Veri-Series Installation Guide

Bioscrypt Inc.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page ii

Introduction

Bioscrypt is proud to present the Veri-Series line of fingerprint authentication

readers including the V-Prox™, V-Flex™, V-Pass™, V-Smart™, and V-Station ™. The

V-Prox™, includes integrated proximity reader and fingerprint verification. The VFlex™ allows for upgrading existing installations and using other card technologies.

The V-Pass™ doesn’t require any cards or PINs, and searches through up to 200

fingerprints. The V-Smart™ incorporates contact-less smart card technology so

that a hardwired network is no longer needed. Finally, the V-Station ™, the most

flexible of the group, offers convenient administration right from its console and

now supports Ethernet. Select versions provide functionality found in each of the

Veri-Series products, including a proximity or smart card reader, and searching

ability.

Bioscrypt's product offerings leverage over 20 years of experience designing

systems for the US Department of Defense. The company's mission is to bring their

patented fingerprint verification technology, once found only in government or

military applications, to a wide range of commercial applications around the

globe at a reasonable cost.

The V-Prox, V-Flex, V-Smart, and V-Station readers prevent unauthorized access

via loaned, lost or stolen proximity or smart cards by requiring that the fingerprint

of the person seeking entry match the identity of the cardholder. Its ability to verify

fingerprints in the face of adverse conditions like soil and other contaminants

makes the Veri-Series readers useful for factories, plants, construction sites and

similar environments that have previously been unable to implement biometricbased access solutions.

The V-Pass reader and V-Station searching version capitalize on this same

fundamental algorithm for matching fingerprints but implement it in such a way as

to be able to search through a database of templates to find the matching

template. Therefore, these systems negate the need for cards at all, providing a

convenient yet secure access control solution.

Fingerprint verification has been around for over 100 years, but during that time it

has progressed from an intensive manual operation to an automated computer

operation. The Veri-Series readers represent the state-of-the-art in fingerprint

verification technology. It uses a 100% solid-state design. There are no moving

parts, no optics or lenses, and it provides a variety of communications options.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page iii

Disclaimer

The instructions in this document have been carefully checked for accuracy and

are presumed to be reliable. Bioscrypt, Inc. and its writers assume no responsibility

for inaccuracies and reserve the right to modify and revise this document without

notice.

It is always our goal at Bioscrypt, Inc. to supply accurate and reliable

documentation. If you discover a discrepancy in this document, please e-mail

your comments to support@Bioscrypt.com, or contact Bioscrypt Technical Support

at the telephone number listed below.

No part of this publication may be placed in a retrieval system, transmitted, or

reproduced in any way, including, but not limited to, photograph, photocopy,

computer disk or other record, without prior agreement and written permission

from:

Bioscrypt Inc.

5805 Sepulveda Blvd., Suite 750

Van Nuys, CA 91411

Phone 818.304.7150

Toll Free 888.982.4643

http://www.bioscrypt.com

NOTENOTE : This symbol, found both on the device and throughout this

manual, denotes a caution or warning. When this symbol is

encountered during setup or installation, please be sure to first

carefully read the corresponding section in this manual.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page iv

Bioscrypt One Year Limited Warranty Policy

Bioscrypt warrants to the original consumer purchaser (“Customer”) that new

Bioscrypt products will be free from defects in material and workmanship for one

year from the date the product was shipped from Bioscrypt. For replacement

products the warranty on the replacement unit is the remainder of the warranty

on the original product or ninety (90) days, whichever is longer. The Customer is

responsible for making any claims for shipment damage (evident or concealed)

with the freight carrier. Bioscrypt must be notified within thirty days of shipment of

incorrect materials.

If a defect is discovered, Bioscrypt's sole obligation shall be to repair or replace

the Bioscrypt product(s) at its sole discretion at no charge, provided it is returned

to Bioscrypt during the warranty period and is shipped freight and insurance

prepaid. Merchandise must be properly packaged to prevent damage during

shipping. Before returning a Bioscrypt product, contact Bioscrypt Technical

Service to obtain a Return Material Authorization (RMA) number. No product may

be returned whether in warranty or out of warranty without first obtaining

approval from Bioscrypt. The model number, invoice number, and serial number

may be required for warranty service.

This warranty shall not apply to any product or any part of a product, which in the

judgment of Bioscrypt, has been subjected to misuse, negligence, alteration,

accident, improper maintenance, or damage by excessive physical or electrical

stresses. Tampering, such as opening the housing of a biometric reader or

replacing parts will void this warranty. The warranty is void if the serial number of

the Bioscrypt product has been defaced, altered, or removed or if the product

has been modified. Repair and replacement parts will be furnished on an

exchange basis and may be either reconditioned or new. All replaced parts or

products become the property of Bioscrypt. This warranty may also be voided for

failure to comply with Bioscrypt’s return policy.

The warranty is not applicable to:

• Abnormal wear and tear

• Damage caused during installation

• Damage caused by the equipment or system with which the biometric reader

is used

• Damage caused by modification or repairs not made or authorized by

Bioscrypt

• Damage caused by improper packaging

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page v

• Damage caused by lack of ESD protection

• Merchandise that is determined to be stolen

The newest Bioscrypt Veri-Series products are designed to be weather resistant but

no sensor technology exists today that can work in all weather environments. If a

Bioscrypt Veri-Series product is not used in a completely indoor environment, then

a protective cover is required to shield the sensor from moisture, dust, and other

contaminants that will degrade sensor operation and void the product warranty.

This warranty is exclusive and in lieu of all others, whether oral or written, expressed

or implied. Bioscrypt specifically disclaims any and all implied warranties,

including without limitation, warranties of merchantability and fitness for any

particular purpose. No Bioscrypt dealer, agent, or employee is authorized to make

any modification, extension or addition to this warranty.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page vi

Notices

The Veri-Series line of products have been tested for compliance with all

applicable international standards. The resulting approvals are listed below, and

are additionally printed on the labeling located on the rear panel of the product.

The power supply offered by Bioscrypt is CE and CSA approved and UL listed.

V-Flex

V-Prox

V-Pass

V-Smart

V-Station

FCC Information to Users

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his own expense.

FCC Class B Digital Device or Peripheral - User’s Notice (for all V-Station models only)

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one of more of the following measures:

FCC, UL, ULC, CE

FCC, UL, ULC, CE

FCC, UL, ULC, CE

FCC, UL, ULC, CE

FCC, UL, ULC, CE

• Reorient or relocate the receiving antenna

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected

• Consult the dealer or an experienced radio/TV technician for help

CE Information to Users

All Veri-Series devices have the CE mark, for compliance with CISPR22 /EN 55022

requirements. For European Union (EU) countries, V-Prox, V-Smart, and V-Station

(models V-Station A, P, V-Station A, G, and V-Station A, H) are compliant with CE

under the R&TTE Directive, related to the radio transceivers that are part of their

design. The V-Prox and V-Smart are compliant with this directive if, and only if, the

user installs the Bioscrypt specified R&TTE Installation Kit (Bioscrypt part number

832-00103-00). This filter kit should be included with any V-Prox or V-Smart product

if it was shipped to a country within the EU.

The R&TTE Installation Kit consists of two filters: a line filter used to minimize

conducted emissions from power supply lead lengths greater than 3 meters and a

DB-15 “Pass-Thru” filter used to minimize radiated emissions.

Page vii

Line Filter: Manufacturer: JMK Filters

Amhearst, New Hampshire

USA, 03031

www.JMKFilters.com

Part Number: FF-1586-1

Pass-Thru Filter: Manufacturer: Spectrum Control

Fairview, Pennsylvania

USA, 16415

www.SpectrumControl.com

Part Number: 56-605-019

If the filters were not included with the product or if they are desired separately,

they may be ordered from Bioscrypt (part number 832-00103-00) or the distributor

from which the product was purchased. Please see Appendix A for details on

proper installation of these filters.

NOTE: The installation of these filters is mandatory for the registered CE mark, and

associated R&TTE directive compliance to be valid within the European Union.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page viii

Failure to do so will render the CE mark and consequent right to operate the

equipment null and void.

For each device compliant with the R&TTE Directive, Declarations of Conformity

for directives 73/23/EEC, 89/36/EEC and 1999/5/EC can be found on the Bioscrypt

web site at: http://www.bioscrypt.com

Warning to Users

Warning: Changes or modifications not expressly approved by Bioscrypt Inc.

could void the user’s authority to operate the equipment.

