Page 1

50™ TS Washer Instructions for Use

(For In Vitro Diagnostic Use)

April 2017

© April 2017

Part Number 1551010

Revision A

BioTek Instruments, Inc.

Page 2

ii | Preface

Notices

BioTek Instruments, Inc.

Highland Park, P.O. Box 998

Winooski, Vermont 05404-0998 USA

All Rights Reserved

© April 2017, BioTek® Instruments, Incorporated. No part of this publication

may be reproduced, transcribed, or transmitted in any form, or by any means

electronic or mechanical, including photocopying and recording, for any purpose

other than the purchaser’s use without written permission of BioTek

Instruments, Inc.

Trademarks

BioTek

®

is a registered trademark and 50™ TS Washer is a trademark of BioTek

Instruments, Inc.

Microsoft®, Internet Explorer®, Windows®, Windows 7, Windows 10, and Excel®

are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

All other trademarks are the property of their respective holders.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a

commitment by BioTek Instruments, Inc. Changes made to the information in

this document will be incorporated in new editions of the publication. No

responsibility is assumed by BioTek for the use or reliability of software or

equipment that is not supplied by BioTek or its affiliated dealers.

50™ TS Washer

Page 3

Contact Information

Phone:

888-451-5171 (toll free in the U.S.)

802-655-4740 (outside the U.S.)

Fax:

802-655-7941

E-Mail:

customercare@biotek.com

Phone:

800-242-4685 (toll free in the U.S.)

802-655-4740 (outside the U.S.)

Fax:

802-654-0638

E-Mail:

tac@biotek.com

Internet:

www.biotek.de

Phone:

+49 (0) 7136 9680

Fax:

+49 (0) 7136 968 111

E-Mail:

info@biotek.de

BioTek Instruments, Inc.

Highland Park, P.O. Box 998

Winooski, Vermont 05404-0998 USA

Customer Service and Sales

Service/TAC

| iii

European Coordination Center/Authorized European Representative

BioTek Instruments GmbH

Kocherwaldstrasse 34

D-74177 Bad Friedrichshall

Germany

Instructio ns for Use Req uirements

This document fulfills the basic needs of persons operating this device, according to

the requirements of the In Vitro Diagnostic Directive for “Instructions for Use.” Some

of the device’s higher-level functions and features, as well as certain detailed

maintenance and qualification routines, are described in the 50™ TS Washer

Operator’s Manual.

Intended Use Statement

• The 50™ TS Washer provides microplate priming, dispensing, and washing fo r ELISA™,

fluorescence and chemiluminescence immunoassays, cellular and agglutination assays.

BioTek Instruments, Inc.

Page 4

iv | Preface

• If the instrument has an “IVD” label it may be used for clinical and non-clinical

purposes, including research and development. If there is no such label the instrument

may only be used for research and development or other non-clinical purposes

Quality Control

It is considered good laboratory practice to run laboratory samples according to

instructions and specific recommendations included in the assay package insert for

the test to be conducted. Failure to conduct Quality Control checks could result in

erroneous test data.

Warnings

Operate the instrument on a level, stable surface away from excessive humidity.

When operated in a safe environment, according to the instructions in this

manual, there are no known hazards associated with the 50™ TS Washer.

However, the oper ator should be aware of certain situations that could re sult in

serious injury. See Hazards and Precautions

Strict adherence to instrument maintenance and qualification procedures is

required to ensure accurate dispense volumes and risk-free op era t ion.

Error! Bookmark not defined..

50™ TS Washer

Page 5

Hazards and Precautions

supply or power cord must be

Hazards

The following hazards are provided to help avoid injury:

Warning! Power Rating. The instrument’s power

connected to a power receptacle that provides voltage and current within the

specified rating for the system. Use of an incompatible power receptacle may

produce electrical shock and fire hazards.

| v

Warning! Lubricants. Do not apply lubricants to the microplate carrier or

Warning! Electrical Grounding. Never use a plug adapter to connect primary

power to the external power supply. Use of an adapter d isconnects the utility

ground, creating a severe shock hazard. Always connect the power cord directly

to an appropriate receptacle with a functional ground.

Warning! Service. Only qualified technical personnel should perform service

procedures on internal components.

Warning! Accessories. Only accessories which meet the manufacturer’s

specifications shall be used with the instrument.

carrier track. Lubricant on the carrier mechanism will attract dust and other

particles, which may obstruct the carrier path and cause the instrument to

produce an error.

BioTek Instruments, Inc.

Page 6

vi | Preface

Warning! Liquids. Avoid spilling liquids on the instrument; fluid seepage into

internal components creates a potential for shock hazard or instrument damage.

If a spill occurs while a program is running, abort the program and turn the

instrument off. Wipe up all spills immediately. Do not operate the instrument if

internal components have been exposed to fluid.

Warning! Unspecified Use. Failure to operate this equipment according to the

guidelines and safeguards specified in this manual could result in a hazardous

condition.

Warning! Direct Drain Waste. If installed, the direct drain waste system

pumps waste fluids from the washer directly into a s ink or ta nk, and, potentially

into public waste water systems. Because the waste may be a biohazard, you

must ensure that you are in compliance with your local or national government’s

laws regarding safe disposal of the waste.

Warning! Software Quality Control. The operator must follow the

manufacturer’s assay package insert when modifying software parameters and

establishing washing or dispensing methods. Failure to conduct quality

control checks could result in erroneous test data.

Warning! Internal Voltage. Always turn off the power switch and unpl ug the

power supply before cleaning the outer surface of the instrument.

Warning! Potential Biohazards. Some assays or specimens may pose a

biohazard. Adequate safety precautions should be taken as outlined in the

assay’s package insert. This hazard is noted by the symbol shown here. Always

wear safety glasses and appropriate protective equipment, such as chemically

resistant rubber gloves and apron.

Warning! Pinch Hazard. Do not reach under the instrument during operation;

the syringe pump may pinch your fingers.

Precautions

The following precautions are provided to help avoid damage to the instrument:

Caution: Service. The instrument should be serviced by BioTek authorized

service personnel. Only qualified technical personnel should perform

troubleshooting and service procedures on internal components.

50™ TS Washer

Page 7

Cautio n: Spare Parts. Only approved spare parts should be used for

the recommended diluted sodium hypochlorite solution (bleach) for more than 20

p into sensitive components. Make sure that any spilled

formaldehyde, and

Solutions containing proteins, such as bovine

instrument is provided and maintained in order that the device will perform as

maintenance. The use of unapproved spare parts and accessories may result in a

loss of warranty and potentially impair instrument performance or cause damage

to the instrument.

Caution: Environmental Conditions. Do not expose the instrument to

temperature extremes. For proper operation, ambient temperatures should

remain within the range listed in the Specifications section. Performance may

be adversely affected if temperatures fluctuate above or below this range.

Storage temperature limits are broader.

Caution: Sodium Hypochlorite. Do not expose any part of the instrument to

minutes. Prolonged contact may damage the instrument surfaces. Be certain to

rinse and thoroughly wipe all surfaces.

Caution: Buffer Solution. Although many precautions have been t aken to

ensure that the instrument is as corrosion-proof as possible, the instrument is not

sealed and liq uids can see

buffer solution is wipe d off the instrument. Prolonged exposure to sa lt solution

may corrode parts of the microplate carrier, movement rail, springs, and other

hardware.

| vii

Caution: Chemical Compatibility. Some chemicals may cause irreparable

damage to the instrument. The following chemicals have been deemed safe for

use in the instrument: buffer solutions (such a s PBS), saline, surfacta nt s,

deionized wa ter, 70% ethyl, isopropyl, or methyl alcohol, 40%

20% sodium hydroxide. Never use acetic acid, DMSO, or other organic solvents.

These chemicals may cause severe damage to the instrument. Contact BioTek for

more information and prior to using other questionable chemicals.

Caution: Bov ine Serum Albumin.

serum albumin (BSA), will compromise the instrument’s performance over time

unless a strict maintenance protocol is adhered to. See Maintenance procedures

regarding BSA.

Caution: Power Supply. Only use the power supply shipped with the

instrument. Operate this power supply within the range of line voltages listed on

it.

Caution: Disposal. Dispose of the instrument according to Directive

2012/19/EU, “on waste electrical and electronic equipment (WEEE)” or local

ordinances.

Caution: Warranty. Failure to follow preventive maintenance protocols may

void the warranty.

Caution: Shipping Hardware. All shipping hardware (e.g., shipping bracket

etc.) must be removed before operating the instrument and reinstalled before

repackaging the instrument for shipment.

Caution: Electromagnetic Environment. Per IEC 61326-2-6 it is the user’s

responsibility to ensure that a compatible electrom a gnetic environment for this

BioTek Instruments, Inc.

Page 8

viii | Preface

intended.

Do not substitute the fluid supply

Caution: Electromagnetic Compatibility. Do not use this device in close

proximity to sources of strong electromagne tic radiation (e.g., unshielded

intentional RF sources), because these may interfere with the proper operation.

Caution: Use BioT ek-Provided Bottles Only.

and waste bottles provided by BioTek with other com merc ially-available bottles.

BioTek provides bottles that perform well with our liquid handling systems,

including the vacuum pressure of the waste system.

Caution: Touc hscreen. Do not use sharp implements to operate the

touchscreen. Using a s harp stylus or any implemen t harder than a finger may

damage the display.

CE Mark

Based on the testing described below and information contained

herein, this instrume nt bears the CE mark.

Note: See the Declaration of Conformity for specific information.

Directive 2014/30/EU: Electromagnetic Compatibility

Emissions—Class A

The system has been type-tested by an independent, accredited testing laboratory

and found to meet the requirements of EN 61326-1: Class A for Radiated

Emissions and Line Conducted Emissions.

Verification of compliance was conducted to the limits and methods of EN 55011

(CISPR 11) Class A. In a domestic environment it may cause radio interference, in

which case, you may need to mitigate the interference.

Immunity

The system has been type-tested by an independent, accredited testing laboratory

and found to meet the requirements of EN 61326-1 and EN 61326-2-6 for

Immunity. Verification of compliance was conducted to the limits and methods of

the following:

EN 61000-4-2, Electrostatic Discharge

EN 61000-4-3, Radiated EM Fields

EN 61000-4-4, Electrical Fast Transient/Burst

EN 61000-4-5, Surge Immunity

50™ TS Washer

Page 9

EN 61000-4-6, Conducted Disturbances from RFI

EN 61000-4-11, Voltage Dips, Short Interruptions and Variations

Directive 2014/35/EU Low Voltage (Safety)

The system has been type-tested by an independent testing laboratory and was

found to meet the requirements of this Directive. Verification of compliance was

conducted to the limits and methods of the following:

EN 61010-1, “Safety requirement for electrical equipment for measurement,

control and laboratory use. Part 1, General requirements.”

EN 61010-2-081, “Particular requirements for automatic and semi-automatic

laboratory equipment for analysis and other purposes.”

Directive 2012/19/EU: Waste Electrical and Electronic Equipment

| ix

Disposal Notice: Dispose of the instrument according to Directive 2012/19/EU,

“on waste electrical and electronic equipment (WEEE)” or local ordinances.

Directive 98/79/EC: In Vitro Diagnostics (if labeled for this use)

• Product registration with competent authorities.

• Traceability to the U.S. National Institute of Standards and Technology (NIST).

• EN 61010-2-101 Particular requirements for in vitro diagnostic (IVD) medical

equipment.

BioTek Instruments, Inc.

