Bionics IFM-500 User manual

Nemko ref. no.:NK-2E-M-055

DESCRIPTION OF EQUIPMENT UNDER TEST:

This equipment is a fetal monitor, Fetal heart rate(FHR), fetal movement(FM), and uterine

activity(UC) extracted automatically by using Doppler Shift Frequency are displayed and

recorded for monitoring up to fetal status.

For description of operating, please refer to User’s Manual supplied by Man ufacturer.

NAME AND ADDRESS OF PRODUCTION-SITES (FACTORIES):

See front page.

INFORMATION ABOUT THE STANDARDS / DOCUMENTS CONSIDERED:

EN 60601-1 (1990) + A1 (1993) + A2 (1995) +A13 (1996) + Corrigenda (July 1994).

EMC standard : EN 60601-1-2 (2001)

TESTED ACCORDING TO NATIONAL REQUIREMENTS FOR THE

FOLLOWING COUNTRIES:

LIST OF APPENDIXES / ENCLOSURES TO THE TEST REPORT:

This Part 1 TRF contains 69 pages, numbered from 1 to 69

This TRF contains attachments. Attachment #1: Photos. Page 1 to 5

Page 2 of 69

Nemko ref. no.:NK-2E-M-055

SUMMARY OF TESTING

Evaluation of Results

If not explicitly stated otherwise in the standard, the test is passed if the measurement value is equal to or below (above) the

limit line, regardless of the uncertainty of the measurement. If the measurement value is above (below) the limit line, the test

is not passed - ref. IECEE-CTL Guide 001 and Nemko WM L220.

The instrumentation accuracy is within limits agreed (ref. IECEE-CTL/251A and Nemko procedure WM L226) :

The AC/DC adapter is certified by TÜV Rheinland according to EN60601-1.

(refer to “56. list of Critical Component Parts”)

It has double insulation between primary and secondary.

Maximum normal load : Refer to sub-clause 7 (power input)

This equipment was tested with these probes:

• DOP I

• DOP II

• UC Probe

• Event Mark jack

Clause Remarks Information/Comments

Cord set not checked The equipment shall be provided with a cord set

complying with the national regulation of the

countries intended for sale

Page 3 of 69

Nemko ref. no.:NK-2E-M-055

LIST OF ATTACHMENTS PROVIDING FURTHER INFORMATION

ON THE EQUIPMENT TESTED AND THE TEST METHODS

The following attachments are added to this TRF or kept in file at the Testing Station

mentioned at the cover page:

Statements on calibrations and measurement uncertainties (where relevant) of the

measurement and test equipment as identified throughout this TRF:

Calibration

Measurement

uncertainties

Document title/identification:

List of worksheets which describe measurement procedures or test methods where

practicable:

Document title/identification:

List of equipment or units tested and/or accompanying units and accessories (in case not

all individual units can be mentioned on the front-page):

All instruments used in the tests given in this report are calibrated and

traceable to international standards.

Further information about tractability will be given on request.

Measurements uncertainties are calculated for all instruments and

instruments set-ups given in this report. Calculations are based on the

principles given in the standard EA-4/02 (Dec. 1999), IECEECTL/153/NF (2002-04-19), Nemko WM L226 and actual internal

Nemko procedures. Further information about measurements

uncertainties will be given on request

Kept in file at Nemko; P31000

Kept in file at Nemko; P31000

ATT. No.: Not attached

ATT. No.: Not attached

Document title/identification:

Technical design documents of components having basic, supplementary of reinforced

insulation (e.g. transformer specification mentioning the insulation class of the insulation

materials applied - A to H):

Document title/identification:

Description of safety systems (specifying for example safety circuits, redunda nt circuits,

double circuits, hardware/software safety measures, temperature controls, etc.):

Document title/identification:

See summary of testing in this report.

Kept in file at Nemko

Kept in file at Nemko

ATT. No.: Not attached

ATT. No.: Not attached

ATT. No.: Not attached

Page 4 of 69

Nemko ref. no.:NK-2E-M-055

3 GENERAL REQUIREMENTS

3.1 EQUIPMENT when transported,

stored, installed, operated in NORMAL

USE and maintained according to the

instructions of the manufacturer, causes

no SAFETY HAZARD which could

reasonably be fore- seen and which is

not connected with its intended

application in NORMAL CONDITION

and in S.F.C.

3.4 An alternative means of construction is

used to that detailed in this standard

and it can be demonstrated that an

equivalent degree of safety is obtained.

The equipment causes no hazards when used according

the manufacturers instructions.

No alternative construction. —

5 CLASSIFICATION

5.1 Type of protection against electric

shock.

5.2 Degree of protection against electric

shock.

5.3 Classification of the equipment against

ingress of liquids.

Class I equipment

Type BF applied part

IPX0

—

5.5 Degree of safety of application in the

presence of a FLAMMABLE

ANAESTHETIC MIXTURE WITH

AIR or WITH OXYGEN OR

NITROUS OXIDE

5.6 Mode of operation.

The equipment is not an AP or APG category

equipment.

Continuous operation.