V-Smart, A Information for Users

The V-Smart, A includes a contact-less smart card reader (GemEasyLink680SL). This

is a radio-transceiver with the following characteristics:

Operating Frequency Range: 13.553-13.567 MHz

RF Power Rating: 0.0 Watts

RF Output Impedance: 50 Ohms

V-Smart, A, H Information for Users

The V-Smart, A, H includes a contact-less smart card reader (HID iCLASS™ OEM

100/RS232). This is a radio-transceiver with the following characteristics:

Operating Frequency Range: 13.553-13.567 MHz

RF Power Rating: 0.0 Watts

RF Output Impedance: 50 Ohms

V-Prox, A, H Information for Users

The V-Prox, A, H includes a HID contact-less proximity reader. This device has the

following characteristics:

Transmit Frequency: 125 KHz

Excite Frequency: 125 KHz

V-Station, A, G Information for Users

The V-Station, A, G includes a contact-less smart card reader (GemEasyLink680SL).

This is a radio-transceiver with the following characteristics:

Operating Frequency Range: 13.553-13.567 MHz

RF Power Rating: 0.0 Watts

RF Output Impedance: 50 Ohms

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

V-Station, A, H Information for Users

The V-Station, A, H includes a contact-less smart card reader (HID iCLASS™ OEM

100/RS232). This is a radio-transceiver with the following characteristics:

Operating Frequency Range: 13.553-13.567 MHz

RF Power Rating: 0.0 Watts

RF Output Impedance: 50 Ohms

V-Station, A, P Information for Users

The V-Station, A, P includes a HID contact-less proximity reader. This device has

the following characteristics:

Transmit Frequency: 125 KHz

Excite Frequency: 125 KHz

Page ix

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page x

Version Notes

Version 7.20: This is the version described in this manual. Versions equal to or

greater than 7.0 support the V-Station. With this release, the V-Station Prox, VStation MIFARE, V-Station iCLASS, and V-Station Searching models are supported.

Version 7.10: This version began support for Ethernet communication on all VStation models.

Version 7.00: This is the first version released with the V-Station. Versions 7.x are

intended only for use on V-Stations

Versions 5.20 – 6.xx: Please refer to the MV1200 Release Notes document for

further information on changes from one version to the next. Version 5.20 and

above are intended only for MV1200 based Veri-Series products.

Versions 1.0 - 3.30: These versions apply only to older MV1100 based products,

and are not compatible with newer MV1200 based products. Version history for

these versions may also be found in the MV1200 Release Notes document.

NOTE: Future versions of the Veri-Series hardware and software may be

significantly different than described in this manual. Please make sure that you

are using a manual that correctly coincides with the hardware version you are

installing. Please contact Bioscrypt if you have any questions or visit

www.bioscrypt.com to download updated documentation and firmware.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page xi

Table of Contents

Introduction............................................................................................................................................ii

Disclaimer...............................................................................................................................................iii

Bioscrypt One Year Limited Warranty Policy..............................................................................iv

Notices...................................................................................................................................................vi

FCC Information to Users..............................................................................................................vi

FCC Class B Digital Device or Peripheral - User’s Notice (for all V-Station models

only)....................................................................................................................................................vi

CE Information to Users................................................................................................................vii

Warning to Users.............................................................................................................................viii

V-Smart, A Information for Users................................................................................................viii

V-Smart, A, H Information for Users...........................................................................................viii

V-Prox, A, H Information for Users..............................................................................................viii

V-Station, A, G Information for Users........................................................................................viii

V-Station, A, H Information for Users...........................................................................................ix

V-Station, A, P Information for Users...........................................................................................ix

Version Notes........................................................................................................................................x

Table of Contents ................................................................................................................................xi

Notes......................................................................................................................................................xii

About the Veri-Series Products........................................................................................................1

About this Manual...............................................................................................................................4

Steps in a comprehensive installation...........................................................................................5

Planning the Installation ....................................................................................................................6

Component Selection........................................................................................................................7

Mounting................................................................................................................................................8

Mounting Templates.......................................................................................................................9

Power Distribution & Device Hookup...........................................................................................12

Selecting the Right Power Supply.............................................................................................13

Device Hook-up (V-Prox/V-Flex/V-Pass/V-Smart).................................................................14

Device Hook-up (V-Station) ........................................................................................................16

Wiegand Connections.................................................................................................................19

ESD Shield Earth Ground Requirement ...................................................................................19

RS-485................................................................................................................................................19

Ethernet (V-Station only)..............................................................................................................19

TTL (V-Station only).........................................................................................................................19

Cabling and Interconnection........................................................................................................20

When is an RS-485 network required?.....................................................................................20

When is an RS-485 network required?.....................................................................................21

When is an Ethernet network required?..................................................................................21

RS-485 Cable Specification ........................................................................................................21

Ethernet Cable Specification.....................................................................................................22

RS-485 Network Topology............................................................................................................23

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page xii

Ethernet Network Topology........................................................................................................24

RS-485 Cable Termination...........................................................................................................24

Extending the RS-485 Specification..........................................................................................26

Connecting to the Computer .......................................................................................................28

System Turn-up Procedures.............................................................................................................30

Device Configuration Check.....................................................................................................30

Ground Potential Difference Check........................................................................................31

General Installation Guidelines......................................................................................................32

Installation Issues:...........................................................................................................................32

Network Operation Issues:..........................................................................................................32

Operational Issues:........................................................................................................................33

Appendix A – Installing the R&TTE Installation Kit Filters..........................................................34

R&TTE Wiring Instructions for the V-Prox, A, H.........................................................................34

R&TTE Wiring Instructions for the V-Smart, A and V-Smart, A, H .......................................35

References...........................................................................................................................................37

Bioscrypt Contact Information......................................................................................................39

Notes

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

About the Veri-Series Products

Figure 2: The V-Smart

Bioscrypt’s V-Prox (figure 1) two-in-one solution combines a selfcontained fingerprint verification package about the size of a

business card (the MV1200), with an embedded proximity card

reader. The two technologies are housed together in a modern

case that conforms to mullion mount standards.

The V-Flex (figure 1) provides all of the same capabilities of the

V-Prox. Instead of having an embedded proximity card reader,

the V-Flex requires an external Wiegand input from a card

Page 1

reader or keypad. Both the V-Prox and V-Flex store

thousands of templates.

Figure 1: The V-Prox

/ V-Flex / V-Pass

The V-Pass (figure 1) reader does not use cards or PINs.

By simply placing your finger on the sensor, the device will

search through its database of hundreds of stored

templates and respond via Wiegand to a door controller

with the ID number of the user that matched the

candidate image.

The V-Smart (figure 2) provides all the capability of the V-

Flex and includes an internal smart card reader (either

MIFARE or iCLASS). Fingerprint templates are securely

stored on a smart card and carried by the employee.

The smart card is presented to the V-Smart and the

template is read from the card and verified against the

employee’s live image. Storing the template on the smart card allows the V-Smart

to have an unlimited user base, removing the need for a physically-wired network.

The V-Station (figure 3) is the first stand-alone version

of the Veri-Series product line with an integrated

keypad and LCD display. Many actions can be

performed right from the console, thereby freeing

users from having to administer the device from a PC.

The standard version stores more than 3000 templates

based on an ID entered on the keypad, but versions

are available which include an enclosed proximity

reader (V-Station A, P) or smart card reader (V-Station

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Figure 3: The V-Station

Page 2

A, G and V-Station A, H). A searching version (V-Station A, S) is also available. In

addition, this is the first product to offer built-in Ethernet support, and is by far the

most flexible of the available devices.

All of the Veri-Series readers are stand-alone or network readers that perform

enrollment and verification and provide standard communication options that

enable it to be easily incorporated into access control systems.

The response time is less than 5 seconds for fingerprint enrollment and less than

one second for fingerprint verification. The system is compact, versatile, and can

be configured in a variety of ways. The readers support the industry-standard

Wiegand interface that can be used to connect to most any door controller or

alarm panel. The unit supports RS-232 for administration through a PC connection,

and it also supports RS-485 for multiple-unit operation and administration. The VStation also supports administration over an Ethernet network.

The Bioscrypt products use the latest generation of solid-state (chip) fingerprint

scanners or sensors. This type of sensor is being provided by a variety of

electronics manufacturers and the Veri-Series products are the only devices to be

compatible with a variety of sensors – this is Bioscrypt’s sensor interoperability.

The following paragraphs refer to operation and administration of the V-Prox

device, however the same functions can be performed through the VeriAdmin

software provided, or through the keypad on a V-Station.

The operation of the V-Prox is very simple: a user places or waves their card near

the V-Prox unit, the unit prompts the user to place their finger on the sensor

(communication is by means of a multi-colored LED), the V-Prox then reads the

fingerprint and compares it to a stored record of the user. If the comparison yields

a high degree of match, the user fingerprint is accepted and the user’s ID number

is transmitted to the access control unit over the Wiegand connection. If the

match fails, then either nothing is sent to the controller or a failure code is sent so

that the controller can log failed access attempts. The controller unlocks the door

for the user if the user has access. Therefore, the procedure is simple: present a

card, place finger, and open the door. The whole process takes less than 5

seconds.

