The world of flow

Instruction Manual

ARS - Totaliser Model

260 / 260-EC-01

Type 260-A

Table of Contents

1. Safety Instructions

2. Product ID - Dimensions

3. Function Description

4. Installation – Battery Replacement

5. Programming

6. Technical Data

7. Spare Parts

Type 260-EC-01

Seite 1

The world of flow

1. Safety Instructions

This instrument has been manufactured in accordance

with the applicable state of the art and meets all safety

regulations as shipped from the factory. Installation and

startup must be performed by qualified electricians only!

Operate instrument only when properly installed!

If safe operation can no longer be ensured, disable the

instrument and secure it against unauthorized operation.

Prevent injury to people or damage to property due to

failure or malfunction of the equipment through additional

safety measures such as limit switches, protective

equipment, etc. .

Read the Instruction Manual carefully before startup!

Seite 2

The world of flow

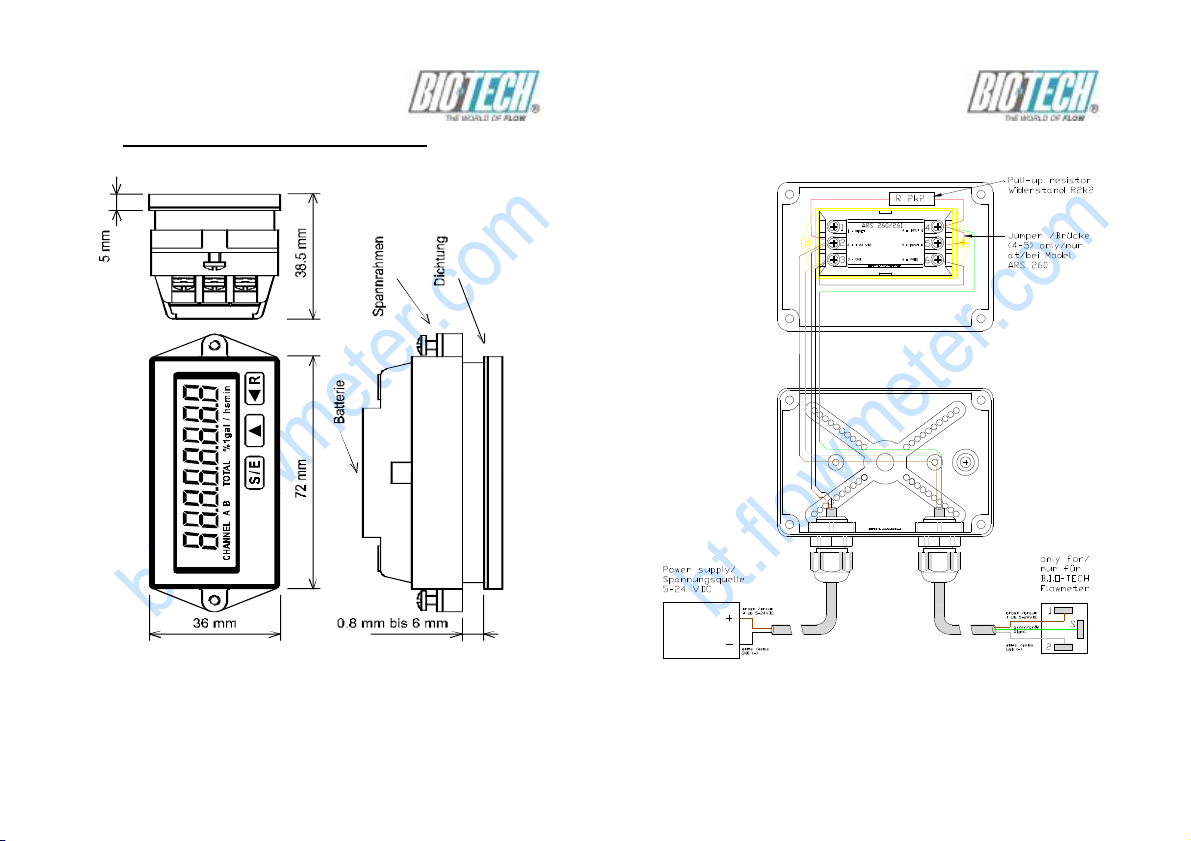

2. Product Identification – Dimensions

Seite 3

The world of flow

Seite 4

The world of flow

3. Function Description

This instrument can be used as a rate meter and as a

pulse counter.

The instrument has been pre-programmed in the factory

and must be adapted to your process for both the rate

meter function and pulse counting (see Section 5 –

Programming).

The instrument is ready for operation when the

programming input is not wired. You can switch

between Rate meter and Pulse Counter displays

using the S/E key during operation at any time.