Page 10

x | Preface

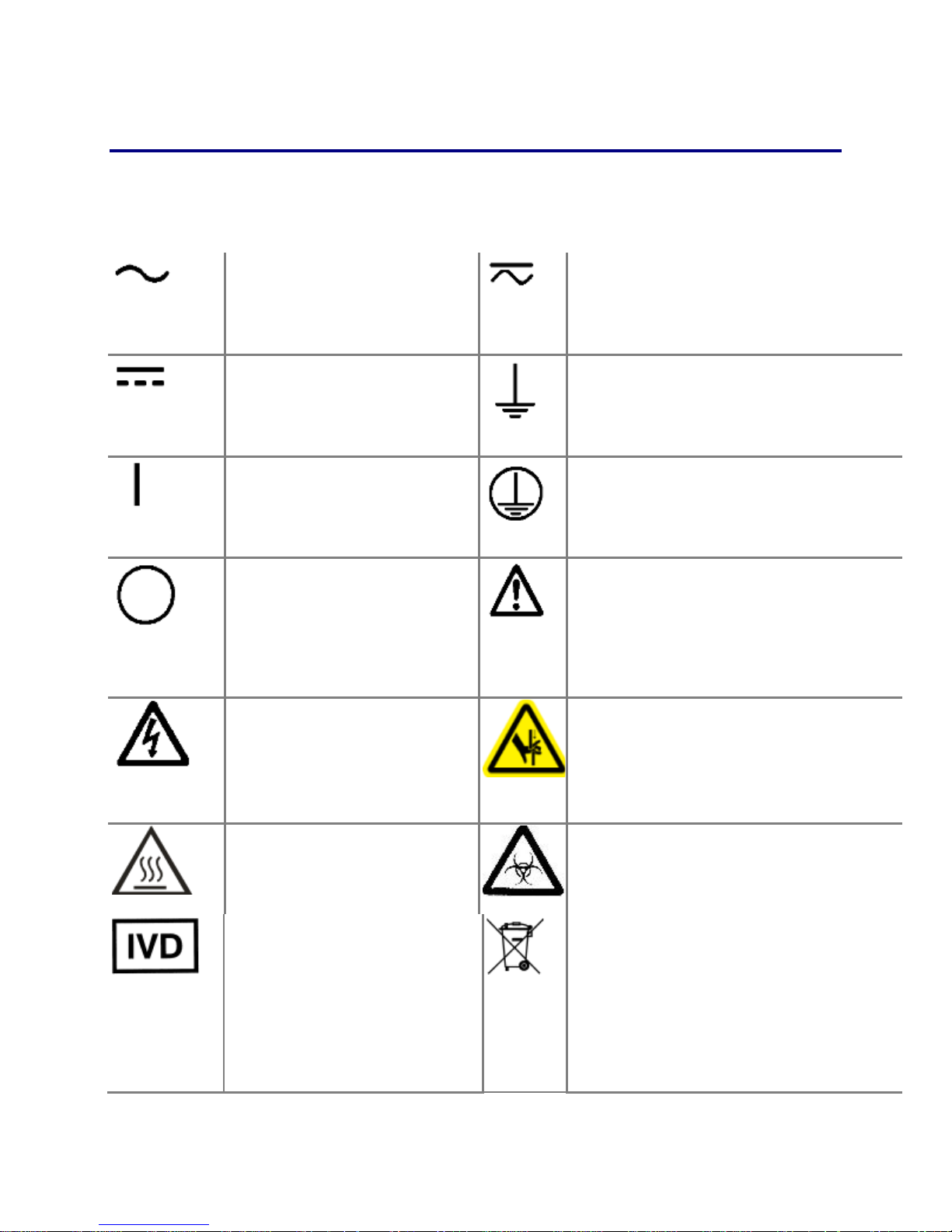

Alternating current

Both direct and alternating current

Corrente continua e correntealternata

Direct current

Earth ground terminal

Terra (difunzionamento)

On (Supply)

Protective conductor terminal

Terra diprotezione

Off (Supply)

Caution (refer to accompanying

Attenzione, consultare la doc annessa

Warning, risk of electric shock

Attenzione, rischiodiscossae lettrica

Warning, risk of crushing or pinching

Attenzione, rischiodischiaccia reedintrappolarsi

Warning, hot surface

Attenzione, su p erficiecalda

Warning, poten tia l b iohazards

Attenzione, rischiobiologico

In vitro diagnost ic m e dic al device

Separate collection for electrical a nd

elettriche ed elettroniche

Safety Symbols

Some of these symbols appear on the instrument or accessories:

Courant altern a tif

Wechselstrom

Corrientealterna

Correntealternata

Courant continu

Gleichstrom

Corriente continua

Corrente continua

Marche (alimen tation)

Ein (VerbindungmitdemNetz)

Conectado

Chiuso

Arrêt (alimenta tion)

Aus (TrennungvomNetz)

Desconectado

Aperto

(sconnessionedallaretedialimentazi

one)

Attention, risq ue de choc

électrique

Gefährlicheelektrischeschlag

Precaución, riesgo de

sacudidaeléctrica

Courant continu et courant alternatif

Gleich - und Wechselstrom

Corriente continua y corrientealterna

Bo, height,rne de terre

Erde (Betriebserde)

Borne de tierra

Borne de terre de protection

Schutzleiteranschluss

Borne de tierra de protección

documents)

Attention (voir documents

d’accompanement)

AchtungsieheBegleitpapiere

Atención (vease los documentosincluidos)

Attention, risqued’écra s ement et pincement

Warnen, Gefahr des Zerquetsc hens und

Klemmen

Precaución, riesgo del machacamiento y

sejeción

Attention, surface chaude

Warnen, heißeOberfläche

Precaución, superficiecaliente

Dispositif médic a l d e diagnostic in

vitro

Medizinisches In-VitroDiagnostikum

Dispositivo médico de diagnóstico

in vitro

Dispositivo medico diagnostico in

50™ TS Washer

vitro

Attention, risq uesbiologiquespotentiels

Warnung! MoeglichebiologischeGiftstoffe

Atención, riesgos biológicos

electronic equipment

Les équipements électriques et électroniques

font l’objet d’u ne collecte sélectiv e

Getrennte Sammlung von Elektro- und

Elektronikgeräten

Recogida selectiva de aparatos eléctricos y

electrónicos

Raccolta separata delle apparecchiature

Page 11

| xi

Consult instructions for use

Consultare le istruzioni per uso

Consulter la notic e d ’emploi

Gebrauchsanweisung beachten

Consultar las instrucciones de uso

BioTek Instruments, Inc.

Page 12

Section 2

Installation

This section provides detailed installation instructions.

Unpack and Inspect the Instrument ................................................... 2

Setting Up the 50 TS .......................................................................... 3

Connect the Fluid Supply and Waste System ...................................... 4

Install the Microplate Carrier ........................................................... 13

Attach the Mis t Shield ...................................................................... 15

Page 13

2 |

Unpack and Inspect the Instrument

Important: Save all packaging materials. If the washer is shipped to the

factory for repair or replacement, it must be carefully repackaged in the original

packing materials. Using other forms of commercially available packing

materials, or failure to follow the repackaging instructions may void your

warranty. Improper packaging that results in damage to the instrument may

lead to additional charges

Inspect the shipping box, packaging, instrument, and accessories for signs of

damage.

If the washer is damaged: Notify the carrier and your BioTek representative.

Keep the shipping cartons and packing material for the carrier's inspection.

BioTek will arrange for immediate repair or replacement of your instrument.

Unpack the accessories and the washer. Washers are shipped with two or three

2-liter supply bottles and one 2-liter waste bottle. The 50 TS with Buffer

Switching (“V” version) includes three supply bottles.

Liquid Level Alert™

If you purchased the Liquid Level Alert system, its components are shipped in

a separate box.

• For washers with Buffer Switching (“V” version washers), PN 4070036 includes

a select box, three 2-liter supply bottles, and one 2-liter waste bottle.

• For washers without Buffer Switching, PN 4070035 includes a select box, one 2-

liter supply bottle, and one 2-liter waste bottle.

50™ TS Washer

Page 14

Setting Up the 50 TS

Important: Avoid excessive humidity. Condensation directly on the sensitive

electronic circuits can cause the instrument to fail internal self checks.

Important: The manifold dispense tubes have a protective Teflon collar at the

tip. This is to prevent dripping. Do not remove these coverings!

Operating Environment

The 50 TS washer is sensitive to extreme environmental conditions. For

optimal operation, install the washer:

• on a stable, level surface,

| 3

• in an area where ambient temperatures between 15° - 40°C (59° - 104°F)

can be maintained, and

• away from excess humidity.

BioTek Instruments, Inc.

Page 15

4 |

points towards the manifold.

Connect the Fluid Supply and Waste System

Caution. The washer manifold, the vacuum port, and the supply

bottles have Luer fittings. Finger-tighten only!!

Place the supply and waste bottles on the same horizontal plane as the

washer. This ensures optimum pump performance.

Liquid Level Alert System: If you purchased the optional level alert

accessory, use the special supply and waste bottles provided with the

kit during this installation procedure. Unlike the standard bottles, the

liquid level alert bottles have a sensing device inside, connected to an

electrical cable in the top. When the washer is installed, follow the

instructions to enable the system, See Install the Liq uid Level Alert

System (Optional) on page 9.

Connect the Fluid Supply

Fluid Supply without Buffer

Switching is shown in this photo.

The tubing connects directly from

the bottle to the syringe pump to

the wash manifold.

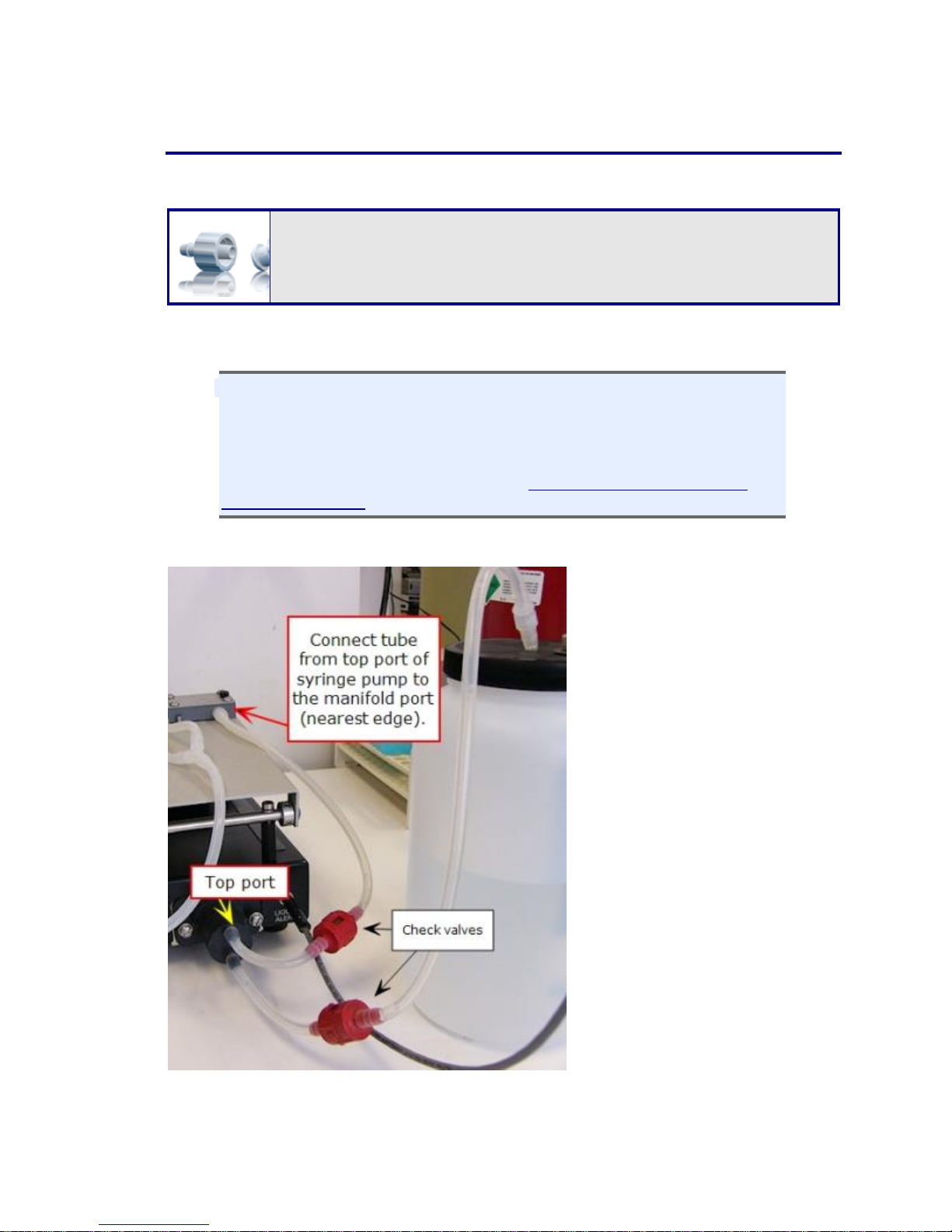

1. Locate the tubing with the

check valves used for the

fluid supply, PN: 4070510.