Administration of the V-Prox is also simple. Any number of cards can be set up as

Enroll or Delete cards. These cards are maintained by the system administrator(s)

responsible for the access control system (one or more cards can be kept off-site

for added safety). To enroll a new user within a V-Prox unit, present an Enroll card,

verify the fingerprint of an authorized Enroller, present an unused card, and finally

place the finger of the user on the system. The user is now enrolled in this V-Prox

unit. If the installation has multiple V-Prox units you will have to either repeat this

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 3

enroll process on other units or use software (if the units are connected via a RS485 or Ethernet network) to transfer the templates. The User ID will also have to be

added to the access control system. Deleting a user from the V-Prox is just as easy

– just use the Delete card instead of the Enroll card and follow the same

procedure.

All Veri-Series products also include an auxiliary port in the bottom of the unit. This

auxiliary port supports RS-232 communications with a host computer. You can use

this port to transfer templates, manage enroll and delete cards, etc.

An additional Ethernet port is now available on V-Station products, enabling

administration and template management over an Ethernet compatible network,

using the VeriAdmin software.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 4

About this Manual

This manual provides a simple step by step procedure for defining the RS-485 or

Ethernet network which will be used to communicate to a number of Veri-Series

readers as well as making connections to those readers. The Veri-Series Operation

Manual (under different cover) will provide the user or installer with information

required to configure the readers for communications on an RS-485 or Ethernet

network and for making other configuration changes such as for Wiegand format.

The V-Prox, V-Flex, and V-Pass readers are designed to be compatible with mullion

mount applications. Mullion mounting is not required, however, and the readers

can be mounted on any flat surface. The installer will want to take into account

codes and ordinances which affect the installation. The readers can also be

mounted on a single gang electrical box. Bioscrypt provides both a narrow and a

trimmed out wall plate for these applications.

Bioscrypt offers a Veri-Series Operations Manual under a separate cover. This

guide describes in complete detail the administration and day-to-day operation

of the Veri-Series unit. Bioscrypt also offers a Veri-Series Setup Guide , a quick stepby-step guide for initial Veri-Series setup and use. Both of these are included on

the installation CD.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 5

Steps in a comprehensive installation

Every installation is unique. In some cases, the issues are well understood and can

be handled in a standard fashion. In other cases, there are issues that are specific

to the installation, and may not be immediately recognizable. This document

attempts to address many of the issues that you will be faced with during

installation. The steps for a successful installation are:

Ø Planning the installation – outlining the different components in the

installation, determining the interconnections between different

components, identifying issues specific to the installation

Ø Component selection – deciding on the right Veri-Series product(s) to use,

choosing a door controller, which type of proximity or smart cards to use,

which type of PC to use (optional, except for V-Pass), etc.

Ø Mounting – proper mounting hardware and location must be chosen in

accordance with applicable regulations as well as desired esthetics and

convenience

Ø Power Distribution / Device hook-up – proper power must be supplied to

each unit and consideration must be given to using UPS, avoiding

interference, proper grounding, etc.

Ø Cabling and Interconnection issues – the topology, type of network, and

type of cable used will be determined by requirements such as number of

units, distance between units, data throughput, etc. Each device on the

network must be assigned a unique ID (and IP address for Ethernet) to avoid

communication collisions

Ø Power-up procedure – units should be brought up one at a time in a

thoughtful sequence to help trouble-shoot any problem areas

The following sections will provide more information on each of these steps.

WARNING WARNING

Veri-Series devices must be installed by a qualified technician.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 6

Planning the Installation

Planning the installation is probably the single most important aspect to a

successful installation. Good planning will be comprehensive, accurate, and

adaptable. Planning for an Access Control installation must consider: the access

controller, the door locks, and the readers. Readers provide a means for the users

to request access to a controlled area. The Veri-Series products are different from

typical readers in that they provide not only verification of the presence of an

authorized card, but also the assurance that the authorized holder is presenting

the card.

During the planning phase, you should determine:

Ø How many doors need to be protected

Ø What type of reader on each door (maybe some doors are internal and

don’t require the added security of the Veri-Series)

Ø If multiple Veri-Series units are to be networked, a dedicated PC is

recommended to administer the system. This can be done through RS-232

(primary or auxiliary ports), RS-485, or via Ethernet (V-Station only).

Ø The controller must support any of the Wiegand formats supported by the

Veri-Series units.

Ø If the installation requires RS-485 or Ethernet network cabling for template

distribution/management

When planning the system, identify all wiring by the signal levels they are to carry.

Wires can be generally separated into the following groups:

1. Power distribution: Wires carry power to devices, door strikes, etc.

2. Data communication: RS485, RS-232, Ethernet, Wiegand, etc.

3. Sensor: Door contact, request to exit push button, alarm input, etc.

Use separate cable/conduit for different signal groups to avoid cross talk. Observe

the distance limitation of each type of signal when planning device placement.

Line extenders or repeaters can be used for extended distances when required.

Do not run any wires near utility AC power wiring, lightning rod grounding wire,

etc. to avoid externally generated transients. Grounding equipment is required for

ESD protection and safety.

Do research on the environment where the equipment will operate. If used

outdoors, it may be necessary to seal the readers or protect the installation with a

weather shield.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 7

Component Selection

Component selection will be based on customer demands and requirements. We

are glad that you are considering or have selected Bioscrypt products as part of

your system integration. We hope that you find the readers to be easy to use

while offering an unparalleled level of security.

The readers do not have built-in relays that would allow them to control a door

lock, and therefore, they must be part of a larger system such as a door control

system. Each of the Veri-Series readers offer RS-232 and RS-485 communications

channels for communicating with a PC or host controller. In addition, the VStation supports communication via a 10base-T Ethernet port. Each reader also

uses the Wiegand protocol to interface with Access Control equipment such as

door controllers (outputs) or additional readers (inputs).

Therefore, a minimum system would consist of a fingerprint reader unit mounted

on or near a door mullion, an electric lock, and the door controller. More

complex systems may consist of readers on multiple doors, each door with an

electric door lock, a multi-door controller, and a PC to run the door controller and

Veri-Admin management software. Some installations will require anti-passback

capabilities, and these will typically use standard proximity card readers

(compatible with the V-Prox system) on “request to exit”.

In addition to the hardware components, the installation will contain proximity or

smart cards, cabling, and will likely include a PC, an RS-232/RS-485 converter, and

software. Equipment for setting up an Ethernet network may also be needed,

including, hubs, switches, network cards, etc. Some installations may wish to utilize

