Page 1

Model P720 Peristaltic Pump

Operation Manual

NOTE: This pump is a laboratory device. It is not

Instech Laboratories, Inc. cannot assume liability from i m proper use of its products.

not intended for use on humans.

notnot

Page 2

Instech’s Model P720 pump is a full-featured, miniature peristaltic

pump designed specifically for low flow laboratory applications.

Instech’s wide variety of pump tube sets let you configure this

pump to run at flow rates from 0.2 to 180 ml/hr, to work with a

variety of solutions, and to pump in single or dual channel mode.

The Model P720 can operate as a stand-alone pump or as an element in closed loop control applications using the external speed

control input. The pump has an internal battery that will operate

the pump continuously for up to 30 hours if the power should fail

or if you just want to move the pump around your lab without

turning it off.

This pump’s circuitry has been designed to minimize electromagnetic radiation, making it ideal for use near sensitive microelectrodes. For quietest operation, run the pump using the internal

battery.

1

Page 3

p

)

p

co n

Set-up

Check for signs of shipping damage. You should have received:

1 ....Model P720 pump

1 ....Wall mounted 9V DC power adapter

2 ....Pump tube sets (of your choice)

1. ...9V lithium battery

1 ....3.5mm stereo jack (for external speed control)

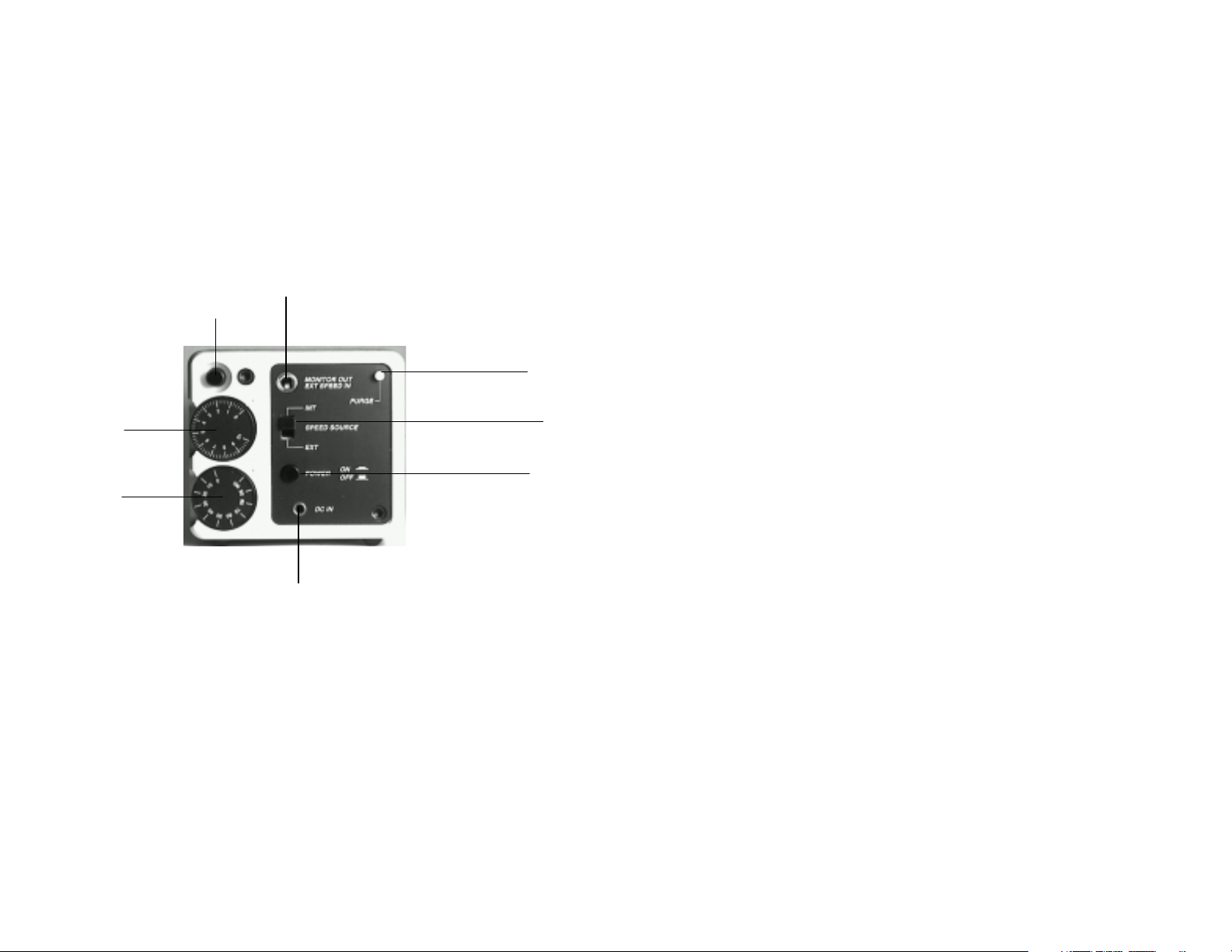

Monitor output and external analog control input –

Motor run/stop

use stereo jack for co n nection

Pump runs at full speed

while pressed

Fine

eed

s

Coarse speed

trol

Input for 9VDC power adapter

(does not charge battery)