2. Connect the short tube to

the top port of the syringe

pump and to the port on the

wash manifold nearest the

edge. Make sure the flow

arrow on the check valve

50™ TS Washer

Page 16

| 5

3. Connect the cut end of the short tube to the top port of the syringe

pump. Connect the Luer fitting end to the port on the wash manifold

closest to the edge. Make sure the flow arrow on the check valve points

towards the manifold.

4. Connect the long tube to the bottom port of the syringe pump. This is the

fluid supply "Input." Make sure the flow arrow points toward the washer.

5. Without Buffer Switching: Connect the long tube to the top of the supply

bottle.

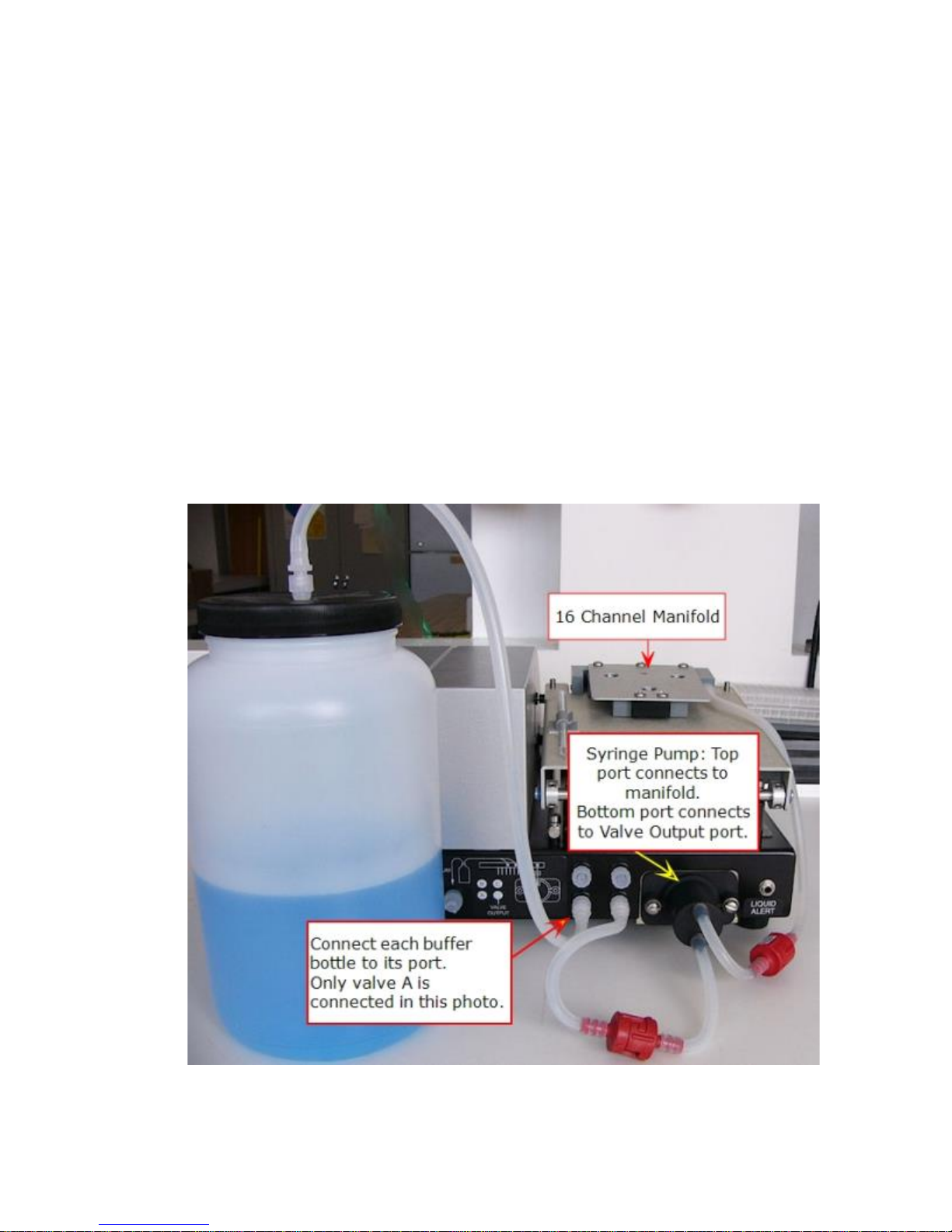

With Buffer Switching: The tube will extend only from the syringe pump

to the Valve Output port next to the pump.

1. First, remove the Luer fitting on one end of the tube and cut the long

tube to about 5” (12.7 cm) from the check valve.

2. Reinsert the Luer fitting and connect it to the Valve Output port on the

back of the washer.

Fluid supply with Buffer Switching: tubing connects to internal valves

BioTek Instruments, Inc.

Page 17

6 |

5. Connect the three supply bottles, A, B, C, to their respective ports.

50™ TS Washer

Page 18

Connect the Waste System

Finger-tighten only all fittings!

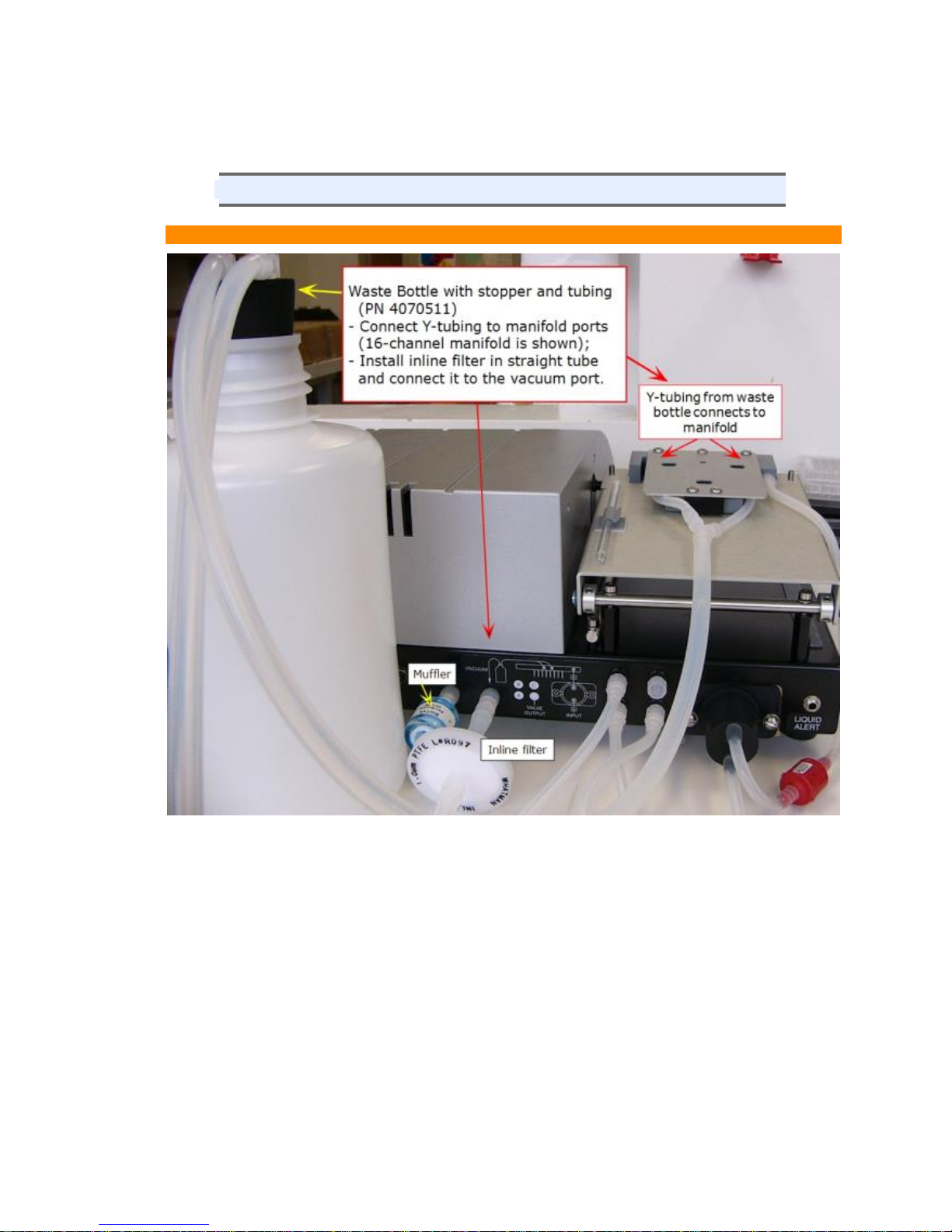

All 50 TS models except 8MF, 8M, 8F:

| 7

Connecting the Waste system tubing on the back of the washer

1. Remove the waste bottle cover and replace it with the stopper from the

waste tubing set.

2. Attach the Y-shaped tubing from the waste bottle stopper to the two waste

ports on the back of the wash manifold.

3. Install the inline vacuum filter:

BioTek Instruments, Inc.

Page 19

8 |

1. Cut the tubing that will connect the

about an inch of tubing extending from

Insert the vacuum filter between the cut

waste bottle to the Vacuum port: leave

the Luer fitting that will connect with

the washer.

2.

ends of the tubing.

The inline vacuum filter (PN: 48146)

is optional but strongly

recommended to (1) prevent waste

material aerosols from escaping into

the air, and (2) to serve as a

temporary fluid barrier if the waste

bottle is allowed to overfill.

4. (After inserting the inline vacuum filter) Connect the tubing from the waste

bottle to the Vacuum port on the back of the washer.

