Product Description

Safety Instructions

Operating Instructions

for

BINKS

Airless Model HP 6/60

These operating instructions are part of the equipment. Please read and follow

all instructions and safety precautions before using the equipment. Disregarding

can causes injuries on people and/or damages on the unit.

ITW Finishing Systems and Products

Ringwood Road, Bournemouth BH11 9LH, England

Phone +44 (0) 1202 / 571111 Telefax +44 (0) 1202 / 581940

Internet www.itwifeuro.com

Correspondance address:

ITW Oberflächentechnik GmbH & Co.

Justus-von-Liebig-Straße 31, 63128 Dietzenbach, Deutschland

Telefon +49 (0) 6074 / 403-1 Telefax +49 (0) 6074 / 403-281

Internet www.itwifeuro.com

Correspondance address:

ITW Surfaces et Finitions

163-171 Avenue des auréats BP 1453, 26014 Valence Cedex France

Téléphone +33 (0) 4 7575 2700 Fax +33 (0) 4 7575 2799

Internet www.itwifeuro.com

Edition 08/07

2

3

TABLE OF CONTENTS

1. DESIGNATED USE................................................................................................... 3

2. BRIEF DESCRIPTION .............................................................................................. 4

3. TECHNICAL DATA ................................................................................................... 8

4. SAFETY .............................................................................................................. 9

4.1 Principle of operation; intended use ..................................................................... 9

4.2 Safe working conditions ......................................................................................... 9

4.3 Particular danger spots .......................................................................................... 11

5. START UP AND OPERATION .................................................................................. 12

5.1 Grounding the BINKS airless pump....................................................................... 12

5.2 Preparing to start up the BINKS airless pump ...................................................... 12

5.3 Rinsing the BINKS airless pump ............................................................................ 13

5.4 Preparing and adjusting the spray material .......................................................... 14

5.5 Start-up .............................................................................................................. 14

5.6 Work stoppages ...................................................................................................... 15

6. SHUT-DOWN ............................................................................................................ 16

7. CLEANING YOUR BINKS UNIT ............................................................................... 16

8. MALFUNCTIONS, POSSIBLE CAUSES AND REMEDIAL MEASURES .................. 17

8.1 Compressed air supply unit ................................................................................... 17

8.2 Pneumatic drive and control system unit.............................................................. 17

8.3 Spray material pump unit ....................................................................................... 18

8.4 Suction system unit ................................................................................................ 18

9. INSTRUCTION MANUAL .......................................................................................... 19

10. COMPULSORY TESTING ........................................................................................ 19

11. TEST DOCUMENTS ................................................................................................. 20

12. SPARE PARTS LISTS .............................................................................................. 21

13. RECOMMENDED GUN ............................................................................................ 40

14. EC DECLARATION OF CONFORMITY .................................................................... 41

15. WARRANTY STATEMENT ....................................................................................... 42

4

1. DESIGNATED USE

BINKS airless pumps are used exclusively to output and apply spray material. Any materials can

be sprayed, if they are approved by spray material manufacturers for use with airless spraying

equipment. These include:

• Water-thinnable lacquers and paints

• Solvent-based lacquers and paints

• Base paints and primers

• Micaceous iron ore

• Zinc-rich paints

• Epoxy and polyurethane paints

• Oils

• Liquid synthetic materials

• Wax-based underbody sealant materials

• Low-solvent and solvent-free spray material

Please observe the working guidelines and safety instructions supplied by the spray material manufacturer.

You should avoid using abrasive, granular spray material. Such spray material can

cause heavy wear and tear on the valves and packing sets of the material pump, and

on the nozzles used on the airless gun.

ATTENTION !

BEFORE STARTING UP PUMP FILL UP LUBRICATION FLUID

FOR WATERBORNE PAINT: 0114-014871

FOR SOLVENT PAINT: 0114-009433

5

2. BRIEF DESCRIPTION

(FIGURE 1)

1 Pneumatic drive 9 Ball valve

2 Compressed air supply connection piece 10 Release agent chamber

3 Water seperator 11 High pressure filter

4 Spray material pump 12 High pressure filter relief valve

5 Suction system 13 Return pipe

6 Oiler 14 Grounding terminal

7 Compressed air control valve 15 Spray material outlet connection piece

8 Pressure reducer 16 Grounding terminal (if used without HP-filter)

6

Comments on figure 1

The pneumatic motor (1) drives the BINKS airless pump. An airflow controller in the pneumatic

drive applies compressed air alternately to the pneumatic motor piston . This sets the piston

moving upwards and downwards.

The pneumatic motor is flange-mounted directly to the material pump (4). A moving axle connects

the pneumatic drive butt plate to the double piston of the material pump.

The ascending stroke of the double piston draws in the material through the suction system (5)

and the foot valve of the spray material pump. At the same time, the material which is already in

the material pump above the double piston, is ejected through a check valve into the high pressure

filter (11).

The descending stroke of the double piston closes the foot valve and the material which has been

drawn in, is forced through a plunger valve into the space above the double piston. At the same

time, the material which is already there is ejected into the high pressure filter.

If the airless gun take-off is not operative, counter pressure will build up in the material line. The

pump will stop. Spray material from the airless gun and the BINKS airless pump will start up again.

The area of the motor piston is greater than the area of the material piston. This difference in area

causes the pressure to intensify. With an area ratio of 60/1, for example, a working pressure of

1 bar at the pneumatic drive will be intensified to a working pressure of 60 bar at the spray material pump.

The lubrication chamber (10) physically separates the pneumatic motor from the material pump.

The lubrication chamber is filled with lubricant (Order Code 0114-014871 for waterborne paint,

Order Code 0114-009433 for solvent paint). The lubricant cleans the double piston of the spray

material pump and lubricates the packing and the moving axle.

The volume of air and thus the delivered volume of material is regulated by the working pressure

at the compressed air control valve (7). The compressed air control valve is equipped with an excess pressure safety valve, which is triggered if the maximum working pressure at the pneumatic

motor is exceeded.

The material pump can draw in spray material in two ways.

Direct suction:

This involves immersing the suction system in the spray material.

Suction through a flexible suction system:

This involves connecting the material pump to a flexible suction system. The free end of the suction system is inserted into the tank containing the spray material.

7

The extracted spray material is filtered through the high pressure filter (standard filter on HP 6/60:

type 11 - order-no. 0114-011760), before being driven out through the spray hose and the airless

gun. We recommend the following filter cartridges for the various types of spray material:

Filter size Nozzle Spray material

M 200 less than 0.3 mm colourless lacquer

M 150 greater than 0.3 mm surfacer, filler, red lead

M 100 greater than 0.3 mm surfacer, filler, red lead

M 70 greater than 0.5 mm micaceous iron ore, red lead

M 50 greater than 0.6 mm emulsion, loaded spray materi-

al

Do not use a filter cartridge for fibre-loaded spray material!

HD filter cartridges (overview)

Filter-type

Order-no.

01

0114-013525

03

0110-009130

11

0114-011760

Screen area 29 cm2 84 cm2 118 cm2

Core material polyamide stainless steel polyamide

Figure 2

8

Packings:

The lifetime and the maintenance rate of a pump depend crucially on the right packing. The packing for solvent and waterbased paint are different.

For the use of high viscosity or high corrosion materials we recommend high-strength packing.

Depending on the field of application there are different packings for solvent and waterbased materials.