Model P720 pump controls

Speed source selector

(set to INT for normal use)

Power on/off (Red LED

on pump head indicates

ower on

Battery Installation

1. Place POWER switch in off position (out).

2. Remove screw holding access cover on underside of pump and

remove plate.

3. Withdraw connector and attach to battery terminals. A lith-

ium U9VL is preferred due to its long shelf life and higher capacity (about twice the operating time as an alkaline)

although an alkaline will suffice.

4. Make sure that the removal ribbon is below the battery.

2

Page 4

5. Place the battery into the compartment and replace access

plate.

Testing Battery Backup Operation

1. Place speed source selector in INTernal position.

2. With no external adapter attached, turn on POWER switch

and check pump end for illumination of red LED.

3. Press PURGE. The rotor should turn at full speed.

4. Set speed to some value other than zero and turn on motor by

pressing the RUN/STOP button.

5. While motor is running, check that the amber LOW BAT-

TERY LED has not come on (battery voltage below 7.5V); if

so, replace battery.

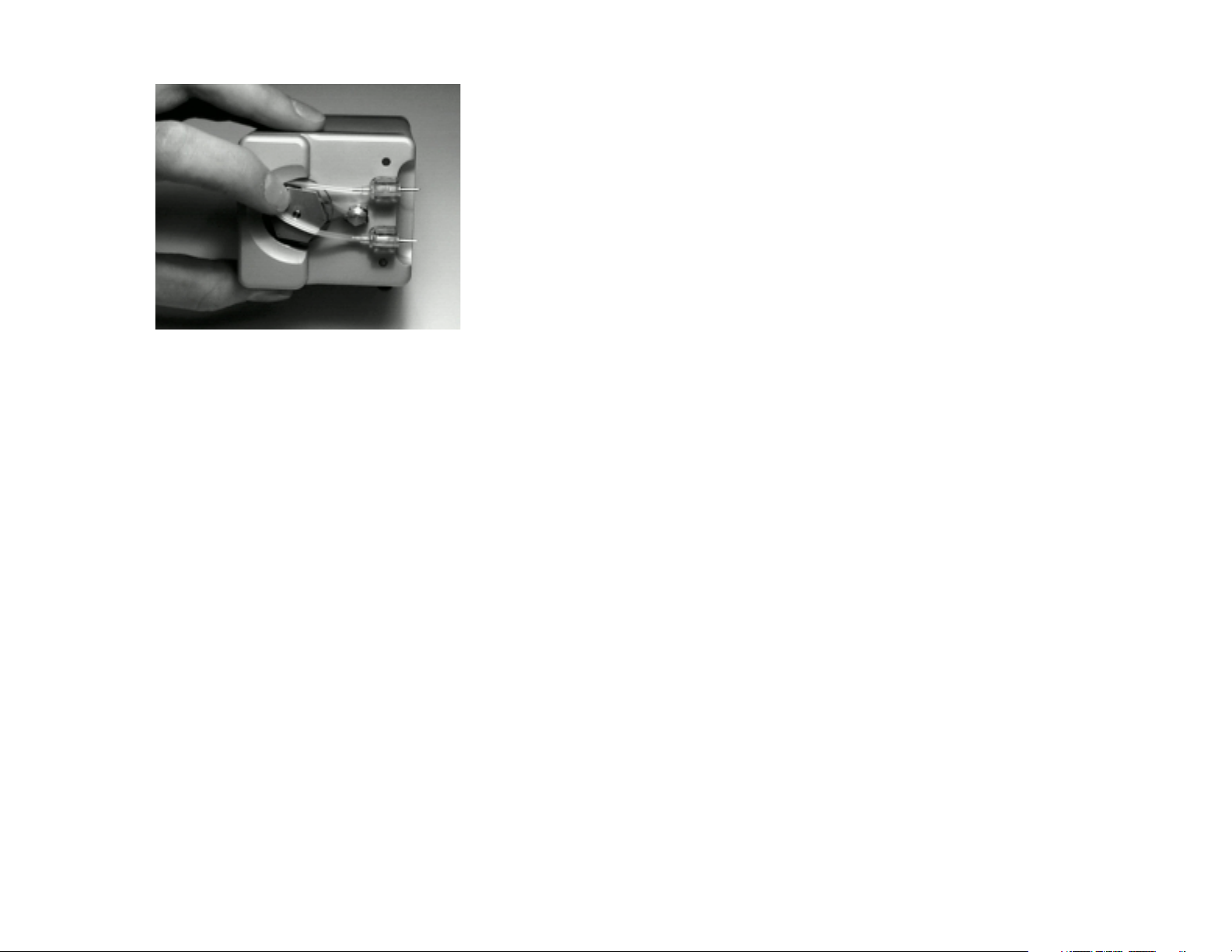

Pump Tube Installation

1. Slip the tubular portions extending from the bottom of the

connector blocks into the mounting holes with the silicone

tube just above the rotor.

2. Actuate the rotor, using the PURGE button, while guiding the

tubing down and around the rotor with your finger (see figure

below).

3. Press in both connectors so that they align with the square

depressions in the pump.

4. Again press PURGE button to check that the tube has been

