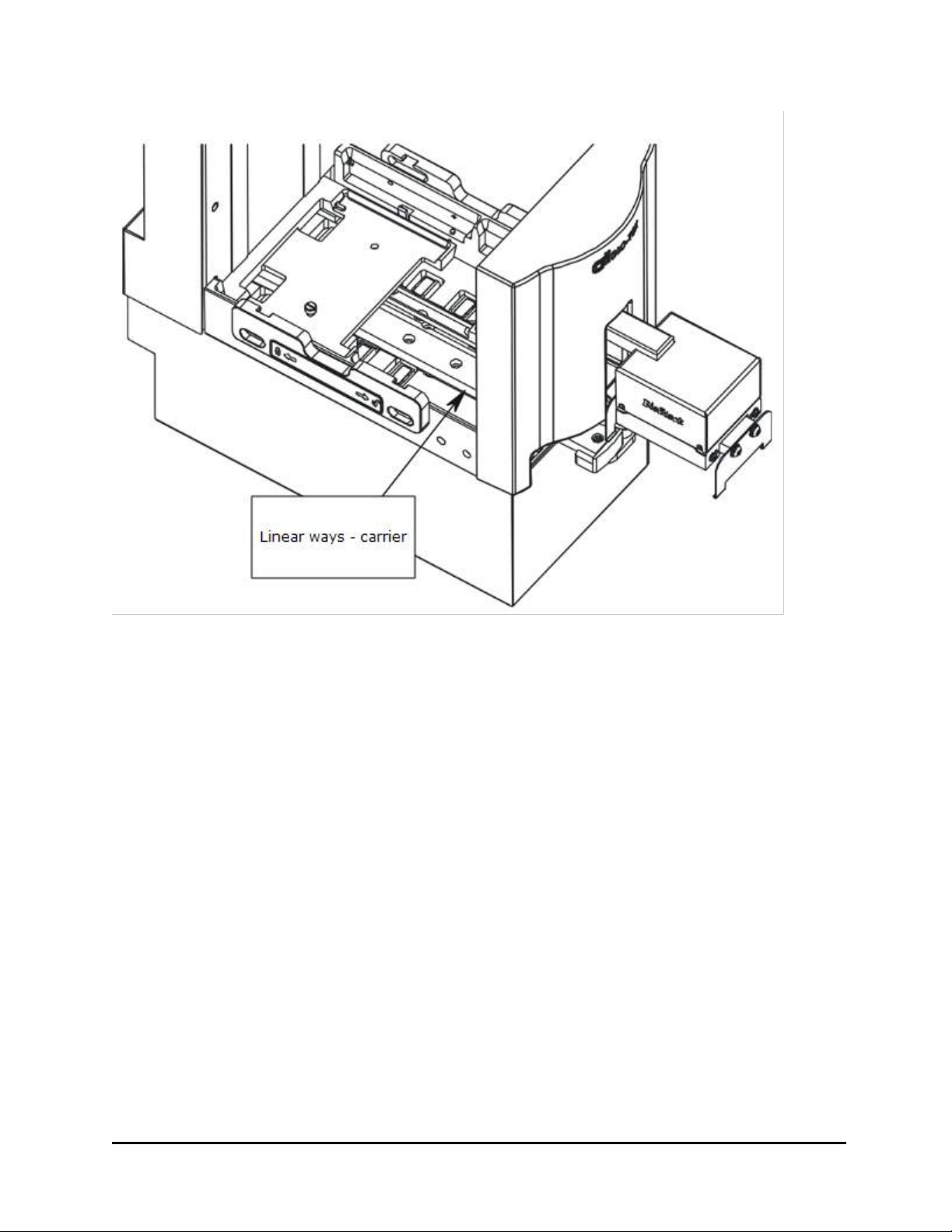

Cleaning and Lubricating the Linear Ways 66

Qualification 69

Overview 70

Recommended Qualification Schedule 70

Installation Qualification 72

Operational Qualification Procedure 72

Troubleshooting & Error Codes 73

Troubleshooting 74

Communication Error Codes 74

BioStack Instrument Errors 76

Plate Lid Definition Errors 82

BioStack™ Microplate Stacker

Page 7

Notices| v

Washer or Dispenser Communication Error Codes 85

BioStack Sensor Numbers 86

BioStack Motor Numbers 87

Interfacing Instrument Numbers 87

Plate Stacked Height 88

Change Setting for Low-Profile Plates 89

Loosen Plate Carrier Set Screws - BioStack 4 Only 90

Adjust the Stack Dogs 91

Install the Barcode Scanner 93

Barcode Scanner Overview 94

Install the Barcode Scanner 94

Change Dip Switch Setting for Barcode Scanner 97

Install the Scanner Cable Duct 97

Preparing and Attaching Barcode Labels 99

Scanner Test with Readers 101

To Report Barcodes with Reader Results 101

Scanner Test with Precision/XS 103

To Report Scanned Codes with Precision/XS 104

BioTek Instruments, Inc.

Page 8

vi | BioStack Operator's Manual

Contact Information

BioTek Instruments, Inc.

Highland Park, P.O. Box 998

Winooski, Vermont 05404-0998 USA

Global Service and Support

BioTek instrument service and repair is available worldwide at several of BioTek’s

International Service Centers and in the field at your location. To arrange for service

or repair, contact the office nearest you; visit www.biotek.com for up-to-date

contact information. For customer service, sales, and technical assistance, refer to

the information below.

Customer Service and Sales

Internet: www.biotek.com

Phone:

802-655-4740(outsidetheUS)

Fax: 802-655-7941

Email: customercare@biotek.com

888-451-5171 (toll-free in the US)

Service/Technical Assistance Center (TAC)

Phone:

802-655-4740(outsidetheUS)

Fax: 802-654-0638

Email: tac@biotek.com

800-242-4685 (toll-free in the US)

European Coordination Center/Authorized European Representative

BioTek Instruments GmbH

Kocherwaldstrasse 34

D-74177 Bad Friedrichshall

Germany

Internet: www.biotek.de

BioStack™ Microplate Stacker

Page 9

Revision History| vii

Phone:

Fax: +49(0)7136968111

Email: info@biotek.de

+49 (0) 7136 9680

Revision History

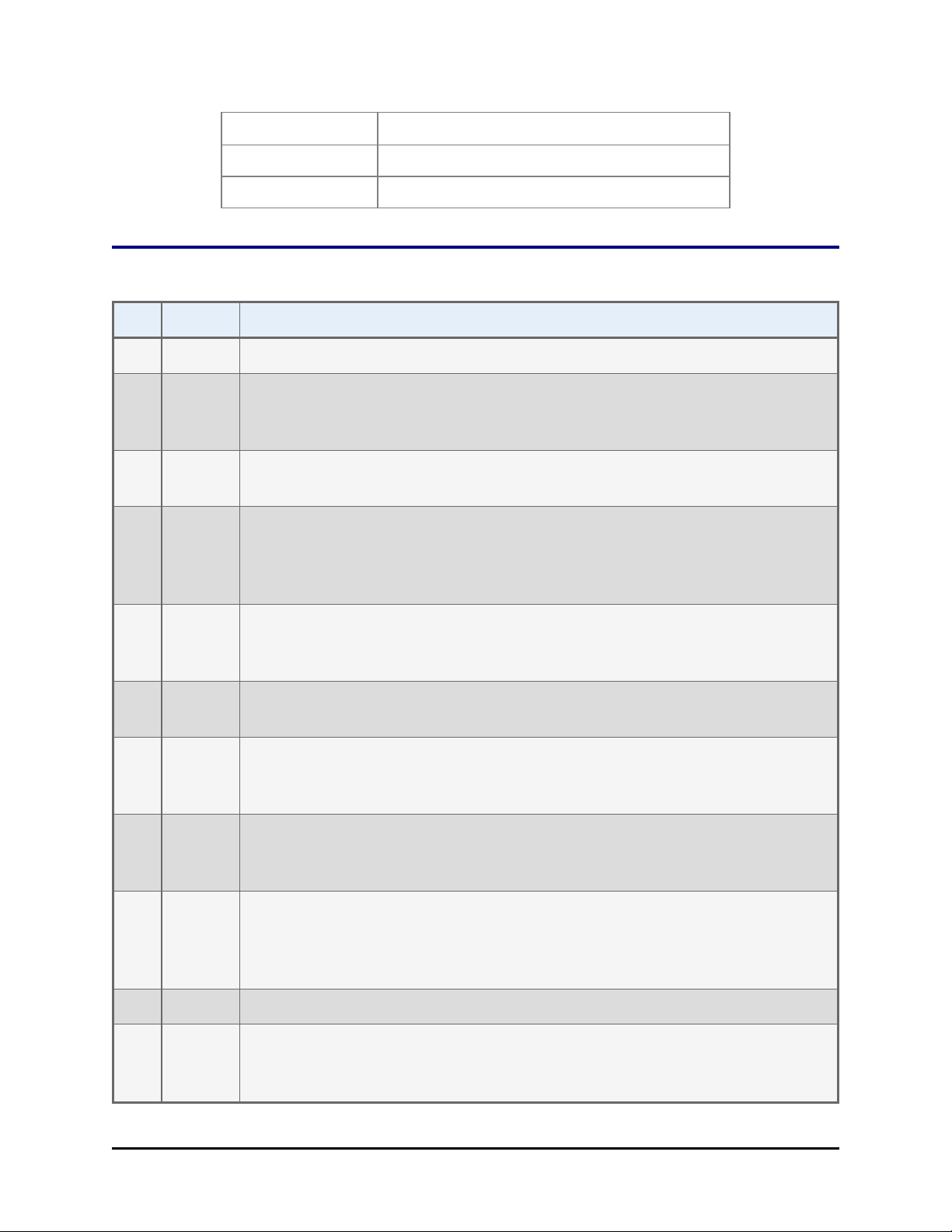

Rev Date Changes

A 11/2002 First issue.

B 5/2003 Throughout: Clarified the compatibility of the ELx405 with the BioStack by

specifying the Washer’s Auto Plate and Select models only. Updated

contact information, Safety Symbols, and Warranty.

C 10/2003 Preface: Updated the Intended Use statement to distinguish between the

European Union and all other jurisdictions.

D 06/2004 Throughout: Reformatted manual for cosmetic effect. Added references

about compatibility of the BioStack with the ELx405 HT and ELx405 Select

CW Microplate Washers. Added new sections about compatibility,

installation, operation, alignment, etc., of the Precision and Precision XS.

Revised the Technical Support section and added new sections on Depot

Service Contracts and Applications Support. Enhanced Introduction,

Installation, Operation, and Maintenance chapters.

E 06/2005 Throughout: Added information on the new barcode scanner and USB port.

Changed ELx405 “Auto” model to “ELx405.”

Moved instructions from former Appendix B, Serial Cable Connections and

Appendix C, Mounting the Aligning Plates and Posts into Chapter 3,

Installation.

Chapter 5: Simplified/clarified IQ and OQ sections. Chapter 7: Added KC4

error codes for BioStack operation with readers, and BioStack barcode

scanner error codes.

F 05/2006 Added instructions for using Gen5 software. Preface: Updated safety

information and removed Warranty, Registration Card, and Registration

Online sections in Preface. Added laser beam warning. Appendix B: Added

laser beam warning.

G 07/2006 Added instructions for installing/operating the BioStack with the Synergy 2.

H 12/2006 Added instructions for installing and operating the BioStack with the

NanoQuot. In Chapter 5 and Appendix B: Added the Barcode Scanner Test

as an optional IQ and OQ test.

BioTek Instruments, Inc.

Page 10

viii | BioStack Operator's Manual

Rev Date Changes

I 06/2007 Added instructions for installing and operating the BioStack with the

Synergy 4. Updated error code information. Incorporated manual update

revision H1 as Appendix C, Reconfiguration of the BioStack. Added

Appendix D, Required Software Versions.

J 08/2007 Added references to the Liquid Handling Control (LHC) Software throughout

the manual, and instructions for installation/operation of the software for

PC control of the BioStack and ELx405.

K 10/2007 Added instructions for installing and operating the BioStack with the

MicroFlo Select.

L 03/2008 Added instructions for installing and operating the BioStack with the

PowerWave XS2. Changed “μFill” to “MicroFill.”

M 06/2008 Changed “Bio-Stack” to “BioStack.” Added references to the fixed wrist

model (PN BIOSTACK2) and rotational wrist model (PN BIOSTACK2WR).

Added instructions for installation/operation of the new models with

interfacing instruments.

N 10/2008 Added instructions for installing and operating the BioStack with the EL406.

Changed “Alignment Kit” to “Integration Kit” throughout. Added more

information about installation of two BioStacks with two interfacing

instruments (ELx405, MicroFlo Select, EL406).

O 12/2008 Added instructions for installing and operating the BioStack with the

Synergy Mx. Removed references to obsolete BioStack PN BIOSTACK.

P 04/2009 Added information regarding instrument control of the EL406 and

installation/operation instructions for controlling the BioStack and EL406

via the keypad. Added more information about how the BioStack barcode

scanner works in Appendix B. Added instructions or notes throughout the

manual instructing the user to turn the BioStack on before the interfacing

instrument, and to manually raise the BioStack’s claw/gripper above the

interfacing instrument’s plate carrier or supply station (Precision) before

turning the BioStack on.

Q 01/2010 Added instructions for installing and operating the BioStack with the

Synergy H4 reader.

R 09/2010 Overall: Streamlined and rearchitected content to enhance usability and

support maintenance and reuse. Moved installation and operation

instructions, software version compatibility tables, software data sheets,

and information on obtaining software version information out of the main

Operator’s Manual and into individual, instrument-specific PDF files on the

BioStack Operator’s Manual CD. Added support for the MultiFlo Dispenser.

Preface: Updated Intended Use Statement; Warnings, Hazards, and

BioStack™ Microplate Stacker

Page 11

Revision History| ix

Rev Date Changes

Precautions; Directives; and Safety Symbols.

Chapter 1 Introduction: Updated Package Contents and Optional

Accessories lists. Chapter 2 Installation: Added “Configure for 50-Plate

Stacks.” Chapter 5 Instrument Qualification: Removed IQ Checklists.

Moved the Software Data Sheets to the individual instrument-specific PDF

files. Chapter 6 Error Codes: Removed error code tables for MicroFlo and

EL406 Interface Software, and Gen5/KC4 Function Call Errors.

S 11/2010 Added instructions for installing and operating the BioStack with the

Synergy H1 reader. Emphasized the importance of orienting microplates in

the input stack to match the expected placement of well A1 on the

interfacing instrument’s plate carrier.

T 8/2011 Added instructions for installing/operating the BioStack with the Eon,

Epoch.

U 3/2012 Added instructions for installing and operating the BioStack with the 405

TS. Added references to the 10-plate stacks.

V 6/2012 Added support for BIOSTACK3WR (for liquid handlers). Removed

references to BioStack2. Added ‘Service’ and ‘Accessories’ hazard

warnings. Added ‘Spare Parts’ precaution. Changed all references from

claw/gripper to gripper. Added Wrist Angle Setting Requirement and Dip

switch Settings content. Revised descriptions of the microplate

requirements. Replaced former Appendix B, Microplate Stack

Adjustment/Configuration for Half-Height Plates with section in

Troubleshooting chapter: Adjust Stack Dogs. Updated error codes and

added Troubleshooting guidelines to the same chapter. Omitted former

Appendix C, Information for External Developers, as it was obsolete.

Updated format and text styles, replaced some drawings with photos.

Revised the liquid handler instrument-specific sections; conversely, the

reader instrument-specific PDFs are unchanged since the last revision. The

Nanoquot instrument-specific section has been omitted.

W 7/2012 Added support for BioStack3 for readers and for controlling both BioStack

models using Gen5 alone (i.e. BioStack PC Control Software is no longer

needed for the readers). Consolidated the Integration Kits when applicable,

i.e. universal aligning base plates support both BioStack models. Removed

references to obsolete aligning base plate in instrument-specific

instructions. Added units to the barcode label graphic.

X 4/2013 Added instructions for installing and operating the BioStack with the

Cytation 3. Corrected or improved content based on suggestions from field

staff, including deleting the statement that barcode labels can be purchased

from BioTek. Added references to the rubber band that secures the

BioStack3's wrist during shipping. Recommended using rubber bands to

BioTek Instruments, Inc.

Page 12

x | BioStack Operator's Manual

Rev Date Changes

secure gripper before moving the BioStack 3.

Y 11/2013 Added instructions for installing and operating the BioStack with the

MultiFlo FX. Added Precision Universal models (PRC384U) to the list of

instruments that are not BioStack-compatible. Restored references to, and

added a diagram for 0° integration for liquid handlers and the

BIOSTACK2WR. Added "Space Requirement Dimensions" for most

interfacing instruments.

Z 12/2013 Introduced BioStack 4 and its support of plate lids during processing. Added

hazard label and description: cutting fingers/hand. Added "Plate

Compatibility Test" for BioStack4 only. Added support for the Synergy Neo

- BioStack4 integration.

AA 6/2014 Added support for new instruments: Epoch2 and Synergy HTX. Added a

warning that the PowerWave HT is not compatible with the BioStack 4 and a

"strong recommendation" to measure the plate and lid type before use to

verify they meet the minimum requirements for de-lidding operations with

the BioStack 4.

AB 9/2014 Updated specifications to include certain low-density plates with lids that

are supported in "stay-on lid" mode. Added references to stay-on lid mode

where applicable. Corrected the space requirement for liquid handlers:

increased the depth required by six inches to account for wrist movement.

AC 12/2014 Added support for Cytation 5. Updated the "Stay-on Lid" mode description

to describe the newly relabeled stacks required to support this feature, i.e.,

Tall Lidded Plate Stacks. Updated notice of compliance with EU Directives.

AD 2/2015 Updated Synergy Neo integration instructions to match new and improved

alignment hardware. Added new 28 volt power supply to parts list.

AE 3/2015 Reverted contents to match revision AC.

AF 7/2015 Added support for Synergy Neo2, updated Contact Information, changed

RMA to Service Call Notice (SCN) number, updated Synergy Neo and

Synergy Neo2 integration kit to PN 7310055

AG 2017 Updated PN for replacement shipping materials 7313002 to 1163003;

removed reference to the ANSI standard in the microplate specification section; add note to “Install and Run BioStack with the Synergy H1” to point

out position of bracket on alignment plate, which varies depending on

which BioStack is used; added Cytation 1 support; resolved EPR 24692 by

adding error code 2002 to the list; modified instructions for installing software and testing communication in the Install and Operate the BioStack

with Precision document; added USB and serial cable part numbers to the

fluid interfacing instrument documents.

BioStack™ Microplate Stacker

Page 13

Document Conventions| xi

Rev Date Changes

AH 12/2018 Updated Epoch 2 information to correspond with the updated Epoch 2 instru-

ment; corrected alignment plate PN for Synergy H1; updated the drawing

of the Cytation showing the space needed for an instrument with a Cooling

Accessory installed; updated PN for BioStack2 shipping container to PN

7310014; updated BioStack leg PN for use with Epoch 2 to 7310570;

updated the PN for the baseplate for the Microflo FX to 7312138; added

error code 020D.

