Page 1

Appendix A – Notices

The Veri-Series product line has been tested for compliance with all applicable

international standards. The resulting approvals are listed below, and are

additionally printed on the labeling located on the rear panel of the product.

The power supply offered by Bioscrypt is CE and CSA approved and UL listed.

V-Flex FCC, UL 294, CSA, CE

V-Prox FCC, UL 294, CSA, CE

V-Pass FCC, UL 294, CSA, CE

V-Smart FCC, UL 294, CSA, CE

V-Station FCC, UL 294, CSA, CE

FCC Information to Users

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his own expense.

FCC Class B Digital Device or Peripheral - User’s Notice (for all V-Station models only)

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one of more of the following measures:

• Reorient or relocate the receiving antenna

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Page 2

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected

• Consult the dealer or an experienced radio/TV technician for help

CE Information to Users

All Veri-Series devices have the CE mark, for compliance with CISPR22 /EN 55022

requirements. For European Union (EU) countries, V-Prox, V-Smart, and V-Station

(models V-Station A, P, V-Station A, G, and V-Station A, H) are compliant with CE

under the R&TTE Directive, related to the radio transceivers that are part of their

design. More information can be found regarding the CE R&TTE directive online

at the European Union web site:

http://www.europa.eu.int/comm/enterprise/rtte/index.htm

The V-Prox and V-Smart are compliant with this directive if, and only if, the user

installs the Bioscrypt specified R&TTE Installation Kit (Bioscrypt part number 832-

00103-00). This filter kit should be included with any V-Prox or V-Smart product if it

was shipped to a country within the EU.

The R&TTE Installation Kit consists of two filters: a line filter used to minimize

conducted emissions from power supply lead lengths greater than 3 meters and a

DB-15 “Pass-Thru” filter used to minimize radiated emissions.

Line Filter: Manufacturer: JMK Filters

Amhearst, New Hampshire

USA, 03031

Part Number: FF-1586-1

Pass-Thru Filter: Manufacturer: Spectrum Control

Fairview, Pennsylvania

www.JMKFilters.com

USA, 16415

Part Number: 56-605-019

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

www.SpectrumControl.com

Page 3

If the filters were not included with the product or if they are desired separately,

they may be ordered from Bioscrypt (part number 832-00103-00) or the distributor

from which the product was purchased. Please see Appendix C for details on

proper installation of these filters.

NOTE: The installation of these filters is mandatory for the registered CE mark, and

associated R&TTE directive compliance to be valid within the European Union.

Failure to do so will render the CE mark and consequent right to operate the

equipment null and void.

Warning to Users

Warning

could void the user’s authority to operate the equipment.

V-Prox, A, H Information for Users*

The V-Prox, A, H includes a HID contact-less proximity reader. This device has the

following characteristics:

: Changes or modifications not expressly approved by Bioscrypt Inc.

Transmit Frequency: 125 KHz

Excite Frequency: 125 KHz

V-Smart, A Information for Users

The V-Smart, A includes a contact-less smart card reader (GemEasyLink680SL). This

is a radio-transceiver with the following characteristics:

Operating Frequency Range: 13.553-13.567 MHz

RF Power Rating: 0.0 Watts

RF Output Impedance: 50 Ohms

V-Smart, A, H Information for Users

The V-Smart, A, H includes a contact-less smart card reader (HID iCLASS™ OEM

100/RS232). This is a radio-transceiver with the following characteristics:

Operating Frequency Range: 13.553-13.567 MHz

RF Power Rating: 0.0 Watts

RF Output Impedance: 50 Ohms

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Page 4

V-Station, A, G Information for Users

The V-Station, A, G includes a contact-less smart card reader (GemEasyLink680SL).

This is a radio-transceiver with the following characteristics:

Operating Frequency Range: 13.553-13.567 MHz

RF Power Rating: 0.0 Watts

RF Output Impedance: 50 Ohms

V-Station, A, H Information for Users

The V-Station, A, H includes a contact-less smart card reader (HID iCLASS™ OEM

100/RS232). This is a radio-transceiver with the following characteristics:

Operating Frequency Range: 13.553-13.567 MHz

RF Power Rating: 0.0 Watts

RF Output Impedance: 50 Ohms

V-Station, A, P Information for Users*

The V-Station, A, P includes a HID contact-less proximity reader. This device has

the following characteristics:

Transmit Frequency: 125 KHz

Excite Frequency: 125 KHz

*Warning to Users

Within the European Community, use of the 125 kHz band is not

harmonized. Therefore this product requires notification to the Nationa l

Regulatory Body and requires product registration for a particular

country. If you intend to move this device within the EU, please contact your

distributor first in order to check if this device is approved for use in that parti cular

country.

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Page 5

Appendix B – European Certification Documentation

This appendix contains data related to the Veri-Series product line regarding the

test procedures and Declarations of Conformity as required under the R&TTE

directive by the European Union for all devices containing radio transmitters. The

following Bioscrypt products contain radio transmitters:

Name Model Number

V-Prox V-Prox, A, H

V-Smart / MIFARE V-Smart, A

V-Smart / iCLASS V-Smart, A, H

V-Station / Prox V-Station, A, P

V-Station / MIFARE V-Station, A, G

V-Station / iCLASS V-Station, A, H

Hereby, Bioscrypt, declares that the V-Prox, V-Smart/MIFARE, and V-Smart/iCLASS

are in compliance with the essential requirements and other relevant prov isions o f

Directive 1999/5/EC.

Restrictions of Use

Bioscrypt has notified the following EU countries and gained approval to sell the Prox, V-Smart/MIFARE, and V-Smart/iCLASS products:

• Belgium

• France

• Germany

• Nederland

• Spain

There are no restrictions of use for any of these products within those countries.

V-Station/Prox, V-Station/MIFARE, and V-Station/iCLASS individual country

approval is pending. For latest product approval status and updates, please refer

to the Bioscrypt web page at:

http://www.bioscrypt.com

Declaration of Conformity

For each product, Declarations of Conformity are listed on the following pages for:

