Billy Goat Z3000 Owner's Manual

Not for

Reproduction

COMMERCIAL RIDE ON DEBRIS BLOWER Owner’s Manual

Z3000 HURRICANE RIDE ON DEBRIS BLOWER Owner's Manual

Copyright © Briggs & Stratton Corporation,

Milwaukee, WI, USA. All rights reserved.

IMPORTANT- READ CAREFULLY BEFORE USE AND KEEP FOR FUTURE REFERENCE

5901807

Original Instructions

5107445

Rev A

Not for

Reproduction

billygoat.com

Not for

Reproduction

Table of Contents

T ABLE OF CONTENTS

IDENTIFICATION ...............................................................................1

Product Identifi cation Tag ......................................................... 1

INTRODUCTION ................................................................................2

Using Y our Operator’s Manual ..................................................2

Safety Alert Symbol and Signal Words ....................................2

California Proposition 65 Statement ........................................2

SPECIFICA TIONS .............................................................................3

SAFETY .............................................................................................4

Operator Training Required ......................................................4

Preparation .................................................................................4

Operating Safely ........................................................................4

Using a Spark Arrestor ..............................................................5

Checking Working Area ............................................................. 5

Parking Safely ............................................................................5

Rotating Impeller is Dangerous ................................................6

Protect Children .........................................................................6

Avoid Tipping .............................................................................6

Keep Riders Off ..........................................................................7

Avoid High Pressure Fluids ......................................................7

Checking Wheel Hardware ........................................................7

Wear Appropriate Clothing .......................................................7

Maintenance and Storage .........................................................7

Prevent Fires ..............................................................................8

Tire Safety...................................................................................8

Handling Fuel Safely ..................................................................8

Handling Waste Product and Chemicals .................................. 9

SAFETY AND OPERATIONAL DECALS ........................................10

OPERATING .................................................................................... 11

Operator Station Controls .......................................................11

Parking Brake ......................................................................11

Operator Station Controls .......................................................12

Misc. Controls and Checks .....................................................13

T esting the Safety Systems ....................................................15

T esting the Parking Brake .......................................................15

Using the Throttle and Choke .................................................16

Starting Using the Throttle and Choke .................................16

Filling Fuel T ank .......................................................................16

Transaxle Bypass V alve ..........................................................17

Using the Hydrostatic Motion Controls ..................................18

Using the Blower and the Defl ector Controls ........................19

Dual Defl ector System (Left Defl ector) ...................................19

Not for

Reproduction

Table of Contents

SERVICE .........................................................................................21

Service Intervals ......................................................................21

Service Engine .........................................................................21

Checking Engine Oil Level ......................................................22

Changing Engine Oil and Filter ...............................................23

Cleaning Engine Oil Cooler and Checking Air Filter .............23

Checking Air Filter Elements .................................................. 24

Replacing Fuel Filter ................................................................24

Checking Engine Cooling Intake and Fan ..............................25

Checking Spark Plugs .............................................................25

Checking Carburetor Adjustment ........................................... 25

Service Hydraulics ...................................................................25

Checking Hydraulic Oil Level ..................................................25

Changing Hydraulic Oil and Filters ........................................26

Impeller Removal and Inspection ...........................................28

Changing Drive Belt .................................................................28

Service Parking Brake .............................................................29

Service Motion Controls ..........................................................30

Service Tires.............................................................................32

Service Electrical .....................................................................33

TROUBLESHOOTING .....................................................................35

Using the Troubleshooting Chart ...........................................35

STORAGE .......................................................................................38

Storing Machine Safety ...........................................................38

Preparing Machine for Storage ...............................................38

Preparing Fuel and Engine For Storage .................................38

Removing Machine From Storage ..........................................39

WARRANTY ST A TEMENT ..............................................................40

Cleaning the Engine Oil Cooler ............................................23

Purging Procedure ..............................................................27

Adjusting the Motion Controls ..............................................30

Adjusting Motion Controls - Checking Neutral Center ..........30

Adjusting Motion Controls Neutral Center ............................30

Removing and Installing Rear Drive Wheels ........................32

Removing and Installing Front Caster Wheels .....................32

Checking Tire Pressure .......................................................32

Replacing Fuse ...................................................................33

Removing and Installing Battery ..........................................33

Cleaning Battery and T erminals ...........................................34

Using Booster Battery or Jump Starting ...............................34

billygoat.com

Not for

Reproduction

Identification

SSE

1, US

IDENTIFICATION

Product Identifi cation Tag

The product identifi cation tag can be found on the

left side of the engine deck.

