Page 1

800™ TS

Absorbance Reader

Instructions for Use

BioTek® Instruments, Inc.

© 2017

PN 1561011, Rev A

Page 2

BioTek Instruments, Inc.

ii | Notices

Notices

BioTek® Instruments, Inc.

Highland Park, P.O. Box 998

Winooski, Vermont 05404-0998 USA

All Rights Reserved

© 2017, BioTek® Instruments, Incorporated. No part of this publication may be reproduced, transcribed, or

transmitted in any form, or by any means electronic or mechanical, including photocopying and recording, for any

purpose other than the purchaser’s use without written permission of BioTek Instruments, Inc.

Trademarks

BioTek® is a registered trademark, and 800™ TS and Gen5™ are trademarks of BioTek Instruments, Inc. BioCell™ is

a trademark of BioTek Instruments and is patented under U.S. patent number 5,963,318.

Microsoft®, Windows®, and Excel® are either registered trademarks or trademarks of Microsoft Corporation in

the United States and/or other countries.

All other trademarks are the property of their respective holders.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by BioTek Instruments,

Inc. Changes made to the information in this document will be incorporated in new editions of the publication. No

responsibility is assumed by BioTek for the use or reliability of software or equipment that is not supplied by

BioTek or its affiliated dealers.

Page 3

Contact Information | iii

Contact Information

BioTek® Instruments, Inc.

Highland Park, P.O. Box 998

Winooski, Vermont 05404-0998 USA

Global Service and Support

BioTek instrument service and repair is available worldwide at one of BioTek's

International Service Centers and in the field at your location. To arrange for service or

repair of your instrument, contact the office nearest you; visit www.biotek.com for up-todate contact information. For customer service, sales, and technical assistance, refer to the

information below.

Customer Service and Sales

Internet: www.biotek.com

Phone: 888-451-5171 (toll-free in the U.S.)

802-655-4740 (outside the U.S.)

Fax: 802-655-7941

Email: customercare@biotek.com

Service/Technical Assistance Center (TAC)

Phone: 800-242-4685 (toll-free in the U.S.)

802-655-4740 (outside the U.S.)

Fax: 802-654-0638

Email: tac@biotek.com

European Coordination Center/Authorized European Representative

BioTek® Instruments GmbH

Kocherwaldstrasse 34

D-74177 Bad Friedrichshall

Germany

Internet: www.biotek.de

800 TS

Phone: +49 (0) 7136 9680

Fax: +49 (0) 7136 968 111

Email: info@biotek.de

Page 4

BioTek Instruments, Inc.

iv | Instructions for Use Requirements

Instructions for Use Requirements

This document fulfills the basic needs of persons operating this device, according to the

requirements of the In Vitro Diagnostic Directive for “Instructions for Use.” Some of the

device's higher-level functions and features, as well as certain detailed maintenance and

qualification routines, are described in the Synergy Neo Operator's Manual.

Intended Use Statement

The 800 TS is a single-channel, filter-based absorbance reader designed to perform

measurements of samples in a microplate format. The performance characteristics of the

data reduction software have not been established with any laboratory diagnostic assay.

Users must evaluate this instrument and PC-based software in conjunction with their

specific assay(s). This evaluation must include the confirmation that performance

charactertistics for the specific assay(s) are met.

Quality Control

It is considered good laboratory practice to run laboratory samples according to

instructions and specific recommendations included in the assay package insert for the test

to be conducted. Failure to conduct Quality Control checks could result in erroneous test

data.

Warnings

Operate the instrument on a level, stable surface away from excessive humidity.

Bright sunlight or strong incandescent light can reduce the linear performance

range of the instrument.

Measurement values may be affected by extraneous particles (such as dust) in the

microplate wells. A clean work area is necessary to ensure accurate readings.

When operated in a safe environment according to the instructions in this

document, there are no known hazards associated with the instrument. However,

the operator should be aware of certain situations that could result in serious

injury; these may vary depending on the instrument model. See Hazards and

Precautions.

Page 5

Hazards

The following hazards are provided to help avoid injury:

Warning! Power Rating. The instrument’s power supply or power cord must

be connected to a power receptacle that provides voltage and current within

the specified rating for the system. Use of an incompatible power receptacle

may produce electrical shock and fire hazards.

Warning! Electrical Grounding. Never use a plug adapter to connect primary

power to the external power supply. Use of an adapter disconnects the utility

ground, creating a severe shock hazard. Always connect the power cord

directly to an appropriate receptacle with a functional ground.

Warning! Service. Only qualified technical personnel should perform service

procedures on internal components.

Warning! Accessories. Only accessories that meet the manufacturer's

specifications shall be used with the instrument.

Warning! Lubricants. Do not apply lubricants to the microplate carrier or

carrier track. Lubricant on the carrier mechanism or components in the

carrier compartment will attract dust and other particles, which may obstruct

the carrier path and cause the instrument to produce an error.

Hazards | v

Warning! Liquids. Avoid spilling liquids on the instrument; fluid seepage into

internal components creates a potential for shock hazard. If a spill occurs

while a program is running, abort the program and turn off the instrument.

Wipe up all spills immediately. Do not operate the instrument if internal

components have been exposed to fluid. Contact BioTek TAC for assistance.

Warning! Unspecified Use. Failure to operate the equipment according to the

guidelines and safeguards specified in this manual could result in a hazardous

condition.

Warning! Software Quality Control. The operator must follow the

manufacturer’s assay package insert when modifying software parameters

and establishing reading methods. Failure to conduct quality control checks

could result in erroneous test data.

Warning! Reader Data Reduction Protocol. No limits are applied to the raw

measurement data. All information exported via computer control must be

thoroughly analyzed by the operator.

800 TS

Page 6

BioTek Instruments, Inc.

vi | Precautions

Warning! Hot Surface.The tungsten lamp assembly is hot when the

instrument is turned on. Turn off the reader and allow the lamp to cool for at

least 15 minutes before attempting to replace it.

Warning! Internal Voltage. Always turn off the power switch and unplug the

power supply before cleaning the outer surface of the instrument.

Warning! Potential Biohazards. Some assays or specimens may pose a

biohazard. This hazard is noted by the symbol shown here. Adequate safety

precautions should be taken as outlined in the assay’s package insert. Always

wear safety glasses and appropriate protective equipment, such as chemicalresistant rubber gloves and apron.

Precautions

The following precautions are provided to help avoid damage to the instrument:

Caution: Service. The instrument should be serviced by BioTek-authorized

service personnel. Only qualified technical personnel should perform service

procedures on internal components.

Caution: Spare Parts. Only approved spare parts should be used for

maintenance. The use of unapproved spare parts and accessories may result in

a loss of warranty and potentially impair instrument performance or cause

damage to the instrument.

Caution Touchscreen. Do not use sharp implements to operate the

touchscreen. Using a sharp stylus or other implement may damage the display.

Caution: Environmental Conditions. Do not expose the system to temperature

extremes. For proper operation, ambient temperatures should remain within

the range listed in Appendix A, Specifications. Performance may be adversely

affected if temperatures fluctuate above or below this range. Storage

temperature limits are broader.

Caution: Sodium Hypochlorite. Do not expose any part of the instrument to the

recommended diluted sodium hypochlorite solution (bleach) for more than 20

minutes. Prolonged contact may damage the instrument surfaces. Be certain to

rinse and thoroughly wipe all surfaces.

Caution: Power Supply. Use only the power supply shipped with the instrument.

Operate this power supply within the range of line voltages listed on it.

Page 7

Precautions | vii

Caution: Shipping Hardware.The shipping hardware must be removed before

operating the instrument and reinstalled before repackaging the instrument for

shipment.

Caution: Disposal. Dispose of the instrument according to Directive

2012/19/EU, “on waste electrical and electronic equipment (WEEE)” or local

ordinances.

Caution: Warranty. Failure to follow maintenance protocols may void the

warranty. See Chapter 4, Maintenance.

Caution: Electromagnetic Environment. Per IEC 61326-2-6 it is the user’s

responsibility to ensure that a compatible electromagnetic environment for this

instrument is provided and maintained in order that the device will perform as

intended.

Caution: Electromagnetic Compatibility. Do not use this device in close

proximity to sources of strong electromagnetic radiation (e.g., unshielded

intentional RF sources), because these may interfere with the proper operation.

800 TS

Page 8

BioTek Instruments, Inc.

viii | CE Mark

CE Mark

Based on the testing described below and information

contained herein, this instrument bears the CE mark

Refer to the Declaration of Conformity for more specific information.

Directive 2014/30/EU: Electromagnetic Compatibility

Emissions—Class A

The system has been type-tested by an independent, accredited testing laboratory and

found to meet the requirements of EN 61326-1: Class A for Radiated Emissions and Line

Conducted Emissions.

Verification of compliance was conducted to the limits and methods of EN 55011 – (CISPR

11) Class A. In a domestic environment it may cause radio interference, in which case you

may need to mitigate the interference.

Immunity

The system has been type-tested by an independent, accredited testing laboratory and

found to meet the requirements of EN 61326-1 and EN 61326-2-6 for Immunity.

Verification of compliance was conducted to the limits and methods of the following:

EN 61000-4-2, Electrostatic Discharge

EN 61000-4-3, Radiated EM Fields

EN 61000-4-4, Electrical Fast Transient/Burst

EN 61000-4-5, Surge Immunity

EN 61000-4-6, Conducted Disturbances from RFI

EN 61000-4-11, Voltage Dips, Short Interruptions and Variations

Directive 2014/35/EU Low Voltage (Safety)

The system has been type-tested by an independent testing laboratory and was found to

meet the requirements of this Directive. Verification of compliance was conducted to the

limits and methods of the following:

EN 61010-1. "Safety requirement for electrical equipment for measurement, control and

laboratory use. Part 1, General requirements."