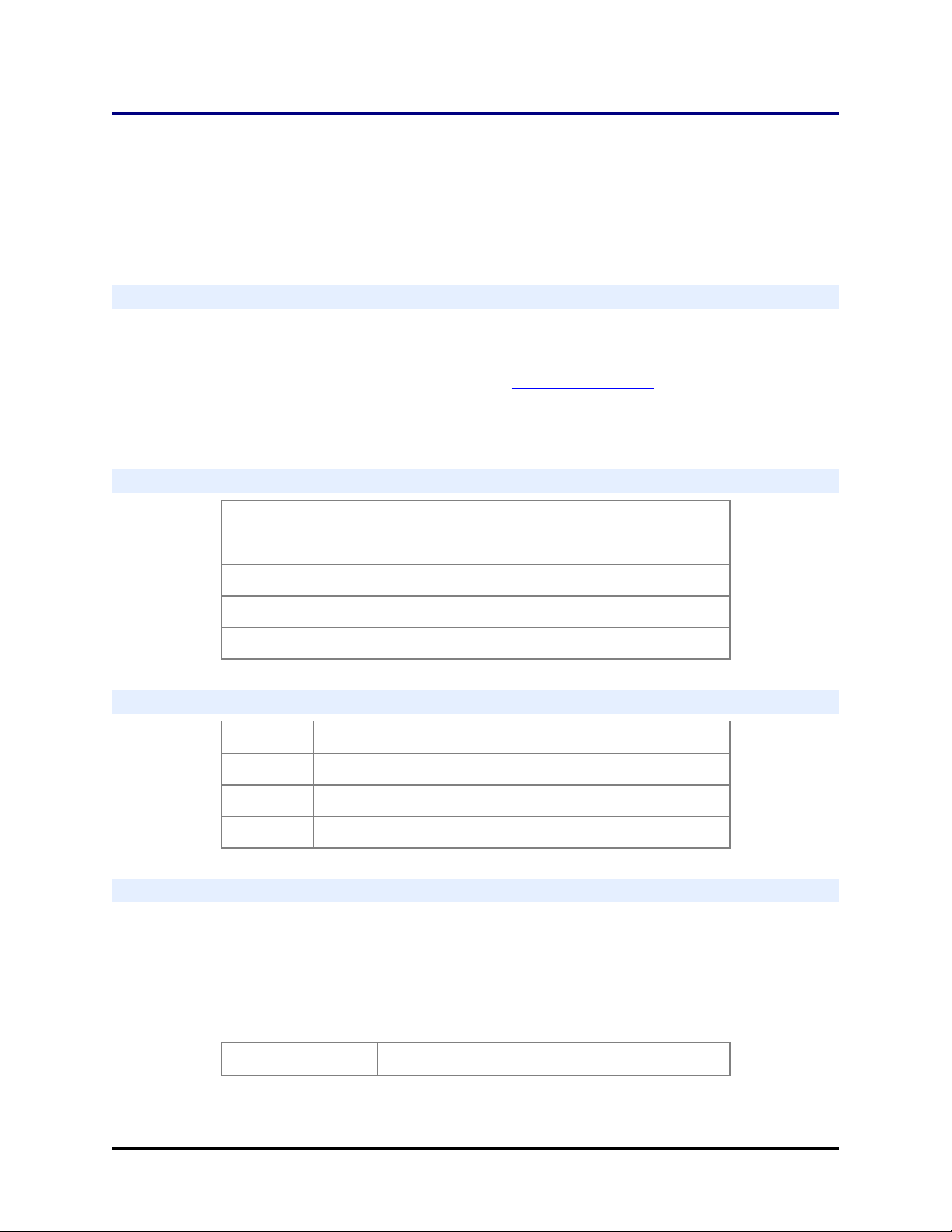

Document Conventions

This manual uses the following typographic conventions:

n This note format calls attention to important information.

Warnings are presented in this style to call attention to potential hazards and

other safety concerns.

This icon calls attention to important safety information.

Tips and suggestions for improving performance are formatted this way.

Intended Use Statement

The BioStack Microplate Stacker is an automated microplate stacking system that is

designed to systematically transfer a stack of microplates to and from compatible

BioTek laboratory instruments wherever washing, dispensing, pipetting, or reading

of multiple microplates is performed.

If the instrument has an “IVD” label it may be used for clinical and non-clinical

purposes, including research & development. If there is no such label the

instrument may only be used for research & development or other non-clinical

purposes.

BioTek Instruments, Inc.

Page 14

xii | BioStack Operator's Manual

Quality Control

It is considered good laboratory practice to run laboratory samples according to

instructions and specific recommendations included in the assay package insert for

the test to be conducted. Failure to conduct Quality Control checks could result in

erroneous test data.

Warranty and Product Registration

Please take a moment to review the Warranty information that shipped with your

product. Please also register your product with BioTek to ensure that you receive

important information and updates about the product(s) you have purchased.

You can register online through BioTek’s Customer Resource Center (CRC) at

www.biotek.com or by calling 888/451-5171 or 802/655-4740.

Warnings

Operate the instrument on a level, stable surface away from excessive

humidity.

When operated in a safe environment, according to the instructions in this

manual, there are no known hazards associated with the BioStack. However,

the operator should be aware of certain situations that could result in serious

injury: see Hazards and Precautions.

BioStack™ Microplate Stacker

Page 15

Hazards

The following hazard warnings are provided to help avoid injury:

Warning! Power Rating. The instrument’s power supply or power cord must

be connected to a power receptacle that provides voltage and current within the

specified rating for the system. Use of an incompatible power receptacle may

produce electrical shock and fire hazards.

Hazards| xiii

Warning! Electrical Grounding. Never use a plug adapter to connect primary

power to the external power supply. Use of an adapter disconnects the utility

ground, creating a severe shock hazard. Always connect the power cord directly to

an appropriate receptacle with a functional ground.

Warning! Service. Only qualified technical personnel should perform service

procedures on internal components.

Warning! Accessories. Only accessories which meet the manufacturer’s

specifications shall be used with the instrument.

Warning! Liquids. Avoid spilling liquids on the instrument; fluid seepage into

internal components creates a potential for shock hazard or instrument damage. If a

spill occurs while a program is running, abort the program and turn the instrument

off. Wipe up all spills immediately. Do not operate the instrument if internal

components have been exposed to fluid.

Warning! Unspecified Use. Failure to operate this equipment according to the

guidelines and safeguards specified in this manual could result in a hazardous

condition.

Warning! Software Quality Control. The operator must follow the

manufacturer’s assay package insert when modifying software parameters and

establishing reading, washing, or dispensing methods. Failure to conduct quality

control checks could result in erroneous test data.

Warning! Internal Voltage. Always turn off the power switch and unplug the

power supply before cleaning the outer surface of the instrument.

Warning! Potential Biohazards. Some assays or specimens may pose a

biohazard. Adequate safety precautions should be taken as outlined in the assay’s

package insert. This hazard is noted by the symbol shown here. Always wear safety

glasses and appropriate protective equipment, such as chemically resistant rubber

gloves and apron.

Warning! Laser Beam. Serious eye injury may occur if you stare directly into

the laser beam of the barcode scanner during operation of the scanner. This hazard

is noted by the symbol shown here. Do not look directly into the laser beam during

operation of the scanner.

BioTek Instruments, Inc.

Page 16

xiv | BioStack Operator's Manual

Warning! Pinch Hazard. Some areas of the instrument or its components can

present pinch hazards when the instrument is operating. These areas are marked

with the symbol shown here. Keep hands/fingers clear of these areas when the

instrument is operating.

Warning! Cutting of Fingers or Hand Hazard. The metal plate gripper

presents a cutting hazard to fingers/hands when the instrument is operating. The

gripper is marked with the symbol shown here. Keep fingers/hands away from the

gripper when the instrument is operating.

Precautions

The following precautions are provided to help avoid damage to the instrument(s):

Caution: Service. The instrument should be serviced by BioTek-authorized

service personnel. Only qualified technical personnel should perform troubleshooting

and service procedures on internal components.

Caution: Spare Parts. Only approved spare parts should be used for

maintenance. The use of unapproved spare parts and accessories may result in a

loss of warranty and potentially impair instrument performance or cause damage to

the instrument.

Caution: Environmental Conditions. Do not expose the instrument to

temperature extremes. For proper operation, temperaturess near the instrument

should remain within the range listed in the Specifications section. Performance

may be adversely affected if temperatures fluctuate above or below this range.

Caution: Sodium Hypochlorite. Do not expose any part of the instrument to

the recommended diluted sodium hypochlorite solution (bleach) for more than 20

minutes. Prolonged contact may damage the instrument surfaces. Be certain to

rinse and thoroughly wipe all surfaces.

Caution: Power Supply. Only use the power supply shipped with the

instrument. Operate this power supply within the range of line voltages listed on it.

Caution: Disposal. Dispose of the instrument according to Directive

2002/96/EC, “on waste electrical and electronic equipment (WEEE),” or local

ordinances.

Caution: Warranty. Failure to follow preventive maintenance protocols may

void the warranty.

Caution: Shipping Hardware. All shipping hardware (e.g., shipping panel,

shipping block, carrier shipping screws, etc.) must be removed before operating the

instrument and reinstalled before repackaging the instrument for shipment.

Caution: Waste Sensor Port (for customers who have purchased the

BioStack for use with the ELx405, 405 TS/LS, or EL406). The waste sensor port on

the back of the washer/dispenser is the same type as the 24-VDC power connector

on the back of the BioStack. Do not plug the BioStack’s external power supply into

BioStack™ Microplate Stacker

Page 17

Precautions| xv

the washer’s/dispenser’s port; it will permanently damage internal components.

Caution: Aligning Posts. When installing the BioStack’s four aligning posts,

use caution not to cross thread these parts. Finger-tighten only!

Caution: BioStack Barcode Scanner Mirror. Do not scratch or damage

the mirror when unpacking or installing the barcode scanner.

Caution: Electromagnetic Environment. Per IEC 61326-2-6 it is the user’s

responsibility to ensure that a compatible electromagnetic environment for this

instrument is provided and maintained in order that the device will perform as

intended.

Caution: Electromagnetic Compatibility. Do not use this device in close

proximity to sources of strong electromagnetic radiation (e.g., unshielded

intentional RF sources), because these may interfere with the proper operation.

BioTek Instruments, Inc.

Page 18

xvi | BioStack Operator's Manual

CE Mark

Based on the testing described below and information contained

herein, this instrument bears the CE mark.

n Note: Refer to the Declaration of Conformity for specific details.

Directive 2014/30/EU: Electromagnetic Compatibility

Emissions—Class A

The system has been type-tested by an independent, accredited testing

laboratory and found to meet the requirements of EN 61326-1: Class A for

Radiated Emissions and Line Conducted Emissions.

Verification of compliance was conducted to the limits and methods of EN 55011

(CISPR 11) Class A. In a domestic environment it may cause radio interference,

in which case, you may need to take measures to mitigate the interference.

Immunity

The system has been type-tested by an independent, accredited testing

laboratory and found to meet the requirements of EN 61326-1 and EN 61326-2-6

for Immunity. Verification of compliance was conducted to the limits and

methods of the following:

EN 61000-4-2, Electrostatic Discharge

EN 61000-4-3, Radiated EM Fields

EN 61000-4-4, Electrical Fast Transient/Burst

EN 61000-4-5, Surge Immunity

EN 61000-4-6, Conducted Disturbances from RFI

EN 61000-4-11, Voltage Dips, Short Interruptions and Variations

Directive 2014/35/EU Low Voltage (Safety)

The system has been type-tested by an independent testing laboratory and was

found to meet the requirements of this Directive. Verification of compliance was

conducted to the limits and methods of the following:

EN 61010-1, “Safety requirement for electrical equipment for measurement,

control and laboratory use. Part 1, General requirements.”

EN 61010-2-081, “Particular requirements for automatic and semi-automatic

laboratory equipment for analysis and other purposes.”

BioStack™ Microplate Stacker

Page 19

Electromagnetic Interference and Susceptibility| xvii

Directive 2012/19/EU: Waste Electrical and Electronic Equipment

Disposal Notice: Dispose of the instrument according to Directive 2012/19/EU,

“on waste electrical and electronic equipment (WEEE)” or local ordinances.

Directive 98/79/EC: In Vitro Diagnostics (if labeled for this use)

n Product registration with competent authorities

n Traceability to the U.S. National Institute of Standards and Technology (NIST).

EN 61010-2-101 Particular requirements for in vitro diagnostic (IVD) medical

equipment.

Electromagnetic Interference and Susceptibility

USA FCC CLASS A

RADIO AND TELEVISION INTERFERENCE

NOTE: This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user

will be required to correct the interference at their own expense.

In order to maintain compliance with FCC regulations shielded cables must be

used with this equipment. Operation with non-approved equipment or

unshielded cables is likely to result in interference to radio and television

reception.

Canadian Department of Communications Class A

This digital apparatus does not exceed Class A limits for radio emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Le present appareil numerique n'émet pas de bruits radioelectriques depassant

les limites applicables aux appareils numerique de la Class A prescrites dans

le Reglement sur le brouillage radioelectrique edicte par le ministere des

Communications du Canada.

BioTek Instruments, Inc.

Page 20

xviii | BioStack Operator's Manual

User Safety

This device has been type-tested by an independent laboratory and found to meet

the requirements of the following:

l Underwriters Laboratories UL 61010-1 “Safety requirements for electrical

equipment for measurement, control and laboratory use; Part 1: general

requirements.”

l Canadian Standards Association CAN/CSA C22.2 No. 61010-1 “Safety

requirements for electrical equipment for measurement, control and

laboratory use; Part 1: general requirements.”

l EN 61010 Standards. See CE Mark on page xvi.

BioStack™ Microplate Stacker

Page 21

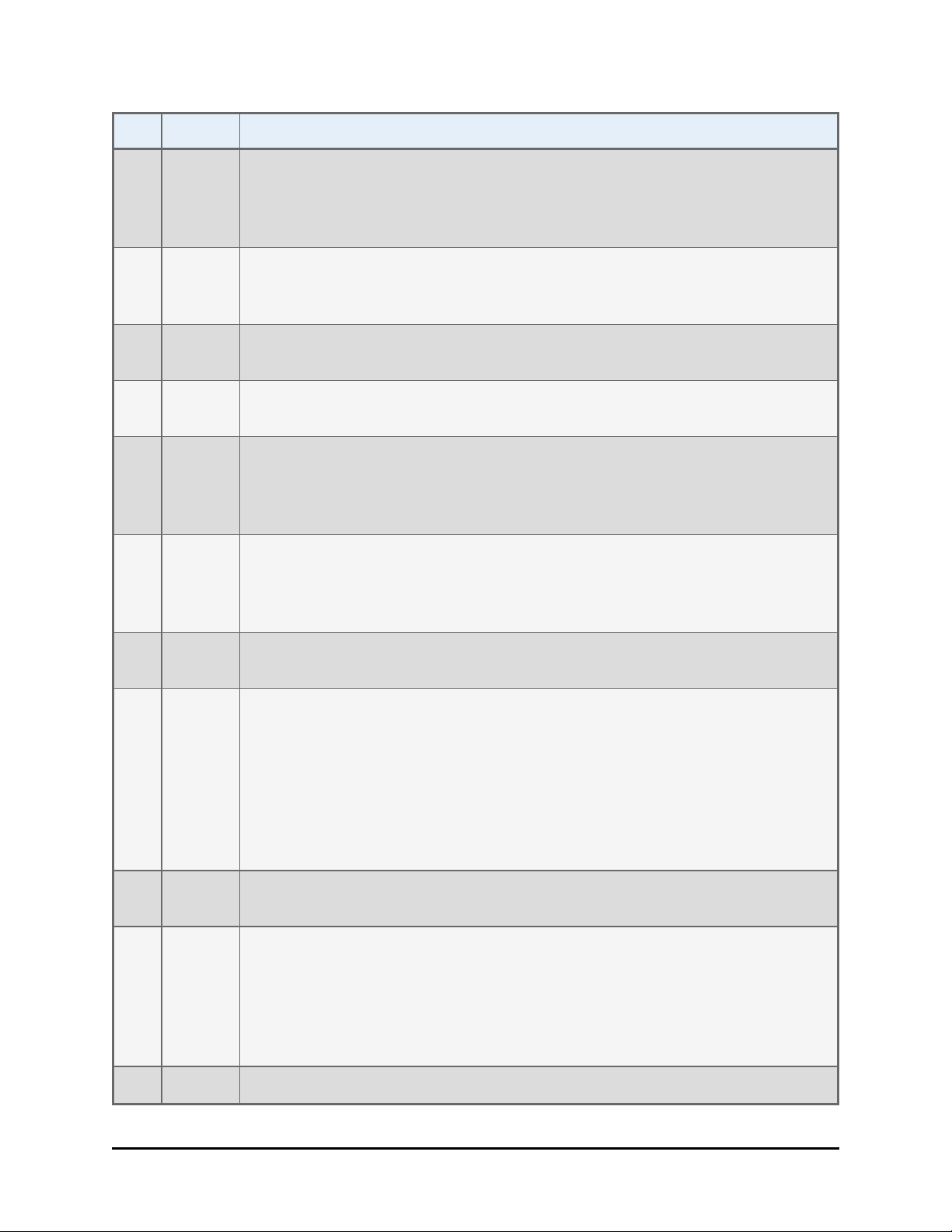

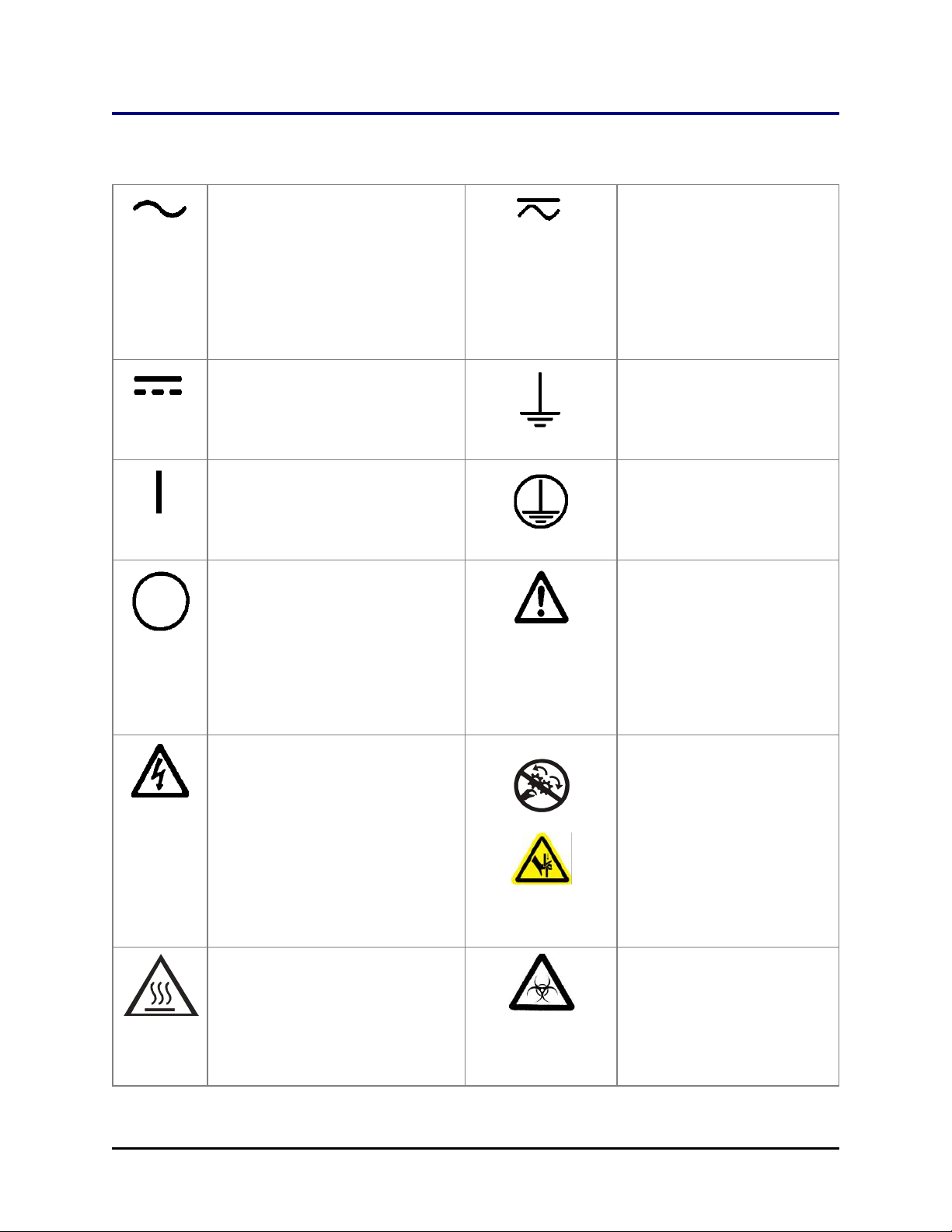

Safety Symbols

Some of these symbols appear on the instrument or accessories:

Alternating current

Courant alternatif

Wechselstrom

Corrientealterna

Correntealternata

Safety Symbols| xix

Both direct and alternating

current

Courant continu et courant

alternatif

Gleich - und Wechselstrom

Corriente continua y

corrientealterna

Corrente continua e

correntealternata

Direct current

Courant continu

Gleichstrom

Corriente continua

Corrente continua

On (Supply)

Marche (alimentation)

Ein (VerbindungmitdemNetz)

Conectado

Chiuso

Off (Supply)

Arrêt (alimentation)

Aus (TrennungvomNetz)

Desconectado

Aperto

(sconnessionedallaretedialimentazi

one)

Warning, risk of electric shock

Attention, risque de choc électrique

Gefährlicheelektrischeschlag

Precaución, riesgo de

sacudidaeléctrica

Attenzione, rischiodiscossaelettrica

Earth ground terminal

Borne de terre

Erde (Betriebserde)

Borne de tierra

Terra (difunzionamento)

Protective conductor terminal

Borne de terre de protection

Schutzleiteranschluss

Borne de tierra de protección

Terra diprotezione

Caution (refer to

accompanying documents)

Attention (voir documents

d’accompanement)

AchtungsieheBegleitpapiere

Atención (vease los

documentosincluidos)

Attenzione, consultare la doc

annessa

Warning, risk of crushing or

pinching

Attention, risqued’écrasement

et pincement

Warnen, Gefahr des

Zerquetschens und Klemmen

Precaución, riesgo del

machacamiento y sejeción

Attenzione,

rischiodischiacciareedintrappol

arsi

Warning, hot surface

Attention, surface chaude

Warnen, heißeOberfläche

Precaución, superficiecaliente

Attenzione, superficiecalda

Warning, potential biohazards

Attention,

risquesbiologiquespotentiels

Warnung!

MoeglichebiologischeGiftstoffe

Atención, riesgosbiológicos

Attenzione, rischiobiologico

BioTek Instruments, Inc.

Page 22

xx | BioStack Operator's Manual

In vitro diagnostic medical device

Dispositif médical de diagnostic in

vitro

Medizinisches In-VitroDiagnostikum

Dispositivo médico de diagnóstico in

vitro

Dispositivo medico diagnostico in

vitro

Consult instructions for use

Consulter la notice d’emploi

Gebrauchsanweisung beachten

Consultar las instrucciones de uso

Consultare le istruzioni per uso

Separate collection for

electrical and electronic

equipment

Les équipements électriques

et électroniques font l’objet

d’une collecte sélective

Getrennte Sammlung von

Elektro- und

Elektronikgeräten

Recogida selectiva de aparatos

eléctricos y electrónicos

Raccolta separata delle

apparecchiature elettriche ed

elettroniche

Laser radiation: Do not stare

into beam

Rayonnement laser: Ne pas

regarder dans le faisceau

Laserstrahlung: Nicht in den

strahl blicken

Radiación de láser: No mire

fijamente al rayo

Radiazione di laser: Non stare

nel fascio

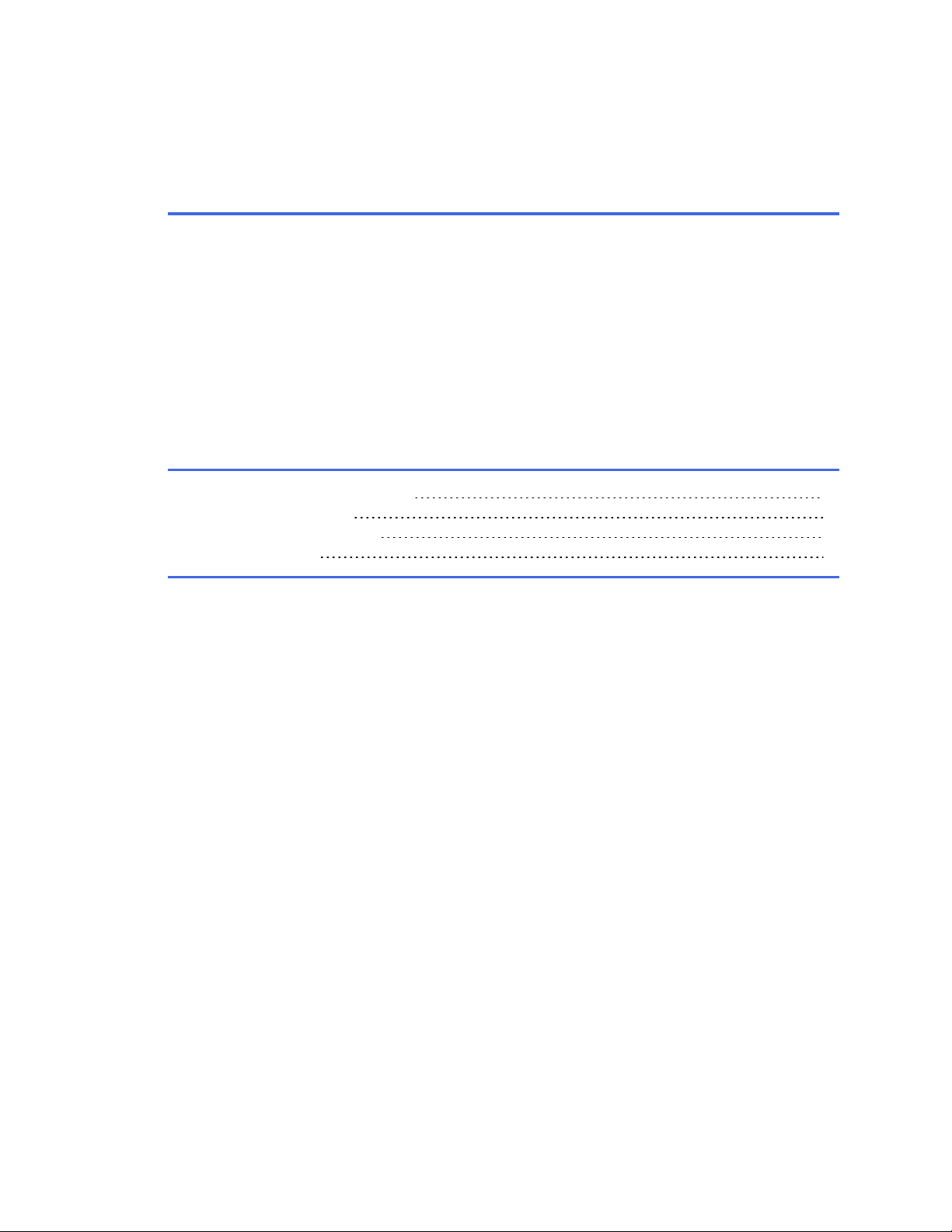

BioStack 3 and BioStack 4: Secure Gripper Before Moving

Note: Do not let the gripper flop around! Before moving the BioStack 3 or BioStack 4,

secure the gripper with a rubber band or tape to prevent it from losing its alignment. A

complex recalibration is required if it is knocked out of position.

BioStack™ Microplate Stacker

Page 23

Chapter 1

Introduction

Thank you for purchasing the BioStack™ Microplate Stacker.

This chapter describes its features and specifications and

includes important contact information.

Introducing the BioStack 2

Package Contents 6

Optional Accessories 6

Specifications 9

Page 24

2 | Chapter 1: Introduction

Introducing the BioStack

This manual covers the BioStack (BIOSTACK2WR), BioStack3 (BIOSTACK3WR),

and BioStack4 (BIOSTACK4). Unless otherwise specified, the term BioStack refers

to all models.

BioStack 3 shown without stacks

Side view

1. Gripper—arm with wrist and gripper

2. Plate carrier Back view

3. Stack locks 1. Power switch

4. Dip switch access 2. Power cable port

3. LED status indicator

4. Barcode scanner port

5. Computer and interfacing

instrument ports

BioStack™ Microplate Stacker

Page 25

Introducing the BioStack | 3

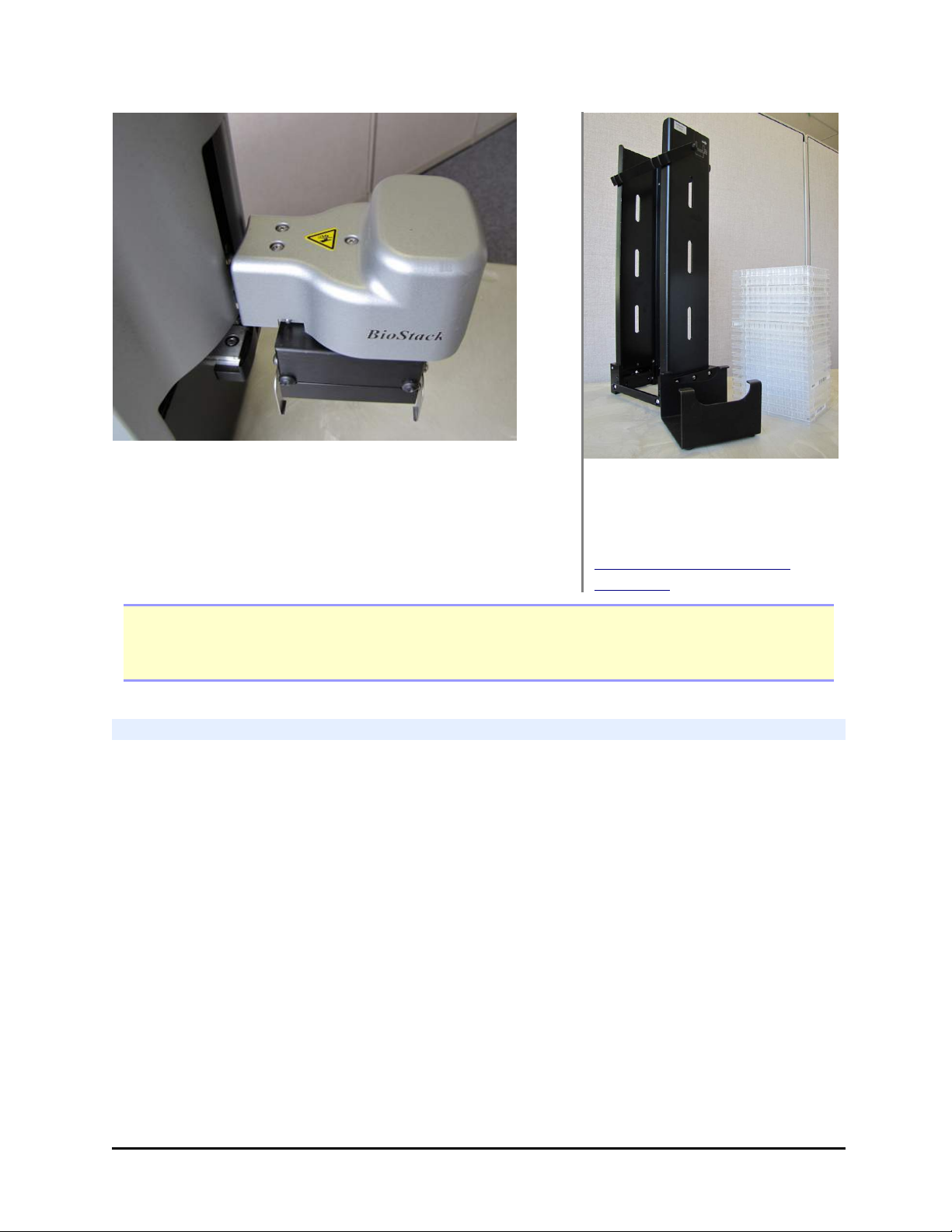

BioStack Gripper arm Stack, pedestal and plates

All current BioStack models have rotational wrists that

enable them to interface with most BioTek instruments in

the most convenient and comfortable angle/position.

A tool to help load plates into

the stack, called a pedestal, is

provided with the BioStack: See

Load Plates Using the

Pedestal on page 44.

Important: Review the Wrist Angle Setting Requirements on page 26 to determine

if you need to change the wrist angle setting to interface correctly with your BioTek reader

or liquid handler.

Product Description

The BioStack Microplate Stacker is a simple and cost-effective solution for benchtop

automation of BioTek’s microplate instrumentation. The BioStack's compatibility

with a range of detection and liquid handling systems provides laboratories high

throughput processing for a variety of applications in genomics, proteomics, drug

discovery, and clinical diagnostics. Speed, ease of use, and walk-away automation

are guaranteed for any routine microplate process.

The BioStack’s small footprint fits easily in standard laboratory hoods and may not

require a computer. As a batch processor for BioTek readers and liquid handlers,

the BioStack interfaces seamlessly with BioTek’s Gen5 Data Analysis Software and

Liquid Handling Control (LHC) Software.

Up to two BioStacks (2WR models only) can interface with the Precision Microplate

Pipetting System for unattended plate replication, bulk reagent dispensing, or other

liquid handling operations.

BioTek Instruments, Inc.

Page 26

4 | Chapter 1: Introduction

Features:

l Automates routine laboratory procedures

l 10, 30, or 50 standard height microplates per interchangeable stack

l Simple to use for all laboratory personnel

l Restacking capability

l Small footprint conserves precious benchtop space

l Universal design compatible with all supported BioTek instrumentation

l Designed for heavy use with aluminum precision-ground base and synchronistic

movement

l Linear mechanisms built around proven BioTek technology

l Quiet operation with cams activated by stepper motors

l Reliable transport with microplate gripped from below during transfers

l Onboard self-diagnostics ensures trouble-free operation

l BioStack 4 Only: Handles microplates with lids: removes the lid before plate transfer to

the attached instrument, and replaces the lid after retrieval from the instrument,

except in "stay-on lid" mode.

Models:

l PN BIOSTACK2WR: Supports 90° and 0° integrations; one plate at a time transfer.

l PN BIOSTACK3WR and BIOSTACK4: Support +90°, -90°, and 0° integrations; two

plates in motion for every transfer. BioStack 4 processes plates with or without lids.

BioStack 4: Notes about Handling Lidded Plates

The BioStack 4 functions similarly and can do everything the other BioStack models

do, and it can process microplates with lids.

l The required stacks are labeled "TALL LIDDED PLATE STACK" to process plates with

lids.

l The BioStack 4 supports standard stack types when not handling lids. (Conversely, do

not use the "tall lidded plate stacks" with BioStack 2/3 models.)

l The "tall lidded plate stack" also supports taller plates without lids; it can handle plates

up to 22 mm. (Maximum supported height of plate + lid = 23.2 mm when Stay-On Lid

Mode requirements are met.)

l Standard stacks are recommended for handling low-profile PCR plates. The BioStack 4

has been designed to better handle these plates that warp easily, but the best

performance is achieved combining the BioStack 4 with the standard stacks.

l Only 30- and 10-plate stacks are supported when processing lids. And, the stacks hold

fewer plates when lids are included: the 30-plate stack holds about 25 plates with lids

and the 10-plate stack holds approximately 8 plates with lids, depending on the plate

BioStack™ Microplate Stacker

Page 27

Introducing the BioStack | 5

and lid type and manufacturer. Another limiting factor is the total weight of the filled

plates in the stack cannot exceed 7.0 lbs (3.2 kg).

l When processing plates with lids the BioStack 4 performs several extra error-checking

movements, using its fingers to determine if the expected labware, i.e., a plate, lid, or

combination, is present. You'll observe several extra finger movements during

processing.

l

Except in Stay-On Lid Mode, lids are always

removed from the plates during processing even when the option to "Keep lids on

during read" is selected. In this case, the lid is removed briefly and replaced almost

immediately. Lid integrity is maintained: the lid removed from a plate is always the

same lid restored to the plate.

l A Plate Lid Definition file is required to process plates with lids.

n Gen5: Lid dimensions are stored in the Plate Type Database record. BioTek

updated the most commonly used plate type records with lid dimensions and

users can add more, as needed.

n LHC and touch screen liquid handlers: Several plate lid definition files are

provided to support the most common types of plates and new files can be

created. Important: A copy of the Plate Lid Definition file is attached to the

protocol for processing. The protocol no longer references the original lid

definition file, only its copy. If the original plate-lid definition file is modified,

those changes are not applied to the copies of the file attached to protocols.

n Keypad Liquid Handlers: Must use LHC to process plates with lids. Keypad

instruments can control the BioStack 4 when not processing plates with lids,

identical to BioStack 3 behavior.

l Certain plate types are not compatible with the de-lidding operation. Measure your

plate and lid type before use to verify they meet the minimum requirements:

Specifications on page 9. The BD Falcon 351172, for example, is a nonsupported

plate type.

BioTek Instruments, Inc.