L

AL

CLOSE

Product

º»ÄÊ¿Ű¹·Ê¿ÅÄ

· ½

Record your model number, serial number, and angine model and serial number in the space provided

for easy access.

BRIGGS & STRATTON

CORPORATION

MILWAUKEE, WI 53201, USA

ASSEMBLED IN THE USA

PART NO.

XXXXXXX

PRODUCT REFERENCE DATA

Unit Model Number:

Unit Serial Number:

Dealer Name:

Date Purchased:

ENGINE REFERENCE DATA

Engine Make:

Engine Model:

Engine Type / Specifications:

Engine Code / Serial Number:

SERIAL NO.

XXXXXXXXX

Product Identifi cation Tag Location

When contacting your authorized serivce dealer for

replacement parts, service, or information you MUST

have these numbers.

Note: For the location of the engine identification

numbers, refer to the engine owner’s manual.

1

Not for

Reproduction

Introduction

INTRODUCTION

Using Y our Operator’s Manual

This manual is an important part of your machine and

should remain with the machine when you sell it.

Use the safety and operating information in the machine Operator’s Manual to operate and service the

machine safely and correctly.

This operator’s manual explains the features and promotes the safe use of this machine. Please read it in

its entirety and follow the instructions carefully so that

you may have many years of safe and productive operation.

An engine manufacturer’s owner’s manual has been

provided with your machine. This will provide maintenance and troubleshooting information for the engine

installed in your machine.

BILLY GOAT is a trademark of Billy Goat Industries,

Inc.

Safety Alert Symbol and Signal Words

The safety alert symbol

safety information about hazards that can

result in personal injury. A signal word

(DANGER, WARNING, or CAUTION) is used

with the alert symbol to indicate the likelihood

and the potential severity of injury . In addition,

a hazard symbol may be used to represent

the type of hazard.

DANGER indicates a hazard which, if not

avoided, will result in death or serious injury.

WARNING indicates a hazard which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazard which, if not

avoided, could result in minor or moderate injury.

NOTICE indicates a situation that could result in

damage to the product.

( ) is used to identify

California Proposition 65 Statement

WARNING

This product can expose you to

chemicals including gasoline engine

exhaust, which is known to the State of

California to cause cancer, and carbon

monoxide, which is known to the State of

California to cause birth defects or other

reproductive harm. For more information

go to www.P65Warnings.ca.gov.

2 billygoat.com

Not for

Reproduction

Specifications

SPECIFICATIONS

Specifi cations are correct at time of printing and are subject to change without notice.

ENGINE

For complete engine specifi cations see the engine manufacturer’s operator’s manual included with your unit.

Fits models: 5901807

Briggs & Stratton

Make Briggs & Stratton

Model 613477-0057-J1

Electrical System 12 volt, 20 amp alternator; Battery: 340 CCA

CHASSIS

Fuel Tank Capacity 10 gallons (38 L) total

Rear Wheels

Tire Size 22 X 11.00 - 11

Infl ation Pressure 22 psi (1,5 bar)

Front Wheels

Tire Size 13 X 5.50 -6

Infl ation Pressure 28 psi (1,9 bar)

TRANSMISSIONS

Make Hydro-Gear®

Model ZT3100 Transaxles

Hydraulic Fluid Mobil 1™ 15W-50 synthetic or equivalent

Speed Infi nitely Variable

DIMENSIONS:

Width 45” (114 cm)

Height 56” (142 cm)

Length 65” (165 cm)

Weight 895 lbs (406 kg)

3

Not for

Reproduction

Operator Safety

SAFETY

Operator Training Required

Read the Operator’s Manual and other training

•

material. If the operator or mechanic cannot read

English, it is the owner’s responsibility to explain

this material to them. This publication is available

in other languages.

Become familiar with the safe operation of the

•

equipment, operator controls, and safety signs.

All operators and mechanics should be trained.

•

The owner of the machine is responsible for training the users.

Never let children or untrained people operate or

•

service the equipment. Local regulations may restrict the age of the operator.