correctly installed and that the amber Kapton tape has not

been displaced. There will be slack in the tape as the rotor

turns; this is normal.

3

Page 5

Pump tube installation

Pump Tube Removal

1. Press the purge button.

2. Lift the input side of the tube out of the holder.

3. As the rotor turns, lift the input side until the entire tube has

disengaged.

4. Remove the output side from its holder.

4

Page 6

Operation

Stand Alone Operation

1. Insert the power jack into the pump first, then plug the 9V DC

wall mount supply into an AC outlet.

2. Press in the pump POWER switch.

3. Attach inlet and outlet lines as required. Due to the low flow

rates, it is usually best to attach the lines to the pump tube

connector, fill the system, clear any air bubbles, pinch off the

line to stop any flow and then install the pump tube into the

pump as described above. The rotor will prevent flow when it

is not turning. Pump tube installation may be performed

without the external supply if it is more convenient.

4. Set desired flow rate using the two setting control knobs in

conjunction with previously obtained calibration plot of flow

vs. Dial Settings or MONITOR Voltage (see Calibration).

5. Check that SPEED SOURCE is in the INTernal position. If

this switch has inadvertently been moved to the EXTernal

position without an external input the pump will not run or

respond to dial settings.

6. Press MOTOR RUN/STOP button to start pumping. Use this

button to start and stop the pump rather than the POWER; it

provides more rapid starts and stops.