• R&TTE Directive 1999/5/EC

• EMC Directive 89/336/EEC

• Low Voltage Safety Directive 73/23/EEC

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Page 6

i

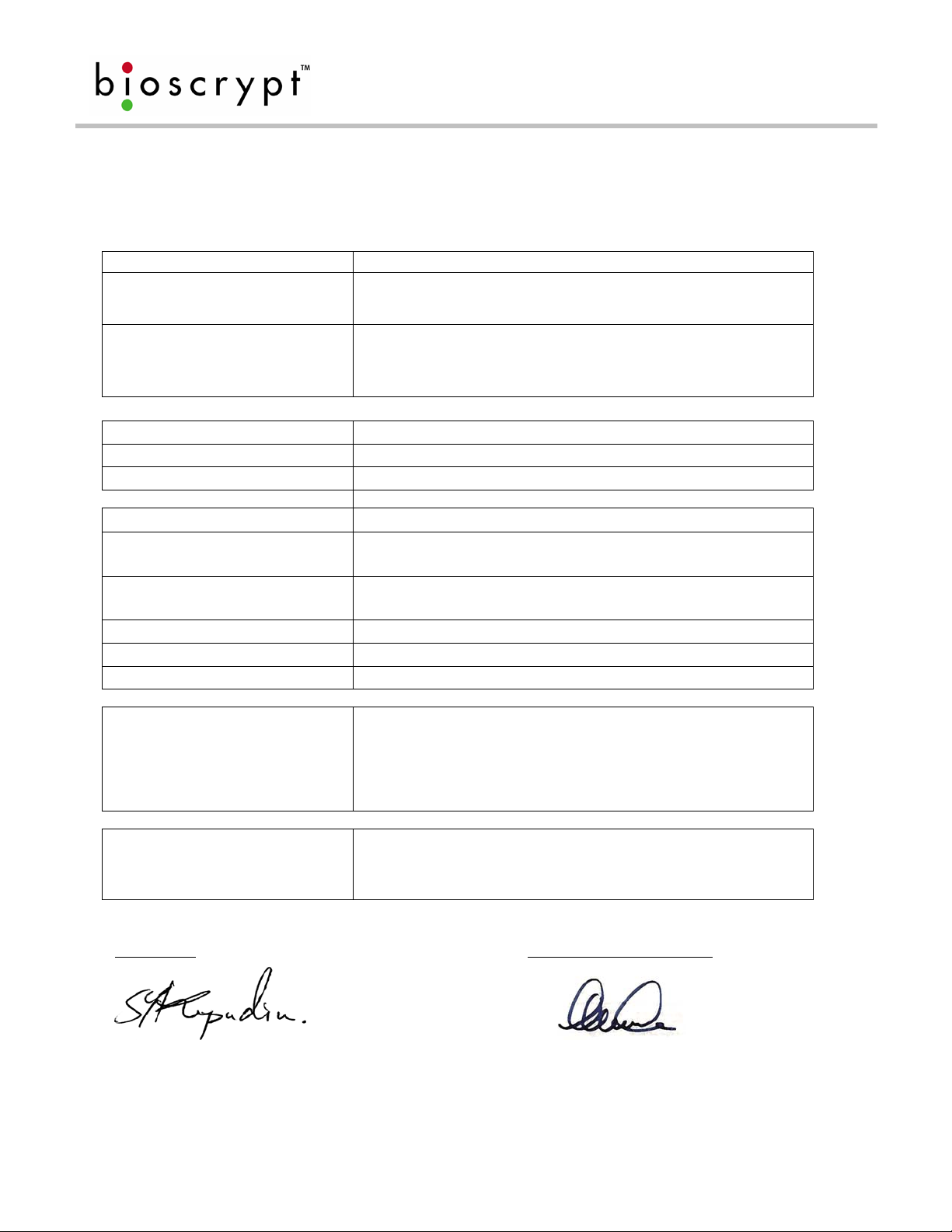

DECLARATION OF CONFORMITY

FOR THE R&TTE DIRECTIVE 1999/5/EC

Manufacturer’s Name/Address:

Address: 505 Cochrane Drive

Contact Person: Mr. Shiraz Kapadia, Vice President of Opera tions

Equipment Type: Radio Communications Equipment

Product Name: V-Prox, A

Model No.: V-Prox, A, H

RF Output Power:

Transmitter Operating Frequency

Range:

Bioscrypt Inc.

Markham Ontario

Canada, L3R 8E3

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

-6.9 dBuA/m 10 meters

125 kHz

Emission Designation: 5K7N0N

Duty Cycle: 18.8%

Year of manufacture: 2003

Country Of Manufacture: Canada

The above product has been

tested by UltraTech Engineering

Labs Inc., and found to comply

with:

Test Laboratories: UltraTech EMC Labs Inc.

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to un

Manufacturer Legal Representative in Europe

European Telecommunications Standards Institute (ETSI)

EN 300 330-1 V1.3.1 (2001-06) & EN 300 330-2 V1.1.1 (2001-06)

Radio Equipment and Systems; Short Range Devices (SRD);

Technical Characteristics and Test Meth ods for Radio Equipment

in the Frequency Range 9 kHz to 25 MHz and Inductive Loop

Systems in the Frequency Range 9 kHz to 30 MHz, Parts 1 and 2.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 November 25, 2002

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

.

FOR THE EMC DIRECTIVE 89/336/EEC

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter Operating Frequency

Range:

Page 7

DECLARATION OF CONFORMITY

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Prox, A

V-Prox, A, H

-6.9 dBuA/m 10 meters

125 kHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by

UltraTech Engineering Labs Inc.,

and found to comply with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units

Manufacturer Legal Representative in Europe

5K7N0N

18.8%

2003

Canada

European Telecommunications Standards

Institute (ETSI)

EN 301 489-1 V1.4.1 (2002-04) & EN 301 489-3 V1.4.1 (2002-08) –

Electromagnetic Compatibility and Spectrum Matters (ERM);

Electromagnetic Compatibility (EMC) Standard for Radio Equipment

and Services, Parts 1 and 3.

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 November 25, 2002

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

.

FOR THE LOW VOLTAGE SAFETY DIRECTIVE 73/23/EEC

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter Operating Frequency

Range:

Page 8

DECLARATION OF CONFORMITY

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Prox, A

V-Prox, A, H

-6.9 dBuA/m 10 meters

125 kHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by

UltraTech Engineering Labs Inc.,

and found to comply with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units

Manufacturer Legal Representative in Europe

5K7N0N

18.8%

2003

Canada

EN 60215:1996 +A1:1996 - Safety Requirements for Radio

Transmitting Equipment

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 November 25, 2002

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Page 9

DECLARATION OF CONFORMITY

FOR THE R&TTE DIRECTIVE 1999/5/EC

Manufacturer’s Name/Address:

Address:

Contact Person: Mr. Shiraz Kapadia, Vice President of Opera tions

Equipment Type: Radio Communications Equipment

Product Name: V-Smart

Model No.: V-Smart, A

RF Output Power:

Transmitter & Receiver Operating

Frequency Range:

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

-19.3 dBuA/m 10 meters

13.553-13.567 MHz

Emission Designation: 3K0D1D

Duty Cycle: 100%

Year of manufacture: 2003

Country Of Manufacture: Canada

The above product has been

tested by UltraTech Engineering

Labs Inc.,

and found to comply with:

Test Laboratories: UltraTech EMC Labs Inc.

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

European Telecommunications Standards Institute (ETSI)

EN 300 330-1 V1.3.1 (2001-06) & EN 300 330-2 V1.1.1 (2001-06)

Radio Equipment and Systems; Short Range Devices (SRD);

Technical Characteristics and Test Meth ods for Radio Equipment

in the Frequency Range 9 kHz to 25 MHz and Inductive Loop

Systems in the Frequency Range 9 kHz to 30 MHz, Parts 1 and 2.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 November 25, 2002

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter & Receiver Operating

Frequency Range:

Page 10

DECLARATION OF CONFORMITY

FOR THE EMC DIRECTIVE 89/336/EEC

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Smart

V-Smart, A

-19.3 dBuA/m 10 meters

13.553-13.567 MHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by

UltraTech Engineering Labs Inc.,

and found to comply with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

3K0D1D

100%

2003

Canada

European Telecommunications Standards

Institute (ETSI)

EN 301 489-1 V1.4.1 (2002-04) & EN 301 489-3 V1.4.1 (2002-08) –

Electromagnetic Compatibility and Spectrum Matters (ERM);

Electromagnetic Compatibility (EMC) Standard for Radio Equipment

and Services, Parts 1 and 3.

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 November 25, 2002

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

FOR THE LOW VOLTAGE SAFETY DIRECTIVE 73/23/EEC

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter & Receiver Operating

Frequency Range:

Page 11

DECLARATION OF CONFORMITY

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Smart

V-Smart, A

-19.3 dBuA/m 10 meters

13.553-13.567 MHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by UltraTech Engineering

Labs Inc., and found to comply

with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

3K0D1D

100%

2003

Canada

EN 60215:1996 +A1:1996 - Safety Requirements for Radio

Transmitting Equipment

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 November 25, 2002

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter & Receiver Operating

Frequency Range:

Page 12

DECLARATION OF CONFORMITY

FOR THE R&TTE DIRECTIVE 1999/5/EC

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Smart

V-Smart, A, H

4.6 dBuA/m 10 meters

13.553-13.567 MHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by UltraTech Engineering

Labs Inc., and found to comply

with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

3K0D1D

100%

2003

Canada

European Telecommunications Standards Institute (ETSI)

EN 300 330-1 V1.3.1 (2001-06) & EN 300 330-2 V1.1.1 (2001-06)

Radio Equipment and Systems; Short Range Devices (SRD);

Technical Characteristics and Test Meth ods for Radio Equipment

in the Frequency Range 9 kHz to 25 MHz and Inductive Loop

Systems in the Frequency Range 9 kHz to 30 MHz, Parts 1 and 2.

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 November 25, 2002

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter & Receiver Operating

Frequency Range:

Page 13

DECLARATION OF CONFORMITY

FOR THE EMC DIRECTIVE 89/336/EEC

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Smart

V-Smart, A, H

4.6 dBuA/m 10 meters

13.553-15.567 MHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by UltraTech Engineering

Labs Inc., and found to comply

with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

3K0D1D

100%

2003

Canada

European Telecommunications Standards

Institute (ETSI)

EN 301 489-1 V1.4.1 (2002-04) & EN 301 489-3 V1.4.1 (2002-08) –

Electromagnetic Compatibility and Spectrum Matters (ERM);

Electromagnetic Compatibility (EMC) Standard for Radio Equipment

and Services, Parts 1 and 3.

