Page 1

Smart-Max

Multi-functional platform

Operator’s Manual

Page 2

Smart-Max

Multi-functional platform

Operator's Manual

OM - 2320

Date of release: 13 December 2013

OM – 2320 – 00 – 00

Page 3

TABLE OF CONTENTS

1. Preface ....................................................................................... 1

2. Smart-Max main unit ................................................................. 9

3. Smart-Max menus .................................................................... 13

4. Cryo-SC protocol ..................................................................... 23

5. Maintenance ............................................................................. 33

6. Contacts ................................................................................... 35

OM – 2320 – 00 – 00

Page 4

OM – 2320 – 00 – 00

Page 5

1. Preface

1.1 Introduction to the Smart-Max device and its features

The Smart-Max uses a thermal plate for controlled cooling and heating of blood,

blood derivatives or cellular products.

The Smart-Max allows mixing of product bags by means of compressed air inside

polyurethane cuff bags.

The device can inject biological products inside product bags by means of two

peristaltic pumps.

The Smart-Max device consists of:

• Cooling/heating plate

• Universal mixing device

• Injection device

1.2 Indication for use

The Smart-Max device is intended for use in the processing of blood, blood

derivatives or cellular products in order to cryo-prepare, thaw, incubate or inject

biological products for medical purpose.

The Smart-Max device is intended for the safe and reproducible mixing of bag(s)

under regulated temperature (cooling or heating) and / or injection of biological

additives into the bag at a controlled rate.

1.3 Manufacturer

Biosafe SA is an ISO 9001 / ISO 13485 certified company, working under a number

of national and regional directives.

1.3.1 Address

Biosafe SA • Route du Petit-Eysins 1 • 1262 Eysins • Switzerland

Telephone: +41 22 365 27 27 • Fax: +41 22 365 27 37

www.biosafe.ch • info@biosafe.ch

Biosafe America, Inc. • 1225 North Loop West, Suite 120 • Houston, TX 77008 • USA

Telephone: +1 713 936 26 15 • Fax: +1 713 456 27 66

www.biosafeamerica.com • info@biosafeamerica.com

Biosafe Asia-Pacific Ltd. • Room 3012, 30/F, Tower 1, The Gateway, 25 Canton

Road • Tsim Sha Tsui, Kowloon • Hong Kong

Telephone: +852 2956 7500

www.biosafeasiapacific.com • info@biosafeasiapacific.com

Biosafe Medical Device International Trading (Shanghai) Co. Ltd. • Rm 80, 38F, Park

Place No.1601 Nanjing West Road • Shanghai 200040 • China

Telephone: +86 21 61373214 • Fax: +86 21 61373210

www.biosafechina.com • info@biosafechina.com

Preface OM – 2320 – 01 – 00 1

Page 6

1.4 How to use this manual

This operating manual is organized in functional sections to provide easy access to

information concerning the Smart-Max device.

Prior to using the Smart-Max device, this manual should be read in its entirety.

The Table of Contents can be used to locate specific information.

1.4.1 Proprietary clause

The content of this manual is the exclusive property of Biosafe SA.

It is strictly forbidden to reproduce and/or disseminate any of the contents without the

prior written permission of Biosafe SA.

1.5 Warnings and Precautions

1.5.1 General

To ensure safe and effective use of the Smart-Max, operation should only be

entrusted to trained personnel.

The Smart-Max equipment has not been designed for any modification by the enduser or third party.

Intervention such as modification, revision, maintenance or repair should only be

performed by approved Biosafe technicians.

Unauthorized intervention performed by the user may result in

incorrect operation of the system.

Prior to using any part of the Smart-Max, the operator should read all instructions in

this manual.

In addition, the operator must check that the equipment functions safely and ensure

proper working conditions prior to use.

A Biosafe representative should be contacted if any doubt exists concerning the use

of the Smart-Max device.

Biosafe is not liable for any injury or damage resulting from use of the Smart-Max

device that does not conform to the indications in this Operator’s Manual.

Biosafe cannot be held responsible for the quality and subsequent effects of products

processed on the Smart-Max that have undergone subsequent post-processing.

1.5.3 Blood manipulations

If blood spillage or leakage occurs, the product should be discarded (see Chapter 6

for cleaning procedures).

Gloves and protective clothing should be worn for all blood handling operations.

1.5.4 Electro-Magnetic Compatibility

Recommendations as required by IEC 60601-1-2 §6.8.2.201

Medical Electrical Equipment needs special precautions regarding EMC and needs to

be installed and put into service according to the EMC information provided in this