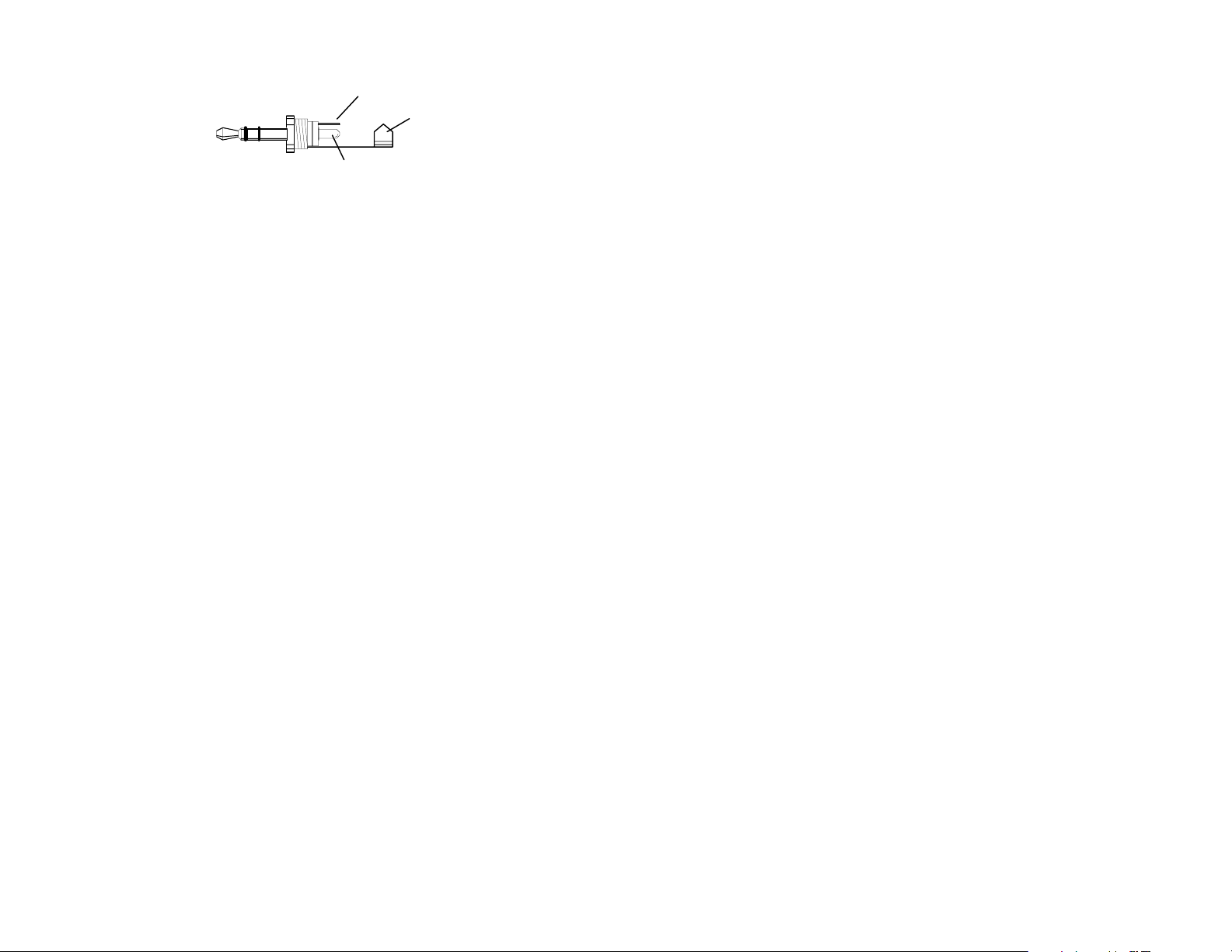

External Speed Control

In this mode you will be supplying an analog voltage to control

the speed of the pump. Bi-directional control is possible using this

mode. The MOTOR RUN/STOP behaves normally. Set the

SPEED SOURCE to EXTernal and apply the voltage via the center

ring of the 3.5 mm stereo phono jack input at the top of the

control panel.

5

Page 7

EXT speed input

GND

Set voltage monitor

Stereo jack connections for EXTernal speed control

The control voltage passes through the speed control potentiometers and can be attenuated via the knob settings. This is a useful

feature when operating more than one pump from a common

control line since it allows individual speed adjustment for each

pump. It is also useful when a digital level is used as a control

voltage.

The input parameters are as follows:

Ensure that maximum MONITOR VOLTAGE (after knob at-

tenuation) does not exceed ±1.75 volts. An input of +1.5V will

produce a MONITOR voltage of about –1.75V when the dials are

at 100 and 10.

Zero volts = Zero flow rate (actively controlled). Note: TTL 0

state may not be 0 volts. CMOS is usually close enough to work

directly.

Positive Control voltage will cause the rotor to rotate clockwise

(outflow will be on the top).

Negative control voltage will cause the rotor to rotate counterclockwise (outflow on the bottom).

To establish the maximum dial setting (assuming you desire full

motor speed at your full peed signal):

1. Set Speed Source to EXT.

2. Apply power and press Power Switch IN.

3. Turn dials to 0.

4. Apply the maximum control signal that your system will de-

liver. Increase the dials until the MONITOR voltage reaches a

maximum of 1.75V.

5. You may now perform a calibration of Flow vs. Monitor

voltage as detailed below by either varying the incoming sig-

6

Page 8

0 20 40 60 80

0 10 20 30 40 50 60 70 80 90

nal or with a constant input and varying the dials. Remember

not to exceed the values determined in step 4 above.

6. Turn on the MOTOR RUN/STOP switch. You may leave the

switch in this position and stop the pump by applying zero

volts to the control input.

