User Manual

55190.R000.082010

Assurance GDS User Manual

®

Assurance GDS

_____________________________________________________________ 3

Overview________________________________________________________________________ 3

Required Materials _______________________________________________________________ 3

Designated Assurance GDS Equipment ____________________________________________ 3

Assurance GDS Rotor-Gene ___________________________________________________ 4

Components_____________________________________________________________________ 4

Operating Conditions ____________________________________________________________ 4

Dimensions ______________________________________________________________________ 4

Installation ______________________________________________________________________ 4

Rotor-Gene (front view) __________________________________________________________ 5

Rotor-Gene (rear view) ___________________________________________________________ 5

Loading the Assurance GDS Rotor-Gene ___________________________________________ 6

Unloading the Assurance GDS Rotor-Gene_________________________________________ 6

Assurance GDS Rotor-Gene Software ___________________________________________ 7

Overview________________________________________________________________________ 7

System Start up__________________________________________________________________ 7

User Levels ______________________________________________________________________ 7

Entering Sample Information _____________________________________________________ 8

Viewing Results __________________________________________________________________ 9

Interpreting Results _____________________________________________________________ 11

Virtual Mode / Analysis Only Mode _______________________________________________ 12

Reports ________________________________________________________________________ 12

Maintenance _______________________________________________________________ 13

Preventive Maintenance _________________________________________________________ 13

Service and Support_____________________________________________________________ 13

Contamination Prevention ___________________________________________________ 14

Recommended Laboratory Organization and Workflow ____________________________ 14

Recommended Laboratory Practices for Contamination Control____________________ 16

Use of Vapor-Lock with Positive Controls _________________________________________ 16

Routine Cleaning and Decontamination of Assurance GDS

®

Equipment______________ 17

Decontamination ___________________________________________________________ 17

Environmental sampling for DNA contamination with Assurance GDS ______________ 17

®

Assurance GDS

2 55190.R000.082010

Equipment Warranty Terms ___________________________________ 18

Assurance GDS User Manual

Assurance GDS®

Assurance GDS (Genetic Detection System) is an automated nucleic acid amplification system for the detection of

pathogenic organisms in foods, ingredients, and environmental samples.

Overview

Enrichment: Each sample must be enriched via the appropriate protocol, specific to the target organism,

prior to amplification and detection with the Assurance GDS Rotor-Gene

Sample Preparation: Following enrichment, target organisms, if present, are concentrated and separated

from the enriched sample.

Amplification and Detection: The concentrated sample is transferred to amplification tubes containing

polymerase enzyme and lyophilized reagents specific for the detection of the target organism. If present,

amplified nucleic acid sequences specific to the target organism generate a fluorescent signal which is read and

interpreted by the Assurance GDS Rotor-Gene to determine test results.

Required Materials

Assurance GDS Test Kit

Polymerase Enzyme

®

.

Instrumentation and Supplies

Additional instrumentation and supplies are required to perform Assurance GDS assays. All instrumentation

is included in the Assurance GDS start-up package. Supplies are available for purchase through BioControl

Systems, Inc.

Instrumentation Supplies

Assurance GDS Rotor-Gene Assurance GDS PickPen tips

Laptop computer Pipette tips

Vortex mixer Assurance GDS Sample wells

Assurance GDS Pick-Pen

Pipetters Adhesive film strips

Incubator (60°C for Listeria)

®

Resuspension plates

Designated Assurance GDS Equipment

The instrumentation supplied with the Assurance GDS start-up package must be designated for use exclusively

with the Assurance GDS system. Use of any of these instruments for general microbiology work may lead to

contamination of samples and or reagent solutions.

The supplied repeater pipette should only

The supplied 1mL (1,000 µL) micropipette should only

(A separate pipettor must be used to extract enriched sample aliquots.)

The supplied 8-channel micropipette should only

the amplification tubes.

The Assurance GDS PickPen is for use

be used to dispense GDS reagents.

be used to prepare the polymerase enzyme.

be used to transfer samples from the resuspension plate to

with Assurance GDS and reagents only.

All associated pipette and PickPen tips must

3 55190.R000.082010

be used with the Assurance GDS system only.