Standard packing:

Upper packing:

Mixed standard packing (for solvent paint materials) Part-no.: 0114-014477

Consisting of: PTFE/Leather packing

Standard packing (for waterborne paint materials) Part-no.: 0114-018924

Consisting of: PTFE packing

Lower packing:

Mixed standard packing (for solvent paint materials) Part-no.: 0114-014476

Consisting of: PTFE/Leather packing

Standard packing (for waterborne paint materials) Part-no.: 0114-018925

Consisting of: PTFE packing

Packings for high-strength and corrosion materials:

Upper packing:

Mixed high-strength packing (for solvent paint materials) Part-no.: 0114-016289

Consisting of: PTFE(high-strength)/Leather packing

High-strength packing (for waterborne paint materials) Part-no.: 0114-016287

Consisting of: PTFE(high-strength) packing

Lower packing:

Mixed high-strength packing (for solvent paint materials) Part-no.: 0114-016290

Consisting of: PTFE(high-strength)/Leather packing

High-strength packing (for waterborne paint materials) Part-no.: 0114-016288

Consisting of: PTFE(high-strength) packing

Note:

To the high-strength packings graphite is added to the PTFE. This improves the lubrication qualities. High strength packings are not recommended for bright finish paint. Graphite can change the

colour of the finish paint.

If you need special packings without graphite admixture please contact your dealer.

Our pumps are supplied fitted work-sided with mixed packing for the application of solvent paint.

9

3. TECHNICAL DATA

BINKS HP 6/60

Theoretical

transmission

60 : 1

Air motor Air inlet pressure 6,5 bar

Diameter cylinder 140 mm

Material pump Volume double stroke 38 ccm

Operating pressure max. 390 bar

Piston stroke 75 mm

Free flow capacity nominal 2,3 ltr./min.

Piston diameter D1 18 mm

Piston diameter D2 25 mm

Connections Air inlet Stem for quick disconnection

or R 3/8" (m)

Fluid outlet on HP-filter

1/4" NPS (m) and

3/8" NPS (m)

Dimensions of

bare pump

L x W x D in mm 725 x 220 x 190

The nameplate on your outfit is attached to the spray material pump. Enter the data from the

nameplate into figure 3. Have this information ready when you call customer service.

Figure 3

ITW Finishing Systems and Products

Ringwood Road, Bournemouth BH11 9LH, England

Phone +44 (0) 1202 / 571111 Telefax +44 (0) 1202 / 581940

Internet www.itwifeuro.com

ITW Finishing Systems and Products

Ringwood Road, Bournemouth BH11 9LH, England

10

4. SAFETY

As well as the operating instructions and the applicable legal and other mandatory regulations relevant to accident prevention in the country of use and at the place of use, you

must also observe the recognised special engineering regulations governing safe and professional working practices.

4.1 PRINCIPLE OF OPERATION; INTENDED USE

1. BINKS airless spraying equipment has been built to comply with state-of-the-art standards and

recognised safety rules. Nevertheless, its use may constitute a risk to life and limb for the user

or for third parties, or cause damage to the BINKS airless pump and other assets.

2. The BINKS airless pump must only be used in technically perfect condition in accordance with

the regulations and the instructions set out in the operating instructions and only by safetyconscious persons fully aware of the risks involved. Any malfunctions, especially those affecting safety, must be rectified immediately. The spray material line must not be dragged across

sharp-edged objects and must always be checked before use to ensure that it is in perfect

condition.

3. BINKS airless pumps are designed exclusively for the designated use stated in Section 1. Using them for purposes other than those mentioned is considered contrary to the intended use.

The manufacturer/supplier cannot be held liable for any damage resulting from such use. The

user alone must bear the risk.

4. The manufacturer is not liable for any unauthorised modifications or repairs made to the

BINKS airless pump.

5. In accordance with the professional association directives governing spray equipment , ZH

1/406, paint spraying equipment should be checked by experts on request, or at least every

12 months, to ensure that there is no risk involved in its continued operation. If the units are

idle, the examination can be delayed until the next period of operation. The operator is obliged

to register the equipment for testing and to keep written records of the results of such testing.

4.2 SAFE WORKING CONDITIONS

1. The requirements of the (German) accident prevention and safety regulation “Working with

surface coating compounds” (VBG 23) and the (German) directives governing spray equipment (ZH 1/406) and static electricity (ZH 1/200) provided by the professional associations,

must be observed.

2. Every person using a BINKS airless pump must have read and understood the operating instructions, in particular the chapter on “Safety”.

3. If work is to be carried out in enclosed areas, effective, technical ventilation must be provided.

4. Use only those spray material lines and airless guns that are designed for use at the relevant

maximum permitted working pressure of the spray material pump.

5. Be careful that there are no sources of ignition in the vicinity, for example, an open fire,

sparks, glowing wires, hot surfaces, burning cigarettes, etc. There must be a distance of at

11

least 5 m between the spray jet outlet and any possible source of ignition (the spray mist is ignitable and there is a risk of fire or explosion).

6. The spray material leaves the nozzle under pressure. Do not direct the spray jet towards people or animals, as this could cause injuries. If the skin is broken and comes into contact with

paint, lacquer or solvent, there is a risk of infection. Consult a doctor immediately to obtain

professional, expert treatment. Tell the doctor which spray material or solvent is involved. Present the safety data sheet.

7. Be aware that working with sprays may produce vapours which can damage your health (see

information on the safety data sheet and the tins of material). You must therefore use a personal breathing equipment, as indicated by the spray material manufacturer. Keep children

and all people right away from the work area.

8. Keep the BINKS airless pump in a safe place to which children and unauthorised persons do

not have access. Make sure that unauthorised personnel (and children in particular) cannot

start up the BINKS airless pump.

9. Store the BINKS airless pump in a dry place.

10. Use only original BINKS accessories and original BINKS replacement parts.

11. Repair work must only be carried out by authorised specialised companies or by ITW

You can obtain the addresses of specialised companies from ITW or from your

specialised dealer.

12. When repairing and mounting the pump it is necessary that all connections are clean and

mounted correctly.

Before re-starting the pump the correct resistance (1 MΩ) must be measured.

The resistance has to be determined between foot valve and upper top point of the pump.

13. You must be careful when carrying out spraying work, not to direct the jet towards the

BINKS airless pump unit.

14. Dispose of cleaning and spraying material waste in accordance with the information provided

by the respective spray material and solvent manufacturers.

15. If work is interrupted, to change the nozzle, for example, lock the safety lever on the airless

gun. Release pressure from the system.

12

4.3 PARTICULAR DANGER SPOTS

1. The flow of material escaping from the airless gun is under great pressure and thus has a

powerful cutting effect.

You must therefore never point the airless gun at yourself or any other person, animal

or plant. Never touch the spray jet with your fingers or hand, or hold them in front of

the airless gun.

Note:

If the cutting effect of the flow of material causes injury seek medical advice immediately.

Tell the doctor which spray material (paint) and/or solvent (thinners) was involved and provide

the relevant information from the manufacturer as per the safety data sheet (supplier, his

phone number, the material number).

2. The escaping spray material generates recoil power. You must therefore always hold the air-

less gun securely and make sure that you have a well-balanced stance.

3. In enclosed systems, or systems which are under pressure, where aluminium or galvanised

parts come into contact with the liquid, there can be dangerous chemical reactions if 1.1.1 trichloroethane, methylene chloride or other solvents containing halogenated chlorinated hydrocarbons, are used.