The instrument has two counter inputs. Use counter

input A (“High” active) for rate meter with pulse

sequences up to 10 kHz; use input B (“Low” active

or “High” active) for pulse counter with pulse sequences

up to 30 Hz or 10 kHz.

The backlighting is activated and load on the internal

battery is reduced by applying an external supply

voltage of 24 VDC.

Seite 5

The world of flow

All stored data is lost when the battery is replaced.

The message “260_ xx” (xx for software

version number)

appears after the new battery is installed.

The instrument

is ready to operate after the S/E key is depressed,

which activates the factory programming.

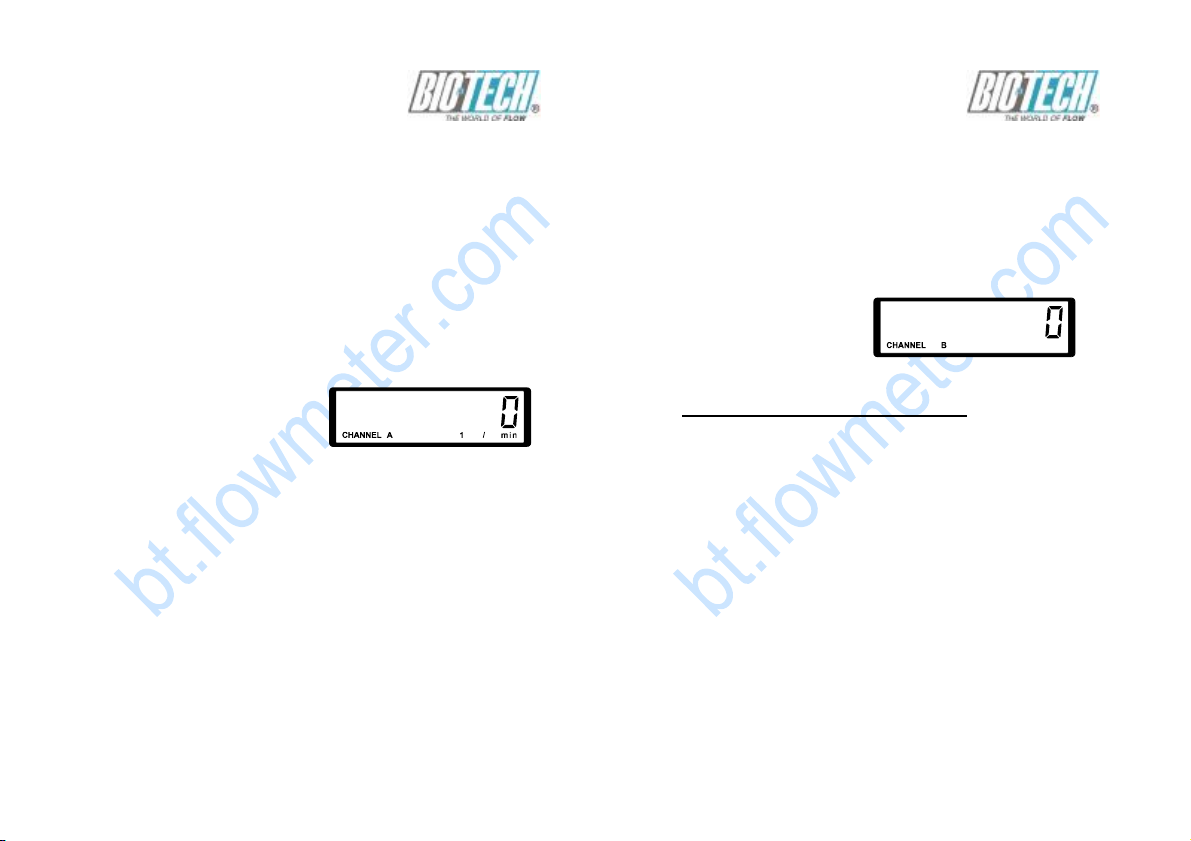

Rate meter

The rate meter operates by the principle of period

length measurement with ARS (Auto Range System).

You can adapt the display to your operation using

the programming sequence:

1. Input the physical unit of the rate meter

(time basis)

2. Select accuracy

3. Set sensor pulse constant, and

4. If necessary, program a suitable scaling

factor.

ARS helps minimize display process-related fluctuations

depending on the selected accuracy, rounds off the

displayed value, and sets the decimal point automatically.

Seite 6

The world of flow

Measurement starts with the active edge at the counter

input A. After the measurement time (1 sec) has elapsed,

the measurement is completed with the next active edge,

and the value is displayed in CHANNEL A.

If no active edge appears within the “time out” period

you have programmed, the rate meter is reset to zero.

At frequencies > 1 Hz the average is calculated. When

the allowable count frequency is exceeded, the value

zero appears in the display; if the possible display range

(99999999) is exceeded, the display “E” appears.