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 November 25, 2002

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

FOR THE LOW VOLTAGE SAFETY DIRECTIVE 73/23/EEC

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter & Receiver Operating

Frequency Range:

Page 14

DECLARATION OF CONFORMITY

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Smart

V-Smart, A, H

4.6 dBuA/m 10 meters

13.553-13.567 MHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by UltraTech Engineering

Labs Inc., and found to comply

with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

3K0D1D

100%

2003

Canada

EN 60215:1996 +A1:1996 - Safety Requirements for Radio

Transmitting Equipment

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 November 25, 2002

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Page 15

DECLARATION OF CONFORMITY

FOR THE R&TTE DIRECTIVE 1999/5/EC

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type: Radio Communications Equipment

Product Name: V-Station

Model No.: V-Station, A, P

RF Output Power:

Transmitter Operating Frequency

Range:

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

3.2 dBuA/m 10 meters

120.45– 129.45 kHz

Emission Designation:

Duty Cycle:

Year of manufacture: 2003

Country Of Manufacture: Canada

The above product has been

tested by UltraTech Engineering

Labs Inc., and found to comply

with:

Test Laboratories: UltraTech EMC Labs Inc.

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

4K6N0N

19.9%

European Telecommunications Standards Institute (ETSI)

EN 300 330-1 V1.3.1 (2001-06) & EN 300 330-2 V1.1.1 (2001-06)

Radio Equipment and Systems; Short Range Devices (SRD);

Technical Characteristics and Test Meth ods for Radio Equipment

in the Frequency Range 9 kHz to 25 MHz and Inductive Loop

Systems in the Frequency Range 9 kHz to 30 MHz, Parts 1 and 2.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 January 6, 2003

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter Operating Frequency

Range:

Page 16

DECLARATION OF CONFORMITY

FOR THE EMC DIRECTIVE 89/336/EEC

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Station

V-Station, A, P

3.2 dBuA/m 10 meters

120.45– 129.45 kHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by

UltraTech Engineering Labs Inc.,

and found to comply with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

4K6N0N

19.9%

2003

Canada

European Telecommunications Standards

Institute (ETSI)

EN 301 489-1 V1.4.1 (2002-04) & EN 301 489-3 V1.4.1 (2002-08) –

Electromagnetic Compatibility and Spectrum Matters (ERM);

Electromagnetic Compatibility (EMC) Standard for Radio Equipment

and Services, Parts 1 and 3.

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 January 6, 2003

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

FOR THE LOW VOLTAGE SAFETY DIRECTIVE 73/23/EEC

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter Operating Frequency

Range:

Page 17

DECLARATION OF CONFORMITY

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Station

V-Station, A, P

3.2 dBuA/m 10 meters

120.45– 129.45 kHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by

UltraTech Engineering Labs Inc.,

and found to comply with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

4K6N0N

19.9%

2003

Canada

EN 60215:1996 +A1:1996 - Safety Requirements for Radio

Transmitting Equipment

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 January 6, 2003

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Page 18

DECLARATION OF CONFORMITY

FOR THE R&TTE DIRECTIVE 1999/5/EC

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type: Radio Communications Equipment

Product Name: V-Station

Model No.: V-Statio n, A,G

RF Output Power:

Transmitter & Receiver Operating

Frequency Range:

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

-10.6 dBuA/m 10 meters

13.553-13.567 MHz

Emission Designation:

Duty Cycle: 100%

Year of manufacture: 2003

Country Of Manufacture: Canada

The above product has been

tested by UltraTech Engineering

Labs Inc.,

and found to comply with:

Test Laboratories: UltraTech EMC Labs Inc.

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

421K3D1D

European Telecommunications Standards Institute (ETSI)

EN 300 330-1 V1.3.1 (2001-06) & EN 300 330-2 V1.1.1 (2001-06)

Radio Equipment and Systems; Short Range Devices (SRD);

Technical Characteristics and Test Meth ods for Radio Equipment

in the Frequency Range 9 kHz to 25 MHz and Inductive Loop

Systems in the Frequency Range 9 kHz to 30 MHz, Parts 1 and 2.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 January 6, 2003

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter & Receiver Operating

Frequency Range:

Page 19

DECLARATION OF CONFORMITY

FOR THE EMC DIRECTIVE 89/336/EEC

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Station

V-Station, A, G

-10.6 dBuA/m 10 meters

13.553-13.567 MHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by

UltraTech Engineering Labs Inc.,

and found to comply with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

421K3D1D

100%

2003

Canada

European Telecommunications Standards

Institute (ETSI)

EN 301 489-1 V1.4.1 (2002-04) & EN 301 489-3 V1.4.1 (2002-08) –

Electromagnetic Compatibility and Spectrum Matters (ERM);

Electromagnetic Compatibility (EMC) Standard for Radio Equipment

and Services, Parts 1 and 3.

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 January 6, 2003

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

FOR THE LOW VOLTAGE SAFETY DIRECTIVE 73/23/EEC

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter & Receiver Operating

Frequency Range:

Page 20

DECLARATION OF CONFORMITY

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Station

V-Station, A, G

-10.6 dBuA/m 10 meters

13.553-13.567 MHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by UltraTech Engineering

Labs Inc., and found to comply

with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

421K3D1D

100%

2003

Canada

EN 60215:1996 +A1:1996 - Safety Requirements for Radio

Transmitting Equipment

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 January 6, 2003

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter & Receiver Operating

Frequency Range:

Page 21

DECLARATION OF CONFORMITY

FOR THE R&TTE DIRECTIVE 1999/5/EC

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Station

V-Station, A, H

-6.4 dBuA/m 10 meters

13.553-13.567 MHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by UltraTech Engineering

Labs Inc., and found to comply

with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

20K0D1D

100%

2003

Canada

European Telecommunications Standards Institute (ETSI)

EN 300 330-1 V1.3.1 (2001-06) & EN 300 330-2 V1.1.1 (2001-06)

Radio Equipment and Systems; Short Range Devices (SRD);

Technical Characteristics and Test Meth ods for Radio Equipment

in the Frequency Range 9 kHz to 25 MHz and Inductive Loop

Systems in the Frequency Range 9 kHz to 30 MHz, Parts 1 and 2.

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 January 6, 2003

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter & Receiver Operating

Frequency Range:

Page 22

DECLARATION OF CONFORMITY

FOR THE EMC DIRECTIVE 89/336/EEC

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Station

V-Station, A, H

-6.4 dBuA/m 10 meters

13.553-13.567 MHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by

UltraTech Engineering Labs Inc.,

and found to comply with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

20K0D1D

100%

2003

Canada

European Telecommunications Standards

Institute (ETSI)

EN 301 489-1 V1.4.1 (2002-04) & EN 301 489-3 V1.4.1 (2002-08) –

Electromagnetic Compatibility and Spectrum Matters (ERM);

Electromagnetic Compatibility (EMC) Standard for Radio Equipment

and Services, Parts 1 and 3.

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 January 6, 2003

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

FOR THE LOW VOLTAGE SAFETY DIRECTIVE 73/23/EEC

Manufacturer’s Name/Address:

Address:

Contact Person:

Equipment Type:

Product Name:

Model No.:

RF Output Power:

Transmitter & Receiver Operating

Frequency Range:

Page 23

DECLARATION OF CONFORMITY

Bioscrypt Inc.

505 Cochrane Drive

Markham Ontario

Canada, L3R 8E3

Mr. Shiraz Kapadia, Vice President of Operations

Phone #: 905-940-7784

Fax #: 905-940-7642

Email Address: shiraz.kapadia@bioscrypt.com

Radio Communications Equipment

V-Station

V-Station, A, H

-6.4 dBuA/m 10 meters

13.553-13.567 MHz

Emission Designation:

Duty Cycle:

Year of manufacture:

Country Of Manufacture:

The above product has been

tested by UltraTech Engineering

Labs Inc., and found to comply

with:

Test Laboratories:

I, the undersigned, hereby declare that the equipment as tested is representative within manufacturing tolerance to units.

Manufacturer

Legal Representative in Europe

20K0D1D

100%

2003

Canada

EN 60215:1996 +A1:1996 - Safety Requirements for Radio

Transmitting Equipment

UltraTech EMC Labs Inc.