a database or custom software for template management and access

scheduling.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Mounting

Reader

2

543

wall

Page 8

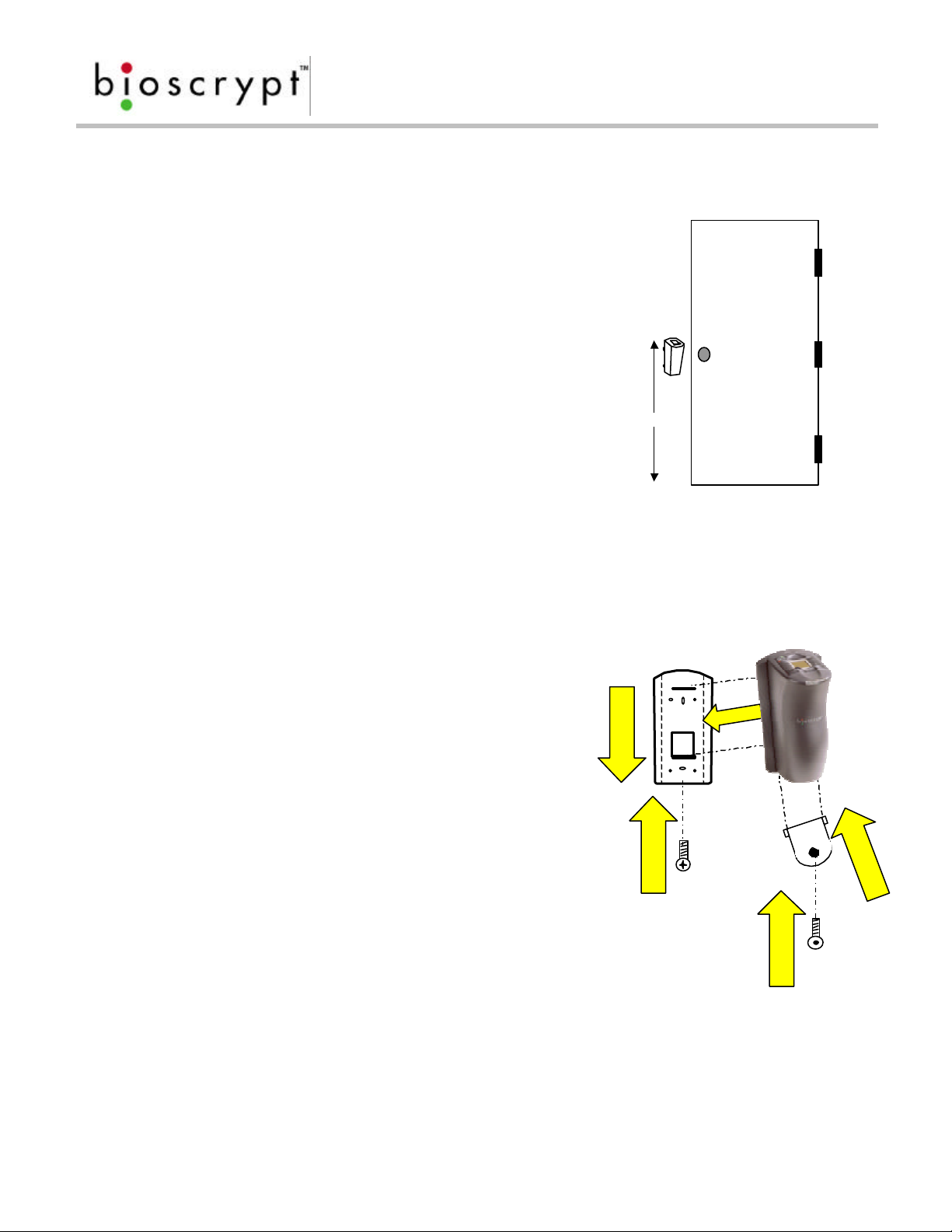

The readers can be mounted to any flat surface. The

following describes the V-Prox/V-Flex/V-Pass mounting,

but the same concept applies to mounting the V-Smart

and V-Station (except for mullion mounting).

The mounting plate is 2 inches wide, which is suitable

for mounting in a door mullion. The mounting plate

hole pattern is also compatible with single gang box

mounting. The pig-tail protruding from the rear of the

48 – 54 ”

unit is for connecting the reader to the rest of the

system.

Factors in determining the position of the reader on the

wall should include mounting in-line with other switch

Figure 3: Positioning the

plates or fixtures, approximately 54 inches from floor to

top of unit (see figure 4), mounted on knob-side of door, and in accordance with

Americans with Disabilities Act.

Reader mounting is very simple. The mounting

plate is attached to the wall or mullion using screws

and anchors to secure it in place (see figure 4 ).

1

The reader body has two tabs which slide into the

wall plate. Use the following procedure:

1. Align reader body with wall plate

2. Slide reader body down, locking tabs into

wall plate

3. Set reader body in place with Phillips-head

#4-40 screw

4. Attach Aux. port door to bottom of reader

with a twisting motion

5. Secure door to reader with pin-in-hex #6-32

screw

Figure 5: Mounting the reader to the

All of the readers in the Veri-Series line are

constructed out of durable ABS plastic. The mounting plate is also constructed

out of ABS plastic. This system provides for a very lightweight, yet sturdy system.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

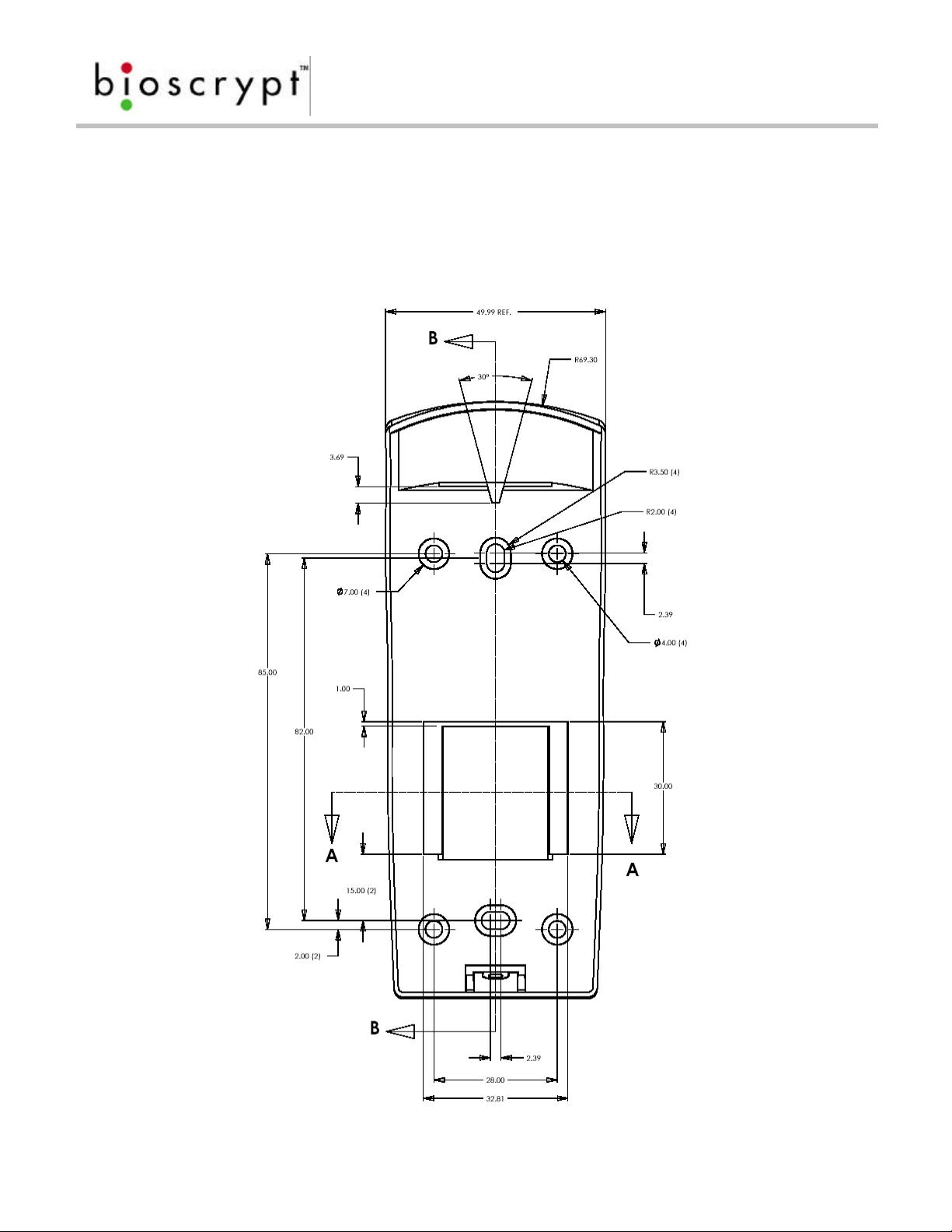

Mounting Templates

o For mounting into wall anchors, wood or sheet metal use #4 flat head

screws (<0.125 inch thread width, <0.250 inch head width).

o For mounting onto gang box, use #6-32 machine screws with flat head.

Page 9

Figure 6: V-Prox/V-Flex/V-Pass Mullion Mounting Template

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 10

Figure 7: V-Smart Mounting Plate Template

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 11

Figure 8: V-Station Mounting Plate Template

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 12

Power Distribution & Device Hookup

The Veri-Series product as well as other components in the system will rely on

power provided to the system for operation. In a small installation, power may be

provided by means of an AC adapter placed near the V-Prox reader itself. In

larger installations, power will be distributed from either a central source or various

sources.

Power to the Veri-Series units should be:

o Isolated from other equipment

o Filtered

o Protected by means of a uninterruptible power supply (UPS) or battery

backup

o If transients are an issue in the installation, a transient voltage suppression

device is also recommended

When planning a system, know the power requirement of each device. If multiple

devices are to share a common power supply, care must be exercised to avoid

excessive voltage loss on the wires. Voltage loss can lead to communication

problems when devices are talking/listening on different ground references.