Preface OM – 2320 – 01 – 00 2

Page 7

accompanying document. Portable and mobile RF communications equipment can

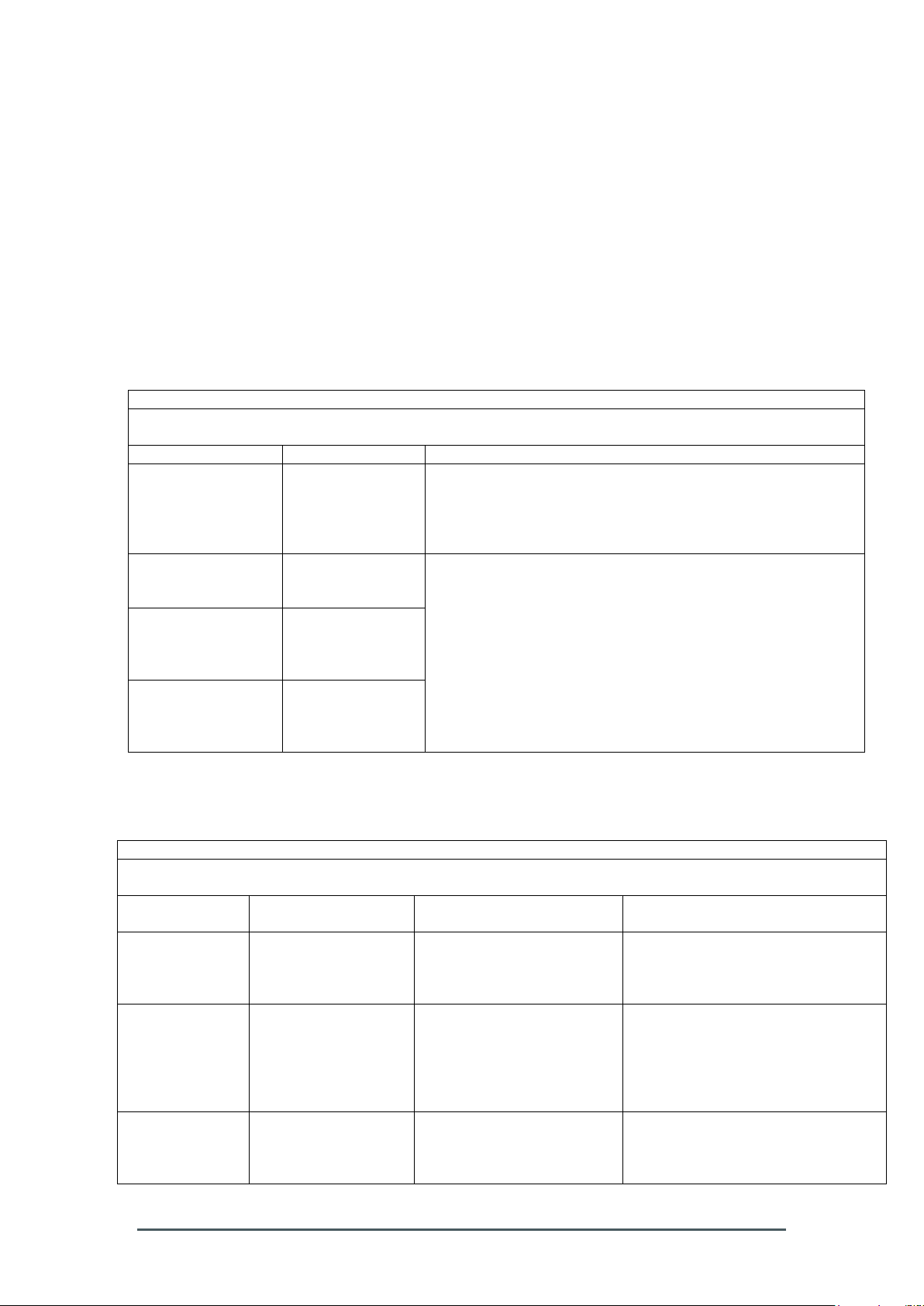

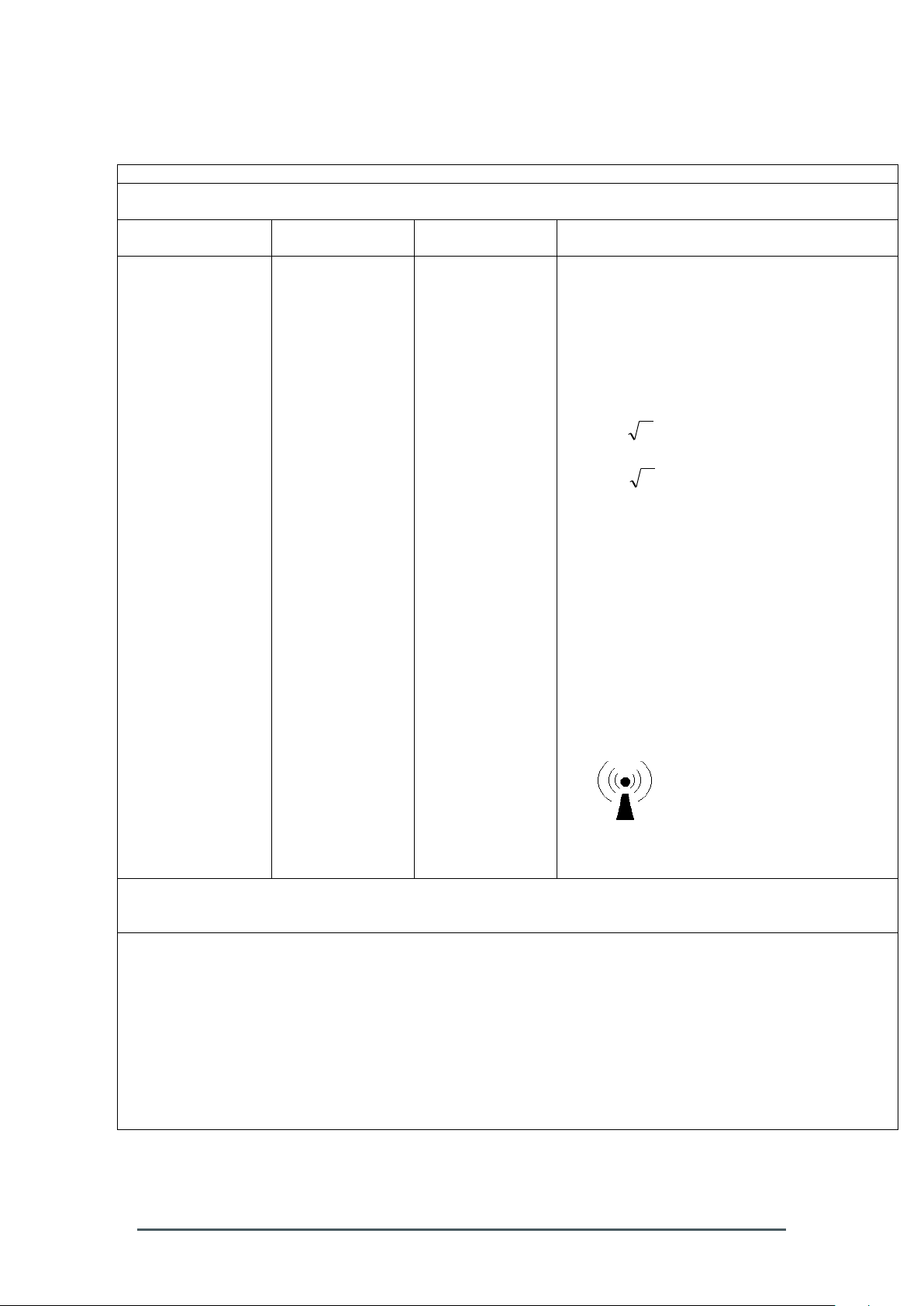

Guidance and manufacturer’s declaration – electromagnetic emission

The Smart-Max is intended for use in the electromagnetic environment specified below. The customer or

the user of the Smart-Max should assure that it is used in such an environment.

Emissions test

Compliance

Electromagnetic environment - guidance

RF emissions

CISPR 11

Group 1

The Smart-Max uses RF energy only for its internal function.

Therefore, its RF emissions are very low and are not likely to

cause any interference in nearby electronic equipment.

RF emissions

CISPR 11

Class A

The Smart-Max is suitable for use in all establishments other

than domestic and those directly connected to the publicvoltage power supply network that supplies buildings used for

domestic purposes.

Harmonic emissions

IEC 61000-3-2

Class A

Voltage fluctuations

/

flicker emissions

IEC 61000-3-3

Complies

Guidance and manufacturer´s declaration – electromagnetic immunity

The Smart-Max is intended for use in the electromagnetic environment specified below. The user of the SmartMax should assure that it is used in such an environment.

Immunity test

IEC 60601

test level

Compliance level

Electromagnetic environment -

guidance

Electrostatic

discharge (ESD)

IEC 61000-4-2

± 6 kV contact

± 8 kV air

± 6 kV contact

± 8 kV air

Floors should be wood, concrete or

ceramic tile. If floors are covered

with synthetic material, the relative

humidity should be at least 30 %.

Electrical fast

transient / burst

IEC 61000-4-4

± 2 kV for power

supply lines

± 1 kV for input/output

lines

± 2 kV for power

supply lines

± 1 kV for input/output

lines

Main power quality should be that of

a typical commercial or hospital

environment.

Surge

IEC 61000-4-5

± 1 kV differential

mode

± 2 kV common mode

± 1 kV differential

mode

± 2 kV common mode

Main power quality should be that of

a typical commercial or hospital

environment.

affect Medical Electrical Equipment.