The owner/user can prevent and is responsible

•

for accidents or injuries occurring to themselves,

other people, or property.

Train operators on the machine in an open, unob-

•

structed area under the direction of an experienced operator.

Check that the operator’s presence controls,

•

safety switches and shields are attached and

functioning properly. DO NOT operate unless

they are functioning properly.

Operating Safely

NEVER run an engine in an enclosed area where

•

dangerous carbon monoxide fumes can collect.

Only operate in good light, keeping away from

•

holes and hidden hazards.

Be sure all drives are in NEUTRAL and parking

•

brake is ENGAGED before starting engine. Only

start engine from the operator’s position.

Slow down and use extra care on hillsides. Be

•

sure to travel in the recommended direction on

hillsides. For this machine, drive across hillsides,

not up and down. Turf conditions can affect the

machine’s stability. Use caution while operating

near drop-offs. DO NOT operate machine within

5 feet of an embankment or drop-off.

Slow down and use caution when making turns

•

and when changing directions on slopes.

Preparation

Evaluate the terrain to determine what accesso-

•

ries and attachments are needed to properly and

safely perform the job. Only use accessories and

attachments approved by the manufacturer.

Wear appropriate clothing including hard hat,

•

safety glasses and hearing protection. Tie back

long hair, remove loose clothing or jewelry that

may get tangled in moving parts.

Inspect the area where the equipment is to be

•

used and remove all objects such as rocks, toys,

etc. which can be thrown by the machine.

Use extra care when handling gasoline and other

•

fuels. They are fl ammable and vapors are explo-

sive.

Allow engine to cool down before fueling.

•

a. Use only an approved container.

b. Never remove gas cap or add fuel when en-

gine is running. Do not smoke.

c. Never refuel or drain the machine indoors.

NEVER operate with the shields, or other guards,

•

not securely in place. Be sure all interlocks are

attached, adjusted properly, and functioning

properly.

Do not change the engine governor setting or

•

overspeed the engine. Operating the engine at

excessive speed can increase the hazard of personal injury and machine damage.

Stop on level ground, engage parking brake,

•

close defl ectors, and shut off engine before leav-

ing the operator’s position for any reason.

Stop equipment and inspect impeller if an abnor-

•

mal vibration occurs. Make necessary repairs before resuming operations.

Keep hands and feet away from the intake and

•

discharge.

Look behind and down before backing up to be

•

sure of a clear path.

Never carry passengers. Keep pets and bystand-

•

ers away.

4 billygoat.com

Not for

Reproduction

Operator Safety

Slow down and use caution when making turns

•

and crossing roads and sidewalks. Close defl ec-

tors if not blowing. Watch for traffi c when operat-

ing near or crossing roadways.

Be aware of the blower discharge direction and

•

DO NOT point it at anyone.

DO NOT operate the machine while under the

•

infl uence of alcohol or drugs.

Use care when loading or unloading the machine

•

into or off of a trailer or truck.

Use care when approaching blind corners,

•

shrubs, trees, or other objects that may obscure

vision.

Inspect machine before you operate. Be sure

•

hardware is tightened securely . Repair or replace

damaged, badly worn, or missing parts. Be sure

guards and shields are in good condition and fastened in place. Make any necessary adjustments

before you operate.

Before using, always visually inspect to see

•

that the impeller, its bolt, and blower assembly

are not worn or damaged. Replace worn or damaged impeller and bolt.

Using a Spark Arrestor

The engine in this machine is equipped with a spark

arrestor muffl er. It is a violation of California Public

Resource Code Section 4442 to use or operate this

engine on or near any forest-covered, brush-covered

or grass-covered land unless the exhaust system is

equipped with a spark arrestor meeting any applicable

local or state laws. Other states or federal areas may

have similar laws.

An installed spark arrestor must be maintained in

good working order by the operator.

Checking Working Area

Evaluate the terrain to determine what accesso-

•

ries and attachments are needed to properly and

safely perform the job.

Clear work area of objects that might be thrown.

•

Keep people and pets out of working area.

Study working area. Set up a safe blowing pat-

•

tern. Do not blow where traction or stability is

doubtful.

Test drive through area with blower not running.

•

Slow down when you travel over rough ground.