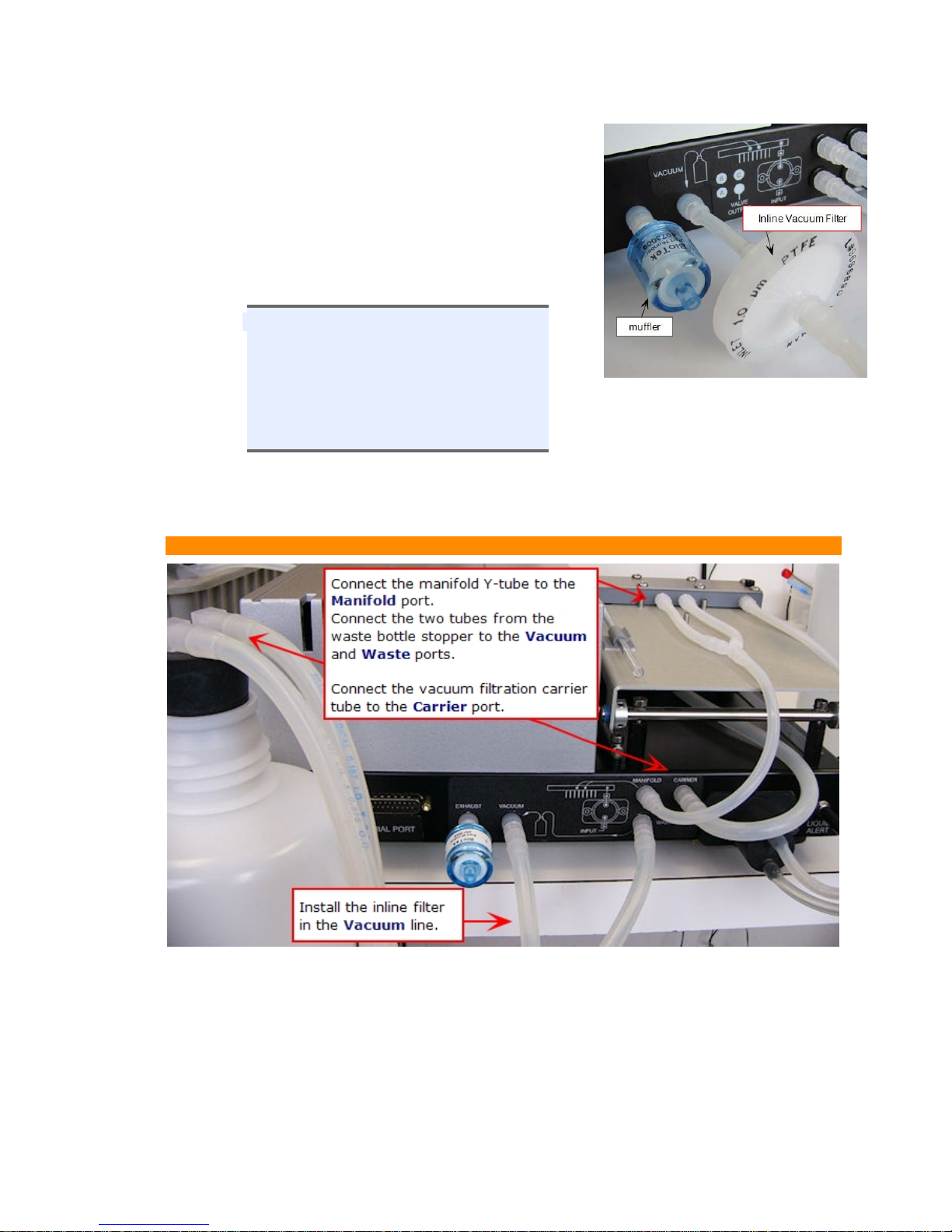

50 TS/8F, 8M, 8MF models (for vacuum filtration)

Installing the W aste system for vacuum filtration models: 8F, 8M, and 8MF models.

1. Attach the Y-shaped tubing to the two waste ports on the back of the wash

manifold (two center ports).

2. Connect the end of the Y-waste tubing to the Manifold port on the back of

the washer.

50™ TS Washer

Page 20

| 9

3. Remove the waste bottle cover and replace it with the stopper from the

waste tubing set. Take note of the distinct fittings at the end of each tube:

one connects to the Vacuum port, the other to the Waste port on the back

of the washer.

4. To install the optional inline vacuum filter:

1. Cut the tubing that will connect the waste bottle to the Vacuum port

leaving about an inch of tubing extending from the washer,

2. Insert the vacuum filter between the cut ends of the tubing.

5. Attach the tubing from the waste bottle to their respective ports on the back

of the washer:

• Vacuum port to connect the vacuum pump to the waste bottle,

• Waste port to capture waste fluid from the washer.

6. Connect the tubing from the vacuum filtration carrier to the Carrier port on

the back of the washer.

Disconnect the waste tube from the Carrier port when you are not

using the vacuum filtration carrier. An internal valve preserves the

vacuum required to perform standard aspiration.

Install the Liquid Level Alert System (Optional)

The Liquid Level Alert select box has ports, labeled A, B, and C, for the

supply bottles, and Waste.

1. If you have not already done so, connect the waste and fluid supply

bottles as described on the previous pages.

2. Connect the cables from the supply and waste bottles to the select box:

BioTek Instruments, Inc.

Page 21

10 |

o For washers with Buffer Switching, connect the supply bottle cables to

the appropriate ports in the select box. If a port is left empty, insert one

of the supplied “shorting plugs” (all ports must be filled).

o For washers without Buffer Switching, connect the s upply bo ttle cable to

port A and then insert the shorting plugs into ports B and C.

o For all washers, connect the waste bottle cable to the WASTE port.

3. Connect the select box to the LIQUID ALERT port on the back of the

washer.

4. Enable Liquid Level Alert by selecting: Instrument>Options and making

Liquid Level Alert Enabled.

Liquid Level Alert Setup

Install Vacuum Pump Muffler (Optional)

Install the optional vacuum pump muffler (PN 4073009) to reduce noise

during operation.

50™ TS Washer

Page 22

| 11

Connect the muffler's Luer fitting on to the Exhaust port (in between the

USB and vacuum ports) on the back of the washer.

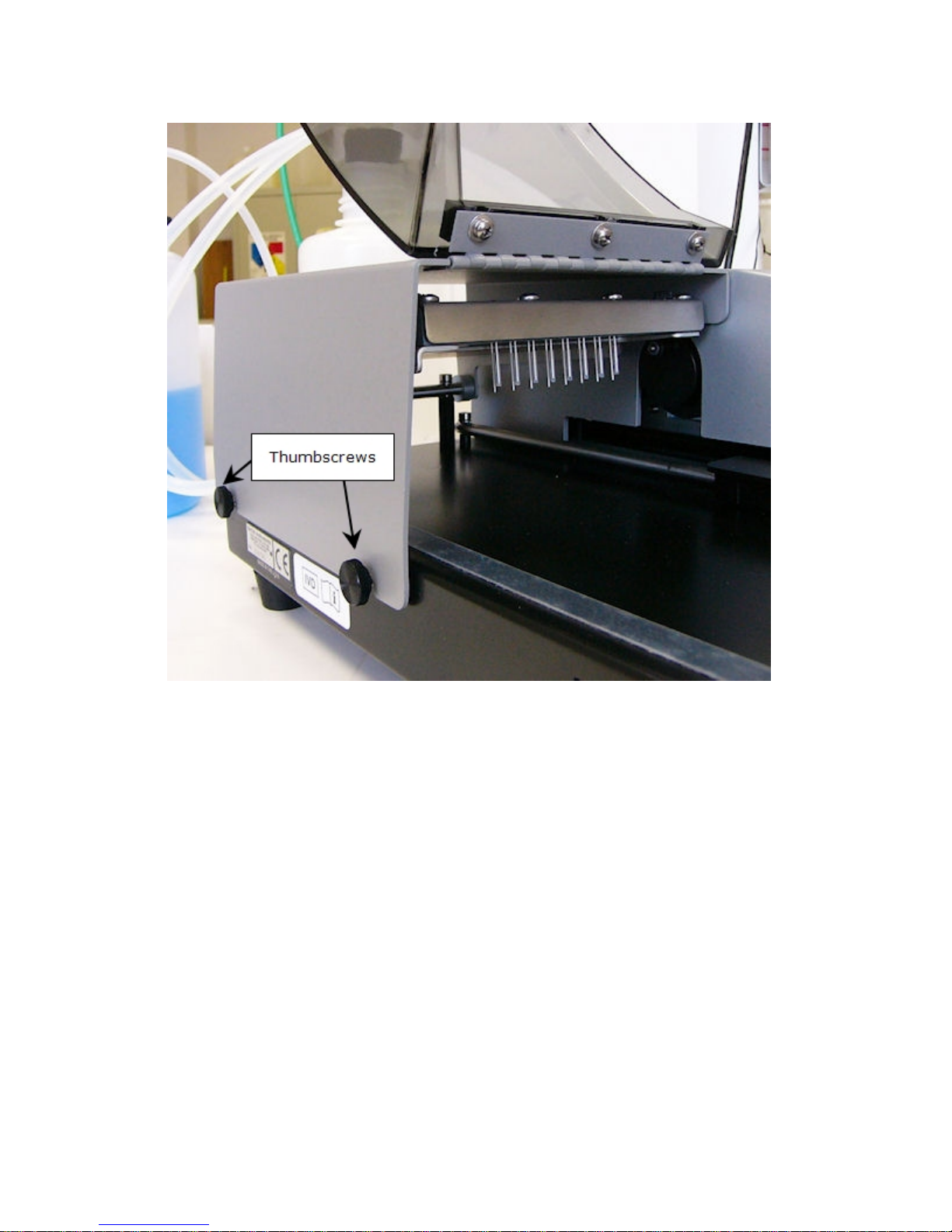

Install the 8-, 8s-, 12-, 2x8, or 4 Well Manifold

To install any ma nifold except the 8,16 Well manif old: rest it on the two ou ter posts and

secure with thumbscrews

1. Orient the manifold with the aspirate and dispense tubes facing down,

and the fittings for the supply and waste tubing facing the back of the

washer.

2. Place the manifold gently onto the two support pins on the manifold

mounting bracket closest to the front of the washer.

3. Insert the thumbscrews (2). Do not overtighten.

See also Connect the Fluid Supply and Waste System page 4 for

descriptions of the manifold tubing connections.

BioTek Instruments, Inc.

Page 23

12 |

Install the 8,16-Well Manifold

Secure the 16 Well manifold on the 3 posts

with the 3 thumb screws.

1. Orient the manifold with the aspirate and dispense tubes facing down,

and the fittings for the supply and waste tubing facing the back of the

washer.

2. Place the manifold gently onto the three support pins on the manifold

mounting bracket.

3. Insert the thumbscrews (3). Do not overtighten.

See also Connect the Fluid Supply and Waste System on page 4 for

descriptions of the manifold tubing connections.

50™ TS Washer

Page 24

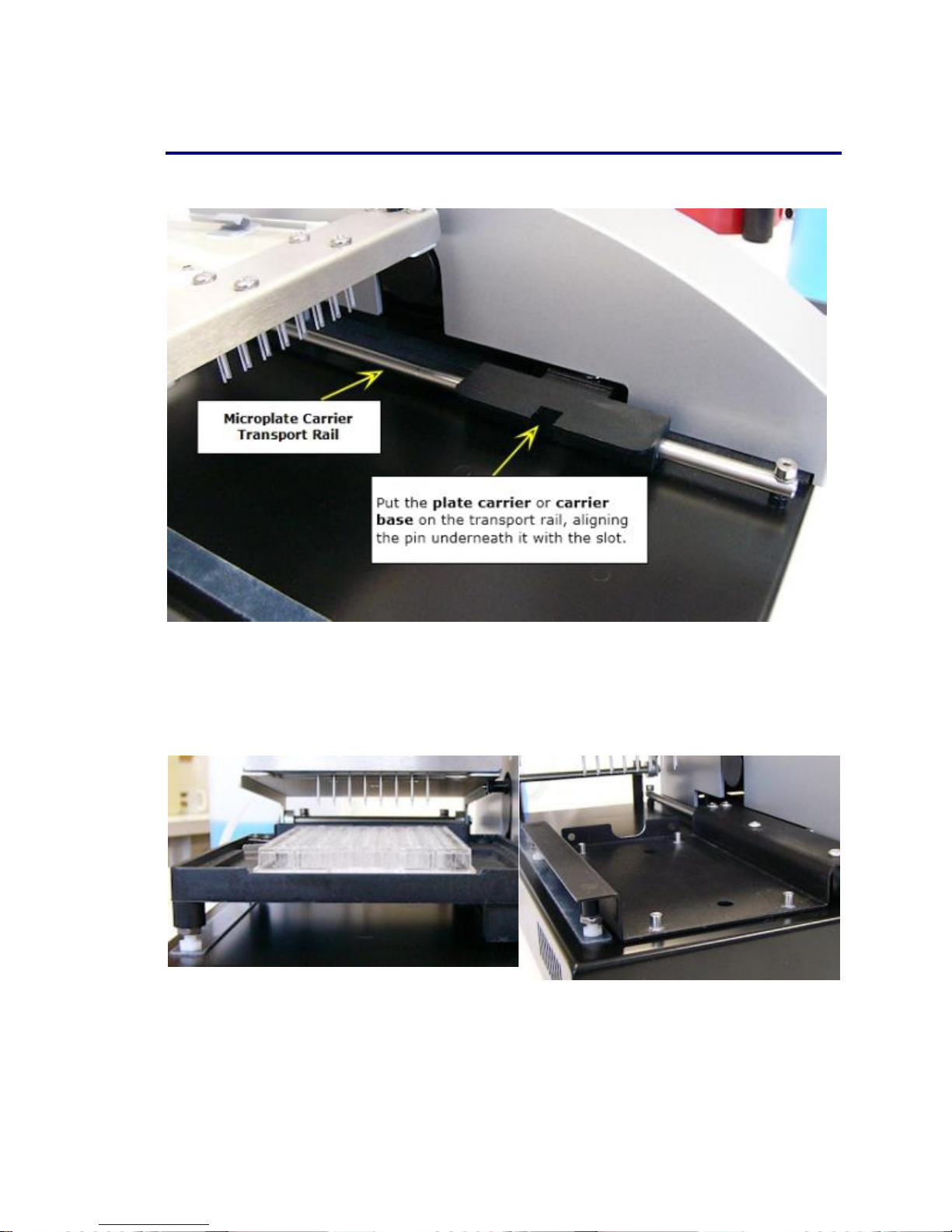

Install the Microplate Carrier

| 13

1. Position the microplate carrier or the carrier base of “F” and “M”

models so the priming trough is closest to the rear of the washer.