Voltage loss is directly proportional to wire resistance and the current the wire

carries. Place the power supply as close to the equipment as possible. Select

appropriate wire size for the load. The Veri-Series readers run on DC power

between 6 and 24 VDC (V-Smart operates between 8-12V DC and V-Station

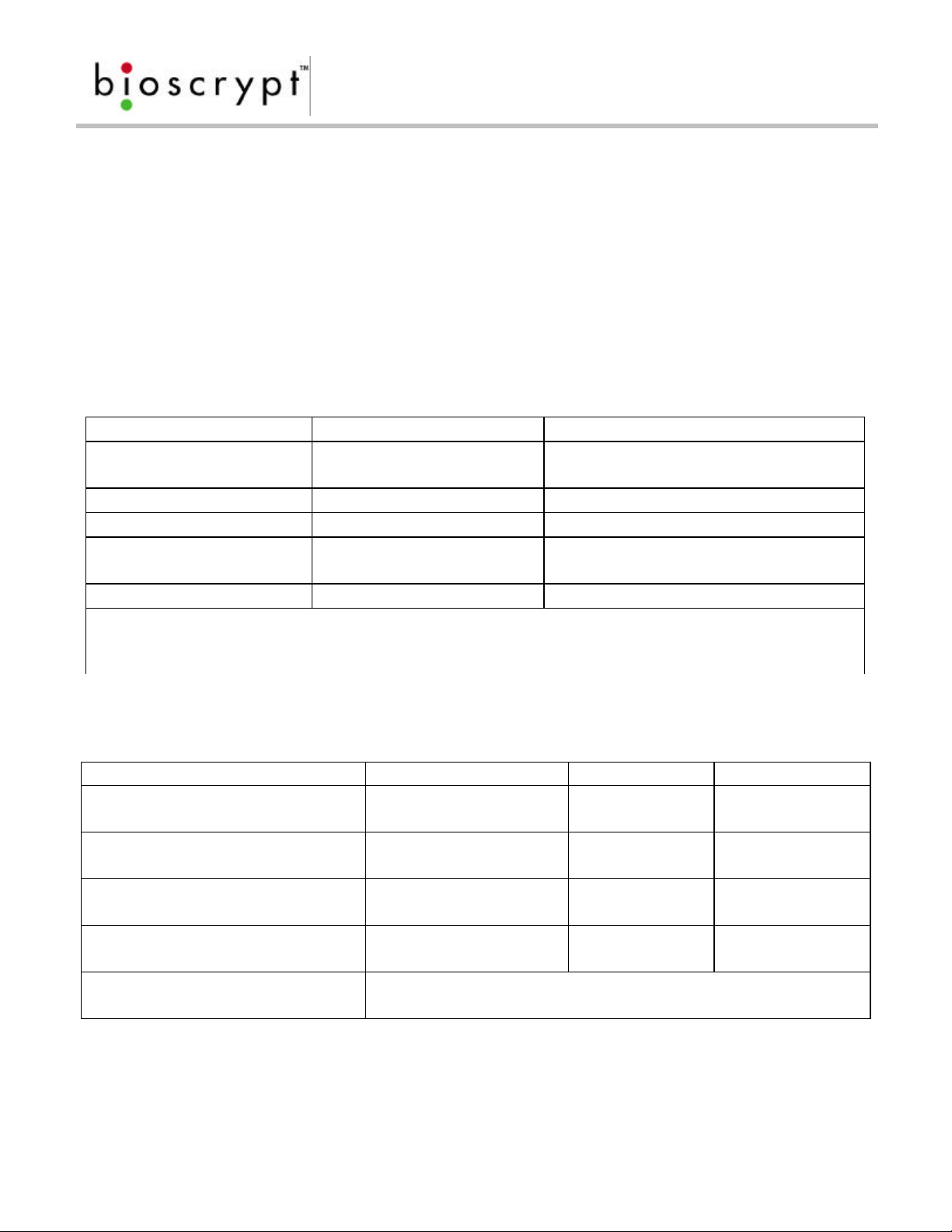

between 12-24V DC). Power requirements are as listed in Table 1.

V-Prox/V-Flex/

V-Smart (all

models)

Power Requirement: 5 Watts 5 Watts 5 Watts

Input Voltage Range: 8-12VDC 6-24 VDC 12-24 VDC

Peak Current:

6 VDC N/A 800 mA N/A

12 VDC 400mA 400 mA 500mA

24 VDC N/A 200 mA 200mA

Current at 12 VDC:

Verification 300-400 mA 300-400 mA 300-400 mA

Idle (non V-PASS) 160 mA 60 mA 300 mA

Idle (V-Pass) N/A 150-200 mA N/A

V-Pass

V-Station (all

models)

Table 1: Veri-Series Power Requirements

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Selecting the Right Power Supply

Most power supplies in the market today provide good input/output isolation,

however those which do not provide isolation (or have hit leakage capacitance),

coupled with accidental AC power lines interchange, present serious ground fault

problems for installers. With ground fault, the signal reference between subsystems

may be 115 VAC apart. If these subsystems are interconnected, the large

potential difference will cause equipment damage or personal injury. We

recommend use of isolated power supplies only.

All factory supplied power supply assemblies are either switching or regulated

linear supplies and are isolated for safety and to minimize ground loop problems.

Page 13

WARNINGWARNING

Use only a UL-Listed Class II power supply at 12V DC, 500mA.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Device Hook-up (V-Prox/V-Flex/V-Pass/V-Smart)

Green/Yellow

The readers are connected to other components of an integrated system through

the pig-tail wire bundle that protrudes from the rear of the unit. This wire bundle is

made up of the connections described in Table 2.

PIN SIGNAL COLOR

Pigtail Jacket Blue

1 Wiegand Data0 Out Green

2 Wiegand Data0 In Green/White

3 Wiegand Data1 Out White

4 Wiegand Data1 In White/Black

5 Line Trigger Gray

6 Wiegand Ground Black/White

7 RS-485 (-) Blue/Black

8 RS-485 (+) Blue

9 RS-232 (Tx)

Violet

*N/A on V-Smart

10 RS-232 (Rx)

Violet/White

*N/A on V-Smart

11 Power Ground Black

12 RS-232 Signal Ground Black/Red

13 Power In

Red

8-12VDC - V-Smart

6-24VDC - all others except

V-Station

14 5 VDC output

Red/White

*N/A on V-Smart

*No-connect for MV1200

based units

15 Earth Ground

Page 14

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 15

Table 2: Veri-Series Pigtail Connections

WARNING

The RJ-11 connector is intended for RS-232 communication only! Any attempt to

connect it to a phone line will damage the unit.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Device Hook-up (V-Station)

The V-Station readers do not have a pig-tail wire bundle as do the other Veri-Series

products. Connections are made using RJ-45/RJ-11 or Weidmuller connections.

Tables 3 and 4, shown below, describe V-Station’s connections while Figure 9

shows the layout on the back of the V-Station.

GROUP PIN SIGNAL

Ethernet RJ-45 1 Receive +

2 Receive 3 Transmit +

4 NC

5 NC

6 Transmit 7 NC

8 NC

RS-485 RJ-45 1 Transmit +

2 Transmit 3 Ground

4 Receive +

5 Receive 6 NC

7 NC

8 NC

RS-232 RJ-11 1 TX

2 RX

3 RTS*

4 CTS*

5 Ground

6 NC

Page 16

Table 3: V-Station Ethernet, RJ-45, and RJ-11 Connections

*Not connected but may be used in the future

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

GROUP LABEL SIGNAL

RS-485 TX(+) Transmit +

TX(-) Transmit -

RX(+) Receive +

RX(-) Receive -

GND RS-485 Ground

RS-232 GND RS-232 Ground

TX Transmit

RX Receive

Power/E-Ground +(POS) 12 - 24 VDC +

-(NEG) 12 - 24 VDC EGND Earth Ground

Wiegand IN 0 Data 0 In

IN 1 Data 1 In

OUT 0 Data 0 Out

OUT 1 Data 1 In

LED IN LED In

LED OUT LED Out

GND Wiegand Ground

TTL (IN) IN 0 TTL Data 0 In

IN 1 TTL Data 1 In

TTL (OUT) OUT 0 H TTL Data 0 Out

OUT 1 L TTL Data 1 Out

GND TTL Ground

Page 17

Table 4: V-Station Weidmuller Connections

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 18

Figure 9: Rear Diagram of V-Station

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Wiegand Connections

Wiegand output lines should be connected to the Wiegand compatible

controller. When connecting Wiegand output to a controller, you must make that

connection using Data0, Data1, and a common Ground reference. Wiegand

input lines can be used for an alternate Wiegand input device (this connection is

required for the V-Flex device).

ESD Shield Earth Ground Requirement

The Finger mask (conductive plastic surrounding the fingerprint sensor) is

sometimes referred to as an ESD Shield. Pin 15 on the Pigtail (EGRND on the

input/earth-ground connector for V-Station) is connected to the ESD shield of the

fingerprint sensor. This should be connected in such a way as to make a lowimpedance connection to Earth ground. DO NOT CONNECT THE SHIELD TO

POWER GROUND. Improper connections will potentially create ground loops that

may cause damage to the Veri-Series and other equipment. Furthermore,

neglecting to provide a path for ESD to Earth ground puts the electronics at risk if

ESD is discharged into the unit from a user.

Page 19

RS-485

RS-232 and RS-485 are used for communication with a PC running Veri-Series

compatible software (such as our VeriAdmin software). RS-485 connections

among various readers should be made by connecting the (+) and (-) lines of the

differential RS-485 in a daisy chain manner. For instance, from V-Prox to V-Prox,

the (+) line from one V-Prox is connected to the (+) line of the next V-Prox and so

on; likewise for the (-) lines. Additionally, connect the grounds from each V-Prox

unit back to the signal ground connection for the PC.