Assurance GDS User Manual

Assurance GDS Rotor-Gene

Components

The Assurance GDS Rotor-Gene includes the following components:

Assurance GDS Rotor-Gene unit

Assurance GDS Rotor-Gene serial cable

Assurance GDS Rotor-Gene USB cable

Assurance GDS 36-well rotor and locking ring

Assurance GDS aluminum cooling block

International power cord set (USA, UK, European Union, Switzerland, and Australia)

Operating Conditions

Power 100-240 V AC, 50-60Hz. 520 VA (peak)

Power consumption 8 VA (standby)

Mains supply voltage fluctuations are not to exceed 10% of the nominal

supply voltages.

Fuse F5a 250 V fuse

Heat dissipation/thermal load Average: 0.183 kW (632 BTU/hour)

Peak: 0.458 kW (1578 BTU/hour)

Over voltage category II

Air temperature 18 to 30°C (64 to 86°F)

Relative Humidity 10 to 75 % (noncondensing)

Altitude Up to 2,000 m (6,500 ft.)

Place of operation For indoor use only

Dimensions

Width 37 cm (14.6 in.)

Height 27.5 cm (10.8 in.)

Depth (without cables) 42 cm (22 in.)

Depth (door open) 56 cm (22 in.)

Mass 12 kg (26.5 lb.)

Installation

To install the Assurance GDS Rotor-Gene, remove it from its packing materials and place it on a secure bench

top. Connect the power cable to a suitable line conditioner and battery backup (i.e. APC Back-UPS RS, 600

watts/1000VA, Input 120V/Output 120V and Tripp Lite LC1200 Line Conditioner or equivalent) connected to

a grounded electrical outlet.

The Assurance GDS Rotor-Gene can be connected to the communications port of the Assurance GDS lap

top computer (provided by BioControl) via either the serial cable or USB cable included with the Assurance

GDS Rotor-Gene. It is important to only use the authorized laptop provided by BioControl with the

Assurance GDS Rotor-Gene.

Note: The side exhaust vent and the air intake vent on the bottom off the unit must remain

unobstructed to ensure suitable air flow and proper operation of the Assurance GDS

Rotor-Gene.