Page 28

6 | Chapter 1: Introduction

Package Contents

n Part numbers and package contents are subject to change and vary according

to instrument model. Please contact BioTek Customer Care if you have any

questions.

n BioStack Microplate Stacker (PN BIOSTACK2WR, BIOSTACK3WR, BIOSTACK4)

n Power supply: 24 volt (PN 01281)

n Plate stacking pedestal (PN 7312083)

n Grease kit (PN 7110017)

n BioStack Operator’s Manual (PN 7311000) on USB flash drive (PN 7310571)

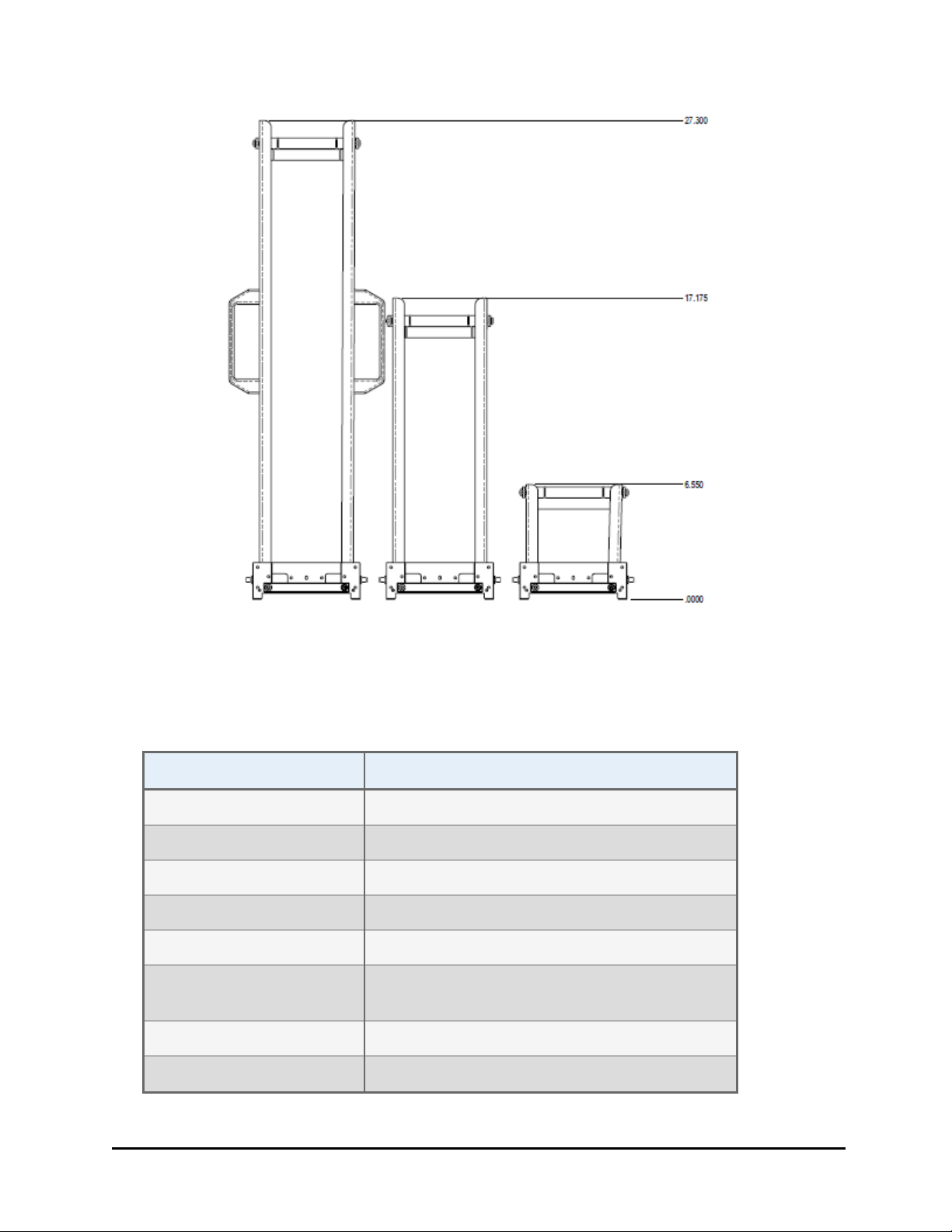

Optional Accessories

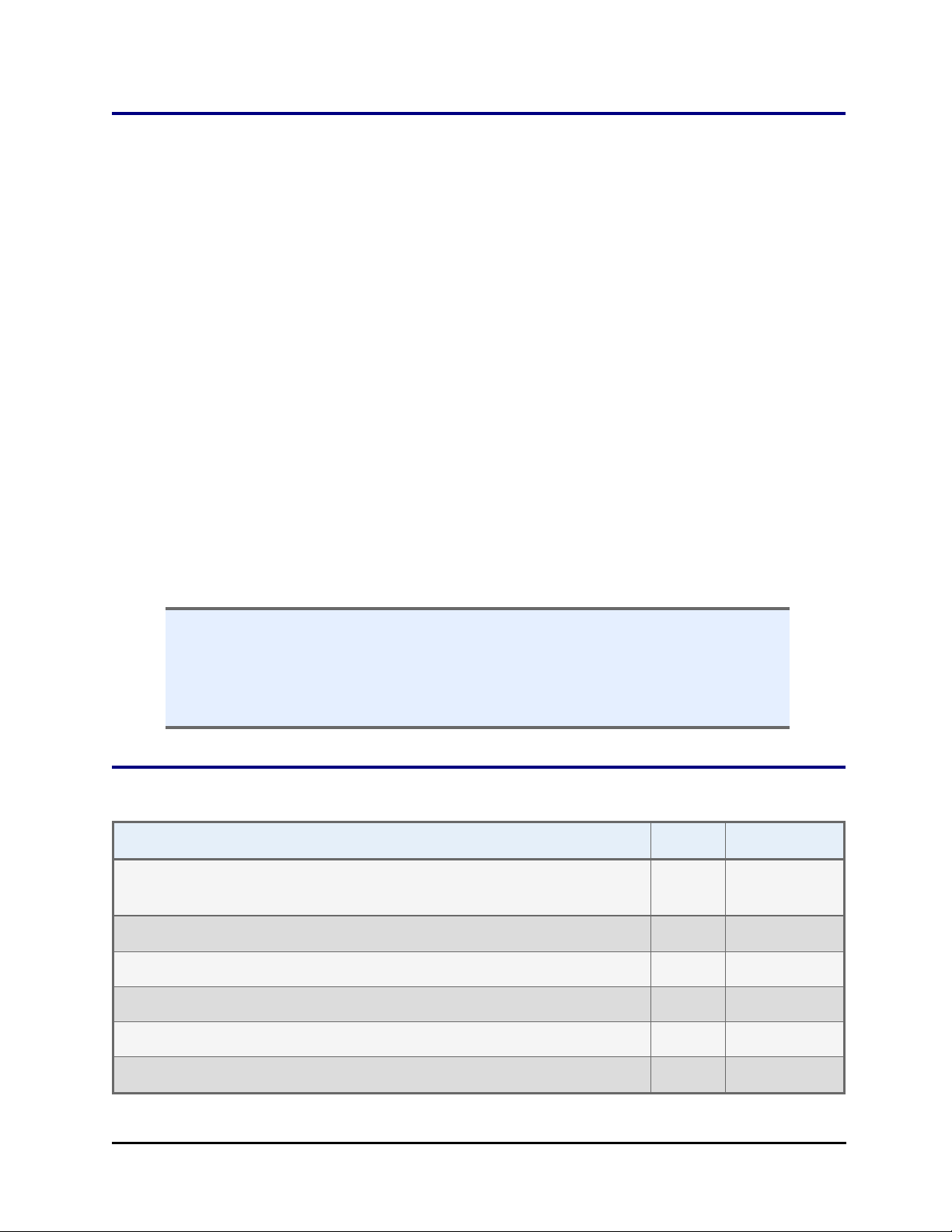

l Set of two microplate stacks

Stack Type Any BioStack

¥

BioStack 4*

30-plate 7310008‡ 1230004

10-plate 7310030 1230003

50-plate 7310539 N/A

* These stacks are required for transferring plates with lids. The 50-plate stacks can be used on the

BioStack 4 to process plates only, not plates with lids.

¥ Recommended for low-volume PCR plates.

‡ Also supports up to 44 low-profile, 1536-well plates without lids.

Note: Stack Types are named for the number of plates they can hold without lids.

When using lids, the approximate number of plates with lids the 30-plate stack holds is 25;

for the 10-plate stack, it's 8, depending on the manufacturer. Another limiting factor is

that the total weight of the filled plates in the stack cannot exceed 7.0 lbs (3.2 kg).

BioStack™ Microplate Stacker

Page 29

Optional Accessories | 7

Microplate Stacks with height in inches: 50-, 30-, and 10-plate

l Instrument Qualification package (PN 7310530)

l Barcode scanner and installation kit (PN 7310017)

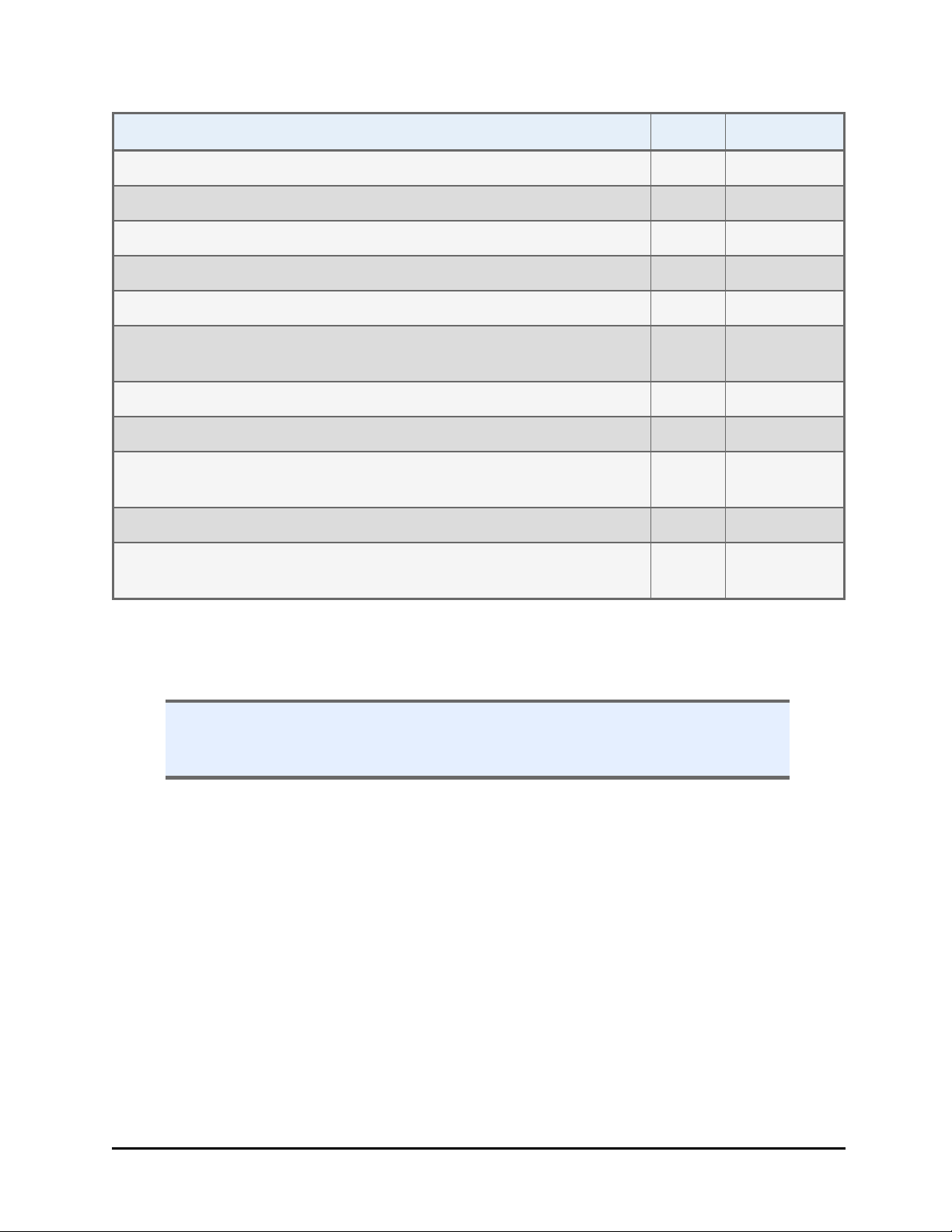

l Integration Kits for use with interfacing instruments:

Instrument Integration Kit

405 TS/LS PN 7310040

Cytation 1/3/5 PN 7310053

EL406 PN 7310042

ELx405 PN 7310041

Eon PN 7310049

EpochR BIOSTACK2WR: PN 7310032

BIOSTACK3WR/BIOSTACK4: PN 7310043

Epoch 2 PN 7310054

MicroFill* PN 7310012

BioTek Instruments, Inc.

Page 30

8 | Chapter 1: Introduction

Instrument Integration Kit

MicroFlo Select* PN 7310020

MultiFlo/MultiFlo FX PN 7310044

PowerWave HT

¥

PN 7310048

¥

Precision, Precision XS* PN 7110004

Synergy HT/HTX PN 7310046

Synergy 2/4/Mx/H4 PN 7310047

Synergy H1 PN 7310045

Synergy Neo and Synergy

PN 7310055

Neo2‡

*Compatible with BIOSTACK2WR only.

‡

Compatible with BioStack 4 only and uses its own barcode scanner, i.e., not compatible with the BioStack

barcode scanner listed above.

¥

Not compatible with BIOSTACK4.

BioStack™ Microplate Stacker

Page 31

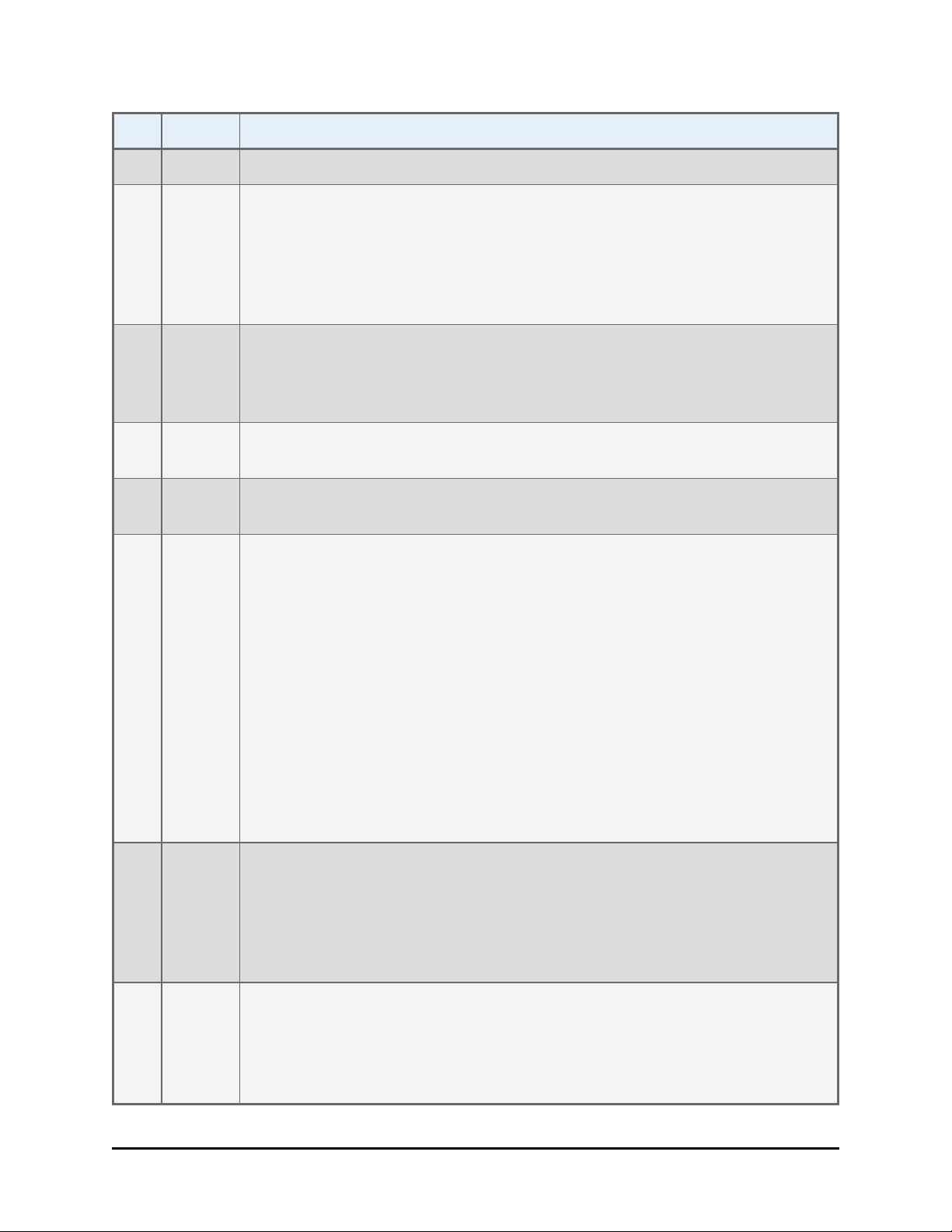

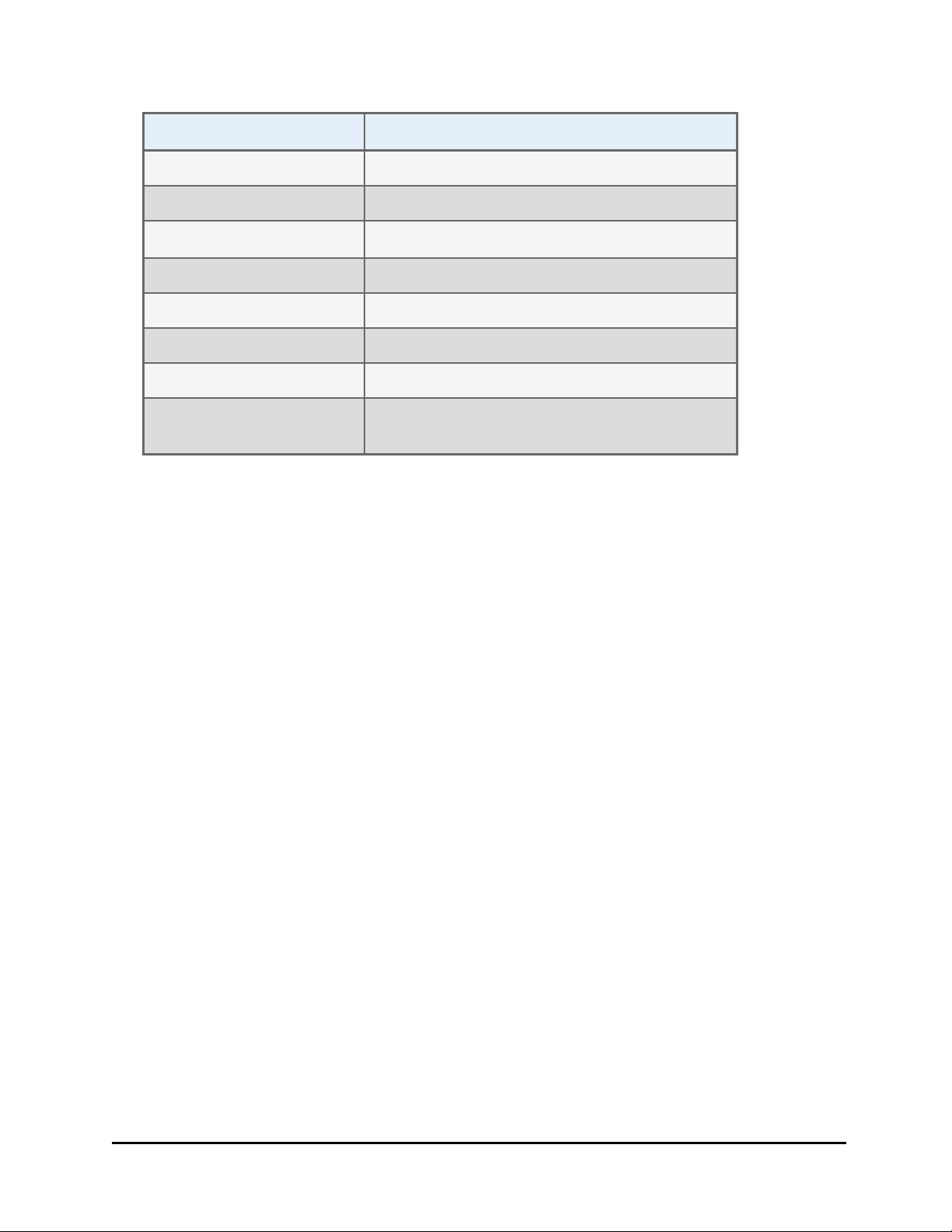

Specifications

Characteristics Description

Specifications | 9

Dimensions:

Instrument only

(not including

stacks)

Weight: BIOSTACK2WR: 24 lbs (10.9 kg)

Power Supply: Compatible with 100 to 240 V~ ± 10% @50-60 Hz

Power

Consumption:

Operating

Temperature:

Humidity: Operate in a noncondensing humid environment having a maximum

BIOSTACK2WR: Length 18.5" (46.9 cm), width 7" (17.8 cm), height

14" (35.6 cm)

BIOSTACK3WR: Length 21" (54 cm), width 8" (21 cm), height 15" (38

cm)

BIOSTACK4: Length 21" (54 cm), width 8" (21 cm), height 16" (40

cm)

BIOSTACK3WR: <26 lbs (11.8 kg)

BIOSTACK4: <30 lbs (13.6 kg)

40 watts maximum

18°C to 40°C (64.4°F to 104°F)

relative humidity of 80% at temperatures up to 31° C decreasing

linearly to 50% relative humidity at 40° C.