2. Line up the pin on the underside of the carrier with the slot on the

carrier transport rail and install the carrier. Rail guides under the carrier

sit on rail.

Standard microplate carrier with p la te . Carrier base for biomagnetic separation and

vacuum filtration plate carriers.

BioTek Instruments, Inc.

Page 25

14 |

Vacuum Filtration and Biomagnetic Separation Carrier

The 50 TS: “F” or “M” models ship with one or two microplate carriers

which fit into the microplate carrier base.

Vacuum filtration plate carrier Biomagnetic separation plate carrier

1. Install the microplate carrier base as described above; except 8F models:

the vacuum filtration carrier is already attached to the carrier base.

2. Observe on the underside of the vacuum filtration and biomagnetic

separation carriers the holes for pins in each of the four corners. Align

the carrier to fit on top of the pins in the carrier base.

3. Vacuum filtration carrier: connect the tubing on the special plate carrier

to the Carrier port on the back of the washer.

• The biomagnetic-separation carrier's priming trough is removable. Make

sure the trough is installed before operation.

Biomagnetic plate carrier with separate priming trough

For vacuum filtration and biomagnetic se paration ass ays, insta ll

the 8- or 8s Well manifold.

50™ TS Washer

Page 26

Disconnect the waste tube from the Carrier port when you are not

using the vacuum filtration carrier. An internal valve preserves the

vacuum required to perform standard aspiration.

Installation Final Check

1. Verify that the tubing was not crimped during installation.

2. Make sure the fluid supply and the waste output tubes are attached to

the appropriate manifold ports. Lift the manifold mounting bracket up

or back to make sure the tubing to the manifold is not being pulled too

tightly.

3. Vacuum Filtration models: make sure there is sufficient room behind

the washer for the waste tubing attached to the special carrier to move

during operation.

| 15

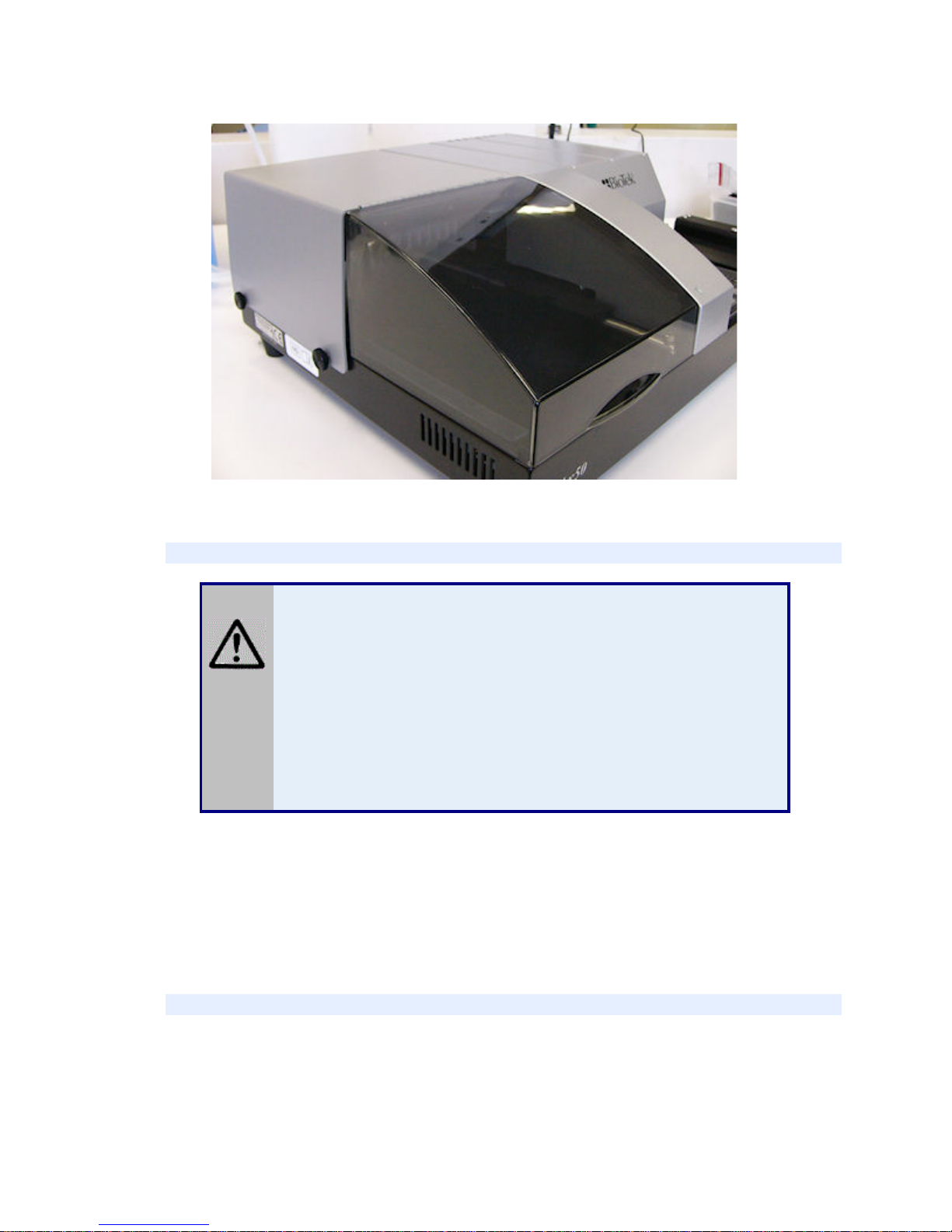

Attach the Mist Shield

The mist shield is also called the aerosol cover.

BioTek Instruments, Inc.

Page 27

16 |

Mist Shield: open

1. Insert the two thumbscrews into the slots on the washer’s left side. Do

not tighten completely.

2. With the door toward the front of the washer, slide the mist shield

down onto the thumbscrew shafts while inserting the two pins into the

slots on the top left side.

3. Tighten the thumbscrews.

50™ TS Washer

Page 28

Mist Shield: clos ed

| 17

Connecting t he Power Supp ly and Cord

Warning! Po w er Rating. The 50 TS power supply must be

connected to a power receptacle that provides voltage and

current within the specified rating for the system. Use of an

incompatible power receptacle may produce electrical shock

and fire hazards.

Warning! E lec t r ical Grounding. Never use a two-prong plug

adapter to connect primary power to the 50 TS power supply.

The 50 TS Washer uses an external 24-volt power supply. The power

supply automatically adjusts for input voltage in the range of 100 - 250 V~.

1. Plug the power supply’s plug into the washer’s rear panel.

2. Insert the power cord into the power supply and into an appropriate

Use of a two-prong adapter disconnects the utility gro und,

creating a severe shock hazard. Always connect the power cord

directly to a three-prong receptacle with a functional ground.

wall outlet.

Verify Performance

Before using the 50 TS washer for the first time, verify that it is operating

properly by turning the washer on. Turning on the washer initiates a system

BioTek Instruments, Inc.

Page 29

18 |

Self-Test to check the manifold, microplate carrier, vacuum pump and syringe

pump positioning and operation.

When the self test has completed successfully, the washer is ready for use.

If the test passes, the Main Menu is displayed.

If the test fails, the washer beeps repeatedly and displays an error code. If

this happens, note the error code and then press Stop on the keypad to stop

the beeping. Look up Error Codes on page 1 to determine its cause. If the

problem is something you can fix, turn off the washer, fix the problem, and

then turn the washer back on. Otherwise, contact BioTek’s Technical

Assistance Center.

The Instrument Testing section provides recommended procedures to

perform after the instrument is installed and set up as described in this

chapter, and before the instrument is used in a laboratory environment.

The successful completion of the Installation Qualification confirms that the

washer and its components have been supplied as ordered and ensures that

they are assembled and configured properly for your lab environment. The

successful completion of the Operational Qualification confirms that the

washer is operating according to specification.

Note: An instrument qualification package (PN 155) for the 50 TS

is available for purchase from BioTek. The pac kage contains thorough

procedures for per forming Installation Qualif ication, Operational

Qualification and Performance Qualification (IQ/OQ/PQ) and

preventive maintenance (PM). Extensive Checklists and Logbooks are

included for recording results. Contact your local dealer for more

information.

Important! Review Optimize Performance recommendations in the

operator's manual, which describes necessary steps to perform before

running the washer.

50™ TS Washer

Page 30

Section 3

Getting Started

This section introduces the basics of operating the 50 TS. For

more detailed and comprehensive instructions, please refer

to the operator's manual.

AutoPrime .......................................................................................... 2

Wash a Plate ...................................................................................... 4

Optimize Performance ........................................................................ 7

Run a Predefined Protocol .................................................................. 8

Create a Protocol .............................................................................. 13

Instrument Configuration - Setup Cont rols ...................................... 23

Page 31

2 |

smaller amount of fluid

Quick Prime

Select Quick>Prime.

BioTek defines two types of prime:

• Manifold: uses a

to condition the

dispense tips.

Press the “Priming

” button to run a

for

manifold prime

immediately before a

wash or dispense step

to correct for

evaporation between

runs.

• System: priming is necessary when changing fluids, and at the start a nd end of

the day to flush the tubing. Except b uffer switching models should run the

System option when the instrument has been idle be t ween runs.

Best practice: for the most precise dispense volumes, always run a "Quick

Manifold Prime" before a basic wash or dispense. Buffer Switching models may

require a “System” prime if the instrument has been idle.

AutoPrime

LHC: Tools>Instrument Utilities> AutoPrime

From the Home screen: Instrument>AutoPrime

Recommended for optimum performance, AutoPrime keeps the tubing wet in

between runs and can be an essential part of your daily maintenance routine.

About AutoPr ime

AutoPrime automatically primes the tubing whenever the instrument is idle

for a specified time. Keeping the tubes wet prevents clogging and mitigates

fluid evaporation at the tips. AutoPrime's submerge feature lets you soak the

tubes for extended periods, which is an effective maintenance option.

50™ TS Washer

Page 32

Specify the Interval a nd Auto Prime Parameters

Touchscreen:

LHC:

time interval that

will trigger priming; up to

AutoPrime only runs when the Main Menu (Home) is displayed and the

instrument has been idle for a specified interval.

To set AutoPrime:

| 3

1. Select Instrument at the main menu and

select AutoPrime.

1. Select Tools>Instrument

Utilities> AutoPrime

tab.

2. “Enable” AutoPrime and

specify the parameters:

• the idle-

24 hours.

• Set the Submerge

Duration

• Flow rate, volume, and

buffer valve, if

applicable.