Keep safety decals visible when installing acces-

•

sories and attachments.

Do not wear radio or music headphones. Safe

•

service and operation require your full attention.

When machine is left unattended, stored, or

•

parked, remove the key.

Parking Safely

1. Stop machine on a level surface, not on a slope.

2. Close defl ectors.

3. Engage the parking brake.

4. Stop the engine.

5. Remove the key.

6. Wait for engine and all moving parts to stop before you leave the operator’s station.

7. Close fuel shut-off valve, if your machine is

equipped.

8. Disconnect the negative battery cable or remove

the spark plug wires (for gasoline engines) before

servicing the machine.

5

Not for

Reproduction

Operator Safety

Rotating Impeller is Dangerous

WARNING

Rotating impeller can cut off arms and

legs, and throw objects. Failure to observe

safety instructions could result in serious

injury or death.

Keep hands, feet and clothing away from blow-

•

er housing when engine is running.

Be alert at all times, drive forward carefully. Peo-

•

ple, especially children can move quickly into the

working area before you know it.

Protect Children

Death or serious injury can occur when young

•

children associate having fun with a lawn equipment simply because someone has given them a

ride on a machine.

Children are attracted to lawn equipment and ac-

•

tivities. They don’t understand the dangers or the

fact that the operator is unaware of their presence.

Children who have been given rides in the past

•

may suddenly appear in the work area for another ride and be run over or backed over by the

machine.

Tragic accidents with children can occur if the op-

•

erator is not alert to the presence of children, especially when a child approaches a machine from

behind. Before and while backing up, look

down and behind the machine carefully, especially for children.

NEVER carry children on a machine or attach-

•

ment. Do not tow children in a cart or trailer. They

can fall off and be seriously injured or interfere

with safe machine operation.

Never use the machine as a recreational vehicle

•

or to entertain children.

Never allow children or an untrained person to

•

operate the machine. Instruct all operators not to

give children a ride on the machine or in an attachment.

Keep children indoors, out of the work area, and

•

in the watchful eye of a responsible adult, other

than the operator, when a machine is being operated.

Stay alert to the presence of children. Never as-

•

sume that children will remain where you last saw

them. Turn the machine OFF if a child enters the

work area.

Avoid Tipping

Slopes are a major factor related to loss-of-con-

•

trol and tip-over accidents, which can result in

severe injury or death. Operation on all slopes

requires extra caution.

Blow across slopes, not up and down.

•

Watch for holes, ruts, bumps, rocks, or other hid-

•

den objects. Uneven terrain could overturn the

machine. Tall grass can hide obstacles.

Choose a low ground speed so you will not have

•

to stop while on a slope.

Do not blow or operate machine on wet grass.

•

Tires may lose traction.

Tires may lose traction on slopes even though the

•

brakes are functioning properly.

Avoid starting, stopping or turning on a slope. If

•

the tires lose traction, turn and proceed slowly,

straight down the slope.

Keep all movement on slopes slow and gradual.

•

Do not make sudden changes in speed or direction, which could cause the machine to roll over.

Use extra care while operating machine with at-

•

tachments, they can affect stability of the machine. Do not use on steep slopes.

Do not blow near drop-offs, ditches, embank-

•

ments, or bodies of water. The machine could

suddenly roll over if a wheel goes over the edge

or the edge caves in.

Follow the manufacturer ’s recommendations for

•

wheel weights or counterweights for added stability when operating on slopes or using front or rear

mounted attachments. Remove weights when

not required.

Drive machine very slowly and avoid quick stops.

•

6 billygoat.com

Not for

Reproduction

Operator Safety

Keep Riders Off

Only allow the operator on the machine. Keep

•

riders off.

Riders on the machine or attachment may be

•

struck by foreign objects or thrown off the machine causing serious injury.

Riders obstruct the operator ’s view resulting in

•

the machine being operated in an unsafe manner.

Avoid High Pressure Fluids

Hydraulic hoses and lines can fail due to physical

•

damage, kinks, age, and exposure. Check hoses

and lines regularly . Replace damaged hoses and

lines.

Hydraulic fl uid connections can loosen due to

•

physical damage and vibration. Check connections regularly. Tighten loose connections.

Escaping fl uid under pressure can penetrate the

•

skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic

or other lines. Tighten all connections before applying pressure.

