Operation Manual:

MODEL BBR PRESSURE/SIPHON FEED

HAND GUN

Important:

Read and follow all instructions and SAFETY PRECAUTIONS

before using this equipment

This is a production hand spray gun suitable for use with solvent and water based coating materials. The performance of this gun is

achieved by a range of air nozzles combined with large, smooth flowing air passages and an oversize air valve which gives a lower

pressure drop. The gun is designed to be used with a siphon cup or material feed hose. Fluid passages are all stainless steel as an

option.

IMPORTANT: These guns are not designed for use with highly corrosive or highly abrasive coating material and if used with such

materials it must be expected that the need for thorough cleaning and/or the necessity for replacement parts will be increased. If there

is any doubt regarding the suitability of a specific material, advise what material is to be used and/or submit a sample for test.

DESCRIPTION

SB-E-A1-21-1

©ITW BINKS 1999

Body: Aluminium alloy polished and anodised.

Air Nozzle: Brass Nickel Plated with taper location on material nozzle to ensure concentricity.

Material Nozzle: Stainless steel, located in body and in air nozzle by tapers.

Needle Valve: Stainless Steel / Delrin adjustable .

Trigger: Pressed steel for durability & polished

Air Valve: PTFE

Springs: All springs are stainless steel.

Connections: Air inlet connection is 1/4” BSP and fluid connection is 3/8” BSP (NPS available)(All 60oCone).

Finish: Gun body red anodised. All brass parts are nickel plated.

Weight: 0.57 kg (1Ib. 4 oz).

Dimensions: Less Cup (17. 5 X 3.65 X19 cm) (7 long X 1 1/2wide x 71/2” high).

Max Working Pressure: Air & Fluid 10 bar (145 psi)

Max Fluid Temp: 500C (1220 F)

SPECIFICATIONS

GROUP A

Normal range of finishing materials from thin spirits to heavy enamels.

Figure in ( ) brackets is air consumption in c.f.m at 4.8 bar (70 psi).

Figure in [ ] brackets is air consumption in m3/ hr at 4.8 bar (70 psi).

