Document ID: 54408

EN

Operating instructions

NCR-21

Document ID: 54408

925-0374

2

Contents

NCR-21 4 … 20 mA

54408-01-190131

Contents

1 About this document ....................................... 23

1.1 Function ........................................................23

1.2 Target group .................................................23

1.3 Symbols used ...............................................23

2 For your safety .................................................. 23

2.1 Authorised personnel ...................................23

2.2 Appropriate use ............................................23

2.3 Warning about incorrect use .........................23

2.4 General safety instructions ...........................23

2.5 EU conformity ...............................................24

2.6 Radio licenses for Europe .............................24

2.7 Radio approval for USA ................................24

2.8 Radio approval for Canada ...........................25

2.9 Installation and operation in the USA and

Canada .........................................................25

2.10 Radio license for South Africa ......................25

2.11 Security concept, Bluetooth operation ..........26

2.12 Environmental instructions ...........................26

3 Product description ......................................... 26

3.1 Conguration ................................................26

3.2 Principle of operation ....................................27

3.3 Adjustment ...................................................27

3.4 Packaging, transport and storage .................27

4 Mounting ........................................................... 28

4.1 General instructions .....................................28

4.2 Mounting versions ........................................28

4.3 Mounting instructions ...................................29

5 Connecting to power supply ........................... 29

5.1 Preparing the connection..............................29

5.2 Wiring plan ...................................................29

6 Set up Bluetooth connection with smartphone/

tablet .................................................................. 30

6.1 Preparations .................................................30

6.2 Connecting ...................................................30

6.3 Sensor parameter adjustment ......................30

7 Set up Bluetooth connection with PC/notebook

31

7.1 Preparations .................................................31

7.2 Connecting ...................................................31

7.3 Parameter adjustment ..................................32

8 Diagnosis, asset management and service .. 32

8.1 Maintenance .................................................32

8.2 Measured value and event memory ..............32

8.3 Asset Management function .........................33

8.4 Rectify faults .................................................35

8.5 How to proceed if a repair is necessary ........35

9 Dismount ........................................................... 36

9.1 Dismounting steps ........................................36

9.2 Disposal .......................................................36

10 Supplement ....................................................... 37

10.1 Technical data ..............................................37

10.2 Radio astronomy stations .............................40

10.3 Dimensions ..................................................41

10.4 Industrial property rights ...............................42

10.5 Hash function acc. to mbed TLS ...................42

10.6 Trademark ....................................................42

Safety instructions for Ex areas

Take note of the Ex specic safety

instructions for Ex applications. These

instructions are attached as documents

to each instrument with Ex approval and

are part of the operating instructions.

Editing status: 2019-01-23

925-0374

3

NCR-21 4 … 20 mA

54408-01-190131

2 For your safety

1 About this document

1.1 Function

This operating instructions provides all the

information you need for mounting, connection

and setup as well as important instructions for

maintenance and fault rectication. Please read

this information before putting the instrument

into operation and keep this manual accessible

in the immediate vicinity of the device.

1.2 Target group

This operating instructions manual is directed to

trained personnel. The contents of this manual

must be made available to the qualied personnel and implemented.

1.3 Symbols used

Information, tip, note

This symbol indicates helpful additional

information.

Caution: If this warning is ignored, faults

or malfunctions can result.

Warning: If this warning is ignored,

injury to persons and/or serious damage

to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or destruction

of the instrument can result.

Ex applications

This symbol indicates special

instructions for Ex applications.

•

List

The dot set in front indicates a list with

no implied sequence.

→

Action

This arrow indicates a single action.

1 Sequence of actions

Numbers set in front indicate successive

steps in a procedure.

Battery disposal

This symbol indicates special information about the disposal of batteries and

accumulators.

2 For your safety

2.1 Authorised personnel

All operations described in this documentation

must be carried out only by trained, qualified

personnel authorised by the plant operator.

During work on and with the device, the requi-

red personal protective equipment must always

be worn.

2.2 Appropriate use

NCR-21 is a sensor for continuous level

measurement.

You can find detailed information about the area

of application in chapter "Product description".

Operational reliability is ensured only if the instrument is properly used according to the speci-

fications in the operating instructions manual as

well as possible supplementary instructions.

2.3 Warning about incorrect use

Inappropriate or incorrect use of this product

can give rise to application-specific hazards,

e.g. vessel overfill through incorrect mounting or

adjustment. Damage to property and persons or

environmental contamination can result. Also,

the protective characteristics of the instrument

can be impaired.

2.4 General safety instructions

This is a state-of-the-art instrument complying

with all prevailing regulations and directives.

The instrument must only be operated in a

technically flawless and reliable condition. The

operator is responsible for the trouble-free

operation of the instrument. When measuring

aggressive or corrosive media that can cause a

dangerous situation if the instrument

malfunctions, the operator has to implement

suitable measures to make sure the instrument

is functioning properly.

During the entire duration of use, the user is

obliged to determine the compliance of the

necessary occupational safety measures with

the current valid rules and regulations and also

take note of new regulations.

The safety instructions in this operating

instructions manual, the national installation

standards as well as the valid safety regulations

and accident prevention rules must be observed

925-0374

4

2 For your safety

NCR-21 4 … 20 mA

54408-01-190131

by the user.

For safety and warranty reasons, any invasive

work on the device beyond that described in the

operating instructions manual may be carried

out only by personnel authorised by the manu-

facturer. Arbitrary conversions or modications

are explicitly forbidden. For safety reasons, only

the accessory specied by the manufacturer

must be used.

To avoid any danger, the safety approval

markings and safety tips on the device must

also be observed and their meaning read in this

operating instructions manual.

Depending on the instrument version, the

emitting frequencies are in the C, K or W band

range. The low emission power is far below the

internationally approved limit values. When used

correctly, the device poses no danger to health.

2.5 EU conformity

The device fulls the legal requirements of the

applicable EU directives. By axing the CE

marking, we conrm the conformity of the instru-

ment with these directives.

You can nd the EU conformity declaration on

our website under www.vega.com/downloads.

2.6 Radio licenses for Europe

VEGAPULS WL S 61

The instrument was tested according to the

latest issue of the following harmonized standards:

•

EN 302372 - Tank Level Probing Radar

•

EN 302729 - Level Probing Radar

It is hence approved for use inside and outside

closed vessels in countries of the EU.

Use is also approved in EFTA countries,

provided the respective standards have been

implemented.