Search for leaks with a piece of cardboard. Pro-

•

tect hands and body from high pressure fl uids.

If an accident occurs, see a doctor immediately.

•

Any fl uid injected into the skin must be surgically

removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury

should reference a knowledgeable medical

source.

Checking Wheel Hardware

Wear Appropriate Clothing

Always wear safety goggles, or safety glasses

•

with side shields, and a hard hat when operating

the machine.

Wear close fi tting clothing and safety equipment

•

appropriate for the job.

While blowing, always wear substantial footwear

•

and long trousers. DO NOT operate the equip-

ment when barefoot or wearing open sandals.

Wear a suitable hearing protection device such

•

as earplugs. Loud noise can cause impairment

or loss of hearing.

Maintenance and Storage

NEVER operate machine in a closed area where

•

dangerous carbon monoxide fumes can collect.

Disengage drives, engage parking brake, stop

•

engine and remove key or disconnect spark plug

(for gas engines). Wait for all movement to stop

before adjusting, cleaning or repairing.

Clean all debris from machine, drives, muffl ers,

•

and engine to help prevent fi res. Clean up oil or

fuel spillage.

Let engine cool before storing and do not store

•

near fl ame.

Shut off fuel while storing or transporting. Do not

•

store fuel near fl ames or drain indoors.

Park machine on level ground. Never allow un-

•

trained personnel to service machine. Understand service procedure before doing work.

An accident could occur causing serious injury if

•

wheel hardware is not fastened.

Check wheel hardware tightness often during the

•

fi rst 100 hours of operation. Torque to 75 ft-lbs.

Wheel hardware must be tightened to specifi ed

•

torque using the proper procedure anytime it is

loosened.

Use jack stands or lock service latches to support

•

components when required. Securely support

any machine elements that must be raised for

service work.

Before servicing machine or attachment, care-

•

fully release pressure from any components with

stored energy, such as hydraulic components or

springs.

Release hydraulic pressure by moving hydraulic

•

control levers back and forth with the engine OFF .

7

Not for

Reproduction

Operator Safety

Disconnect battery or remove spark plugs (for

•

gas engines) before making any repairs. Disconnect the negative terminal fi rst and the positive

last. Reconnect positive fi rst and negative last.

Use care when checking impeller. Wear gloves,

•

and use caution when servicing them. Only REPLACE impeller. Never attempt to straighten or

weld them.

Keep hands, feet, clothing, jewelry and long hair

•

away from moving parts. If possible, do not make

adjustments with the engine running.

Charge battery in an open well ventilated area,

•

away from spark and fl ames. Unplug charger be-

fore connecting or disconnecting from battery.

Wear protective clothing and use insulated tools.

Keep all parts in good working condition and all

•

hardware tightened. Replace all worn or damaged decals.

Keep all nuts and bolts tightened securely, espe-

•

cially impeller attachment bolts, to be sure the

equipment is in safe working condition.

Check brake operation frequently.

•

Prevent Fires

Always maintain the correct tire pressure. DO

•

NOT infl ate the tires above the recommended

pressure. Never weld or heat a wheel and tire

assembly. The heat can cause an increase in air

pressure resulting in a tire explosion. Welding

can structurally weaken or deform the wheel.

When infl ating tires, use a clip-on chuck and ex-

•

tension hose long enough to allow you to stand to

one side and NOT in front of or over the tire assembly.

Check tires for low pressure, cuts, bubbles, dam-

•

aged rims or missing studs and nuts.

Handling Fuel Safely

To avoid personal injury or property damage, use ex-

treme care in handling fuel. Fuel is extremely fl am-

mable and fuel vapors are explosive:

Extinguish all cigarettes, cigars, pipes, and other

•

sources of ignition.

Use only an approved fuel container. Use only

•

non-metal, portable fuel containers approved by

the Underwriter’s Laboratory (U.L.) or the American Society for Testing & Materials (ASTM). If using a funnel, make sure it is plastic and has no

screen or fi lter.

Remove debris from engine compartment and

•

muffl er area, before and after operating machine,

especially after blowing in dry conditions.

ALWAYS shut off fuel when transporting or stor-

•

ing machine, the machine has a fuel shutoff.