All staff involved must receive an explanation of the ESD warning symbol and

training in ESD precautionary procedures, and that the users hand should be

discharged by earth bonding (Refer to 1.8 Symbol chart and abbreviations).

The Smart-Max should not be used adjacent to or stacked with other equipment. If

adjacent or stacked use is necessary, the Smart-Max should be observed to verify

normal operation in the configuration in which it will be used. Tables below help to

determine such conditions.

Table 201 – Guidance and manufacturer´s declaration – electromagnetic

emission – for all EQUIPMENT AND SYSTEMS (see 6.8.3.201 a) 3))

Table 202 – Guidance and manufacturer's declaration – electromagnetic

immunity – for all EQUIPMENT and SYSTEMS (see 6.8.3.201 a) 6))

Preface OM – 2320 – 01 – 00 3

Page 8

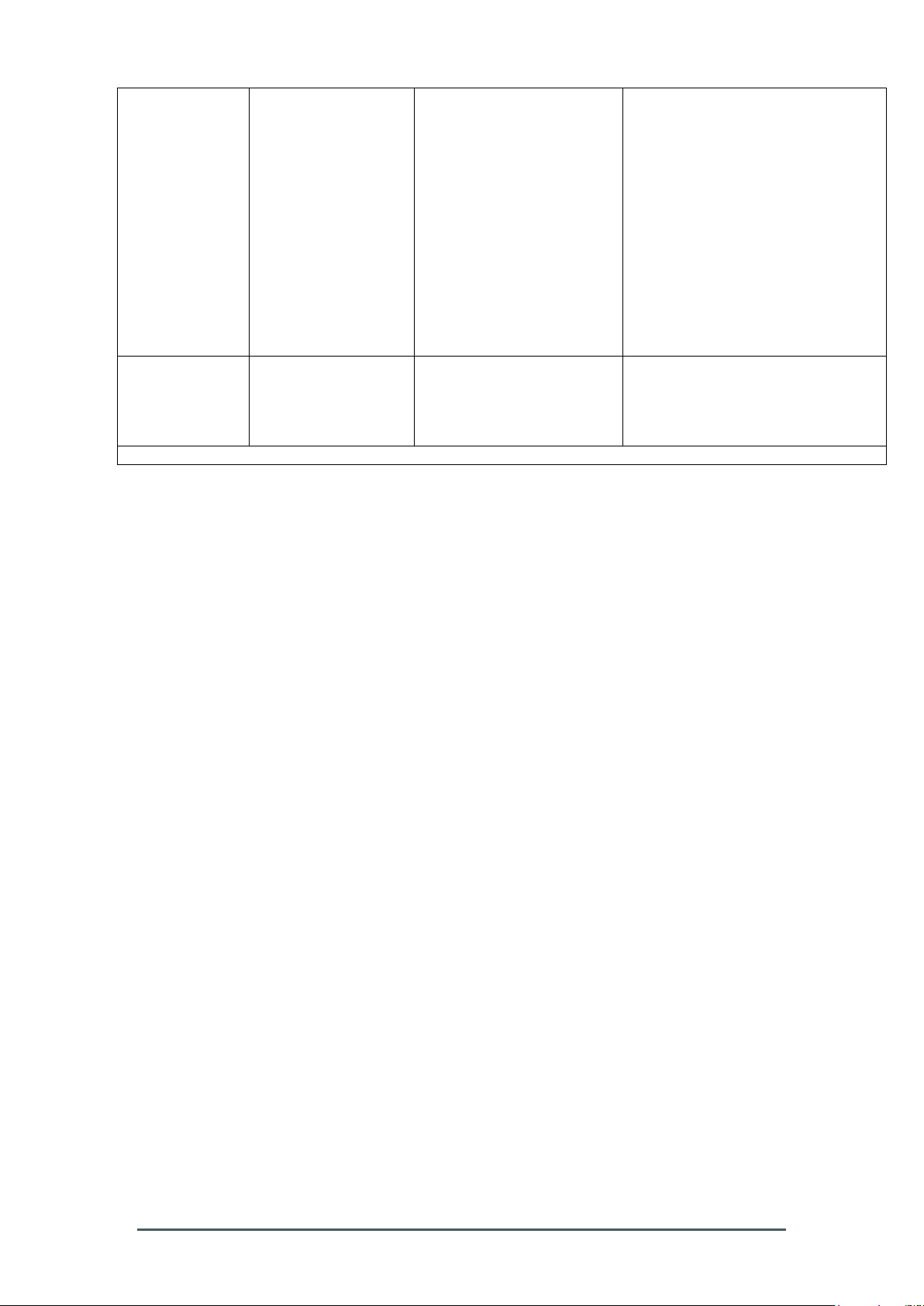

Voltage dips,

short

interruptions and

voltage variations

on power supply

input lines

IEC 61000-4-11

< 5 % UT

(>95 % dip in UT )

for 0,5 cycle

40 % UT

(60 % dip in UT )

for 5 cycles

70 % UT

(30 % dip in UT )

for 25 cycles

95 % UT

(5 % dip in UT )

for 5 seconds

< 5 % UT

(>95 % dip in UT )

for 0,5 cycle

40 % UT

(60 % dip in UT )

for 5 cycles

70 % UT

(30 % dip in UT )

for 25 cycles for 115V only

95 % UT

(5 % dip in UT )

for 5 seconds

Main power quality should be that of

a typical commercial or hospital

environment. If the user of the

Smart-Max requires continued

operation during power interruptions,

it is recommended that the SmartMax be powered from an

uninterruptible power supply or a

battery.

Power frequency

(50/60 Hz)

magnetic field

IEC 61000-4-8

3 A/m

30 A/m

Power frequency magnetic fields

should be at levels characteristic of

a typical commercial or hospital

environment.

NOTE UT is the a. c. mains voltage prior to application of the test level.