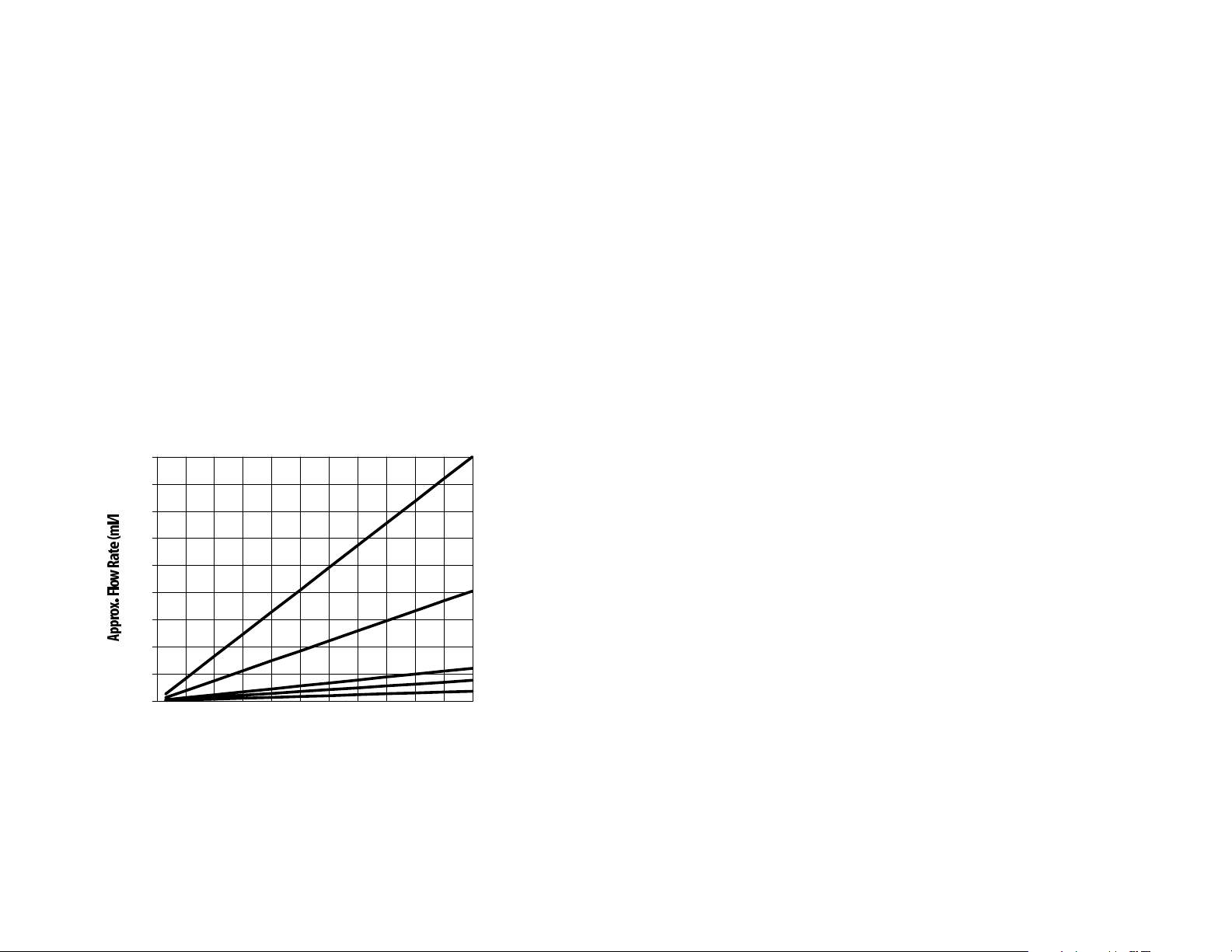

Calibration

Instech’s peristaltic pumps use tube sets of different sizes to cover

the range of flow rates from 0.2 to 180 ml/hr (see chart below).

To determine the flow rate at a given rotor speed you will need to

calibrate your pump. We have designed our pumps so that the

relationship between the rate setting on the controller and the

rotor’s speed is extremely linear; therefore, in most cases you only

need to perform a single-point calibration. For maximum accuracy, we recommend that you calibrate each pump tube that you

use, since each tube set may vary slightly.

180

160

140

120

100

Dial Setting (INTernal speed control)

Dial Setting (INTernal speed control)

Dial Setting (INTernal speed control)Dial Setting (INTernal speed control)