3000 Bristol Circle

Oakville, Ontario, Canada, L6H 6G4

Shiraz Kapadia Neil McDonald

Vice President, Operations Director of Sales, EMEA

Markham, ON, Canada High Wycombe, England

September 9, 2003 January 6, 2003

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Page 24

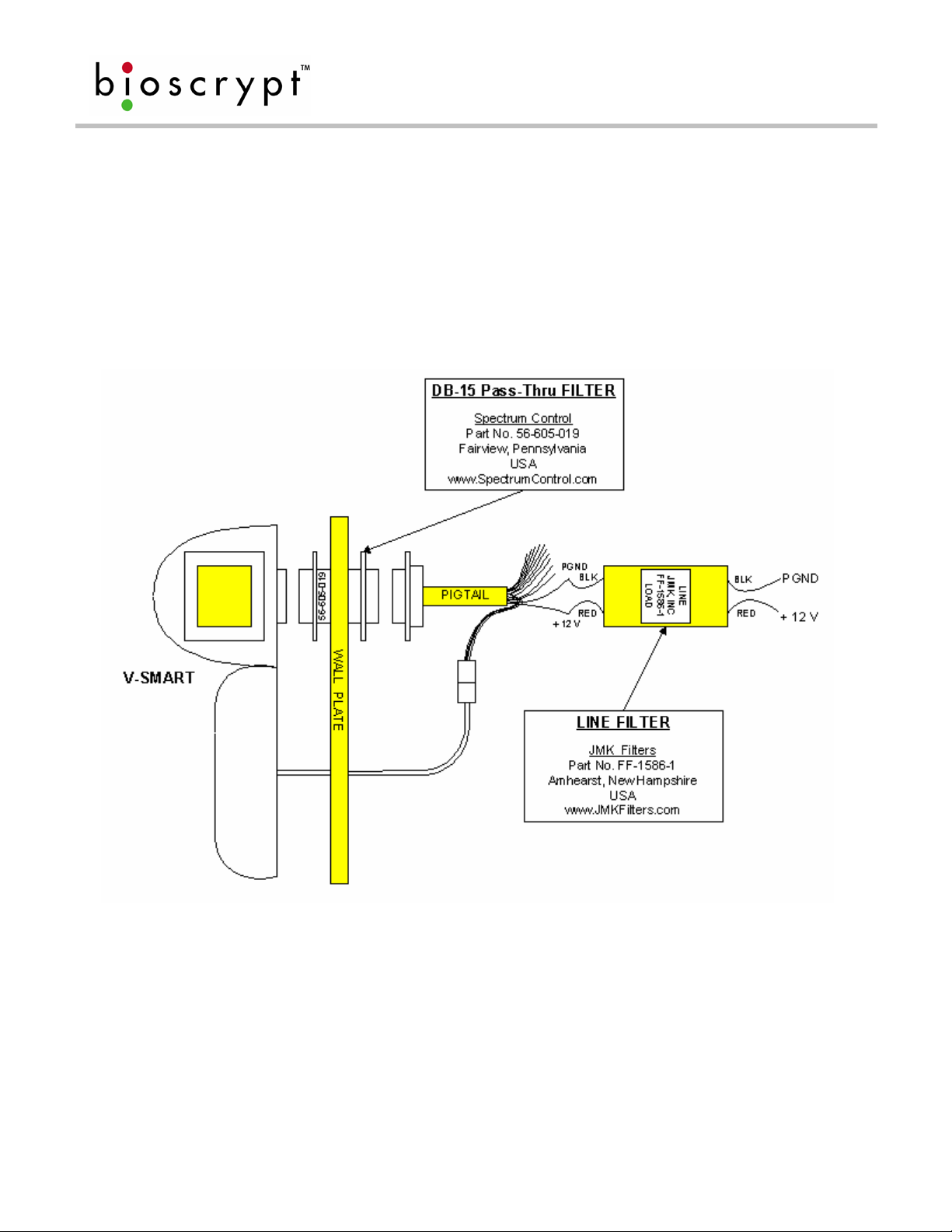

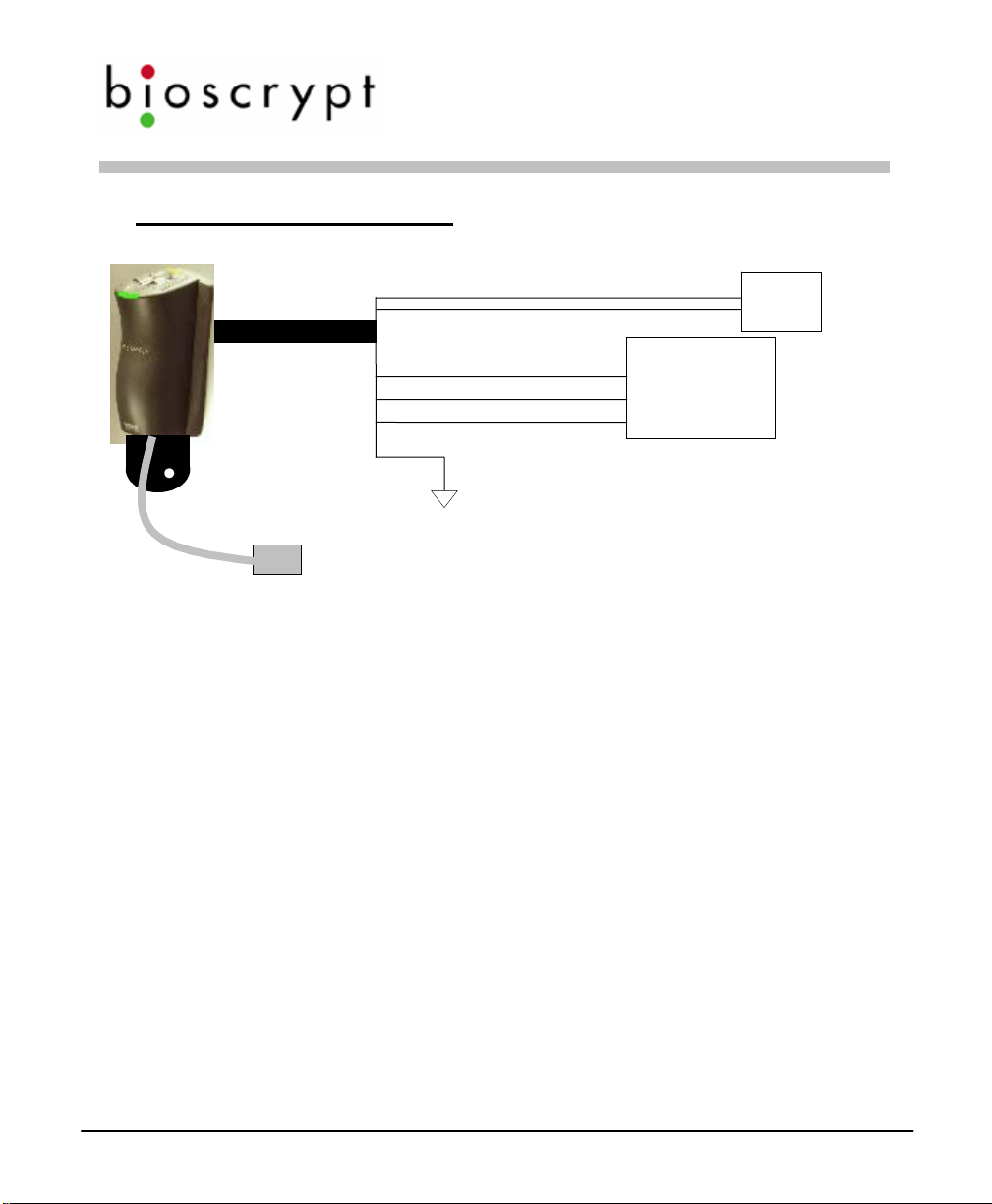

Appendix C – Installing the R&TTE Installation Kit Filters

The following two sections describe the proper procedures for installing the R&TTE

Installation Kit filters, which are required in certain European countries for full CE

compliance. These kits are required only for the V-Prox and V-Smart products and

are not required for any other Bioscrypt product. More information can be found

regarding the CE R&TTE directive online at the European Union web site:

http://www.europa.eu.int/comm/enterprise/rtte/index.htm

R&TTE Wiring Instructions for the V-Prox, A, H

In order to comply with the conducted emissions requirements of the European

Union (EU) directive EN 55022 for DC power input/output ports, an additional line

filter is needed for installations where power supply cables are greater than 3

meters in length. The required filter is manufactured by JMK Filters (Amhearst, New

Hampshire, USA), Part No. FF-1586-1, and is shipped as part of the installation kit.