4 55190.R000.082010

r

t

r

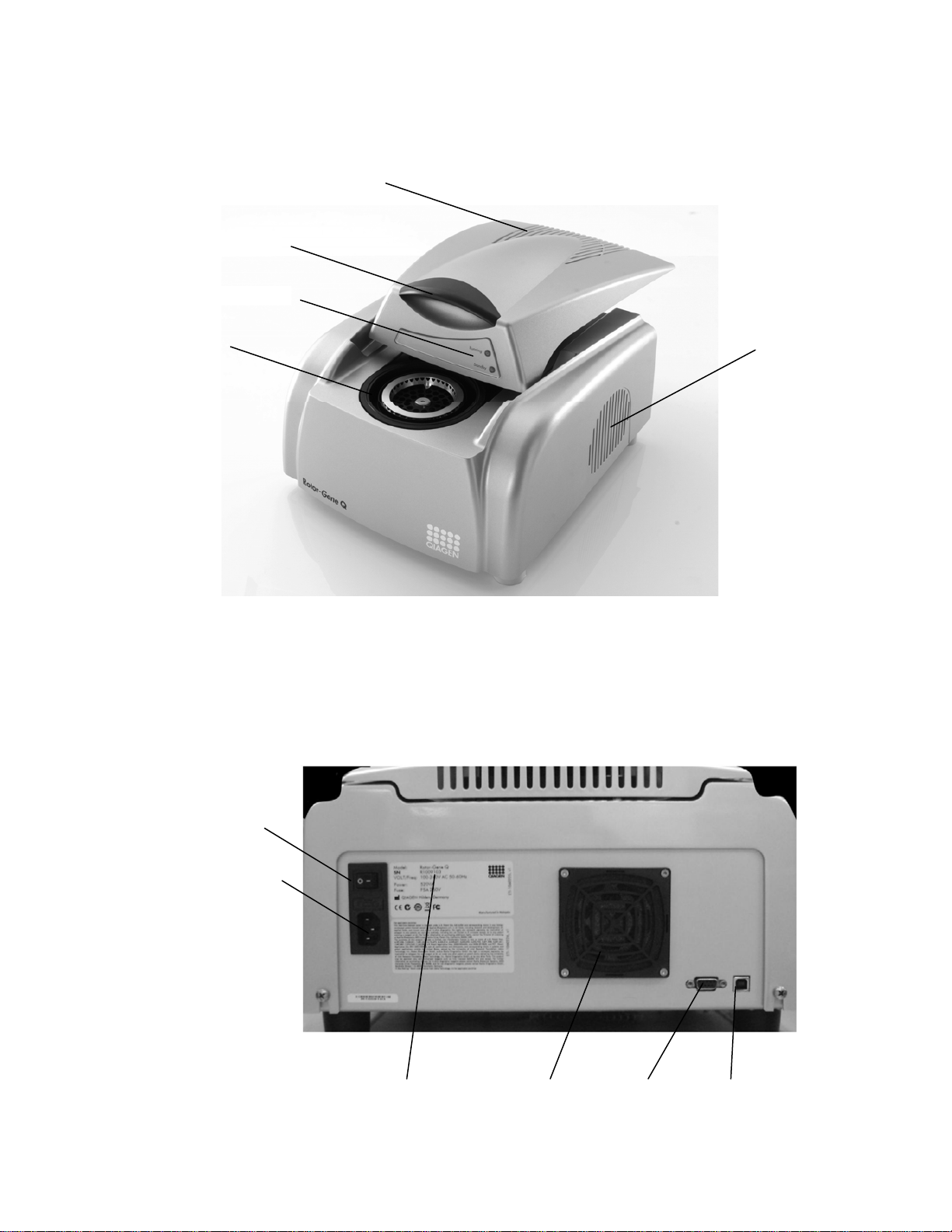

Rotor-Gene (front view)

Lid handle

Instrument status lights

Rotor chambe

Rotor-Gene (rear view)

Power switch

Power supply port

Serial numbe

Air vents

Cooling fan

Assurance GDS User Manual

Serial por

Exhaust vent

USB port

5 55190.R000.082010

Loading the Assurance GDS Rotor-Gene

Turn on the Assurance GDS Rotor-Gene.

Assurance GDS User Manual

Open the Assurance GDS Rotor-Gene by pushing the cover

back.

Ensure that the rotor is correctly positioned in the Rotor-

Gene by aligning the hole in the center circle of the rotor

with the alignment pin on the Rotor-Gene. Press down firmly

on the rotor, when installed properly the rotor will snap in

place.

Load the first amplification tube containing prepared sample

(see Assurance GDS kit directions-for-use) into the rotor

position labeled as 1. Follow in a consecutive pattern around

the rotor until all amplification tubes are loaded. Each

amplification tube should snap into place and sit flat in the

rotor.

Place locking ring over the top of the tubes. Snap the ring

into place, by aligning the pins at the bottom of the ring with

the holes in the rotor. The domed caps of the tubes should

sit in the open slots of the locking ring.

Close the Rotor-Gene. You are now ready to enter sample

information using the Assurance GDS Rotor-Gene software.

Rotoralignment

hole

Unloading the Assurance GDS Rotor-Gene

When the Rotor-Gene run is finished, open the Rotor-Gene by pushing the cover back.

Rotor

Locking ring

Amplification tubes

DO NOT attempt to remove used amplification tubes while rotor is in the Rotor-Gene.

Remove the rotor with the locking ring in place. Push down on the spring-loaded button in the center of area

of the rotor to release the rotor. Remove the locking ring. Invert the rotor containing the amplification tubes

over a sealable, disposable vessel containing sufficient 20% bleach solution to cover the tubes and gently push

on the bottom of the amplification tubes to pop them out of the rotor. The sealed vessel should be disposed

of daily in a trash receptacle outside of the laboratory. Used amplification tubes should never be opened or

transported throughout the laboratory.

DO NOT open used amplification tubes

DO NOT autoclave used amplification tubes

Important Technique

After working with the Assurance Rotor-Gene technicians should remove and dispose of

their gloves before moving into any other work zone. Lab coats used in work zone 3

should not be used in any other lab areas.

6 55190.R000.082010

Assurance GDS User Manual

Assurance GDS Rotor-Gene Software

Overview

The Assurance GDS Rotor-Gene software analyzes the signal from each individual amplification tube and

automatically interprets the test results.

System Start up

The Assurance GDS software will only recognize the Assurance GDS Rotor-Gene if the Rotor-Gene is

powered on. To start the system, power on the Assurance GDS Rotor-Gene followed by the lap top

computer. Select the appropriate Assurance GDS user access level and enter the appropriate password.