EN 61010-2-081. “Particular requirements for automatic and semi-automatic laboratory

equipment for analysis and other purposes.”

EN 61010-2-010. “Particular requirements for laboratory equipment for the heating of

materials.“

Page 9

Electromagnetic Interference and Susceptibility | ix

Directive 2012/19/EU: Waste Electrical and Electronic Equipment

Disposal Notice: Dispose of the instrument according to Directive 2012/19/EU, “on waste

electrical and electronic equipment (WEEE)” or local ordinances.

Directive 98/79/EC: In Vitro Diagnostics (if labeled for this use)

•

Product registration with competent authorities

•

EN 61010-2-101. “Particular requirements for in vitro diagnostic (IVD) medical

equipment.”

•

Traceability to the U.S. National Institute of Standards and Technology (NIST).

Electromagnetic Interference and Susceptibility

USA FCC CLASS A

RADIO AND TELEVISION INTERFERENCE

NOTE: This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their own expense.

In order to maintain compliance with FCC regulations, shielded cables must be used with

this equipment. Operation with non-approved equipment or unshielded cables is likely to

result in interference to radio and television reception.

Canadian Department of Communications Class A

This digital apparatus does not exceed Class A limits for radio emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadians Department of

Communications.

Le present appareil numerique n'emet pas du bruits radioelectriques depassant les limites

applicables aux appareils numerique de la Class A prescrites dans le Reglement sur le

brouillage radioelectrique edicte par le ministere des Communications du Canada.

800 TS

Page 10

BioTek Instruments, Inc.

x | User Safety

User Safety

This device has been type-tested by an independent laboratory and found to meet the

requirements of the following:

•

Underwriters Laboratories UL 61010-1, “Safety requirements for electrical

equipment

requirements.”

•

Canadian Standards Association CAN/CSA C22.2 No. 61010-1, “Safety

requirements

laboratory use; Part 1:

•

EN 61010 Standards, see

for measurement, control and laboratory use; Part 1: General

for electrical equipment for measurement, control and

General requirements.”

CE Mark

starting on page viii.

Page 11

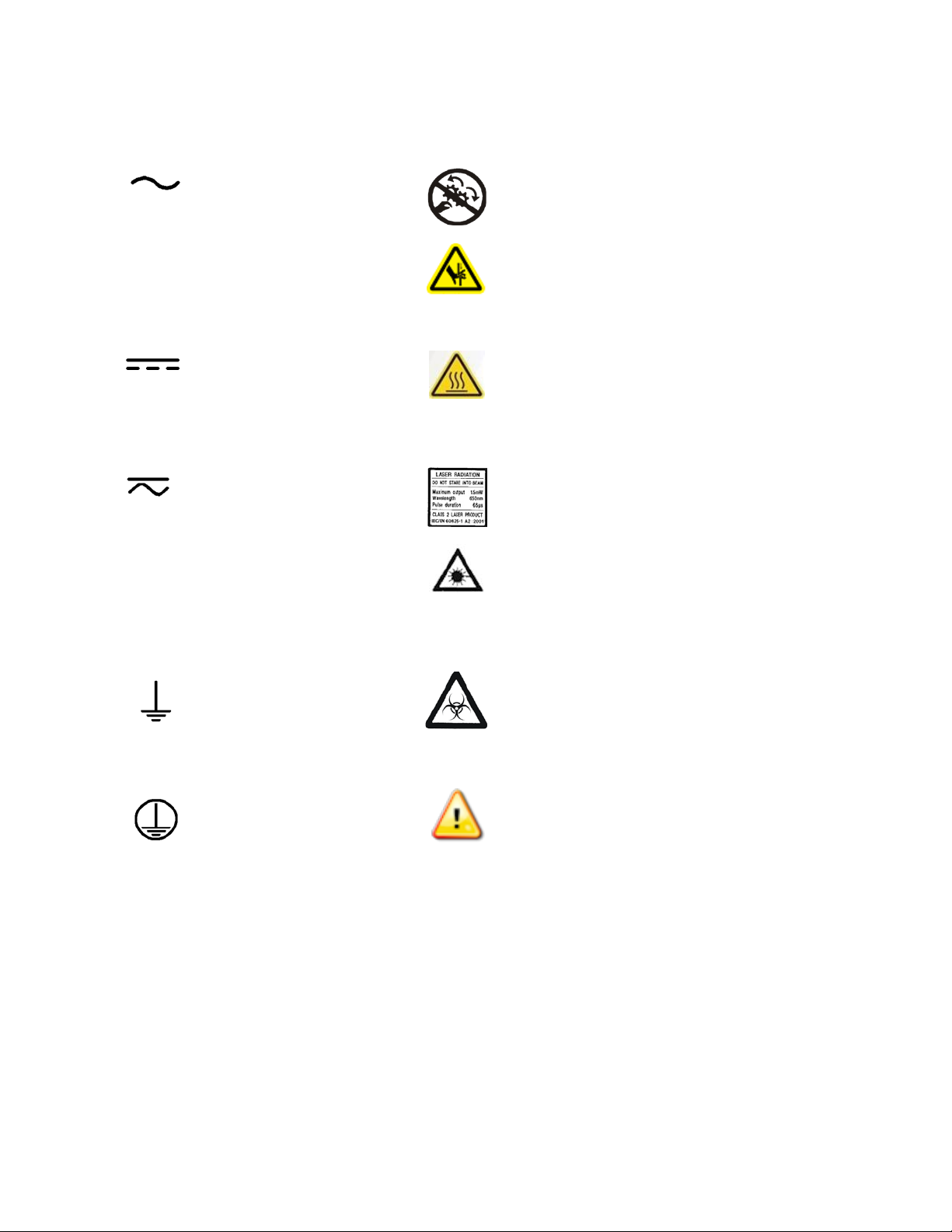

Safety Symbols

Some of the following symbols may appear on the instrument or accessories:

Alternating current

Courant alternatif

Wechselstrom

Corriente alterna

Corrente alternata

Direct current

Courant continu

Gleichstrom

Corriente continua

Corrente continua

Both direct and alternating

current

Courant continu et courant

alternatif

Gleich - und Wechselstrom

Corriente continua y

corriente alterna

Corrente continua e

corrente alternata

Earth ground terminal

Borne de terre

Erde (Betriebserde)

Borne de tierra

Terra (di funzionamento)

Protective conductor

terminal

Borne de terre de

protection

Schultzleiteranschluss

Borne de tierra de

protección

Terra di protezione

Warning, risk of crushing or pinching

Attention, risque d'écrasement et pincement

Warnen, Gefahr des Zerquetschens und

Klemmen

Precaución, riesgo del machacamiento y

sejeción

Attenzione, rischio di schiacciare ed

intrappolarsi

Warning, hot surface

Attention, surface chaude

Vorsicht, heiße Oberfläche

Precaución, superficie caliente

Attenzione, superfice calda

Laser radiation: Do not stare into beam

Rayonnement laser: Ne pas regarder dans le

faisceau

Laserstrahlung: nicht in den strahl blicken

Radiación de laser: No mire fijamente al rayo

Radiazione di laser: Non stare nel fascio

Warning, potential biohazards

Attention, risques biologiques potentiels

Warnung! Moegliche biologische Giftsoffe

Atención, riesgos biológicos

Attenziones, rischio biologico

Caution (refer to accompanying documents)

Attention (voir documents

d'accompanement)

Achtung siehe Begleitpapiere

Atención (vease los documentos incluidos)

Attenzione, consultare la doc annessa

Safety Symbols | xi

800 TS

Page 12

xvi | Safety Symbols

BioTek Instruments, Inc.

Page 13

Installation

Page 14

2 | Package Contents

Package Contents

Item Part #

800 TS Operator's Manual on USB flash drive 1561000

Power supply

Power cord varies according to country of use

USB cable 75108

Blank 4 GB USB flash drive 01087

Dust cover 7332040

Gen5 RC software GEN5RC

Non-incubation models: 01281

Incubation models: 02395

1. Unpack and Inspect the Reader

Save all packaging materials. If you need to ship the reader to BioTek for repair or

replacement, you must use the BioTek-supplied materials. Using other forms of

commercially available packaging, or failing to follow the repackaging instructions,

may void your warranty.

During the unpacking process, inspect the packaging, reader, and accessories for

shipping damage. If the reader is damaged, notify the carrier and your BioTek

representative. Keep the shipping boxes and the packaging materials for the carrier's

inspection. BioTek will arrange for repair or replacement immediately.

1. Place the packaging materials back into the shipping box for reuse if the instrument

needs to be shipped again.

BioTek Instruments, Inc.