Display as delivered:

Pulse Counter

The pulses entering at the input B are added

and displayed

in CHANNEL B. The input B is programmable

as “HIGH

SPEED” - or “SLOW SPEED” - input. Further

you can scale

the display using an appropriate scaling factor.

Seite 7

The world of flow

You can also set a fixed decimal point and

program the pulse counter so

that you can reset it either through the regular

electrical

reset on the back or through the red R key on

the front.

After pressing the S/E key:

4. Installation – Battery replacement

After unpacking the instrument, remove the light-colored

frame from the back of the housing by simultaneously

bending both long sides of the frame slightly apart to

disengage them from the locking holes.

Then slide the housing through the cutout prepared in

the

front panel, attach the frame onto the back of the housing,

slide it all the way against the back of the front panel, and

carefully attach it with the two side screws to the front

panel.

In this way, you can compensate for different front panel

thicknesses. Class IP 65 front protection is achieved

through the seal integrated in the housing.

See the wiring diagram below for the electric wiring.

Seite 8

The world of flow

0 V

Programmier-

24 VDC Eingang

"LOW"-aktiv

"HIGH"- aktive Sensoren

"HIGH"-aktiv

Modell 260

24 VDC

The battery is accessible from the back of the

instrument.

There is a vertical notch under the middle of

the nameplate.

Cut through the nameplate there.

Then slide out the two-part battery cover to

one side along the guide grooves, and replace

the battery observing the correct polarity.

The instrument should not be connected to

24 VDC at this time!

Zähleingang B bei "LOW"-aktiv Programmierung (Kontakt nicht dargestellt)

"LOW"-aktiv

1

2

3

Rückstelleingang

für Backlight

Masse

Eingang A

Zähleingang B

eingang

Seite 9

4

5

6

"HIGH"-aktiv

IG

IG

The world of flow

5. Programming

The instrument can only be programmed by setting the

programming input PROG to 0 V.

Please note that this causes the pulse counter to be reset

internally.

After having set the programming input PROG to 0 V, the

following is displayed:

This display identifies the rate meter (Channel A); it cannot

be changed.

By repeatedly pressing the S/E key, you can cycle through

the individual menu items. The following figures correspond

to the factory settings of the instrument:

Physical unit, Accuracy,

Channel A Channel A

Sensor pulse constant, Scaling factor,

Channel A Channel A

Seite 10

The world of flow

Time-out period, Channel A

This display identifies the pulse counter (Channel B); it

cannot be changed.

Count frequency, Channel B Scaling factor, Channel B

The world of flow

2. Press ^ repeatedly if necessary:

Set the desired parameter.

3. Press S/E:

The parameter just set is confirmed and

displayed steadily.

4. Press S/E again:

You reach the next menu item.

See the possible settings allowed in each menu from the

following figures.

Flashing display elements are shown in a lighter color.

Physical unit, Channel A – Rate meter

Selecting the physical unit:

Decimal point, Channel B Reset-key enabled,

Channel B

You can make changes within each menu point as follows:

1. Press the <R key:

The parameter to be changed is activated, i.e., it begins to

flash.

Seite 11

Physical unit: 1/min Physical unit: 1/h

Physical unit: l/s Physical unit: l/min

Seite 12

The world of flow

Physical unit: l/h Physical unit: gal/s

Physical unit: gal/min Physical unit: gal/h

The world of flow

Sensor Pulse Constant, Channel A – Rate meter

You can set the pulse constant of the sensor in the range

of 1 to 99999.

The sensor pulse constant provides the number of pulses

per unit.

Example: Set a sensor constant of 500 pulses per

revolution

Press <R:

Physical unit: 1/s

Accuracy, Channel A – Rate meter

Setting measurement accuracy. See also page 13.

Accuracy 1% Accuracy 10%

Accuracy 0.1%

Seite 13

Press ^ 10 times: Press <R twice:

Press ^ 5 times: Press S/E:

Seite 14

The world of flow

Scaling factor, Channel A - Rate meter

You may set the scaling factor (SF) in the range of 0.0001

to 99.9999 as explained for setting the pulse constant.

The scaling factor is used when converting one physical

unit to another (e.g., diameter to perimeter, liters to gallons).

Time-out Period, Channel A - Rate meter

You can set the desired timeout period (time out) after

which the display is reset to zero if the operating frequency

is so low (or zero) that the measuring time would be

intolerably long.

The timeout period can be set in the range of 1s to 99s.

Example: Set timeout period to 10s

Press <R:

Press ^ 5 times: Press <R:

The world of flow

Count Frequency, Channel B – Pulse Counter

maximum frequency 10 kHz maximum frequency 30 Hz

Scaling Factor, Channel B – Pulse Counter

You can set the Scaling Factor in the range of 0.0001 to

99.9999.