To launch the Assurance GDS Rotor-Gene software double-click on the Assurance GDS RotorGene program icon found the on the computer desktop.

Note: If the Assurance GDS Rotor-Gene software is launched while the computer is disconnected from the

Assurance GDS Rotor-Gene or if the Assurance GDS Rotor-Gene is not powered on, a warning screen will

appear giving the user the option to operate the software in “Demo Mode”. Demo Mode is intended to allow

users to familiarize themselves with the use of the software or to demonstrate its use. If the software is

operating in Demo Mode it will not control the Rotor-Gene.

User Levels

The Assurance GDS Rotor-Gene software is equipped with three different user access levels.

The “GDS Administrator” user level provides IT

professionals or administrators with the ability to set up new

users, assign individual passwords, and configure the

computer’s operational settings This log in is intended for use

by qualified IT personnel only and is password protected.

The “GDS Analyst” user level provides Quality and

Laboratory Managers with the ability to analyze data in greater

detail. Analysts have the ability to generate a report that can

be saved to a file, printed, or e-mailed directly from the GDS

Rotor-Gene software and is password protected.

The “GDS Operator” is the default access level that allows

the user to enter sample information and provides a

convenient results table. Operators have the ability to

generate a report that can be saved to a file, printed, or emailed directly from the GDS Rotor-Gene software.

1

Necessary passwords can be obtained from BioControl Technical Services.

7 55190.R000.082010

Assurance GDS User Manual

Entering Sample Information

The Rotor-Gene software opens to the Setup menu shown below. A new run is automatically opened each

time the Rotor-Gene software is launched.

Operator: Enter name of user.

Notes: Enter comments or other description of run.

Name: Click in the desired cell to enter sample names. No results will be reported for any sample that is

not identified with a name in the setup screen. (required field)

Description: Enter description of sample matrix to be analyzed.

Kit lot number: Enter lot number from kit label. (required field)

Assay: To select an assay, position your cursor in the Assay column. Click on the down arrow in the

“Samples:” window. Click to select the appropriate assay. (required field)

8 55190.R000.082010

Assurance GDS User Manual

Note: to select the same assay type, lot number, or

description for multiple samples:

Click the first cell within the corresponding column.

Drag the pointer or use shift+arrow key to highlight

the desired cells

Type in the description or lot number for this series

or for assay type, select the desired assay type from

the drop-down menu.

The software will automatically fill all cells in the

selected series.

After entering sample data, review all entries to ensure they are correct prior to starting run

Once a run has started changes to the sample information will not be allowed.

After confirming sample information, select Start Run. You will be prompted to save the run. Select the

desired folder and type in the desired file name. The default file name is “BioControlassay<date>.

Select Save to begin the run.

.

Viewing Results

Upon initiating a run, the Analysis screen shown below will appear with the time to results countdown.

9 55190.R000.082010

Assurance GDS User Manual

Viewing Results as GDS Operator

When logged in as a “GDS Operator” the Assurance GDS Rotor-Gene software will display results in the

table format only.

Viewing Results as GDS Analyst

When logged in as a “GDS Analyst” the Assurance GDS Rotor-Gene software will display amplification curves

for the “Test Samples” and “Internal Control” for each tube. The graph will begin to display the fluorescence

signal for each sample after a number of cycles have been completed to generate baseline signal. At that

point the established Threshold lines will appear in the Test Sample and Internal Control windows.

Viewing Multiple Assay Results

Multiple assays can be run simultaneously on the Assurance GDS Rotor-Gene. Results for all assays appear in

the results table by sample number. To enhance readability, the graphic representation of these results is by

assay type. To change assay type select the desired assay from the “Show results for” drop down menu.

10 55190.R000.082010

Assurance GDS User Manual

Viewing Specific Samples or Groups of Samples

During or upon completion of a run, samples can be viewed individually or in groups.

To select a range of samples, click on the graph near the first sample and draw a box around the samples of

interest. When you release the mouse button, a menu will appear.

Clicking Select Only These Samples will only show those samples selected.

Deselect These Samples will show all samples except those that have been selected.

To return to a view of all samples right-mouse-click on the graph. A menu will appear.

Select All Named Samples.

Interpreting Results

When logged in as a “GDS Analyst” the Assurance GDS Rotor-Gene software will display amplification curves for

the “Target(s)” and “Internal Controls” for each sample. The graph will begin to display the fluorescence signal for

each sample. Once the run has been completed all samples and their determination will appear in the Results

table. The table shows the determination of test results for each sample. Results can be Positive, Negative, or

invalid as a result of no amplification (No amp).