Page 15

Remove the Shipping Hardware | 3

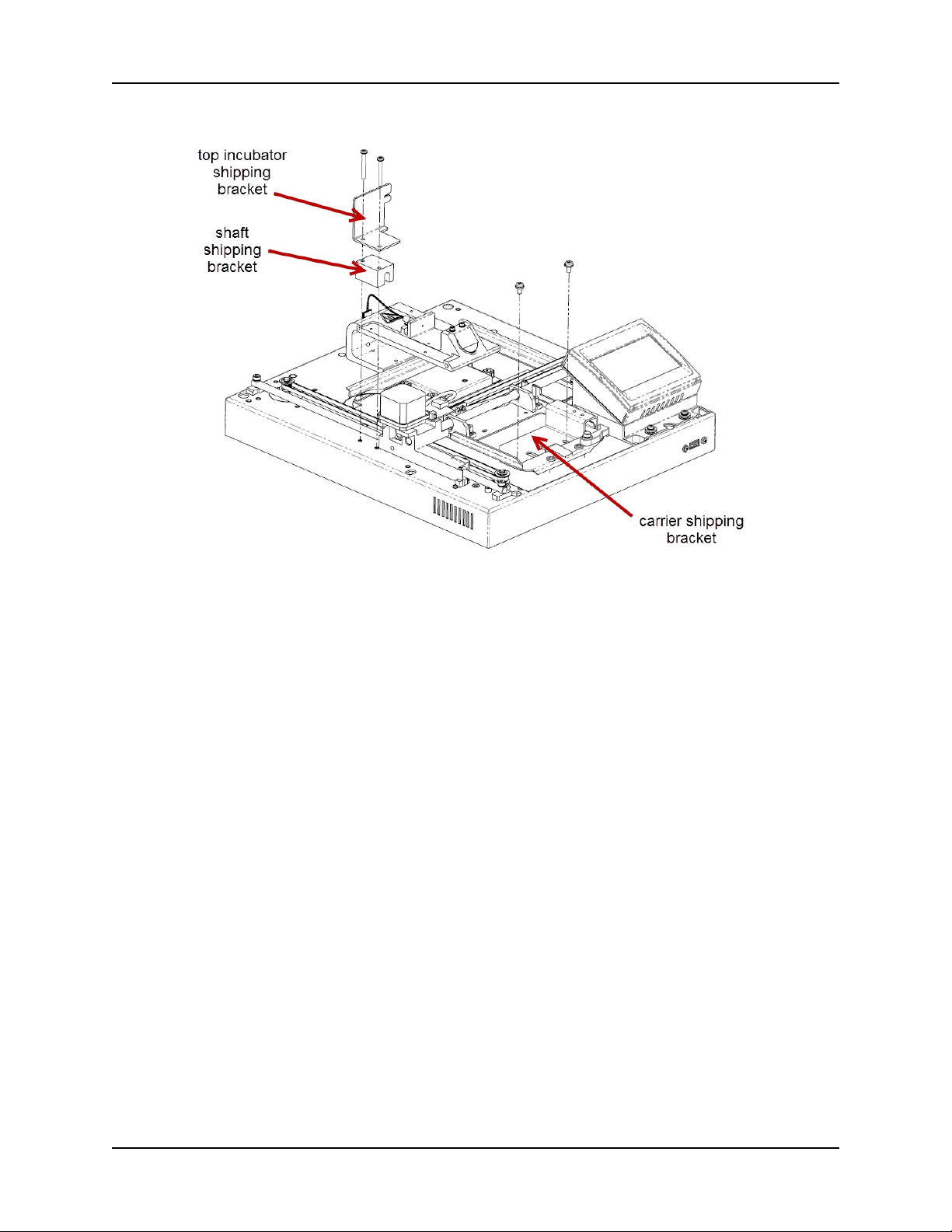

2. Remove the Shipping Hardware

Remove and store all shipping hardware before you turn on the reader.

1. Carefully turn the reader upside down on a level surface.

2. Remove the six black screws holding the cover to the base, then lift the base off the

cover and set it right side up on a level surface.

3. Remove the two screws on each of the shipping brackets, remove the brackets, and

store the screws in the holes on the brackets.

800 TS

Page 16

4 | Verify the Filter Wheel Contents

4. Store the shipping hardware in a safe place in case it is needed in the future.

5. If applicable (described in the next section), install the door now.

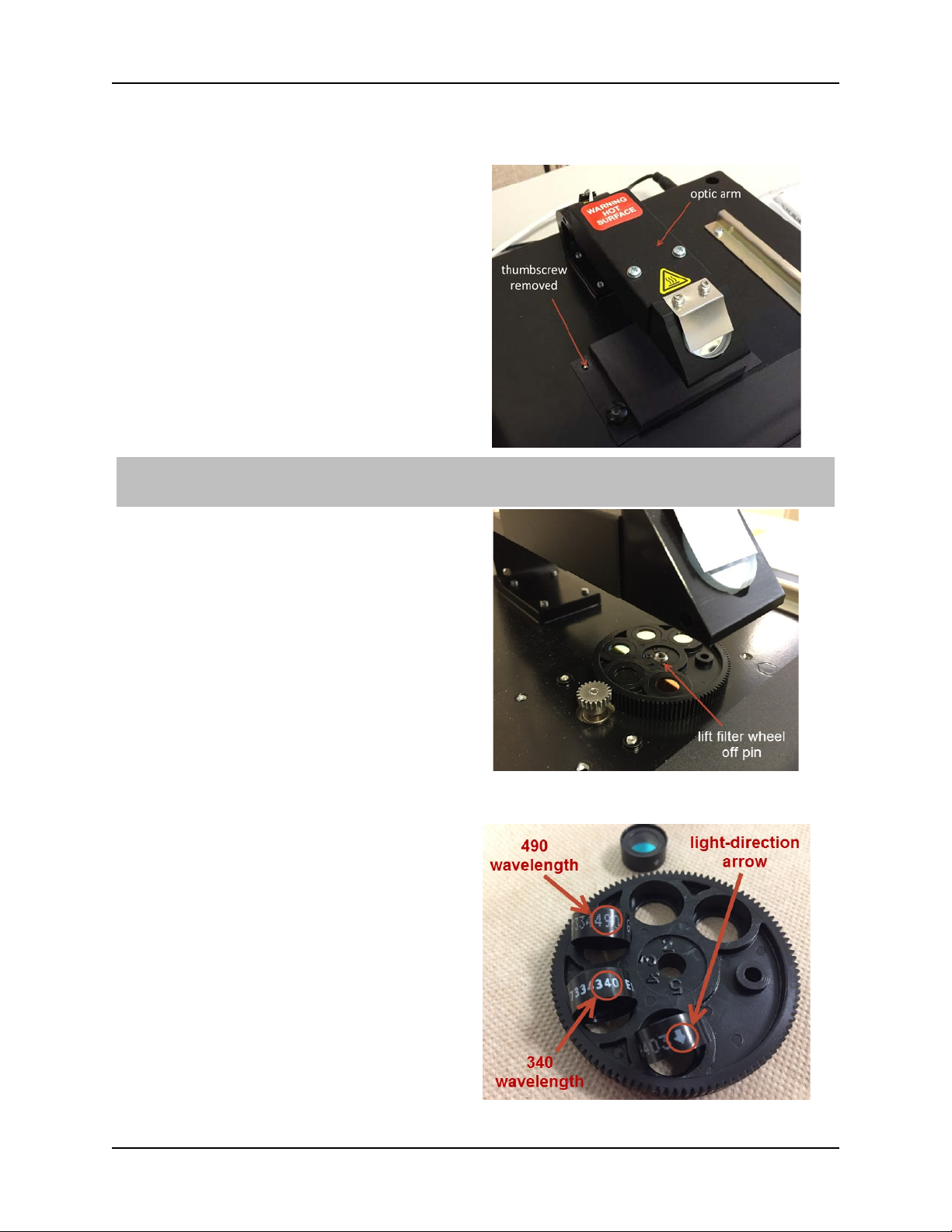

3. Verify the Filter Wheel Contents

The 800 TS ships with up to five preordered filters in the filter wheel. During installation, it

is good practice to verify the filters and their placement, and to confirm that the software

filter table matches the filter wheel’s configuration (discussed later). All five locations in

the wheel must contain either a filter or a plug.

Before continuing, obtain a clean, lint-free cloth.

BioTek Instruments, Inc.

Page 17

Verify the Filter Wheel Contents | 5

For models with incubation capability: You must first remove the incubation housing to

access the filter wheel.

1. With the top case removed from the reader (see Remove the Shipping Hardware

on page 3 for directions), remove the four thumbscrews from the optic arm, and lift

the optic arm cover off (if equipped).

2. Disconnect the two connectors on the back of the incubation housing, then gently lift

the housing off of the reader.

800 TS

Page 18

6 | Verify the Filter Wheel Contents

To access the filter wheel:

1. With the top case removed from the reader

(see Remove the Shipping Hardware on page 3

for directions), remove the four thumbscrews

from the filter wheel cover. This cover is directly

under the optics arm.

Note: The filters are not held in place and fall out of the wheel easily, so make sure to have a clean, lintfree cloth in place before turning over the filter wheel.

2. Lift the filter wheel off its pin, then remove

the filters by turning the wheel upside down

over a clean, lint-free cloth. Write down which

filters are installed in the filter wheel and the

location of each filter. You will use this

information later to verify/edit the software

filter table.

Compare the filters with your model’s default

filters or with the purchase order if different

filters were ordered. Contact BioTek Customer

Care if you did not receive the expected

filters/plugs.

Each filter is labeled with a wavelength and an

arrow showing the light direction. The arrows

must point downward when the filter wheel is

installed on the reader.

BioTek Instruments, Inc.

Page 19

Select an Appropriate Location | 7

3. When you are finished examining the filters,

replace the filters in the filter wheel, being

careful to insert them in the correct direction

(indicated by the arrow printed on the side of

each filter).

4. Replace the filter wheel on its pin, and then

replace the filter wheel cover using the four

thumbscrews removed during step 1.

5. Tape the door closed, if equipped.

6. Carefully turn the reader upside down over its

cover, and reattach the reader to the top cover

by replacing the six screws.

4. Select an Appropriate Location

Install the reader on a level, stable surface. Select an area where ambient temperatures

between 18°C (71.6°F) and 40°C (104°F) can be maintained.

The reader is sensitive to extreme environmental conditions. Avoid the following:

•

Excessive humidity.

Condensation directly on the sensitive electronic circuits can

cause the instrument to fail internal self-checks. The humidity must be in the range of

10–85%, non-condensing.

•

Excessive ambient light.

reducing its linear range.

•

Dust.

Readings may be affected by extraneous particles (such as dust) in the

Bright light may affect the reader’s optics and readings,

microplate wells. A clean work area is necessary to ensure accurate readings.