Set the scaling factor as described under Scaling Factor,

Channel A.

Decimal point, Channel B – Pulse Counter

Press ^: Press S/E:

Seite 15

Seite 16

The world of flow

Reset Key enabled, Channel B – Pulse Counter

Reset key enabled Reset key disabled

If you have not enabled the reset key, the string “TOTAL“

is displayed.

Having completed the programming, disconnect the

programming input PROG from 0 V.

Please note that only the parameters confirmed with S/E

are accepted.

6. Technical Data

Displays

Special LC display with dimension line, 8 digits, 10 mm

digit height, pre-decimal point zero suppressed.

Display Capacity: Rate meter 99999999

Automatic decimal point

Pulse counter 99999999

Programmable decimal point

Accuracy

Period measurement accuracy:

Programmable to 0.1%, 1%, or 10% (corresponds to a

minimum resolution of 4, 3, or 2 digits, respectively).

Seite 17

The world of flow

Power Supply

internal lithium battery 3.6 V / 1.2 Ah

Average battery life 5 years

LED – Display backlighting

The LED display backlighting must be operated with

external voltage connected to 24 VDC and 0 V screw

terminals.

External Voltage: 24 VDC max. residual ripple 5%

absolute limits 19 to 30 VDC

Electromagnetic Compatibility (EMC)

Interference emission EN 55011 Group 1 Class B

Interference strength EN 50082-2

EN 61010-1 Measuring Insulation Voltage

100 Veff, Contamination Class 2, Surge Category III

DIN VDE 0411 Protection Class

Protection Class II

Electrical Connection

Terminal screw connection, P Phillips screws, size 1

max. lead section 2 x 1.5 mm²

min. lead section 2 x 0.2 mm²

IEC 529 Protection Class

IP 65 front

Temperature / Humidity range

Operating temperature range - 10°C to + 50°C

Storage temperature range - 20°C to + 70°C

Temperature / Humidity 90% relative humidity @ 38°C

Seite 18

The world of flow

IEC 68-2-6 Vibration Strength

Variable frequency range 10 to 500 Hz

0.35 mm or 5 g amplitude 10 Frequency

cycles per axis

Dimensions

Frontal dimensions 36 mm x 72 mm

Total depth 38.5 mm

Fastening

Front panel mount via frame

Front panel thickness 0.8 mm to 6 mm

Front panel cutout DIN 43700

33 +0.6 mm x 68 + 0.6 mm

Weight

approx. 95 g

Housing Material / Combustibility

PC plastic

Combustibiity V0 under UL Standard 94

Inputs

Counter Input A (Rate meter)

Pulse shape any

“HIGH - SPEED“ input “High” active

Signal level L<= 1 VDC H>= 5 VDC

Seite 19

The world of flow

Max. voltage amplitude ± 30 VDC

Input resistance approx. 39 kOhm

Max. frequency (pulse duty factor 1:1) 10 kHz

min. pulse time 50 µs

min. pulse pause 50 µs

Active edge High/Low

Counter Input B (Pulse Counter)

Pulse shape any

Programmed as “HIGH - SPEED” input “High” - active

Signal level L<= 1 VDC H>= 5 VDC

Max. voltage amplitude ± 30 VDC

Input resistance approx. 39 kOhm

Max. frequency (pulse duty factor 1:1) 10 kHz

min. pulse time 50 µs

min. pulse pause 50 µs

Active edge High/Low

Programmed as “SLOW – SPEED” input “Low” - active

Signal level L<= 0 VDC H>= 5 VDC or open

Max. voltage amplitude ± 30 VDC

Input resistance approx. 1 MOhm

Max. frequency (pulse duty factor 1:1) 30 Hz

min. pulse time 16 ms

min. pulse pause 16 ms

Seite 20

The world of flow

Active edge Low/High

Reset Input R (Pulse Counter)

Pulse shape any

Signal level L<= 0 VDC H>= 5 VDC or open

Max. voltage amplitude ± 30 VDC

Input resistance approx. 1 MOhm

Static response ”Low” - active

min. pulse time 65 ms

Programming Input PROG

Static response “Low” active

Input open Operating mode

Input connected to “0 V” Programming mode

7. Spare Parts

Lithium battery Art.-Nr.: 82202233

Technische Änderungen vorbehalten Stand 7.2011 We reserve the right to make technical changes without notice.

B.I.O-TECH e.K. | Zeitlarner Str. 32 | D- 94474 Vilshofen | Germany

Tel: +49 (0) 8541-91 00 47 | Fax: +49 (0) 8541-96 89 98 0

E-Mail: info@btflowmeter.com | Internet: www.btflowmeter.com

Seite 21

Loading...

Loading...