Positive: Sample tests positive for the target organism and internal control is positive.

Positive: Samples test positive for target organism and internal control is negative (in the case of strong positives

the amplification of the target may use all reaction resources not leaving any for the internal control).

Negative: Samples test negative for target organism and internal control is positive

No Amp: Sample tests negative for target organism and internal control is negative. This means that amplification

did not occur. User should go back to enriched sample and re-run assay. If problem persists, contact

BioControl Technical Services.

11 55190.R000.082010

Assurance GDS User Manual

Virtual Mode / Analysis Only Mode

The Rotor-Gene software can be run independent of the Assurance Rotor-Gene instrument for demonstration

purposes or to view results from past runs. This mode of operation is termed “Virtual Mode” or “Analysis Only

Mode”. During this mode of operation no data is actually acquired from the Rotor-Gene. If a run is initiated in

Virtual Mode, all named samples will be reported as No Amp. When a run is started in Virtual Mode the file name

at the top of the screen will begin with "Analysis-Only Assurance Rotor-Gene VIRTUAL MODE", the “running”

status light will remain dark, and no sound will be emitted by the Assurance GDS Rotor-Gene.

Virtual Mode and Analysis Only Mode can be accessed by launching the Assurance GDS Software while the RotorGene is powered off or disconnected from the computer.

Reports

Upon completion of the run, the Report button located at the top right of the Analysis Screen becomes

selectable. Selecting the Reports button opens the report screen shown below.

BioControl Analysis (Concise) – This report generates a results table for each assay.

BioControl Analysis (Full Report) – This report generates a results table and amplification curves for each

assay – Analyst level users only.

Using the buttons on the top, the reports can be printed, saved, emailed or exported to Word.

The report contains a table showing all run information including operation, date, time, and valid signature.

The Run Signature is a non-reversible key which is regenerated every time the file is changed. If any section

of the file is modified outside of the software, the signature and the file will no longer match. Using the

signature, you can ensure that the data has not been modified. The signature also protects against nonmalicious corruption, such as file-system errors.

12 55190.R000.082010

Assurance GDS User Manual

Maintenance

Preventive Maintenance

Optical performance of the Assurance GDS Rotor-Gene is maintained by ensuring that the lenses, located at

both the emission and detection source, are clean. This is achieved by gently wiping a cotton tip applicator,

moistened with ethanol, over the lenses.

Note: Clean the lenses at least once a month, depending on usage. Wipe the rotor chamber at the same time.

Keep the bench area clean and free from dust and sheets of paper. The air inlet of the Assurance GDS RotorGene is at the bottom and loose material such as paper or dust may compromise performance.

Service and Support

For technical assistance or questions about the Assurance GDS Rotor-Gene or system please contact:

BioControl Technical support at 1.800.245.0113

13 55190.R000.082010

Assurance GDS User Manual

Contamination Prevention

Assurance GDS™ is a highly sensitive and specific test based on the principles of DNA amplification and detection.

Due to the sensitive nature of this assay certain precautions must be taken to avoid potential sample

contamination and produce accurate test results.

Contamination can be caused by live organisms (from samples, positive controls, and the environment) or from

amplified DNA produced by a positive Assurance GDS reaction. The amplification reaction produces billions of

copies of DNA, allowing highly sensitive detection of specific target sequences. Microscopic volumes of amplified

reactions have the potential to cause cross contamination if spread by contact or aerosols. Improper workflow and

handling of used Assurance GDS amplification tubes may result in DNA contamination of laboratory work surfaces

and equipment.

If the work areas or equipment are believed to be contaminated with the amplified DNA, the lab should be

decontaminated via the method described under Decontamination section of this manual (p. 17).

Recommended Laboratory Organization and Workflow

To help avoid contamination of reagents and samples it is highly recommended that 3 distinct work zones be

established within the laboratory for performing various aspects of the GDS assay.

Work Zone 1 – Reagent Preparation

Work Zone 1 should be an area where bacterial cultures and food samples are not handled or stored. All

handling and preparation of Assurance GDS reagents should be performed in this area including:

Addition of reagents, buffers, and media to the sample block and resuspension plate

Preparation of the polymerase enzyme

Addition of prepared polymerase enzyme to amplification tubes

Laboratory personnel should don new gloves upon entering Work Zone 1. The same gloves may be worn

when moving forward into higher work zones (e.g. Work Zone 1 to Work Zone 2).