Microplates

Running without Lids

Width: 85.48 mm (3.365") ± 0.25 mm

(0.009") at the corners

Width above flange: Min 81.0 mm; Max

Length: 127.76 mm (5.030") ± 0.25 mm

(0.015") at the corners

Max

Height:

Min approximately 10.16 mm (0.400") 7.60 mm (0.299")

14.60 mm (0.575")

22.0 mm (0.866") using BioStack 4

Lidded Plate Stacks.

Running with Lids

(BioStack 4 Only)

85.48 mm (3.365") ± 0.25 mm (0.009")

at the corners

83.2 mm

127.76 mm (5.030") ± 0.25 mm

(0.015") at the corners

Typical 96-, 384-, 1536-well plates:

16.9 mm (0.665") plate + lid combined:

plate max is 14.60 mm, except in Stay-

on Lid Mode.

BioTek Instruments, Inc.

Page 32

10 | Chapter 1: Introduction

Running without Lids

Height:

Note: The minimum plate height is a

function of the stacked height, the

plate skirt height, the plate height

dip switch setting, and the control

method. See Control Method

Limitations: on page 89.

Warp: The warp for all models complies with SLAS standards: When resting on a flat

surface, the top surface of the plate must be parallel to the resting surface

within 0.76 mm (0.0299"); except BioStack 4 supports low-profile plates with

a warp value within 2.2 mm.

Important: Less-rigid polypropylene, low-profile PCR plates must have

sealing tape applied over the entire top surface.

Max

Weight:

Maximum weight for all plates with fluid in a single stack.

12.0 lbs (5.5 kg) 7.0 lbs (3.2 kg)

Running with Lids

(BioStack 4 Only)

See Microplate and Lid Dimensions

on page 53.

The BioStack is not compatible with removable-strip-type microplates.

Lids BioStack 4 Only

Width: 85.48 mm (3.365") ± 0.50 mm (0.019") along entire edge

Length: 127.76 mm (5.030") ± 0.50 mm (0.019") along entire edge

Minimum Height: 3.5 mm (0.138")

Other requirements:

Minimum Gap: 1.25 mm (0.049") Plate short-side flange to lid

Lid on Plate: 16.9 mm (0.665") Max overall height

Plate on Lid: 23.2 mm (0.913") Max overall height

Stay-On Lid Mode (BioStack 4 Only)

When these conditions are met the BioStack 4 handles certain low-density plates

with lids. This mode offers the ability to keep the lid on the plate for the duration of

the protocol.

BioStack™ Microplate Stacker

Page 33

Minimum software versions:

l BioStack 4 basecode: PN 1230200 version 1.05 (or higher)

l Gen5: version 2.07 (or higher)

l LHC: version 2.18 (or higher)

l Note: Gen5 TS (for touch screen models) does not support stay-on lid mode.

Certain 6-, 12-, 24-, and 48well microplates with lids that

conform to ANSI/SLAS 2-2004

standard dimensions, as

specified, and with a:

l Minimum gap between plate

and lid when plate is on lid:

1.5 mm

l Maximum height of plate +

lid combined: 23.2 mm (also

called "stacked-plate-withlid" height)

Specifications | 11

Use calipers to measure the gap

between lid and plate.

Tall Lidded Plate Stacks

are required.

Uniquely designed stacks

labeled "Tall Lidded Plate

Stacks" support stay-on lid

mode and tall plate processing

without lids.

Stack Weights: PN 1230008

BioTek offers this accessory to

prevent the last plate's lid from

hanging in the stack during stayon lid mode. Better performance

was observed when using the

weights with taller-than-standard

plates without lids, as well.

Gen5 will keep the lid on the plate during processing when its plate type Lid

BioTek Instruments, Inc.

Page 34

12 | Chapter 1: Introduction

Parameters are defined to support it: Fill the checkbox in Advanced Options. Plate Type

records for Nunc 6-, 12-, 24-, and 48-well plates and lids that meet these requirements are

ready for selection, e.g., "Nunclon 24 well." You can create or modify the plate type record of

other plates that meet the requirements. Learn more in Gen5's Help.

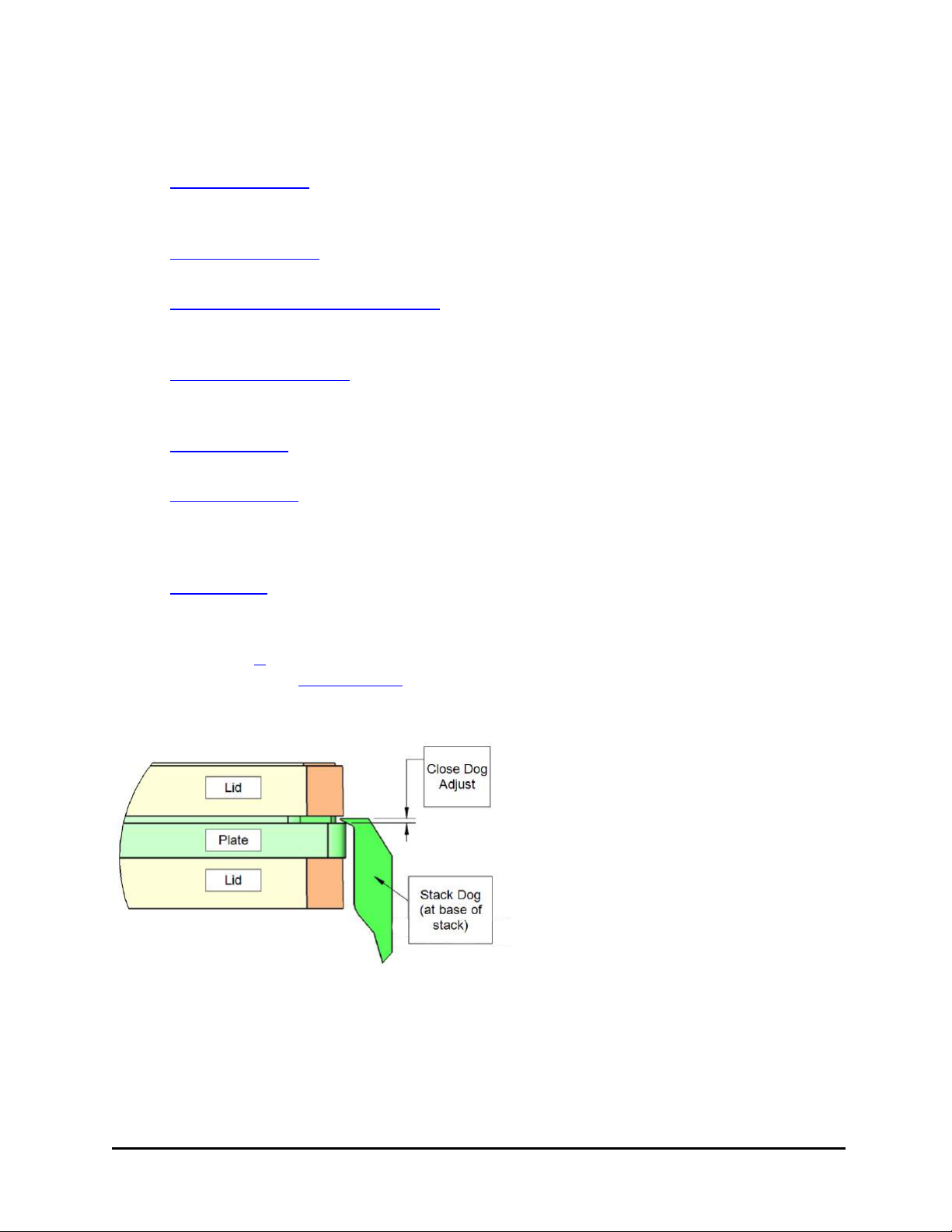

Note: A small number of stacks

with a Lidded Plate Stacks label

were released to support stay-on

lid mode before the label was

changed to Tall Lidded

Plate Stack. The "stack dogs,"

inside and at the bottom of the

stacks, were modified to better

handle plates with external trim

or ridges. If the dogs on your

stacks match those shown here,

with shortened top lips, they can

be used for stay-on lid mode.

BioStack™ Microplate Stacker

Page 35

Chapter 2

Installation

This chapter contains instructions for setting up and

configuring the BioStack. Instructions for installing the

BioStack with the interfacing instruments are contained in

individual PDF files on the BioStack Operator’s Manual USB

Flash Drive (PN 7311067).

Upgrade Scenarios 14

Unpack and Inspect the Instrument 15

Setting Up the BioStack 17

Remove the Shipping Hardware—BIOSTACK2WR 18

Remove the Shipping Hardware—BioStack 3 20

Remove the Shipping Hardware—BioStack 4 23

Dip Switch Settings 28

Connect to Power 31

Where to Go Next 35

Repacking the BioStack 36

Install the Shipping Hardware—BioStack2WR 37

Install the Shipping Hardware—BioStack 3 37

Install the Shipping Hardware—BioStack 4 38

Page 36

14 | Chapter 2: Installation

Upgrade Scenarios

If you purchased the BioStack to interface with an existing instrument, you may

need to upgrade the hardware and/or software on that instrument. Refer to the

table below and contact BioTek TAC with any questions.

Minimum computer control software for:

PC Software BioStack 3 BioStack 4

LHC (Liquid Handling Control) 2.12 or higher 2.16 or higher

Gen5 (Data Analysis ) 2.01 or higher 2.05 or higher

If you have: You may need:

ELx405

with Serial Number <=182187 A BioStack-compatible microplate carrier and new

basecode software (upgrade kit PN 7310006). The carrier

must be installed by authorized personnel.

with Serial Number

>=182188 and <185301

Eon

with Serial Number <1310151 Instruments with a lower serial number may not have a

Epoch

Any serial number.

Compatible instruments have a

“BioStack Ready” sticker: R

models.

MicroFill‡

with Serial Number <185105 New basecode software (upgrade kit PN 7310015).

MicroFlo Select‡

with basecode version <1.06 New basecode software.

PowerWave

with Serial Number <1310151 Instruments with a lower serial number may not have a

New basecode software (upgrade kit PN 7310013).

BioStack-compatible plate carrier. Contact BioTek TAC.

A BioStack-compatible microplate carrier, which must be

installed by authorized Service personnel. Gen5 v.2.0 is

required.

BioStack-compatible plate carrier. Contact BioTek TAC.

PowerWave HT is not compatible with BioStack4.

BioStack™ Microplate Stacker

Page 37

Unpack and Inspect the Instrument | 15

If you have: You may need:

Precision**‡

with Serial Number >=187931 Basecode software version 2.14 or greater.

Synergy HT

with Serial Number <181151 A BioStack-compatible microplate carrier and new

basecode software (upgrade kit PN 7310007). Note: The

carrier must be installed by authorized Service personnel.

‡ Not compatible with BioStack3/BioStack4.

** The following Precision Microplate Pipetting Systems are not BioStack-

compatible:

oInstruments with Serial Number < 187931,

o12-channel model

oUniversal models (PRC384U).

Unpack and Inspect the Instrument

n Save all packaging materials. If you need to ship the instrument or accessories

to BioTek for repair or replacement, you must use the original packaging. Using

other forms of commercially available packaging is not recommended and can

void the warranty. If improper packaging results in damage to the instrument

during shipping, BioTek may impose additional charges.

Inspect the shipping boxes, packaging, instrument, and accessories for signs of

damage.

If the BioStack is damaged, notify the carrier and your BioTek representative. Keep

the shipping cartons and packing material for the carrier’s inspection. BioTek will

arrange for repair or replacement of your instrument immediately, before the

shipping-related claim is settled.

Unpack the boxes containing the instrument and other equipment:

l BioStack

l Microplate Stacks

l Barcode scanner (optional).

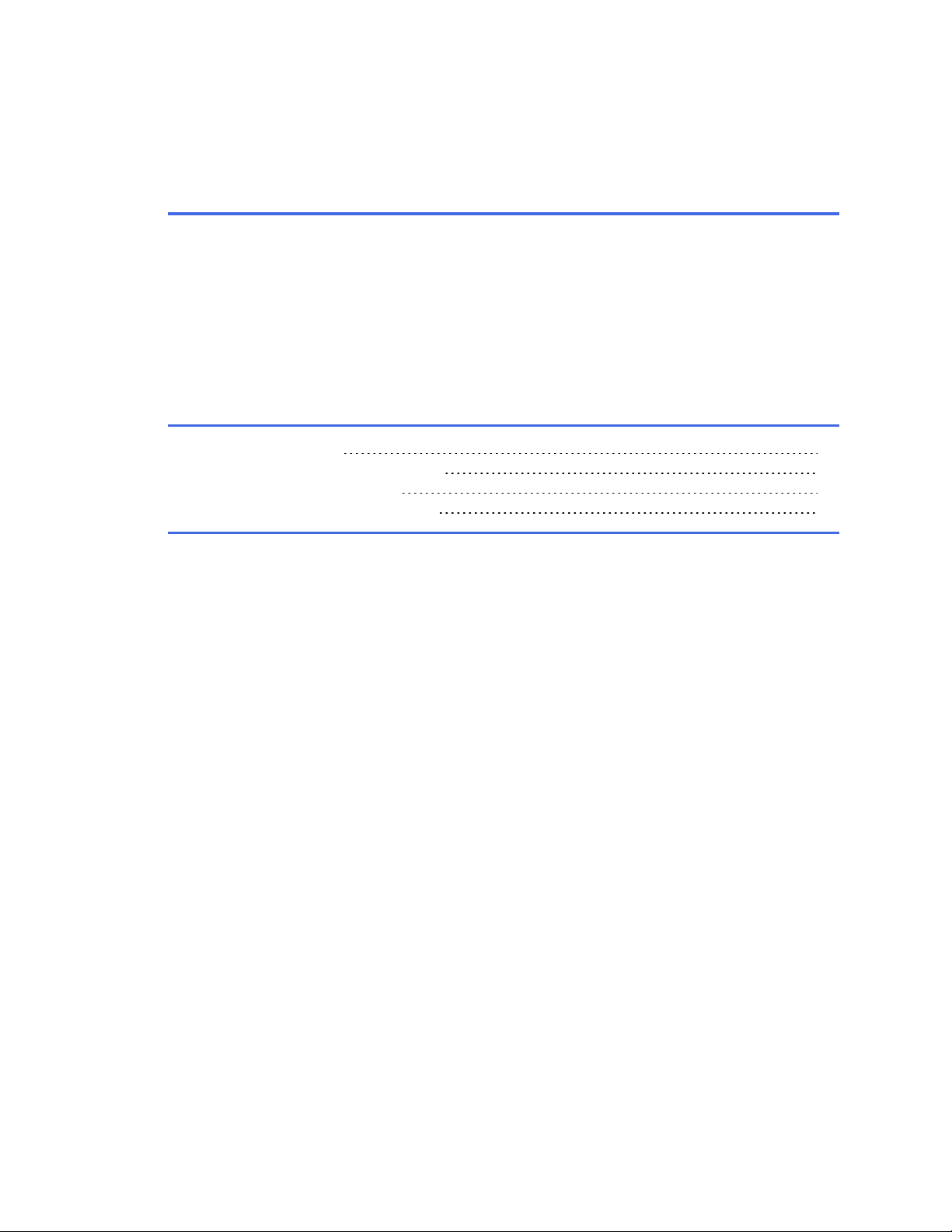

Remove the Shipping Panel

Tools: flat screwdriver

BioTek Instruments, Inc.

Page 38

16 | Chapter 2: Installation

1. Grasp the handles on the shipping panel to lift the instrument from the inner

box.

2. Gently lay the BioStack on its side on the work surface, so the panel hangs over

the edge.

3. Remove the screws and washers that attach the shipping panel to the instrument.

4. Save the panel and all packing materials for possible future reshipment.

BioStack™ Microplate Stacker

Page 39

Setting Up the BioStack | 17

Setting Up the BioStack

Important: Avoid excessive humidity. Condensation directly on the sensitive

electronic circuits can cause the instrument to fail internal self-checks.

Install the instrument on a level, stable surface in an area where temperatures

between 18°C (64°F) and 40°C (104°F) can be maintained.

Avoid:

l Excessive humidity: Condensation directly on the sensitive electronic

circuits can cause the instrument to fail internal self-checks. Operate in a

noncondensing humid environment having a maximum relative humidity

of 80% at temperatures up to 31° C decreasing linearly to 50% relative

humidity at 40° C.

l Dust: Efficient microplate transporting may be affected by extraneous

particles (such as dust) on the carrier’s linear ways. A clean work area is

necessary to ensure smooth plate transporting.

BioTek Instruments, Inc.

Page 40

18 | Chapter 2: Installation

Remove the Shipping Hardware—BIOSTACK2WR

Warning: Remove the shipping hardware before turning on the BioStack.

Tools: You need a standard screwdriver, a small Phillips-head screwdriver, and

3/32" hex wrench.

Shipping hardware in the BioStack's interior (BIOSTACK2WR)

1. Locate and remove the shipping block and four mounting screws inside the

BioStack.

2. Remove the carrier shipping screw.

3. Remove the gripper shipping screw.

BioStack™ Microplate Stacker

Page 41

Remove the Shipping Hardware—BIOSTACK2WR | 19

Wrist/gripper cover removed exposing small wrist shipping bracket

4. Remove the gripper cover (with the BioStack label) using the Phillips

screwdriver to expose the small wrist shipping block.

5. Use the 3/32 hex wrench to remove the wrist shipping block.

6. Reinstall the wrist/gripper cover.

7. Store the screws with the other packaging materials in the shipping boxes.

BioTek Instruments, Inc.