For operation inside of closed vessels, points a

to f in annex E of EN 302372 must be fullled.

For operation outside of closed vessels, the

following conditions must be fullled:

•

The installation must be carried out by

trained qualied personnel

•

The instrument must be stationary moun-

ted and the antenna directed vertically

downward

•

The mounting location must be at least 4 km

away from radio astronomy stations, unless

special permission was granted by the responsible national approval authority

•

When installed within 4 to 40 km of a radio

astronomy station, the instrument must not

be mounted higher than 15 m above the

ground.

You can nd a list of the respective radio astronomy stations in chapter "Supplement".

Bluetooth radio module

The radio module used in the instrument for wireless Bluetooth communication was tested by

the manufacturer according to the latest edition

of the following standard:

•

EN 300328 – Wideband transmission

systems

It is hence for use inside closed vessels in countries of the EU and EFTA.

2.7 Radio approval for USA

This approval is only valid for USA. Hence

the following text is only available in English

language.

This device complies with Part 15 of the FCC

Rules.

Operation is subject to the following conditions:

•

This device may not cause interference, and

•

This device must accept any interference,

including interference that may cause

undesired operation of the device

This device has been approved for open air

environments with the following limitations:

•

This device shall be installed and maintai-

ned to ensure a vertically downward orien-

tation of the transmit antenna's main beam.

Furthermore, the use of any mechanism that

does not allow the main beam of the trans-

mitter to be mounted vertically downward is

prohibited.

•

This device shall be installed only at xed

locations. The LPR device shall not operate

while being moved or while inside a moving

container.

•

Hand-held applications are prohibited.

•

Marketing to residential consumers is

prohibited.

Changes or modications not expressly approved by the manufacturer could void the user’s

authority to operate this equipment.

925-0374

5

2 For your safety

NCR-21 4 … 20 mA

54408-01-190131

2.8 Radio approval for Canada

This approval is only valid for Canada. Hence

the following texts are only available in English/

French language.

This device complies with Industry Canada's

license-exempt RSS standard(s).

Operation is subject to the following conditions:

•

This device may not cause interference, and

•

This device must accept any interference,

including interference that may cause

undesired operation of the device

This device has been approved for open air

environments with the following limitations:

•

This device shall be installed and maintai-

ned to ensure a vertically downward orien-

tation of the transmit antenna's main beam.

Furthermore, the use of any mechanism that

does not allow the main beam of the trans-

mitter to be mounted vertically downward is

prohibited.

•

The installation of the LPR/TLPR device

shall be done by trained installers, in

strict compliance with the manufacturer's

instructions.

•

This device shall be installed only at xed

locations. The LPR device shall not operate

while being moved or while inside a moving

container.

•

Hand-held applications are prohibited.

•

Marketing to residential consumers is

prohibited.

•

The use of this device is on a "no-interfe-

rence, no-protection" basis. That is, the user

shall accept operations of high-powered

radar in the same frequency band which

may interfere with or damage this device.

•

However, devices found to interfere with

primary licensing operations will be required

to be removed at the user's expense.

2.9 Installation and operation in

the USA and Canada

This information is only valid for USA and Canada. Hence the following text is only available in

the English language.

Installations in the US shall comply with the

relevant requirements of the National Electrical

Code (ANSI/NFPA 70).

Installations in Canada shall comply with the

relevant requirements of the Canadian Electrical

Code

A Class 2 power supply unit has to be used for

the installation in the USA and Canada.

2.10 Radio license for South

Africa

The instrument was released by the ICASA

under the certificate number TA 2017-1763.

925-0374

6

3 Product description

NCR-21 4 … 20 mA

54408-01-190131

2.11 Security concept, Bluetooth

operation

Sensor adjustment via Bluetooth is based on a

multi-stage security concept.

Authentication

When starting Bluetooth communication, an authentication is carried out between sensor and

adjustment device by means of the sensor PIN.

The sensor PIN is part of the respective sensor

and must be entered in the adjustment device

(smartphone/tablet). To increase adjustment

convenience, this PIN is stored in the adjustment device. This process is secured via an

algorithm acc. to standard SHA 256.

Protection against incorrect entries

In case of multiple incorrect PIN entries in the

adjustment device, further entries are possible

only after a certain amount of time has passed.

Encrypted Bluetooth communication

The sensor PIN as well as the sensor data

are transmitted encrypted between sensor

and adjustment device according to Bluetooth

standard 4.0.

2.12 Environmental instructions

Protection of the environment is one of our most

important duties. That is why we have introduced an environment management system with

the goal of continuously improving company

environmental protection. The environment

management system is certied according to

DIN EN ISO 14001.

Please help us full this obligation by observing

the environmental instructions in this manual:

•

Chapter "Packaging, transport and storage"

•

Chapter "Disposal"

3 Product description

3.1 Conguration

Scope of delivery

The scope of delivery encompasses:

•

Radar sensor with integrated Bluetooth

module

•

Documentation

– This operating instructions manual

– Supplement with sensor PIN

Scope of this operating instructions

This operating instructions manual applies to

the following instrument versions:

•

Hardware version from 1.0.0

•

Software version from 4.5.3

Type label

You can nd the type label on the sensor

housing as well as on the type label support on

the connection cable.

It contains the most important data for identication and use of the instrument.

2

1

12

13

14

11

10

9

5

6

4

3

7

8

Abb. 18: Layout of the type label (example)

1 Instrument type

2 Product code

3 Field for approvals

4 Voltage supply and signal output, electronics

5 Protection rating

6 Measuring range

7 Process and ambient temperature, process pres-

sure

8 Material wetted parts

9 Serial number of the instrument

10 Data matrix code for VEGA Tools app

11 Symbol of the device protection class

12 Reminder to observe the instrument documentati-

on

13 Radio approval for South Africa

14 Bluetooth symbol

Serial number - Instrument search

The type label contains the serial number of

the instrument. With it you can nd the following

instrument data on our homepage:

•

Product code (HTML)

•

Delivery date (HTML)

•

Order-specic instrument features (HTML)

•

Operating instructions at the time of shipment (PDF)

•

Order-specic sensor data (XML)

Go to "www.vega.com", "Search". Enter the

serial number.