800 TS

Page 20

8 | Install the Power Supply

5. Install the Power Supply

Power Rating. The instrument must be connected to a power receptacle that

provides voltage and current within the specified rating for the system. Use of an

incompatible power receptacle may produce electrical shock and fire hazards.

Electrical Grounding. Never use a plug adapter to connect primary power to the

instrument. Use of an adapter disconnects the utility ground, creating a severe

shock hazard. Always connect the system power cord directly to an appropriate

receptacle with a functional ground.

a. Connect the power cord to the external power supply.

b. Locate the power inlet on the rear of the reader.

c. Plug the rounded end of the power supply's cord into the power inlet.

d. Plug the other end of the power cord into an appropriate power receptacle.

6. (Optional) Install Gen5 on the Host Computer

There is a certain sequence of events that must be followed to ensure that the

software is properly installed and configured. Please follow the instructions

provided in Gen5 Getting Started Guide to install the software.

BioTek Instruments, Inc.

Page 21

(Optional) Install the USB Driver | 17

7. (Optional) Install the USB Driver

Refer to the instructions that shipped with the Gen5 software to install the necessary

drivers. The driver must be installed on the computer before you connect the

instrument.

8. (Optional) Connect the Host Computer

The USB port is located on the rear of the reader.

1. Turn off the computer. If the reader is on, turn it off.

2. Using the supplied USB cable, connect the square end of the cable to the USB port on

the back of the reader.

3. Connect the other end of the cable to an available USB port on the computer.

9. Turn on the Reader

1. Locate the power on/off switch on the right side of the instrument, and turn on the

reader. The reader delays any action until the bulb has warmed up: three minutes for

narrow beam and UV models, and 30 seconds otherwise. Then the reader performs a

power-up system test.

If using Gen5, do not attempt to communicate with the reader until the system

test is finished.

2. When the system test is completed, the touchscreen displays its main screen.

800 TS

Page 22

18 | Set Date and Time on Touchscreen

10. Set Date and Time on Touchscreen

The date and time are included in the instrument’s system test report. Define these

settings now to ensure correct information when you perform step 14.

1. From the Main Menu, tap Instrument, the

Config tab, then the Time button

2. Tap the hour value, and use the keypad to

enter the correct time for both the hour and

minutes, then click OK.

Note: You can change just the minutes value: Tap

the minutes value and enter the correct time.

3. Tap the Date button.

4. Tap month, day, or year, and use the keypad

to set the current date. Tap OK when done.

11. Verify the Reader's Filter Table

Before using the 800 TS, verify that the filter table reflects the filters installed in the filter

wheel.

Important! The reader’s filter table must exactly match the contents of the installed

filter wheel.

BioTek Instruments, Inc.

Page 23

(Optional) Establish Communication | 19

the absorbance test plate setup screen.

1. From the Main Menu, tap Instrument, the

Config tab, and then Filter Table. Filter wheel

locations 1 through 5 are shown, with each

location’s filter value (in nm) or “plug” for a

blank filter.

2. Verify that the values match the contents of

the filter wheel. See the Installation chapter

for instructions for accessing the filter wheel.

3. To change the setting for a filter wheel

position, tap its value and use the keypad to

enter a wavelength value (in nm), or select

Plug. Tap OK when finished.

4. If you made any changes, tap Save in the

Installed Filters screen. The filter values are

now available for selection in protocols and

12. (Optional) Establish Communication

NOTE: Instrument must be at the Main Menu screen for Gen5 communication to occur.

1. On the host computer, start Gen5 and log in if prompted. The default System

Administrator password is admin.

2. From the Gen5 main screen, select System > Instrument Configuration and click Add.

3. Set the Reader Type to 800 TS.

4. Perform one of the following steps, as applicable:

•

Select

Plug & Play.

An 800 TS must be connected via USB to the computer and turned on to appear

in the Available Plug & Play Readers list.

•

Set the Com Port to the computer's COM port to which the reader is

connected.

800 TS

Page 24

20 | Run a System Test

The information can be found via the Windows Control Panel, under Ports in the

Hardware/Device Manager area of System Properties (e.g., Serial Port (COM5)).

5. To verify that Gen5 can communicate with the instrument, click Test Comm. If the

communication attempt is successful, Gen5 displays a success message. Return to

Gen5’s main screen.

Communication Errors

If the communication attempt is not successful, try the following:

•

Is the reader connected to the power supply and turned on?

•

Is the communication cable firmly attached to both the reader and the

computer?

•

Did you select the correct Reader Type in Gen5?

•

Try a different COM Port in Gen5 or use Plug & Play.

•

Did you install the USB driver software?

•

Is the touchscreen at the Main Menu?

If you remain unable to get Gen5 and the reader to communicate with each other,

contact BioTek’s Technical Assistance Center.

13. Run a System Test

Running a system test will confirm that the reader is functioning properly, or will provide

an error code if a problem is detected.

Using the Touchscreen

1. If the reader is equipped with an incubator, turn it on.

a. On the Main Menu, tap the temperature display (circled in the following image).

When the incubator is turned on, the dashes are replaced by the reader’s internal

temperature, in degrees Celsius.

BioTek Instruments, Inc.

Page 25

Run a System Test | 21

b. On the Incubate tab of the Quick Menu screen, turn on the Temperature Control and

enter a setpoint of at least 37°C, then tap Home to return to the Main Menu.

c. Wait for the temperature display to reach the defined setpoint before continuing.

2. From the Main Menu, tap Instrument > Options.

800 TS

Page 26

22 | Run a System Test

3. Under System test, tap Start.

4. When the test finishes, tap USB Report to save the test results to a USB flash drive,

Print to print the test results, or Exit to close the screen.

5. If applicable, turn off incubator.

Using Gen5

1. If necessary, launch Gen5 and turn on the incubator:

•

From the Gen5 main screen, select

•

Click the

•

Enter a Requested temperature of at least 37°C and click On.

•

Wait until the incubator temperature reaches the set point before continuing.

Pre-Heating

tab.

2. Return to Gen5’s main view and select System > Diagnostics > Run System Test. If

prompted to select a reader, select 800 TS and click OK.

System > Instrument Control > 800 TS.

3. If a message appears, stating that the reader has a pending system test report, click OK,

then click Close.

The reader ran a "power-up" system test, but that test did not include verifying

that the incubator reaches a set temperature. Therefore, you will run another

system test.

Again, select System > Diagnostics > Run System Test. If prompted to select a reader, select 800

TS and click OK.

4. When the test is completed, a dialog requesting additional information appears. Enter

the information and click OK.

5. The results report appears and should contain the text "SYSTEM TEST PASS."

• If required, print the report and store it with your records.

• The Gen5 software stores system test information in its database; you can

retrieve it at any time.

•

You can save the system test report as a text file: click Save As in the System

Test Results dialog.

BioTek Instruments, Inc.

Page 27

as a whole set under this part number and cannot be ordered separately.

6. If applicable, turn off the incubator:

•

Select

•

Click the

•

Return to Gen5’s main view.

System > Instrument Control > 800 TS.

Pre-Heating

tab and click

Repackaging and Shipping Instructions

Important! Please read all of the information provided below

If the reader has been exposed to potentially hazardous material, decontaminate

it to minimize the risk to all who come in contact with the reader during shipping,

handling, and servicing. Decontamination prior to shipping is required by the U.S

Department of Transportation regulations. See the As-Needed Maintenance

chapter for decontamination instructions.

Remove any labware from the carrier before shipment. Spilled fluids can

contaminate the optics and damage the instrument.

before preparing the 800 TS for shipment.

Repackaging and Shipping Instructions | 23

Off.

The instrument’s packaging design is subject to change. If the instructions in this

section do not appear to apply to the packaging materials you are using, please

contact BioTek’s Technical Assistance Center for guidance.

Replace the shipping hardware before repackaging the instrument. Please

800 TS

contact BioTek if you need to replace any of these items:

•

Carrier shipping bracket (PN 1560517)

•

Carrier shipping bracket screws (PN 19668)

•

Shaft shipping bracket (PN 7332041)

•

Shaft shipping bracket screws (PN 19337)

•

If applicable, top incubation shipping bracket (PN 1562072)

If you need to ship the 800 TS to BioTek for service or repair, be sure to use the

BioTek-supplied packaging materials. Other forms of commercially available

packaging are not recommended and can void the warranty.

If the packaging materials have been damaged or lost, or if the same set has

been used more than four times, contact BioTek to order replacement part

number 1563000. The shipping box, accessories box, and foam trays are included

Page 28

BioTek Instruments, Inc.

24 | Repackaging and Shipping Instructions

Page 29

Getting Started

Page 30

26 | Overview

Overview

The 800 TS is a compact, filter-based, single-channel absorbance microplate reader. All

models are equipped with a touchscreen interface and support endpoint dual-wavelength

reads from 400-750 nm on standard 6- to 96-well plates. The narrow beam (NB) model

supports 384-well plates. UV models support a measurement range from 340-750 nm.

Some models offer incubation to 50˚C and/or linear plate shaking.

Basic data analysis, reporting, and exporting are provided via the touchscreen. With

optional Gen5 software, kinetic and well area scanning read modes are supported, along

with BioCell and 60-, 72-, and 96-well Terasaki plates. Gen5 also offers extensive data

analysis and reporting and exporting capabilities. The reader is available in five models.

The filter wheel contains up to five filters and is user accessible. For models with fewer

than five filters, removable plugs are installed in the empty wheel locations.

The 800TS and 800TSI models use a tungsten bulb as their light source. The other

models, 800TSUV, 800TSUVI, and 800TSNB, use a halogen bulb.

Refer to the 800 TS Operator’s Manual for recommendation for ensuring optimum

performance.

BioTek Instruments, Inc.

Page 31

External Components

1

Microplate carrier

| 27

2

Touchscreen

3

Power switch

4

USB flash drive port for USB flash drive

Note that the photo does not show the door.