Please note the orientation of the filter: the end labeled “LOAD” is to be

connected to the V-Prox device, the end labeled “LINE” is to be connected to

the system power supply.

In order to comply with the radiated emissions requirements of the European

Union R&TTE directive CISPR22, a high-density DB-15 “pass-thru” filter is required.

The required filter is manufactured by Spectrum Control (Fairview, Pennsylvania,

USA), Part No. 56-605-019, and is shipped as part of the installation kit. Please note

that it is necessary to rotate the filter to pass through the aperture of the wall plate

or mullion. It is easiest if the filter is first connected to the pigtail wiring harness

supplied. The cable assembly (and connected filter) is now rotated 90 degrees to

allow passage through the aperture of the wall plate. The V-Prox device should

next be connected to the cable assembly, and then pushed back through the

aperture until the wall plate is between the two mounting flanges of the filter. The

device may now be rotated back 90 degrees to the upright position and lowered

onto the mounting hooks of the wall plate.

Please see figure 16 for wiring details.

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Page 25

R&TTE Wiring Instructions for the V-Smart, A and V-Smart, A, H

In order to comply with the conducted emissions requirements of the European

Community directive EN 55022 for DC power input/output ports, an additional line

filter is needed for installations where power supply cables are greater than 3

meters in length. The required filter is manufactured by JMK Filters (Amhearst, New

Hampshire, USA), Part No. FF-1586-1, and is shipped as part of the installation kit.

Please note the orientation of the filter: the end labeled “LOAD” is to be

connected to the V-Smart device, the end labeled “LINE” is to be connected to

the system power supply.

In order to comply with the radiated emissions requirements of the European

Community R&TTE directive CISPR22, a high-density DB-15 “pass-thru” filter is

required. The required filter is manufactured by Spectrum Control (Fairview,

Pennsylvania, USA), Part No. 56-605-019, and is shipped as part of the installation

kit. Please note that it is necessary to rotate the filter to pass through the aperture

of the wall plate or mullion. It is easiest if the filter is first connected to the pigtail

wiring harness supplied. The cable assembly (and connected filter) is now rotated

90 degrees to allow passage through the aperture of the wall plate. The V-Smart

device should next be connected to the cable assembly, and then pushed back

Figure 16: V-Prox R&TTE Installation Kit Wiring Diagram

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Page 26

through the aperture until the wall plate is between the two mounting flanges of

the filter. The device may now be rotated back 90 degrees to the upright position

and lowered onto the mounting hooks of the wall plate.

Please see figure 17 for wiring details.

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Figure 17: V-Smart R&TTE Installation Kit Wiring Diagram

References

(1) B & B Electronics offers an Application Note on RS-485 devices, system

configuration, and termination.

B & B Electronics

707 Dayton Road

P.O. Box 1040

Ottawa, IL 61350

(815)433-5100

http://www.bb-elec.com

(2) Robust Data Comm provides services and a vast amount of information at

their WWW site.

Robust Data Comm, Inc.

St. Paul, MN 55112

(612)628-0533

http://www.robustdc.com

Page 27

(3) The Specification is formally named TIA/EIA-485-A and can be purchased

from Global Engineering Documents:

http://global.ihs.com

(4) National Semiconductor provides a number of Application Notes:

http://www.national.com/an/AN/

(5) Belden Wire and Cable Company offers a variety of cables suitable for RS-

485 use and has a number of technical papers:

http://www.belden.com

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Page 28

(6) Alpha Wire Company offers a variety of cables suitable for RS-485 use and

has a number of technical papers:

http://www.alphawire.com

(7) Cisco Systems, Inc., provides a comprehensive guide to Ethernet 802.x

standards and implementation issues:

http://www.cisco.com/univercd/cc/td/doc/cisintwk/ito_doc/ethernet.htm

(8) Charles Spurgeon provides an excellent online Ethernet resource:

http://www.ethermanage.com/ethernet/ethernet.html

(9) The CE R&TTE directive is outlined on the EU website at:

http://www.europa.eu.int/comm/enterprise/rtte/index.htm

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Page 29

Bioscrypt Contact Information

Technical Support Contact Information:

Telephone: 866.304.7180 (toll free)

818.304.7180 (direct)

Fax: 818.304.7187

Email:

Web: http://www.bioscrypt.com

Hours: 5:30A – 5:00P PST (Monday – Friday)

Address: Bioscrypt Inc

Technical Support Dept

5805 Sepulveda Blvd, Suite 750

Van Nuys, CA, 91411

Corporate & Canadian Office

505 Cochrane Dr.

Markham, ON, Canada L3R 8E3

T 905 940 7750

F 905 940 7642

www.bioscrypt.com

support@bioscrypt.com

U.S. Office

5805 Sepulveda Blvd., Suite 750

Van Nuys, CA 91411

T 818 304 7150

F 818 461-0843

U.K. Office

35 Jackson Court, Hazlemere

High Wycombe, Buckinghamshire

England HP15 7TZ

T +44 (0) 1494 814 404

F +44 (0) 1494 815 513

Document #430-90003-16 © Copyright 2005 Bioscrypt Inc. All Rights Reserved.

Checklist For Unpacking

Veri-Series reader

(V-Smart and V-Station differ

from picture shown)

Wall mounting plate /

Mullion mounting plate

(V-Smart and V-Station differ

from picture shown )

Pigtail cable

(not included for V-Station)

Documentation

Veri-Series Setup Guide

Veri-Series Setup Guide

Tools

1/8” security hex key

Hardware

(4) #6-32 screws

(4) #6 self-tapping

screws

(4) #4-8 wall anchors

(14) crimps

(1) plastic Aux port

door

(2) #4-40 screws

Documentation provided with your new fingerprint reader is installed onto your

computer when you install the VeriAdmin software (also available online at

http://www.bioscrypt.com). To view the documentation you can use Windows

Explorer (available from the Start Menu under Programs) to navigate to

C:\Program Files\Bioscrypt\VeriAdmin\Docs or another location that you defined

during the installation procedure. The documentation is provided in Adobe®

Acrobat® format (PDF). The Adobe Acrobat reader is available on the CD or online at

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

www.adobe.com.

1

Veri-Series Setup Guide

Other required equipment

(optional for V-Station)

PC

One available COM port

(or Ethernet card)

Windows 98, ME, NT4,

2000, or XP

486-compatible

16 MB RAM

30 MB disk space

Door controller

Power supply

Networking cable

RS-232/RS-485 Converter

CD with VeriAdmin

software and documentation

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

P/S for converter

User Documentation

(included on

VeriAdmin CD)

2

Veri-Series Setup Guide

Introduction

The Veri-Series Setup Guide provides you with general information on

installing your fingerprint reader and using the reader and associated software.

This document is not a substitute for the more comprehensive documentation

provided with your reader and available on the CD-ROM or installed on your

computer with the VeriAdmin software. Please refer to the

Installation Guide and the Veri-Series Operations Manual for additional

information. If there are any questions about information in this guide or in the

more comprehensive documentation please contact Bioscrypt Technical

Support using the contact information located in the Warranty and Returns

section of this document.

Please see the Release Announcement document on the CD-ROM for the latest

updates to this and other documentation.

Veri-Series

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

3

b

Veri-Series Setup Guide

Learning More About Your New Fingerprint

Reader

Pass/Fail Indicator

Amber – place finger

Off – remove finger

Green – Pass

Red – Fail

Conductive Plastic Mask

Power Indicator

RidgeLock™ to aid in

consistent finger placement

Fingerprint Sensor

ABS Plastic Body

Aux. Port

Internally, your fingerprint reader is powered by hardware and software developed

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

y Bioscrypt. The “bioscrypt on board™” logo signifies that Bioscrypt's biometric

technology has been integrated into this product. It provides the assurance that

Bioscrypt's high standards of biometric quality and security reside within the

product.