Page 42

20 | Chapter 2: Installation

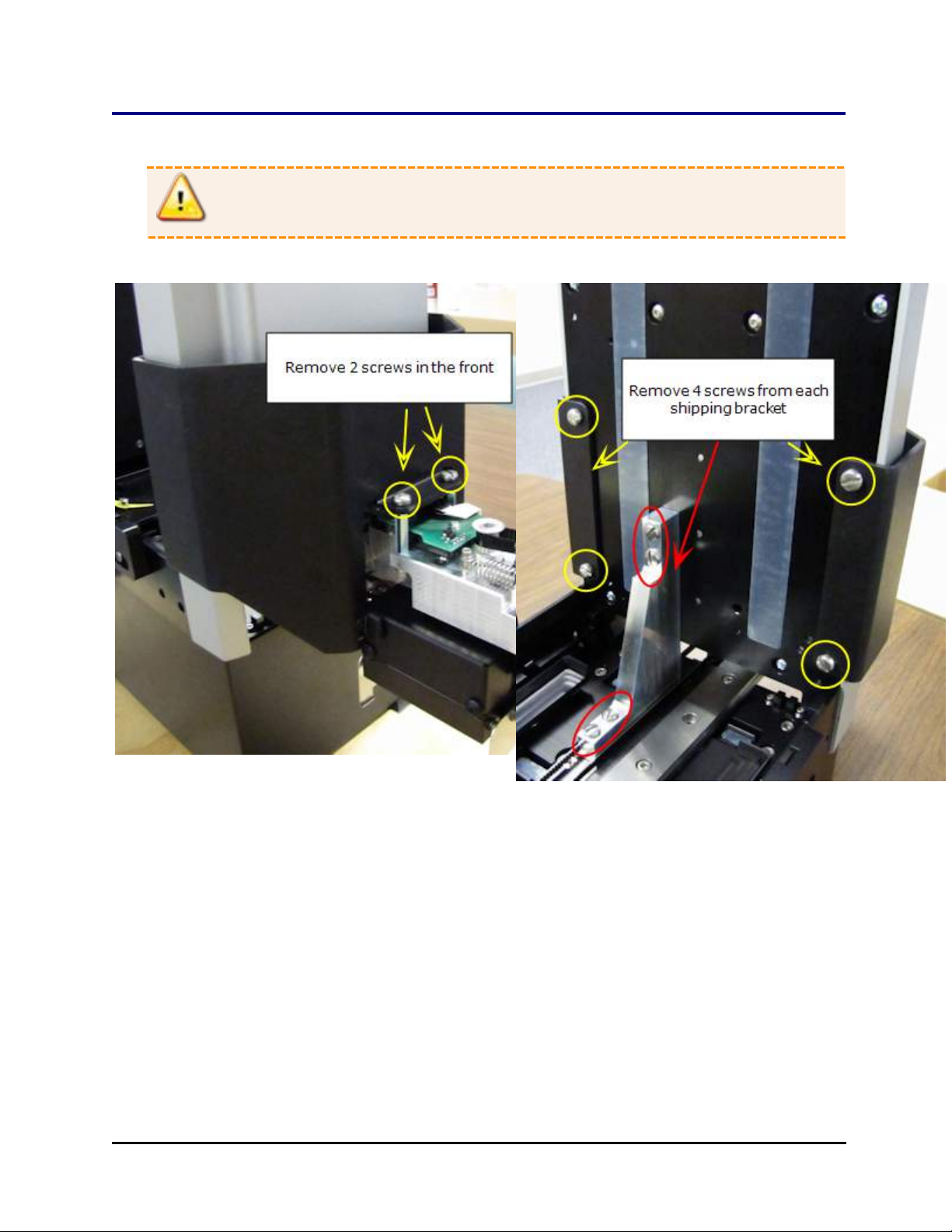

Remove the Shipping Hardware—BioStack 3

Warning: Remove the shipping hardware before turning on the BioStack.

Tools: You need a standard screwdriver and a small Phillips-head screwdriver.

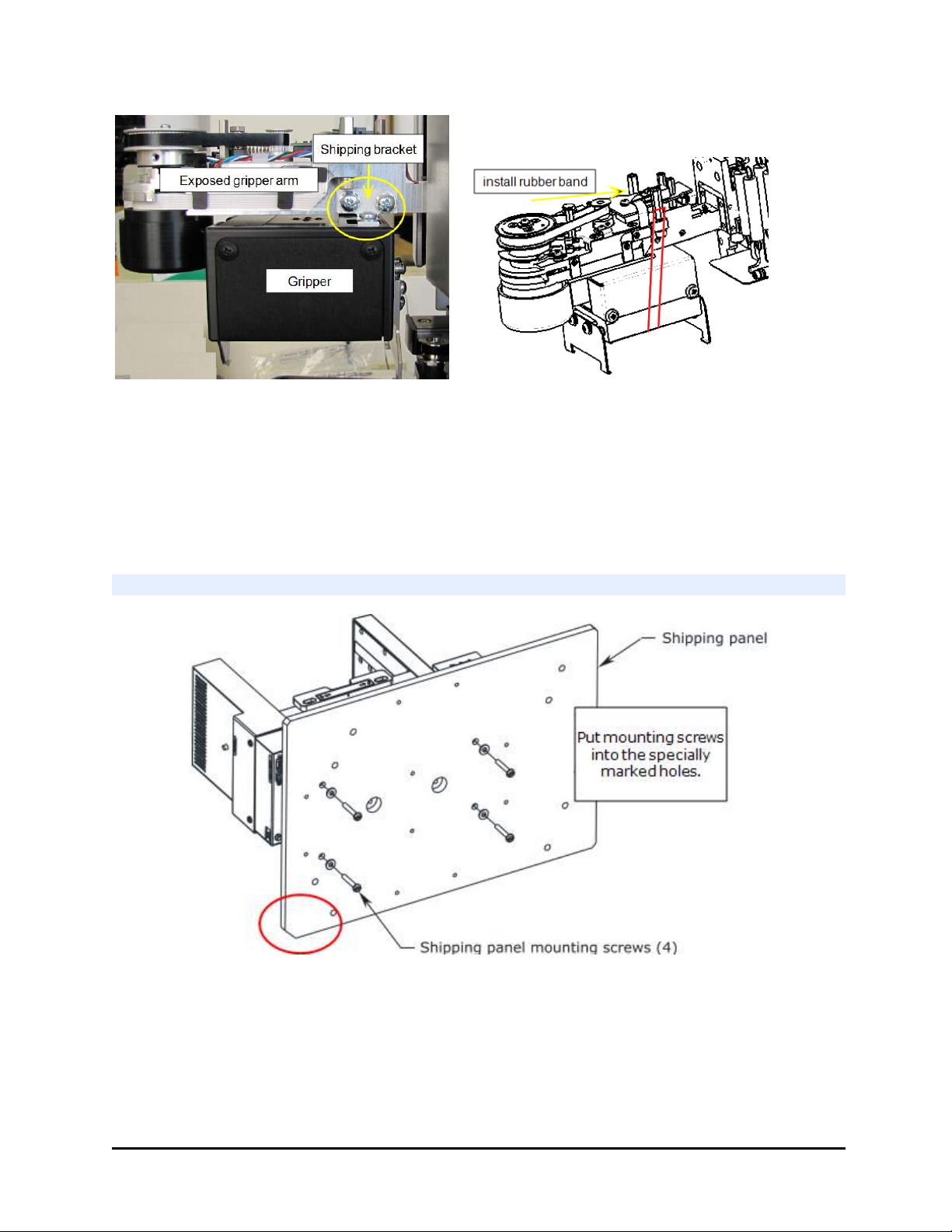

One shipping bracket wraps around the front Another shipping block sits inside

1. Remove the two screws from the front of the instrument.

2. Remove the remaining 4 screws inside that hold the bracket onto the instrument.

Carefully remove the bracket.

3. Locate and remove the shipping block and four mounting screws inside the

BioStack.

BioStack™ Microplate Stacker

Page 43

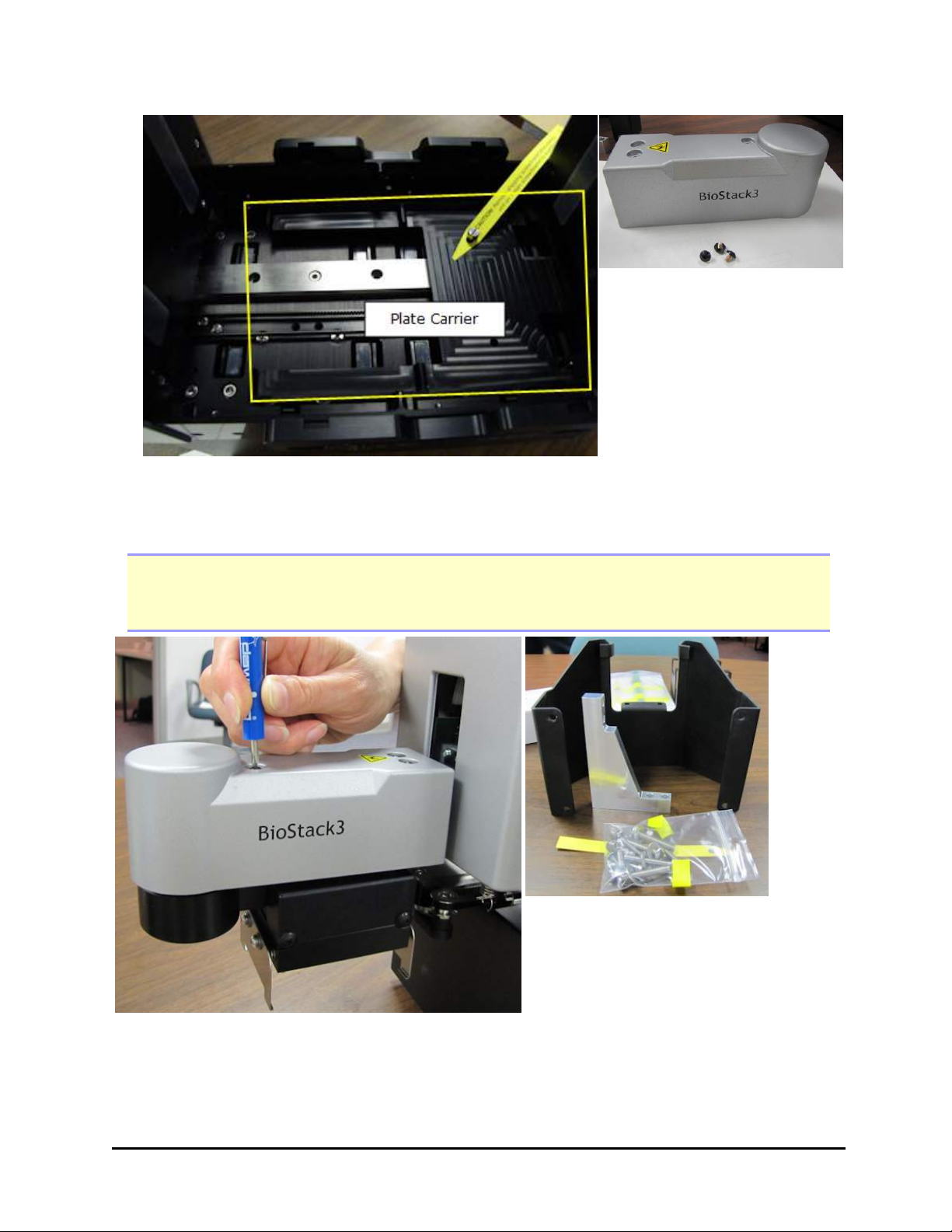

4. Remove the plate carrier shipping screw.

Remove the Shipping Hardware—BioStack 3 | 21

Gripper arm cover and screws

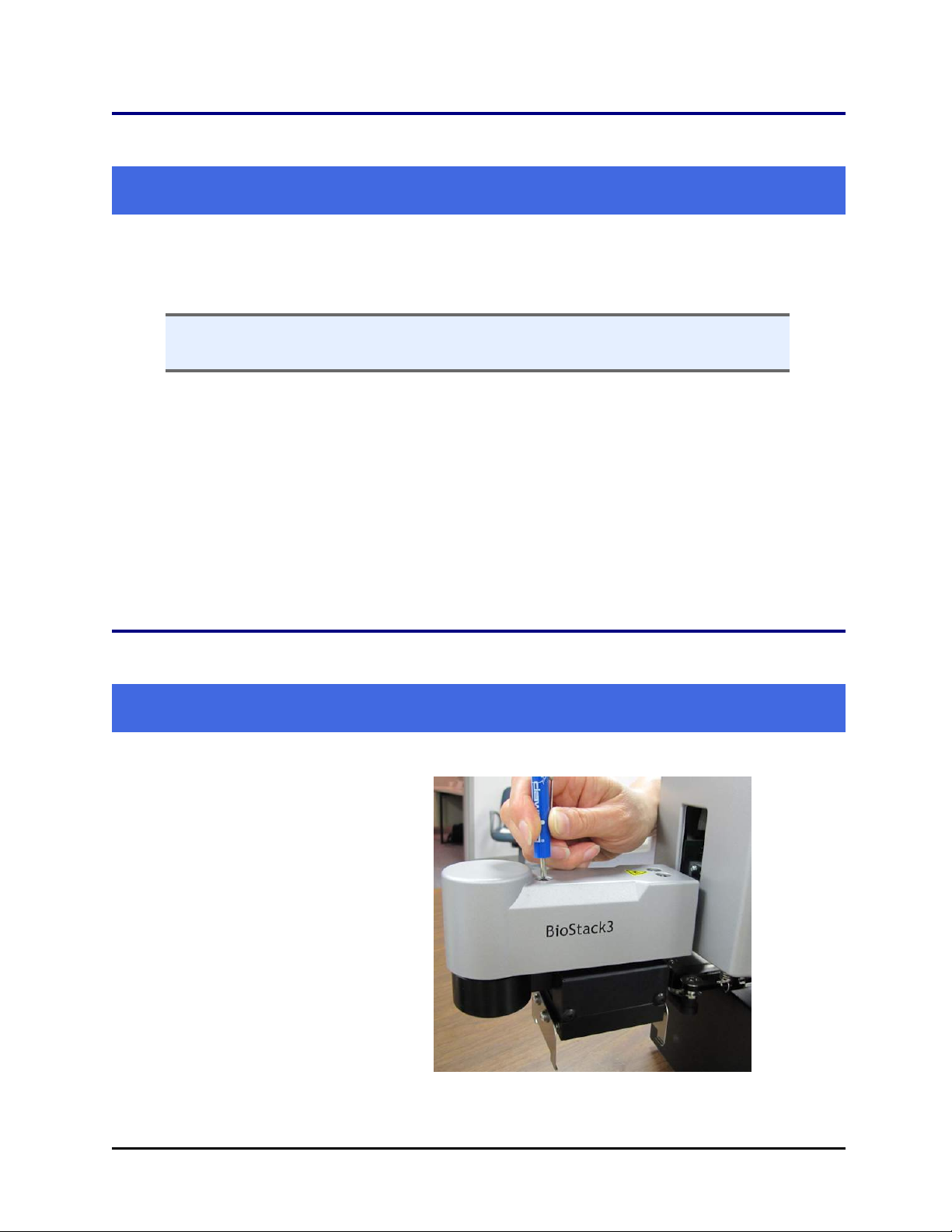

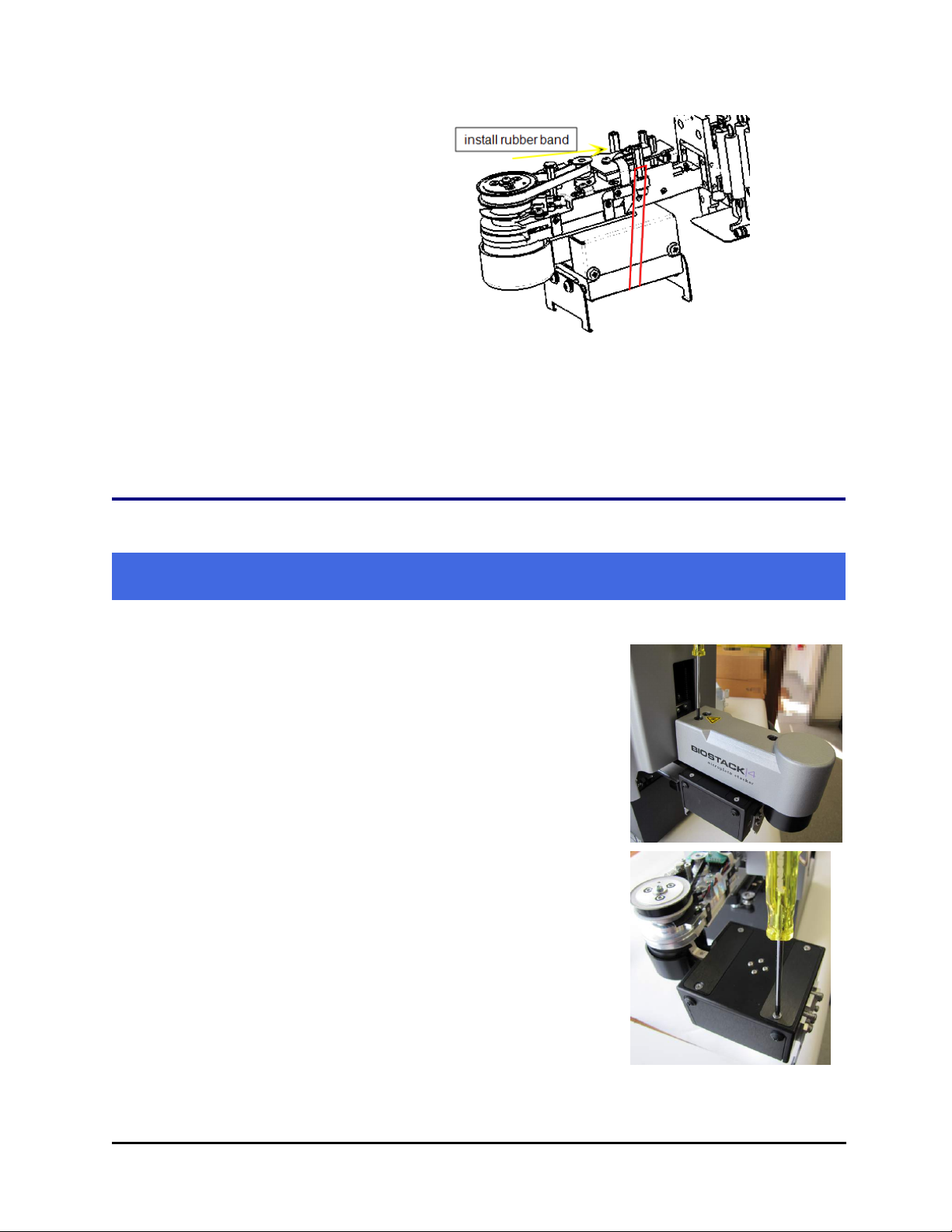

5. Remove the rubber band that holds the rotational wrist secure.

Note: Do not let the gripper flop around! Before moving the BioStack 3 or BioStack 4,

secure the gripper with a rubber band or tape to prevent it from losing its alignment. A

complex recalibration is required if it is knocked out of position.

Save the shipping hardware

Installing the gripper arm cover

6. Locate and install the gripper arm cover using the small Phillips-head

screwdriver.