Page 5 of 69

E

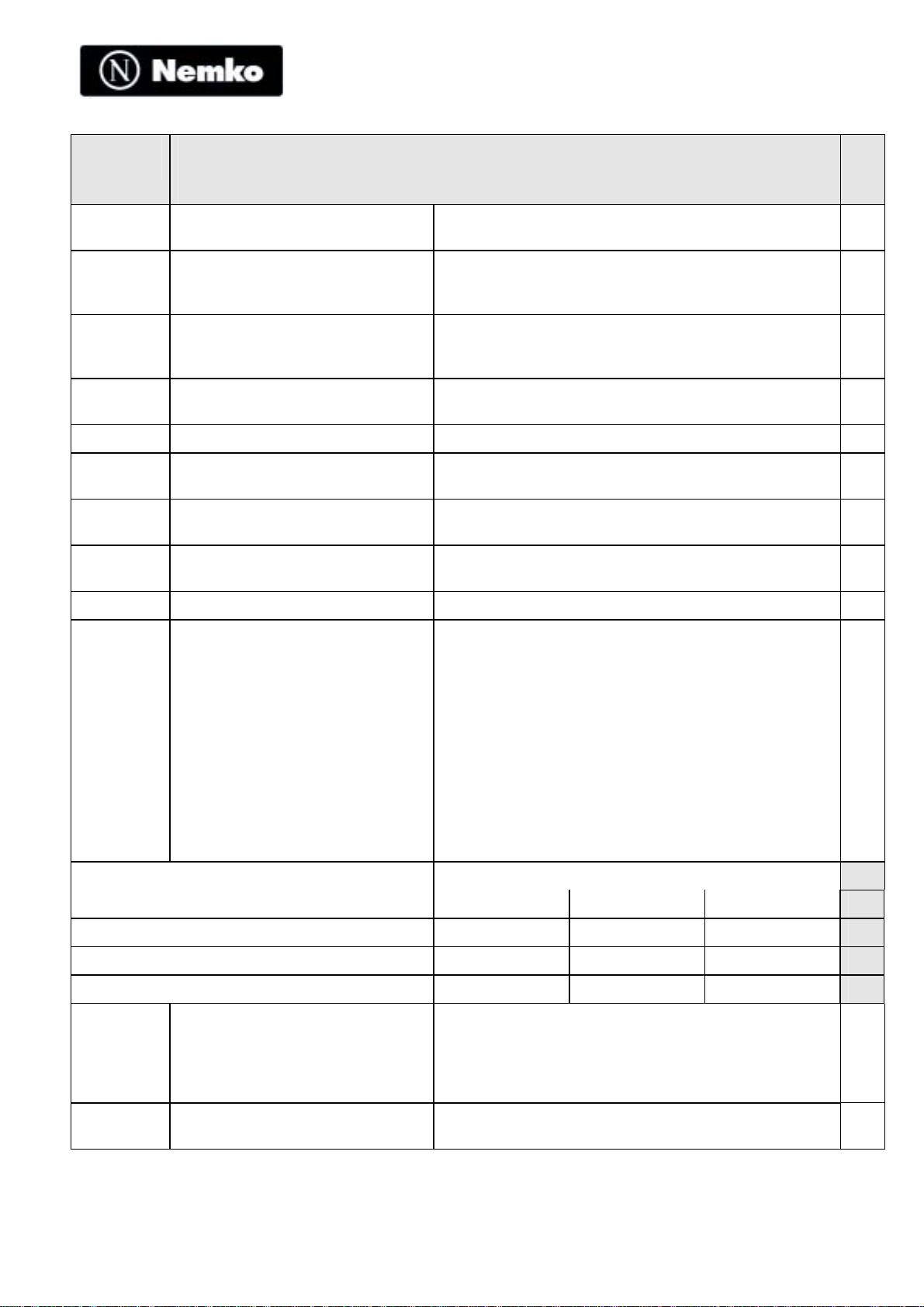

Nemko ref. no.:NK-2E-M-055

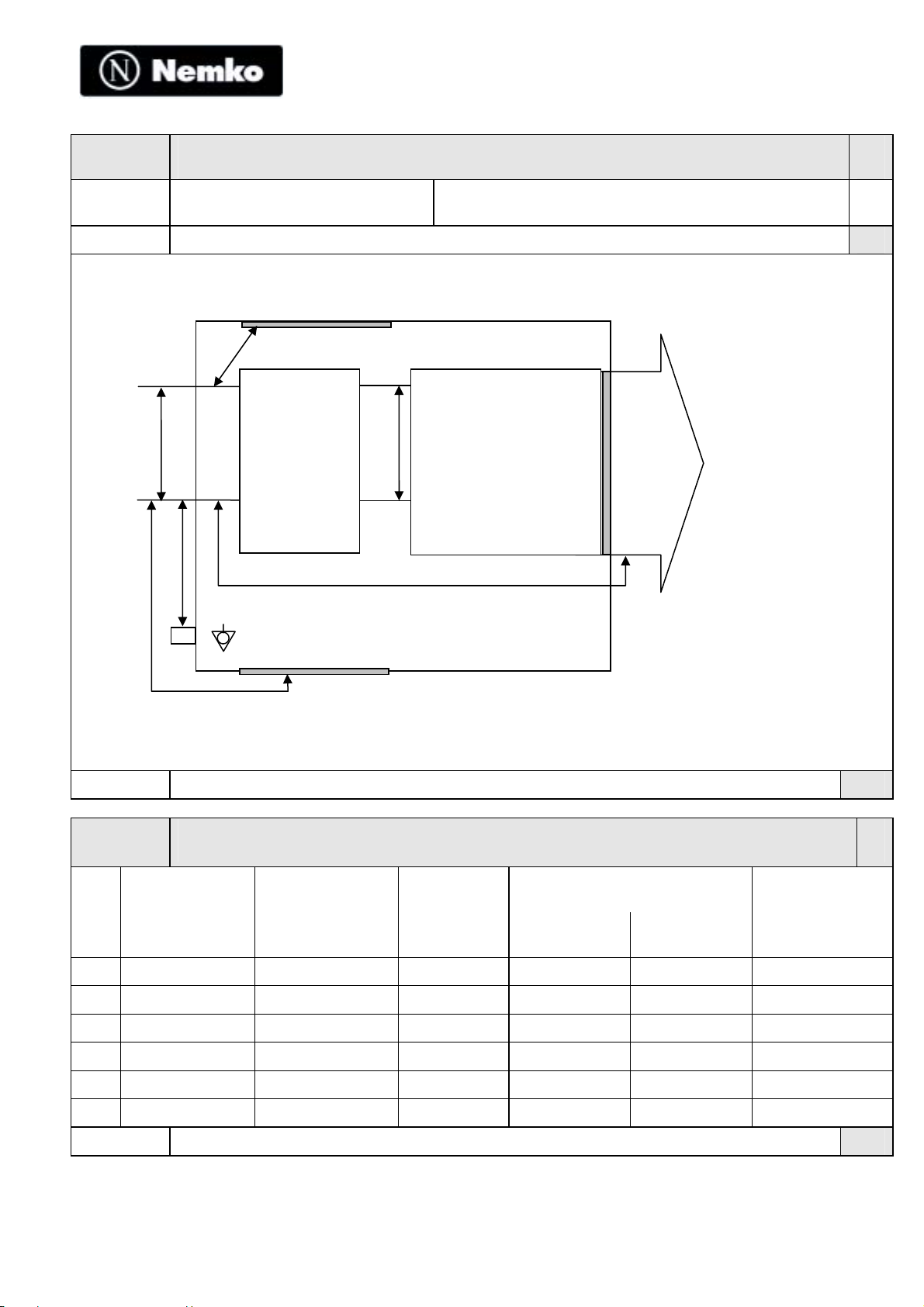

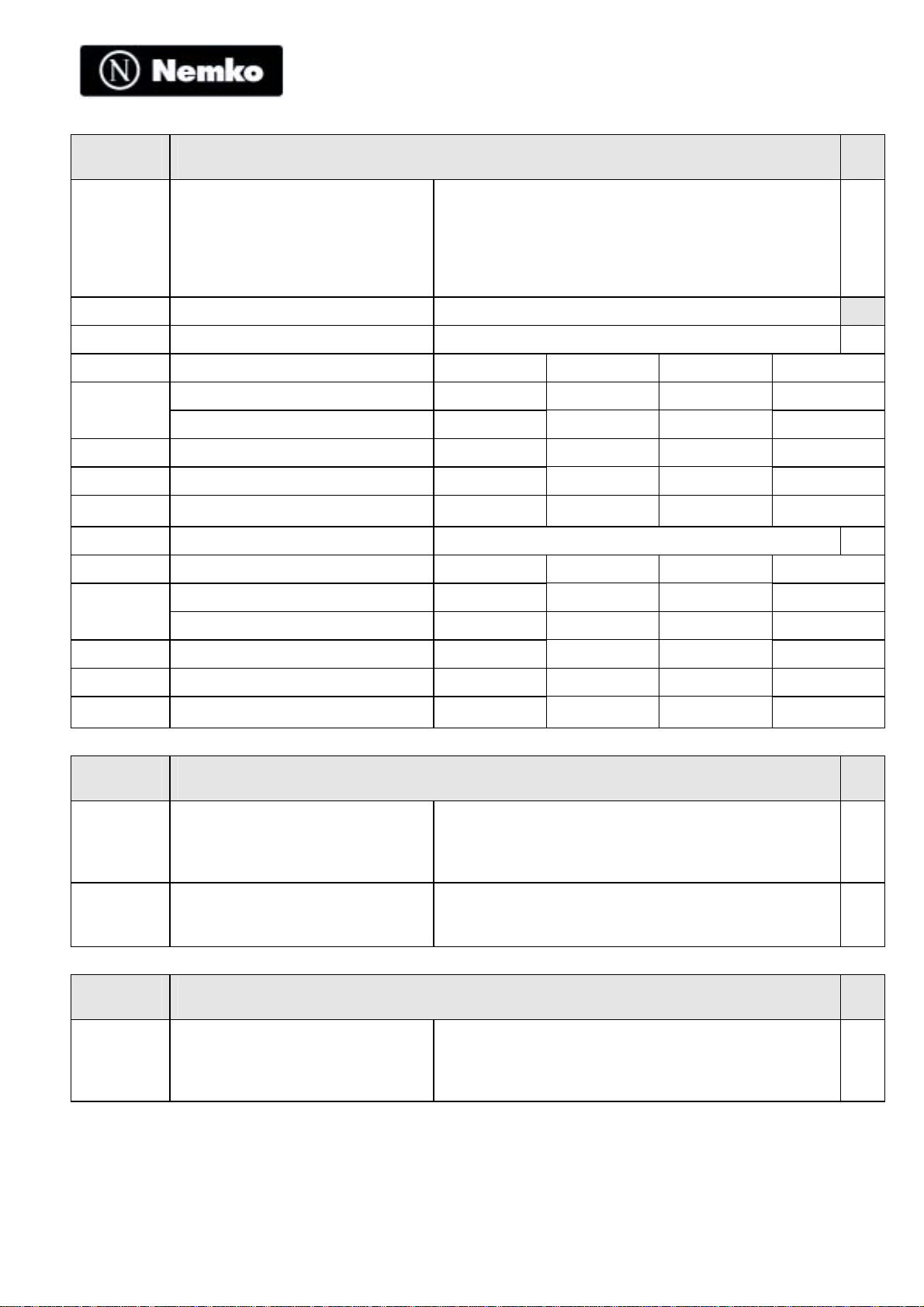

INSULATION DIAGRAM

Protection against electric shock -

Block diagram of system

Drawing

Enclosure connected to PE

E

L

N

G

A

F

TUV Certified

by EN60601-1

AC/DC

Adapter

(100-240Vac,

50/60Hz, 1.2A,

Output:

+12Vdc, 3.5A)

D

B

Refer to table on next page. P

Main board

DOP1

DOP2

UC Probe

Event Mark jack

PLASTIC ENCLOSUR

Comments

TABLE TO INSULATION DIAGRAM ON PREVIOUS PAGE

Area Distance

(Test Refer to

20.1 + 20.2)

Insulation type

Basic/Supplement./

Double/Reinforced

Insulation

A A-f Basic 250 V a.c. 1.6 mm 3.0 mm Not applicable

B A-f Basic 12 V d.c. 1.6 mm 3.0 mm Not applicable

D B-a Double/Reinforce 250 V a.c 5.0 mm 8.0 mm 4 000 V a.c.

E A-a1 Basic 250 V a.c. 2.5 mm 4.0 mm 1 500 V a.c.

F A-a1 Basic 250 V a.c. 2.5 mm 4.0 mm 1 500 V a.c.

G A-a2 Double/Reinforce. 250 V a.c. 5.0 mm 8.0 mm 4 000 V a.c.