Alternatively, you can access the data via your

smartphone:

925-0374

7

3 Product description

NCR-21 4 … 20 mA

54408-01-190131

•

Download the VEGA Tools app from the

"Apple App Store" or the "Google Play

Store"

•

Scan the Data Matrix code on the type label

of the instrument or

•

Enter the serial number manually in the app

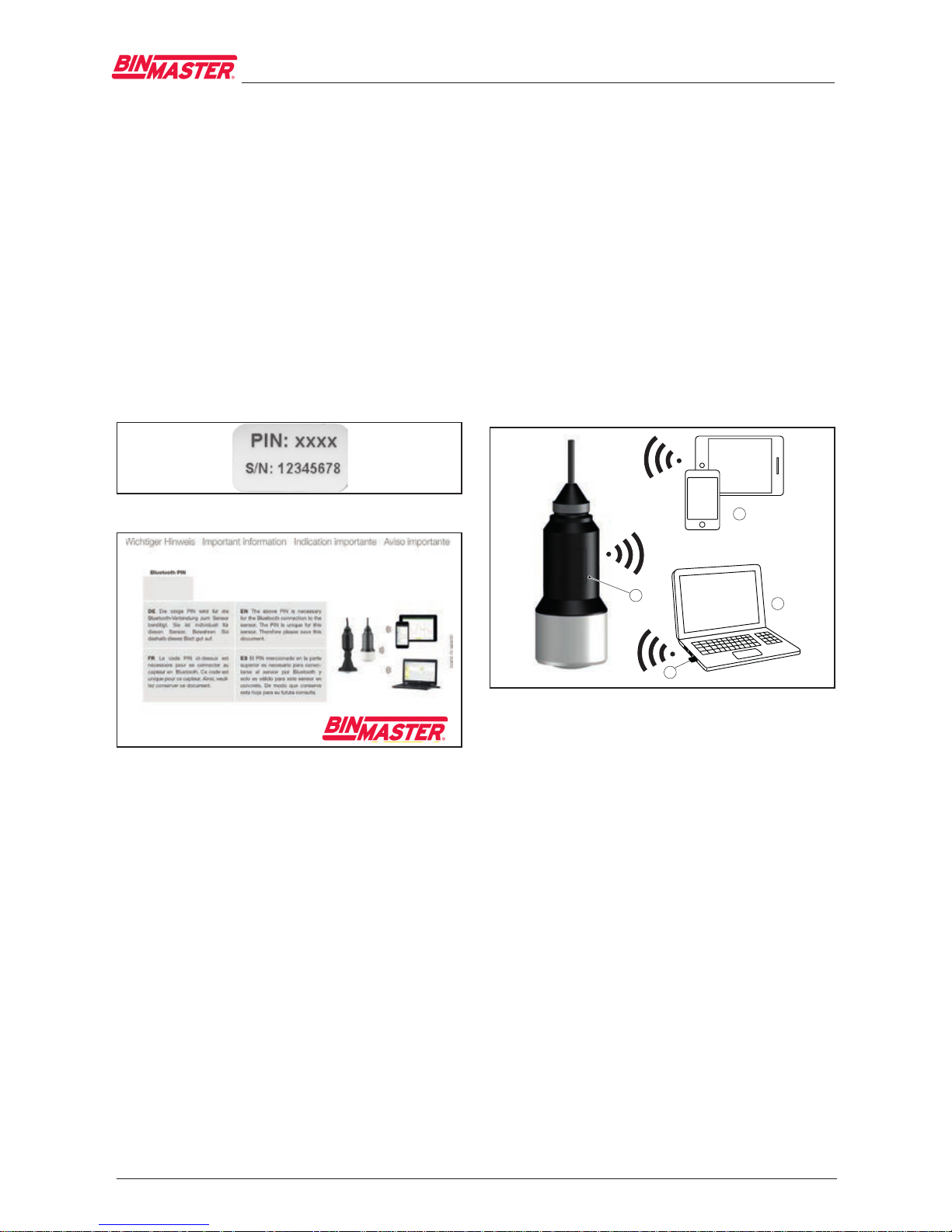

Sensor PIN

The 4-digit PIN is necessary for the Bluetooth

connection to the sensor. The PIN is unique and

is only valid of this sensor.

You can nd the PIN:

•

Next to the type label on the connection

cable

•

On the information sheet of the documentation

Abb. 19: Bluetooth PIN next to the type label

XXXX

Abb. 20: Bluetooth PIN on the information sheet

3.2 Principle of operation

Application area

The radar sensor NCR-21 is the ideal sensor

for typical applications in the water and waste

water industry. It is particularly suitable for

level measurement in water treatment, in

pump stations as well as storm water overflow

tanks. The flood-proof IP 68 housing of

NCR-21 ensures a maintenance-free

permanent operation. An integrated Bluetooth

module enables the wireless communication

with smartphone, tablet or PC.

Functional principle

The antenna of the radar sensor emits short

radar pulses with a duration of approx. 1 ns.

These pulses are reected by the product and

received by the antenna as echoes. The transit

time of the radar pulses from emission to reception is proportional to the distance and hence to

the level. The determined level is converted into

an appropriate output signal and outputted as

measured value.

3.3 Adjustment

Wireless adjustment

The adjustment of NCR-21 is carried out

via

standard adjustment instruments:

•

Smartphone/tablet (iOS or Android operating system)

•

PC/notebook with Bluetooth USB adapter

(Windows operating system)

1

4

2

3

Abb. 21: Wireless connection to standard operating

devices

1 Sensor

2 Smartphone/Tablet

3 Bluetooth USB adapter

4 PC/Notebook

3.4 Packaging, transport and

storage

Packaging

Your instrument was protected by packaging

during transport. Its capacity to handle normal

loads during transport is assured by a test

based on ISO 4180.

The packaging of standard instruments consists

of environment-friendly, recyclable cardboard.

For special versions, PE foam or PE foil is also

used. Dispose of the packaging material via

specialised recycling companies.

Transport

Transport must be carried out in due conside-

925-0374

8

4 Mounting

NCR-21 4 … 20 mA

54408-01-190131

ration of the notes on the transport packaging.

Nonobservance of these instructions can cause

damage to the device.

Transport inspection

The delivery must be checked for completeness

and possible transit damage immediately at receipt. Ascertained transit damage or concealed

defects must be appropriately dealt with.

Storage

Up to the time of installation, the packages

must be left closed and stored according to the

orientation and storage markings on the outside.

Unless otherwise indicated, the packages must

be stored only under the following conditions:

•

Not in the open

•

Dry and dust free

•

Not exposed to corrosive media

•

Protected against solar radiation

•

Avoiding mechanical shock and vibration

Storage and transport temperature

•

Storage and transport temperature see

chapter "Supplement - Technical data Ambient conditions"

•

Relative humidity 20 … 85 %

Lifting and carrying

With instrument weights of more than 18 kg

(39.68 lbs) suitable and approved equipment

must be used for lifting and carrying.