Important Technique

Before entering Work Zone 1 and handling GDS reagents, technicians should put on clean

gloves and a clean lab coat.

Work Zone 2 - Sample Preparation

This area should conform to typical specifications for a microbiological work station. All handling and

processing of samples and enrichments should be conducted in this area including:

Transfer of enriched sample to prepared sample block

Pick-Pen transfers of concentrated samples to prepared resuspension plate

Transfer of resuspended sample to prepared amplification tubes

Laboratory personnel in Work Zone 2 should wear gloves (may be the same gloves from Work Zone 1).

When moving from Work Zone 2 to Work Zone 3 the same gloves may be worn.

Important Technique

To avoid potential reagent contamination, lab coats, gloves, lab equipment, and disposable

materials such as pipette tips used in Work Zone 2 should not be used in Work Zone 1.

14 55190.R000.082010

Assurance GDS User Manual

Work Zone 3 – Amplification & Detection

This area should contain a suitable work surface and power source for the Assurance GDS Rotor-Gene

and lap top workstation. No cultures, food samples or disposable supplies should be stored or prepared in

this area.

Double gloves should always be worn when loading or unloading tubes from the Rotor-Gene. The outer

pair of gloves should be removed immediately after working with the Rotor-Gene and before touching any

other equipment or supplies in Work Zone 3 such as the computer. A second pair of gloves should be

donned if the technician needs to return to handling the Rotor-Gene or tubes. The second pair of gloves

should always be removed immediately after handling the Rotor-Gene and tubes.

All used amplification tubes should be appropriately disposed of in a sealed, disposable vessel containing

sufficient 20% bleach (1.2% sodium hypochlorite) solution to cover the tubes. The sealed vessel should be

disposed of daily in a trash receptacle outside of the laboratory. Do not autoclave used amplification tubes.

Used amplification tubes should never be opened or transported throughout the laboratory.

Important Technique

Technicians should always wear two pairs of gloves when loading or unloading the

Assurance GDS Rotor-Gene. After working with the Assurance GDS Rotor-Gene

technicians should remove and dispose of their outer pair of gloves before working with

any other equipment or supplies in Zone 3. Lab coats used in Work Zone 3 should not

be used in any other lab areas. All gloves worn in Work Zone 3 should be removed

before moving to other areas of the lab.

When leaving Work Zone 3 all gloves should be removed before moving to any other part of the

laboratory including Work Zones 1 and 2. Refer to the diagram below for work zone flow and glove

requirements.

Don

Don

Double

Double

Gloves

Gloves

Work Zone 1

Retain

Both

Gloves

Remove

Outer

Gloves

and

Replace

Work Zone 2

Retain

Both

Gloves

Remove

All

Gloves

and

Replace

Work Zone 3

Remove

Remove

All

All

Gloves

Gloves

Other Areas of

Laboratory

15 55190.R000.082010

Assurance GDS User Manual

Recommended Laboratory Practices for Contamination Control

The equipment supplied with the Assurance GDS start-up package must be designated for use with Assurance

GDS assays only. Use of any of these instruments including pipettors for other general microbiology work

may lead to contamination of samples and/or reagent solutions.

Technicians should follow standard good laboratory practices to prevent microbial and DNA contamination.

Prior to beginning tests and upon completion of tests, clean all work surfaces and equipment (i.e. pipettes,

PickPen, vortex mixer, Rotor-Gene, etc…) with a 10-20% bleach solution followed by a 70% alcohol solution.

To clean the Assurance GDS Rotor-Gene, remove the rotor and locking ring. Wipe down both items 10-20%

bleach solution followed by a 70% alcohol solution. To clean the internal chamber, apply a 10-20% bleach

solution to a low particulate cloth or towel and gently wipe the chamber surfaces. Repeat procedure with a

70% alcohol solution. Do not spray any solutions directly into the Rotor-Gene chamber.

To help prevent contamination of pipettes, aerosol barrier tips must be used for all pipetting steps.

Observe vortex mixing action. During the vortex mixing steps, media within the sample wells should not

vortex up to within ½ inch of well opening. If the vortex action is causing droplets of media to splash up and

adhere to the underside of the adhesive strips, turn down the rpm speed setting.