Comments

Maximum

circuit

Required distances (mm) Dielectric strength

test voltage

voltage Clearance Creepage Refer to 20.3

Page 6 of 69

Nemko ref. no.:NK-2E-M-055

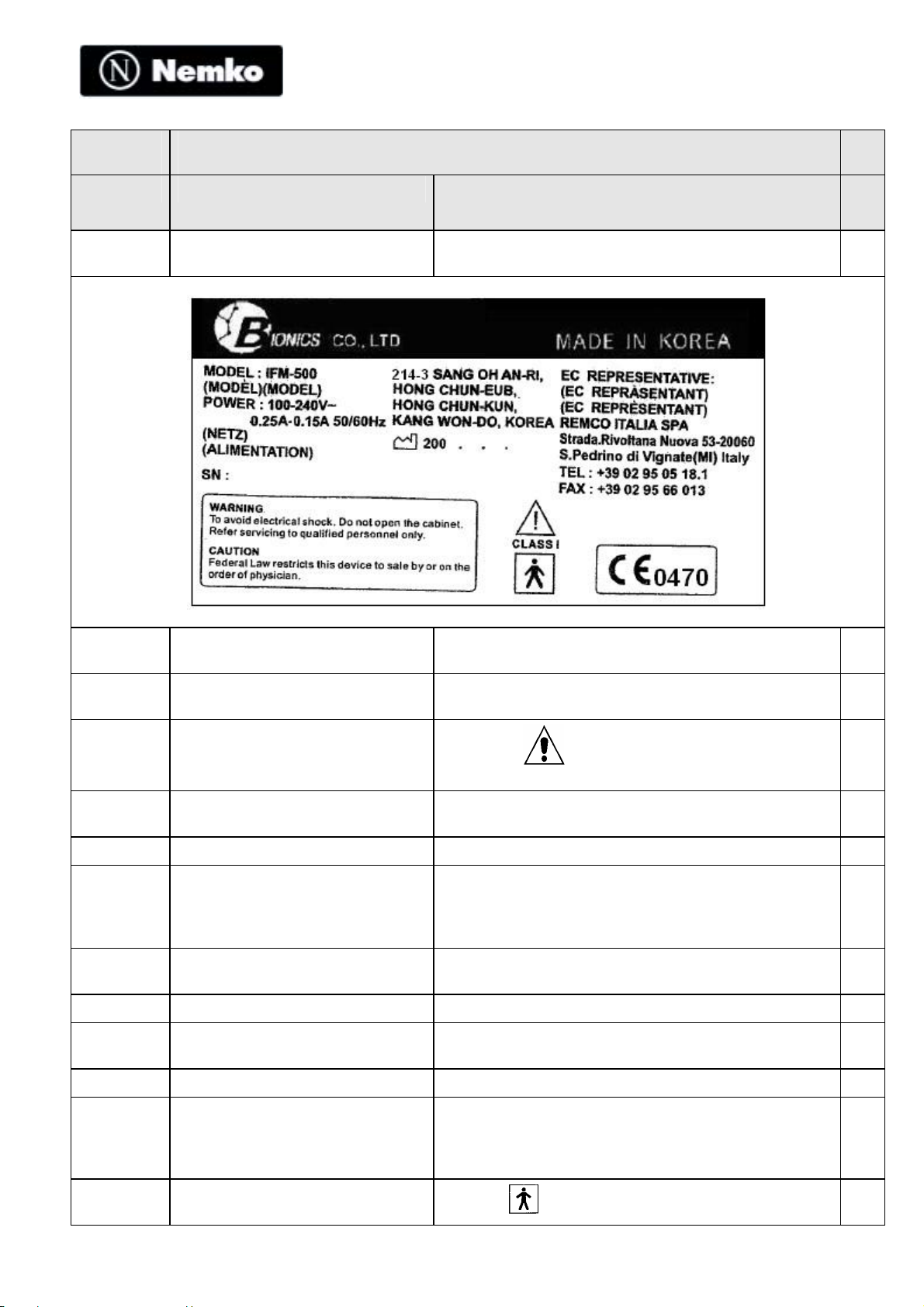

6 IDENTIFICATION, MARKING AND DOCUMENTS

6.1

Marking on the outside Example of marking label:

6.1 a Markings of Mains operated

EQUIPMENT

6.1 b Markings of Internally Powered

EQUIPMENT

See below P

Not applicable. No Internally Powered EQUIPMENT N

6.1 c Markings of EQUIPMENT supplied

from a specified power supply

6.1 d Minimum requirements if limited space

for marking

6.1 e Name and/or trademark of the

manufacturer or supplier

6.1 f Model or type reference

6.1 g Rated supply voltage(s) or voltage

range(s)

Number of phases

Type of current

6.1 h Rated frequency or rated frequency

range(s) in Hz

6.1 j Rated power input (VA, W or A)

6.1 k Power output of auxiliary mains socket

outlets

6.1 l Class II symbol

Symbol for degree of protection with

respect to harmful ingress of water

according to EN 60529 (IPX0 not

required to be marked)

N

P

Symbol 14

from DI is included in accompanying

documents.

Bionics P

IFM-500 P

100-240 V

P

Single phase

∼

50/60 Hz. P

0.25-0.15A P

No socket outlet is provided N

Not applicable. N

Ordinary equipment. IPX 0. P

Symbol for protection against electric

shock:

Type BF

. Symbol

P

Page 7 of 69

6.1 m Mode of operation (if no marki n g,

suitable for continuous operation)

Nemko ref. no.:NK-2E-M-055

Continuous operation. N

6.1 n Types and rating of external accessible

fuses

6.1 p Rated output voltage and current or

power, output frequency (where

applicable)

6.1 q Symbol for physiological effect(s):

6.1 r Anaesthetic-proof symbol:

6.1 s High voltage symbol:

6.1 t Special cooling requirements

6.1 u) Limited mechanical stability

6.1 v Protective packing requirement(s).

Marking(s) for unpacking safety

hazard(s)

6.1 y Earth terminals:

6.1 z Removable protective means

Durability of markings

“T1AL 250V” marked P

No auxiliary mains socket outlets. N

Not applicable. No need for marking. N

Not of category AP or APG. N

Not applicable. No parts with a voltage over 1 000 V a.c.

N

or over 1 500 V d.c. or 1 500 V peak value.

No special cooling requirements N

No limited mechanical stability N

No special measures during transport or storage N

Symbol 9 of table DI, POTENTIAL EQUALIZATION

TERMINAL

is used.

P

No removable protective means N

Tested with a cloth of rack soaked with, in turn, water,

P

methylated spirit and isopropyl alcohol.

6.2

Marking on the inside

6.2 a Marking clearly legible

Nominal supply voltage of

permanently installed equipment

marked inside or outside of equipment

6.2 b Maximum power loading of heating

elements or lamp holders for heating

lamps clearly and indelibly marked

near or in the heater

Heating elements or lamp holders for

heating lamps not intended to be

changed by operator and which can be

changed only with the use of a tool,

have at least an identifying marking

referring to information stated in the

accompanying documents

6.2 c High voltage parts:

6.2 d Type of battery and mode of insertion

(if applicable) marked (see Sub-clause

56.7 b)

The sample label withstood the test.

Not applicable. No permanently installed equipment

No heating elements or holders for heating lamps

Not applicable.

P

N

N

N

No high voltage part N

Not applicable.

N

Batteries not intended be changed by

operator and which can be changed

only with use of tool have at least

marking referring to information in

accompanying documents

6.2 e Fuse type and rating or reference stated

Not applicable.

N

N

Page 8 of 69

6.2 f

Protective earth terminal marked

6.2 g Functional earth terminal marked

6.2 h Terminals for supply neutral conductor

in permanently installed equipment

marked (N)

Nemko ref. no.:NK-2E-M-055

Appliance inlet is used in an according to IEC 60320

No Functional earth terminal.

No permanently installed equipment.

N

N

N

6.2 j Markings required in Sub-clause 6.2 f,

h, k and l

6.2 k The supply connections are clearly

marked adjacent to the terminals or in

accompanying documents (for small

equipment)

6.2 l Statement for suitable wiring materials

(at temperatures over 75°C) locates at

or near the point of the supply

connections and is clearly discernible

after connection

6.2 n Capacitors and/or circuit parts are

marked as required in Sub-clause 15 c

6.3

Marking of controls and instruments

6.3 a Mains switch clearly identified. ”On”

and “off” positions marked or

otherwise indicated

6.3 b Adequate indications of different

positions of controls and other switches

6.3 c Adequate indication of the direction of

setting devices if change of setting of a

control could cause a safety hazard

Not applicable. No temp. over 75°C.