4 Mounting

4.1 General instructions

Suitability for the process conditions

Make sure before mounting that all parts of the

instrument exposed to the process are suitable

for the existing process conditions.

These are mainly:

•

Active measuring component

•

Process tting

•

Process seal

Process conditions in particular are:

•

Process pressure

•

Process temperature

•

Chemical properties of the medium

•

Abrasion and mechanical inuences

You can nd detailed information on the process

conditions in chapter "Technical data" as well as

on the type label.

Suitability for the ambient conditions

The instrument is suitable for standard and

extended ambient conditions acc. to IEC/

EN 61010-1.

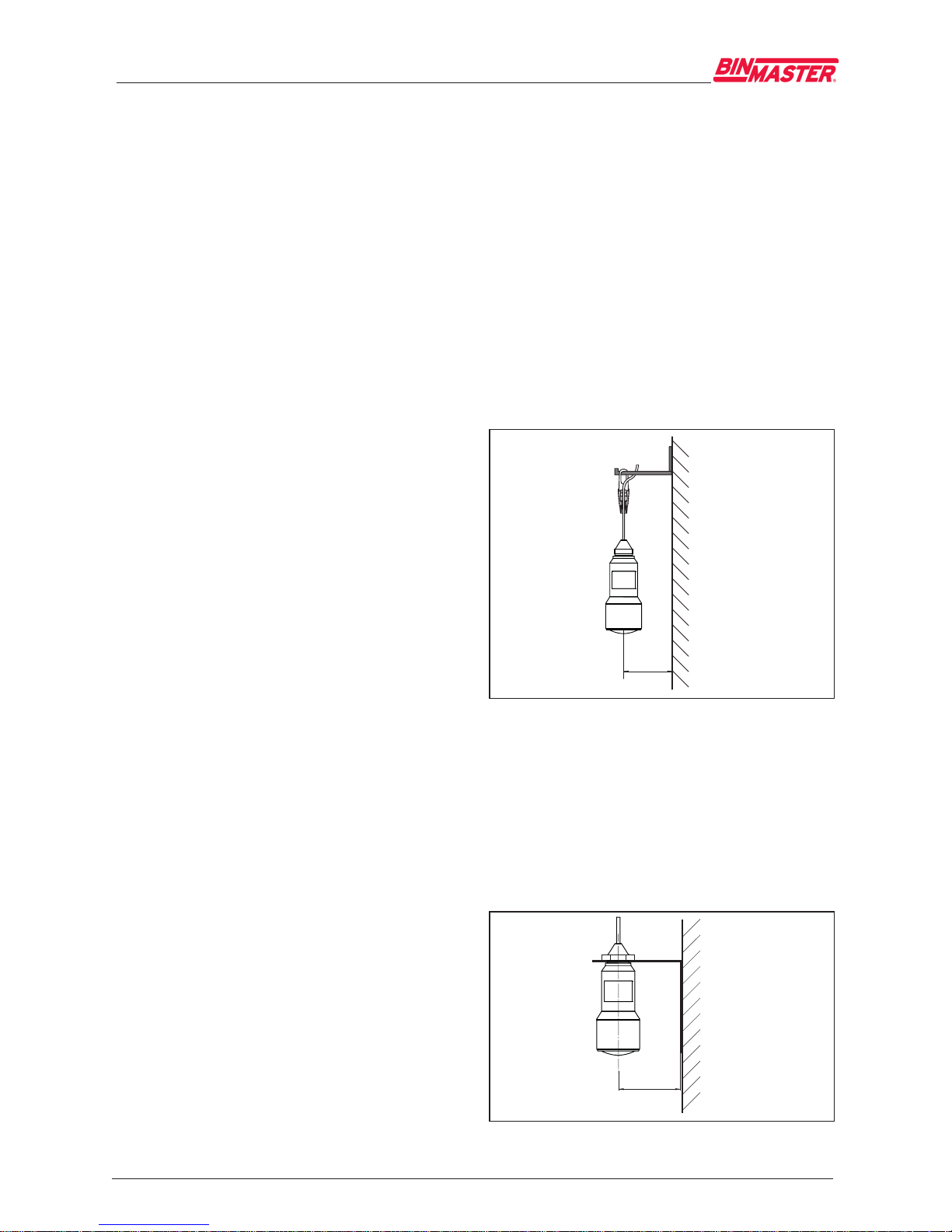

4.2 Mounting versions

Straining clamp

Most simply mount the instrument via the

straining clamp. For this purpose, the connection cable is provided with a strain relief wire of

Kevlar.

In order to avoid faulty measured values, make

sure that the sensor does not oscillate.

> 200 mm

(7.87")

Abb. 22: Mounting via a straining clamp

Mounting bracket

For a rigid mounting, a mounting bracket with

opening for thread G1½, e.g. from the VEGA

product range, is recommended. The mounting

of the sensor in the bracket is carried out via a

G1½ counter nut of plastic. Take note of chapter

"Mounting instructions" for the distance to the

wall.

> 200 mm

(7.87

")

Abb. 23: Mounting via a mounting bracket

925-0374

9

5 Connecting to power supply

NCR-21 4 … 20 mA

54408-01-190131

4.3 Mounting instructions

Polarisation

The emitted radar impulses of the radar sensor

are electromagnetic waves. The polarisation is

the direction of the electrical wave component.

By turning the instrument in the mounting strap,

the polarisation can be used to reduce the

eects of false echoes.

The position of the polarisation is in the middle

of the type label on the instrument.

1

Abb. 24: Position of the polarisation

1 Middle of the type label

Inowingmedium

Do not mount the instrument in or above the

lling stream. Make sure that you detect the

product surface, not the inowing product.

Abb.25:Mountingoftheradarsensorwithinowing

medium

5 Connecting to power

supply

5.1 Preparing the connection

Safety instructions

Always keep in mind the following safety

instructions:

•

Carry out electrical connection by trained,

qualied personnel authorised by the plant

operator

•

If overvoltage surges are expected, overvoltage arresters should be installed

Warning:

Connect only in the complete absence

of line voltage.

Voltage supply

Power supply and current signal are carried on

the same two-wire cable. The operating voltage

can dier depending on the instrument version.

The data for power supply are specied in chap-

ter "Technical data".