800 TS

Page 32

28 | External Components

Rear ports on a reader without incubation capability

1

Power port

2

USB port

3

DO NOT USE! For BioTek Service only

4

USB port for printer

Rear ports on a reader with incubation capability

1

Power port

2

USB port

3

DO NOT USE! For BioTek Service only

4

USB port for printer

BioTek Instruments, Inc.

Page 33

Operate the Reader Using the Touchscreen| 29

Operate the Reader Using the Touchscreen

General Information

Do not use a sharp stylus or pencil on the touchscreen. Doing so can damage the

touchscreen's surface. You can use a stylus designed for capacitive touchscreens.

When you turn on the 800 TS, the touchscreen turns on automatically and opens to the

Main Menu after the start-up system test and bulb warm-up. The length of the bulb warmup process varies from three minutes for narrow beam and UV models, and 30 seconds

otherwise.

•

To select a button or check box or to activate a tab, tap the item once.

•

To return to the Main Menu from any other screen, tap

corner.

•

For instructions on cleaning the touchscreen, see the Maintenance chapter.

Home

in the top-left

Note:

the Instrument or Quick Menu. Note that if you turn off the bulb, the reader will go

through the bulb warm-up process when you turn the bulb back on (three minutes for

narrow beam and UV models, and 30 seconds otherwise).

Main Menu

To preserve the life of the bulb, turn it off when not needed by tapping

in

800 TS

Page 34

30 | Operate the Reader Using the Touchscreen

800TSI and 800TSUVI models: When the incubator is turned on, the reader’s internal

temperature is displayed at the top of the screen, as shown above. When the incubator

is off, dashes are displayed.

The left side of the Main Menu screen lists the assay protocols defined on the reader. As

shipped, the reader contains no protocols and the list is empty. Up to 40 uniquely named

protocols can be programmed and stored. Tap Next to scroll through the list.

On the right side of the Main Menu are the following options:

•

Quick:

Define and run a simple single- or dual-wavelength protocol. You can

select the primary and secondary wavelength values and the plate type. If

applicable to your reader model, shake and/or incubate options are available.

•

Protocol:

Edit, create (and save), delete, and copy protocols. You can define

the protocol name; select the primary and secondary wavelength values, read

speed, and plate type; and define blank well(s). If applicable to your reader

mode, shake options

are available.

The reader automatically performs delta OD and blank subtraction. To select the

dataset(s) for print or export, tap Instrument and then the Output tab.

•

Results:

reader (for the 12 most recently run protocols).

•

Instrument:

results output criteria; run an Absorbance Plate Test; and more.

View and optionally print/export measurement data stored on the

Configure the reader, printer, and USB flash drive settings; define

Configure Your 800 TS

After you install the reader, and before you use it to create and run protocols, perform the

tasks in this section to define important instrument settings.

Set the Time and Date

When you turn on the 800 TS for the first time, set or confirm the date and time at your

location.

BioTek Instruments, Inc.

Page 35

Operate the Reader Using the Touchscreen| 31

1. From the Main Menu, tap Instrument, the Config tab,

then the Time button.

2. Tap the hour value, and use the keypad to enter the

correct time for both the hour and minutes, then click OK

.

Note: You can change just the minutes value: Tap the

minutes value and enter the correct time.

3. Tap the Date button.

4. Tap month, day, or year, and use the keypad to set the

current date. Tap OK when done.

Verify or Change the Reader’s Filter Table

Important! The reader’s filter table must exactly match the contents of the installed

filter wheel.

800 TS

Page 36

32 | Operate the Reader Using the Touchscreen

Define Regional Settings

1. From the Main Menu, tap Instrument, the Config tab,

and then Filter Table. Filter wheel locations 1 through 5

are shown, with each location’s filter value (in nm) or

“plug” for a blank filter.

2. Verify that the values match the contents of the filter

wheel. See the Installation chapter for instructions for

accessing the filter wheel.

3. To change the setting for a filter wheel position, tap its

value and use the keypad to enter a wavelength value (in

nm), or select Plug. Tap OK when finished.

4. If you made any changes, tap Save in the Installed Filters

screen. The filter values are now available for selection in

protocols and the absorbance test plate setup screen.

1. From the Main Menu, tap Instrument, the Config tab,

and then Regional Settings.

Define Output Formats for Measurement Data

2. Tap to toggle between:

-Time format: AM/PM or 24 hour

-Date format: mm/dd/yyyy or dd/mm/yyyy

-Decimal symbol: period or comma (Note: This setting

does not apply to the system test report content.)

-List separator: comma or semicolon (used in the

exported report .csv file)

If you want to send results to a printer connected to the

reader:

1. From the Main Menu, tap Instrument, then tap the

Output tab.

2. Toggle the Printer button to Enabled, and select the

data to be included on the printout (you can select more

than one):

BioTek Instruments, Inc.

Page 37

Operate the Reader Using the Touchscreen| 33

•

Raw OD

: The raw measurement value for each well.

•

Delta OD

: Applicable only when a secondary wavelength is selected. This is the calculated

value for each well of the primary wavelength measurement minus secondary wavelength

measurement.

Blanked

•

. The calculated value for each well, either Raw OD minus the average of the

blank wells for single-wavelength reads or Delta OD minus the average of the blank wells

for dual

wavelength reads.

If you want to send results to a USB flash drive inserted in the reader, on the Output tab,

toggle the USB Flash Drive button among the options.

•

Report

: Generates a CSV file containing the measurement values (with Raw OD/Delta

OD/blanked values, as applicable). This file can be opened in Excel or other spreadsheet

software.

Gen5 Input

•

: Generates a text file that can be opened in Gen5 using the Read from File option.

This file contains only raw data, not delta ODs or blanks.

See page 92 for sample CSV and text files.

Define and Start a Quick Protocol

1. From the Main Menu, tap Quick.

2. In the Quick Menu, set the Primary and, if

applicable, Secondary wavelengths and plate type,

then tap Start.

Note: This screenshot is from an instrument

Note: You cannot define blank wells for a Quick read.

When the read is finished, the results are displayed.

Tap Output to send results to the printer or USB flash

drive.

with incubation and shake capabilities.

Create and Save a Protocol

The maximum number of uniquely named protocols that can be saved on the

touchscreen at the same time is 40.

Create a Protocol

1. From the home screen, tap Protocol, then tap Create.

800 TS

Page 38

34 | Operate the Reader Using the Touchscreen

2. Use the onscreen keyboard to enter a name for the

protocol, then tap OK.

Note: The <-- key circled in the figure is the backspace

key.

3. Toggle through the values to set a Primary

wavelength.

4. If applicable, toggle through the values to set a

Secondary wavelength. Otherwise, leave as “---.”

Note: The reader automatically performs Delta OD

subtraction.

5. Toggle to set a read speed: Normal, Rapid, or

Note that the Options tab is not displayed on all

instruments.

6.

Toggle to set the plate type: 6-, 12-, 24-, 48-, 96, or 384*-well microplates. Note: Only full plate

Sweep. See the Throughput values associated with

each read speed type in the Specifications appendix.

Note that Sweep is not available on the NB model.

reads are supported on the touchscreen. To read a partial plate, you must use Gen5.

7. If applicable, tap the Blank tab to add blank wells.

a. In the Blank Well screen, use the keypad to enter which well should be blank, then

tap OK.

b. Tap Add to enter more blank wells, up to 12.

8. If the reader is equipped with shake capability, tap Options and define a shake step, if

desired. Set the shake’s duration using the keypad and intensity by toggling through the

options.

9. Tap Save. The protocol now appears in the protocol list.

*Not all instruments support 384-well microplates.

BioTek Instruments, Inc.

Page 39

Operate the Reader Using the Touchscreen| 35

Start a Protocol

For instruments equipped with incubation capability: To perform incubation during

measurement, either turn on incubation from the Incubate tab (Quick Menu) or tap the

temperature to the left of the Run Protocol (in a defined protocol).

The onboard storage for the touchscreen can accommodate data for up to 12

microplate reads. The data is stored by date and time, not by filename. If 12 results are

already in onboard storage, the next read data saved will overwrite the oldest of the

saved results.

Note that only plate read results are saved. System Test and Absorbance Plate Test

results are not saved; they can only be exported to USB flash drive or printed.

1. From the Main Menu, tap the protocol you

want to run. The Run Protocol screen opens,

displaying the protocol’s parameters.

2. Place the microplate on the carrier, and tap

Start. When the read is finished, the results are

displayed. Tap Output to send results to the

printer or USB flash drive.

Change the Protocol Display Order

1. From the Main Menu, tap Instrument, then tap the Options tab.

2. In the Protocol display order field, select Alphabetically or Last accessed first.

Edit, Delete, or Copy a Protocol

Edit a Protocol

1. From the Main Menu, tap Protocol.

2. Tap the protocol that you want to modify, then tap Edit.

3. Make any desired changes, then tap Save.

800 TS

Page 40

BioTek Instruments, Inc.

36 | Operate the Reader Using Gen5 Software

Delete a Protocol

1. From the Main Menu, tap Protocol.

2. Tap the protocol you want to delete, then tap Delete.

Copy a Protocol

Copying an existing protocol and then editing it is a quick way to create a new protocol.

1. In the Main Menu, select the protocol you want to copy, then tap Copy.

2. You are prompted to enter a name for the copied protocol.

3. Make any desired changes, then tap Save.

View or Output Results Stored on the Reader

1. In the Main Menu, tap Results, then select the date/time of the read for which you

want to view or output results. The results are displayed on the touchscreen.

2. Tap Output. The results are printed and/or saved to the USB flash drive, depending

on the output format you selected.