BioTek Instruments, Inc.

Page 44

22 | Chapter 2: Installation

7. Store all the shipping hardware and screws with the other packaging materials in

the shipping boxes and keep for future use.

BioStack™ Microplate Stacker

Page 45

Remove the Shipping Hardware—BioStack 4 | 23

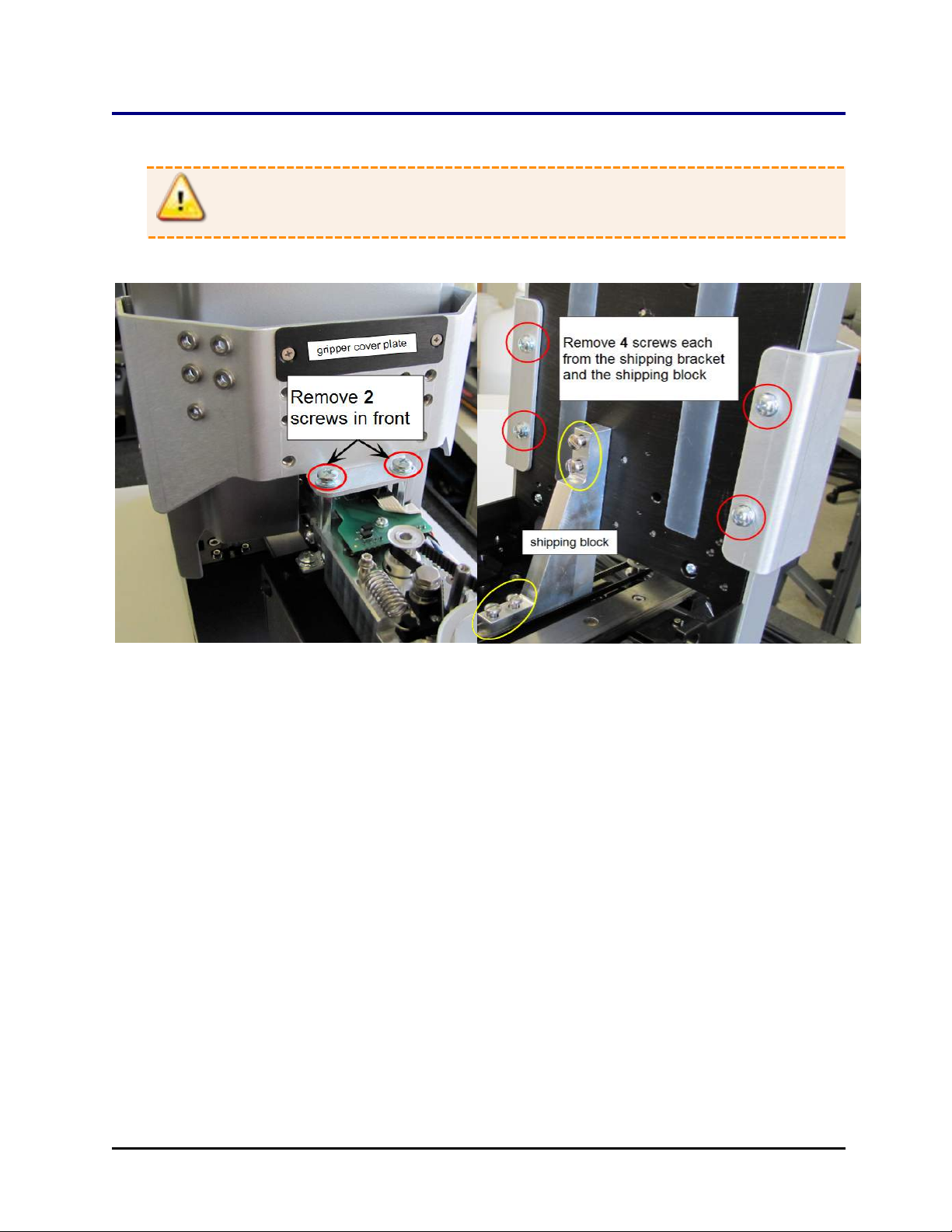

Remove the Shipping Hardware—BioStack 4

Warning: Remove the shipping hardware before turning on the BioStack.

Tools: You need a standard screwdriver and a small Phillips-head screwdriver.

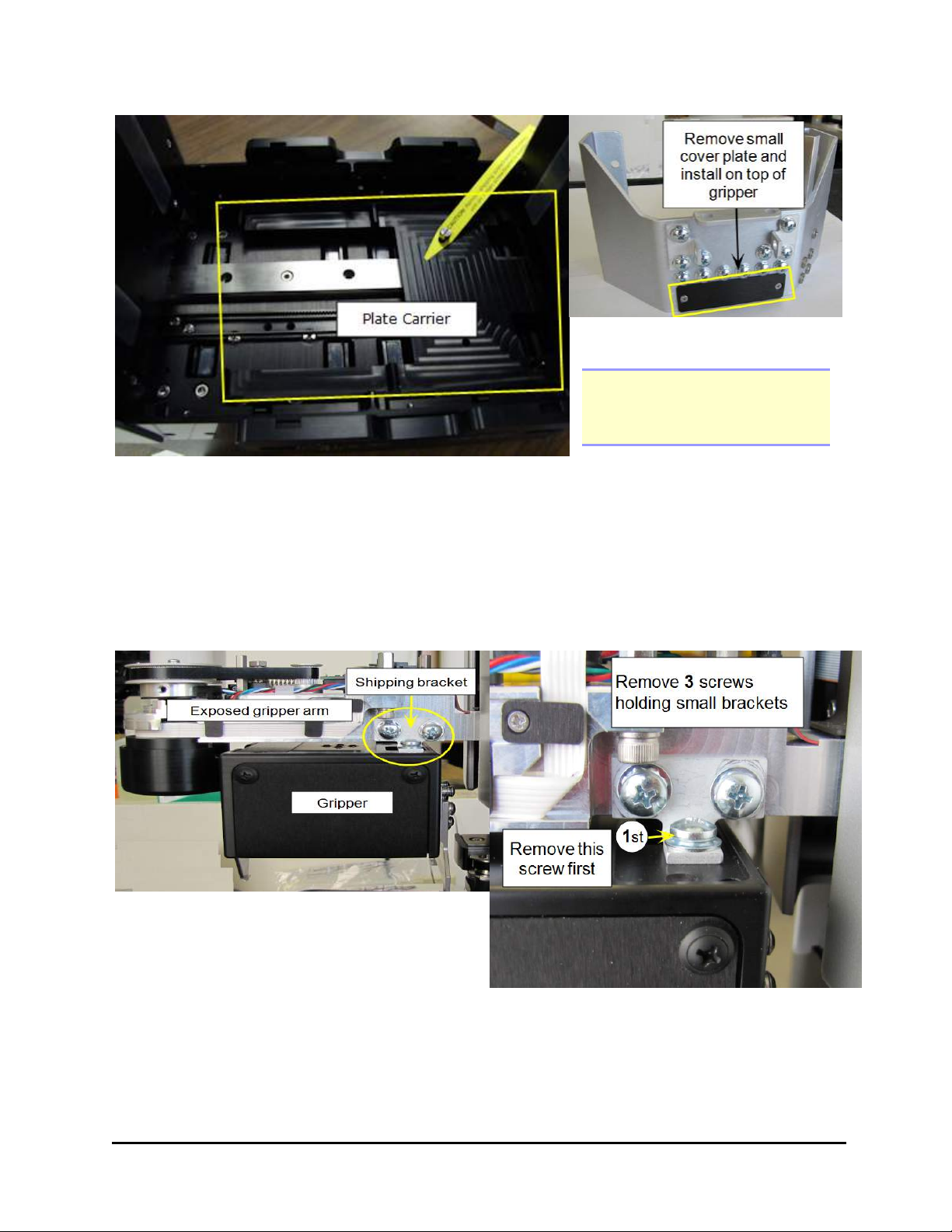

One shipping bracket wraps around the front and attaches to the inside. A shipping block sits inside.

1. Remove the two screws from the front of the instrument.

2. Remove the remaining 4 screws inside that hold the bracket onto the instrument.

Carefully remove the bracket.

3. Remove the shipping block and four mounting screws inside the BioStack.

4. Remove the small, black cover plate that is stored on the shipping bracket. (See

picture below.)

BioTek Instruments, Inc.

Page 46

24 | Chapter 2: Installation

Remove the gripper cover plate

Note: Screw the screws into

the shipping bracket for

storage.

5. Remove the plate carrier shipping screw.

6. Returning to the front of the BioStack, remove the rubber band that holds the

rotational wrist secure.

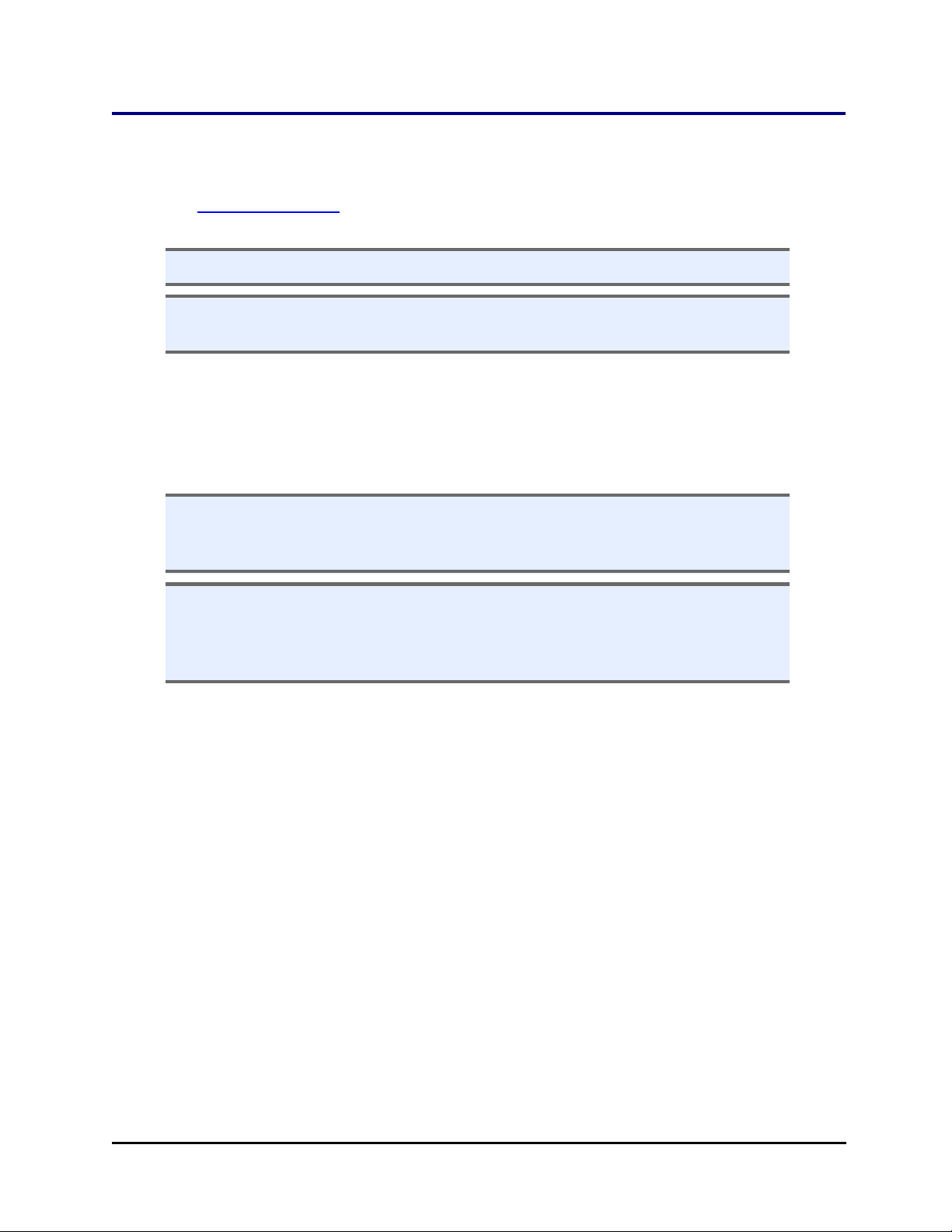

7. Remove the small shipping brackets on each side of the wrist that hold the

gripper steady. On both sides, first remove the screw from the gripper itself,

then remove the two screws from the gripper arm.

BioStack™ Microplate Stacker

Page 47

Remove the Shipping Hardware—BioStack 4 | 25

Gripper Arm Cover

8. Install the small cover plate you removed from the shipping bracket on top of

the gripper, using the small Phillips-head screwdriver.

Note: Do not let the gripper flop around! Before moving the BioStack 3 or BioStack 4,

secure the gripper with a rubber band or tape to prevent it from losing its alignment.

A complex recalibration is required if it is knocked out of position.

Save the shipping hardware

Installing the gripper arm cover

BioTek Instruments, Inc.

Page 48

26 | Chapter 2: Installation

9. Locate and install the gripper arm cover using the small Phillips-head

screwdriver.

10. For safekeeping, screw all the screws and washers, the small shipping brackets

and the large shipping block onto the large shipping bracket. Store the shipping

hardware with all the other packaging materials in the shipping boxes and keep

for future use.

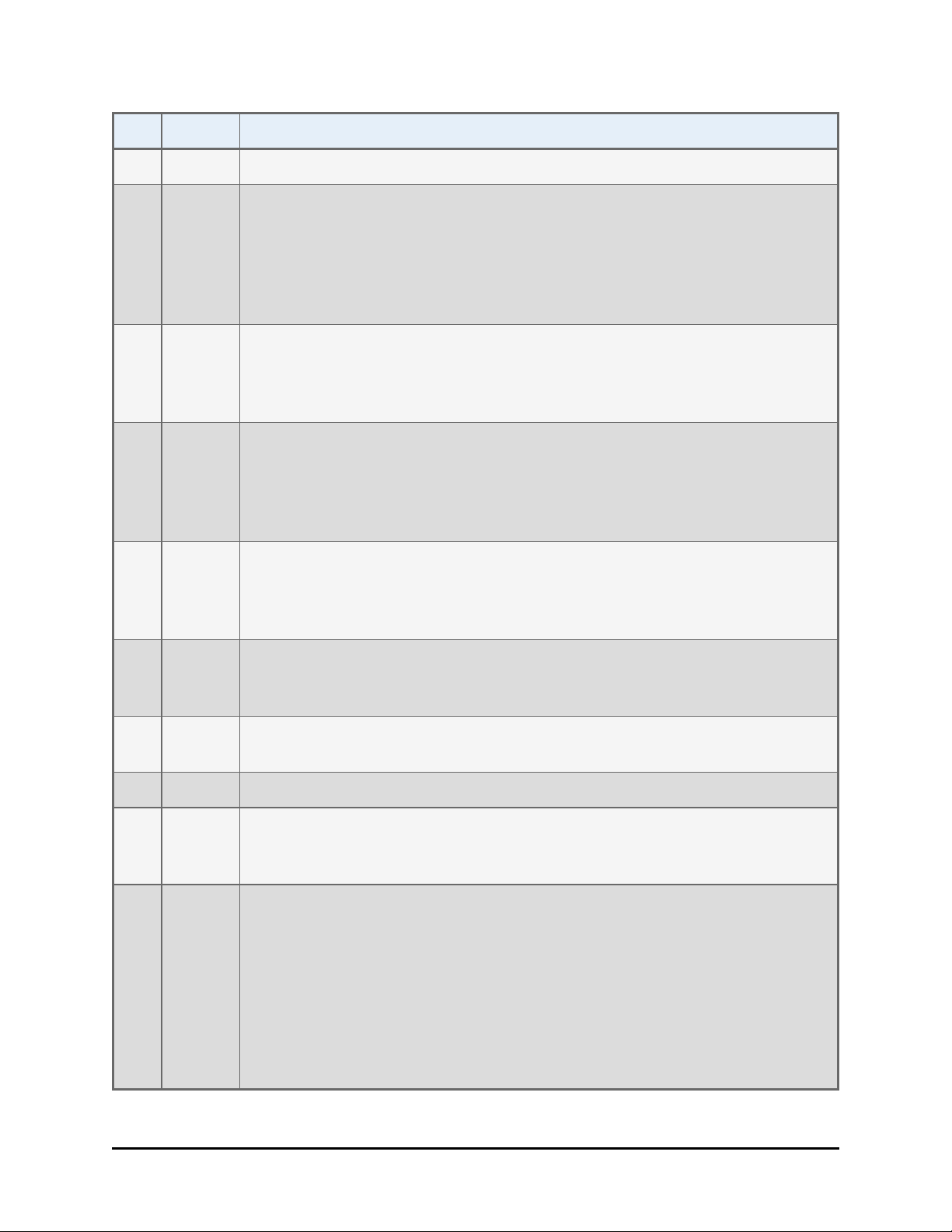

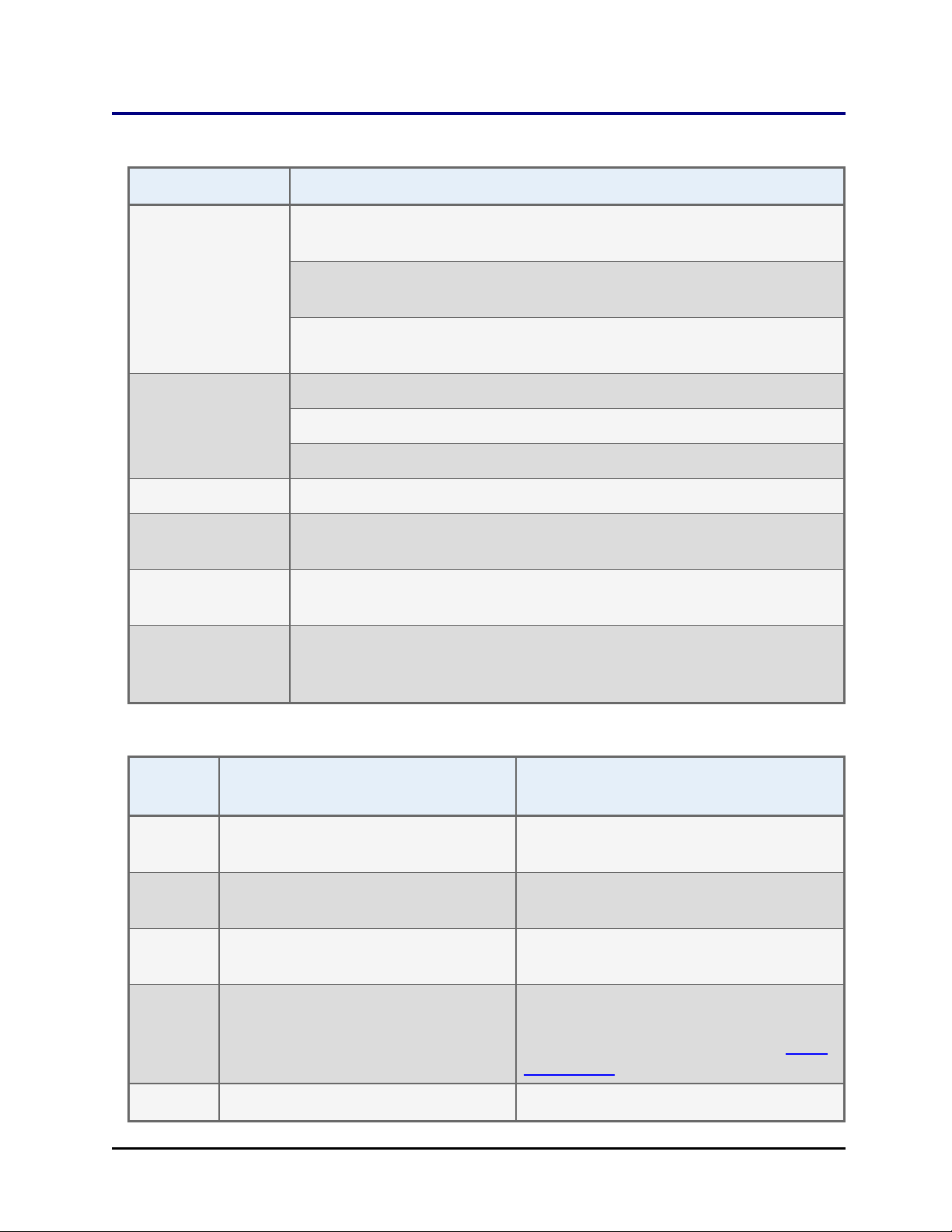

Wrist Angle Setting Requirements

Each instrument requires the BioStack to have a certain wrist angle setting:

l The BIOSTACK2WR ships with the wrist angle set to 90°; its other setting is 0°.

l The BIOSTACK3WR/BIOSTACK4 ships with the wrist angle set to +90°; its other

settings are 0° and -90°.