If you use the named solvents or paints which contain these solvents, we recommend that you

contact the spray material manufacturer or ITW Oberflächentechnik.

4. If there are malfunctions or obstructions, you must immediately shut off the compressed air

supply at the ball valve. Disconnect the unit from the compressed air system, operate the airless gun and open the high pressure filter relief valve before removing the airless gun or the

hose.

5. To prevent static charging from causing a fire or an explosion, the equipment must be proper-

ly grounded (the pump, the material tank, the object to be coated). If using materials with a

flash point under 21°C of ignition group G1-G3, there must be an additional conductive connection between the material tank and the pump (potential equalisation cable). The material

tank must always be made of metal.

6. Prevent spray back into a closed tank, as an ignitable gas/air mixture will build up. Take par-

ticular care with materials with a flash point less than 21°C.

7. The A-weighted sound level of pumps may exceed 85 dB (A).

Local conditions may dictate a higher noise level, which could cause noise deafness. If this is the

situation, operating personnel must be protected by suitable protective equipment or safety

measures.

13

5. START-UP AND OPERATION

5.1 GROUNDING THE BINKS AIRLESS PUMP

To prevent static charging igniting the flammable spray material, the BINKS airless

pump must be grounded in accordance with professional association regulation

ZH 1/200 (Germany), “Static Electricity”, before it is started up. A grounding cable is

included in the supply schedule.

1. Grounding wire has to be mounted on the grounding terminal of the high pressure filter or (if

pump is used without HP-filter) on the middle section of the pump.

2. Connect the other end of the grounding cable to a suitable grounding device (e.g. grounding

bar).

5.2 PREPARING TO START UP THE BINKS AIRLESS PUMP

Proceed as follows:

1. Check that the lubrication chamber is full. To do this, open the screw plug on the filler neck of

the lubrication chamber. If necessary, top up the lubricant (Order Code for solvent paint:

0114-009433, for waterborne paint: 0114-014871) and close the screw plug again.

2. Select a suitable filter cartridge using the table in section 2, Brief Description and insert it into

to the high pressure filter.

3. Attach a suitable hose to the spray material outlet connection piece on the high pressure filter.

The spray material lines in the BINKS supply programme are identified on the screw

fitting with the maximum permitted working pressure and the bursting pressure. The

lesser value, the maximum permitted working pressure, must be greater than the

maximum permitted working pressure of the spray material pump (see 3, Technical

Data).

4. Connect the airless gun designed at least for the maximum permitted working pressure of the

spray material pump, to the fluid hose.

We recommend for Airless: BINKS Airless spray gun HAP 50 with max. pressure 500 bar or

BINKS Airless spray gun Airless 1 with max. pressure 420 bar.

We recommend for Aircombi: BINKS Aircombi spray gun AA 4000 with max. pressure

275 bar or BINKS Aircombi spray gun DSG-2000 with max. pressure 250 bar.

5. Make sure that the ball valve on the pneumatic drive is closed.

6. Connect the compressed air supply at the compressed air supply connection piece.

7. The airless pump is equipped with an air pressure regulator.

14

The filter cleans the compressed air from water condensate, scale, rust particles etc.

Drain off the water condensate at regular intervals and clean the sintered filter if it is dirty.

Before putting the pressure line into operation, relieve the filter regulator by fully unscrewing

the regulating screw. Thereafter rotate the regulating screw clockwise until the pressure

gauge on the filter regulator indicates the required pressure (please consider the min. and the

max. data - see section 3 Technical Data).

5.3 RINSING THE BINKS AIRLESS PUMP

Wear eye protection

Every BINKS airless pump is tested with water during final inspection and thoroughly rinsed with a

non-gumming preservative oil. With this rinsing process, it is possible that the residual moisture of

water emulsion will be left in the pump.

Before the unit is started up for the first time, a suitable solvent must be used to thoroughly rinse

out the remains of the preservative fluid and the unavoidable impurities introduced during equipment assembly.

Proceed as follows:

1. Prepare the BINKS airless pump for start-up in accordance with section 5.2.

2. Close the high pressure filter relief valve.

3. Immerse the spray material pump or the suction system in the tank of solvent.

4. Insert the high pressure filter return pipe into the tank of solvent. Open the high pressure filter

relief valve.

5. Open the ball valve of the air supply and set the compressed air control valve on the pressure

regulator to approximately 1 bar. The spray material pump or the suction system now draws in

the solvent. The solvent runs back to the tank through the high pressure filter, the high pressure filter relief valve and the return pipe.

6. Point the airless gun into the tank. Unlock the safety lever on the airless gun, operate the air-

less gun trigger and close the high pressure relief valve. The solvent will now flow through the

high pressure filter, the spray material line and the airless gun, back into the tank.

The time of rinsing depends on the length of the material lines and the solubility of the spray

material. We recommend a short reflush with "fresh" solvent.

7. Release the airless gun take-off.

8. Slowly increase the pressure at the compressed air control valve of the pressure reducer to

maximum working pressure (see section 3, Technical Data), while checking and testing that

all lines and screw and plug caps are tightly sealed. If there are any leaks in the system, shut

down the BINKS airless pump immediately. Only re-start the BINKS airless pump once you

have repaired the leak.

9. Reduce the pressure at the compressed air control valve of the pressure reducer again and

close the ball valve.

15

10. Make sure that the return pipe is still directed into the solvent tank. Carefully open the high

pressure filter relief valve to reduce the pressure in the spray material pump and in the high

pressure filter.

11. Point the airless gun into the tank of solvent and operate the trigger, to reduce any pressure

which may still exist in the spray material line and in the airless gun.

If working with waterborne spray material, the BINKS airless pump must again be

thoroughly rinsed with water before it is started up.

5.4 PREPARING AND ADJUSTING THE SPRAY MATERIAL

To be able to work without trouble and obtain a perfect surface, special care must be taken in preparing and adjusting the lacquers and paints (please contact spray material manufacturer).

Before starting to spray, it may be necessary to use the solvent prescribed by the manufacturer to

thin the spray material. Add thinners until, after a good stir, the spray material runs easily off the

stick used for stirring. To prevent any uncertainty, we recommend that you use a dip measuring

cup, where the run-out time of the spray material indicates whether the spray material is still too

thick and therefore whether it is necessary to add more thinners. According to experience, the flow

time for lacquers and paints is 18 to 22 DIN4 sec. and for effect lacquer and coating filler materials

25 to 50 DIN4 sec. These figures relating to DIN EN ISO 2431 and have been established at a

temperature of 20°C. The lacquer and paint manufacturers generally state the best spraying consistency for each of their products. If you use motor driven mixers, you must ensure that no air

bubbles form in the spray material.

To take a measurement, proceed as follows:

Immerse the measuring cup into the lacquer or paint which is ready for spraying until it is full to the

brim. To make the measurement, quickly take out the dip measuring cup and count how many

seconds it takes for the entire contents of the cup to run through the 4mm nozzle, i.e. up to the

time when you can establish the break-off point of the out-flowing paint. Count off the seconds on

a wristwatch, or time with a stopwatch. If, for example, a consistency of 19 DIN4 sec. is prescribed, but the measurement is 24 DIN4 sec., you must add some more thinners and make the

measurement again.

We recommend that once you have used it, you clean the dip measuring cup immediately, so that

it can be used again for the next measurement.