.093" ID

.062" ID

.031" ID

.020" ID

.015" ID

100 110

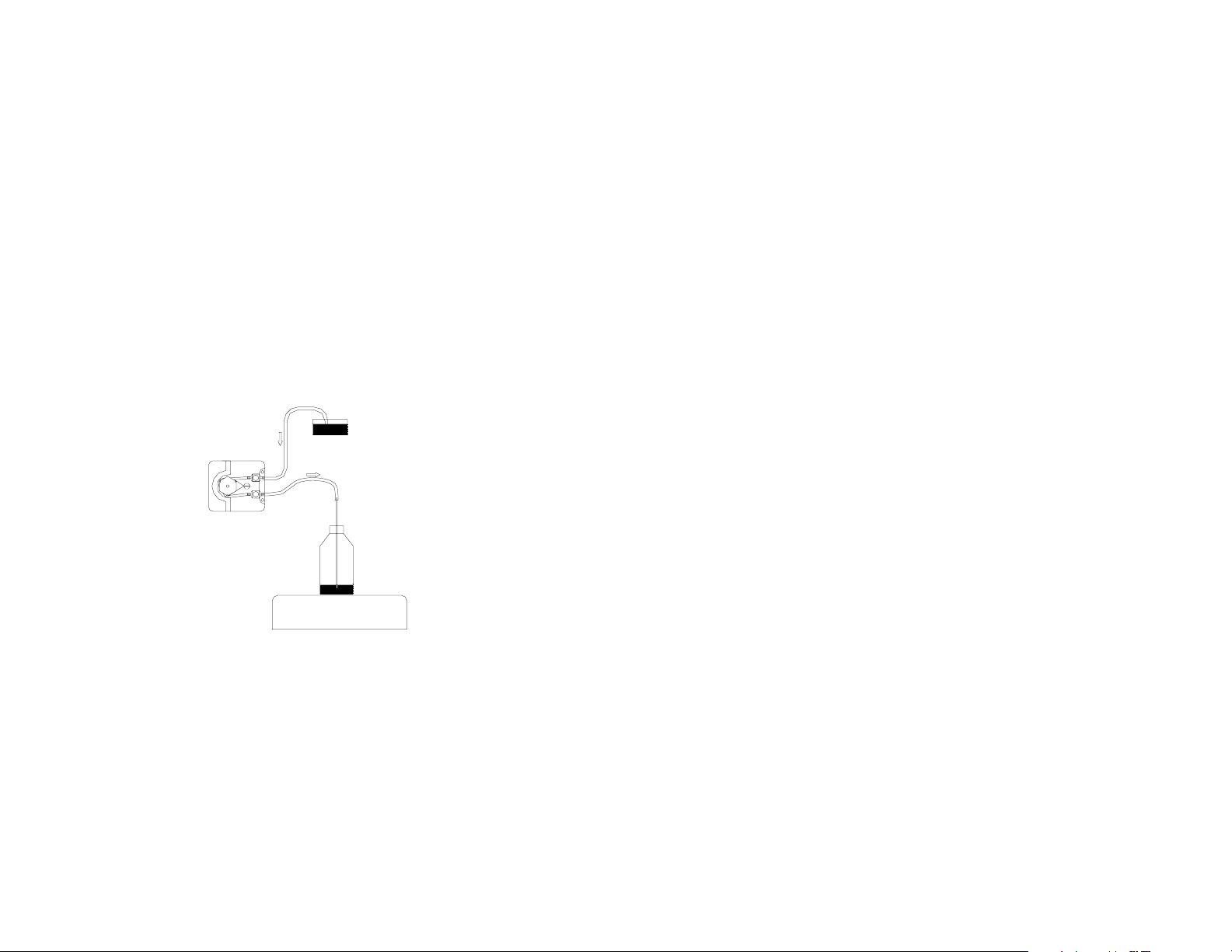

1. Attach either the inflow or the outflow tube to a container on

a balance, or one whose weight is precisely known. Ensure

that all the air has been removed from the lines.

7

Page 9

2. Set the pump dials to 110 to run the motor at maximum speed

(coarse speed control: 100, fine speed control: 10), and turn

on the pump motor. (Alternatively, when using the external

speed control, or when you need more precision, you may

calibrate vs. Monitor Voltage instead of dial settings. To read

the Monitor Voltage connect a digital voltmeter between

ground and the tip of the 3mm stereo jack plugged into the

monitor jack.)

3. Collect or withdraw a timed sample, typically for 10 minutes.

The total delivered volume upon which the calibration is

based should exceed 0.5 ml (approximately 6 minutes when

using the smallest tubing), assuming that the sample is being

weighed with a resolution of 1 mg.

4. Weigh the sample and calculate the actual flow rate. Flow

rates should be linear with dial settings between 3 and 110.

Reservoir

Scale

Tips for Most Accurate Calibration

• Calibrating the pump by measuring the sample in a graduated

pipette is usually less accurate than weighing the sample as

described above.

• When using new tube sets, run the pump at full speed for 20

to 30 minutes to allow the pump tube to stretch into its final

shape.

• Use the same liquid that you will be using under actual oper-

ating conditions.

8

Page 10

• When calibrating at very low flow rates, beware of evapora-

tion. Use a covered container or one with a small surface

area.

• If possible, simulate the pressure differences across the pump

tube that will be experienced under actual operating conditions. Increased back pressure on the outflow side will cause a

slight increase in delivery rate due to tubing dilation, though

this effect is usually less than 1%.

Replacement Parts

Kapton Strips

This amber strip reduces tube wear and minimizes the tendency

for the peristaltic action to walk the tube through the pump,

which can stretch the tube and alter the flow rate calibration. The

strip should never be tight around the rotor. Replacement strips

area available—specify part number KSK.