4

Veri-Series Setup Guide

The V-Smart™ Fingerprint Reader

Pass/Fail Indicator

Amber – place finger

Off – remove finger

Green – Pass

Red – Fail

Conductive Plastic Mask

Fingerprint Sensor

RidgeLock™ to aid in consistent

finger placement

Power Indicator

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

MIFARE® or

iCLASS™ smart card

reader

ABS Plastic Body

Aux. Port

5

Veri-Series Setup Guide

The V-Station™ Fingerprint Reader

Conductive Plastic

Fingerprint

Sensor

RidgeLock™

Power

Indicator

Some models:

MIFARE

iCLASS™ smart

card reader or

HID Proximity

reader

®

or

Pass/Fail Indicator

Amber – place finger

Off – remove finger

Green – Pass

Red – Fail

LCD Backlit

Display

Illuminated

Keypad

Aux. Port ABS Plastic Body

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

6

Veri-Series Setup Guide

The Veri-Series Product Line

The Veri-Series fingerprint readers are used in access control and other related

fields. There are a variety of features common to the various products, but

there are differences as well, as described below. For more on the operational

differences between the products please see Basic Operation on page 29.

Common Features

The various products in the Veri-Series line have some features in common

such as both RS-232 and RS-485 serial communications protocol support

for connection to a PC, Wiegand input and output protocol support for

connection to access control equipment, a wide power input range (9-24

Volts DC) except for the V-Smart (9-12 Volts DC) and V-Station (12.5-24

Volts DC), and a requirement for earth ground connection to dissipate static

electricity (ESD).

Product Specific Differences

V-Prox

the need for external Wiegand input, and provides one-to-one fingerprint

authentication. The V-Prox is capable of storing up to 4000 fingerprint

templates (a “template” is a mathematical model of the fingerprint that is

generated during enrollment). The device can be mounted on door Mullion

or single-gang electrical box.

V-Flex

described above except that there is no built-in HID proximity card reader.

Therefore the V-Flex requires an external Wiegand input signal. The VFlex is designed for retrofit applications and for applications where a card

technology other than HID is desired.

V-Pass

small user populations (the system is optimized for user populations up to

100, but can be used for populations up to 200). The V-Pass provides

fingerprint only identification – no cards or PINs are required to use the

™

: The V-Prox has a built-in HID proximity card reader that negates

™

: The V-Flex has all the capabilities and features of the V-Prox

™

: The V-Pass provides one-to-many fingerprint identification for

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

7

Veri-Series Setup Guide

system. The V-Pass is also small enough to be mounted on a door mullion

or a single-gang electrical box.

V-Smart

means of an industry standard MIFARE

™

: The V-Smart supports one-to-one fingerprint authentication by

®

-compatible or iCLASS™

contactless smart card reader. The fingerprint template is stored on the

smart card, not on the reader, so the user population is unlimited – simply

issue a smart card to each employee.

V-Station™

: The newest addition to the Veri-Series product line, the VStation contains a backlit LCD display and keypad, enabling template

management and unit configuration directly from the unit; a PC is not

required. Variations of this product are offered with an HID proximity card

reader, a Smartcard reader (MIFARE or iCLASS), or as a searching unit.

Also, this is the first product to offer Ethernet support. It is probably the

most versatile product in the Veri-Series.

MIFARE® is a registered trademark of Philips Semiconductors

iCLASS™ is a trademark of HID Corporation

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

8

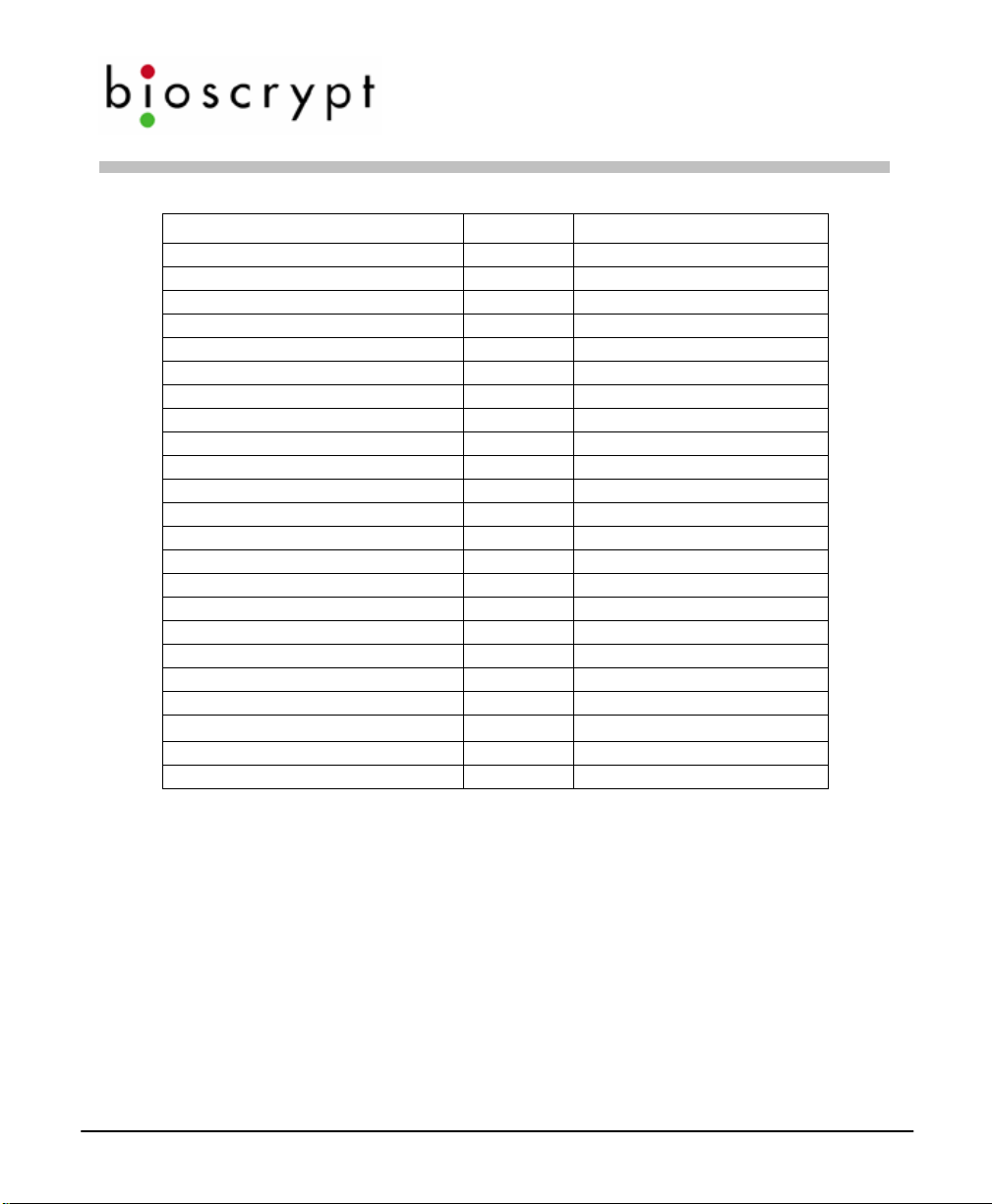

Required Connections

The following table shows required and optional connections to the various

products.

Product Power

V-Prox

V-Flex

V-Pass

V-Smart

V-Station

*

The power input on V-Smart is 9-12 VDC and 12.5-24VDC on V-Station instead of 9-24

VDC on the other products.

**

RS-485 communication is typically used for template distribution to multiple units.

***

Wiegand output is typically used to send the user in formation (ID number and facility

code from card) to an access control panel, but this connection is not strictly required.

Input

*

*

Veri-Series Setup Guide

Wiegand

Input

*** **

***

***

*** **

Wiegand

Output

Serial

Comm.

*** **

Ground

Earth

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

9

Preparing Wiring

1. Wiring connections to be made:

Wiegand

conductors depending on which signals will be carried, shielded cable is

recommended, and typically the conductors are made of stranded wire.

Minimum connections: Data0, Data1, Wiegand Ground

RS-485

Ethernet

Power

Earth Ground

Warning: Do not use Power Ground as a substitute for Earth Ground.

– should be 18-22 AWG (10-7 MWG) wire, between 3 and 6

– use category 5 shielded cable.

– use category 5 shielded cable

– should be 18 – 22 AWG (10 – 7 MWG) wire, 2 conductors.

– use a single wire with heaviest gauge reasonable.