Instrument BIOSTACK2WR BIOSTACK3WR/BIOSTACK4

Liquid Handlers

405 TS, 405 LS* 90° +90°

EL406, ELx405* 90° +90°

MicroFlo Select* 90° N/A

MultiFlo, MultiFlo FX* 90° +90°

Precision/XS, MicroFill 0° N/A

Readers

Cytation 1, 3, 5 N/A +90°

Eon 0° 0°

EpochR 0° -90°

Epoch 2 90° +90°

PowerWave HT 90° +90°

Synergy H1 90° +90°

Synergy 2, 4, MX, HT,

HTX, H4

0° -90°

Synergy Neo/Synergy

Neo2

BioStack™ Microplate Stacker

N/A 0° (BioStack4 Only)

Page 49

Remove the Shipping Hardware—BioStack 4 | 27

* 0° orientation (front-facing integration) is possible with these liquid handlers and

the BIOSTACK2WR. See 0 Degree Orientation for Liquid Handlers below.

If your instrument requires a wrist angle other than the default (shipped) setting

you must follow the procedure: Change Setting for Wrist Angle on page 29

The wrist angle designates the position of the gripper:

-90° angle +90° angle 0° angle

clockwise counterclockwise no rotation

When viewed from above, the +90° angle setting turns the wrist counterclockwise,

the -90° turns the wrist clockwise, and the 0° angle does not turn the wrist.

n Always put the barcode scanner on the opposite side of the gripper's position.

+90°/90° put scanner on right side; -90 put the scanner on the left side of the

instrument as you are facing it.

0 Degree Orientation for Liquid Handlers

Most BioTek liquid handlers can interface with the BIOSTACK2WR in a front-facing

or 0° orientation. This may be necessary to fit both the instrument and the BioStack

in a safety hood, for example. Or when bench space is limited.

n This option is not supported with BioStack 3 or BioStack 4.

Change the dipswitch setting as described below. Attach the BioStack aligning plate

to the instrument's aligning plate in the front holes provided, as shown here:

BioTek Instruments, Inc.

Page 50

28 | Chapter 2: Installation

0° Integration Position

Dip Switch Settings

Two sets of dip switches on the BioStack control variable options, e.g., to change the

wrist angle, use 50-plate stacks, or install the barcode scanner.

Dip switch 1 and 2

Two arrays of dip switches, switch 1:

SW1 and switch 2: SW2. On each switch,

note the sequence, from right to left, of

the four switches.

Closed = toward board; Open = away from

board. All SW1 switches are closed in the

photo above.

Back of the BioStack showing dip switch access

openings: 1 and 2.

BioStack™ Microplate Stacker

Page 51

Dip Switch Settings | 29

Warning: Do not change a switch setting unless explicitly instructed to do so.

Switch 1 All Models

SW1 - 1 Plate Height: Closed = Normal, standard plates; Open = for low-profile

plates.

SW1 - 2 Do Not Change! 2WR = Closed, 3WR = Open.

SW1 - 3 Barcode Scanner: Closed = Not installed; Open = Installed.

SW1 - 4 Closed: Do Not Change!

Switch

2

SW2 - 1 Closed = for 10 or 30 plate stacks; Open = for 50 plate stacks

SW2 - 2 Closed: Do Not Change! Closed: Do Not Change!

SW2 - 3 Wrist Angle: Open = 90°;

SW2 - 4 Closed: Do Not Change! SW2-3 Open and SW2-4 Closed = +90° Wrist

SW2-3 Closed and SW2-4 Closed = -90°

BIOSTACK2WR BIOSTACK3WR/BIOSTACK4

SW2-3 Closed and SW2-4 Open = 0° Wrist

Closed = 0°

Angle

Angle

Wrist Angle

Change Setting for Wrist Angle

Most BioTek instruments require the BioStack wrist to be set at a specific angle.

Follow these instructions to change the wrist angle dip switch setting for your

instrument.

See Wrist Angle Setting Requirements on page 26

1. Turn off the BioStack.

2. Two plugs on the rear wall of the instrument cover two sets of dip switches.

Remove plug #2, the plug on the right when viewing the instrument from the

rear.

3. Using a pencil tip, change the switch settings to suit your instrument:

BioTek Instruments, Inc.

Page 52

30 | Chapter 2: Installation

Switch 2

Wrist Angle BIOSTACK2WR BIOSTACK3WR/BIOSTACK4

90°/+90° SW2 - 3 = Open SW2-3 Open and SW2-4 Closed

0° SW2 - 3 = Closed SW2-3 Closed and SW2-4 Open

-90° N/A SW2-3 Closed and SW2-4 Closed

4. Replace the plug.

Change Setting for 50-Plate Stacks

For better performance when using 50-plate stacks and routinely processing more

than 30 plates, change the dip switch setting. This changes the BioStack's behavior to

better handle the heavier load.

1. Turn off the BioStack.

2. Two plugs on the rear wall of the instrument cover two sets of dip switches.

Remove plug #2, the plug on the right when viewing the instrument from the

rear.

3. Using a pencil tip, push SW-2 switch #1 (the right-most dip switch) to its Open

position, away from the instrument.

4. Replace the plug.

Test Plates for Compatibility—BioStack 4 Only

Perform this simple test to make sure your microplates are compatible with the

BioStack 4:

BioStack™ Microplate Stacker

Page 53

Connect to Power | 31

1. Turn off and unplug the BioStack, if necessary. Raise the gripper and move its

wrist out of the way.

2. Expose the BioStack's plate carrier: slip your hand inside the front of the

BioStack under the gripper, feel for the outer edge of the plate carrier and gently

pull it out.

3. Put one of your microplates on the carrier and slide it around a bit to make sure

there is at least some room around the plate, i.e., enough space to move the

plate.

If the plate fits too snugly in the carrier, you can loosen screws in the side of the

carrier to give the plate more room: See Loosen Plate Carrier Set Screws -

BioStack 4 Only on page 90.

Strongly recommended: Measure your plate and lid type to verify they meet the

minimum requirements before use: See Specifications on page 9. Some plate types are

not compatible.

Connect to Power

Warning! Power Rating. The BioStack must be connected to a power

receptacle that provides voltage and current within the specified rating for the system.

Use of an incompatible power receptacle may produce electrical shock and fire hazards.

Warning! Electrical Grounding. Never use a plug adapter to connect primary

power to the BioStack. Use of an adapter disconnects the utility ground, creating a

severe shock hazard. Always connect the system power cord directly to an appropriate

receptacle with a functional ground.

The BioStack supports voltage in the range of 100–240 V~ at 50–60 Hz.

1. Connect the power cable to the power supply.

2. Plug the cable into the power socket in the rear panel of the BioStack. Tighten

the knurled nut.

3. Insert the three-prong plug into an appropriate receptacle.

BioTek Instruments, Inc.

Page 54

32 | Chapter 2: Installation

Connect to Computer

For Gen5 and LHC users

Note: See Connect to Liquid Handler on the facing page if you are not controlling

your washer/dispenser with BioTek's LHC software.

Epoch 2T and EPOCH2TC models with onboard Gen5 TS: connect the

BioStack directly to the reader (rather than an external computer, if

desired). Use the USB cable provided with the BioStack, then follow Gen5

TS instructions below, to control the BioStack with the touch screen.

(Find the USB port in the top left corner of the Epoch 2's rear panel. Only

one device can be connected at a time.)

When operating the BioStack with a reader (except touch screen instruments) or with

a liquid handler being controlled by LHC (BioTek's Liquid Handling Control

software), connect the BioStack to the host computer:

1. Use the USB or serial cable to connect the BioStack to the computer.

l If using a USB cable, and you have not already done so, follow the

instructions to install the USB Virtual COM Driver Software and to identify

the COMport. (Skip this step for the EPOCH2T and EPOCH2TC models.)

2. Turn on the BioStack and Test Communication between the BioStack and the

computer:

LHC Gen5/Gen5 TS

1. Select System>Instrument

Configuration>Add Stacker.

2. Select the Com Port and click Test

Comm.

If you have two readers set up in Gen5, select the

checkbox to tell one to Use the stacker.

Select the BioStack checkbox and specify

its COM port . Click the Test

Communication link.

Refer to Gen5's Help and the instrumentspecific instructions provided.

BioStack™ Microplate Stacker

Page 55

Connect to Power | 33

l If the test passes, return to the main view.

l If the test fails, check the cable connection to the BioStack or try a different

port. Contact BioTek TAC if problems persist.

Connect to Liquid Handler

Warning! Keep your hands away from the BioStack's gripper and microplate

carrier while the instruments are powering up.

To control the BioStack with the washer or dispenser, rather than LHC:

1. Turn off both instruments.

2. Plug in the serial cable supplied to connect the two instruments. Tighten the

securing screws.

3. BIOSTACK2WR: If the gripper is resting on the interfacing instrument's plate

carrier, manually raise it above the carrier.

4. Turn on the BioStack (the power switch is located on the rear panel). The

BioStack will home all axes (gripper, carrier, input and output stack lifts) and

perform a System Test.

l If the System Test passes, the LED status light on the rear panel will turn

on and flash until the power-up process is complete (approximately 20

seconds), then it will remain on.

l If the System Test fails, the LED status light will flash repeatedly. If this

happens, turn off the BioStack. Make sure there is no plate on the carrier,

and check for any obstructions. Ensure that all of the shipping hardware

has been removed. If you cannot resolve the problem, contact BioTek’s

Technical Assistance Center.

Configure the Liquid Handler to Control the BioStack

Note: The keypad instructions may vary slightly for your washer or dispenser. Refer to its

operating manual, if needed, for more precise instructions.

1. Turn on the washer/dispenser and allow its System Test to complete.

2. Press the Setup Menu key.

3.

Select g, BIOSTK > CONF.

4. Select BIOSTACK.

BioTek Instruments, Inc.

Page 56

34 | Chapter 2: Installation

5. When RE-STACK? appears, select YES.

6. Press the Main Menu key.

405 TS and MultiFlo FX (Touch Screen Instruments) Only

Enable the BioStack to operate with the washer/dispenser:

1. Turn on the washer/dispenser and allow its System Test to complete.

2. At the Home screen, select Instrument > Next > BioStack.

3. Select the BioStack checkbox to show it is installed.

4. Press Get Basecode Version to ensure the instruments are communicating. If

you get an error message, check the cabling and restart both instruments.

Test Communication

n (Optional) Use the Software Data Sheet on page 30 to record software version

and checksum information.

n If software version/checksum information is displayed without error, the

Communication Tests completed successfully.

Keypad: From the main menu, select UTILS > TESTS > CHKSUM/SOFTWARE >

BIOSTACK.

Touch screen: At the Home screen, select Instrument > Next > BioStack

Communication is successful if the BioStack basecode software version (the first

number), interface definition version (the second number), and checksum are

displayed.

If communication is not successful, look up the error code: Communication Error

Codes on page 74. Contact BioTek if you cannot resolve the problem.

BioStack™ Microplate Stacker

Page 57

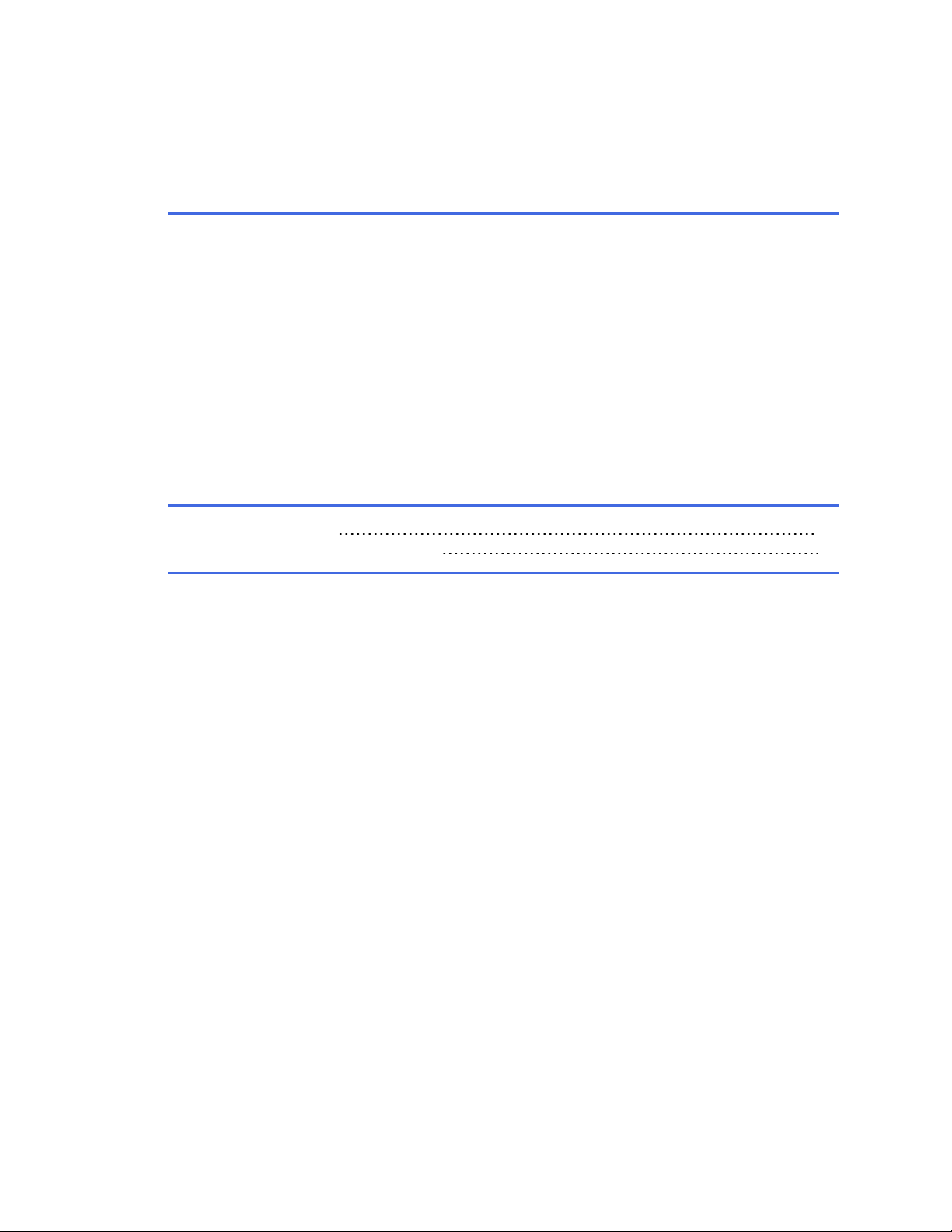

Where to Go Next

To See

Where to Go Next | 35

Install the BioStack

with an interfacing

instrument

Install the barcode

scanner (if purchased)

Operate the BioStack The Operation chapter beginning on page 41

Maintain the BioStack The Maintenance chapter beginning on page 59 for cleaning and

Qualify the BioStack The Qualification chapter beginning on page 69 for recommended

Interpret error codes

or resolve problems

The instrument-specific PDF files for alignment instructions

The Barcode Scanner section beginning on page 93

decontamination instructions

procedures to qualify the initial and ongoing performance of the

BioStack

The Troubleshooting chapter beginning on page 73

BioTek Instruments, Inc.

Page 58

36 | Chapter 2: Installation

Repacking the BioStack

Prior to sending your instrument to us for repair, log into the Customer Resource

Center (www.biotek.com) to submit a Service Request for a Service Call Notice

(SCN) number. Your instrument's serial number is needed to process an SCN.

n Decontaminate the instrument before returning it: See Decontamination

n Failure to comply with the following instructions will void the instrument’s

warranty and result in additional charges if the instrument is damaged.

If you have lost the original packing materials, contact BioTek TACto order:

l BIOSTACK2WR: PN 7310014

l BIOSTACK3WR: PN 1160003

l BIOSTACK4: PN 1230007

n The instrument’s packaging design is subject to change. If these instructions do

not apply to the packaging materials you are using, please contact BioTek’s

Technical Assistance Center for guidance.

n If the packaging materials have been damaged, lost, or used more than four

times, contact BioTek to order replacements: PN 7310014 for BIOSTACK2WR;

PN 1163003 for the BIOSTACK3WR; PN 7313007 for the 10-plate stacks; PN

7313001 for the 30-plate stacks; PN 7313006 for the 50-plate stacks.

l The microplate stacks do not need to be returned with the instrument

unless a problem has occurred with plates in the stacks.

l The barcode scanner does not need to be returned with the instrument

unless a problem has occurred with the scanner. Remove the scanner

before repacking the BioStack.

Obtain a Work Order Number:

l Contact BioTek TAC to obtain a work order number

l Include the work order number in the shipping address label:

BioTek Instruments, Inc.

ATTN: work order number xxxxx

15 Tigan Street

Winooski, Vermont 05404 USA

BioStack™ Microplate Stacker

Page 59

Install the Shipping Hardware—BioStack2WR | 37

Install the Shipping Hardware—BioStack2WR

Reverse the process of uninstalling the shipping hardware. Refer to photos on

page 18.

Tools: You need a standard screwdriver, a small Phillips-head screwdriver and

3/32" hex wrench.

1. Turn on the BioStack to keep the gripper arm in its highest position.

n If the BioStack cannot be turned on, manually raise the gripper to its full height

and hold it there.

2. Install the gripper shipping screw (see below).

3. Remove the gripper arm cover and install the wrist shipping block using the

hex wrench.

4. Replace the gripper arm cover.

5. Install the shipping block inside the instrument.

6. Install the plate carrier shipping screw.

Next step: Repacking—Install Shipping Panel on page 39.

Install the Shipping Hardware—BioStack 3

Reverse the process of uninstalling the shipping hardware. Refer to the photos

on page 20.