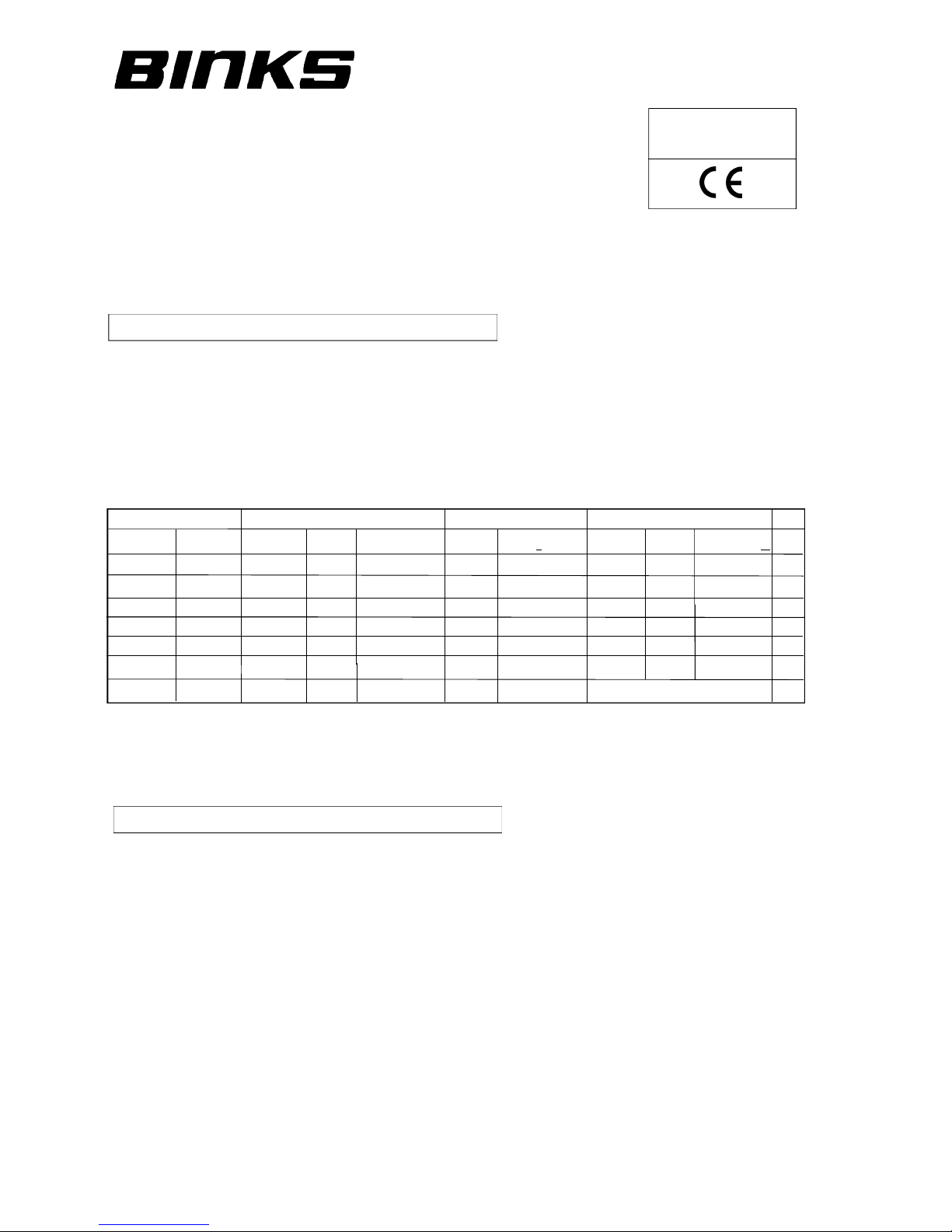

SPRAYGUN MATERIAL NOZZLE NEEDLE AIR NOZZLE

PART No THREAD PART NO CODE BORE PART NO MAT

L

PART NO CODE AIR CONS NGRP

102506 BSP 200500 A047 0.046”,1.15mm 188318 ST ST/DELRIN 200607 AP21 (23.0) [38.6] A

102507 BSP 200500 A047 0.046”,1.15mm 188318 ST ST/DELRIN 200604 AP19 (21.0) [35.3] A

102516 BSP 200501 A061 0.059”,1.5mm 188318 ST ST/DELRIN 200604 AP19 (21.0) [35.3] A

102517 BSP 200501 A061 0.059”,1.5mm 188318 ST ST/DELRIN 200613 AS20 (21.0) [35.3] A

102520 BSP 200502 A072 0.073”,1.85mm 188318 ST ST/DELRIN 200601 AS17 (17) [28.6] A

102526 BSP 200502 A072 0.073”,1.85mm 188318 ST ST/DELRIN 200613 AS20 (21) [35.3] A

102853 NPS 200501 A061 0.059”,1.5mm 188318 ST ST/DELRIN NO AIR CAP A

Chart 1 Ordering Information :

2 ©ITW BINKS 1999 – SB-E- A1-21

Parts list

Ref. No. Order No. Description Qty.

1 18 00 80 NEEDLE STEM 1

2* 16 02 85 SPRING (33 mm) 2

3* 16 03 20 SPRING (27 mm) 1

4* 16 16 07 O -RING 2

5* 16 60 00 CIRCLIP 1

6 18 02 07 AIR CONTROL SPINDLE 1

7* 18 02 08 O -RING 1

8 18 02 22 TRIGGER SCREW 1

9 18 02 27 GUN BRUSH (NOT SHOWN) 1

10 18 02 31 AIR CONNECTION 1

11 18 28 27 TRIGGER STUD 1

12 18 47 88 SPANNER (NOT SHOWN) 1

13 18 79 85 NEEDLE CONTROL KNOB 1

14 18 79 86 AIR CONTROL KNOB 1

15 18 79 87 PACKING SCREW 1

16 18 79 88 TRIGGER SPOOL 1

17 18 79 90 AIR VALVE HOUSING 1

18 18 79 91 NEEDLE LOCKNUT 1

AAA19 18 79 92 NEEDLE ADJUSTING NUT 1

Ref. No Order No. Description Qty.