Veri-Series Setup Guide

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

10

Veri-Series Setup Guide

2. Pigtail Connections (V-Prox, V-Flex, V-Pass, V-Smart):

Pin # Signal Description Original Cable New Cable

Jacket Gray Blue

1 Wiegand Out Data 0 Red w/ Black Green

2 Wiegand In Data 0 Green w/ Black Green/White

3 Wiegand Out Data 1 Org White

4 Wiegand In Data 1 Org w/ Black White/Black

5 Line Trigger Green Gray

6 Wiegand GND Red Black/White

7 RS-485 (-) Blue w/ Black Blue/Black

8 RS-485 (+) White Blue

9 RS-232 Tx Black w/ White Violet

10 RS-232 Rx Red w/ White Violet/Whit e

11 Power GND Black Black

12 Signal GND Green w/ White Black/Red

13 Power input (9-24 VDC)

*(9-12 VDC) for V-Smart

14 Reserved Blue Red/White

15 Earth ground White w/ Black Green/Yellow

Blue w/ White Red

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

11

Veri-Series Setup Guide

3. Weidmuller Connections (V-Station only):

Group Label Signal Description

RS-485 TX(+) Transmit +

TX(-) Transmit RX(+) Receive +

RX(-) Receive GND RS-485 Ground

RS-232 GND RS-232 Ground

TX Transmit

RX Receive

Power/Ground +(POS) 12.5 - 24 VDC +

-(NEG) 12.5 - 24 VDC EGND Earth Ground

Wiegand IN 0 Data 0 In

IN 1 Data 1 In

OUT 0 Data 0 Out

OUT 1 Data 1 In

LED IN LED In

LED OUT LED Out

GND Wiegand Ground

TTL (IN) IN 0 TTL Data 0 In

IN 1 TTL Data 1 In

TTL (OUT) OUT 0 H TTL Data 0 Out

OUT 1 L TTL Data 1 Out

GND TTL Ground

4. [RS-485 network only]: Use a daisy chain network design as depicted in the

following figure. Do not use a star or other multi-drop configuration.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

12

Veri-Series Setup Guide

Power

Supply

Controller

Door

2

Unit Unit Unit Unit

Data0

Data1

3

Wiegand Gnd.

Cat5

Twisted

Pair

RS-232

/RS-485

Converter

Computer

Use one pair (e.g. blue/white and white/blue) for RS-485 connections.

Connect readers identically at each reader (e.g. blue/white on Cat5 to RS485 (-) on pigtail/Weidmuller Connector and white/blue on Cat5 to RS-485

(+) on pigtail/Weidmuller Connector).

5. [RS-485 network only]: At converter, jumper TD(A) with RD(A) and

TD(B) with RD(B). Connect Blue/white from Cat5 to either of A terminals

and White/blue from Cat5 to either of B terminals. Make certain to connect

power correctly.

Twisted Pair.

Connect to

Earth Ground

Use Cat5 rated cable

RS-485 (-)

RS-485 (+)

TD(A)

TD(B)

RD(A)

RD(B)

+12VDC

GND

RS-232

6. [RS-485 network only]: RS-485 supports distances up to 4,000 feet (1,200

meters) and/or 31 readers. To extend these limitations, contact Bioscrypt

Technical Support. Typically no end-of-line termination is required unless

the total run exceeds 2,000 feet.

7. [RS-485 network only]: Set up network using 9600 baud rate. Only

increase this data rate after the system is operating properly at 9600.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

13

Veri-Series Setup Guide

8. [Ethernet network only]: Typically a star network topology is used with a

network switch or hub, but a bus topology may be used. Be sure to connect

all devices using straight-thru (as apposed to cross-over) cables. The

exception to this is when connecting a single device directly to the

computer Ethernet adaptor.

9. [Ethernet network only]: Up to 254 readers can reside on a single Ethernet

bus, although repeaters may be required to boost the signal over longer

distances. The V-Station supports 10base-T Ethernet (10 Mbps)*. A 10

Mbps Ethernet network supports distances up to 100 meters (328 ft.)

between readers (2,500m with repeaters). Bioscrypt recommends isolating

your network of readers from computers (other than the admin PC) and

other devices to maximize security. A firewall is highly recommended if

the network will include other devices or PCs. For obvious reasons, it is not

a good idea to expose your network of readers to the outside world (i.e., the

Internet).

*Ethernet communication is supported in firmware versions 7.10 and higher.

VeriAdmin 5.10 or higher is required for administration over Ethernet.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

14

p

r

Configuring Readers

Pigtail OR

Weidmuller

See Page 11 for Color Codes

Wiegand Out Data0

Wiegand Out Data1

Wiegand Ground

Veri-Series Setup Guide

+12 VDC

Ground

Data 0

Data 1

Common

Power

Supply

Door

Controller

Earth

Ground

Com

To

ute

1. Set up a configuration station

a. Wire the unit for power:

• V-Prox/V-Flex/V-Pass: Connect the RED pigtail wire to 9-24V

DC power and the BLACK wire to power ground.

• V-Smart: Connect the RED pigtail wire to 9-12V DC power and

the BLACK wire to power ground.

• V-Station: Connect 12.5-24V power in to the +(POS)

Weidmuller connector and the power ground to the –(NEG)

connector.

b. Optionally wire up Wiegand output to a door controller.

c. Have a computer running VeriAdmin software available.

d. Have RJ11 communications cable available.

2. Connect the reader for communication

a. Connect RJ11 to reader and DB9 to PC COM port.

b. Plug pigtail cable into reader (if not a V-Station) and connect power

to appropriate conductors identified in the charts on pages 11 and

12.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

15

Veri-Series Setup Guide

3. Configure the device using the VeriAdmin software provided

a. If running VeriAdmin for the first time, you will be directed to the

Network Setup dialog. This dialog is also reached by clicking on

this icon:

. Select the serial (COM) port(s) you intend to use or

Ethernet and click OK. It is recommended that you check “Auto”.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

16

Veri-Series Setup Guide

b. This will bring you to the Network Configuration Manager dialog.

First click on the Comm port or Ethernet within the network tree

which you have connected the unit to (the

or icon). Then

click on the “Add Unit” button (lower left).

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

17

Veri-Series Setup Guide

c. VeriAdmin should establish communication with the unit. The Unit

Status field should indicate ONLINE, you may hear the unit beep,

and other fields on the right side should populate. If you are

connecting via Ethernet, you must first assign the unit an IP address

from the unit’s keypad and then type in the address under Ethernet

Settings and click the Refresh button.

d. If VeriAdmin shows NOT RESPONDING, check the connections

and then press the Refresh button to try again.

e. You may assign the unit a name (default is “New Bioscrypt Unit”) if

desired.

f. The network tree shown on the left will show a small icon

representing the current unit

, just below the icon under the

port you selected. Double-click on this icon to open the Unit

Parameters dialog.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

18

Veri-Series Setup Guide

g. Change desired parameters. Typical changes are:

i. Communication Tab: Network ID (default is 0, but each

unit must have a unique ID number such as 1, 2, 3, 4, etc.)

ii. Wiegand Tab: Wiegand parameters

NOTE: We do not recommend changing the Aux. port Baud rate at this

time.

4. Repeat steps 2-4 (skipping 3a) for the next reader until all readers are

configured.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

19

Veri-Series Setup Guide

5. If placing units on a RS-485 network, you will also need to set up the

computer for RS-485 communications.

a. Connect the RS-232/RS-485 converter to the PC’s COM port (must

support Send Data – a means of automatically sensing data sent

from the RS-232 port – we suggest the B&B Electronics,

www.bb-

elec.com, model 485TBLED or equivalent).

b. Run category 5 rated cable from the converter to the first reader in

the daisy chain.

6. V-Smart considerations

a. The V-Smart does not require an RS-485 network. There is no need

to distribute templates because the templates are carried by the users

in the cards.

b. One security aspect of the V-Smart is that a site key is used to

secure the information on the smart card. If a card is presented to

the V-Smart it uses the programmed site key to unlock the data from

the card. The V-Smart is shipped with a default site key (a blank

field). If the programmed site key does not unlock the data from the

card, the user cannot verify their fingerprint. This provides system

administrators with a means to further protect their facilities from

unauthorized access.

c. If the system administrator wants to periodically change the site key

(to further minimize the risk of compromised or lost cards), then this

can be done through an RS-485 network or by making the

appropriate changes to the reader through the Aux port.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

20

Veri-Series Setup Guide

7. V-Station considerations

a. The V-Station does not require configuration via a PC. Nearly all

configuration options can be set using the menus on the unit.