Provide a reliable separation between the

supply circuit and the mains circuits according

to DIN EN 61140 VDE 0140-1.

Power the instrument via an energy-limited circuit acc. to IEC 61010-1, e.g. via Class 2 power

supply unit.

Keep in mind the following additional factors

that inuence the operating voltage:

•

Lower output voltage of the power supply

unit under nominal load (e.g. with a sensor

current of 20.5 mA or 22 mA in case of fault)

•

Inuence of additional instruments in the

circuit (see load values in chapter "Technical

data")

Connection cable

The instrument is connected with standard

two-wire cable without screen. If electromagnetic interference is expected which is above the

test values of EN 61326-1 for industrial areas,

screened cable should be used.

Make sure that the cable used has the required

temperature resistance for the max. occurring

ambient temperature

5.2 Wiring plan

Wire assignment, connection cable

1

2

Abb. 26: Wire assignment in permanently connected

connection cable

1 Brown (+) and blue (-) to power supply or to the

processing system

2 Shielding

925-0374

10

6 Set up Bluetooth connection with smartphone/tablet

NCR-21 4 … 20 mA

54408-01-190131

6 Set up Bluetooth connec-

tion with smartphone/tablet

6.1 Preparations

System requirements

Make sure that your smartphone/tablet meets

the following system requirements:

•

Operating system: iOS 8 or newer

•

Operating system: Android 4.3 or newer

•

Bluetooth Smart from 4.0

Download the app "VEGA Tools" from the Apple

App Store or Google Play Store to your smartphone or tablet.

6.2 Connecting

Connecting …

Start the "VEGA Tools" app and select the function "Setup". The smartphone/tablet searches

automatically for Bluetooth-capable instruments

in the area.

The message "Searching …" is displayed.

The found instruments will be listed on the left

side of the adjustment window. The search is

continued automatically.

Select the requested instrument in the device

list.

The message "Connecting …" is displayed.

Authenticate

For the rst connection, the operating device

and the sensor must authenticate each other.

After successful authentication, the next connection functions without authentication.

iOS

During the pairing process, the following mes-

sage is displayed: "Pairing request (Bluetooth),

e.g. 12345678 wants to pair with your iPad".

Press "Pair".

Android

The coupling passes through automatically.

Enter PIN

For authentication, enter in the next menu window the 4-digit PIN.

You can nd the PIN:

•

Next to the type label on the connection

cable

•

On the supplement to the documentation

Note:

If an incorrect sensor PIN is entered,

the PIN can only be entered again after

a delay time. This time gets longer after

each incorrect entry.

The message "Waiting for authentication" is

displayed on the smartphone/tablet.

Connected

After connection, the sensor adjustment menu

is displayed on the respective adjustment

instrument.

If the connection is interrupted, e.g. due to a too

large distance between sensor and operating

device, this is displayed on the operating device.

The message disappears when the connection

is restored.

Change sensor PIN

It is recommended to change the default setting

of the sensor PIN to your own sensor PIN. To do

this, go to the menu item "Lock adjustment".

After the sensor PIN has been changed, sensor

adjustment can be enabled again. For access

(authentication) with Bluetooth, the PIN is still

eective.

6.3 Sensor parameter

adjustment

Enter parameters

The sensor adjustment menu is divided into two

halves:

On the left you'll nd the navigation section with

the menus "Setup", "Display", "Diagnosis" and

others.

The selected menu item, recognisable by the

colour change, is displayed in the right half.

925-0374

11

7 Set up Bluetooth connection with PC/notebook

NCR-21 4 … 20 mA

54408-01-190131

Abb. 28: Example of an app view - Setup sensor

adjustment

Enter the requested parameters and conrm via

the keyboard or the editing eld. The settings

are then active in the sensor.

Close the app to terminate connection.

7 Set up Bluetooth connec-

tion with PC/notebook

7.1 Preparations

System requirements

Make sure that your PC/notebook meets the

following system requirements:

•

Operating system Windows

•

DTM Collection 07/2019 or higher

•

USB 2.0 interface

•

Integrated Bluetooth LE

Activate Bluetooth connection

Activate the Bluetooth connection via the VEGA

project assistant.

Note:

Older systems do not always have an

integrated Bluetooth LE. In these cases,

a Bluetooth USB adapter is required

Activate the Bluetooth USB adapter

via the VEGA project assistant (see

supplementary instructions "Bluetooth

USB adapter").

After activating the integrated Bluetooth or the

Bluetooth USB adapter, sensors with Bluetooth

are found and created in the project tree.

7.2 Connecting

Connecting …

Select the requested sensor for the online parameter adjustment in the project tree.

Authenticate

The window "Authentication" is displayed. For

the rst connection, the operating device and

the sensor must authenticate each other. After

successful authentication, the next connection

functions without authentication.

Enter PIN

For authentication, enter in the next menu window the 4-digit PIN.

You can nd the PIN:

•

Next to the type label on the connection

cable

•

On the supplement to the documentation

Note:

If an incorrect sensor PIN is entered,

the PIN can only be entered again after

a delay time. This time gets longer after

each incorrect entry.

Connected

After connection, the sensor DTM appears.

If the connection is interrupted, e.g. due to a too

large distance between sensor and operating

device, this is displayed on the operating device.

The message disappears when the connection

is restored.

Change sensor PIN

It is recommended to change the default setting

of the sensor PIN to your own sensor PIN. To do

this, go to the menu "Additional adjustments",

menu item "PIN".

925-0374

12

8 Diagnosis, asset management and service

NCR-21 4 … 20 mA

54408-01-190131

7.3 Parameter adjustment

Prerequisites

For parameter adjustment of the instrument

via a Windows PC, the conguration software

PACTware and a suitable instrument driver

(DTM) according to FDT standard are required. The latest PACTware version as well as all

available DTMs are compiled in a DTM Collection. The DTMs can also be integrated into other

frame applications according to FDT standard.

Abb. 30: Example of a DTM view - Setup, sensor

adjustment

8 Diagnosis, asset manage-

ment and service

8.1 Maintenance

Maintenance

If the device is used properly, no special maintenance is required in normal operation.

Cleaning

The cleaning helps that the type label and markings on the instrument are visible.

Take note of the following:

•

Use only cleaning agents which do not corrode the housings, type label and seals

•

Use only cleaning methods corresponding

to the housing protection rating

8.2 Measured value and event

memory

The instrument has several memories available

for diagnostic purposes. The data remain there

even in case of voltage interruption.