20* 18 79 94 AIR VALVE SPINDLE 1

21 18 79 95 AIR CONTROL SEAL HOUSING 1

22 18 80 14 TRIGGER 1

23 18 81 38 SPANNER (NOT SHOWN) 1

24 18 81 51 AIR CONTROL SPINDLE ASSY 1

25 18 82 33 AIR CONTROL ASSY 1

26 18 82 57 PLUG 1

27 18 83 28 188329 C/W PAINT REGULATOR 1

28 18 83 29 FLUID INLET (ST ST) 1

29 18 83 91 O-RING HOUSING (ST ST) 1

30* 18 97 36 PACKING 2

31 19 10 96 O-RING HOUSING PP 1

32 20 00 87 GUN BODY 1

33 20 11 16 HEAD INSERT 1

34 20 41 41 RETAINING RING 1

35 20 64 72 FLUID INLET (NICKEL PLATED) 1

36 see table 1 AIR CAP 1

37 see table 1 FLUID NOZZLE 1

38 18 83 18 NEEDLE ASSY 1

Recommended spares kit with quantities based on 12 months supply with meduim wear materials 25 02 58. Items shown on parts

list by *

©ITW BINKS 1999 –SB-E- A1-21 3

CONNECTING GUN TO AIR HOSE

Gun should be connected by a suitable length of 5/16” (7.94 mm) bore air hose fitted with a connector with a 1/4” B.S.P union nut at

gun end. It is recommended that the air supply be filtered to 50 microns maximum, however alternative air preparation may be

required for special applications.

CONTROLLING THE MATERIAL FLOW

The rate of flow is adjusted by the Material Control knob (13) which acts as an adjustable stop limiting the travel of the Material

Needle Valve. Turning it clockwise will reduce the rate of flow and anti clockwise will increase flow. When used with a gravity cup an

increase in air pressure will increase the rate of flow.

ADJUSTMENT OF MATERIAL NEEDLE VALVE

The needle valve assembly is adjustable for length by means of the needle locking screw and needle end assembly. These should

be adjusted so that when the trigger is in contact with the air valve stem there is about 1/32” (.79 mm) clearance between the trigger

and the needle assembly . In no circumstances must the needle valve open before the air valve.

CONTROLLING THE FAN SPRAY

The fan spray is controlled by means of the Air Control Assembly (25) Turning this control clockwise until it is closed will give a

round spray; turning it anti-clockwise will widen the spray into a fan shape. The fan spray can be turned anywhere through 360 by

rotating the Air Nozzle (36) relative to the gun. To effect this - slacken retainer ring, position Nozzle (34) then tighten retainer ring.

CONNECTING GUN TO MATERIAL HOSE

Gun should be connected by a suitable length of 3/8” bore (9.5 mm) material hose fitted with a connector with a 3/8“ B.S.P union nut

at the gun end1/4” (6.35 mm) bore hose is recommended for use with low viscosity materials. Fluid hoses of different materials are

available for special fluids.

CONNECTING GUN TO SIPHON CUPS

The union nut of the cup should be attached to the material connection of the gun and firmly tightened. It is important that there is no

leakage at this point. The siphon pipe should be positioned at the front of the gun. i.e under the nozzles, and the vent hole in the cup

lid positioned under the trigger.

CONNECTING GUN TO PRESSURE CUPS

Attach an air hose from a supply point to the inlet connection of the pressure cup. The air outlet of the cup should then be

connected with an air hose to the air inlet of the spraygun. Connect the pressure cup fluid outlet with a suitable fluid hose to the

spraygun fluid inlet.

Air pressure to the gun should be regulated in line after the pressure cup. The paint flow through the spraygun is regulated by the

air pressure set on the cup regulator, combined with the spraygun fluid tip size and needle setting. (always read instructions

supplied with pressure cup prior to use).

OPERATION

4 © ITW LTD 1994 – SB-E-2-252-B

SAFETY WARNINGS

Solvents and coating materials can be highly flammable or combustible, especially when sprayed.

• Work stations must be provided with adequate ventilation/exhaust to prevent the build-up of flammable vapours.

• Smoking and naked flames must not be allowed in the spraying or mixing areas.

• Fire extinguishing equipment must be provided in the spraying and mixing areas.

Users must comply with all local and national codes of practice and insurance company requirements governing ventilation, fire

precautions, operation, maintenance and housekeeping of work stations.