Operate the Reader Using Gen5 Software

Gen5 RC (Reader Control) software is supplied with the 800 TS. This edition supports

only instrument control and data reporting/exporting. To perform kinetic reads, data

reduction, and custom exports, a software upgrade is required; contact BioTek

Customer Care.

BioTek Gen5 software supports all 800 TS reader models. Use Gen5 to control the reader;

perform data reduction and analysis on the measurement values; print or export results;

and more. This section provides brief instructions for working with Gen5 to create

protocols and experiments and read plates. Refer to the Gen5 Help system for more

information.

Page 41

Maintenance

Page 42

38 | Maintenance Overview

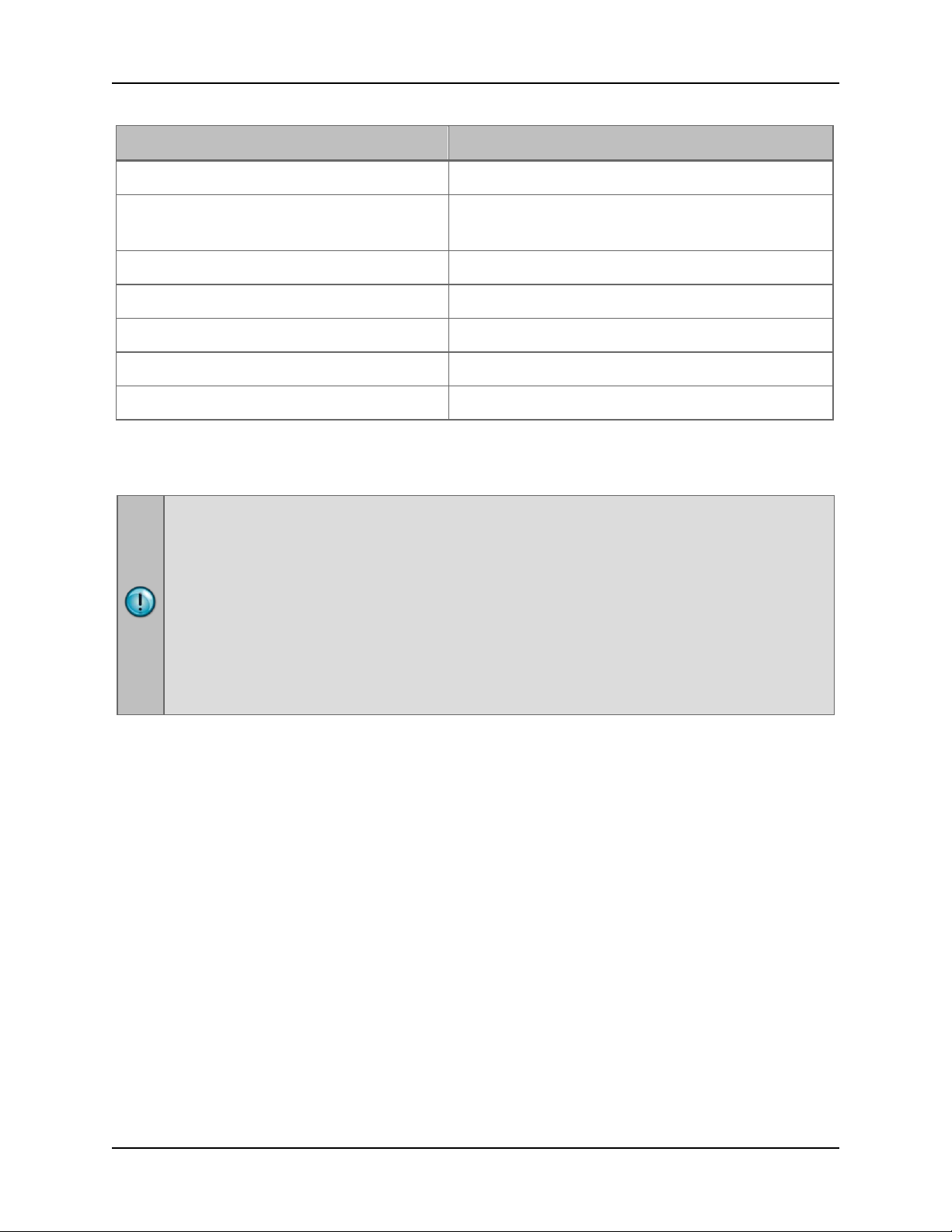

Task

Daily

Quarterly

As Needed

All models:

Clean exposed surfaces

x x

Inspect/clean touchscreen

x

Inspect/clean the wavelength filters

x

Decontamination

Before shipment or storage

handling contaminated instruments. Gloved

Maintenance Overview

A general maintenance regimen for all 800 TS models includes periodically cleaning all

exposed surfaces and decontaminating the instrument before storage or shipment.

Schedule

The risk and performance factors associated with your assays may require performing some of all of

the procedures more frequently than presented in this schedule.

Warnings and Precautions

Read the following before performing any maintenance procedures:

Warning! Internal Voltage. Turn off and unplug the instrument for all maintenance

and repair operations.

Important! Do not immerse the instrument, spray it with liquid, or use a drippingwet cloth on it. Do not allow water or other cleaning solution to run into the

interior of the instrument. If this happens, contact the BioTek Service Department.

Do not soak the touchscreen! This will cause damage. Moisten a clean cloth with

deionized or distilled water and wipe the touchscreen. Dry immediately with a

clean, dry cloth.

Important! Do not apply lubricants to the microplate carrier or carrier track.

Lubricant attracts dust and other particles, which may obstruct the carrier path and

cause errors.

Warning! Wear protective gloves when

hands should be considered contaminated at all times; keep gloved hands away

from eyes, mouth, nose, and ears.

BioTek Instruments, Inc.

Page 43

Clean Exposed Surfaces | 39

Warning! Mucous membranes are considered prime entry routes for infectious

agents. Wear eye protection and a surgical mask when there is a possibility of

aerosol contamination. Intact skin is generally considered an effective barrier

against infectious organisms; however, small abrasions and cuts may not always be

visible. Wear protective gloves when handling contaminated instruments.

Clean Exposed Surfaces

This procedure is for the housing of the 800 TS instrument. See "Clean the Touch

Screen" on page 39 for the cleaning procedure for the touchscreen.

Exposed surfaces may be cleaned (not decontaminated) with a cloth moistened (not soaked)

with water or water and a mild detergent. You’ll need:

•

Mild detergent

•

Deionized or distilled water

•

Clean, lint-free cotton cloths

1. Turn off and unplug the instrument.

2. Wet a clean cotton cloth with water, or with water and mild detergent, then

thoroughly wring out the cloth so that liquid does not drip from it.

3. Wipe the plate carrier, the inside of the plate carrier door (if equipped), and all exposed

surfaces of the instrument.

4. If detergent was used, wipe all surfaces with a cloth moistened with water.

5. Use a clean, dry, lint-free cloth to dry all wet surfaces.

Clean the Touchscreen

Important! Never spray solutions directly on the touchscreen.

Materials

Use the following products to safely clean the touchscreen:

•

Deionized or distilled water

•

Dish soap or other mild cleaner

•

Lintfree disposable towels

800 TS

Page 44

40 | Decontamination

Avoid the following cleaning products:

•

Strong solvents, such as alcohol, acetone, ammonium chloride,

methylene

chloride, and hydrocarbons, which can permanently damage

the surface of the touchscreen.

•

Fibrous materials, such as paper towels, which can scratch the

touchscreen. Over time, dirt particles and cleaning agents can get

trapped

in the scratches.

Procedure

Important! Never spray solutions directly on the touchscreen.

Turn off and unplug the instrument.

1. Moisten a clean, lint-free disposable cloth with water, or with water and mild detergent,

then thoroughly wring it out so that liquid does not drip from it. Do not soak the cloth.

2. Wipe the touch screen gently with the moist cloth.

3. If detergent was used, wipe the touchscreen with a cloth moistened with water.

4. Dry the screen gently using another cloth.

Decontamination

Any laboratory instrument that has been used for research or clinical analysis is considered

a biohazard and requires decontamination prior to handling.

Decontamination minimizes the risk to all who come into contact with the instrument

during shipping, handling, and servicing. Decontamination is required by the U.S.

Department of Transportation regulations.

Persons performing the decontamination process must be familiar with the basic setup and

operation of the instrument.

Turn off and unplug the instrument for the decontamination procedure.

BioTek Instruments, Inc., recommends the use of the following decontamination

solutions and methods based on our knowledge of the instrument and

recommendations of the Centers for Disease Control and Prevention (CDC). Neither

BioTek nor the CDC assumes any liability for the adequacy of these solutions and

methods. Each laboratory must ensure that decontamination procedures are

adequate for the biohazard(s) they handle.

BioTek Instruments, Inc.

Page 45

Wear prophylactic gloves when handling contaminated instruments. Gloved hands

should be considered contaminated at all times; keep gloved hands away from

eyes, mouth, and nose. Eating and drinking while decontaminating instruments is

not advised.

Mucous membranes are considered prime entry routes for infectious agents. Wear

eye protection and a surgical mask when there is a possibility of aerosol

contamination. Intact skin is generally considered an effective barrier against

infectious organisms; however, small abrasions and cuts may not always be visible.

Wear protective gloves when performing the decontamination procedure.

Decontaminating the Reader Housing

Required Materials

•

Sodium hypochlorite (NaClO, or bleach)

•

70% isopropyl alcohol (as an alternative to bleach)

•

Deionized or distilled water

Decontamination | 41

•

Safety glasses

•

Surgical mask

•

Protective gloves

•

Lab coat

•

Biohazard trash bags

•

125-mL beakers

•

Clean, lint-free cotton cloths

Procedure

1. Turn off and unplug the reader from the power supply.

2. Prepare an aqueous solution of 0.5% sodium hypochlorite (NaClO, or bleach). If the

effects of bleach are a concern, 70% isopropyl alcohol may be used.