Measured value memory

Up to 100,000 measured values can be stored

in the sensor in a ring memory. Each entry contains date/time as well as the respective measured value. Storable values are for example:

•

Distance

•

Filling height

•

Percentage value

•

Lin. percent

•

Scaled

•

Current value

•

Measurement reliability

•

Electronics temperature

When the instrument is shipped, the measured

value memory is active and stores distance,

measurement reliability and electronics temperature every 3 minutes.

The requested values and recording conditions

are set via a PC with PACTware/DTM or the

control system with EDD. Data are thus read out

and also reset.

Event memory

Up to 500 events are automatically stored with a

time stamp in the sensor (non-deletable). Each

entry contains date/time, event type, event description and value. Event types are for example:

•

Modication of a parameter

•

Switch-on and switch-o times

•

Status messages (according to NE 107)

•

Error messages (according to NE 107)

The data are read out via a PC with PACTware/

DTM or the control system with EDD.

Echo curve memory

The echo curves are stored with date and time

and the corresponding echo data. The memory

is divided into two sections:

Echo curve of the setup: This is used as

reference echo curve for the measurement

conditions during setup. Changes in the measurement conditions during operation or buildup

on the sensor can thus be recognized. The echo

curve of the setup is stored via:

•

PC with PACTware/DTM

•

Control system with EDD

•

Display and adjustment module

Further echo curves: Up to 10 echo curves

can be stored in a ring buer in this memory

section. Additional echo curves are stored via:

925-0374

13

8 Diagnosis, asset management and service

NCR-21 4 … 20 mA

54408-01-190131

•

PC with PACTware/DTM

•

Control system with EDD

8.3 Asset Management function

The instrument features self-monitoring and

diagnostics according to NE 107 and VDI/

VDE 2650. In addition to the status messages

in the following tables there are more detailed

error messages available under the menu item

"Diagnostics" via app or PACTware/DTM.

Status messages

The status messages are divided into the

following categories:

•

Failure

•

Function check

•

Out of specication

•

Maintenance requirement

and explained by pictographs:

41 2 3

Abb. 31: Pictographs of the status messages

1 Failure - red

2 Outofspecication-yellow

3 Function check - orange

4 Maintenance - blue

Failure: Due to a malfunction in the instrument,

a fault message is output.

Function check: The instrument is being

worked on, the measured value is temporarily

invalid (for example during simulation).

Outofspecication: The measured value is

unreliable because an instrument specication

was exceeded (e.g. electronics temperature).

Maintenance: Due to external inuences, the

instrument function is limited. The measurement

is aected, but the measured value is still valid.

Plan in maintenance for the instrument because

a failure is expected in the near future (e.g. due

to buildup).

Information:

The status messages are always active.

It cannot be deactivated by the user.

Failure

Code

Text mes-

sage

Cause Rectication

F013

no measured

value available

•

Sensor does not

detect an echo

during operation

•

Antenna system

dirty or defective

•

Check or correct

installation and/

or parameter

settings

•

Clean or

exchange process component

or antenna

F017

Adjustment

span too

small

•

Adjustment not

within specication

•

Change adjustment according

to the limit

values (dierence between

min. and max.

≥ 10 mm)

F025

Error in the li-

nearization

table

•

Index markers

are not continuously rising,

for example

illogical value

pairs

•

Check linearisation table

•

Delete table/

Create new

F040

Error in the

electronics

•

Hardware defect• Exchanging the

electronics

•

Send instrument

for repair

F080

•

General software error

•

Disconnect operating voltage

briey

F105

Determine

measured

value

•

The instrument

is still in the

start phase, the

measured value

could not yet be

determined

•

Wait for the end

of the switch-on

phase

•

Duration up to

approx. 3 minutes depending

on the version

and parameter

settings

F113

Communica-

tion error

•

EMC interference

•

Remove EMC

inuences

F125

Impermissib-

le electronics

temperature

•

Temperature of

the electronics

in the non-

specied range

•

Check ambient

temperature

925-0374

14

8 Diagnosis, asset management and service

NCR-21 4 … 20 mA

54408-01-190131

Code

Text mes-

sage

Cause Rectication

F260

Error in the

calibration

•

Error in the

calibration

carried out in the

factory

•

Error in the

EEPROM

•

Exchanging the

electronics

•

Send instrument

for repair

F261

Error in the

conguration

•

Error during

setup

•

False signal

suppression

faulty

•

Error when

carrying out a

reset

•

Repeat setup

•

Repeat reset

F264

Installation/

Setup error

•

Adjustment not

within the vessel

height/measuring range

•

Max. measuring

range of the

instrument not

sucient

•

Check or correct

installation and/

or parameter

settings

•

Use an instrument with bigger

measuring

range

F265

Measure-

ment function

disturbed

•

Sensor no longer carries out a

measurement

•

Operating voltage too low

•

Check operating

voltage

•

Carry out a reset

•

Disconnect operating voltage

briey

Tab. 8: Error codes

and text messages,

information on

causes as well as

corrective measures

Function check

Code

Text mes-

sage

Cause Rectication

C700

Simulation

active

•

A simulation is

active

•

Finish simulation

•

Wait for the

automatic end

after 60 mins.

Tab. 9: Error codes

and text messages,

information on

causes as well as

corrective measures

Outofspecication

Code

Text mes-

sage

Cause Rectication

S600

Impermissib-

le electronics

temperature

•

Temperature of

the electronics

in the non-

specied range

•

Check ambient

temperature

S601

Overlling

•

Danger of ves-

sel overlling

•

Make sure

that there is no

further lling

•

Check level in

the vessel

Tab. 10: Error codes

and text messages,

information on

causes as well as

corrective measures

Maintenance

Code

Text mes-

sage

Cause Rectication

M500

Error during

the reset "delivery status"

•

The data could

not be restored

during the reset

to delivery

status

•

Repeat reset

•

Load XML le

with sensor data

into the sensor

M501

Error in the

non-active linearisation

table

•

Hardware error

EEPROM

•

Send instrument

for repair

M502

Error in the

diagnostics

memory

•

Hardware error

EEPROM

•

Send instrument

for repair

M503

Measu-

rement

reliability too

low

•

The echo/noise

ratio is too small

for reliable

measurement

•

Check installation and process

conditions

•

Clean the

antenna

•

Change polarisation direction

M504

Error at a

device interface

•

Hardware defect• Check connec-

tions

•

Send instrument

for repair

925-0374

15

8 Diagnosis, asset management and service

NCR-21 4 … 20 mA

54408-01-190131

Code

Text mes-

sage

Cause Rectication

M505

No echo

available

•

Level echo can

no longer be

detected

•

Clean the

antenna

•

Remove possible false echoes

•

Optimize sensor

position and

orientation

Tab. 11: Error codes

and text messages,

information on

causes as well as

corrective measures

8.4 Rectify faults

Reaction when malfunction occurs

The operator of the system is responsible for

taking suitable measures to rectify faults.