No such a capacitor

P

N

P

N

“I/O” marked close to the switch on front side P

P

P

6.3 f Functions of operator controls and

indicators identified

6.3 g Numeric indications of parameters are

in SI units according to ISO 1000.

Units outside the International System

as specified

All control buttons marked. All functions and marking

described in user manual.

All control buttons marked. All functions and marking

described in user manual.

P

P

Page 9 of 69

Nemko ref. no.:NK-2E-M-055

6.4

Symbols

6.4 a Marking symbols compliance with

appendix D, where applicable

6.4 b Symbols for controls and performance

conform to IEC 60 878, where

applicable

Durability of marking symbols

6.5

Colours of insulation of conductors

6.5 a Protective earth conductor has

green/yellow insulation

6.5 b All insulations of internal protective

earth conductors are green/yellow, at

least at the terminations of the

conductors

6.5 c Only protective earth-, functional

earth-, potential equalisation and inside

earthing conductors (cf. 6.5 b) are

green/yellow

6.5 d Colour of neutral conductor: light blue

according to IEC 60 227 or 245

Complied with appendix D, where applicable P

P

Tested in Clause 6.1. P

P

P

Protective earth conductor P

Light Blue P

6.5 e Colours of phase conductors in power

supply cord according to IEC 60 227 or

245

6.5 f Additional protective earthing in multiconductor cords are marked

green/yellow at the ends of the

additional conductors

6.6

Identification of medical gas

cylinders and connections

6.6 a Identification of content in accordance

with ISO/R32

6.6 b Identification of connection point that

errors are avoided when a replacement

is made

Brown, VDE Certified P

No Additional protective earthing N

Not applicable. Not use of medical gas cylinders N

Not applicable. N

Page 10 of 69

Nemko ref. no.:NK-2E-M-055

6.7

6.7 a Colour red only used for warning of

Indicator lights and push-buttons

Not used of colour red.

danger or/and need for urgent action.

Dot-matrix/alphanumeric displays not

The unit used dot-matrix / alphanumeric display

considered to be indicator lights

6.7 b Colours of unilluminated push-but t o ns.

No emergency switch N

Colour red only used in case of

emergency

Location Meaning of indicator lights Illuminated push-button (see IEC 60

73)

Front of enclosure

Operating / LED — Green

(For “Volume”)

Front of enclosure

Operating / LED — Green

(For “Record”)

Front of enclosure

Operating / LED Green

(For “Alarm”)

6.8

6.8.1 Equipment is accompanied at least by

- instructions for use

Accompanying documents

User Manual P

P

Colour

- technical description

- an address to which the user can refer

All applicable classifications specified

in Clause 5 are included in instructions

for use and technical description

markings in Sub-clause 6.1 included in

accompanying documents if not

permanently affixed to equipment

Warning statements and explanations

of warning symbols are provided in

accompanying documents

Language of accompanying documents

P

In both the above mentioned booklets P

In both the above mentioned booklets P

P

Properly described in user manual P

English. Will be in the language required for the market

P

where the equipment is intended to be sold.

Page 11 of 69

6.8.2 Instructions for use

Nemko ref. no.:NK-2E-M-055

6.8.2 a General information

Necessary information to operate the

Included in user manual P

equipment

Explanation of the function of controls,

Included in user manual P

displays and signals

Sequence of operation

Connection and disconnection of

Included in user manual P

Included in user manual P

detachable parts and accessories

Replacement of material which is

Included in user manual P

consumed during operation

Indications of recognised accessories,

Included in user manual P

detachable parts and materials, if the

use of other parts or materials can

degrade minimum safety

Cleaning, preventive inspection and

Included in user manual P

maintenance to be performed including

the frequency of such maintenance

Information about safe performance of

Included in user manual P

routine maintenance

Information about preventive

Included in user manual P

inspection and maintenance to be

performed by other persons

Meanings of figures, symbols, warning

statements and abbreviations on

equipment explained in the instructions

for use

Instruction for use states the function

and intended application of equipment

Instructions for use provide user with

information regarding potential

electromagnetic or interference and

advice how to avoid such interference

6.8.2 c Signal output and signal input parts

Signal output or signal input parts

intended only for connection to

specified equipment stated in

instruction for use

6.8.2 d Cleaning, disinfection and sterilisation

of parts in contact with the patient

Details about cleaning or disinfection

or sterilisation methods that may be

used for equipment parts which come

into contact with the patient during

normal use given in instruction for use

Included in user manual P

Included in user manual P

Included in user manual N

No SIP/SOP parts N

Properly described. P

Page 12 of 69

6.8.2 e Mains operated equipment with

additional power source

Nemko ref. no.:NK-2E-M-055

A warning statement referring to the

necessity for periodical checking or

replacement of an additional power

source

If Class I equipment a statement saying

that where the integrity of the external

protective conductor in the installation

or its arrangement is in doubt,

equipment shall be operated from its

internal electrical power source

6.8.2 f Removal of primary batteries (i.e. not

rechargeable batteries):

Instruction for use contains a warning

to remove batteries if equipment is not

likely to be used for some time ,unless

no risk of safety hazard

6.8.2 g Rechargeable batteries:

Instructions to ensure safe use and

adequate maintenance

6.8.2 h Equipment with a specified power

supply or battery charger:

Instructions for use identify power

supplies or battery chargers necessary

to ensure compliance with the

requirements of IEC 601-1

This equipment is Alternatively using an internal

P

electrical power source and main supply

Included in user manual P

No primary battery N

Not rechargeable batteries N

Not applicable. N

6.8.2 j Instructions for use identify risks

associated with disposal of waste,

residues etc. and of

equipment/accessories at end of their

lives. Further it provides advice on

minimising these risks

6.8.3 Technical description

6.8.3 a General

Technical description provides all data

essential for safe operation including

data in Sub-clause 6.1 and all

characteristics of the equipment

A statement whether particular

measures or particular conditions are to

be observed for installing equipment

and bringing equipment into use

6.8.3 b Replacement of fuses and other parts :

Required type and rating of fuses

utilised in the mains supply circuit

external to permanently installed

equipment

Instructions for replacement of

interchangeable and/or detachable parts

which are subject to deterioration

during normal use

The item is properly described. Reference to the user

P

Manual.

The Technical and Service Manual is well written and

P

contains all necessary information required.