Because two filters are used in the BINKS airless unit, a suction filter and the high pressure filter, it

is not necessary to filter the spray material before working with it.

If particularly high-quality coating work is involved, you can also use a gun filter from the BINKS

accessories range.

5.5 START-UP

1. Prepare the BINKS airless pump for start-up in accordance with section 5.2 and if necessary,

rinse in accordance with section 5.3.

16

2. Close the high pressure filter relief valve.

3. Immerse the spray material pump or the suction system in the spray material to be used for

working.

4. Place the high pressure filter return pipe in the tank. Then open the high pressure filter relief

valve.

5. Open the ball valve for the compressed air supply and use the pressure regulator to set the

compressed air supply to 1 bar. The material spray pump will now draw in the spray material.

The spray material flows back into the tank through the high pressure filter, the high pressure

filter relief valve and the return pipe.

6. Point the airless gun into the tank. Unlock the safety lever on the airless gun. Operate the

airless gun take-off and close the high pressure relief valve. The spray material will now flow

through the high pressure filter, the spray material line and the airless gun, back into the tank.

7. Release the airless gun take-off and set the working pressure at the pressure control valve of

the pressure reducer.3

Before carrying out any coating work, we recommend a test spray (e.g. on to paper or wood). Only

if the test gives you the desired result should you start to coat the actual object.

Make sure that the edges and the fringe areas of the object to be coated are also given an even

coating.

5.6 WORK STOPPAGES

• If working with 2-K spray material, you must note the given pot life and follow it

precisely. Within this time, the unit must be carefully cleaned and rinsed with the

recommended solvent. There must be no residue left in the spray material pump,

the high pressure filters or the airless gun.

• When work is stopped, the safety lever of the airless gun must be locked.

For work stoppages of between 10 and 30 minutes, please proceed as follows:

Wear eye protection

1. Lock the safety lever on the airless gun.

2. Shut off the compressed air supply by closing the ball valve.

3. Briefly open the high pressure relief valve, taking care that the return pipe is not pointed at other people or at yourself, until the pressure has reduced. Then close the high pressure relief

valve again.

4. Clean the outside of the airless nozzle from spray material residue.

17

6. SHUT-DOWN

Once work is completed, the BINKS airless unit must be thoroughly cleaned. Under no

circumstances must you allow paint residue to dry out in the unit. To clean the airless

unit, use a solvent appropriate to the spray material.

Wear eye protection

1. Close the ball valve for the compressed air supply.

2. Make sure that the return pipe is still directed into the spray material tank. Carefully open the

high pressure filter relief valve to reduce the pressure in the spray material pump and in the

high pressure filter.

3. Point the airless gun into the tank of spray material and operate the take-off to reduce any

pressure which may still exist in the spray material line and in the airless gun.

4. Lock the safety lever on the airless gun.

5. Remove the spray material pump or suction system from the spray material.

7. CLEANING YOUR BINKS UNIT

In no case spray material or solvent should soak into the ground or the canalisation.

Wear eye protection

1. Clean the pump and the suction system from the outside. Immerse the spray material pump or

the suction system in the tank of solvent.

2. Clean the fluid tip / tip system as described in the service bulletin of the spray gun. We recom-

mend to stock the fluid tip in solvent.

3. Unlock the safety lever of the airless gun without fluid tip but with mounted tip system or tip

guard. Operate the gun. Close the high pressure filter relief valve. Set the incoming air pressure

to max. 2 bars and open slowly the ball valve. Let the solvent runs through the system so that

the spraying material could rinse out.

4. Let the solvent runs through the system for a couple of minutes until the solvent runs clear

through the airless gun. Close the ball valve and lock the safety lever of the gun

5. Clean the airless gun from the outside and check the filter on the handle (if mounted).

6. Clean the filter insert of the high pressure filter.

7. Clean the filter of the suction pipe.

8. We recommend to remain the equipment filled with liquid.

We recommend to preserve the BINKS airless equipment if it is not used for a longer period of

time. Please rinse the complete system with silicon-free oil as described in section 5.3.

18

8. MALFUNCTIONS, POSSIBLE CAUSES AND REMEDIAL

MEASURES

In case of a break down of your equipment please contact your dealer or the manufacturer of the

unit who will lead a professional repair.

8.1 COMPRESSED AIR SUPPLY UNIT

Type of defect Appearance of de-

fect

Possible cause Remedy

No flow through

BINKS airless pump.

Spray material pressure drops.

BINKS airless pump

does not start.

No compressed air.

Nozzle on airless

gun blocked.

Check compressed air

supply.

Clean or replace nozzle.

Reduction of area.

Air motor controller

blocked.

Pipeline kinked,

pressure controller

contaminated.

Contaminated compressed air.

Check lines.

Clean pressure control

valve.

Filter compressed air.

8.2 PNEUMATIC DRIVE AND CONTROL SYSTEM UNIT

Type of defect Appearance of de-

fect

Possible cause Remedy

Erratic operation,

number of strokes

reduced, pneumatic

drive stops.

Faulty piston valve. Wear.

Foreign matter in the

control system.

Replace parts.

Remove foreign matter, replace faulty

parts.

Pneumatic drive

frozen up.

Compressed air too

damp.

Condensation in the

compressed air supply.

Too many strokes.

Install water separator.

Check compressor.

Use smaller spray

nozzle.

Modify working conditions.

Install oiler.

Reduce air pressure.

19

8.3 SPRAY MATERIAL PUMP UNIT

Type of defect Appearance of de-

fect

Possible cause Remedy

Material coming from

the spray material

chamber.

Upper packing of

spray material pump

faulty.

Replace spray material pump packing.

BINKS airless pump

runs non-stop.

BINKS airless pump

runs on despite stopping spraying.

Lower packing of

spray material pump

faulty

Replace spray material packing.

BINKS airless pump

does not stop on

down-stroke.

Foot valve or plunger

valve faulty or stuck.

Wear.

Dried material.

Replace parts.

Careful cleaning necessary.

BINKS airless pump

does not stop on upstroke.

Foot valve or plunger

valve faulty or stuck.

Wear.

Dried material.

Replace parts.

Careful cleaning necessary.

Spray material escape at double piston.

Grooving in the slide

faces.

Wear. Replace parts.

8.4 SUCTION SYSTEM UNIT

Type of defect Appearance of de-

fect

Possible cause Remedy

BINKS airless pump

works erratically.

Suction screen

blocked.

Spray material contaminated.

Clean or replace suction screen.

BINKS airless pump

runs, but there is no

flow.

No suction power. Suction filter dirty.

Foot valve ball sticks

to valve seat.

Suction system not

properly screwed

down.

Spray material pump

draws air, screw

down properly.

Clean.

Make practicable.

20

9. INSTRUCTION MANUAL

Depending on the type of application and the place of installation, the operator must use the operating instructions to provide more details on the safe operation of the BINKS airless pump, in the

form of an instruction manual in the language of the workforce. This instruction manual is to kept

in a suitable location at the place of work and the workforce informed of its whereabouts. The

workforce should comply with the instructions contained in this instruction manual.

10. COMPULSORY TESTING

In accordance with the professional association directives governing spray equipment , ZH 1/406,

paint spraying equipment should be checked by an expert on request, or at least every 12

months, to ensure that there is no risk involved in its continued operation. If the units are idle, the

examination can be delayed until the next period of operation. The operator is obliged to register

the equipment for testing and to keep written records of the results of such testing.