Tube Sets

Your Model P720 pump includes 2 pump tube sets that were chosen when you ordered the pump. Tube sets will typically last

about one month under continuous operation. Dual tube sets

place greater stress on the pump motor than do single tube sets,

and thus they may shorten the life of the motor.

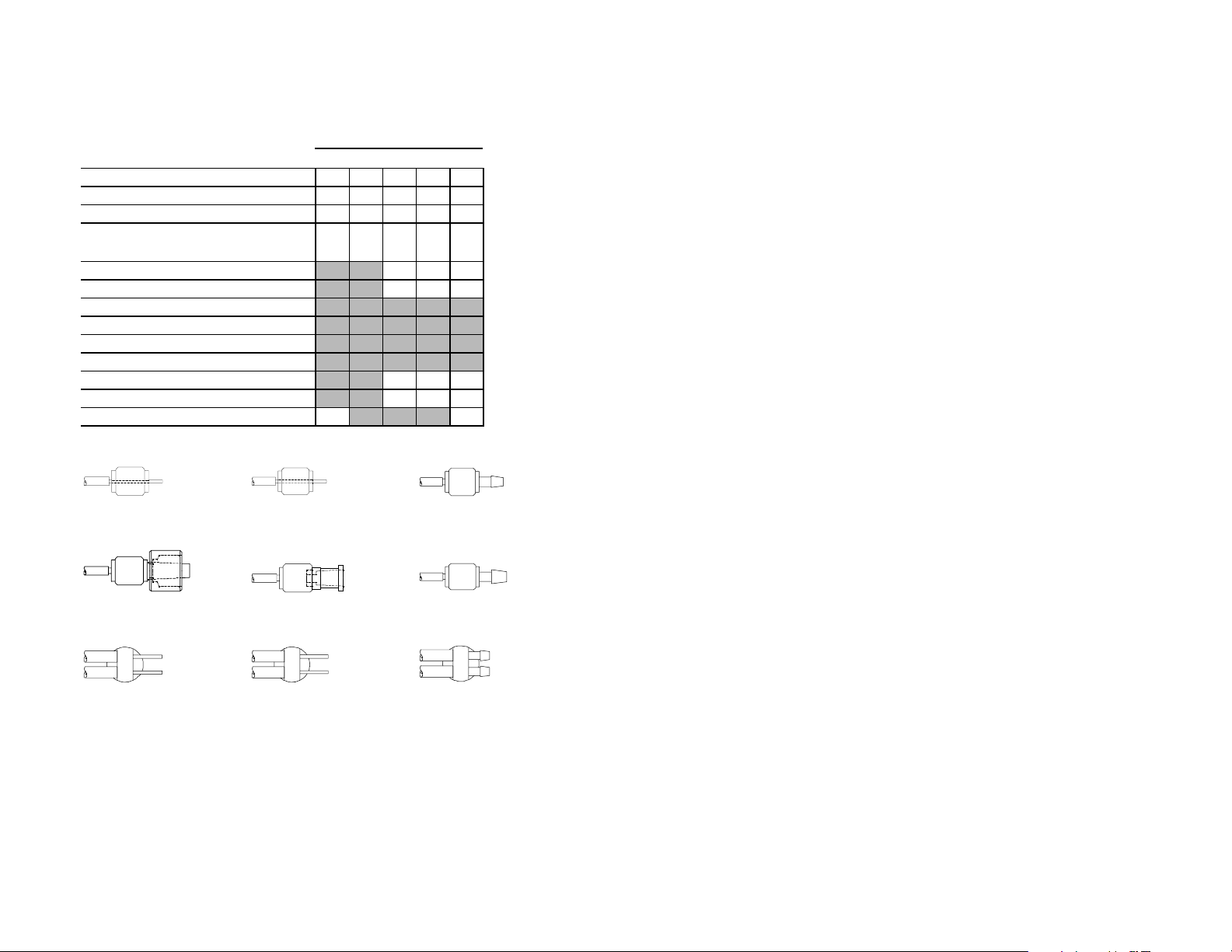

You may order additional tube sets directly from Instech. First

choose the size of tube you need based on your expected flow rates

(refer to the graph above). Next choose the tube material and

inlet and outlet connectors using the table below. When ordering,

give us a part number that specifies: inlet connector–tubing–outlet

connector. For example, LL-020S-22 specifies a single channel

.020” silicone tube with a male Luer lock inlet connector and a 22

gauge hypodermic tubing outlet connector. Note that you can

have different inlet and outlet connectors on the same tube set.

Call for current prices.