, if desired.

3. LHC users: click Send to

transfer the settings to the

instrument.

BioTek Instruments, Inc.

Page 33

4 |

performance.

: two options for

on daily

to prime

dispense tips to correct

for evaporation.

wash.

Wash a Plate

Two ways to wash a plate:

• Quick Wash: use the

Quick menu to wash

strips or a plate using

default instrument

settings.

• Protocol: run a

predefined wash

protocol: touch your

choice on the Main

Menu. Protocols let

you customize the

wash parameters to

improve assay

Quick Wash

Press Quick at the Main

Menu (Home) to Prime the

tubing and run a Basic

Wash.

• Prime

the most comm

uses: System

all the tubing, when

changing buffers, for

example, and

Manifold to prime the

• Basic Wash: after priming the tubing, specify the volume-per-well, buffer

bottle, if applicable, number of wash cycles and how many strips (or rows) to

When you are ready to wash a plate:

1. Fill the supply bottle and connect it to the washer, (empty the waste bottle,

if necessary).

2. Prime the tubing: use Quick Prime or run a Maintenance protocol.

3. Properly seat the microplate or microstrips holder in the plate carrier with

well A1 closest to the manifold/dispense tips.

50™ TS Washer

Page 34

4. Press .

Wash Protocol

Predefined protocols,

including sample protocols

provided with the 50 TS

reside on the Main Menu.

Touch a protocol to run it.

See Create a Protocolon

page 13.

| 5

If more precise positioning of the aspirate tubes, more or fewer wash cycles, or

a slower aspirate travel rate would improve your results, e.g. reduce residuals,

use the Protocol menu to customize a protocol for your assays. Several sample

protocols are provided, which can be used as templates to give you shortcut to

creating your own protocols. "Copy" a sample protocol to preserve the

original, and start the customization with optimized parameters for the plate

type.

BioTek Instruments, Inc.

Page 35

6 |

About Wash Protocols

Minimally, a wash protocol has one wash cycle, which is an aspirate step

followed by a dispense step. By default, the 50 TS’s wash protocol has three

wash cycles followed by a Final Aspirate step. You can customize the wash

protocol:

o Change the number of cycles,

o Add pre-wash steps like bottom wash , fo r ve ry vi g orous w ash ing,

o Remove the final aspirate step and raise the aspirate height to increase

residu als in t he wells,

o Shake the plate to mix the contents,

o Add a Soak or delay to incubate the contents at room temperature,

o Etc.

See Run a Predefined Protocol on page 8.

See Create a Protocol on page 13.

50™ TS Washer

Page 36

| 7

Optimize Performance

Important: Always fully prime the washer before running a wash or dispense program. Do

not rely on AutoPrime to pre-prime the tubing for a protocol. AutoPrime is designed for

maintenance purposes to keep the tubing in a wetted state between runs. Enable "Prime before

Washing" when creating a protocol and when using the Quick menu, prime the tubing before

running a basic wash.

Always prime the washer with dispense fluid before a run and when finished with the

washer. Flush the tubing by running a prime or maintenance program. Find

guidelines in the Mainte n ance chapter.

Vacuum Inline Filter: Installing the hydrophobic inline vacuum filter before using

the 50 TS is strongly recommended.

Before Running the Washer

• Fill the wash/rinse bottles with sufficient fluid. Make sure the supply tube is in

the liquid.

• Empty the waste bottle and firmly seat the waste bottle’ s s topper. To prevent

fluid from backing up into the vacuum pump, never allow the waste bottle to

become more than three-quarters full. Alternatively, install the Liquid Level

Alert.

• Check the external tubing connections for kinks and clogs.

• Make sure the bottles, solutions, and tub i ng are clean and do not contain any

particles or mold.

• To avoid creating air bubbles every time the supply bottle is filled, make a mark

halfway down the bottle a nd refill when the fluid level dro p s to that point.

Unscrew the cap and let it hang over the side just enough to avoid emptying the

inside tube and enough to refill the bottle.

• Enable AutoPrime to keep the tubing wet during idle periods.

• Always use the correct microplate/microstrip types for the manifold:

• 8, 8s, and 2x8 Well manifold: 96-well plates, 8-well strips.

• 12 Well manifold: 96-well plates, 12-well strips.

• 8,16 Well manifold: 96- or 384-well plates, 8-well strips.

• 4 Well manifold: 24-well plates.

• Vacuum filtration is performed only on ful l plates. Microstrips are no t

supported.

• Always put microstrips in the holder before loading them onto the carrier.

• Position microplates or strip holders with well A1 closest to the rear of the

washer.

• Vacuum filtration models: make sure there is sufficient flex room for the tubing

connected to the vacuum filtration carrier during operation.

BioTek Instruments, Inc.

Page 37

8 |

Keep the Washer and Supplies Clean

Perform daily, overnight, and periodic maintenance as described in the

Maintenance Chapter including:

• Cleaning the manifold tube s and chambers.

• Cleaning the plate carrier.

• Cleaning the supply, rinse, and waste bottles.

• Rinsing and checking the tubing.

Protocol Parameters and Instrument Settings

• Be sure to enter the correct ‘First Strip’ and ‘Number of Strips’ values at run-

time.

• Washers with Buffer Switching (“V” version washers): Specify the correct

reagent bottle (A, B, or C).

• Make sure the Dispense (overflow) Height (Z-axis position) in the wash protocol

is low enough to remove (aspirate) excess fluid during the dispense step.

• If you use more than one manifold, make sure the instrument’s setting matches

the installed manifold and plate carrier.

Run a Predefined Protocol

BioTek ships the 50 TS with several predefined protocols onboard. See

Predefined Onboard Protocols Listing

on page 9.

Certain prompts are displayed when a protocol is selected for run. Obey the

prompts by making selections and completing required tasks.

Two options:

1. At the Main Menu, touch the protocol you want to run, or navigate to the

desired protocol using the Next and Prev(previous) buttons.

2. Select Maintenance at the Main Menu to run a maintenance or instrument

qualification (QC) protocol.

Running a Protocol

When you run a protocol on the 50 TS the following prompt may appear,

depending on the type of protocol.

50™ TS Washer

Page 38

Options Actions

Protocol Name

COSTAR_FLAT

COSTAR_ROUND

NUNC_FLAT

NUNC_ROUND

Plate Type

96

96

96

96

Number of Cycles

3 3 3

3

Wash Format

Plate

Plate

Plate

Plate

Soak After Dispense

No

No

No

No

Shake After Soak

No

No

No

No

Prime After Soak

No

No

No

No

Dispense Volume

300

300

300

300

Dispense Flow Rate

5 5 5

5

Dispense Height: Z

Offset

116

116

116

116

Dispense Position: Y

Offset

0 0 0

0

Bottom Wash First

No

No

No

No

Prime Before Start

Yes

Yes

Yes

Yes

Prime Volume

5 5 5 5 Prime Flow Rate

5 5 5

5

First Strip Specify the number of the first strip to be washed.

| 9

Number of

Strips

Specify the number of microwell strips (microplate rows or

columns) to be processed:

• 1 to 12 for the 8- or 8s Well manifold

• 1 to 8 for the 12 Well manifold

• 1 to 24 for the 8,16 Well manifold

• 1 to 6 for the 4 Well manifold

• An even number between 1 to 12 for the 2x8 Well manifold

Predefined Onboard Protocols Listing

BioTek installs these predefined protocols onboard compatible 50 TS

models. Run predefined protocols from the Main Menu (Home). Protocol

settings have been optimized based on experience in our applications lab.

Sample Wash Protocols for all 50 TS Models with 8, 8s, and 12 Well

Manifolds:

BioTek Instruments, Inc.

Page 39

10 |

Protocol Name

COSTAR_FLAT

COSTAR_ROUND

NUNC_FLAT

NUNC_ROUND

Aspirate Height: Z

Offset

28

30

25

33

Aspirate Positi on: Y

Offset

-20

12

-20

12

Aspirate Rate

5 5 5

5

Aspirate Delay

0 0 0 0 Crosswise Aspir a tion

No

No

No

No

Final Aspirate

Yes

Yes

Yes

Yes

Final Aspirate Delay

0 0 0

0

Protocol Name

COSTAR_

FLT16_96

COSTAR_

FLT16_384

NUNC_

FLT16_96

NUNC_

FLT16_384

Plate Type

96

384

96

384

Number of Cycles

3 3 3

3

Wash Format

Plate

Plate

Plate

Plate

Soak After Dispense

No

No

No

No

Shake After Soak

No

No

No

No

Prime After Soak

No

No

No

No

Dispense Volume

300

100

300

100

Dispense Flow Rate

5 5 5

5

Dispense Height

120

120

120

120

Horizontal Dispe nse

Position

0 0 0

0

Bottom Wash First

No

No

No

No

Prime Before Start

Yes

Yes

Yes

Yes

Prime Volume

5 5 5

5

Prime Flow Rate

5 5 5

5

Aspirate Height

26

22

26

22

Horizontal Aspirate

Position

0 0 0

0

Aspirate Rate

5 5 5 5 Aspirate Delay

0 0 0 0 Crosswise Aspir a tion

No

No

No

No

Sample Wash Protocols for all 50 TS Models with 8,16 Well Manifolds:

50™ TS Washer

Page 40

Protocol Name

COSTAR_

FLT16_96

COSTAR_

FLT16_384

NUNC_

FLT16_96

NUNC_

FLT16_384

Final Aspirate

Yes

Yes

Yes

Yes

Final Aspirate Delay

0 0 0

0

Biometric Separation Sample Protocols for 50TS: 8M, 8MV, 8MF Models

Protocol Name

LUM_MAG_FLAT_96

LUM_MAG_RND_96

Plate Type

96

96 Shake 1 sec, 1 (15Hz), soak 1 min

Number of Cycles

2 2 Wash Format

Plate

Plate

Soak After Dispense

Yes, 30 sec

Yes, 30 sec

Shake After Soak

No

No

Prime After Soak

No

No

Dispense Volume

200

100

Dispense Flow Rate

3

5

Dispense Height

120

128

Horizontal Dispe nse Position

0

0

Bottom Wash First

No

No

Prime Before Start

Yes

Yes

Prime Volume

5

5

Prime Flow Rate

5

5

Aspirate Height

29

58

Horizontal Aspirate Position

0

24

Aspirate Rate

7 1 Aspirate Delay

0 0 Crosswise Aspir a tion

No

No

Final Aspirate

Yes

Yes

Final Aspirate Heig ht

38

58

Final Horizontal Aspirate Position

0

24

Final Aspirate Rate

7 1 Final Aspirate Delay

0

0

| 11

BioTek Instruments, Inc.

Page 41

12 |

DISPENSE

µL/well

Dispense Height (Z)

Flow Rate

accuracy_qc_test

300

146

5

accur_qc_test384

100

120

6

ASPIRATE

Height (Z)

Asp Horizontal (Y)

Travel Rate

residual_qc_test

28

-20

1

resid_qc_test384

22 0 3

Vacuum Filtration

Volume: µL/well

Flow Rate

VAC30

300

6

MAINTENANCE

DAY_RINSE

DECONTAMINATION

LONG_SHUTDOWN

OVERNIGHT_LOOP

RINSE_AND_SOAK

PRIME_ALL_BUFFERS1

Qualification Protocols

Select the Maintenance menu on the Home screen.

Maintenance Protocols

1

For "V" models with buffer switching capability.

50™ TS Washer

Page 42

Create a Protocol

Enter a unique name for the

Follow these general guidelines for creating a protocol. See Protocol Parameters

Reference Tables on page 15.

1. Select Protocol at the main

menu.

2. Select Create.

3.

new protocol.

4. Select the Plate Type and

press Save.

| 13

5. Press Add and select the

type of action to perform.

6. Define the parameters for

the step and add more

steps, as needed.

BioTek Instruments, Inc.