An expert is someone whose professional training and experience has given him adequate

knowledge and understanding of jet stream units and who is sufficiently acquainted with the relevant national health and safety and work and accident prevention regulations, directives and generally recognised technical regulations, that he is able to assess whether jet stream units are safe

to operate.

The employer (operator) must make sure that test results for each jet stream unit are kept as a

written record and that this is retained until the next text. We provide a blank "Test record for

spraying equipment" form for this purpose. Please make as many copies of this as you need.

Furthermore, you must ensure that this test document is available at the place where the jet

stream unit is in use. A copy of the test record or a test plaque is sufficient for this.

But we also ask you to enter the test document, date and expert in the “Test Document” table.

21

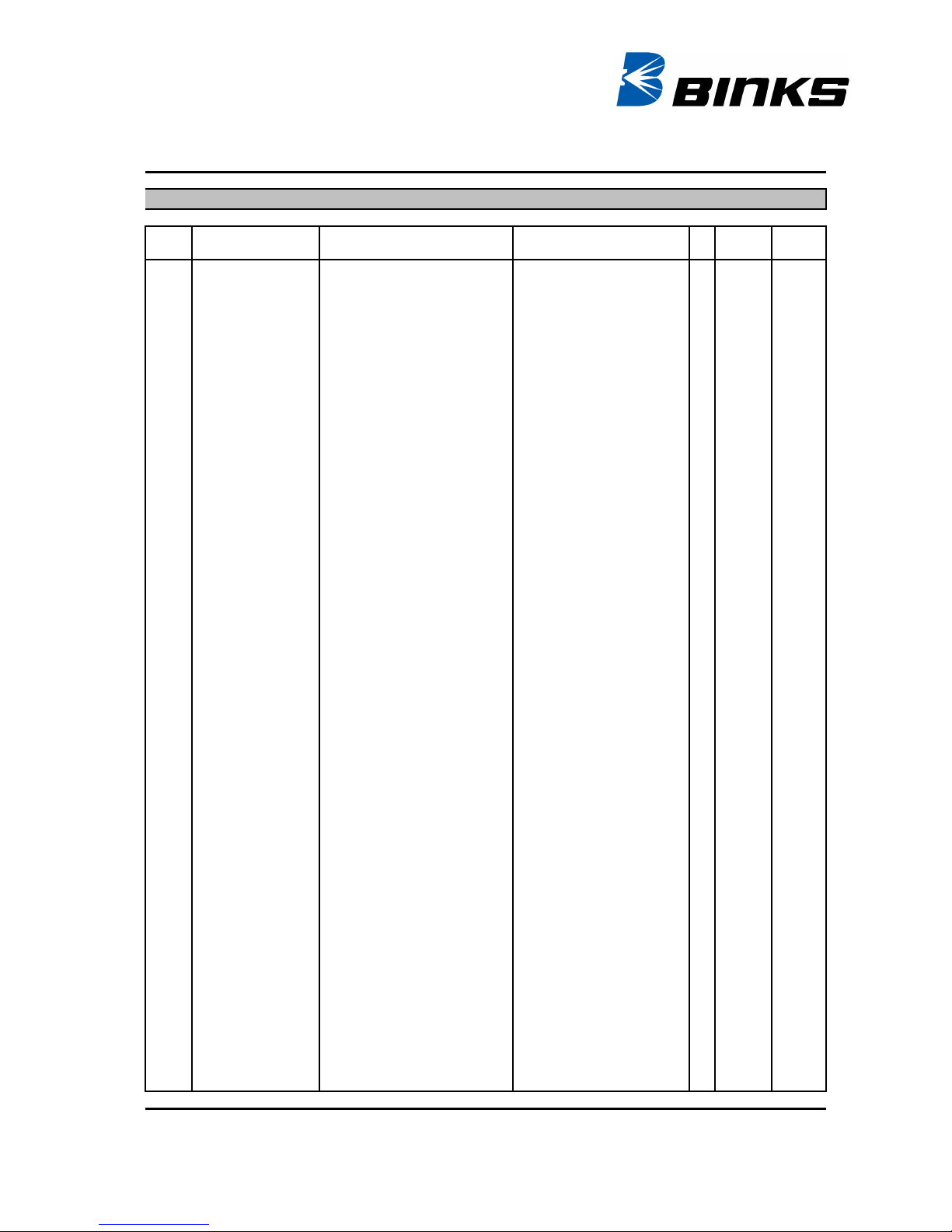

11. TEST DOCUMENTS

Test record for spraying equipment

ITW Oberflächentechnik GmbH & Co. KG

Justus-von-Liebig-Straße 31

D-63128 Dietzenbach

Telefon +49 (0) 6074 / 403-1

Telefax +49 (0) 6074 / 403-281

Date: ..................................

Examiner: ...................................

DEALER STAMP:

ADDRESS OF OPERATOR:

Name: ......................................................

Street: ......................…….........................

Postcode/Town: .......................................

Contact:........................................Phone: ...........……..........

Tested unit:

Manufacturer: ..................................................

Type: .........................................................

Eqpt.-No.: ..................................................

Year of manufacture: .................................

System components used:

O Airless pump

O Airless gun

O Spray material line

O Pump head Cart O

Triprod O

Wall bracket O

Tested components complies not tested does not

comply

retrofit recom-

mended

General condition of system

Jet stream unit

Equipment name plate

Safety valve

Pressure gauge fitting

Pressure relief valve

Jet stream unit with heater

Temperature limitation / control

Temperature display

Spraying device

Max. pressure identification

Equipment number identification

Efficiency

Safety equipment

Hoses and fittings

Hose identification

Fitting identification

Grounding

Between components

Overall system

Measuring of resistance (1 MΩ)

Operating instructions

Function of the overall system

User instructions

Technical condition

Safe condition

Health and safety at work regulations

Overall assessment of the examination

Comments:

ITW Finishing Systems and Products

Ringwood Road, Bournemouth BH11

9LH, England

22

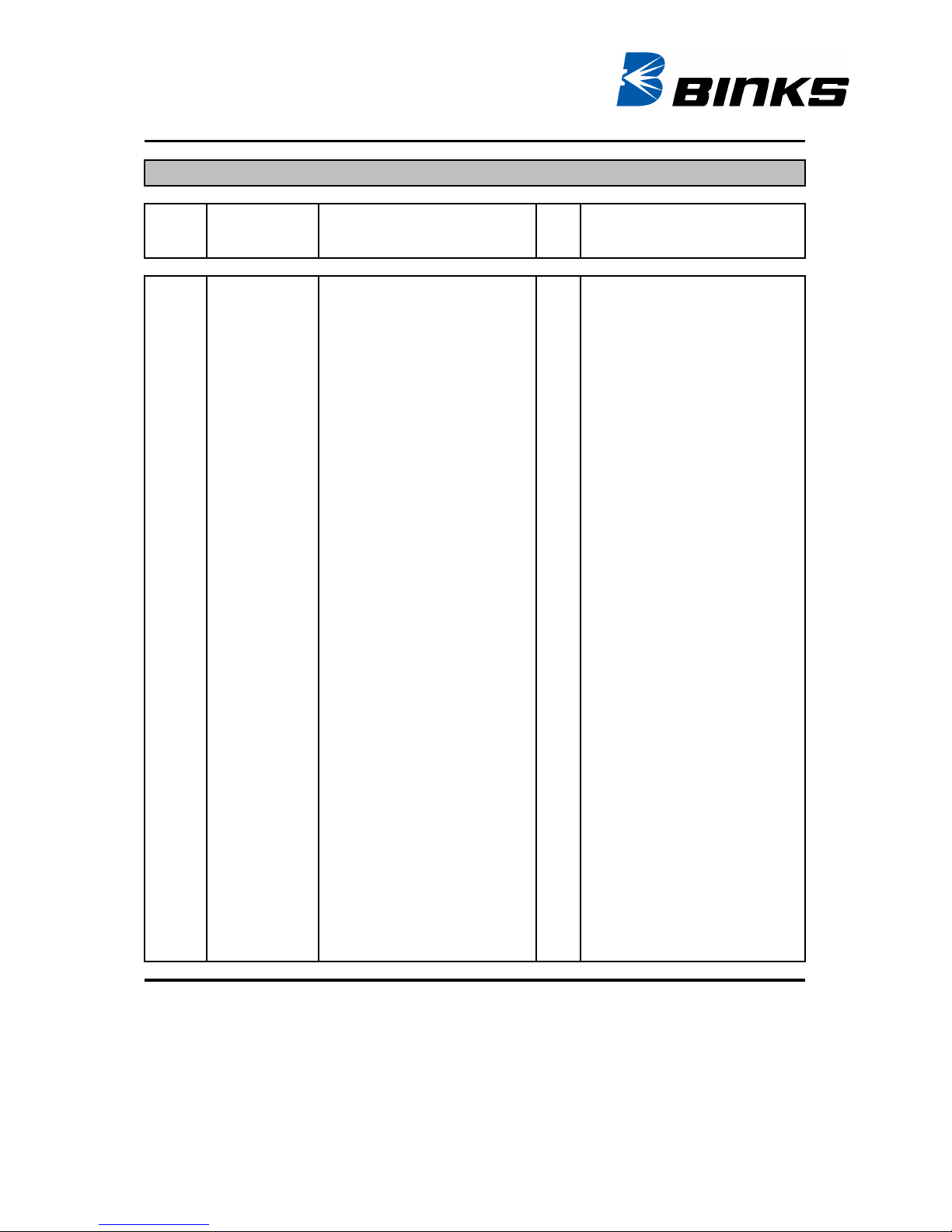

TEST DOCUMENTS

Test document no. Date of test Expert

Company Name

12. SPARE PARTS LISTS

23

Ersatzteilliste / spare parts list

Hochdruckpumpe / high pressure pump HDP 38/60

0114-014572

Hochdruckpumpe

high pressure pump

Luftmotor

air motor

0114-014404

Materialpumpe

material pump

0114-014589

Vorbehaltl. Techn. Änderungen

24

Ersatzteilliste / spare parts list

Luftmotor / air motor LM 140/75

0114-014404

Luftmotor LM 140/75

air motor LM 140/75

Vorbehaltl. Techn. Änderungen

25

Ersatzteilliste / spare parts list

Luftmotor / air motor LM 140/75

0114-014404

Luftmotor LM 140/75

air motor LM 140/75

Vorbehaltl. Techn. Änderungen

26

Ersatzteilliste / spare parts list

Luftmotor / air motor LM 140/75

Pos.

Art.-Nr.

Bezeichnung

Description

Stück

D / R

Pcs.

0114-019095

Luftmotor LM 140/75

air motor LM 140/75

1

0114-014387

Hutmutter

dome nut

11

2

0114-014165

U-Scheibe

washer

13

3

0114-014371

Deckel

cover ass.

1

4

0114-014673

Schalldämpfern kpl.

air muffler cpl.

1

5

0114-014374

Scheibe

spacer

1

6

0114-014666

Stehbolzen

threaded bolt ass.

3

7

0114-014373

Steuerzylinder

control cylinder

1

8

0114-013954

O-Ring

o-ringV4

D / R

9

0114-014372

Sicherungsblech

safety plate

1

10

0114-014656

Steuergehäuse kpl.

control housing cpl.

1

11 0114-014164 Mutter nut 8

12 0114-014388 Steuerkolben kpl. control piston cpl. V 1 R

13 0114-014376 Steuerachse control axle V 1

14 0114-014379 Zentrierstück alignment insert 1

15 0114-014378 Dämpfungsscheibe dampening spacer 2 R

16 0114-014628 Scheibe spacer 1

17 0114-014438 Mitnehmer kpl. carrier ass. V 1

18 0114-014715 Sicherheitsventil 8 bar safety valve 8 bar 1

19 0114-014619 Sicherungsring retaining ring 1 R

20 0114-014618 Scheibe spacer 1 R

21 0114-014608 O-Ring o-ring 3 D / R

22 0114-014305 Schnepper toggle V 2

23 0114-014340 Schnepperlager toggle bearing V 2

24 0114-014067 Druckfeder spring V 2

25 0114-014381 Lagerbuchse bearing bush 2

26 0114-014661 Oberteil cylinder head 1

27 0114-014367 Gewindestift threaded pin 2

28 0114-014380 Nutring u-seal V 1 D / R

29 0114-014212 Sicherungsring retaining ring 1 D / R

30 0114-013992 O-Ring o-ring V 1 D / R

31 0114-014383 Führungsring guide ring 1 D / R

32 0114-014382 Kolbenplatte piston plate 1

33 0114-014384 Scheibe spacer 1

34 0114-014421 O-Ring o-ring V 1 D / R

35 0114-014396 Umsteuerachse kpl. guide axle cpl. V 1

36

0114-014395

Motorachse

motor axle

V

1

37

0114-013993

O-Ring

o-ring2D / R

38 0114-014393 Zylinder cylinder 1

39 0114-014386 Stehbolzen threaded bolt 3

40 0114-014359 Sicherungsring retaining ring 1 D / R

41 0114-014464 Führungsbuchse kpl. bush ass. V 1 D / R

42 0114-013957 O-Ring o-ring 2 D / R

43 0114-014403 Belüftungsrohr air inlet pipe 1

44 0114-014660 Unterteil bottom ass. 1

44.1 0114-014657 Verschlussschraube closing screw 2

45 0114-013679 Winkel elbow 1

46 0114-014561 Einfüllstutzen kpl. filler neck cpl. 1

46.1 0114-013520 Nippel nippel 1

46.2 0114-013670 Winkel elbow 1

46.3 0114-013671 Verschlussschraube closing screw 1

0114-014647 Dichtungssatz seal kit D

0114-014736 Reparatursatz repair kit R

Verschleißteil wearing part V

Vorbehaltl. Techn. Änderungen

27

Ersatzteilliste / spare parts list

0114-014589

Materialpumpe

material pump

Vorbehaltl. Techn. Änderungen

Materialpumpe / material pump MP 38/75

28

Ersatzteilliste / spare parts list

0114-014589

Materialpumpe

material pump

Vorbehaltl. Techn. Änderungen

Materialpumpe / material pump MP 38/75

29

Ersatzteilliste / spare parts list

Pos.

Art.-Nr.

Bezeichnung

Description

Stück

D / R

Pcs.