9

Page 11

-

-

- - -

- - -

- - -

- - -

- -

Available tube set materials, sizes and connectors

Tube size (ID)

Material Infusate

Silicone Saline, most drugs

C-FLEX® IV diets with fats

VITON® Petroleum-based fluids

.015" .020" .031" .062" .093"

015S

015S 020S

020S 031S

031S 062S

062S 093S

015S015S

020S020S

020C

020C 031C

020C020C

020V

020V - 062V

020V020V

031S031S

031C 062C

031C031C

093S

062S062S

093S093S

062C 093C

093C

062C062C

093C093C

062V -

062V062V

Channels Inlet and outlet conne c tors

Single 22 gauge tubing

Single 20 gauge tubing

Single .062" ID barb (soft plastic) BS

Single Male Luer lock

Single Female Luer lock

Single .093" ID barb (soft plastic) 93

Dual

Dual

Dual

VITON is a registered trademark of DuPont Dow Elastomers LLC. C-FLEX is a registered trademark of Consolidated Polymer Technolgies, Inc. Tygon is a registered trademark of Norton

Performance Plastics Corporation.

22

22 22 gauge tubing

2222

Fits PE50, .020” Tygon®

LL

LL Male Luer lock

LLLL

Fits female Luer, .093” Tygon®

D22

D22 Dual 22 gauge tubing

D22D22

Fits PE50, .020” Tygon®

22 gauge tubing

20 gauge tubing

.062" ID barb (soft plastic) DBS

D22

D22

D22D22

D20

D20

D20D20

DBS

DBSDBS

20

20 20 gauge tubing

2020

Fits PE100, .030” Tygon®

FL

FL Female Luer lock

FLFL

Fits male Luer lock

D20

D20 Dual 20 gauge tubing

D20D20

Fits PE100, .030” Tygon®

.015" .020" .031" .062" .093"

22

22

2222

20

20

2020

BS

BSBS

LL

LL

LLLL

FL

FL

FLFL

93

9393

BS

BS .062” ID barb

BSBS

Fits .062” Tygon®

93

93 .093” ID barb

9393

Fits .093” Tygon®

DBS

DBS Dual .062” ID barb

DBSDBS

Fits .062” Tygon®

Tube Set Connectors

10

Page 12

1 lb

Accessories

Instech also offers a range of accessories and replacement parts for

its peristaltic pumps. Call for current prices.

Part Number

RMC

KSK

720BATT

9 VDC/120

9 VDC/220

Description

Rod mounting clamp. Attaches P720 and P820 pumps and controllers to

standard rod mounting systems (including Instech’s UNIMOUNT).

Kapton strip replacement kit. 20 protective strips, 5 retaining clips and 1

insta l lation tool.

9V lithium battery for P720 pump.

120 VAC power adapter for P720 pump.

220 VAC power adapter for P720 pump.

Specifications

Rotor type

Rotor speed

Power supply voltage

RPM supply sensitivity

Typical operating current – single tube

Typical operating current – dual tube

Typical idle current

Monitor voltage (INT)

Nominal external voltage (EXT)

Recommended battery

Alternative battery

Battery voltage triggering amber Lo Bat LED

Size ( WxHxD)

Weight

Typical repeatability

Linearity vs. dial setting

Accuracy

Maximum pressure – .015”-.020” ID tube

Maximum pressure – .031”-.093” ID tube

Printed December 1997

720manln.doc

3 roller

.4 – 14 RPM

+8 to 12 V DC

–.08 %/Volt

25 mA

30 mA

14 mA

±

0 to

1.46 VDC

±

±

1.5 to

10 VDC

Lithium U9VL

Standard 9V alkaline

~7.5 V

2.5”x2.25”x4”

±

3%

±

3%

±

5%

20 PSI

5 PSI

11

Page 13

Instech Laboratories, Inc.

Instech has been a leading provider of

instruments for medical and biological

research for over 25 years. Our reputation

for quality and reliability is recognized by

research facilities, universities and a wide

range of companies throughout the world.

Our design and manufacturing

capabil i ties include:

• Small fluid pumps

• Continuous animal infusion systems

• Dissolved oxygen measurement systems

• Cuvette stirring systems

• Motor controllers

• New product design and development

For more information on the complete line

of Instech systems and custom products, call

us at 800-443-4227 or visit our website at

www.instechlabs.com.

The equipment behind the science.

Instech Laboratories, Inc.

5209 Militia Hill Road

Plymouth Meeting, PA 19462-1216

800-443-4227 • 610-941-0132

FAX 610-941-0134

EMAIL support@instechlabs.com

WEB www.instechlabs.com

Loading...

Loading...