Preface OM – 2320 – 01 – 00 4

Page 9

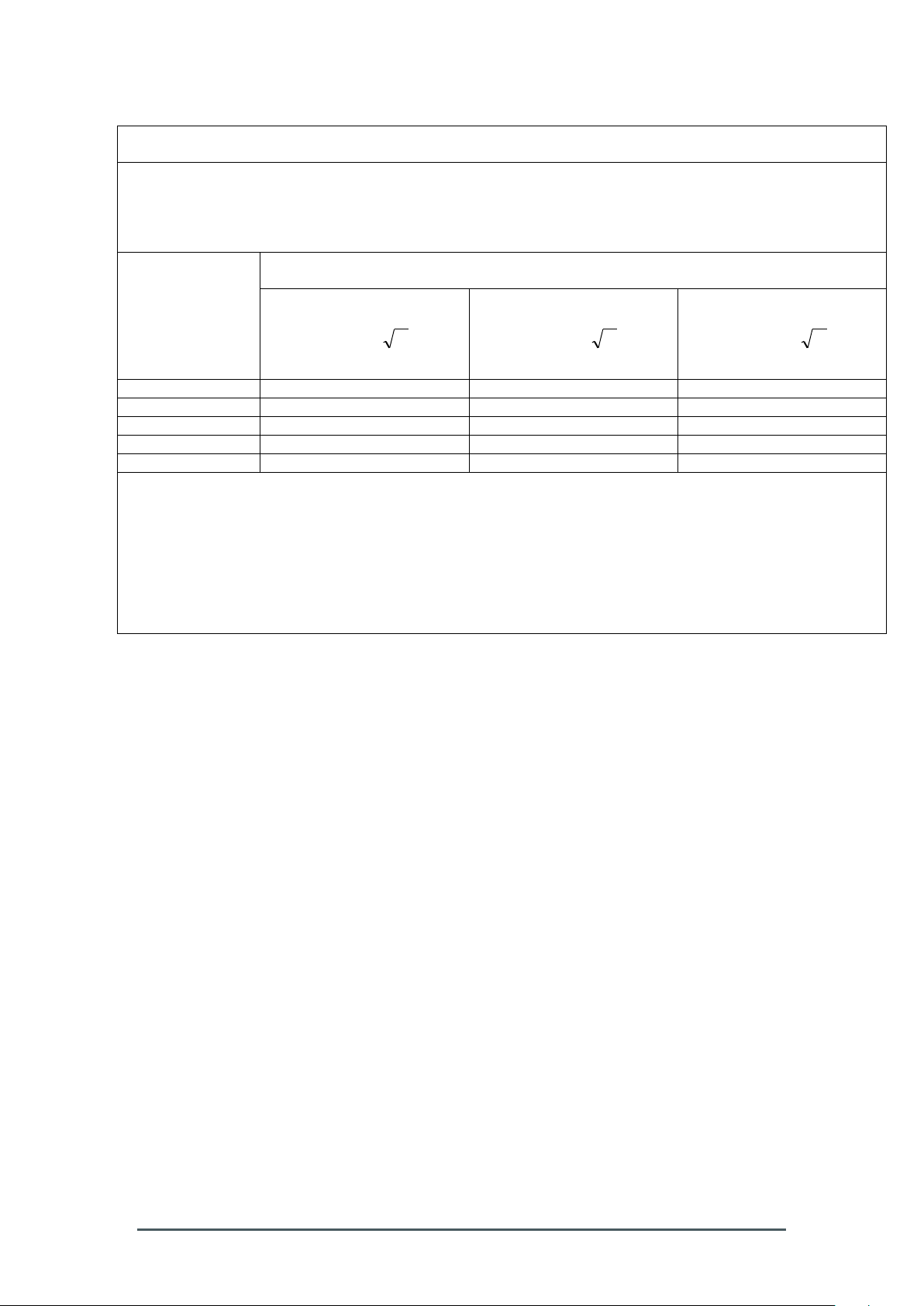

Table 204 – Guidance and manufacturer´s declaration – electromagnetic

Guidance and manufacturer´s declaration – electromagnetic immunity

The Smart-Max is intended for use in the electromagnetic environment specified below. The customer or the

user of the Smart-Max should assure that it is used in such an environment.

Immunity test

IEC 60601 test

level

Compliance level

Electromagnetic environment - guidance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz to 80 MHz

3 V/m

80 MHz to 2,5 GHz

3 Vrms

3 V/m

Portable and mobile RF communications

equipment should be used no closer to any part

of the Smart-Max, including cables, than the

recommended separation distance calculated

from the equation applicable to the frequency of

the transmitter.

Recommended separation distance

Pd 2.1

80 MHz to 800 MHz

Pd 3.2

800 MHz to 2,5 GHz

where p is the maximum output power rating of

the transmitter in watts (W) according to the

transmitter manufacturer and d is the

recommended separation distance in meters

(m).a

Field strengths from fixed RF transmitters, as

determined by an electromagnetic site survey,

should be less than the compliance level in

each frequency range.b

Interference may occur in the vicinity of

equipment marked with the following symbol:

NOTE 1 At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic is affected by absorption and

reflection from structures, objects and people.

a

Field strength from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and

land mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted

theoretically with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an

electromagnetic site survey should be considered. If the measured field strength in the location in which the

Smart-Max is used exceeds the applicable RF compliance level above, the Smart-Max should be observed to

verify normal operation. If abnormal performance is observed, additional measures may be necessary, such as

reorienting or relocating the Smart-Max.

b

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

immunity – for EQUIPMENT and SYSTEM that are not LIFE-SUPPORTING (see

6.8.3.201 b))

Table 206 – Recommended separation distances between portable and mobile

Preface OM – 2320 – 01 – 00 5

RF communications equipment and the EQUIPMENT or SYSTEM -

Page 10

for EQUIPMENT and SYSTEMS that are not LIFE-SUPPORTING (see 6.8.3.201 b))

Recommended separation distances between

portable and mobile RF communications equipment and the Smart-Max device

The Smart-Max is intended for use in an electromagnetic environment in which radiated RF disturbances are

controlled. The customer or the user of the Smart-Max can help prevent electromagnetic interference by

maintaining a minimum distance between portable and mobile RF communications equipment (transmitters)

and the Smart-Max as recommended below, according to the maximum output power of the communications

equipment

Separation distance according to frequency of transmitter

M

Rated maximum

output of

transmitter

W

150 kHz to 80 MHz

Pd 2.1

80 MHz to 800 MHz

Pd 2.1

800 MHz to 2,5 GHz

Pd 3.2

0,01

0.12

0.12

0.23

0,1

0.37

0.37

0.74

1

1.17

1.17

2.33

10

3.69

3.69

7.38

100

11.67

11.67

23.33

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in

meters (m) can be estimated using the equation applicable to the frequency of the transmitter, where P is the

maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE 1 At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by

absorption and reflection from structures, objects and people.

1.6 Warranty

Biosafe’s products are designed and manufactured to provide reliable performance

when properly maintained and used in accordance with the instructions provided in

this manual. Each unit is carefully inspected and tested before shipping.

In case of equipment failure or malfunction, Biosafe will replace or repair the

concerned equipment according to the agreement in place.

Equipment failure or malfunction for reasons other than a manufacturing defect (such

as improper handling of the machine or non-compliance with the Operator’s Manual)

is not covered under the Biosafe warranty program and such equipment will be

replaced or repaired at the charge of the end-user.

Biosafe shall under no circumstances be liable for consequential or economical

damage that may be an indirect or direct consequence of a defective part.

1.7 Customer support

All Smart-Max devices are supplied with a copy of the Operator’s Manual.

In addition, competent technical staff will provide end-user training prior to use and

will be available for specific questions or clarifications.

For assistance in technical or application issues, please contact your local

representative or call Biosafe Customer Service in Switzerland + 41 22 365 2705.