HALOGENATED HYDROCARBON SOLVENTS - for example 1,1,1-Trichloroethane and Methylene Chloride can chemically

react with aluminium and galvanised or zinc coated parts and cause an explosion hazard. Read the label and data sheet of the

material you intend to spray.

DO NOT USE SOLVENTS OR COATING MATERIALS CONTAINING HALOGENATED HYDROCARBONS WITH THIS

EQUIPMENT.

STATIC ELECTRICITY - is generated by fluid moving through pipes and hoses. A static spark, capable of igniting certain

solvents and coating materials, could be produced by high fluid flow rates. To prevent the risk of fire or explosion, earth

continuity to the spray equipment and object being sprayed should be maintained.

TOXIC VAPOURS - when sprayed, certain materials may be poisonous, create irritation or otherwise be harmful to health.

Always read carefully all labels and safety/performance data for the material being sprayed and follow any recommendations.

IF IN DOUBT, CONSULT THE MATERIAL SUPPLIER.

• The use of respiratory protective equipment is recommended at all times when spraying. The type of respiratory protective

equipment used must be compatible with the material being sprayed and the level of concentration.

• Always wear eye protection when spraying or cleaning the equipment.

• Gloves must be worn for spraying or cleaning the equipment when certain coating materials and solvents are used.

Personnel should be given adequate training in the safe use and maintenance of this equipment. Training courses on all

aspects of the equipment are available. For details contact your local representative. The instructions and safety precautions

contained in this literature and the literature supplied with the coating material should be read and understood before the

equipment is used.

• All spray guns project particles at high velocity and must never be aimed at any part of the body.

• Never exceed the recommended safe working pressures for any of the equipment used.

• The fitting of non-recommended or non-original accessories or spare parts may create hazardous conditions.

• Before dismantling the equipment for cleaning or maintenance, all pressures, air and material, must be isolated and

released.

The disposal of non-metallic materials must be carried out in an approved manner. Burning may generate toxic fumes. The

removal of waste solvents and coating materials should be carried out by an authorised local waste disposal service.

The materials used in the construction of this equipment are (bearing in mind the warning on Halogenated Hydrocarbons)

solvent resistant enabling the equipment to be cleaned using gun washing machines. However, this equipment must not be left

inside the gun washing machine for prolonged periods of time after the automatic cleaning cycle has been completed. The

solvents used in the gun washing machine should be regularly checked to ensure that the equipment is not flushed through with

contaminated material. Follow the recommendations of the machine manufacturer.

The continuous A-weighted sound pressure level of this spray gun may exceed 85 dB(A) depending on the air cap/nozzle setup being used. Sound levels are measured using an impulse sound level meter and analyser, when the gun is being used in a

normal spraying application. Details of actual noise levels produced by the various air cap/nozzle set-ups are available on

request.

Spray equipment using high operating pressures may be subject to recoil forces, under certain circumstances such forces could

result in repetitive strain injury to the operator

OPERATING

NOISE LEVELS

MISUSE

TRAINING

PERSONAL PROTECTIVE EQUIPMENT

FIRE AND EXPLOSION

SB-E-2-252-B – © ITW LTD 1994 5

CLEANING GUN USED WITH SYPHON CUP OR MATERIAL SUPPLY HOSE

CUP - Unscrew the cup empty and rinse out carefully with thinners, place clean thinners in the cup and spray this through the

gun until it is clean, then blow air through the gun to dry it.

MODE - Disconnect supply hose at Fluid Inlet, reconnect a supply of clean solvent. Spray through the gun until clean, then

disconnect solvent and replace with an air supply and blow through until dry.

EVERY DAY AFTER CLEANING PLACE A DROP OF OIL IN THE FOLLOWING:

1) Trigger stud.

2) Material needle valve at material packing screw.

3) Air valve stem at gun body.

4) Material needle valve guide at gun body.

NEVER IMMERSE GUN IN SOLVENTS. DO NOT USE SILICONE OILS OR GREASES.

FAULTY SPRAY

This can be caused by improper cleaning, dried material around the material nozzle tip or in the air nozzle. Soak these parts in

thinners that will soften the dried material and remove with a brush or cloth.