Procedureforfaultrectication

The rst measures are:

•

Evaluation of fault messages via the adjustment device

•

Checking the output signal

•

Treatment of measurement errors

Further comprehensive diagnostics options

are available with a PC with PACTware and the

suitable DTM. In many cases, the reasons can

be determined in this way and faults rectied.

Check the 4 … 20 mA signal

Connect a multimeter in the suitable measuring

range according to the wiring plan. The following

table describes possible errors in the current

signal and helps to eliminate them:

Error Cause Rectication

4 … 20 mA

signal not

stable

•

Fluctuating measured value

•

Set damping

Error Cause Rectication

4 … 20 mA

signal missing

•

Electrical connection faulty

•

Check connection, correct, if

necessary

•

Voltage supply

missing

•

Check cables for

breaks; repair if

necessary

•

Operating

voltage too low,

load resistance

too high

•

Check, adapt if

necessary

Current signal greater

than 22 mA,

less than

3.6 mA

•

Sensor electronics defective

•

Exchange the

instrument or

send it in for

repair

Reactionafterfaultrectication

Depending on the reason for the fault and the

measures taken, the steps described in chapter

"Setup" must be carried out again or must be

checked for plausibility and completeness.

24 hour service hotline

Should these measures not be successful,

please call in urgent cases the VEGA service

hotline under the phone no.

+49 1805 858550.

The hotline is also available outside normal

working hours, seven days a week around the

clock.

Since we oer this service worldwide, the

support is provided in English. The service itself

is free of charge, the only costs involved are the

normal call charges.

8.5 How to proceed if a repair is

necessary

You can nd an instrument return form as

well as detailed information about the procedure in the download area of our homepage:

www.vega.com. By doing this you help us carry

out the repair quickly and without having to call

back for needed information.

In case of repair, proceed as follows:

•

Print and ll out one form per instrument

•

Clean the instrument and pack it damageproof

•

Attach the completed form and, if need

be, also a safety data sheet outside on the

packaging

925-0374

16

9 Dismount

NCR-21 4 … 20 mA

54408-01-190131

•

Ask the agency serving you to get the

address for the return shipment. You

can nd the agency on our home page

www.vega.com.

9 Dismount

9.1 Dismounting steps

Warning:

Before dismounting, be aware of

dangerous process conditions such as

e.g. pressure in the vessel or pipeline,

high temperatures, corrosive or toxic

products etc.

Take note of chapters "Mounting" and "Connecting to voltage supply" and carry out the listed

steps in reverse order.

9.2 Disposal

The instrument consists of materials which can

be recycled by specialised recycling companies.

We use recyclable materials and have designed

the electronics to be easily separable.

WEEE directive

The instrument does not fall in the scope of the

EU WEEE directive. Article 2 of this Directive exempts electrical and electronic equipment from

this requirement if it is part of another instrument

that does not fall in the scope of the Directive.

These include stationary industrial plants.

Pass the instrument directly on to a specialised

recycling company and do not use the municipal

collecting points.

If you have no way to dispose of the old instrument properly, please contact us concerning

return and disposal.

925-0374

17

10 Supplement

NCR-21 4 … 20 mA

54408-01-190131

10 Supplement

10.1 Technical data

General data

Materials, wetted parts

Ʋ Antenna PP

Materials, non-wetted parts

Ʋ Housing Plastic PBT (Polyester)

Ʋ Connection cable PUR

Ʋ Type label support on cable PE hard

Thread on the housing

G1½ cylindrical (ISO 228 T1)

Weight

Ʋ Instrument 0.7 kg (1.543 lbs)

Ʋ Connection cable 0.1 kg/m (0.07 lbs/ft)

Input variable

Measured variable The measured quantity is the distance between the lo-

wer antenna side and the product surface. The reference

plane for the measurement is also the lower antenna

side.

2

3

1

Abb. 32: Data of the input variable

1 Reference plane

2 Sensor length

3 Max. measuring range

Max. measuring range 8 m (26.25 ft)

Output variable

Output signal

4 … 20 mA

Range of the output signal 3.8 … 20.5 mA (default setting)

Signal resolution 0.3 µA

Resolution, digital 1 mm (0.039 in)

Fault signal, current output (adjustable) mA-value unchanged 20.5 mA, 22 mA, < 3.6 mA

Max. output current 22 mA

Load See load resistance under Power supply

Starting current

≤ 3.6 mA; ≤ 10 mA for 5 ms after switching on

925-0374

18

10 Supplement

NCR-21 4 … 20 mA

54408-01-190131

Damping (63 % of the input variable),

adjustable

0 … 999 s

Deviation (according to DIN EN 60770-1)

Process reference conditions according to DIN EN 61298-1

Ʋ Temperature +18 … +30 °C (+64 … +86 °F)

Ʋ Relative humidity 45 … 75 %

Ʋ Air pressure 860 … 1060 mbar/86 … 106 kPa (12.5 … 15.4 psig)

Installation reference conditions

Ʋ Min. distance to internal installations > 200 mm (7.874 in)

Ʋ Reector Flat plate reector

Ʋ False reections Biggest false signal, 20 dB smaller than the useful signal

Deviation with liquids ≤ 5 mm (meas. distance > 0.5 m/1.640 ft)

Non-repeatability

5)

≤ 1 mm

Deviation with bulk solids The values depend to a great extent on the application.

Binding specications are thus not possible.

0,5 m (1.640 ft)

10 mm (0.394 in)

- 10 mm (- 0.394 in)

5 mm (0.197 in)

- 5 mm (- 0.197 in)

0

1 2

Abb. 33: Deviation under reference conditions

1 Reference plane

2 Measuring range

Characteristics and performance data

Measuring frequency

K-band (26 GHz technology)

Measuring cycle time approx. 450 ms

Step response time

6)

≤ 3 s

Beam angle

7)

10°

Emitted HF power

8)

Ʋ Average spectral transmission power

density

-34 dBm/MHz EIRP

Ʋ Max. spectral transmission power

density

+6 dBm/50 MHz EIRP

Ʋ Max. power density at a distance of

1 m

< 1 µW/cm²

5)

Already included in the meas. deviation

6)

Time span after a sudden distance change of max. 0.5 m until the output signal reaches for the rst time 90% of

the nal value (IEC 61298-2).