P

No permanently installed equipment N

Properly described. P

Page 13 of 69

6.8.3 c Circuit diagrams, component part lists,

etc.:

Nemko ref. no.:NK-2E-M-055

The technical description contains a

statement that the supplier will make

available on request circuit diagrams,

component part lists, descriptions,

calibration instructions, etc. in order to

assist user in case of necessary

reparations

6.8.3 d Environmental conditions for transport

and storage:

The technical description contains a

specification of the permissible

environmental conditions for transport

and storage

The above said specification also

repeated on the outside of the

packaging

Included in user manual P

Included in user manual

P

P

Page 14 of 69

Nemko ref. no.:NK-2E-M-055

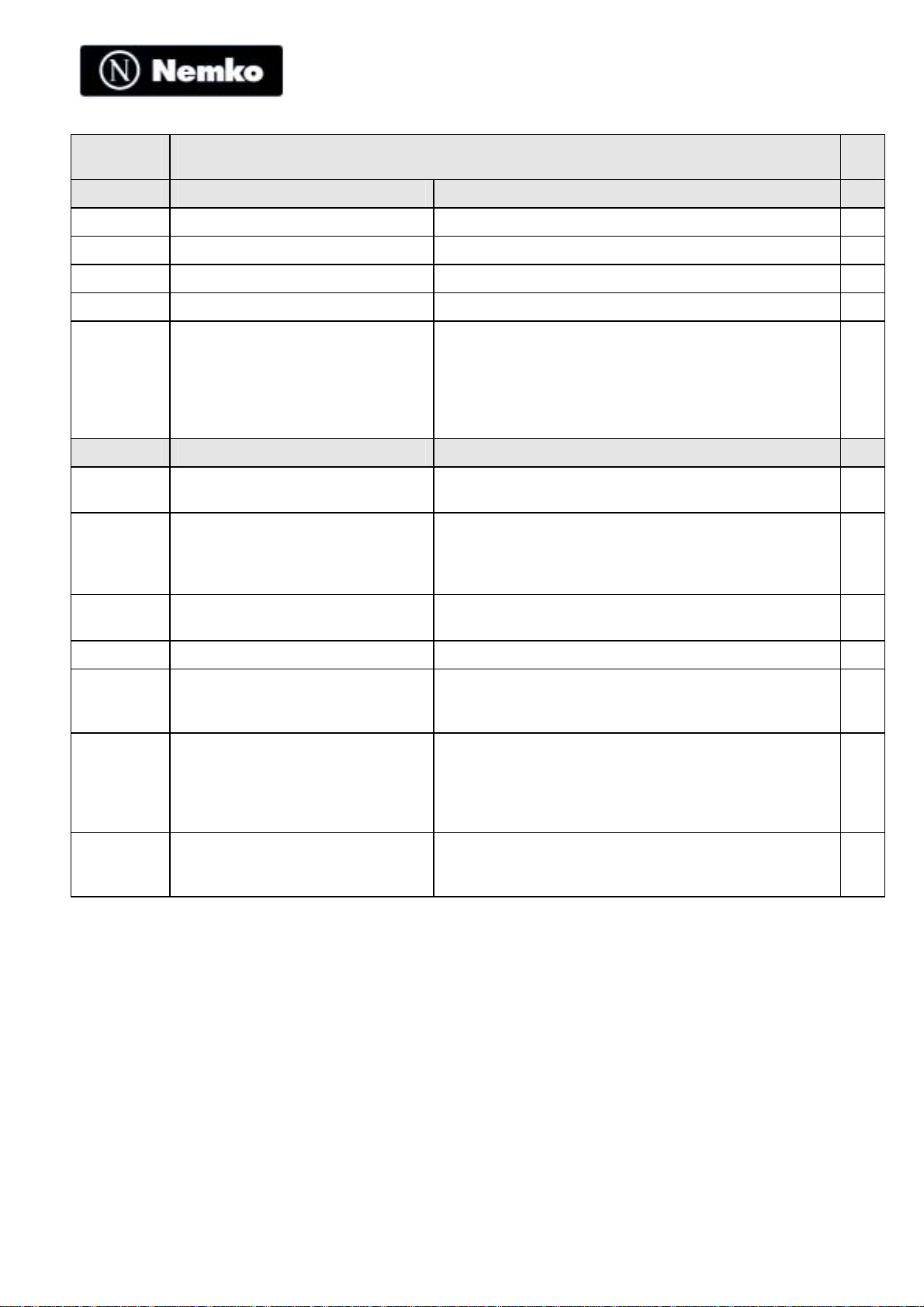

7 POWER INPUT(Continued)

7.1 Steady state current or power input

does not exceed the marked rating by

more than specified

Maximum normal load is followings:

Continuous operation

1. Applied parts

(DOPI, DOPII, UC and Event Mark jack)

2. Max. Volume

3. Printer

Equipment:

50 Hz supply

No. 64

Power input: 100-240VAC, 0.25-0.15A P

Power input Function U

Input current Normal operation (A)

Standby (A)

Input power Normal operation (W)

Input power Standby operation (W)

Power factor

60 Hz supply

cos

ϕ

Power input: 100-240VAC, 0.25-015A P

Power input Function U

Input current Normal operation (A)

Standby (A)

P

N

lower

= 90V

UN = 100V UN = 240V

U

N

upper

= 264V

0.24 0.23 0.14 0.13

— — — —

12.0 12.0 13.0 13.0

23.0 23.0 33.0 34.0

0.52 0.52 0.39 0.38

N

lower

= 90V

UN = 100V UN = 240V

U

=264V

N

upper

0.22 0.21 0.13 0.13

— — — —

Input power Normal operation (W)

Input power Standby operation (W)

Power factor

cos

ϕ

12.0 12.0 13.0 13.0

20.2 21.0 32.0 32.0

0.57 0.55 0.40 0.39

10 ENVIRONMENTAL CONDITIONS

10.1 Equipment capable, while packed for

transport and storage, of being exposed

to environmental conditions as stated

by manufacturer (see 6.8.3 d)

10.2 Operation of equipment according to

specified environment and power

supply

Considered OK. P

Considered OK. P

13 GENERAL

Equipment so designed that risk of

electric shock obviated as far as

practicable (requirements as given in

section three)

Considered OK. P

Page 15 of 69

Nemko ref. no.:NK-2E-M-055

14 REQUIREMENTS RELATED TO CLASSIFICATION

14.1

Class I equipment

14.1 a Parts with Double Insulation

Parts with Reinforced Insulation

Parts with SELV-Voltage

Parts with Protective Impedance

14.1 b If the mains part of equipment

specified for an external d.c. power

source is isolated from accessible

conductive parts by basic insulation

only, a separate protective earth

conductor is provided

14.2

Class II equipment

14.2 a Class II equipment is of one of the

following types:

14.2 b If equipment is fitted with a device for

changing over from class I to class II

protection, the following requirements

are fulfilled:

The change-over device indicates the

selected class clearly

N

CB Certified adapter used N

CB Certified adapter used N

N

Not applicable. N

Not applicable N

Not applicable. N

Not applicable. N

A tool for change-over is necessary

The equipment complies with all

requirements for the selected class at

any given time

Class II position:

The device interrupts the connection of

protective earth conductor to

equipment or changes it into functional

earth conductor (compliance with 18.2)

14.2 c Class II equipment provided with

functional earth connections (cf. Subclause 18 k and l)

Not applicable. N

Not applicable. N

Not applicable. N

Not applicable. N

Page 16 of 69

14.4

Nemko ref. no.:NK-2E-M-055

Class I and II equipment

14.4 a Equipment is provided with an

P

additional protection according to the

requirements of Class I or Class II

equipment

14.4 b No safety hazard develop, when a

P

connection with the wrong polarity is

made in equipment specified for power

supply from an external d.c. power

source (e.g. for use in ambulances)

14.5

14.5 b Equipment also having means of

Internally powered equipment

Not applicable. No external d.c. power source N

connection to supply mains complies

also with requirements for Class I or II

while so connected

14.6

14.6 c Applied parts suitable for direct cardiac

Types B, BF and CF applied parts

Type BF N

application are of type CF

15 LIMITATION OF VOLTAGE AND/OR ENERGY

15 b Equipment with mains plug so

designed that the voltage 1 sec. after

disconnection does not exceed 60 V

Certified AC/DC Adaptor N

Interference suppression capacitors

Capacitance between each line and

N

N

protective earth. Measured value

15 c Accessible live parts of capacitors or

Not applicable. N

related circuits having a residual

voltage above 60 V does not have a

residual energy above 2 mJ (see 15 c

below)

A non-automatic discharging device is

Not applicable N

included and marked

Page 17 of 69

Nemko ref. no.:NK-2E-M-055

16 ENCLOSURES AND PROTECTIVE COVERS

16 a Protection against contact with live

parts.

- and with parts which can become live

in single fault conditions

Instruction for use instructs operator

A tool is needed to open enclosure. No accessible live

parts.

A tool is needed to open enclosure. No accessible live

parts in single fault condition.

Not applicable. N

not to touch such parts and the patient

simultaneously

Equipment:

Standard test finger : No. 97

Straight test finger : No. 105

Pull force measuring device : No. 52

Test pin : No. 98

Test hook : No. 95

Weight : approximately 4.2kg

Location of opening Test result (finger, pin, hook)

Top-side openings Pass

Rear-side openings Pass

Bottom-side openings Pass

16 b Check of openings in top covers with

the vertical suspended test rod

16 c Conductive parts of actuating

No holes in enclosure of the unit.

No handles, knobs, levers for removal N

mechanism of electrical controls after

the removal of handles, knobs, levers

etc. have either resistance to the

protective earth terminal max. 0.2

ohms or the separation from live parts

complies with 17 g

P

P

P

16 d Protection of contact with internal parts

of the equipment with a circuit voltage

exceeding 25 V a.c. or 60 V d.c. which

cannot be disconnected from the supply

by external mains switch or plug

device

16 e Protective enclosures are removable

only with the aid of tool or an

automatic device makes these parts not

live, when the enclosure is opened or

removed

16 f Live parts are inaccessible to the test

rod through openings for adjustment of

pre-set controls

No parts exceeding 25V ac, or 60Vdc N

Screw driver is required to remove enclosures P

N

Page 18 of 69

Nemko ref. no.:NK-2E-M-055

17 SEPARATION

17 a Separation method of the applied part

from live parts so that allowable

leakage currents are not exceeded

17 a 1 Basic insulation - applied part earthed

17 a 2 By protectively earthed conductive part

(e.g. screen)

17 a 3 By separate earthed intermediate circuit

17 a 4 By double or reinforced insulation

17 a 5 By protective impedances limiting

current to applied part

17 a 6 Other method, e.g. specified in

particular standard

17 c There is no conductive connection

between applied parts and accessible

conductive parts, which are not

protectively earthed

17 d Supplementary insulation between

hand-held flexible shafts and motor

shafts (Class I equipment)

Not applicable. N

Not applicable. N

Not applicable. N

DOP I, DOP II, UC Probe and Event Mark jack

P

See table 19 P

Not applicable. N

All accessible conductive parts are protectively earthed. P

No such a part N

Adequate isolation of accessible metal

N

parts from motor shaft

Rated motor voltage

Test voltage

Air clearances/creepage distances

N

N

N

(mm)/(mm)

17 g Separation method of accessible parts

other than applied parts from live parts

so that allowable leakage currents are

not exceeded

17 g 1 Basic insulation - accessible part

Protectively earthed and the applied part has such a low

internal impedance to earth that leakage currents do not

exceed the allowable values in normal condition and

single fault condition.

See above 1) and below 4) N

earthed

17 g 2 By protectively earthed conductive part

See above 1) and below 4) N

(e.g. screen)

17 g 3 By separate earthed intermediate circuit

17 g 4 By double or reinforced insulation

17 g 5 By protective impedances limiting

Unearthed part to mains parts(see insulation diagram) P

See above 1) and 4) P

See above 1) and 4) P

current to accessible part

Leakage currents measurements, when

required

Protectively earthed and the applied part has such a low

internal impedance to earth that leakage currents do not

exceed the allowable values in normal condition and

single fault condition.

P

P

Page 19 of 69

17 h Adequate arrangements used to isolate

defibrillation-proof applied parts from

other parts

Nemko ref. no.:NK-2E-M-055

No defibrillation-proof applied parts N

Impulse voltage tests

Peak voltage between Y1 and Y2 does

not exceed 1 V

After recovery time equipment

continues to perform its intended

function

N

N

N

Page 20 of 69

Nemko ref. no.:NK-2E-M-055

18 PROTECTIVE EARTHING, FUNCTIONAL EARTHING AND

POTENTIAL EQUALIZATION

18 a Sufficiently low impedance to the

protective earth terminal(18 f and 18 g)

18 b Suitable connection between protective

earth terminal and protective conductor

in the installation (18 f)

18 e Means for connection of potentially

equalisation conductor complies with

specified requirements

This connection complies with

following requirements:

- readily accessible

- no possibility to accidental

disconnection in normal use

- conductor is detachable without the

use of a tool

- power supply cord does not include

potential equalisation conductor

- connection is marked with symbol

See 18 f) P

P

P

P

P

P

P

P

P

18 f Impedance of protective earthing

system: Impedance between any

accessible metal part and:

1) protective earth terminal (PE)

(requirement: R max. 0.1 Ohm),

2) protective earth contact in appliance

inlet (requirement: R max.