Ethernet (V-Station only)

The RJ-45 Ethernet connector can also be used for communication with a PC

running Veri-Series compatible software (Version 5.10 and above). Standard

Ethernet patch cables may be used, but care must be taken to identify straightthrough cables versus crossover cables. To wire a V-Station directly to a PC NIC

card, a crossover cable must be used. For connecting multiple V-Stations

together on an Ethernet bus or directly to a switch or hub, straight-through cables

should be used.

TTL (V-Station only)

The TTL Input/Output connections are standard 5V TTL Logic lines and are reserved

for future use.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 20

example, at 9600 baud, a distance of 100 ft. is possible with shielded cable, but at

56 k-baud (kbps) a maximum of 20 ft. is recommended.

Cabling and Interconnection

Cabling may seem to be a trivial aspect to the installation, requiring nothing more

than planning the cabling route and pulling the cable through the building. This is

true for Wiegand and power wiring considerations, however, if your installation

requires the use of RS-485 or Ethernet communications, then the choice of cable,

the cable run length, the network topology, and termination of the network may

be very important aspects that must not be overlooked.

Spec RS-485 RS-232

Mode of Operation: Differential DC

Coupled

DC Isolation: No No

Max. Distance: 4000 ft. 200 ft.*

Number of Devices on

32 2

one line:

Max. Data Rate 56 kbps 56 kbps*

*RS-232 communications distances are dependent on baud rate (bps). For

Single-ended DC Coupled

Table 5: RS-232 / RS-485 Communications Comparison

Parameter 10 Mbps 100 Mbps 1000 Mbps

Maximum collision diameter,

DTE to DTE

Maximum collision diameter

328 ft. UTP 328 ft. UTP

1352 ft. fiber

328 ft. UTP

1037 ft. fiber

8202 ft. 673 ft. 656 ft.

with repeaters

Maximum number of

5 2 1

repeaters in network path

Maximum number of devices

255 255 255

on one line

Maximum Data Rate* *V-Station supports only 10BaseT (10 Mbps); internally,

the product is still limited to 56K or 115K bps

Table 6: Ethernet Comparison

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

When is an RS-485 network required?

RS-485 is a networking specification similar to Ethernet, which is used for computer

networks. RS-485 is different from Ethernet and is not compatible with modern

computer networks. This means that you cannot connect most Veri-Series units

directly up to Ethernet networks. The V-Station does however support Ethernet.

RS-485 has two distinct advantages over the more common RS-232. First, it allows

you to connect up to 31 Veri-Series units to a PC (the PC will either need internal

support for RS-485 or will require an external RS-232/RS-485 converter available

from Bioscrypt). Second, the RS-485 specification allows for cable run lengths up

to 4000 feet (1200 meters) at modest baud rates.

An RS-485 network will need to be implemented in the following circumstances:

o There are multiple readers that must be connected together so that

templates can be distributed among the units

o There is only a single reader, but it is over 100 feet (30 meters) from the host

PC.

Page 21

When is an Ethernet network required?

Ethernet is a networking specification now used all over the world for computers,

IP phones, and other devices. The only Bioscrypt product which currently supports

this standard is the V-Station. Ethernet has many advantages over an RS-485

network, namely, faster data transfer rates over greater distances. However, the

prime advantage to your network of Bioscrypt readers will be the ability to

connect many more units, enjoy easier configuration from the PC, and avoid

conflicts when multiple units transmit at the same time (i.e., if two or more units

have the same unit ID). Care must be taken to ensure the security of V-Stations

placed on a network which is also shared by PCs other than the administration

machine or other peripherals.

RS-485 Cable Specification

The Veri-Series readers provide a 2-wire, half-duplex RS-485 interface. The main

run cable should be low capacitance, twisted pair cable, with approximately 120ohm characteristic impedance. Category 5 rated communications cable is used

in Ethernet networks. This cable is typically 24 AWG (solid), unshielded, twisted-pair

with a shunt capacitance of approximately 17 pF/ft and characteristic

impedance of 100 – 120 ohms. This is the recommended cabling for RS-485

communications. In certain electrically noisy environments, a shielded cable may

be required.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 22

Capacitance (conductor to

Spec Recommendation

<20 pF/ft.

conductor)

Characteristic Impedance 100 – 120 ohms

Nominal DC resistance <100 ohms/1000 ft.

Wire gauge 24 AWG stranded

Conductors/Shielding >2 pair (shielded

optional)

Table 7: Recommended Cable Characteristics

It is often hard to quantify if shielded cable is required in an application or not.

Since the added cost of shielded cable is usually minimal it is worth installing the

first time.

The total length of the communication cable (adding up all of the segments of

the run) must not exceed 4000 ft (1200 m) as outlined in the specification for RS485 (see reference 3).

Although the RS-485 specification calls out a maximum cable length of 1200

meters and a maximum baud rate well above that of the Veri-Series reader, a

more conservative system should be configured for no more than 1000 meters

and running at a baud rate of 9600 bits per second. After the network is

configured and is running in a stable manner, the baud rate can be increased if

faster network communications are desired.

Figure 10: Category 5 cable for RS-485/Ethernet Communications

Drops (down leads) to equipment are not recommended, but if required, should

not exceed 10 feet and should use the same cable recommended above.

Ethernet Cable Specification

Ethernet cables should generally be shielded Category 5 or better. The V-Station

supports only 10Base-T Ethernet. Therefore, it only makes sense to use cable for

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

faster Ethernet varieties (such as gigabit) if PCs or other peripherals are to be

placed on the same network.

With most Ethernet networks, straight-thru cables should be used. However, in the

event of a single reader-to-PC network, a cross-over cable must be used. There

are other special considerations for such a network. Please see the next section

on connecting to the computer.

RS-485 Network Topology

Communication cables for RS-485 should be laid out in a daisy chain. See figure

11. Long stubs (T connections) should be avoided because they create

discontinuities and degrade signal quality. If the stub is long, a signal that travels

down the stub reflects to the main line after hitting the input impedance of the

device at the end of the stub. This impedance is high compared with that of the

cable. The net effect is degradation of signal quality on the bus. Keeping the stubs

as short as possible avoids this problem. Instead of adding a long branch stub,

loop the main cable to the device you wish to connect.

Page 23

DO NOT connect devices in a STAR configuration – this creates long stubs and is a

cause for concern. This configuration usually does not provide a clean signaling

environment even if the cable runs are all of equal length. The star configuration

also presents a termination problem, because terminating every endpoint would

overload the driver. Terminating only two endpoints solves the loading problem

but creates transmission-line problems at the un-terminated ends. A true cascade

or daisy chain connection avoids these problems.

Figure 11: Network Topologies - STAR and CASCADE (Daisy Chain)

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Ethernet Network Topology

Communication cables for Ethernet logically form a straight line bus, however, the

more devices placed on that bus, the less efficient the network due to increased

collisions and the weaker the signal will get due to increased distance. Repeaters

can be used to boost signal strength, however a better solution would be placing

switches at intermediate positions along the bus. The most common Ethernet

topology in use today is the star configuration (see figure 11), with a hub or switch

in the center.

RS-485 Cable Termination

Most RS-485 buses require termination because of fast transitions, high data rates,

or long cables. The purpose of the termination is to prevent adverse transmissionline phenomena, such as reflections.

For example, suppose an installation uses 2000 feet of cable. A round trip, then,

covers 4000 feet. Using a propagation velocity of 0.66c (two thirds the speed of

light – contact the cable supplier for this value for your cable), one round trip is

completed in approximately 6.2 micro-seconds. If we assume the reflections will

damp out in three round trips up and down the cable length, the signal will

stabilize 18.6 micro-seconds after the leading edge of a bit. At 56 k-baud (57,600

bits per second) one bit is 17.4 micro-seconds wide. In this case, the reflections do

not damp out before more information is being sent, and corruption of

information is a potential problem. Termination will solve this problem as will

lowering the baud rate. At 9600 baud, the bit width is 104 micro-seconds wide,

the reflections are damped out much before the center of the bit, and

termination is not required. Longer cable length and higher baud rates each push

the case for use of termination.

Page 24

A common mistake is to connect a terminating resistor at each node - a practice

that causes trouble on buses that have four or more nodes. The active driver sees

the four termination resistors in parallel, a condition that excessively loads the

driver. If each of the four nodes connects a 100Ω termination resistor across the

bus, the active driver sees a load of 25Ω instead of the intended 50Ω. The problem

becomes substantially worse with 32 nodes. If each node includes a 100Ω

termination resistor, the load becomes 3.12Ω.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 25

Power

3

Data0

2

RS-232

Cat5

Compute

Door

+12 VDC

Gnd

-

+

R

R

R

- (B)

+ (A)

R

Figure 12: Termination Options - Failsafe (a) and Passive (b)

Bioscrypt recommends that the RS-485 transmission line be terminated at both

ends. The recommended termination at the PC end of the line is called Failsafe

termination. This terminator (shown in figure 12a) ensures that there is a proper

bias voltage across the receiver inputs. This, in turn, ensures that the receiver is in a

known state and puts less of a strain on the driver to provide that bias. This

termination is typically built into the RS-232/RS-485 converters and internal PC addon boards – you should confirm that such a termination exists, but you likely don’t

have to supply it yourself.