Preface OM – 2320 – 01 – 00 6

Page 11

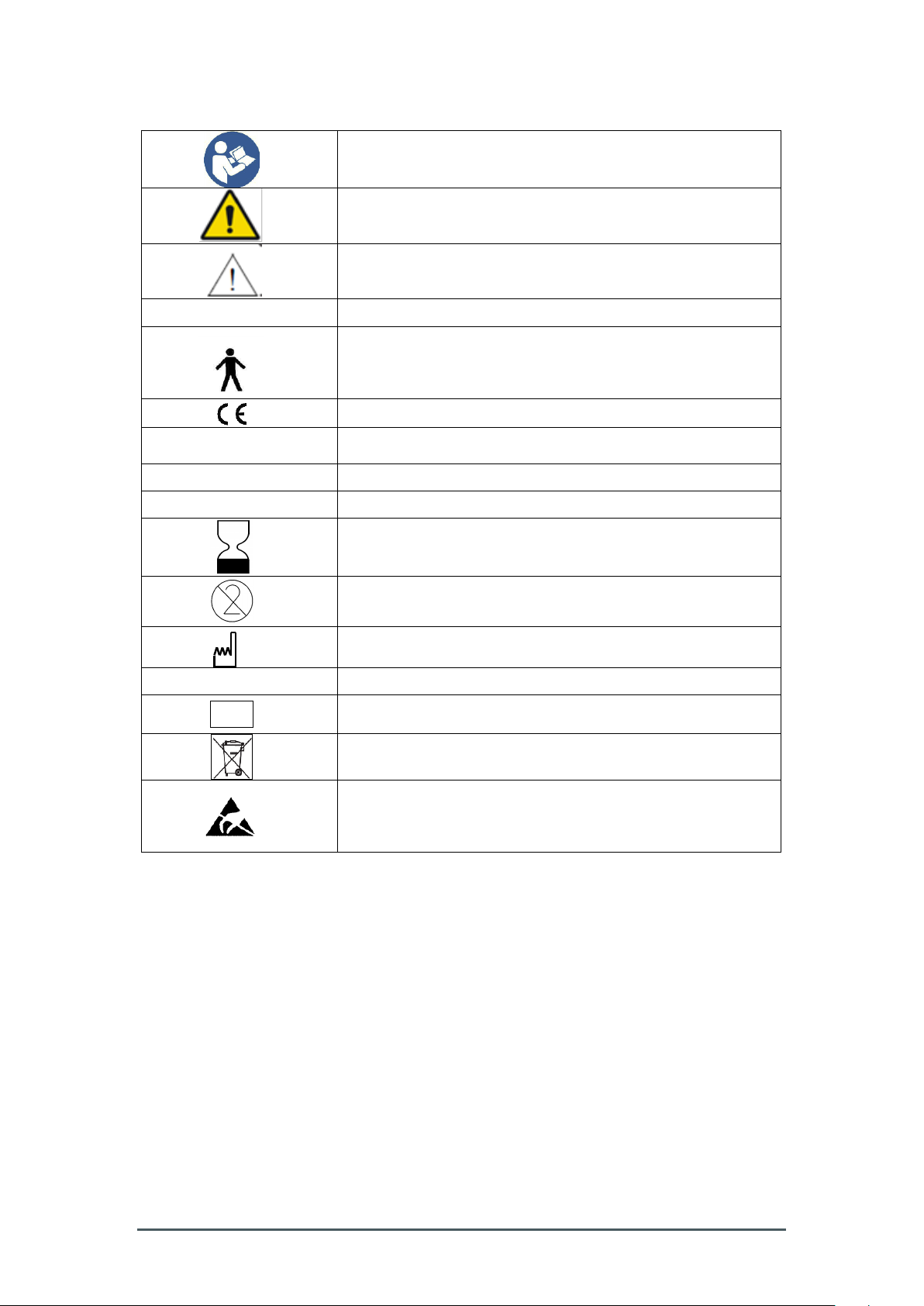

1.8 Symbol chart and abbreviations

Refer to instruction manual/booklet

General warning sign

Caution

Class I

Equipment energized from an external electrical power source

Type B equipment providing a degree of protection against

electrical shocks particularly regarding allowable leakage

current

CE marking of the Smart-Max instrument

~

Alternating current

O

Power off

I

Power on

Expiry date

Not reusable, for single use only.

Date of manufacture

REF

Product number

LOT

Batch designation

Refer to chapter 6.2

Pins of connectors identified with the ESD warning symbol

should not be touched. Connections should not be made to

these connectors unless the user’s hand is discharged by

earth bonding.

Preface OM – 2320 – 01 – 00 7

Page 12

Preface OM – 2320 – 01 – 00 8

Page 13

2. Smart-Max main unit

2.1 General description

The Smart-Max device is intended for the safe and reproducible mixing of bag(s)

under regulated temperature (cooling and heating) and / or injection of biological

additives into the product bag at a controlled rate.

The main features of the Smart-Max are:

USB ports to connect printer, barcode reader, memory stick and other PC

interfaces

LAN, WLAN integration

User selectable multi-language support

Enhanced traceability features (e.g.: procedure report file accessible via USB

key)

Pneumatic mixing with highly flexible pouches

Universal cooling plate for small and large cryobags.

Temperature range involves both cooling and heating between 1°C - 45°C.

2 peristaltic pumps for injection of cryopreservation solution and other

reagents, with the possibility of two parallel injections

Remote access via internet connection

Smart-Max main unit OM – 2320 – 02 – 00 9

Page 14

Mode

Operation

Storage & Transport

Temperature*

+7°C to +27°C

0°C to 45°C

Relative

humidity

30% to 75%, non-condensing

20% to 75%, non-condensing

Maximum

Altitude

2000m, 80 kPa

2000m, 80 kPa

Installation, assembly and modification of the Smart-Max must be done by an approved

Biosafe technician

2.2 Operating and storage requirements

2.2.1 Environmental specifications

The Smart-Max must only be operated under the following environmental conditions:

*The stand-by functioning temperature is +10°C

*Tolerance of the temperature displayed on the screen is +/-1°C

*Tolerance of the injected volume is 5%

The Smart-Max should:

only be operated on a flat, stable, horizontal and clean surface

be used in an open environment to allow sufficient ventilation

be cleaned regularly

be kept upright during transport

be connected to a grounded power supply directly (no adapters or

extension leads)

be installed such that the power switch (located on the back of the machine)

is accessible to power off the device without difficulty

The Smart-Max should not be exposed to:

direct sunlight or strong light sources

liquids or corrosive substances

physical shocks or vibrations

heavy weights

other equipment that contains magnets or generate

magnetic/electromagnetic fields (such as mobile phones)

Smart-Max main unit OM – 2320 – 02 – 00 10

Page 15

8. Peristaltic pumps

5. Bag pole

holder

1. Cover

2. Syringe

holder

3. Closing mechanism

4. Touch screen

6. Pneumatic bags

for mixing

7. Base plate

(small and large bags)

9. Stop button

2.3 Smart-Max Main Processing Unit – Components

Smart-Max main unit OM – 2320 – 02 – 00 11

Page 16

1. Cover

Cover to close or open after bag insertion or removal

2. Syringe holder

Syringe holder adapted for different syringe sizes

3. Closing mechanism

Closing mechanism to lock cover in place

4. Touch screen

Color touch screen

5. Bag pole holder

Support to hang the input, source and other bags. Safe working load is up to 1kg

6. Pneumatic bags for mixing

Pneumatic pouches activated by air pressure

7. Base plate (small and large bags)

Base plate that can accept bags of varying size and volume

8. Peristaltic pumps

Two peristaltic pumps for controlled solution injection

9. Stop button

Stop button to abort a procedure in case of emergency

2.4 Technical specifications of the Smart-Max

Type of protection against electric shock: Class I equipment.