NEVER OPEN TUBES after amplification. To avoid accidental tube

opening, do not attempt to remove tubes from the rotor by pulling

tubes out from the top. To safely remove the tubes, remove the rotor

from the Rotor-Gene, turn it upside down, and push the tubes out

from the bottom into a sealable container containing a 20% bleach

(1.2% sodium hypochlorite) solution sufficient to cover the tubes, e.g.

a zip-lock bag.

Change outer gloves after loading or unloading tubes from the Rotor-Gene. Do not track materials from the

Rotor-Gene to the amplification tube preparation area. Maintain separation between the Rotor-Gene and the

amplification tube preparation area.

If an open tube is observed in the Rotor-Gene after amplification & detection process has finished, carefully

hold the tube closed and remove the rotor. Immerse the rotor and all tubes in 20% bleach solution for 10

minutes. Dispose of the tubes as described above. Clean and decontaminate all work surfaces and equipment

as described below. Before resuming testing, verify that all work areas are free of DNA via the method

described under the Decontamination section of this manual (p. 17).

Use of Vapor-Lock with Positive Controls

Vapor-Lock is a hydrophobic, low viscoscity PCR encapsulation barrier that can be added to positive control

reactions to help minimize the potential for release of the amplified DNA into the laboratory environment.

The procedure for using Vapor-Lock with positive control samples is detailed below.

1. Cool aluminum block at 2-8°C for at least 20 min. prior to use. Remove Amplification Tubes from

foil pouch and place the Amplification Tubes in the aluminum block. Reseal pouch.

2. Open caps of Amplification Tubes in aluminum block. Transfer 10 µL prepared Polymerase Buffer

solution to each Amplification Tube using repeat pipettor and a 0.2 mL pipette tip.

3. Transfer 40 µL of Vapor-Lock to the positive control Amplification Tube. Vapor-Lock is intended

for use with positive control samples only.

4. Transfer 20 µL of sample from resuspension plate well into each Amplification Tube using a multi-

channel pipettor and filter barrier tips.

5. Transfer 20 µL of positive control to the appropriate Amplification Tube containing Vapor-Lock.

6. Firmly press down on each Amplification Tube lid to close. Visually inspect each tube to ensure

that the cap is securely sealed.

7. Prior to placing in rotor, invert Amplification Tubes and shake with a snapping motion to

thoroughly mix contents.

Note: Vapor-Lock is not compatible with Assurance GDS for Cronobacter spp. (Enterobacter sakazakii).

16 55190.R000.082010

Assurance GDS User Manual

Routine Cleaning and Decontamination of Assurance GDS® Equipment

Wipe down laboratory surfaces and pipettes with a 10-20% bleach solution before and after use. To avoid

corrosion of metal surfaces, wipe away bleach solution and wipe down surface with a 70% alcohol solution.

At least once per week, perform preventive cleaning with bleach:

1. Remove the rotor and locking ring and soak in 20% bleach solution for 10 minutes (no longer).

Rinse with a 70% alcohol solution and dry.

2. Spray the aluminum amp tube block with 20% bleach solution, let sit 10 minutes, rinse with a 70%

alcohol solution and dry by tapping to remove any remaining liquid from the wells.

3. Wipe the outside enamel surfaces of the Rotor-Gene and surrounding bench area with 20%

bleach solution, allow to sit for 15 minutes, then wipe with 70% alcohol.

4. Bleach the GDS work bench area and pipettes as above.

Note: Anti-DNA compounds such as DNA-Away may be used instead of bleach.

At least once per week sanitize the Rotor-Gene chamber with UV light. Remove the rotor and locking ring

and position the UV lamp directly over the chamber (maximum 12 inches from the opening). Expose

chamber for 15-10 minutes.

Decontamination

Improper handling and disposal of used Assurance GDS amplification tubes may result in DNA contamination of

laboratory work surfaces and equipment. If the work areas or equipment are believed to be contaminated with

the amplified DNA, the lab should be decontaminated using a 20% bleach solution followed by a 70% ethanol

solution. All opened or partially used disposable items (pipettes, tips, test kits, reagents, plates, etc…) should be

disposed of appropriately. After decontamination, work surfaces and equipment can be sampled via the following

protocol. Any area or piece of equipment still exhibiting contamination should be re-cleaned and tested until

negative test results are obtained.