7)

Outside the specied beam angle, the energy level of the radar signal is 50% (-3 dB) less.

8)

EIRP: Equivalent Isotropic Radiated Power

925-0374

19

10 Supplement

NCR-21 4 … 20 mA

54408-01-190131

Ambient conditions

Storage and transport temperature

-40 … +80 °C (-40 … +176 °F)

Process conditions

For the process conditions, please also note the specications on the type label. The lower value

always applies.

Vessel pressure

-1 … 2 bar (-100 … 200 kPa/-14.5 … 29.0 psig)

Process temperature -40 … +60 °C (-40 … +140 °F)

Vibration resistance acc. to EN/

IEC 60271-3-4

Class 4M5 (1g) in the range of 5 … 200 Hz

Impact resistance acc. to IEC 62262

Ʋ ≥ -10 °C (+14 °F) IK08

Ʋ < -10 °C … ≥ -40 °C

(< +14 °F … ≥ -40 °F)

IK07

Electromechanical data - version IP 66/IP 68 (2 bar)

Cable entry IP 68 cable gland

Connection cable

Ʋ Conguration two wires, one Kevlar cable, braiding, cover

Ʋ Wire cross-section 0.5 mm² (AWG 20)

Ʋ Length 12 m (39.37 ft)

Ʋ Min. bending radius 25 mm (0.984 in) with 25 °C (77 °F)

Ʋ Diameter approx. 8 mm (0.315 in)

Ʋ Wire isolating and cable cover PUR

Ʋ Colour Black

Ʋ Fire protection classication UL94-V0

Bluetooth interface

Standard Bluetooth smart

Eective range

25 m (82.02 ft)

Voltage supply

Operating voltage

9.6 … 35 V DC

Reverse voltage protection Integrated

Permissible residual ripple

Ʋ for 12 V< UN < 14 V ≤ 0.7 Ve (16 … 400 Hz)

Ʋ for 18 V< UN < 35 V ≤ 1.0 Ve (16 … 400 Hz)

Load resistor

Ʋ Calculation (UB - U

min

)/0.022 A

Ʋ Example - Non-Ex instrument with

UB= 24 V DC

(24 V - 12 V)/0.022 A = 545 Ω

Electrical protective measures

Protection rating

IEC 60529 IP 66/IP 68 (2 bar), NEMA Type 6P

925-0374

20

10 Supplement

NCR-21 4 … 20 mA

54408-01-190131

Protection rating (IEC 61010-1) III

10.2 Radio astronomy stations

Certain requirements for the use outside closed vessels result from the radio license for Europe

of NCR-21. You can find the requirements in chapter "Radio license for Europe". Some of these

requirements refer to radio astronomy stations. The following table states the geographic

positions of radio astronomy stations in Europe:

Country Name of the Station Geographic Latitude Geographic Longitude

Finland Metsähovi 60°13'04'' N 24°23'37'' E

Tuorla 60°24'56'' N 24°26'31'' E

France Plateau de Bure 44°38'01'' N 05°54'26'' E

Floirac 44°50'10'' N 00°31'37'' W

Germany Eelsberg 50°31'32'' N 06°53'00'' E

Hungary Penc 47°47'22'' N 19°16'53'' E

Italy Medicina 44°31'14" N 11°38'49" E

Noto 36°52'34" N 14°59'21" E

Sardinia 39°29'50" N 09°14'40" E

Poland Krakow- Fort Skala 50°03'18" N 19°49'36" E

Russia Dmitrov 56°26'00" N 37°27'00" E

Kalyazin 57°13'22" N 37°54'01" E

Pushchino 54°49'00" N 37°40'00" E

Zelenchukskaya 43°49'53" N 41°35'32" E

Spain Yebes 40°31'27" N 03°05'22" W

Robledo 40°25'38" N 04°14'57" W

Switzerland Bleien 47°20’26" N 08°06’44" E

Sweden Onsala 57°23’45" N 11°55’35" E

UK Cambridge 52°09'59" N 00°02'20" E

Darnhall 53°09'22" N 02°32'03" W

Jodrell Bank 53°14'10" N 02°18'26" W

Knockin 52°47'24" N 02°59'45" W

Pickmere 53°17'18" N 02°26'38" W

925-0374

21

10 Supplement

NCR-21 4 … 20 mA

54408-01-190131

10.3 Dimensions

NCR-21

9,5 mm

(0.37")

243 mm

(9.57")

43 mm

(1.69")

18 mm

(0.71")

ø 72 mm

(2.84")

ø 8 mm

(0.32")

G1½

ø 93 mm

(3.66")

Abb. 34: Dimensions NCR-21

925-0374

22

10 Supplement

NCR-21 4 … 20 mA

54408-01-190131

10.4 Industrial property rights

VEGA product lines are global protected by industrial property rights. Further information see

www.vega.com.

10.5 Hash function acc. to mbed TLS

mbed TLS: Copyright (C) 2006-2015, ARM Limited, All Rights Reserved SPDX-License-Identifier:

Apache-2.0

Licensed under the Apache License, Version 2.0 (the "License"); you may not use this

file except in compliance with the License. You may obtain a copy of the License at

http://www.apache.org/licenses/LICENSE-2.0.

Unless required by applicable law or agreed to in writing, software distributed under the License is

distributed on an "AS IS" BASIS, WITHOUT WARRANTIES OR CONDITIONS OF ANY KIND,

either express or implied. See the License for the specific language governing permissions and

limitations under the License.

10.6 Trademark

All the brands as well as trade and company names used are property of their lawful proprietor/

originator.

925-0374

23

Notes

NCR-21 4 … 20 mA

54408-01-190131

925-0374

Printing date:

BinMaster

7201 N 98th St

Lincoln, NE 68507

USA

54408-01-190131

All statements concerning scope of delivery, application, practical use and operating

conditions of the sensors and processing systems correspond to the information

available at the time of printing.

Subject to change without prior notice

© VEGA Grieshaber KG, Schiltach/Germany 2019

Phone: 402-434-9102

Fax: 402-434-9133

E-mail: info@binmaster.com

www.binmaster.com

925-0374

Loading...

Loading...