Degree of protection against electric shock: Type B applied part.

For cleaning procedure, please refer to Chapter 6.1

2.4.1 Dimensions (approximate):

Width: 27 cm (10.6”)

Length: 32 cm (12.7”)

Height: 17 cm (6.7”)

2.4.2 Weight:

8.5 kg (18.7 lbs)

2.4.3 Power:

Use only the original certified cable for the power supply.

The Smart-Max equipment should always be connected to an Uninterruptible Power

Supply (UPS).

Input range: 100 to 240 VAC (The Smart-Max automatically adjusts for the

local supply voltage)

Input frequency: 50/60 Hz

Consumption: 250 VA

Smart-Max main unit OM – 2320 – 02 – 00 12

Page 17

3. Smart-Max Menus

To ensure correct usage of the touch screen display, the user should allow a 1

second delay between each touch of the screen.

3.1 Starting Menu

Upon switching on the Smart-Max, an automatic test is performed and the starting

menu is displayed (Fig. 1).

Fig.1

3.2 Smart-Max Menu

3.2.1 Protocol description

Press the protocol icon to display the list of applications available (Fig. 2):

For each application, the respective protocol can then be selected and launched. For

specific instructions on each protocol, please refer to the corresponding chapter

below.

Smart-Max menus OM – 2320 – 03 – 00 13

Page 18

Fig.2

3.2.2 Settings and Data functions

Settings and Data functions can be accessed by pressing the Menu key. The

settings menu includes a service sub-menu which should only be used by Biosafe

service technicians (Fig. 3).

Smart-Max menus OM – 2320 – 03 – 00 14

Page 19

Fig.3

3.2.3 To change language

Select the “Language” icon and choose the appropriate option (Fig. 4).

Fig. 4

3.2.4 Traceability settings

The Smart-Max can be used with a Traceability Kit composed of a printer and a

barcode reader.

This Traceability Kit enables the traceability function for both the procedure and the

protocol. Report files can be printed directly by the printer supplied as part of the

Traceability Kit. Full protocol data (logfiles) can be downloaded to the USB key

provided with the Smart-Max.

Enabling of the traceability option requires a password. Biosafe provides traceability

option passwords to approved operators.

Select “Edit” on the traceability label in order to input or scan text/values (Fig. 5 and

6).

Smart-Max menus OM – 2320 – 03 – 00 15

Page 20

Fig. 5

Fig. 6

Pressing returns the display to the main screen.

Smart-Max menus OM – 2320 – 03 – 00 16

Page 21

3.2.6 Saving data options

In order to save protocol data, select the “Data” icon which allows the displaying of

various reports available at the end of each procedure (Fig. 7).

Fig. 7

The report files contain statistical information on the procedure, including:

• Date and time of processing

• Temperature

• Volume

These values ensure that the process has been performed correctly and that the

product has suffered no extreme conditions.

The logfiles (protocol data) provide more technical information, including:

• Sensors recordings

• Power supply data

These files are used by Biosafe technicians to diagnose the cause of malfunctions.

The report files are pdf files generated from summary files and include a graph of the

procedure.

Once either “Report Files”, “Save Log Files” or “Save Support File” has been chosen

from the Data menu (Fig. 7), a list of files is displayed along with several options. The

files are identified by the time and date they were created (corresponding to the end

of the procedure).

All files can be saved simultaneously, using the “Save all Files” option. Alternatively,

individual files can be saved by selecting them and using “Save selected Files”.

Smart-Max menus OM – 2320 – 03 – 00 17

Page 22

3.3 Protocol Running

The following screen appears when a Smart-Max protocol is running (Fig. 8).

The screen indicates the following:

1. Procedure phase

2. Remaining procedure time (seconds)

3. Added reagent/solution volume into bag(s)

Fig. 8

3.4 Troubleshooting

3.4.1 General

This chapter describes various alarms that can happen during a procedure, and the

actions that need to be taken in such cases.

Warnings and errors are signaled by an alarm.

“Warning” messages allow the procedure to continue once the problem has been

fixed.

“Error” messages do not allow the procedure to continue and will require the

operator to restart it (Fig. 9).

Smart-Max menus OM – 2320 – 03 – 00 18

Page 23

WARNING MESSAGES

WARNING

ID

DESCRIPTION

CORRECTION

COVER_OPENED

9018

Warning for cover

open.

Close the cover and continue

the procedure.

WARN_TEMPERATURE_LOW

9022

Warning

temperature low.

Temperature was detected

by the protocol as low.

Continue the procedure. If

the warning persists, contact

Biosafe support.

WARN_TEMPERATURE_HIGH

9023

Warning

temperature high.

Temperature was detected

by the protocol as high.

Continue the procedure. If

the warning persists, contact

Biosafe support.

Fig. 9

When an “Error” message appears, you are asked to perform the following steps:

1. Read and write down the error message

2. Press to turn off the alarm

When an error occurs, please inform Biosafe service.

3.4.2 Warning messages during the procedure

Smart-Max menus OM – 2320 – 03 – 00 19

Page 24

ERROR MESSAGES

ERROR ID

DESCRIPTION

CORRECTION

TEMP_1_HIGH

TEMP_2_HIGH

TEMP_3_HIGH

TEMP_12_HIGH

10000

10100

10200

10400

The temperature

measured by the

sensors on the

base plate is high.

Switch-off the Smart-Max

device and wait for a few

minutes to let the device cool

down.

Check that air vents are not

obstructed and restart the

Smart-Max.

If the error persists, call

Biosafe support.

TEMP_5_HIGH

10600

The internal

temperature is

high.

TEMP_1_OUT_OF_RANGE

TEMP_2_OUT_OF_RANGE

TEMP_3_OUT_OF_RANGE

11000

11100

11200

Temperature

sensor on the base

plate is not

functioning

properly.

Switch-off the Smart-Max

device and wait for a few

seconds, then restart.

If the error persists, call

Biosafe support.

TEMP_5_OUT_OF_RANGE

11400

Internal

temperature sensor

is not functioning

properly.

PRESSURE_HIGH

PRESSURE_MAXIMUM

COMPRESSOR_POWER_HIGH

PRESSURE_OUT_OF_RANGE

12000

12050

12100

12200

The mixing

mechanism is not

functioning

properly.

Switch-off the Smart-Max

device and wait for a few

seconds, then restart.

If the error persists, call

Biosafe support.

FAN_DISCONNECTED

FAN_SPEED_LOW

13000

13100

The rear fun is not

functioning

properly.

Switch-off the Smart-Max

device and wait for a few

seconds, then restart.

If the error persists, call

Biosafe support.

PELTIER_POWER_CIRCUIT

14000

Temperature

controlling system

not functioning

properly.

Switch-off the Smart-Max

device, wait few seconds and

then restart.

If the error persists, call

Biosafe support.

COVER_OPENED

15000

Cover has been

opened during a

procedure.

Close the cover and restart

the procedure. Ensure to

check and adapt parameters

(see troubleshooting guide

specific for each protocol).

ELEMENT_EXCEPTION

19999

Software error in

hardware element

handling.