0114-014589

Materialpumpe MP 38/75

material pump MP 38/75

1 0114-013987 O-Ring o-ring 1 D / R

2 0114-014587 Hochdruckkopf pump head 1

3 0114-019093 Ablassventil kpl. outlet valve kpl. 1

3.1 0114-013679 Winkel elbow 1

3.2 0114-013671 Verschlußschraube lock screw 1

5 0114-014269 Dichtring gasket 1 D / R

6

0114-014477

Packung gemischt oben kpl.

packing mixed ass.

V1R

wahlw.

0114-018924

Packung PTFE oben kpl.

packing PTFE ass.

V1R

wahlw.

0114-016285

Packung hochfest gemischt kpl. oben

upper high-strength packing mixed cpl.

V

1

wahlw.

0114-016283

Packung hochfest kpl. oben

upper high-strength packing cpl.

V

1

7 0114-013555 Rückschlagventil kpl. non return valve 1

8 0114-014202 Dichtung gasket 1 D / R

9 0114-014370 Schraube screw 3

10 0114-014047 Druckfeder spring V 1

11 0114-014585 Federgehäuse spring housing 1

12 0114-014159 Spannhülse tension pin 1

13 0114-014459 Doppelkolben dual piston V 1

14 0114-014012 Dichtung gasket 1 D / R

15 0114-014627 Kolbenventil kpl. valve piston ass. 1

15.1 0114-014022 Kugel ball V 1 R

15.2 0114-014755 Kugelführung ball guide 1

15.3 0114-014159 Spannhülse tension pin 1 R

15.4 0114-013783 Ventilgehäuse kpl. valve housing cpl. V 1

16 0114-014476 Packung gemischt unten kpl. packing mixed ass. V 1 R

wahlw. 0114-018925 Packung PTFE unten kpl. packing PTFE ass. V 1 R

wahlw.

0114-016286

Packung hochfest gemischt kpl. unten

lower high-strength packing mixed cpl.

V

1

wahlw.

0114-016284

Packung hochfest kpl. unten lower high-strength packing cpl.

V

1

17 0114-014586 Druckzylinder pressure cylinder 1

18

0114-014460

Anzugring

connecting ring

1

19

0114-013946

O-Ring

o-ring

1

D / R

20 0114-014727 Bodenventil kpl. bottom valve ass. 1

20.1

0114-014237

Kugel

ballV1

R

20.2

0114-014753

Kugelführung

ball guide

1

20.3

0114-014568

Zylinderstift

cylindrical pin

1

R

20.4

0114-014625

Bodenventilgehäuse

valve housing

V

1

20.5

0114-013834

Dichtung

gasket

1

D / R

21

0114-014415

Mutter

nut

3

22

0114-014422

U-Scheibe

washer

3

23

0114-014570

Stehbolzen

threaded bolt

3

0114-014648 Dichtungssatz seal kit D

0114-014754 Reparatursatz (Packung gem.) repair kit (packing mixed) R

0114-016007 Reparatursatz (Packung PTFE) repair kit (packing PTFE) R

Verschleißteil wearing part V

Vorbehalt. Techn. Änderungen

Materialpumpe / material pump MP 38/75

30

Ersatzteilliste / spare parts list

Vorbehaltl. Techn. Änderungen

Reparatursatz Luftmotor / repair kit air motor LM 140/75

0114-014736

1x

0114-014383

Führungsring

L=43,5cm

2x

0114-013993

O-Ring 140x3 mm

1x

0114-013992

O-Ring

129,2x5,7 mm

4x

0114-013954

O-Ring 19x1,8 mm

3x

0114-014608

O-Ring 11x2 mm

1x

0114-014380

Nutring

21,8x12,2x5,2 mm

1x

0114-014619

Si-Ring JV32

1x

0114-014464

Führungsbuchse kpl.

1x

0114-014421

O-Ring

12,3x2,4 mm

1x

0114-014212

Si-Ring JS22

2x

0114-013957

O-Ring

8x1,5 mm

1x

0114-014388

Steuerkolben kpl.

1x

0114-014359

Si-Ring JS40

1x

0114-014618

Scheibe 31x12x9 mm

2x

0114-014378

Dämpfungsscheibe

27x11,7 mm

31

Ersatzteilliste / spare parts list

Vorbehaltl. Techn. Änderungen

Dichtungssatz Luftmotor / seal kit air motor LM 140/75

1x

0114-014383

Führungsring

L=43,5cm

2x

0114-013993

O-Ring 140x3 mm

1x

0114-013992

O-Ring

129,2x5,7 mm

4x

0114-013954

O-Ring 19x1,8 mm

3x

0114-014608

O-Ring 11x2 mm

1x

0114-014380

Nutring 21,8x12,2x5,2 mm

1x

0114-014464

Führungsbuchse kpl.

1x

0114-014421

O-Ring

12,3x2,4 mm

1x

0114-014212

Si-Ring JS22

2x

0114-013957

O-Ring 8x1,5 mm

1x

0114-014359

Si-Ring JS40

0114-014647

34

Ersatzteilliste / spare parts list

Vorbehaltl. Techn. Änderungen

Dichtungssatz Materialpumpe / seal kit material pump MP 38/75

0114-014648

1x

0114-013987

O-Ring 53x2 mm

2x

0114-014269

Dichtring 52x47x2,6

1x

0114-014202

CU-Dichtung 26x21x2

1x

0114-014012

Dichtung 24x20x1,5 mm

1x

0114-013946

O-Dichtung 43x39x2 mm

1x

0114-013834

Dichtung 24,5x18x2 mm

35

Ersatzteilliste / spare parts list

Ersatzteile Fahrgestell / spare parts trolley

Pos.

Art.-Nr.

Bezeichnung

Stk.

Description

pcs.

0114-014614

Fahrgestell Typ 02

trolley type 02

1

0114-014640

Gestell

1

frame

2

0114-014057

Rad2wheel

5

0114-014795

Wandhalter kpl. bestehend aus:

1

wall holder cpl.

0114-019005

Wandhalter

1

wall holder

0114-014164

Mutter4nut

0114-014165

U-Scheibe

4

washer

0114-014216

Schraube

4

screw

6

0114-014164

Mutter4nut

7

0114-014165

U-Scheibe

4

washer

8

0114-014170

Schraube

4

screw

Vorbehaltl. Techn. Änderungen

1

6/7/8

5

2

36

Ersatzteilliste / spare parts list

Ersatzteile Wandhalter / spare parts wall bracket

Pos.

Art.-Nr.

Bezeichnung

Stk.

Description

pcs.

0114-014795 Wandhalter Typ 02 wall bracket assy. type 02

0114-019005 Wandhalter 1 wall bracket

0114-014216 Schraube 4 screw

0114-014165 U-Scheibe 4 washer

0114-014164 Skt.Mutter 4 nut

Vorbehaltl. Techn. Änderungen

37

Ersatzteilliste / Spare parts list

Druckregler / pressure regulator 1/2" Airless

0110-009348

Druckregler

pressure regulator

Pos. Art.-Nr. Bezeichnung Stck. Description

neu Pcs.

1

0114-020291

Druckregler kpl.

1

pressure regulator cpl.

1.1 0114-014048 Manometer 1 pressure gauge

1.2 0114-019051 Druckregler 1 pressure regulator

1.3 0114-014125 Knebelschraube mit Mutter 1 t-handle with nut

2 0114-009044 Einstecknippel 1 nipple

3 0114-009266 Doppelnippel 1 nipple

4 0114-021608 Kugelhahn 1 valve

Vorbehalt. Techn. Änderungen

1.3

2

1.1

1

3

1.2

4

38

Ersatzteilliste / Spare parts list

Ersatzteile HD-Filter / spare parts HP-filter 11-R

Pos.