The termination at the opposite end of the transmission line should be parallel (or

passive) termination (see figure 12b). The value of R in figure 9b is chosen to

correspond to a proper parallel termination, RT, and it is chosen to be slightly

larger than the characteristic impedance of the cable, ZO. Over-termination tends

to be more desirable than under-termination since over-termination has been

observed to improve signal quality. RT is typically chosen to be equal to ZO. When

over-termination is used RT is typically chosen to be up to 10% larger than ZO. The

elimination of reflections permits higher data rates over longer cable lengths.

Suppl

Unit Unit Unit Unit

Twisted

Controll

er

Data1

Wiegand

Pair

/RS-485

Converter

r

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Extending the RS-485 Specification

Wiegand Ground

Wiegand Out Data0

Earth

To

Computer

RS-232

RS-485 (-)

RS-485 (+)

Connect to

Twisted Pair.

Some systems require longer distances or higher numbers of nodes than supported

by RS-485. Repeaters are commonly used to overcome these barriers. An RS-485

repeater can be placed in a system to divide the load into multiple segments.

Each “refreshed” signal is capable of driving another 4000 feet (1200 meters) of

cable and an additional 31 RS-485 unit loads. Using an Ethernet network with

switches can also solve this problem. The Veri-Series units represent a single unit

load to the transmission line.

Use Cat5 rated cable

TD(A)

TD(B)

RD(A)

RD(B)

+12VDC

GND

Earth

Ground

Page 26

Pigtail

Figure 14: Wiring Diagram for RS-232/RS-485 Converter

Power

Supply

Door

Wiegand Out Data1

Ground

+12 VDC

Ground

Data 0

Data 1

Common

Controller

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Figure 13: Network Configuration

Figure 15: Reader Wiring Schematic

Page 27

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 28

Connecting to the Computer

The Veri-Series units can be connected to the computer either through an RS-232

communications link, an RS-485 link, or via Ethernet.

RS-485 and RS-232 are hardware specifications and software protocol is not

specified. It is up to the system designer to define a protocol suitable for the

system. Bioscrypt has done this with the Veri-Series reader system. Detailed

information on the software protocol can be obtained by contacting Bioscrypt.

RS-232 communications with the Veri-Series unit use RX, TX, and GND connections.

The primary communications port is wired through the pig-tail in the rear of the

unit. There is also an auxiliary RS-232 port accessible from the bottom of the unit.

The RS-485 implementation in the Veri-Series uses a two-wire, half-duplex

communication configuration. In RS-485 there can be only one master and all

other units are configured as slaves. A master-slave type system has one node

that issues commands to each of the “slave” nodes and processes responses.

Slave nodes will not typically transmit data without a request from the master

node, and do not communicate with each other. Each slave must have a unique

address so that it can be addressed independent of other nodes. In the VeriSeries reader system the computer is the master and the readers are each slaves

on the network. To connect the computer to the RS-485 transmission line, you

must either have a computer with a built-in RS-485 transceiver or use a converter

attached to the computer’s standard serial port (an RS-232 device). The cable

connection includes a differential line (+ and -) and a GND connection.

With the addition of the V-Station products, installations may now connect to

these readers via an Ethernet network*. Because Ethernet enabled devices like

the V-Station contain unique pre-allocated addresses, there is no need to have a

slave/host configuration. Communication collisions are automatically handled by

the low-level Ethernet protocol. However, the Veri-Series reader protocol is still

used on top of TCP/IP communications protocols. Therefore, a unique IP

addresses must be assigned to each V-Station reader, either through the

VeriAdmin software/LCD Menu or automatically from a DHCP server on the

network**.

In the event that you are connecting a single V-Station directly to the computer’s

Ethernet adaptor, a cross-over cable must be used and the following steps must

be taken.

Both the PC and the V-Station must have assigned IP addresses where the

beginning numbers match in accordance with the subnet mask used on the PC.

For example, if the subnet mask is 255.255.255.0, both the PC and the V-Station

must be assigned an IP address of A.B.C.x where A, B, and C are the same for

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 29

each and x is different. Additionally, the PC’s ARP table may need to be set at

the command prompt to resolve the Ethernet MAC address to IP address

translation. This last step is not needed on a normal Ethernet network which

consists of more than just a single PC-to-V-Station connection. Please see the VeriSeries Operations Manual for more information on this topic.

* Ethernet is fully supported in V-Station firmware versions 7.10 and above

** DHCP support may not be available in some versions

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 30

System Turn-up Procedures

System turn-up must follow a step-by-step procedure. Never wire up a system and

apply power to it all at once. This can turn a potential success into an immediate

disaster.

The following steps should be observed:

1. Do not apply power to any units.

2. Check all wiring and device configuration.

3. Disconnect all units from RS-485 communication line.

4. Check for the correct supply voltage before connecting it to any device.

5. Power up the PC running the VeriAdmin or other software that is designed

to work with the Veri- series readers. The RS-232 to RS-485 converter should

also be powered up at this time. If communicating to units via Ethernet, be

sure the correct cable is connected to the PC NIC card.

6. Configure the PC software.

7. Check for ground fault between the converter and the RS-485

communication line (see figure 13). Find any faults and clear them if they

exist.

8. Connect the PC and converter to the RS-485 line.

9. Power up a SLAVE (V-Prox or other reader), but DO NOT connect it to the

RS-485 line. Verify that it powers up correctly.

10. Check for ground fault between this unit and the RS-485 communication

line. Find any faults and clear them if they exist.

11. Connect this unit to the RS-485 line.

12. Verify that it communicates with the PC software.

13. If there are more SLAVES (V-Prox or other readers), add the subsequent

readers by repeating steps 9-12.

Device Configuration Check

Devices must be configured correctly before they can communicate. Common

problems include not correctly selecting RS-485 as the Com Port, mismatched

baud rates, and incorrect device addresses. Each device sharing the RS-485 line

must have a unique address.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Ground Potential Difference Check

Before a device is connected to an RS-485 subsystem, it must be checked for

ground fault. An uncorrected ground fault can damage all devices connected

to the RS-485 communication line.

To check if there is ground fault for a new unit, follow the steps below:

1. Apply power to all devices already successfully connected to RS-485 line.

2. Power up a new unit, but DO NOT connect it to RS-485 line.

3. Connect the signal ground of the RS-485 line through a 10-kΩ current limiting

resistor to the signal ground (see Table 2) of the Veri-Series unit. There should

NOT be more than 1 volt across the resistor. Otherwise find and clear the

fault.

4. Repeat the steps in #3 with each of the RS-485 signal lines (+ and –)

5. Connect the new unit to the RS-485 line only if no ground fault is found.

Page 31

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

General Installation Guidelines

Installation Issues:

o Use Category 5 cabling for a RS-485 network

o Use Category 5 shielded cabling for a 10Base-T or 100Base-T Ethernet network

and Category 5E cable for Gigabit (1000Base-T) Ethernet and beyond

o Choose one twisted pair of conductors to use for RS-485 differential

connection, other conductors should be used for Signal Ground (Black with

Red stripe from Veri-Series)

o For Ethernet, use a straight-through cable when connecting DTE (V-Station, PC,

etc) to DCE (Switch, Hub, Repeater, etc). Use a crossover cable when

connecting DTE to DTE or DCE to DCE

o RS-232/RS-485 Converter must support “sense data” to switch from send to

receive mode

o If placing a V-Station on a RS-485 network, be sure to set the switch in back to

“RS-485 enable”

Page 32

o Before connecting each unit to the network, do the following:

v Configure the reader using the auxiliary port (RS-232) and a PC (or

directly from the console if a V-Station)

§ Set Network ID to a unique number

§ If a V-Station on Ethernet, set its IP address explicitly, or use DHCP

§ Set host port to RS-485

§ Set host port baud rate to 9600 bps

v Check each unit/cabling for ground fault before connecting to RS-485

network

v Each unit should have its ESD Shield Ground (Green with Yellow stripe)

connected to Earth Ground (EGND connection on V-Station)

v Once all units are configured and connected to the RS-485 network, the

baud rate can be increased to highest supported rate (some

experimentation required)

Network Operation Issues:

o Do not use auxiliary port when RS-485 network is active

o Unit will return a “busy” signal (error –104) if communication cannot be

processed due to current processing – usually enroll or verify

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 33

o V-Stations communicating over the Ethernet port can only accept one

connection at a time

o V-Stations must not be assigned an IP address which is already in use or a

conflict will arise, causing communication errors on both devices

o If using Ethernet, an appropriate subnet mask should be set in VeriAdmin to

ensure proper broadcasting capability to all units on the network. For

example, a class C network (supporting up to 254 readers) should have a

subnet mask of 255.255.255.0. If multiple class C networks are being used within

the same network, the subnet mask should resemble the form 255.255.x.0

where x appropriately masks out the bits common to both network addresses.

o Broadcasting to all V-Stations on a network is accomplished in VeriAdmin using

UDP, a connectionless datagram protocol. This is not a reliable protocol, and

V-Stations will not respond to broadcast communications to verify proper

delivery of the message. This should be used as a convenience but not relied

upon as a guaranteed communication method. This is especially true if

packets are routed, like over the Internet.