However, it may be more convenient to administer the device from

the PC due to the limited size of the LCD screen.

b. To distribute templates to other V-Stations, you will need to place

all V-Stations on a network and administer them via the PC.

Alternatively, templates can be stored on the PC and transferred to

each V-Station separately, via the Host, Aux, or Ethernet ports.

c. To access some advanced features such as the transaction log, you

will need to communicate with the V-Station from the PC.

d. Connecting to a V-Station via Ethernet should be done by a network

administrator or one familiar with TCP/IP operations. The VStation should be assigned an appropriate IP address or be set to use

DHCP*. Caution should be exercised when manually assigning IP

addresses: it should be appropriate for the given network and should

not conflict with other devices or PCs on the network. Bioscrypt

recommends isolating all V-Stations on a closed Ethernet network,

both for security reasons and to avoid conflicts with other

computers and devices on the network.

* DHCP may not be available in some firmware versions.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

21

Veri-Series Setup Guide

Mounting Readers On The Wall

1. The readers come disassembled, however, if your reader has previously been

assembled then disassemble the reader body and smart card module (for VSmart only) from the wall plate.

a. On V-Smart remove security screw securing smart card module

b. For products other than V-Station, remove security screw securing

the Aux. port cover, and remove the Aux. port cover by twisting (see

graphics on page 25).

c. Remove #4-40 screw securing reader body to wall plate.

d. Remove smart card module (on V-Smart only) and reader body by

sliding up and pulling away from the wall plate.

e. Keep screws and Aux. port cover for re-assembling the device.

2. Define a location. A good location will have these qualities:

a. Comfortable height for finger placement

NOTE:

54” or below 48”, please contact Bioscrypt for

available accessories to properly readjust the

angle of the reader for optimal finger

placement. Mounting a reader above or below

the recommended height will not be

ergonomic for the user and will not promote

good finger placement on the sensor.

b. ADA considerations

c. Provide clearance above and below for

d. The access hole in the wall for wiring should be less than 1 ½ inches

e. For V-Smart, the access hole in the wall for wiring should be less

If readers need to be mounted above

48” – 54”

access

wide so that wall plate will cover it. It should be less than 1 ½

inches tall if mounting into dry wall so that there is enough material

to hold the anchor. The recommended size is 1 inch wide by 1

inches tall to match the opening in the wall plate.

than 4 ½ inches wide so that wall plate will cover it. It should be

1/8

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

22

Veri-Series Setup Guide

less than 2 ½ inches tall if mounting into dry wall so that there is

enough material to hold the anchor. The recommended size is 3 ½

inches wide by 2 ½ inches tall.

f. For V-Station, the rear of the unit will protrude past the wall plate

and into the wall approximately 1 inch (depending on the

Weidmuller connectors attached). The access hole must

be exactly

the size of the hole in the wall plate (136mm (~5 3/8”) wide by

69mm (~2 ¾”) tall). It may be helpful to trace the edges of the hole

in the wall plate in pencil before cutting.

g. Please see pages 26 – 28 for templates for the single-gang and

double-gang mounting plates. These templates are dimensioned in

millimeters (mm).

3. Make pigtail (or Weidmuller for V-Station) wiring connections to power,

Wiegand or other connections prior to mounting wall plate.

4. For the V-Smart, feed pigtail cable from Smart Card Module through hole

in wall plate from the front and connect to pigtail cable already wired in

wall cutout.

5. For the V-Smart, connect Smart Card Module to wall plate. Line up four

tabs, push forward and then down. Secure smart card module with the

security screw at the bottom.

6. Feed main pigtail DB15 connector (not applicable to V-Station) through

wall plate from the back and proceed to mount wall plate:

a. Optionally mount to a gang box using #6-32 screws provided.

b. Optionally mount on wall.

i. Use 4 outer mounting points (6 for V-Station).

ii. Up to #6 screws can be accepted (screws and drywall anchors

are provided).

c. Use template provided to mark holes.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

23

7. Attach pigtail to the reader body

(not applicable to V-Station) and

attach body to wall plate using

same motion as for the smart card

module. Secure the body to the

wall plate with the #4-40 screw at

the bottom. Replace the Aux.

port cover (see next page).

8. The RJ11 security cover is

removed to install the reader

body to the wall mount. Once the screw is in place, the security cover can

be snapped into place using the following procedure:

With the textured side facing down,

1) place left tab into left corner groove on reader body

2) rotate cover until right tab easily slides into groove

3) with tab in the reader body groove, rotate the cover clockwise until the

right tab snaps into place at the right rear corner

Veri-Series Setup Guide

Step 1 Step 2 Step 3

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

24

Veri-Series Setup Guide

4) Finally, fold the cover up and secure it using the supplied security screw

and special Allen wrench.

The following pages show the dimensions of the wall mounting plates for the

smaller Veri-Series readers (V-Prox, V-Flex, V-Pass), the V-Smart, and the VStation. The diagrams are not to scale however full-scale drawings can be

found in the Veri-Series Installation Guide.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

25

ø

(

(

)

(82 mm)

(28 mm)

(

)

(32 mm)

Veri-Series Setup Guide

2 ¾”

1 1/8”

28

5/32”

5 5/16”

135 mm

3 ¼”

11/16”

17 mm

1 1/8”

1”

1 ¼”

2 5/8”

Mounting Template for V-Prox / V-Flex / V-Pass (not to scale)

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

26

Veri-Series Setup Guide

Mounting Template for V-Smart (MIFARE and iCLASS) (not to scale)

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

27

Veri-Series Setup Guide

Mounting template for V-Station (all models) (not to scale)

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

28

Veri-Series Setup Guide

Basic Operation

1. Use VeriAdmin software to enroll a new fingerprint:

Enrollment is the process of generating data

that the reader will store and use to later verify

your identity.

a. Make sure that the correct unit is identified on the main toolbar

dropdown.

b. Go to the Template Manager screen.

c. Click on Quick Enroll.

d. Enter an ID number. This can be the number of the user card (prox,

bar code, magnetic stripe, or other technology) or some other

number such as when using the V-Pass or V-Smart.

e. Click on the Enroll button – User must place their finger on the

sensor when the light turns amber and leave their finger on sensor

until the light goes out. Use the RidgeLock during enrollment to

obtain a finger placement consistent with what would be expected

during Verification. The ridge should comfortably fit in the first

crease of the finger. Do not use thumbs for enrollment or

verification.

f. The enrollment will be scored in

terms of Content and Quality on

a scale of 0-5 stars. Bioscrypt

recommends a minimum score of

3 stars for quality and 2 stars for

content. If enrollment scores for

Content and Quality are

acceptable, then click on Accept.

Quality is a measure of how

clearly the fingerprint is shown

in the image.

Content measures how unique

(i.e., curvy) the captured pattern

is.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

29

Veri-Series Setup Guide

g. Fill in desired information and decide where the template will be

stored (either on PC, the unit used to enroll, or a smart card). Click

on the appropriate “Save” button.

h. If templates are saved to the PC or the unit and are to be distributed

to other readers, then this can be done using the Template Manager

functions. In the case of V-Smart, the template is stored on the

smart card and does not need to be distributed.

© Copyright 2005 Bioscrypt Inc. All rights reserved. Document #430-00111-18

30

Veri-Series Setup Guide

2. Using the keypad to enroll a new fingerprint (V-Station only):

a. From the idle screen (showing ”Bioscrypt” with the date and time),

press 0-0-0 (three zeroes) and

. You will be warned about no

admin ID.

b. You are now in the V-Station menu system. From here you may

traverse the menus using the

to enter a menu, and the

and buttons, the button

button to back out to the previous

menu.

c. Enter the Template Admin menu, then the Enroll (Add) User menu.

Enter an enroll ID between 1 and 4294967294.

d. Place your finger on the sensor when the amber LED turns on,

making sure to use the RidgeLock.

e. After retrieving the live fingerprint, you will be shown the content

and quality in stars (asterisks) (5 is the best). Bioscrypt

recommends at least 3 stars for quality and 2 for content. To accept

the enrollment, press 1. To reject it, press 2. To re-try enrollment,

press 3.

f. Choose the finger enrolled, 0 - 9 (0 = left pinky, 9 = right pinky).