Check the percent NaClO of the bleach you are using. Commercial bleach is typically

10.0% NaClO; prepare a 1:20 dilution. Household bleach is typically 5.0% NaClO;

prepare a 1:10 dilution.

3. Moisten a clean, lint-free cloth with the bleach solution, then thoroughly wring it out so

that liquid does not drip from it. Do not soak the cloth.

4. Wipe the plate carrier and all exposed surfaces of the instrument, except the touch

800 TS

screen (if equipped).

Page 46

42 | Filter Storage and Handling

5. Allow the instrument to dry for 20 minutes for thorough decontamination by the bleach.

6. Moisten a cloth with deionized or distilled water and wipe all surfaces of the instrument

that have been cleaned with the bleach solution.

7. Use a clean, dry lint-free cloth to dry all wet surfaces.

8. Discard the used gloves and cloths, using a biohazard trash bag and an approved

biohazard container.

Decontaminating the Touchscreen

When decontaminating the 800 TS, as described on page 47, do not spray the bleach

solution on the touchscreen. Avoid fibrous materials that can scratch the surface. Do not

use a stronger bleach solution or cleaning solvent than recommended.

Filter Storage and Handling

To properly store interference filters during extended periods of non-use, package the

filters in a light-tight envelope or container, away from high humidity. This will ensure the

longest life for the filters. When handling the filters, keep the surfaces clean from

fingerprints and debris by simply wiping with a lens tissue or other lint-free cloth.

When changing or replacing filters, it is critical that the filters be placed in the

filter wheel in the correct orientation, with the light-direction arrow pointing

downward. Also, the reader or Gen5 software filter table must exactly match the

contents of the filter wheel.

1. Use a clean, dry lint-free cloth to dry all wet surfaces.

2. Discard the used gloves and cloths, using a biohazard trash bag and an approved

biohazard container.

Decontaminating the Touchscreen

When decontaminating the 800 TS, as described on page 47, do not spray the bleach

solution on the touchscreen. Avoid fibrous materials that can scratch the surface. Do not

use a stronger bleach solution or cleaning solvent than recommended.

Filter Storage and Handling

To properly store interference filters during extended periods of non-use, package the

filters in a light-tight envelope or container, away from high humidity. This will ensure the

longest life for the filters. When handling the filters, keep the surfaces clean from

fingerprints and debris by simply wiping with a lens tissue or other lint-free cloth.

BioTek Instruments, Inc.

Page 47

Filter Storage and Handling | 43

When changing or replacing filters, it is critical that the filters be placed in the

filter wheel in the correct orientation, with the light-direction arrow pointing

downward. Also, the reader or Gen5 software filter table must exactly match the

contents of the filter wheel.

800 TS

Page 48

BioTek Instruments, Inc.

44 | Filter Storage and Handling

Page 49

Instrument Testing

Page 50

46 | System Test

System Test

Each time the 800 TS is turned on, it automatically performs a series of tests on the

reader’s motors, lamp, and optical systems. If all tests pass, the microplate carrier moves

to its forward position and the Main Menu appears on the touchscreen.

If any test results do not meet the internally coded Failure Mode Effects Analysis (FMEA)

criteria established by BioTek, the reader beeps repeatedly and an error message appears

on the touchscreen. If this occurs, tap OK on the touchscreen to stop the beeping. If

necessary, initiate another system test using Gen5 or the touchscreen to try to retrieve an

error code from the reader.

Absorbance Test Plates

Absorbance Test Plate PN 7260522 uses NIST-traceable neutral density filters to confirm

absorbance specifications in the visible range (400–800 nm). This test plate also contains

precision-machined holes to verify mechanical alignment. Absorbance Test Plate PN

7260551 uses NIST-traceable neutral density filters to confirm absorbance specifications in

the UV range (340 nm).

Define the Absorbance Test Plate Parameters

Using the Touchscreen

1. Obtain the current Test Plate Calibration Certificate.

2. From the Main Menu, tap Instrument, then tap Test Plate.

3. Tap Test Plate Certificate and enter the plate’s serial number and Next Calibration Due

date, then tap Back to return to the Test Plate tab.

4. The wavelength selection buttons reflect the filters installed in the reader. Tap each

button, and enter the OD Standard values from the Calibration Certificate into the grid.

Make sure you enter the correct value for each well/wavelength combination.

Using Gen5

1. Obtain the current Test Plate Calibration Certificate.

2. Start Gen5, and select System > Diagnostics > Test Plates > Add/Modify Plates.

3. Click Add. The Absorbance Test Plate dialog appears.

4. Select the appropriate Plate Type, and then enter the plate's serial number.

5. Enter the Last Certification and Next Certification dates from the calibration label on

the Test Plate.

6. If the wavelength values in the top row of the grid in Gen5 are appropriate for your

tests, enter the OD Standard values from the Calibration Certificate into the grid. Make

sure you enter the correct value for each well/wavelength combination.

BioTek Instrument, Inc.

Page 51

Absorbance Test Plates | 47

If you need to change the wavelength values, click Wavelength List. Add, change, or

delete the values as needed and click OK.

7. Review all of the values that you entered. When finished, click OK to save the

information.

Running the Absorbance Plate Test

Using the Touchscreen

1. Place the Absorbance Test Plate on the microplate carrier, with well A1 in the proper

location.

2. From the Main Menu, tap Instrument and then Test Plate.

3. Tap a Wavelength Selection button, then tap Start.

4. When the test is complete, choose an Output option (Print or USB Report), or tap Exit

to return to the Main Menu.

Using Gen5

1. From the Gen5 main screen, click System > Diagnostics > Test Plates > Run. If

prompted, select the desired Test Plate and click OK.

2. When the Absorbance Test Plate Options dialog appears, enter any required

information.

3. Highlight the wavelength(s) to be included in this test.

You need to select only those wavelengths most appropriate for your use of the reader.

4. (Optional) Enter a comment.

5. Click Start Test.

6. Place the Absorbance Test Plate on the microplate carrier, with well A1 in the proper

location.

7. Click OK to run the test.

8. When the test is complete, the results report appears. Scroll through the report; every

result should show “PASS”.

800 TS

Page 52

48 | Liquid Tests

Liquid Tests

Be sure to use a new microplate, because fingerprints or scratches may cause variations

in readings.

Materials

•

New 96-well, clear, flat-bottom microplate (Corning Costar #3590 recommended)

•

Stock Solution A or B, which may be formulated by diluting a dye solution available

Solution A

from BioTek (A) or from the materials listed below (B).

•

BioTek QC Check Solution No. 1 (PN 7120779, 25 mL; or 7120782, 125 mL)

•

Deionized water

•

5-mL Class A volumetric pipette

•

100-mL volumetric flask

1. Pipette a 5-mL aliquot of BioTek QC Check Solution No. 1 into a 100-mL volumetric flask.

2. Add 95 mL of DI water; cap and shake well. The solution should measure approximately

2.000 OD when using 200 µL in a flat-bottom microwell.

Solution B

•

Deionized water

•

FD&C Yellow No. 5 dye powder (typically 90% pure)

•

Tween 20 (polyoxyethylene (20) sorbitan monolaurate) or BioTek wetting agent, PN

7773002 (a 10% Tween solution)

•

Precision balance with capacity of 100 g minimum and readability of 0.001 g

•

Liter volumetric flask

•

Weigh boat

1. Weigh out 0.092 gram of FD&C No. 5 yellow dye powder into a weigh boat.

2. Rinse the contents into a 1-liter volumetric flask.

3. Add 0.5 mL of Tween 20, or 5 mL of BioTek’s wetting agent.

4. Make up to 1 liter with DI water; cap and shake well.

BioTek Instrument, Inc.

Page 53

Procedure

Be sure to use a new microplate. Debris, fingerprints, or scratches may cause

variations in readings.

1. Using freshly prepared stock solution (Solution A or B), prepare a 1:2 dilution using

deionized water (one part stock, one part deionized water; the resulting solution is a 1:2

dilution). The concentrated stock solution should have an optical density of

approximately 2.000 OD or lower.

2. Pipette 200 µL of the stock solution into column 1.

3. Pipette 200 µL of the diluted solution into column 2.

After pipetting the diluted test solution into the microplate and before reading

the plate, we strongly recommend shaking the plate for four minutes. This will

allow any air bubbles in the solution to settle and the meniscus to stabilize.

Alternatively, wait 20 minutes after pipetting the test solution before reading the

plate.

Liquid Tests | 49

4. Using either the touchscreen or Gen5, read the microplate five times at 405

nm using the Normal Read Speed. When prompted, rotate the plate 180

degrees and read the plate five more time (“Turnaround” plate position), saving

the data after each read.

5. Print the ten sets of raw data, (from the touchscreen) send it to the USB flash

drive for use in another program, or (from Gen5) export it to an Excel

spreadsheet.

Calculations

Absorbance Liquid Test 1

Accuracy Specification:

± 1.0% ± 0.010 OD from 0.000 to 2.000 OD

Repeatability Specification:

± 0.5% ± 0.005 OD from 0.000 to 2.000 OD

1. The plate is read five times in the “Normal” position at 405 nm. Calculate the Mean OD

and Standard Deviation of those five reads for each well in columns 1 and 2.

2. For each well in columns 1 and 2, calculate the Allowed Deviation using the

Repeatability specification for a 96-well plate (Mean OD x 0.05 + 0.005). For each well,

its Standard Deviation should be less than its Allowed Deviation.

800 TS

Page 54

50 | Liquid Tests

Example: Five readings in well A1 of 0.802, 0.802, 0.799, 0.798, and 0.801 result in a

Mean of 0.8004 and a Standard Deviation of 0.0018. The Mean multiplied by 0.5%

(0.8004 * 0.005) equals 0.004, and when added to 0.005 equals 0.009; this is the Allowed

Deviation for well A1. Since the Standard Deviation for well A1 is less than this value, the

well meets the test criteria.