Switch-off the Smart-Max

device, wait few seconds and

then restart.

If the error persists, call

Biosafe support.

SOFTWARE_EXCEPTION

20000

Software error

occurred.

Switch-off the Smart-Max

device, wait few seconds and

then restart.

If the error persists, call

Biosafe support.

DEVICE_STOP

10133

STOP key was

pressed.

Validate to restart when

ready.

3.4.3 Error messages during the procedure

Smart-Max menus OM – 2320 – 03 – 00 20

Page 25

PROTOCOL_ABORT

10134

Cancel/abort

button was

pressed.

The user aborted the

procedure. Start the

procedure again.

PROTOCOL_ERROR

10135

An undefined

protocol error

occurred.

A problem with the protocol

was detected. If the problem

persists, contact Biosafe

support.

MICROCONTROLLER_COMM

20100

An error occurred

in the internal

machine

communication

with the

microcontroller

Switch-off the Smart-Max

device, wait few seconds and

then restart. If the error

persists, call Biosafe support.

3.5 Using the Smart-Max

The user must ensure proper working and environmental conditions, and

check that the equipment functions safely prior to usage.

Smart-Max menus OM – 2320 – 03 – 00 21

Page 26

Smart-Max menus OM – 2320 – 03 – 00 22

Page 27

4. Cryo-SC protocol

The user must ensure proper working and environmental conditions, and

check that the equipment functions safely prior to usage.

The Cryo-SC protocol is designed to allow injection of cryoprotectant solution in

volume reduced cord blood with volumes between 10 and 25 ml (before

cryoprotectant solution addition). The Smart-Max device allows a single cord

procedure at a time or two units in parallel.

4.1 Protocol selection

Switch on the Smart-Max AS-310 and wait until the starting menu is displayed. To

prepare bag(s) for the procedure, it is suggested to cool them down to the desired

temperature (e.g. 4°C) with the Smart-Max by using the pre-cooling feature or in a

standard fridge.

In the main menu, select the protocol icon and enter the Cryo-SC protocol by

pressing on the corresponding icon. This selection automatically triggers the cooling

system to begin reaching the desired temperature of 4°C.

Cryo-SC protocol OM – 2320 – 04 – 00 23

Page 28

Leave the Smart-Max cover closed at all times, opening it only to insert or

remove bags. This ensures the device will reach the required temperature in

the fastest time.

Fig. 1

In the protocol menu (Fig. 1), press to select desired bag configuration.

Selection includes solution addition to a single bag, or two bags in parallel.

If only a single small bag is used, ONLY the right side is selectable and bag

must be placed on right side of the plate.

Make your choice by clicking on the appropriate icon (1 or 2 small bags), then select

to return to the general menu of the protocol (Fig. 1).

4.2 Cryobag preparation and installation on Smart-Max

Prepare cryoprotectant solution to be added to volume-reduced cord blood following

your own validated procedure, in a 10 or 20 ml syringe.

The unit head of processing is responsible for choosing and validating the

cryoprotectant solution and quantity to be added for cryopreservation.

Under aseptic conditions, or using a closed kit, connect the syringe containing the

cryoprotectant solution to the FA-100.1 DMSO extension line. The other end of the

FA-100.1 DMSO extension line should be connected to the cryobag containing the

volume reduced cord blood.

Cryo-SC protocol OM – 2320 – 04 – 00 24

Page 29

For specific characteristics of Biosafe’s single-use kits, please refer to the

related Cryopreparation chapter of the Operator’s Manual which describes

connection and preparation of the cryobag for addition of cryopreservation

solution.

Please remember that is necessary to add an extra amount corresponding to

the dead volume of the tubing (1.5 ml) and of applicable, the DMSO filter (1 ml).

Once the FA-100.1 DMSO extension line clamp is opened and primed, open the

cover of Smart-Max and place the cryobag(s) on the platform(s) (Fig. 2). Pay

attention to properly place the tubing between the cryobag and the syringe in the

designated space.

Fig. 2

Check carefully that the bag(s) is in place and close the cover. Ensure proper locking

of the cover by pressing in the black knob placed on the left side (Fig.3).

Fig. 3

Install the syringe containing the cryoprotectant solution in the dedicated support: 10

ml syringes in the small holder, or 20 ml syringes in the large holder (Fig.4).

Fig. 4

Cryo-SC protocol OM – 2320 – 04 – 00 25

Page 30

Install the connector of the FA-100.1 DMSO extension line in the designated holder,

ensuring proper connection (Fig. 4): this will prevent dislodging of syringe containing

cryoprotectant solution during functioning of the peristaltic pump.

Install the tubing of the FA-100.1 DMSO extension line around the circular pump

head, in the direction indicated in Fig. 5. Ensure no kinks or twists of the tubing occur

and then secure tubing around pump by closing the lever of the pump by rotating

forward.

Perform a visual check to ensure installation has properly occurred.

Fig. 5

4.3 Parameter selection

Press button, and the screen will display the protocol’s specific user

selectable parameters (Fig. 6).

Fig. 6

Cryo-SC protocol OM – 2320 – 04 – 00 26

Page 31

Cooling time

Time for cooling the cryobag(s), before starting cryoprotectant solution addition.

Adjustable value between 0 to 20 minutes. If the cryobag(s) has already been cooled

in a fridge, enter 0 to start injection of cryoprotectant solution immediately.

Default value is 10 minutes.

Injection time

Desired time for injecting cryoprotectant solution. Adjustable parameter between 0 to

20 minutes. Recommended value is 12 minutes.

Volume to inject

Volume of cryoprotectant solution to be added to the cryobag(s). Recommended

value is 5 ml.

Once the desired values have been entered, the corresponding flow rate for injection

will be calculated and compared with the device’s limit.

The maximum flow rate possible with the FA-100.1 DMSO extension line is 0.9

ml/min (higher value will not be accepted by the device).

In case of parallel procedures for two cryobags, the same parameters will be

applied to both units. Please install the first unit and keep the cover closed

until the second unit is ready. When the second unit is ready for cryoprotectant

addition, open the cover, install the cryobag, complete the traceability

information, close the cover and launch the automated procedure.

Press the button: if the traceability option is enabled, you’ll be able to insert

the corresponding values; if the traceability option is not enabled, it will start the

automated procedure.

4.4 Traceability function and launching of the automated procedure

If the traceability option of Smart-Max is enabled, the following screen is displayed

(Fig. 7)

Fig. 7

Cryo-SC protocol OM – 2320 – 04 – 00 27

Page 32

Press on , and you can configure the list of ID’s by selecting those that

you want to insert.

When a specific ID is highlighted, enter the corresponding value using the barcode

reader or displayed keyboard, then press .

Ensure proper locking of the cover by pressing in the black knob placed on the left

side (Fig. 3).

In case some of the traceability ID’s have already been inserted, please check the

exactitude of the values, eventually complete the information and start the automated

procedure.

4.5 Starting of the procedure

Press the button, and the screen will display a list of important points to be

verified prior to start of the automated procedure (Fig. 8):

Fig. 8

Ensure all requirements on the list have been verified, and press to begin

the protocol.