NEVER USE METAL INSTRUMENTS TO CLEAN THE AIR OR MATERIAL NOZZLES. THESE PARTS ARE CAREFULLY

MACHINED AND ANY DAMAGE TO THEM WILL CAUSE A FAULTY SPRAY.

If either the Air Nozzle (36) or Material Nozzle (37) are damaged, these parts must be replaced before a perfect spray can be

obtained.

INTERMITTENT SPRAY.

If the spray flutters, it is caused by one of the following faults: -

1) Insufficient material available. Check supply and replenish if necessary.

2) Loose Material Nozzle (37 ) Tighten but without using undue force.

bb

3) Leakage at Material Needle Valve Packing (30) Tighten or replace Material Needle Valve Packing.

4) Cup connection insufficiently tight, or dirt on cone faces. Correct as necessary.

5) Air vent in cup lid blocked . Remove lid and clear obstruction. Replace lid.

AIR LEAK AT AIR VALVE SPINDLE.

This could be caused by a worn Valve Spindle (20) or Spindle Seals (4) . Remove knob (13) Spring (2) and withdraw needle

assembly (38). Unscrew Valve housing (17) and all valve components can be removed , seals (4), Springs (2) & (3), Seal

housings (31) & (29) and Valve Spindle (20). Replace seals (4) and valve spindle (20) prior to re-assembly which is a reverse of

the above procedure.

Note: ensure Springs (2) and (3) and seal housings (31) and (29) are assembled in the correct order.

AIR LEAKING THROUGH THE GUN

This could be caused by dirt on the Air Valve seat or a damaged air valve which is part of the Spindle (20). Replace the Spindle

(20) and at the same time Spindle Seals (4) as described above in “Air leak at Air Valve Spindle”.

PAINT LEAKING AT NEEDLE GLAND SEAL

Tighten Material Packing Screw (15), do not overtighten as this may cause the needle to stick. To replace Seal unscrew

Material Needle Control knob (13) , remove Material Spring (2) and Material Needle (38). Unscrew Material Packing Screw

(15) and take out old packing.(30)x 2) Refit with Packing (30)x 2) then replace Material Packing Screw, Needle, Spring and

knob then adjust Packing Screw to seal correctly.

MAINTENANCE & FAULT FINDING

AIR HOSE AND CONNECTIONS

17 00 04

5

/16” Bore P.V.C Lined Terylene Reinforced Air Hose.- Specify Length required.

18 42 12

1

/4” BSP(F) Hose Connector

19 16 68 QR Male Stem 1/4” BSP (F)

19 16 47 QR Male Stem 1/4” BSP (M)

19 16 46 QR Female1/4” BSP (M)

FLUID HOSE AND CONNECTIONS

17 00 74

3

/8” Bore nylon lined branded rubber hose

18 42 03

3

/

8 “

BSP (F) Hose Connector

20 11 20 QR Male Stem 3/8” BSP (F) ST.ST

18 39 64 QR Female Body 3/8” BSP (M)

CUPS

10 53 03 EZ2 SIPHON CUP (1 LITRE)

10 53 46 AS 105303 PLUS FILTER

10 53 04 PRESSURE CUP 2 QUART

10 53 08 PRESSURE CUP 2 LITRE C/W HOSES

10 53 60 PRESSURE CUP 2 LITRE REMOTE

10 53 62 PRESSURE CUP 1 1/2LITRE CLASSIC ST.ST.

10 54 33 PRESSURE CUP ST.ST

10 54 28 PRESSURE CUP 2.2 QUART STEADI-GRIP

AIR FILTER AND REDUCING VALVE

10 70 18 V5000 Filter Regulator 2 x 1/4” BSP outlet.

SPARES KIT

250258 See Parts List for included items shown by *

AIR FED VISORS

10 70 30 Visor and Carbon Filter/ Regulator complete with Breather tube.

10 70 29 As 107030 plus Coalescing Filter, Hoses and Spare Elements.

ACCESSORIES

6 © ITW LTD 1994 – SB-E-2-252-B

SB-E-2-252-B – © ITW LTD 1994 7

NOTES

ITW LTD JANUARY 2001 ©ITW BINKS 1999 – SB-E-A1-21

Ringwood Road

Bournemouth BH11 9LH England

Tel. No. (01202) 571111

Telefax No. (01202) 581940

Loading...

Loading...