Page 43

14 |

Select a step and then use the

, and

Cut

reposition steps. To paste a step, select the step

or <end of steps>

the copied or cut step, then press Paste.

to enable and

to better

To fine-tune a

protocol to improve assay

performance, select the protocol

and press Edit at the Protocol

Definition screen. Then, select the

step and press Edit to modify its

parameters.

Press Info to change the

protocol’s name or plate type.

Save time by

copying a similar protocol and

editing its steps.

Wash Step

Touch the

Aspirate and/or

Dispense boxes to modify the

default parameters for these parts

of the wash step.

Press Wash options

define additional actions.

Toggle the Yes/No buttons to

enable or disable an option.

Press Edit to define the

parameters of the option.

See Wash Protocol Parameterson

page 16 for descriptions.

Copy, Paste

buttons as needed to add, remove or

below the desired position of

In an aspirate or dispense step,

press Advanced options

position the manifold tubes in the

Z-axis (height) and Y-axis

(horizontal position). Some

experimentation may be needed to

find optimal settings.

50™ TS Washer

Best practice: In a wash step, set a

dispense height that positions the aspirate

tubes at the top of wells to draw off any

overflow.

Page 44

Protocol Parameters Reference Tables

Review these tables for details about the available protocol parameters:

o Wash Protocol Parameters on page 16

| 15

o Dispense Protocol Parameters

o Aspiration Protocol Parameters

o Soak and Shake Protocol Parameters

on page 17

Define: Wash Parameter Categories

When creating or editing a wash protocol, parameters are organized by

the following categories:

Step Parameters

METHOD

DISP

ASPIR

Wash cycles, plate or strip format, soaking and shaking, soak duration,

shake before soak, shake duration, shake intensity, prime after soak,

prime volume and prime flow rate.

Dispense Volume, Dispense Flow Rate, Dispense Height, Ho rizontal

Dispense Position, Bottom bv Wash First, Bottom Dispense Volume,

Bottom Flow Rate, Bottom Dispense Height, Bottom Horizontal Position,

Prime Before Start, Prime Volume, Prime Flow Rate.

Aspirate Height, Horizontal Aspirate Position, Aspirate Rate, Aspirate

Delay, Crosswise Aspirate, Crosswise On, Crosswise Height, Crosswise

Horizontal Position, Final Aspiration, Final Aspirate Delay.

on page 19

on page 20

BioTek Instruments, Inc.

Page 45

16 |

(except 1-7 for the 12-channel manifold, and 1-5 for the 4-,

Wash Protocol Parameters

Method Action/Description Default

Number of

Cycles

Wash

Format:

Plate or

Strip.

Soak/

Shake

Soak

Duration

One wash cycle includes, at minimum, one aspirate a nd

dispense sequence. Other options added to the protocol, like

shake and soak, are also performed in each cycle. Pre-prime,

when selected, is performed one time before the wash cycles.

Bottom Wash adds another cycle to the protocol when

enabled. Final Aspirate is done once after all cycles are

completed.

Plate format performs each cycle on the entire plate (or all of

the strips) before it starts the next cycle. Strip format

performs all cycles on one strip before it moves to the next

strip. You must specify the number of strips to wash at

runtime.

Enable soaking and/or shaking to steep and/or mix the wash

buffer in the wells after the dispense step; then specify a

duration.

The amount of time to delay processing or to steep fluid in the

wells before aspiration.

A soak begins after the wash buffer is dispensed. In some

assays it enhances washing by allowing unbound material to

diffuse into the wash buffer. When washing strips in a plate

format use a soak that lasts as long as it takes to process one

wash cycle of all strips.

3

Plate

No

30

Shake

Duration

Shake

Intensity

The amount of time to agitate the plate. The duration range is

from1 second to 30 minutes.

Specify the intensity of microwell shaking. The options range

from 1 to 5, where 1 = Least Intense, 5 = Most Intense. The

washer shows the corresponding cycles/sec value for each

option.

Prime

Between

Cycles?

Prime

Volume

Prime Flow

Rate

50™ TS Washer

Choose Yes to prime the dispense tubes between cycles, to

correct for evaporation, for example. Generally, this is only

necessary after a delay or a long soak, >10 minutes.

Specify the volume in milliliters. The range is from 1 to 200

mL.

Specify the rate at which to pump the priming fluid into the

dispense tubes. The flow rate options range from 1 to 9

5

3

No

5

5

Page 46

| 17

and 2x8-well manifolds), w here 1 = Slowest, 9 = Fastest. See

Method Action/Description Default

Dispense and Prime Flow Rates on page 1 .

Dispense Protocol Parameters

Options Actions Default

Dispense Volume The volume to dispense per well per wash cycle. The

volume range is 50 to 3000 µL/well for 96-well pla t e s .

When dispensing to 384-well plates, the range is 253000 μl/well.

Dispense Flow Rate Flow rates range from 1 to 9 (except 1-7 for the 12-

channel manifold, and 1-5 for the 4 and 2x8 Well

manifolds). 1 = Slowest, 9 = Fastest. See Dispense

and Prime Flow Rates on page 1. The flow rate must be

valid for the manifold and dispense volume. For

Troubleshooting: See Dispense Volume Invalid for

Manifold Type (0F00 Error).

Dispense Hei gh t (Zaxis)

The height between the bottom of the aspirate tubes

and the carrier surface when dispensing. The dispense

tubes are shorter than the aspirate tubes.

The Dispense Height range is from 12 to 180 steps.

The washer displays the corresponding millimeters. 12

is closest to the carrier surface, 180 is furthest from

this surface.

Overflow Position: It is considered goo d practice to set

a dispense height that positions the aspirate tubes at

the top of wells to draw off any overflow.

300

5

120

Horizontal Position

(Y-axis)

The position of the manifold tubes in relation to the

center of the microwells.

The Horizontal Disp Pos range is from -24 to 24 for the

8- and 12-channel manifolds and the 2x8 manifold; -88

to 24 for the 8s-manifold; -24 to 15 for the 16-channel

when addressing 96-well plates and -22 to 10 for 384well plates; the 4 (24-well plate) manifold range is 180-60. The washer displays the corresponding

millimeters.

A negative offset moves the dispense tubes back, aw ay

from the front of the washer. A positive offset moves

the dispense tubes toward the front of the washer. A

setting of 0 indicates no offset.

0

BioTek Instruments, Inc.

Page 47

18 |

Options Actions Default

Bottom Wash First?

Bottom washing adds

an initial aspiratedispense sequence to

the specified number

of wash cycles when

extra vigorous

washing is required.

Specify bottom wash parameters to position the

manifold deep in the well. For example, set the Bottom

Disp Height to between 30-50 steps. Reagent is

dispensed and aspirated simultaneously at this height

to create cleaning turbulence. The plate is aspirated

again and the process ends with a final dispense to fill

the wells.

In Vacuum Filtration models, when the aspirate step is

No

defined as VAC, this aspiration method is used for the

Bottom Wash, as wel l.

Bottom Disp Volume The volume range is 50 to 3000 µL/well. 150-400

300

µL/well is typical.

Bottom Flow Rate Valid options: 1 to 9 (except 1-7 for the 12-channel

5

manifold, and 1-5 for t he 4 and 2x8 Well manifolds).

Bottom Disp Height Valid range from 12 to 180 steps. 60

Bottom Horiz Pos Valid range is same as regular wash step (see above). 0

• Negative values: To enter a negative value, toggle the +/- button.

Do not confuse Bottom Wash options with vacuum filtration, which

evacuates filter or membrane plates from below. Bottom wash is for

extra vigorous washing to reduce background or noise when reading

the plate. Review Vacuum Filtration for Filter Plate Assays on page 1.

50™ TS Washer

Page 48

| 19

Aspiration Protocol Parameters

Options Actions Default

Aspirate Type Standard aspiration using the manifold or Vacuum

Filtration for 8F and 8MF models using the vacuum

filtration carrier.

Filtration Time When Aspirate Type is set to Vacuum Filtration. The

range is 1-180 seconds. Experimentation is

recommended to determine the optimal setting for your

assays.

Aspirate Height

(Z-axis)

The height between the bottom of the aspirate tubes and

the carrier surface when aspirating the microwells. The

aspirate tubes are longer than the dispense tubes.

Ranges from 12 to 180 steps. The washer shows the

corresponding millimeters. 12 is the closest to the carrier,

180 is the furthest.

Horizontal Position

(Y-axis)

The position of the manifold tubes in relation to the

center of the microwells.

The Y-axis range is from -24 to 24 for the 8- and 12channel manifolds and the 2x8 ma nifold; -88 to 24 for

the 8s-manifold; -24 to 15 for the 16-channel when

addressing 96-well plates and -22 to 10 for 384-well

plates; the 4 (24-well plate) manifo ld range is -180-60.

The washer displays the corresponding millimeters.

A negative offset moves the aspirate tubes back, away

from the front of the washer. A positive offset moves the

tubes toward the front of the washer. A setting of 0

indicates no offset.

Note: For flat-bottom plates, position the aspirate tubes

near the edge of the well for minimal residual volume.

30

24

0

Travel Rate The rate at which the wash manifold travels down into

Aspirate Delay The time delay starting when the tube is at its aspiration

3

the wells. Options range from 1 to 7, where 1 is slowest

and 7 is fastest. The washer shows the corresponding

mm/sec value for each option.

0

height and ending when it nex t moves. The valid range is

0 to 5000 milliseconds.

The delay applies to the normal (initial) aspiration when

Secondary (aka Crosswise) Aspirate is disabled. If

Secondary Aspiration is enabled, the delay applies to the

second, not t he initial, aspiration.

BioTek Instruments, Inc.

Page 49

20 |

Options Actions Default

Secondary2

aspirate

(Crosswise)

A secondary or crosswise aspiration is a two-step

aspiration. The wells are first aspirated at the horizontal

aspirate position. The aspirate tubes rise a fixed number

of steps and then do a second aspiration at the secondary

position. It is useful for e liminating residual sample o r

reagent from the wall perimeter.

Final Aspirate Select YES to designate a fin al aspiration, leaving the

wells empty.

Final Aspirate

Delay

Same as Aspiration Delay (see above) applied to the final

aspiration.

• Negative values: To enter a negative value, toggle the +/- button.

2

Secondary and Final Aspiration are only available in a wash step, not stand-alone aspiration

steps.

Soak and Shake Protocol Parameters

No

Yes

0

Add a Shake/Soak step to the protocol to mix plate contents.

50™ TS Washer

Page 50

Options Actions

Shake To mix the wells' content during the procedure.

Before shaking begins, the manifold rises and the carrier

returns home so the tubes are above the priming trough

and cannot contaminate the plate/strips.

Shake Duration Defines how long to shake the plate/strips. The duration

range is from 1 second to 30 minutes.

Shake Intensity Specify the shake intensity from 1 to 5, where 1 is least

intense, 5 is most intense. The washer shows the

corresponding cycles/sec or Hertz (Hz) value for each

option.

Soak Duration Soak Duration is the time to allow the wash buffer to

remain in the wells before aspiration. The range is from 1

second to 30 minutes.

Note: When washing strips in a plate format define a soak

that lasts as long as it takes to process one wash cycle of

all strips.

| 21

System Startup

To turn on the 50 TS, press the on/off switch on the right side of the base. The

50 TS performs a self-test each time it is started.

If the self-test fails, the washer will beep and display an error code. Note the

error code and then press OK to stop the beeping. Look up the code in Error

Codes.

Select Instrument>Options to restart the

instrument to clear error messages or to check for errors.

How to copy a protocol

You can save time creating protocols by copying a protocol that shares some of

the same protocol parameters and then editing the copy to meet your needs.

1. Select Protocol at the main menu.

2. Touch the protocol you want to copy, and select Copy.

BioTek Instruments, Inc.

Page 51

22 |

3. Name the new protocol, choose the plate type and press Save.

4. Select Edit to "Add" or “Edit” steps or otherwise change the protocol.

Press Exit when finished.