3. The plate is read five times in the “Turnaround” position at 405 nm. Calculate the Mean

OD of those five reads for each well in columns 11 and 12.

4. Perform a mathematical comparison of the Mean values for each well in its Normal and

Turnaround positions (that is, compare A1 to H12, A2 to H11, B1 to G12,… H2 to A11). To

pass the test, the differences in the compared Mean values must be within the Accuracy

specification for a 96-well microplate.

Example: If the Mean value for well A1 in the Normal position is 1.902 with a specified

accuracy of ±1.0% ±0.010 OD, then the expected range for the Mean of the well in its

Turnaround (H12) position is 1.873 to 1.931 OD. 1.902 x 0.010 + 0.010 = 0.029; 1.902 -

0.029 = 1.873; 1.902 + 0.029 = 1.931.

BioTek Instrument, Inc.

Page 55

Specifications

Page 56

52 | General Specifications

General Specifications

Microplates

The 800 TS accommodates standard 6-, 12-, 24-, 48-, 96-, and (with the NB model) 384-well microplates

with 128 x 86 mm geometry and, if using Gen5 software with the NB model, 60-, 75-, and 96-well

Terasaki plates and BioCell vessels.

Maximum plate height: 0.90" (22.86 mm)

Hardware and Environmental

Light Source

800TS/800TSI models: Tungsten gas-filled bulb.

800TSUV/800TSUVI/800TSNB models: Halogen bulb

Dimensions 16.5" D x 15" W x 7" H (41.9 x 38.1 x 17.8 cm)

Weight: < 22 lbs (10 kg)

Environment: Operational temperature range: 18° to 40°C

Humidity: 10% to 85% relative humidity (non-condensing)

Power Supply: 24-volt DC power supply compatible with 100–240 V AC @50–60 Hz

Power Consumption:

40W maximum, non-incubated models; 150W maximum, incubated

models

Temperature control for 800TSI model: 6°C over ambient to 50°C.

Incubation:

Temperature control for 800TSUVI model: 8°C over ambient to 50°C

Temperature stability and uniformity is ± 0.5°C across the plate @ 37°C.

BioTek Instruments, Inc.

Page 57

Absorbance Specifications

Standard Models (800TS/800TSI)

Wavelength Range: 400 nm to 750 nm

Absorbance Measurement Range

Normal Read Mode: 0.000 to 4.000 OD

Rapid Read Mode: 0.000 to 4.000 OD

Sweep Read Mode: 0.000 to 3.000 OD

Absorbance Resolution

0.001 OD when operated in standalone mode

0.0001 OD when operated with Gen5

General Specifications | 53

Accuracy

Normal Read Mode: ±1.0% ±0.010 OD from 0.000 to 2.000 OD @ 405 nm

Rapid Read Mode: ±2.0% ±0.020 OD from 0.000 to 2.000 OD @ 405 nm

Sweep Read Mode: ±1.0% ±0.020 OD from 0.000 to 1.000 OD @ 405 nm

Linearity

Normal Read Mode: ±1.0% ±0.010 OD from 0.000 to 2.000 OD @ 405 nm

±3.0% ±0.010 OD from 2.000 to 3.000 OD @ 450 nm

Rapid Read Mode: ±2.0% ± 0.010 OD from 0.000 to 2.000 OD @ 405 nm

Sweep Read Mode: ± 1.0% ± 0.010 OD from 0.000 to 1.000 OD @ 405 nm

Repeatability (STD)

Normal Read Mode: ± 0.5% ± 0.005 OD from 0.000 to 2.000 OD @ 405 nm

Rapid Read Mode: ± 1.0% ± 0.010 OD from 0.000 to 2.000 OD @ 405 nm

Sweep Read Mode: ± 2.0% ± 0.020 OD from 0.000 to 1.000 OD @ 405 nm

800 TS

Page 58

54 | General Specifications

Throughput

From carrier start to carrier stop:

96-Well, Single Wavelength, Normal Read Mode: 39 seconds

96-Well, Dual Wavelength, Normal Read Mode: 73 seconds

96-Well, Single Wavelength, Rapid Read Mode: 26 seconds

96-Well, Single Wavelength, Sweep Read Mode: 18 seconds

Ultraviolet (UV) Models (800TSUV/800TSUVI)

Wavelength Range: 340 nm to 750 nm

Absorbance Measurement Range

Normal and Rapid Read Mode (340 nm–399 nm): 0.000 to 4.000 OD

Normal and Rapid Read Mode (400 nm–750 nm): 0.000 to 4.000 OD

Sweep Read Mode (400 nm–750 nm): 0.000 to 3.000 OD

Absorbance Resolution

0.001 OD when operated in standalone mode

0.0001 OD when operated with Gen5

Accuracy (340 nm to 399 nm)

Normal Read Mode: ±2.0% ± 0.010 OD from 0.000 to 2.000 OD @ 340 nm

Rapid Read Mode: ±2.5% ± 0.020 OD from 0.000 to 2.000 OD @ 340 nm

Accuracy (400 nm to 750 nm)

Normal Read Mode: ±1.0% ± 0.010 OD from 0.000 to 2.000 OD @ 405 nm

Rapid Read Mode: ±2.0% ± 0.020 OD from 0.000 to 2.000 OD @ 405 nm

Sweep Read Mode: ±1.0% ±0.020 OD from 0.000 to 1.000 OD @ 405 nm

Linearity (340 nm to 399 nm)

Normal Read Mode: ±2.5% ± 0.010 OD from 0.000 to 2.000 OD @ 340 nm

Rapid Read Mode: ±2.5% ± 0.010 OD from 0.000 to 2.000 OD @ 340 nm

BioTek Instruments, Inc.

Page 59

Linearity (400 nm to 750 nm)

Normal Read Mode: ±1.0% ± 0.010 OD from 0.000 to 2.000 OD @ 405 nm

±3.0% ± 0.010 OD from 2.000 OD to 3.000 OD @ 450 nm

Rapid Read Mode: ±2.0% ± 0.010 OD from 0.000 to 2.000 OD @ 405 nm

Sweep Read Mode: ±1.0% ± 0.010 OD from 0.000 to 1.000 OD @ 405 nm

Repeatability (340 nm to 399 nm)

Normal Read Mode: ±1.5% ± 0.005 OD from 0.000 to 2.000 OD @ 340 nm

Rapid Read Mode: ±2.0% ± 0.020 OD from 0.000 to 2.000 OD @ 340 nm

Repeatability (400 nm to 750 nm)

Normal Read Mode: ±0.5% ± 0.005 OD from 0.000 to 2.000 OD @ 405 nm

General Specifications | 55

Rapid Read Mode: ±1.0% ± 0.010 OD from 0.000 to 2.000 OD @ 405 nm

Sweep Read Mode: ±2.0% ± 0.020 OD from 0.000 to 1.000 OD @ 405 nm

Throughput

From carrier start to carrier stop:

96-Well, Single Wavelength, Normal Read Mode: 39 seconds

96-Well, Dual Wavelength, Normal Read Mode: 73 seconds

96-Well, Single Wavelength, Rapid Read Mode: 26 seconds

96-Well, Single Wavelength, Sweep Read Mode: 18 seconds

Narrow Bean (NB) Models (800TSNB)

Wavelength Range: 400 nm to 750 nm

Absorbance Measurement Range

Normal and Rapid Read Mode (96-well): 0.000 to 4.000 OD

Normal and Rapid Read Mode (384-well): 0.000 to 4.000 OD

800 TS

Page 60

BioTek Instruments, Inc.

56 | General Specifications

Absorbance Resolution

0.001 OD when operated in standalone mode

0.0001 OD when operated with Gen5

Accuracy

Normal Read Mode (96-well): ±1.0% ±0.010 OD from 0.000 to 2.000 OD @ 405 nm

Rapid Read Mode (96-well) ±2.0% ±0.020 OD from 0.000 to 2.000 OD @ 405 nm

Normal Read Mode (384-well): ±2.0% ±0.020 OD from 0.000 to 2.000 OD @ 405 nm

Rapid Read Mode (384-well): ±2.5% ±0.020 OD from 0.000 to 2.000 OD @ 405 nm

Linearity

Normal Read Mode (96-well):

Rapid Read Mode (96-well): ±2.0% ± 0.010 OD from 0.000 to 2.000 OD @ 405 nm

Normal Read Mode (384-well): ±2.5% ± 0.010 OD from 0.000 to 2.000 OD @ 405 nm

Rapid Read Model (384-well): ±2.5% ± 0.010 OD from 0.000 to 2.000 OD @ 405 nm

±1.0% ± 0.010 OD from 0.000 to 2.000 OD at 405 nm

±3.0% ±0.010 OD from 2.000 to 3.000 OD @ 450 nm

Repeatability (STD)

Normal Read Mode (96-well): ±0.5% ± 0.005 OD from 0.000 to 2.000 OD @ 405 nm

Rapid Read Mode (96-well): ±1.0% ± 0.010 OD from 0.000 to 2.000 OD @ 405 nm

Normal Read Mode (384-well): ±1.5% ± 0.010 OD from 0.000 to 2.000 OD @ 405 nm

Rapid Read Mode (384-well): ±2.0% ± 0.010 OD from 0.000 to 2.000 OD @ 405 nm

Throughput

From carrier start to carrier stop:

96-Well, Single Wavelength, Normal Read Mode: 38

seconds 96-Well, Single Wavelength, Rapid Read Mode:

26 seconds

384-Well, Dual Wavelength, Normal Read Mode: 3 minutes, 40

seconds 384-Well, Dual Wavelength, Rapid Read Mode: 2 minutes

Loading...

Loading...