0.1 Ohm),

3) protective earth contact in the mains

plug Test equipment: See attached

list. (requirement: R max. 0,2

Ohm),

are tabled below:

Accessible part and its location R (Ohm) measured against (numbers see above)

1 PE 2 inlet 3 plug

Gnd of Inlet - Accessible metal part

Gnd of Inlet –Probe connector

Gnd of Inlet – Potential equalization connector

18 g If the impedance of protective earth

connections other than in 18 f exceeds

0.1 Ohm, the allowable value of the

enclosure leakage current is not

exceeded in single fault condition

P

—

—

—

Not applicable N

0.02

0.021

0.018

—

—

—

18 k Functional earth terminals are not used

to provide protective earthing

No functional earth N

Page 21 of 69

18 l For Class II equipment with isolated

internal screens and with a power

supply cord:

Nemko ref. no.:NK-2E-M-055

Not applicable. Class I equipment. N

- the third conductor is used only as

functional earth of these screens and is

coloured green/yellow

- insulation of such screens and all

internal wiring connected to them is

double insulation or reinforced

insulation (see also 20.3)

- marking of functional earth terminal

is distinguished from protective earth

terminal and is explained in

accompanying documents

Test of insulation (see Clause 20)

N

N

N

N

Page 22 of 69

Nemko ref. no.:NK-2E-M-055

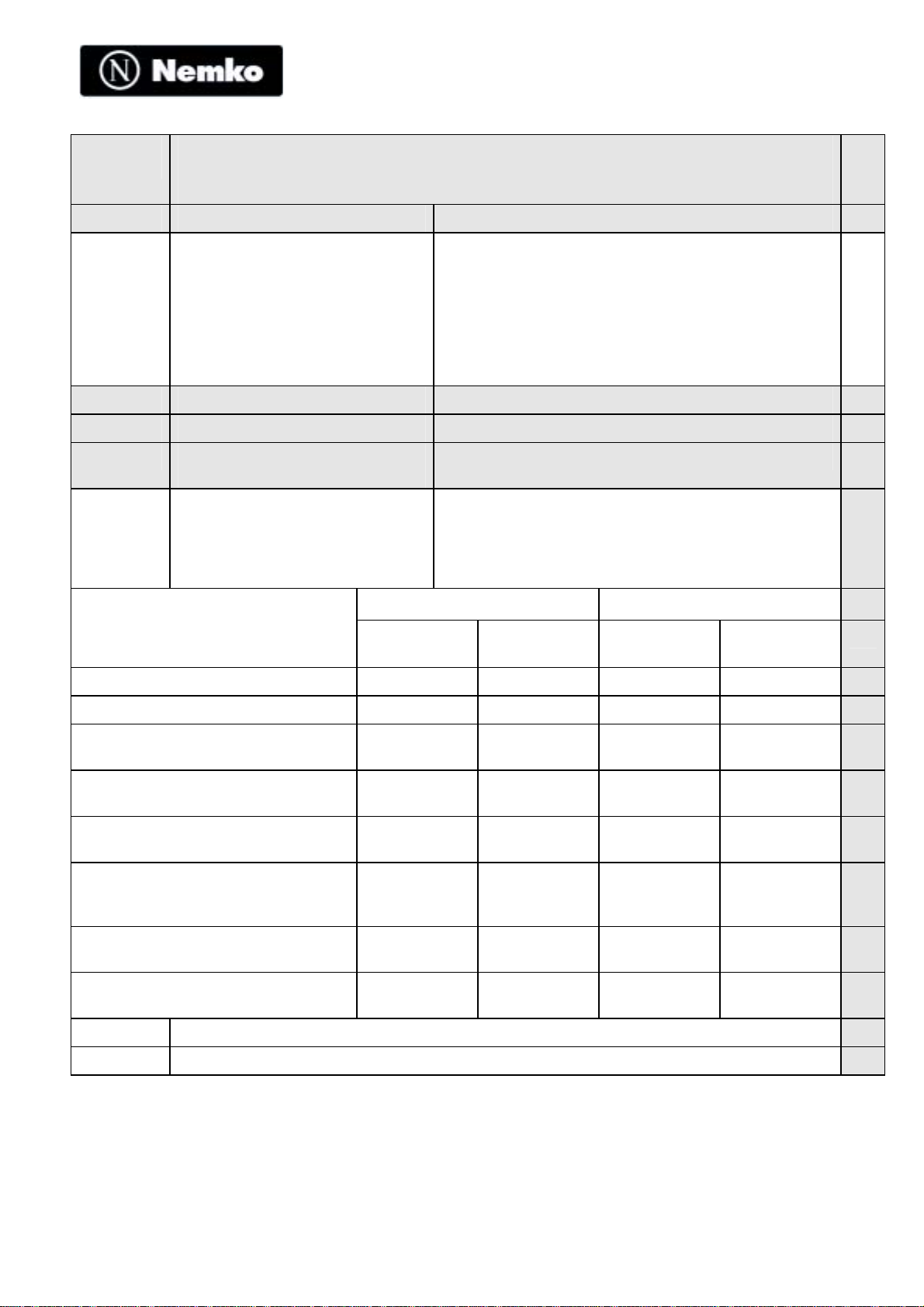

19 CONTINUOUS LEAKAGE CURRENTS AND PATIENTS

AUXILIARY CURRENTS

19.1 General requirements (tests see 19.4)

19.1 g Equipment with multiple patient

connections: Patient leakage current

and patient auxiliary current do not

exceed allowable values while one or

more patient connections are

disconnected from the patient or

disconnected from the patient and

earthed

19.2 Single fault conditions (tests see 19.4)

19.3 Allowable values (see 19.4)

19.4 Tests before humidity preconditioning

treatment

Equipment:

In normal condition In single fault condition

P

See comment below.

Mains voltage : No. 83

AC-voltage : No. 19

DC-voltage : No.19

MD : 03

Equipment for supply connection normal or reverse: 06

Type of leakage current Allowed value

(µA)

Earth leakage current 500

Enclosure leakage current 100

Patient leakage current (p.l.c.), a.c. : B, BF: 100

CF: 10

Patient leakage current (p.l.c.), d.c. : B, BF: 10

CF: 10

P.l.c. (110 % of the mains voltage on the

signal input part or signal output part)

P.l.c. (110 % of mains voltage on the

applied part)

Patient auxiliary current, a.c. : B, BF: 100

Patient auxiliary current, d.c. : B, BF: 10

Comments

—

—

CF: 10

CF: 10

The values listed are the maximum values.

Measured max.

value (µA)

246

56.3

58.7

0.01

—

—

42.1

0.01

Allowed value

(µA)

1000

500

B, BF: 500

CF: 50

B, BF: 50

CF: 50

B: 5000

BF, CF: —

B: —

BF: 5000

CF: 50

B, BF: 500

CF: 50

B, BF: 50

CF: 50

Measured max.

value (µA)

453

57.3

59.3

0.01

—

45.9

47.5

0.01

Page 23 of 69

Loading...

Loading...