When editing a protocol, press Info to change the protocol’s name or

plate type.

How to delete a protocol

Delete a protocol to remove it from the Home screen (Main Menu), and to freeup space onboard for more protocols.

1. Select Protocol at the Home screen.

2. Highlight the protocol you want to remove and press Delete.

3. Confirm your intention to remove the protocol at the prompt.

50™ TS Washer

Page 52

Instrument Configuration - Setup Controls

The Instrument menu leads to controls for:

o Instrument Setup below

o AutoPrime

Instrument Setti ngs

Manifold Selection

Your 50 TS was initially configured for and shipped with a wash

manifold. The washer’s manifold setting must match the type of manifold

installed on the instrument. If you change the hardware, you must also

change the setting.

| 23

Manifold Type PN Plate Type Onboard

4 Well 1550504 24-well 4

8 Well 4070512 96-well 8

8 Well Short Dispense

Tube

2 X 8 Well 1550501 96-well 2x8

12 Well 4070513 96-well 12

8, 16 Well 4070527 96 & 384-well 8,16

Plate Carrier Selection

4070519 96-well 8s

The type of plate carrier installed on the instrument must match this setting to

ensure expected performance.

• Standard

384 Well: compatible with the 8,16 Well manifold.

•

Magnetic Separation: special plate carrier for holding a magnet.

•

Vacuum Filtration: special carrier for performing vacuum aspiration or

•

filtration assays. This setting must be selected to run a vacuum filtration

protocol.

BioTek Instruments, Inc.

Page 53

24 |

Plate Clearance Height

Plate Clearance Height specifies how high to raise the manifold tubes to

prevent crashes when the plate carrier moves. The clearance height range is

12 (3.048 mm) to 195 (24.77 mm), with a default value of 146 (18.55 mm).

Use this option with 8M, 8MV and 8MF models to increase the plate

clearance height for magnetic bead assays.

Note: When using the 4 Well Manifold the Plate Clearance setting is ignored and

the manifold is raised to its highest position during travel.

To change the plate clearance height, select: Instrument>Config>Plate

Clearance

Liquid Level Sensor

.

50 TS washers support Liquid Level Alert: with a level sensing device

inside the supply and waste bottles. The sensor is activated when a supply

bottle’s fluid level drops to approximately 400-450 mL and the waste

bottle’s fluid level rises to approximately 1400-1450 mL.

The washer checks the status of the sensor at the start and end of all runs.

Error codes 2800 or 2900 display when a sensor is activated. If this happens,

press OK, check the state of the supply and waste bottles. You can fill or

empty the bottles, as needed, and then continue the run, if desired.

Sensor detection is disabled on the washer by default. To change the setting,

select: Instrument>Options and set Liquid Level Sensing to Enabled.

Protocol Display Order

Select Instrument>Options to change the sort order of the protocols on the

Main Menu.

• Last run first: reorders the list beginning with the protocol that was last run.

Alphabetically: orders this list by protocol name.

•

AutoPrime

AutoPrime keeps the tubing wet to prevent clogging during idle periods. It

is highly recommended for daily and overnight maintenance.

AutoPrime automatically primes the washer when it has been idle for a

user-specified amount of time. AutoPrime is recommended when the

washer is used intermittently throughout the day, to keep the manifold

tubes in a wetted condition between runs. It is especially useful when using

50™ TS Washer

Page 54

| 25

wash buffers that are prone to harden or crystallize. See AutoPrime on page

2.

BioTek Instruments, Inc.

Page 55

Section 4

Maintenance

This section contains recommendations for maintaining the

50 TS. For more detailed and comprehensive instructions,

please refer to the operator's manual.

About Maintaining the Washer ........................................................... 2

Recommended Maintenance Schedule ................................................ 3

Daily Maintenance: Rinse/Soak t he Fluid Path ................................... 8

Clean Components............................................................................ 11

Decontaminate the Washer .............................................................. 18

Page 56

2 |

About Maintaining the Washer

This section describes a set of procedures to perform regularly to maintain

equipment in top condition. For example, during normal operation, salt

crystals may build up and clog the valves and tubes. Adherence to the

Recommended Maintenance Schedule will reduce this problem, extend the life of

the washer, and enable the washer to meet performance specifications.

The schedule summarizes the recommended maintenance tasks, and indicates

approximately how often to perform each task. Beyond that, it is difficult for

BioTek to recommend a fixed frequency for each task. The risk and

performance factors of your assays must determine the frequency with which

to conduct these tasks. Therefore, BioTek recommends that you develop a

maintenance schedule for your washer based on the characteristics of the

fluids used and the washer’s activity level.

Some questions you should consider are:

• Are the fl uids you’re using prone to dry and harde n quickly? If yes,

the dispense and aspirate tubes can clog quickly, and therefore they must be

rinsed frequently and cleaned regularly.

• Is the washer in use continuously, or does is it idle for several hours

or days at a time? If the washer will be sitting idle, the tubes should be

soaked to keep them in a “wetted” state. Perform the rinsing procedure (or

Enable AutoPrime

• Is a solution containing surfactant used throughout the day? The

nature of the wash so lutions affects the rinsing frequency. If the solution

does not contain surfactant, consider rinsing (o r running AutoPrime) at least

once an hour.

) if the washer is idle for more than 3 hours.

Consider your wash buffer’s properties and always use the same fluid or a

compatible fluid to keep the tubing from clogging up. For example, use DI

water to flush PBS from the system, and an enzyme-active detergent, like Terg-

®

A-Zyme

, to remove proteins. Never use alcohol to flush out BSA.

Important: The risk and performance factors associated with your

assays may require performing some or all of the procedures more

frequently than recommended in the schedule.

50™ TS Washer

Page 57

Recommended Maintenance Schedule

Daily

Monthly

Rinse/Soak the Fluid Path

Clean Components

Decontaminate the Washer

Prepare the Washer for Storage or Shipment

Replace Components

" "

| 3

TASK

Daily maintenance: DAY_RINSE

Daily/Overnight maintenance: AutoPrime

Overnight maintenance: OVERNIGHT_LOOP

As needed: RINSE_AND_SOAK

As needed:Protein-residual removal

Clean bottles

Check/empty waste bottle

Clean manifold

Clean mist shield

Clean aspirate and dispense tubes

Clean microplate carrier

Frequency

Long-Term

Storage

Clean (or replace) check valves

Decontaminate the external surfaces

Run DECONTAMINATION

Run LONG_SHUTDOWN

Check valves

Vacuum filtration carrier gasket

As Needed

BioTek Instruments, Inc.

Page 58

4 |

Prime Programs

Most of the onboard Maintenance programs are predefined

prime protocols. (Instrument qualification protocols are also run from the

Maintenance menu.)

Maintenance Program: DAY_RINSE

Prime Volume: 60 mL

Flow Rate: 5

Soak After Prime? No

Maintenance Program: RINSE_AND_SOAK

Prime Volume: 60 mL

Flow Rate: 5

Soak After Prime? Yes

Soak Duration: 5 minutes

Maintenance Program: OVERNIGHT_LOOP

Prime Volume: 60 mL

Flow Rate: 5

Soak After Prime? Yes

Soak Duration: 4 hours

To keep the washer's dispense tubes wet overnight or over a weekend, the

"Overnight_Loop" protocol repeats the prime and 4-hour soak twelve times

(for approx 48 hours). Fill the supply bottle and empty the waste bottle before

starting the program.

50™ TS Washer

Page 59

Maintenance Program: PRIME_ALL_BUFFERS

Prompt:

Buffer C: 40 mL

Buffer B: 40 mL

Buffer A: 60 mL

Flow Rate: 5

Soak After Prime? No

| 5

Maintenance

Programs:

DECONTAMINATION

Step: Without buffer

switching

Prompt: "Connect disinfectant

bottle"

Prime: 60 mL, rate 5, soak 20

mins

Prime: Buffer B: 40 mL, rate 5, no soak

Prompt: "Connect rinse bottle" "Disinfect to C; rinse to A&B"

Prime: Buffer C: 60 mL, rate 5, soak

Prime: 60 mL, rate 5, soak 2

mins

Prime: Buffer B: 60 mL, rate 5, no soak

With buffer switching

"Conn disinfect bottles to A&B"

Buffer A: 40 mL, rate 5, no soak

20 mins

Buffer A: 60 mL, rate 5, no soak

Prime: Buffer C: 60 mL, rate 5, soak 2

"Connect rinse bottle to C"

mins

BioTek Instruments, Inc.

Page 60

6 |

Prompt:

Washer/Manifold

Dead Volume

Maintenance

Programs:

Step: Without buffer

Prompt: "Connect disinfectant

Prime: 60 mL, rate 5, soak 20

Prime: Buffer B: 40 mL, rate 5, no soak

Prompt: "Connect rinse bottle" "Disinfect to C; rinse to A&B"

Prime: 60 mL, rate 5, soak 2

Prime:

Prime: Buffer B: 60 mL, rate 5, no soak

LONG_SHUTDOWN

switching

bottle"

mins

mins

With buffer switching

"Conn disinfect bottles to A&B"

Buffer A: 40 mL, rate 5, no soak

Buffer C: 60 mL, rate 5, soak

20 mins

Buffer A: 60 mL, rate 5, no soak

"Disconnect bottle" "Connect rinse bottle to C"

Prime: 60 mL, rate 5, no soak Buffer C: 60 mL, rate 5, soak 2

mins

Prompt:

Prime:

Prime: Buffer B: 60 mL, rate 5, no soak

Prime:

Dead Volume

"Disconnect all bottles"

Buffer A: 60 mL, rate 5, no soak

Buffer C: 200 mL, rate 5, soak

2 mins

Consider these approximate dead volumes when defining priming values

to adequately prime the tubing before running a wash or dispense protocol.

BioTek recommends priming with two or three times the dead volume for a

dry instrument and when changing fluids. For example: dead volume (20

mL washer + 5 mL manifold) x 2 = 50 mL prime volume.

50™ TS Washer

Page 61

Washer/Manifold

Dead Volume

50 TS without Buffer Switching 20 mL

50 TS with Buffer Switching ("V" models) with full 28” supply tubing 35 mL

50 TS “V” model with supply tubing cut to 8” 25 mL

All manifolds except the 2x8 Well manifold 5 mL

2x8 Well manifold 10 mL

| 7

BioTek Instruments, Inc.

Page 62

8 |

Daily Maintenance: Rinse/Soak the Fluid Path

Maintenance Programs

Run these predefined maintenance programs to clean the fluid path.

Run these programs dai ly : See page:

DAY_RINSE

OVERNIGHT_LOOP

RINSE_AND_SOAK

page 8

page

9

page 9

Run these programs as needed: See page:

LONG_SHUTDOWN

DECONTAMINATION

1

page 18

For all daily maintenance programs, fill the supply bottle with at least 200 mL

of rinse solution and empty the waste bottle.

To run a maintenance program:

1. Fill the supply bottle with an appropriate cleaning agent for the fluids you

have been dispensing.

2. Select Maintenance from the Main Menu.

3. Select the desired maintenance program.

4. Press

8F/8MF models: Vacuum Filtration Maintenance

START to begin. (To stop a program in progress, press STOP.)

Run the predefined link protocol VAC30_TEST with disinfectant as the fluid

supply to clean the tubing and hardware used to perform filter plate assays.

DAY_RINSE

Flush the washer with an appropriate reagent at the beginning of the day,

using a buffer solution on the same day the microplates are washed. This helps

prevent the aspirate and dispense tubes from clogging between washes.

50™ TS Washer

Page 63

AutoPrime

AutoPrime keeps the tubing wet to prevent clogging during idle periods. It

is highly recommended for daily and overnight maintenance.

AutoPrime automatically primes the washer when it has been idle for a

user-specified amount of time. AutoPrime is recommended when the

washer is used intermittently throughout the day, to keep the manifold

tubes in a wetted condition between runs. It is especially useful when using