During the automated procedure, the display screen reports relevant information for

the procedure (Fig. 9 & 10).

Cryo-SC protocol OM – 2320 – 04 – 00 28

Page 33

Fig. 9

Fig. 10

4.6 Post procedure actions

When the procedure is completed, the following screens are displayed (Fig. 11 & 12):

Before removing the cryobag, remember to close the clamp on the FA-100.1

extension line to avoid unexpected injection of additional solution inside the bag.

Cryo-SC protocol OM – 2320 – 04 – 00 29

Page 34

Fig. 11

Fig. 12

Open the cover by pressing in the black knob on the right side of the cover (Fig. 13),

and remove the bag(s). Opening of the cover will automatically terminate the

procedure and Smart-Max will return to the starting page of the protocol.

Cryo-SC protocol OM – 2320 – 04 – 00 30

Page 35

Fig. 13

Prepare the cryobag(s) for freezing following your own validated procedure.

4.7 Troubleshooting

In case of any error or procedure interruption, a message will appear on the display

(Fig. 14).

Fig. 14

After pressing , the Smart-Max automatically displays the main menu.

For a description of possible errors and corrective actions, please refer to section 3.4

of the Operator’s Manual.

After following the actions reported in the table, you can re-load protocol Cryo-SC to

complete the aborted procedure.

Due to the cord blood unit being in contact with cryoprotectant solution,

troubleshooting actions must be performed as quickly as possible and

validated by the laboratory manager.

Cryo-SC protocol OM – 2320 – 04 – 00 31

Page 36

new Procedure time = new Volume

Initial Volume

Initial time

= 2.5

*

*

12

5

= 6 mins

Before launching the new procedure, all protocol parameters must be checked and

adapted:

Cooling time

In case the interruption occurred during the pre-cooling phase, restart the procedure

and set the parameter at the same value.

In case this phase has already occurred, set the parameter to 0: this will allow

injection to start immediately.

Volume to inject

In case injection of cryoprotectant solution had begun, reduce this value by the

quantity of solution already injected into the cryobag (excluding the volume used for

priming the DMSO extension line).

For example, if the total volume of cryoprotectant in the syringe was 6.5 ml (after

priming) at the start of the procedure, and the syringe contained 4 ml at the moment

of interruption, and the desired volume to inject into the bag is 5ml, the Volume to

add should be set at 5 – (6.5 – 4) = 2.5 ml.

In case the injection of cryoprotectant solution had NOT yet started, set the

parameter at the same value.

Injection time

The value of the parameter must be adapted corresponding to the Volume of

cryoprotectant solution still to be added.

In the previous example Volume to add is now set at 2.5 ml, therefore the new

Procedure time must be set at:

If the parameters have been adapted correctly, the flow rate displayed should be

equal to that of the initial procedure.

Press the button, verify the points listed and the correct installation of the

syringe and the DMSO extension line and then start the automated procedure.

Cryo-SC protocol OM – 2320 – 04 – 00 32

Page 37

5. Maintenance

As with any electrical equipment, fluid entering the Smart-Max can

adversely affect its performance. Do not attempt to clean any internal

parts of the Smart-Max – this should only be done by a Biosafe

approved technician. If in doubt, contact Biosafe for advice.

Any other maintenance or technical intervention should only

be performed by Biosafe approved technicians.

The Smart-Max is designed to require minimal maintenance.

The only maintenance the operator must perform consists of cleaning the outer

surfaces of the Smart-Max and the associated power cables.

The Smart-Max equipment should be serviced every 1000 procedures or, at a

minimum, once per year. The elements that require servicing by the Biosafe

approved technician are described in the Service Manual.

4.1 Cleaning

The Smart-Max should be cleaned on a regular basis or after any incident such as

product leakage.

The following procedure should be used for cleaning:

1. Switch off the Smart-Max before beginning the cleaning procedure to prevent

risk of electrical shock.

2. Rubber gloves and a protective gown should be worn to prevent direct skin

contact with any spilled cord blood during the cleaning procedure.

3. With gauze bandage or a soft paper soaked with warm water clean the blood

off the surface. Dry the damp surface with soft paper and repeat as necessary

to ensure the surface is clean.

4. Use an antibacterial solution to disinfect the surface - such as Meliseptol®.

4.2 Waste management

This product is subject to Directive 2002/96/EC of the European

Parliament and the Council of the European Union on waste electrical

and electronic equipment (WEEE) and, in jurisdictions adopting that

Directive, is marked as being put on the market after August 13, 2005,

and should not be disposed of as unsorted municipal waste. Please

utilize your local WEEE collection facilities in the disposition of this

product and otherwise observe all applicable requirements.

Maintenance OM – 2320 – 05 – 00 33

Page 38

4.3 Warranty

Biosafe products are designed and manufactured to provide reliable, trouble free

performance when properly maintained and used in accordance with the Operator’s

Manual.

Biosafe warrants to the original purchaser that the unit has been fully tested and

delivered according internal Biosafe procedures. Maintenance service and, if

required, repairs are free of charge for one year from the date of shipment.

Equipment failure due to reasons other than manufacturing defects such as

accidents, misuse or failure to perform scheduled maintenance is excluded from

warranty coverage.

Maintenance OM – 2320 – 05 – 00 34

Page 39

6. Contacts

Biosafe SA

Route du Petit-Eysins 1

Telephone: +41 22 365 27 27

1262 Eysins, VD

Fax: +41 22 365 27 37

Switzerland

E-mail: info@biosafe.ch

www.biosafe.ch

Support

Telephone: +41 22 365 27 05

E-mail: support@biosafe.ch

Biosafe America, Inc.

1225 North Loop West

Telephone: +1 713 936 26 15

Suite 120

Fax: +1 713 456 27 66

Houston, TX 77008

E-mail: info@biosafeamerica.com

USA

www.biosafeamerica.com

Support

Telephone: +1 713 936 26 16

E-mail: support@biosafeamerica.com

Biosafe Asia-Pacific Ltd.

Room 3012, 30/F

Telephone: +852 2956 7500

Tower 1, The Gateway

Fax: +852 2956 2110

25 Canton Road

E-mail: info@biosafeasiapacific.com

Tsim Sha Tsui, Kowloon

Hong Kong

www.biosafeasiapacific.com

Support

E-mail: support@biosafeasiapacific.com

Biosafe Medical Device

International Trading (Shanghai)

Co. Ltd

Rm 80, 38F, Park Place No.1601

Telephone: +86 21 61373214

Fax: +86 21 61373210

Nanjing West Road

E-mail: info@biosafechina.com

Shanghai 200040

China

www.biosafechina.com

Support

E-mail: support@biosafechina.com

Biosafe Latin America

Av. Chedid Jafet, 222 – 5th floor

Telephone: +55 11 2655 1731

Fax: +55 11 99326 5454

Block D – Vila Olimpia

E-mail: info@latinamerica.com

04551-065 Sâo Paulo

Brazil

www.biosafelatinamerica.com

Support

E-mail: support@biosafelatinamerica.com

Contacts OM – 2320 – 06 – 00 35

Page 40

Local representative (if applicable)

Contacts OM – 2320 – 06 – 00 36

Loading...

Loading...