DO NOT store machine near an open fl ame or

•

source of ignition, such as a water heater or furnace.

Check fuel lines, tank, cap, and fi ttings frequently

•

for cracks or leaks. Replace if necessary.

Tire Safety

Explosive separation of a tire and rim parts can cause

serious injury or death:

Do not attempt to mount a tire without the proper

•

equipment and experience to perform the job.

Never remove the fuel tank cap or add fuel with

•

the engine running. Allow engine to cool before

refueling.

Never add fuel to or drain fuel from the machine

•

indoors. Move machine outdoors and provide adequate ventilation.

Clean up spilled fuel immediately. If fuel is spilled

•

on clothing, change clothing immediately . If fuel is

spilled near machine, do not attempt to start the

engine but move the machine away from the area

of spillage. Avoid creating any source of ignition

until fuel vapors have dissipated.

Never store the machine or fuel container where

•

there is an open fl ame, spark, or pilot light such

as on a water heater or other appliance.

Prevent fi re and explosion caused by static elec-

•

tric discharge. Static electric discharge can ignite

fuel vapors in an ungrounded fuel container.

8 billygoat.com

Not for

Reproduction

Operator Safety

Never fi ll containers inside a vehicle or on a truck

•

or trailer bed with a plastic liner. Always place

containers on the ground away from your vehicle

before fueling.

Remove fuel-powered equipment from the truck

•

or trailer and refuel it on the ground. If this is not

possible, then refuel such equipment with a portable container, rather than from a fuel dispenser

nozzle.

Keep the nozzle in contact with the rim of the fuel

•

tank or container opening at all times until the

fueling is complete. Do not use a nozzle lock

open device.

Never overfi ll fuel tank. Replace fuel tank cap

•

and tighten securely.

Replace all fuel container caps securely after

•

use.

For gasoline engines, do not use gas with metha-

•

nol. Methanol is harmful to your health and to the

environment.

Handling Waste Product and Chemicals

Waste products, such as, used oil, fuel, coolant,

•

brake fl uid, and batteries, can harm the environ-

ment and people:

DO NOT use beverage containers for waste fl uids

•

- someone may drink from them.

Contact your local Recycling Center or autho-

•

rized dealer to learn how to recycle or get rid of

waste products.

Safety Data Sheets (SDS) provides specifi c de-

•

tails on chemical products: physical and health

hazards, safety procedures, and emergency response techniques. The seller of the chemical

products used with your machine is responsible

for providing the SDS for that product.