Environmental sampling for DNA contamination with Assurance GDS

1. Add 1mL of sterile purified water to each of the required number of wells of a sample block

(1 well/sample).

2. Moisten the tip of a dry Dacron, polyurethane or polyester swab by dipping it into the corresponding well

containing the sterile purified water.

3. Swab the intended sample surface. Avoid surfaces grossly contaminated with particulate matter.

4. Return the swab to the corresponding sample block well and gently stir the swab tip in the water for 10

seconds.

5. Gently press the swab tip against the inside well of the sample block to expel excess liquid and dispose of

the swab as biohazard waste.

6. Transfer 20 µL of sample directly from sample block wells to the appropriate Assurance GDS amp tubes

prepared with polymerase and proceed as indicated by Assurance GDS kit directions for use.

Approved Sample Collection Swabs for Detection of DNA Contamination with Assurance GDS:

Fisher brand Sterile Polyester Swab Berkshire BCR Clean Room Swab Texwipe CleanTip Swab

Fisher Cat. No 14-959-90 Fisher Cat. No 18-999-17 Fisher Cat. No 18-385

17 55190.R000.082010

Assurance GDS User Manual

Assurance GDS® Equipment Warranty Terms

BioControl Systems, Inc. (“BioControl” or “BCS”) warrants the Assurance GDS equipment to be free from

defects in materials and workmanship, when given normal, proper, and intended usage for one (1) year from the

date of delivery of this equipment to the original purchaser (“Buyer”). BioControl agrees during the applicable

warranty period to repair or replace, at BioControl’s option, all defective equipment within 5 days after date of

return to BioControl and without cost to Buyer.

This Limited Warranty shall apply to the following instrumentation included in the Assurance GDS start up

package; Assurance GDS Rotor-Gene, laptop computer, vortex mixer, incubator, PickPen, repeat pipette, single

channel pipette and multi channel pipette. BioControl shall not have any obligation under this Limited Warranty

to make repairs or replacements which are required by normal wear and tear, or which result, in whole or in part,

from catastrophe, fault or negligence of the Buyer, or anyone claiming through or on behalf of the Buyer, or from

improper use of the equipment, or use of the equipment in a manner for which it was not designed, or by causes

external to the equipment.

Buyer shall notify BioControl of any equipment believed to be defective during the warranty period. At

BioControl’s option, such equipment shall be returned by Buyer, transportation and insurance prepaid, to

BioControl’s designated facility for examination and testing. BioControl shall repair or replace, within 5 days of

receipt by BioControl, any such equipment found to be defective and promptly return such equipment to Buyer,

transportation and insurance prepaid. Should BioControl’s examination and testing not disclose any defect covered

by the foregoing warranty, BioControl shall so advise Buyer and return the equipment in accordance with buyer’s

instructions and at Buyer’s sole expense. BioControl warrants its repair work and any replacement parts or

equipment for a period of 30 days from receipt by the Buyer of the repaired or replaced equipment or for the

remaining balance of the original warranty period set forth in the preceding paragraph, whichever is greater.

THE PROVISIONS OF THE FOREGOING LIMITED WARRANTY ARE IN LIEU OF ANY OTHER WARRANTY,

WHETHER EXPRESS OR IMPLIED, WRITTEN OR ORAL INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE). BIOCONTROL’S LIABILITY ARISING OUT

OF THE MANUFACTURE, SALE OR SUPPLYING OF THE EQUIPMENT OR ITS USE OR DISPOSITION,

WHETHER BASED UPON WARRANTY, CONTRACT, TORT OR OTHERWISE, SHALL NOT EXCEED THE

ACTUAL PURCHASE PRICE PAID BY BUYER FOR THE EQUIPMENT. IN NO EVENT SHALL BIOCONTROL

BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, LOSS OF PROFITS OR LOSS OF USE

DAMAGES) ARISING OUT OF THE MANUFACTURE, SALE OR SUPPLYING OF THE EQUIPMENT. THE

FOREGOING WARRANTIES EXTEND TO BUYER ONLY AND SHALL NOT BE APPLICABLE TO ANY

OTHER PERSON OR ENTITY INCLUDING, WITHOUT LIMITATION, CUSTOMERS OF BUYER.

18 55190.R000.082010

Assurance GDS User Manual

19 55190.R000.082010

Loading...

Loading...