Art.-Nr.

Bezeichnung

Description

0114-011760

Hochdruckfilter Typ 11-R

high pressure filter type 11-R

Vorbehaltl. Techn. Änderungen

39

Ersatzteilliste / Spare parts list

Ersatzteile HD-Filter / spare parts HP-filter 11-R

Pos.

Art.-Nr.

Bezeichnung

Stck.

Description

Pcs.

0114-011760

HD-Filter Typ 11-R

high pressure filter type 11-R

1

0114-013847

Filtergehäuse

1

filter casing

2

0114-013952

Dichtung

4

gasket

3

0114-013780

Doppelnippel

1

connection nipple

4

0114-014023

Kugel 12 mm

1

ball 12 mm

5

0114-013799

Hutmutter

1

dome nut

6

0114-013638

Anschlussnippel

1

connection nipple

7

0114-013849

Stehbolzen

1

threaded bolt

8

0114-013850

O-Ring Nylon

1

o-ring

9

0114-014546

Mutter VA

1

nut

10

0114-014884

Filtereinsatz Kunststoff 70 M gelb

1

filter insert 70 M yellow

0114-014917

Filtereinsatz Kunststoff 30 M blau

filter insert 30 M blue

0114-014886

Filtereinsatz Kunststoff 50 M orange

filter insert 50 M orange

0114-014883

Filtereinsatz Kunststoff 100 M schwarz

filter insert 100 M black

0114-014882

Filtereinsatz Kunststoff 150 M rot

filter insert 150 M red

0114-014881

Filtereinsatz Kunststoff 200 M natur

filter insert 200 M nature

11

0114-013855

Reduziernippel

2

nipple

12

0114-014087

Kugelhahn IG 1/4"

1

relief pipe

13

0114-014085

Winkelverschraubung G 1/4"

1

suction tube

14

0114-018637

Entlastungsschlauch

1

hose

15

0114-014166

Flachkopfschraube

1

screw

15a

0114-009743

Federring

2

spring ring

16

0114-013848

Filterverschluß

1

filter cap

17

0114-014114

Stiftschlüssel kpl.

1

key pin

Vorbehaltl. Techn. Änderungen

40

Ersatzteilliste / spare parts list

Ersatzteile Ansaugleitung / spare parts suction system

Pos.

Art.-Nr.

Bezeichnung

St.

Description

Pcs.

0114-014844

Ansaugsystem NW 20 flexibel

suction system DN 20 flexible

1

0114-013801

Reduziernippel

1

reducing nipple

2

0114-018506

Ansaugleitung NW 20

1

suction hose DN 20

3

0114-013734

Siebgehäuse

1

filter housing

4

0114-014112

Materialsieb D 70 M 20

1

strainer 20 mesh

0114-014068

Materialsieb D 70 M 50

strainer 50 mesh

0114-014221

Materialsieb D 70 M 70

strainer 70 mesh

5

0114-014080

Sicherungsring

1

retaining ring

Vorbehaltl. Techn. Änderungen

41

13. RECOMMENDED GUN

High Pressure

Pump

Max. Pressure

Pump (bar)

Recommended

Gun

Max. Pressure

Gun (bar)

HP 3/28

Airless-Outfit

224

HAP 50

Airless 1

500

420

HP 3/28

Aircombi-Outfit

224

AA 4000

DSG-2000

275

250

HP 4/20

Airless-Outfit

100

HAP 50

Airless 1

500

420

HP 4/20

Aircombi-Outfit

100

AA 1500

AA 4000

DSG-2000

105

275

250

HP 4/32

Airless-Outfit

256

HAP 50

Airless 1

500

420

HP 4/32

Aircombi-Outfit

256

AA 4000

DSG-2000

275

250

HP 6/34

Airless-Outfit

272

HAP 50

Airless 1

500

420

HP 6/34

Aircombi-Outfit

272 AA 4000 275

HP 6/60

Airless-Outfit

390

HAP 50

Airless 1

500

420

HP 10/32

Airless-Outfit

256

HAP 50

Airless 1

500

420

HP 10/32

Aircombi-Outfit

256 AA 4000 275

HP 20/66

Airless-Outfit

429 HAP 50 500

HP 25/48

Airless-Outfit

384

HAP 50

Airless 1

500

420

HP 30/32

Airless-Outfit

256

HAP 50

Airless 1

500

420

HP 30/75

Airless-Outfit

474 HAP 50 500

42

4. EC DECLARATION OF CONFORMITY

ITW Finishing Systems and Products

Ringwood Road,

Bournemouth

BH11 9LH,

England

As the representative/manufacturer of the items listed below:

High-Pressure Paint Pump Models BINKS

HP 4/20, HP 3/28, HP 4/32, HP 10/32, HP 6/34, HP 25/48, HP 6/60,

HP 20/66, HP 30/32, HP 30/75

Declare, under our sole responsibility, that the equipment to which this document relates is

in conformity with the following standards or other normative documents:

EN 13463 1:2009, EN 13463 5-2005, EN 982 :1996 + A1 :2008 and EN 12621 :2006

And thereby conform to the protection requirements of Council Directive 98/37/EC relating

to Machinery Safety Directive and council Directive 94/9/EC relating to Equipment and

Protective Systems intended for use in Potentially Explosive Atmospheres;

Issued on: 23/02/10

Authorised by:

Dave Smith

General Manager

2 II Gc T4

43

5. WARRANTY STATEMENT

5 – Year HP Piston Pump Warranty

All Piston Pumps are backed by our 5-year warranty, as a measure of the confidence we place in

the quality of these products - a confidence that you can share.

BINKS HP Piston Pumps Five-Year Warranty

ITW Finishing Systems and Products

(“ITW“) warrants to the original use purchaser of ITW

manufactured HP Piston Pumps that ITW will repair or replace, free of charge, including return

shipping costs within Europe, any such products which under normal use and service proves defective in material or workmanship, as determined by ITW inspection, within FIVE YEARS from

date of shipment from ITW, provided the claimed defective product, or part thereof, is promptly

returned to the ITW factory or ITW authorised warranty repair centre with transportation pre-paid.

This warranty does not cover failure of parts or components due to normal wear or damage, which

in the judgement of ITW, arises from misuse, abrasion, corrosion, negligence, accident, substitution of non ITW parts, faulty installation or tampering.

If ITW inspection discloses no defect in material or workmanship, repair or replacement and return

will not be covered by the ITW warranty.

This warranty covers ITW manufactured Piston Pumps manufactured and shipped on or after

January 1st, 2004.

Equipment not covered by this ITW warranty such as accessories or components of equipment

(switches, connections, fittings, hoses) which are sold by ITW are subject to the ITW Standard

Terms of Sales & Delivery respectively the terms of the individual manufacturer.

The foregoing warranty supersedes, voids and is lieu of all or any other ITW warranties, express

or implied, and no warranty or merchantability or fitness for particular purpose is intended or

made. ITW’s sole obligation and the original use purchaser’s role remedy is as stated above and

in no event shall ITW be liable for any special, direct, indirect, incidental, consequential or other

damages, or expenses of any nature including, without limitation, loss of profits or production time

incurred by the original use purchaser or any other party.

Authorised by:

David Smith

General Manager

Loading...

Loading...