9

Not for

Reproduction

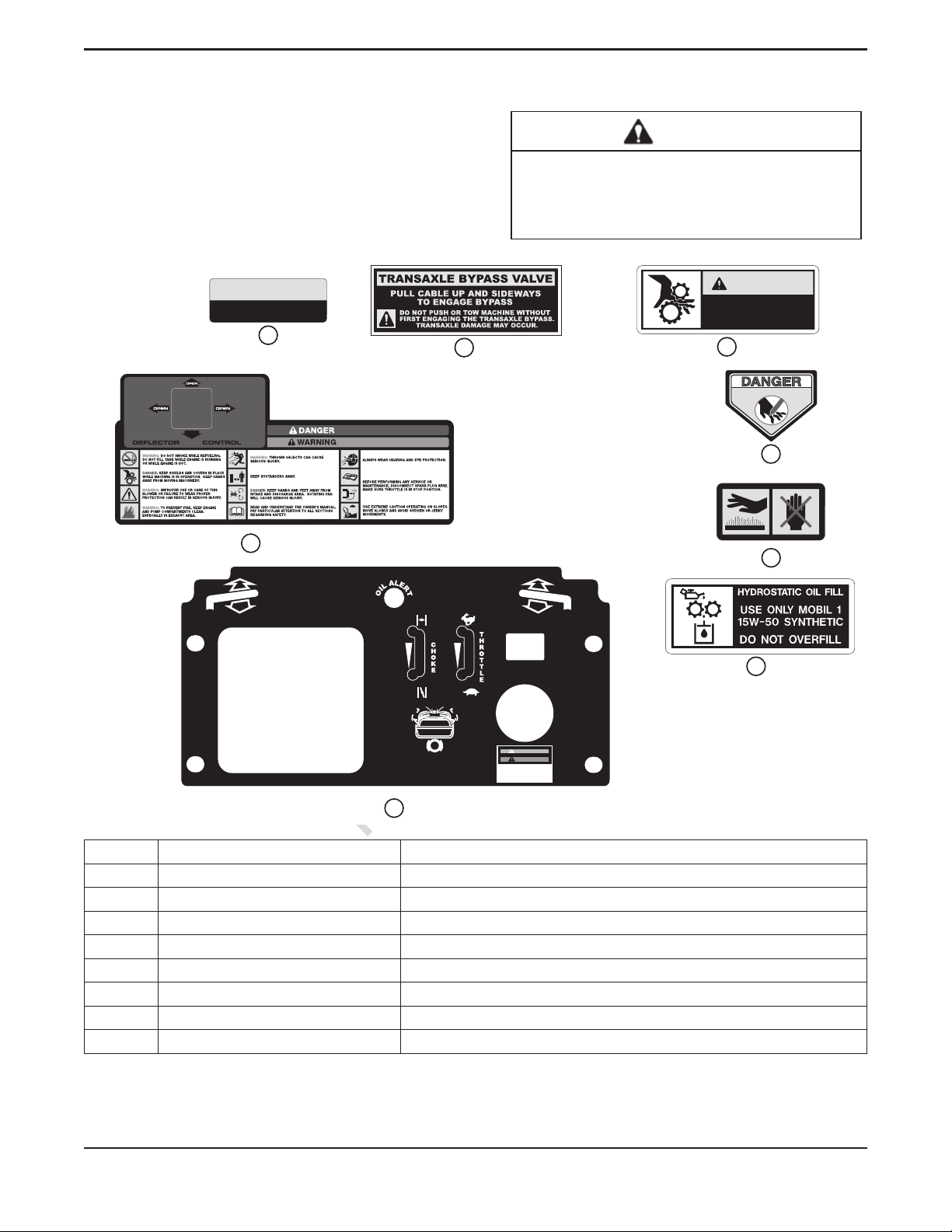

Safety and Operational Decals

DECALS

Before operating your unit, read the safety decals.

The cautions and warnings are for your safety. To

avoid a personal injury or damage to the unit,

understand and follow all safety decals.

WARNING

If any safety decals become worn or

damaged, and cannot be read, order

replacement decals from your local dealer.

CLOSE

ALL

EMERGENCY BRAKE

RELEASE

LIFT LEVER

A

D

FORWARD

REVERSE

FUEL FILL (GASOLINE ONLY)

CAUTION

X3-4211

B

FORWARD

REVERSE

PINCH

POINT

C

KEEP HANDS AND FEET AWAY

E

F

H

P

PARKING BRAKE

RED DOTTED LINE = BRAKE AUTOMATICALLY ENGAGED

GRAY FILL = BRAKE AUTOMATICALLY DISENGAGED

DANGER

WARNING

DO NOT OPERATE THIS EQUIPMENT

WITHOUT PROPER AUTHORIZATION

AND TRAINING. IT IS THE OPERATOR’S

RESPONSIBILITY TO READ AND

COMPLETELY UNDERSTAND ALL

DANGERS, WARNINGS, CAUTIONS AND

INSTRUCTIONS ON THE EQUIPMENT

AND IN THE OPERATOR’S MANUAL.

G

Callout Part Number Description

A 84001535 Decal, Emergency Brake Release

B 84001443 Decal, Transaxle Bypass Valve

C 84001491 Decal, Pinch Point

D 84001867 Decal, Dash, Joystick

E 84001490 Decal, Danger

F 84001489 Decal, Hot

G 84001493 Decal, Dash Controls

H 84001492 Decal, Hydro

10 billygoat.com

Not for

Reproduction

OPERATING

Operator Station Controls

Please take a moment to become familiar with the

•

controls on the dash. A clear understanding of the

operation and function of each control is essential

to the safe and productive use of this machine.

Parking Brake

Operation

Parking Brake Disengaged

This photo shows the parking brake in the DIS-

•

ENGAGED position.

Parking Brake Engaged

This photo shows the parking brake in the EN-

•

GAGED position with all other controls in the

OFF/NEUTRAL position. The parking brake

should be in this position starting, parking, or anytime other than when the machine is in motion

with an operator present at the controls.

11

Loading...

Loading...