Operational Issues:

o V-Prox Cards registered as Command Cards (enroll or delete cards) cannot be

used as user cards

o The V-Pass system requires a PC running VeriAdmin or compatible software in

order to enroll fingerprints

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Appendix A – Installing the R&TTE Installation Kit Filters

The following two sections describe the proper procedures for installing the R&TTE

Installation Kit filters, which are required in certain European countries for full CE

compliance. These kits are required only for the V-Prox and V-Smart products and

are not required for any other Bioscrypt product. More information can be found

regarding the CE R&TTE directive online at the European Union web site:

http://www.europa.eu.int/comm/enterprise/rtte/index.htm

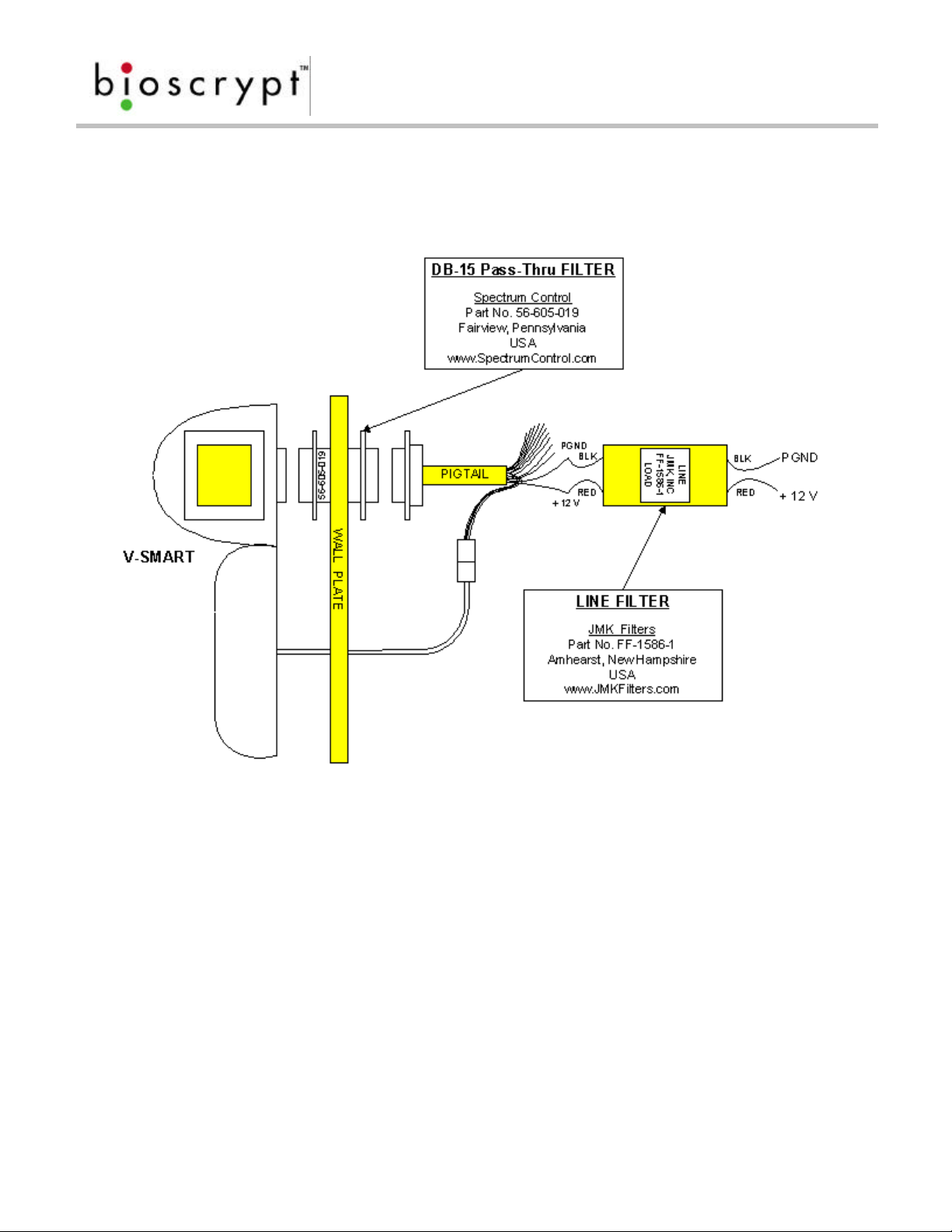

R&TTE Wiring Instructions for the V-Prox, A, H

In order to comply with the conducted emissions requirements of the European

Union (EU) directive EN 55022 for DC power input/output ports, an additional line

filter is needed for installations where power supply cables are greater than 3

meters in length. The required filter is manufactured by JMK Filters (Amhearst, New

Hampshire, USA), Part No. FF-1586-1, and is shipped as part of the installation kit.

Please note the orientation of the filter: the end labeled “LOAD” is to be

connected to the V-Prox device, the end labeled “LINE” is to be connected to

the system power supply.

Page 34

In order to comply with the radiated emissions requirements of the European

Union R&TTE directive CISPR22, a high-density DB-15 “pass-thru” filter is required.

The required filter is manufactured by Spectrum Control (Fairview, Pennsylvania,

USA), Part No. 56-605-019, and is shipped as part of the installation kit. Please note

that it is necessary to rotate the filter to pass through the aperture of the wall plate

or mullion. It is easiest if the filter is first connected to the pigtail wiring harness

supplied. The cable assembly (and connected filter) is now rotated 90 degrees to

allow passage through the aperture of the wall plate. The V-Prox device should

next be connected to the cable assembly, and then pushed back through the

aperture until the wall plate is between the two mounting flanges of the filter. The

device may now be rotated back 90 degrees to the upright position and lowered

onto the mounting hooks of the wall plate.

Please see figure 16 for wiring details.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 35

R&TTE

Wirin

g

Instru

ction

s for

the

VSmart

, A

and

VSmart

, A, H

In

order to comply with the conducted emissions requirements of the European In

order to comply with the conducted emissions requirements of the European

Community directive EN 55022 for DC power input/output ports, an additional line

filter is needed for installations where power supply cables are greater than 3

meters in length. The required filter is manufactured by JMK Filters (Amhearst, New

Hampshire, USA), Part No. FF-1586-1, and is shipped as part of the installation kit.

Please note the orientation of the filter: the end labeled “LOAD” is to be

connected to the V-Smart device, the end labeled “LINE” is to be connected to

the system power supply.

In order to comply with the radiated emissions requirements of the European

Community R&TTE directive CISPR22, a high-density DB-15 “pass-thru” filter is

required. The required filter is manufactured by Spectrum Control (Fairview,

Pennsylvania, USA), Part No. 56-605-019, and is shipped as part of the installation

kit. Please note that it is necessary to rotate the filter to pass through the aperture

of the wall plate or mullion. It is easiest if the filter is first connected to the pigtail

wiring harness supplied. The cable assembly (and connected filter) is now rotated

90 degrees to allow passage through the aperture of the wall plate. The V-Smart

device should next be connected to the cable assembly, and then pushed back

through the aperture until the wall plate is between the two mounting flanges of

the filter. The device may now be rotated back 90 degrees to the upright position

and lowered onto the mounting hooks of the wall plate.

Please see figure 17 for wiring details.

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 36

Figure 17: V-Smart R&TTE Installation Kit Wiring Diagram

Document #430-90003-08 © Copyright 2003, Bioscrypt Inc. All rights reserved.

Page 37

References

(1) B & B Electronics offers an Application Note on RS-485 devices, system

configuration, and termination.

B & B Electronics

707 Dayton Road

P.O. Box 1040

Ottawa, IL 61350

(815)433-5100

http://www.bb-elec.com/bb-elec/literature/485appnote.pdf

(2) Robust Data Comm provides services and a vast amount of information at

their WWW site.

Robust Data Comm, Inc.

St. Paul, MN 55112

(612)628-0533

http://www.robustdc.com/rdc_apno.htm

(3) The Specification is formally named TIA/EIA-485-A and can be purchased

from Global Engineering Documents:

http://global.ihs.com/cgi-bin/detdoc.cgi?FRITTER=111167&DOCID=6798420

(4) National Semiconductor provides a number of Application Notes: