Page 1

MODEL SC121H

OPERATING AND SAFETY INSTRUCTIONS

370406 F103104A

1

Page 2

370406 F103104A

2

Page 3

- SOD CUTTER MANUAL CONTENTS

1. USE OF THE MANUAL.........................................................................page 4

2. NOTICES ON THE MACHINE...............................................................page 5

3. TECHNICAL DATA.................................................................................page 7

4. LIFTING AND TRANSPORTATION..........................................................page 8

5. MAIN PARTS OF THE MACHINE...........................................................page 9

6. CONTROLS AND ADJUSTMENTS......................................................page 10

7. ASSEMBLY INSTRUCTIONS FOR THE HANDLEBARS AND

END PART OF THE CUTTING HEIGHT ADJUSTMENT LEVER..........page 11

8. SAFETY INFORMATION

A) GENERAL INSTRUCTIONS...............................................................page 12

B) TRAINING.........................................................................................page 12

C) PREPARATION.................................................................................page 12

D) WORKING USE..................................................................................page 13

E) AFTER USE........................................................................................page 15

9. TRANSPORTATION OF THE MACHINE................................................page 15

10. DESCRIPTION OF THE SAFETY SYSTEMS AND GUARDS..............page 16

11. OPERATIONS TO BE CARRIED OUT BEFORE SWITCHING ON......page 16

12. STARTING AND DRIVING THE TURF CUTTER.................................page 17

13. CUTTING TIPS.....................................................................................page 19

14. CHECKS

A) TYRE PRESSURE...........................................................................page 19

B) CABLE CONTROL ADJUSTMENT ...................................................page 19

C) BELT REPLACEMENT AND ADJUSTMENT.....................................page 20

D) SERVICE BRAKE CHECKING.........................................................page 21

E) CHECKING AND REPLACING THE BLADE.....................................page 24

15. MAINTENANCE AND STORAGE..........................................................page 25

16. CLEANING THE MACHINE..................................................................page 26

17. SEASONAL LONG-TERM STORAGE PERIODS..................................page 26

18. DECOMMISSIONING AND SCRAPPING.............................................page 27

19. TECHNICAL ASSISTANCE...................................................................page 27

20. WARRANTY..........................................................................................page 27

21. TROUBLESHOOTING............................................................................page 28

370406 F103104A

3

Page 4

OPERATING AND SAFETY INSTRUCTIONS

SOD CUTTER MODEL SC121H

FOREWORD

This machine may only be utilized for the purpose for which it was designed, i.e. to cut

30cm-wide strips of turf.

Any other use other than that stated, not covered or deducible from this Ma-nual and the

enclosed Engine Manual is “PROHIBITED”.

Failure to comply with instructions in this Manual and in the Engine Manual releases the

manufacturer from all liability, in particular for any damage resulting from improper or

incorrect use, through negligence, superficial interpretation or flagrant disregard for the

safety requirements herein.

Get your dealer to explain how to use the machine in optimum safety conditions.

Always perform the checks as prescribed herein before each work session with the machine.

Should any information given in the following pages be unclear or not straightforward

please contact the manufacturer directly.

1. USE OF THE MANUAL

This Manual consists of numbered pages and enclosures featured in the list of contents.

Before operating the machine the user must read the instructions in the Operator’s Manual

carefully as well as those of the Engine Manual enclosed.

Use of the turf cutter by more than one operator (individually), means that they must have

carefully read the Operator’s Manual and the Engine Manual before using it.

The aforementioned manuals form an integral part of the machine and must therefore be

kept intact and in good condition, in a known, easily accessible place for the entire working

life of the machine, even if the turf cutter is passed on to another owner. The purpose of

these manuals is to provide the information necessary for the safe and competent use of

the product. In the instance of wear or purely for a greater technical working knowledge,

the manufacturer may be contacted directly. The Notes Section at the end of the Turf

cutter Manual is for the addition of any complementary notes.

In this Manual all safety information appears in special boxes headed “WARNING”.

WARNING

This heading is used to draw the user’s attention to hazardous areas or moving parts of

the machine. It is also used in instances where failure to comply with the instructions given

may result in injury to persons and animals or damage to property.

370406 F103104A

4

Page 5

2. NOTICES ON THE MACHINE

WARNING

The Engine Exhaust from this product contains chemicals known to the State of California

to cause cancer, birth defects or other reproductive harm.

The symbols affixed to the machine serve to warn of danger during its use and maintenance.

It is vitally important to understand the meaning of the danger notices and all messages

should be kept in legible condition. In the instance of wear these notices should be replaced

and use of the machine suspended while without such notices.

The operator is advised to observe the warnings given on the affixed notices.

The symbols affixed to the machine serving to warn of danger during its use and

maintenance are as follows:

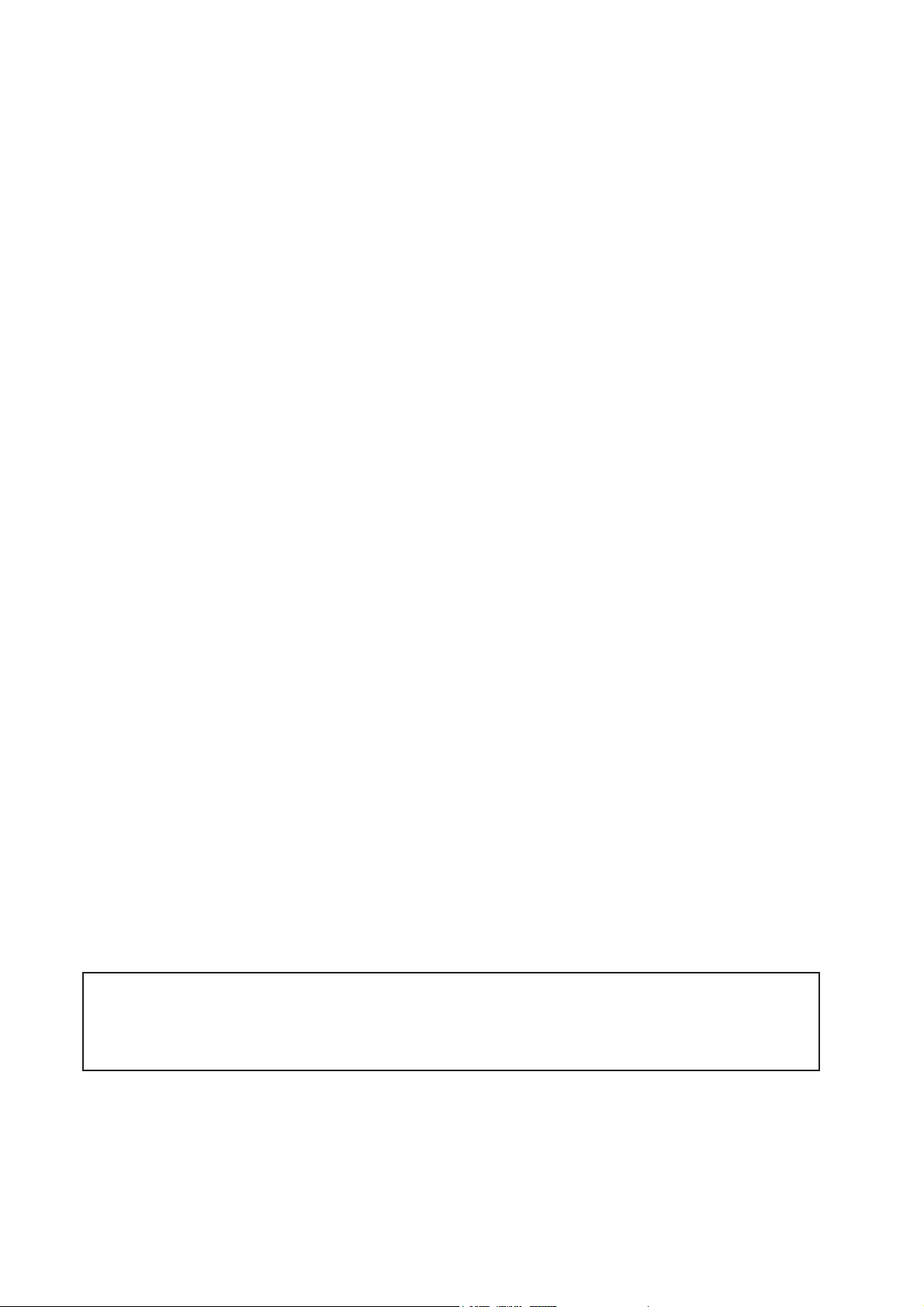

400268 - Label Hot Engine, Qty. 1

400424 - Label Warning, Qty. 2

370406 F103104A

5

Page 6

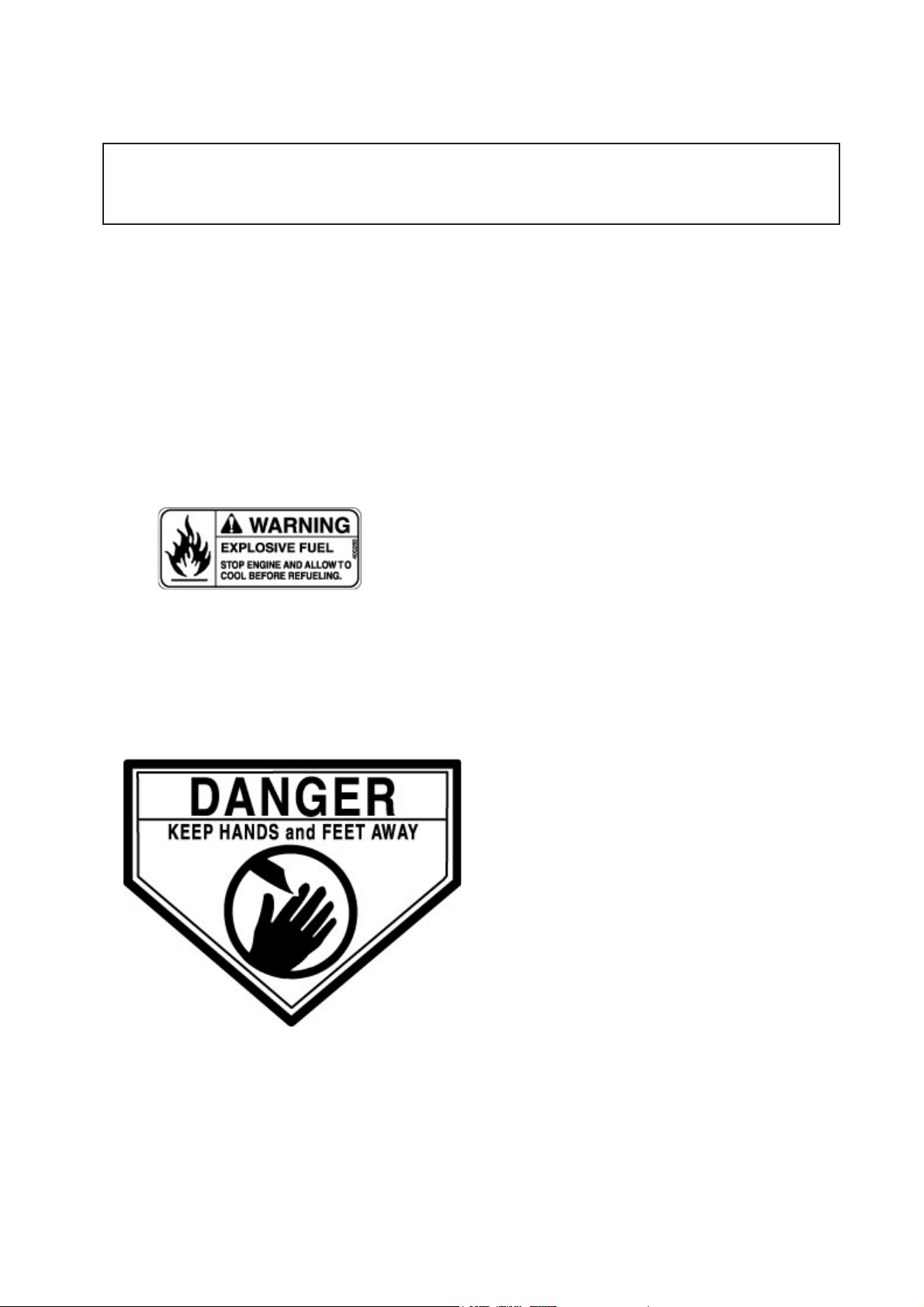

370405 - Label Controls Instuction, Qty. 1

370300 - Label Instructions, Qty. 1

370406 F103104A

6

Page 7

3. TECHNICAL DATA FOR THE SOD CUTTER SC121H

ENGINE : Gasoline, HONDA GX 160 K1

ENGINE CAPACITY : 5.5 Hp (4.0 kW)

CUTTING WIDTH : 12” (30 cm)

CUTTING HEIGHT : adjustable up to 35 mm

SPEED GEARS : 2 forward gears

TRANSMISSION : mechanical

GEARS : in oil bath

START : recoil

HANDLEBARS : height-adjustable

TYRES : front tyres GARDEN 3.00-4

rear tyres TRACTOR 3.00-4

DIMENSIONS L x W x H (mm) : 780 x 420 x 610 mm

WEIGHT (kg) : 73

ACOUSTIC PRESSURE, measured according to EN 12733: 86,2 dBA

ACOUSTIC POWER, measured according to EN 12733: LWA 97 dBA

VIBRATION LEVEL TRANSMITTED TO THE HANDLEBAR ( EN 12 733) AW: 1,8 m/s²

Environmental conditions

Unless otherwise stated at the time of ordering it is understood that the machine is to work

normally in the environmental conditions covered by the following points.

Environmental conditions other than those described may cause mechanical breakage

resulting in the creation of dangerous situations for persons.

ALTITUDE

The altitude of the place in which the machine is to be used must not exceed 1500 m

above sea level.

TEMPERATURE

Minimum ambient temperature: -5°C

Maximum ambient temperature: +50°C

ATMOSPHERIC CONDITIONS

The electrical equipment will function correctly in atmospheric conditions with a relative

humidity up to 50% at a temperature of 40°C and at 90% with a temperature up to 20°C

(without condensate).

ATMOSPHERE WITH RISK OF EXPLOSION AND/OR FIRE

The standard machine herein described is not designed to work in explosive atmospheres

or in those with risk of fire.

370406 F103104A

7

Page 8

4. LIFTING AND TRANSPORTATION

All material is carefully checked by the manufacturer before shipping. The turf cutter is

delivered in a cardboard box with the handlebars and end part of the cutting height

adjustment lever disassembled.

Upon receipt of the machine make sure that it has not been damaged during transit and

that the packaging has not been tampered or any parts removed. Report any damage or

missing parts immediately to the carrier and the manufacturer with photographic

documentation.

After assembling the handlebars and the end part of the cutting height adjustment lever

as per the instructions given in paragraph 7 of this manual, the machine may be moved

on its own wheels.

The manufacturer is not liable for any damage caused by transportation of the machine

after its delivery.

WARNING

Extreme care must be taken during handling to prevent overturning. Avoid steep gradients

to prevent loss of control.

Make sure that there are no persons present within the danger area.

370406 F103104A

8

Page 9

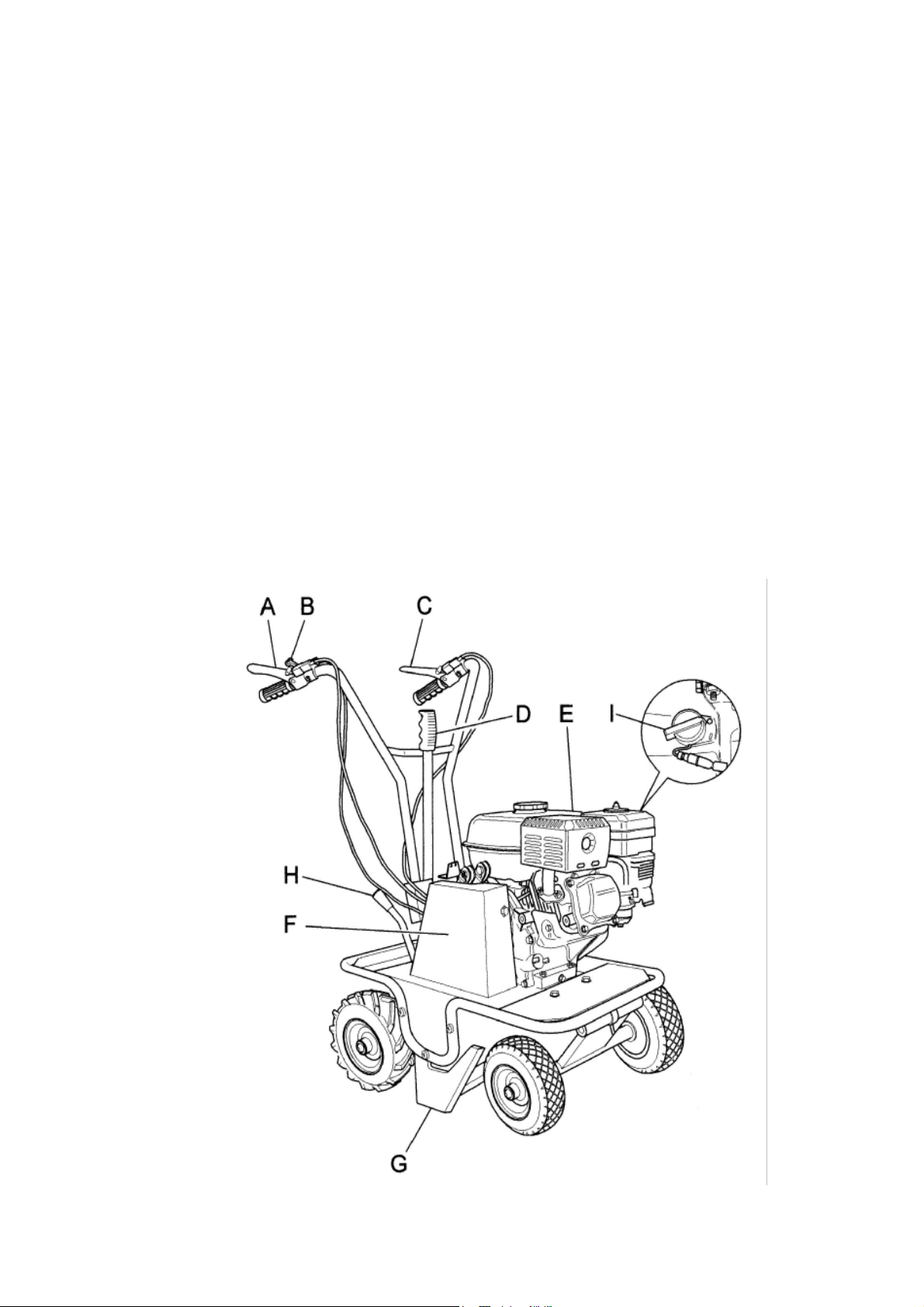

5. MAIN PARTS OF THE MACHINE

The machine consists of the following main parts:

A - BLADE CLUTCH CONTROL LEVER

B - ACCELERATOR CONTROL LEVER

C - FORWARD CLUTCH CONTROL LEVER

D - CUTTING HEIGHT ADJUSTMENT LEVER

E - ENGINE

F - COVER

G - BLADE

H - FORWARD-NEUTRAL GEAR SELECTOR LEVER

I - ON/OFF SWITCH (1/0)

Figure 1

370406 F103104A

9

Page 10

6. CONTROL AND ADJUSTMENTS

A) BLADE CLUTCH CONTROL LEVER

This is used to engage and disengage the blade movement. Lowering the lever engages

the clutch and releasing it disengages the clutch.

WARNING

The blade will continue to move if the engine is running and the blade clutch is engaged,

regardless of the position of the forward clutch.

B) ACCELERATOR CONTROL LEVER

This is used to adjust the number of engine revolutions according to the operations to be

carried out. Hence at switch on the lever will be positioned on the minimum setting whilst

during work operations it will be positioned as required by use.

C) FORWARD CLUTCH CONTROL LEVER

This lever only has two positions: engage and disengage. Lowering the lever engages

the clutch and releasing it disengages the clutch.

This lever automatically operates the service brake: when released the lever engages the

brake, when engaged the lever disengages the brake.

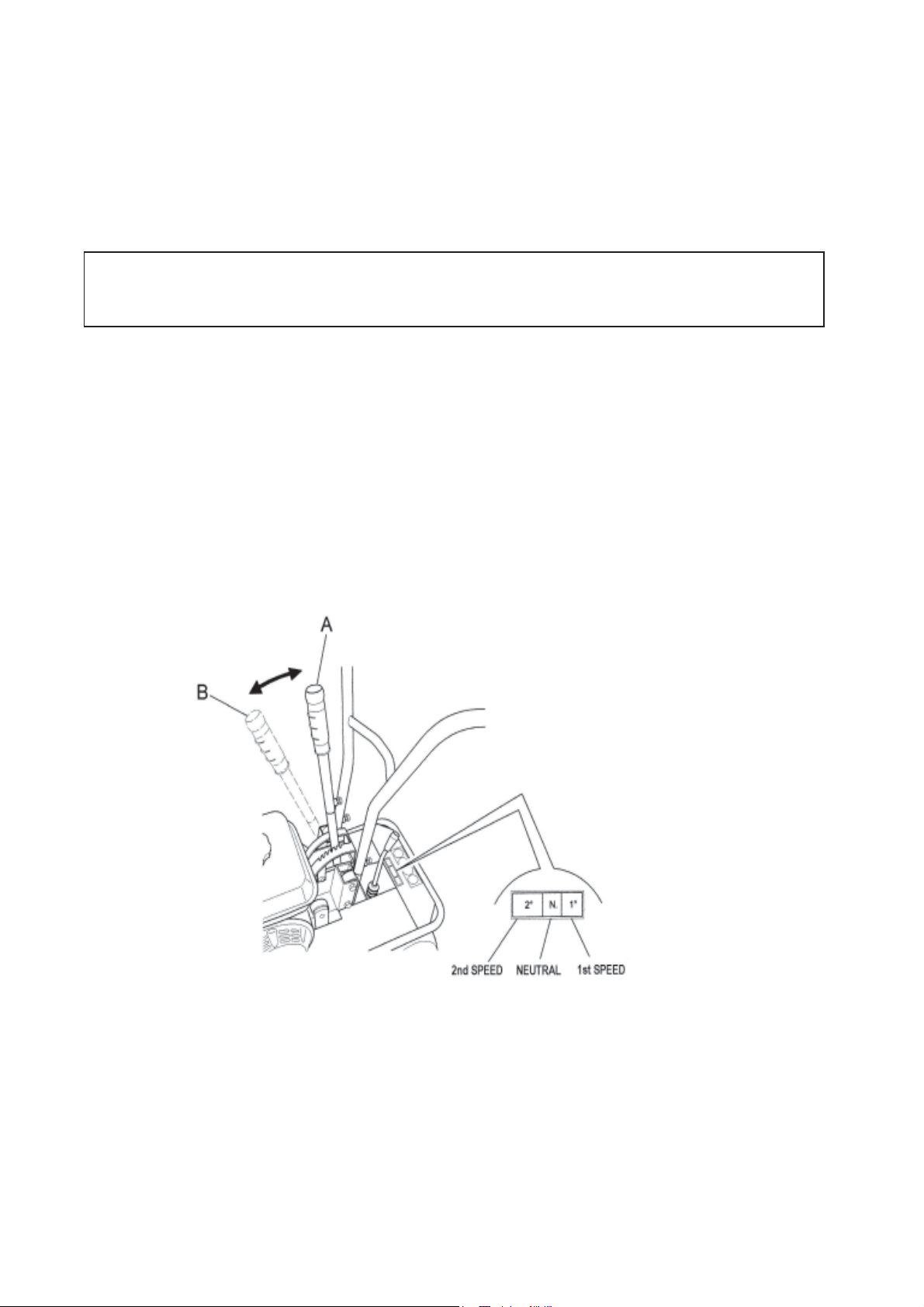

Figure 2

D) CUTTING HEIGHT ADJUSTMENT LEVER

This lever serves to adjust the cutting height according to the type of terrain and the

thickness of the turf to be cut. (Fig.2 Ref. A)

F) COVER

The cover ( Fig. 1, ref. F) prevents any contact with the moving parts of the machine. Use

of the machine without the said cover is strictly prohibited.

370406 F103104A

10

Page 11

I) ON SWITCH

Two-position switch:

(1) for starting the engine

(0) for switching off the engine

L) FORWARD-NEUTRAL GEAR SELECTOR LEVER

This lever selects the gear forward (1st, 2nd) or neutral.

WARNING

Select the required gear only after disengaging the forward clutch by releasing the relative

lever (Fig. 1, ref. C).

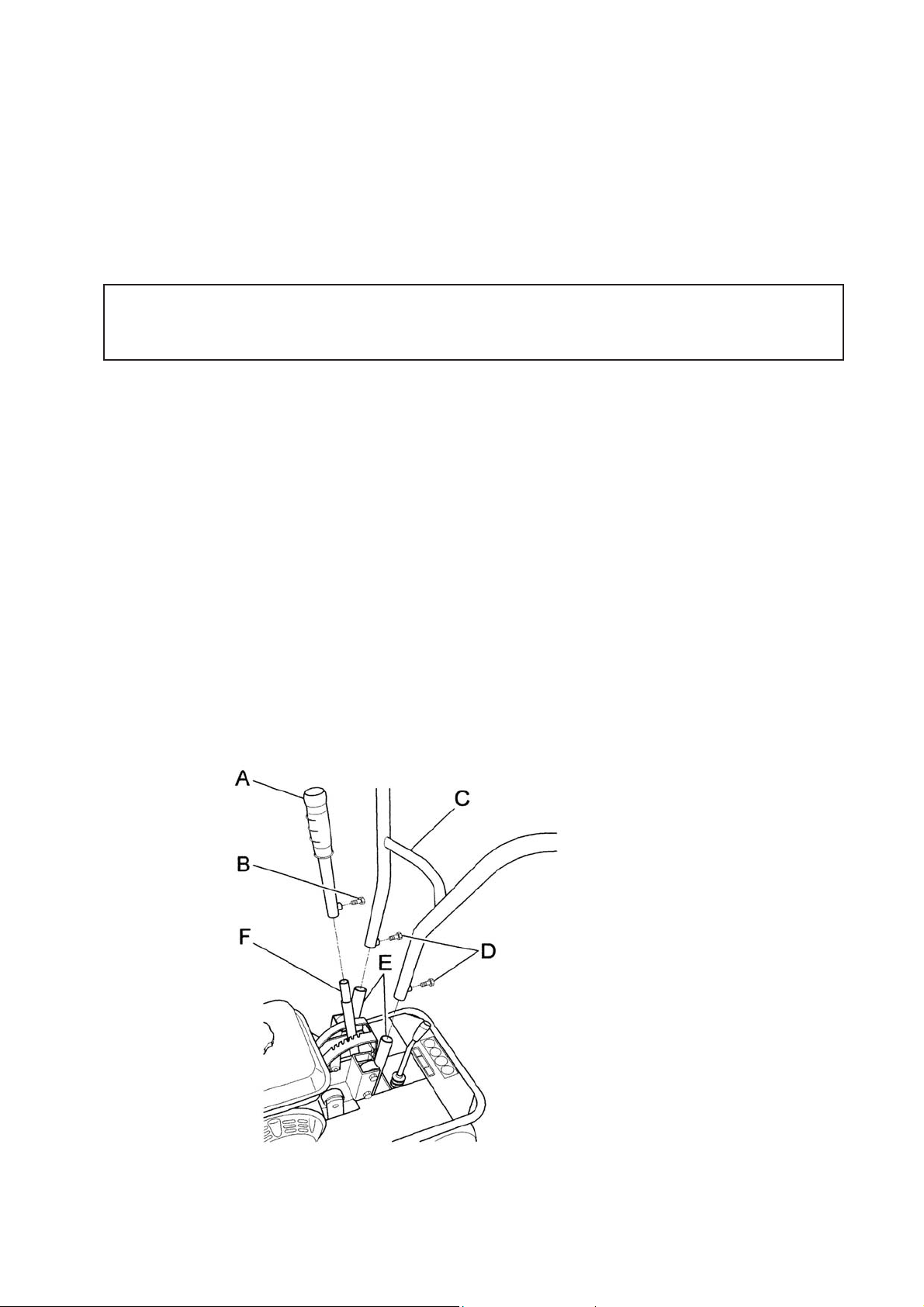

7. ASSEMBLY INSTRUCTIONS FOR THE HANDLEBARS AND

END PART OF THE CUTTING HEIGHT ADJUSTMENT LEVER

The turf cutter is delivered with the handlebars and the end part of the cutting height

adjustment lever disassembled. Remove the cardboard packaging (to be disposed of in

an appropriate manner, in accordance with current regulations in force).

To assemble proceed as follows :

Lift the handlebar (Fig. 3 Rif. C) and insert it in the supports shown in Fig. 3 rif. E.

Select the required cutting height and secure the setting using the screws provided

(Fig. 3 ref. D).

Fit the end part of the cutting height adjustment lever (Fig. 3 Ref. A) into its relative

support (Fig. 3 ref. F) and secure using the screw provided (Fig. 3 Ref.B).

Figure 3

Before switching on ensure that the machine has been fully assembled correctly.

370406 F103104A

11

Page 12

8. SAFETY INFORMATION

Before using the turf cutter it is essential that the operator has understood the warnings,

do’s and don’ts and precautionary measures given in this manual and in the engine manual:

the prevention of injury to the operator, third parties, animals or objects directly depends

on observance of these instructions.

A) GENERAL INSTRUCTIONS

Use of the turf cutter for purposes other than those envisaged is strictly prohibited.

Climbing aboard and/or riding on the turf cutter is strictly prohibited.

Tampering with the safety systems and guards is strictly prohibited.

Modifications to devices/components not envisaged by the manufacturer are strictly

prohibited.

The electrical parts of the engine must be protected at all times.

B) TRAINING

Read the Operator’s Manual and the Engine Manual before using the machine.

Use of the machine by minors under the age of 16 years or by persons without the

necessary psychological and physical capabilities is forbidden.

Do not use the machine near other persons or within enclosed areas.

The placing of hands, other parts of the body and clothing in the moving parts of the

machine is prohibited.

It is forbidden to approach the moving parts.

Before carrying out any inspection or servicing operations make sure that the engine

has been switched off and the spark plug wire removed.

C) PREPARATION

Make sure that the working area around the machine is free of obstacles and has

sufficient lighting.

Before switching on the engine make sure there are no persons, animals or vehicles in

the vicinity .

Before switching on the engine make sure that both engagement levers (forward clutch

control lever - Fig. 1, ref. C and blade clutch control lever - Fig. 1, ref. A) are in the

disengaged position (released) ; then place the gear lever in neutral (Fig. 2, ref. C )

Before switching on the machine make sure that the screws, fixing elements and

protection devices are in place and that the affixed notices are legible.

Then: Make sure that the wheel fixing bolts have been tightened fully.

Secure all blade nuts and fixing bolts to prevent their loss during work operations.

Replace any old or worn blades.

The cover ( Fig. 1, ref. F) should not be moved for any reason whatsoever while the

machine is in use.

When switching on the engine check the position of the various control levers (see the

section on “Controls and adjustments”).

370406 F103104A

12

Page 13

Supervise the clothing of personnel operating the machine: a long-sleeved jacket with

close-fitting cuffs, long, close-fitting trousers, heavy-duty footwear, and a protective

cap or helmet should be worn. Avoid wearing loose-tailed clothing, unbuttoned jackets

or torn, undone or partially zipped up items to prevent them from being caught up in

the moving parts.

Safety goggles and ear protection devices must be worn. Safety gloves must also be

worn during machine operation and maintenance.

Do not switch on and operate the turf cutter in enclosed areas since the engine gives

off carbon monoxide fumes which are colourless, odourless, tasteless and extremely

dangerous.

Take care when handling fuel. Fuel is highly flammable and its vapours explosive :

- Only use an approved container

- Take care not to remove fuel caps or top up the tank with the engine running.

- Allow the engine to cool before proceeding with fuel-filling operations.

- Do not smoke during this operation.

- Never fill the machine with fuel in an indoor ambient

- It is advisable to use a wide funnel to prevent spillage of fuel on the engine and

on other surfaces of the turf cutter.

- If any fuel is spilled do not attempt to switch on the engine; simply move the

machine away from the area of spillage before switching on.

- After filling up with fuel reposition and screw the fuel tank cap right down.

Do not rest the turf cutter or the fuel container in indoor environments with naked

flames

D) WORKING USE

When working keep everyone at a minimum distance of 10 metres from the machine.

Keep the engine well ventilated and clog-free (materials and other residue) to prevent

demage to the engine and risk of fire. Clean the cooling fan and fins regularly.

Clean the air filter at the same time as well.

Drive smoothly, avoiding brusque starts, braking and turns.

Take care not to touch the silencer when hot.

If a slipping belt causes abnormal noise, smells or overheating, switch off the engine

immediately and check the machine to prevent the outbreak of fire and damage to the

transmission.

The blade is extremely dangerous. Take great care during operation. Do not use feet

or hands to push the machine down into the turf and do not allow anyone to stand

either in front of the machine or in its direction of travel.

370406 F103104A

13

Page 14

WARNING

During operation the lawn and turf are cut into strips. Should the cutter's wheels skid

during use it is advisable to adjust the cutting height using the special lever (Fig. 3, ref.A).

If this operation does not prevent this occurence check the state of the terrain. If it is too

dry it should be wetted so that the blade encounters a slight resistance, thus making

cutting operations easier.

WARNING

When working in a stony or obstacle-riddled area try to remove as many objects as possible

before commencing cutting. Then work at a greater cutting height than usual.

WARNING

Stones and other objects may be thrown outwards in direction of the perator or of other

persons in the vicinity. Keep at a safe distance from persons, nimals and objects.

If the cutting mechanism accidentally comes into contact with an object (stump or

stone), switch off the engine and carry out the following operations:

- Inspect the damage

- Do not attempt to repair it if unskilled to do so

- Check that no parts have come loose

Do not use the machine if it does not work properly or is broken: seek authorized

service.

It is strictly prohibited to leave the turf cutter running whilst unsupervised.

It is strictly prohibited to transport the machine with the engine running. When loading

the machine onto a vehicle, the inclination of the ramps must not exceed 15°.

WARNING

EXERCISE CAUTION WITH GRADIENTS. Danger of machine overturning.

Given its outdoor use, it is advisable not to use the turf cutter when it is raining.

The area next to the engine exhaust may reach a high temperature.

WARNING

Danger of burns.

Do not go near water fountains or precipices and do not cross narrow bridges during

work operations to prevent the risk of falling.

Do not work on steep banks.

In the instance of difficulty or emergency stop simply release the forward clutch control

and blade movement levers and return the gear lever to neutral position.

Work on flat ground for the utmost safety.

370406 F103104A

14

Page 15

E) AFTER USE

Before moving away from the machine, place the gear lever in neutral (Fig. 2, ref. C)

and switch off the engine by moving the switch (Fig.1,ref.I) to the 0 position.

For greater safety shut off the feed cock (Fig. 4).

9. TRANSPORTATION OF THE MACHINE

LOADING AND UNLOADING FROM A VEHICLE

For transportation it is preferable to use a vehicle with an open bed.

Choose firm, flat ground.

Switch off the vehicle’s ignition, put into reverse gear, pull on the hand brake and block

the tyres with chocks to prevent accidental movement of the vehicle.

WARNING

Raise the blade to maximum height to prevent danger of its catching the ramp edges.

Do not stand in front of the machine

Firmly hook the loading ramps onto the vehicle bed.

Use stable load ramps with a non-slip surface strong enough to take the weight of the

machine. The inclination of the ramps must not exceed 15°.

Recommended length : at least 31/2 times the vehicle bed’s height from the ground.

Recommended width : to be chosen according to the tyre width of the machine

Proceed with the loading of the machine, manoeuvring it carefully. Set the accelerator

lever at minimum (Fig. 1, ref. B)and using the lever as shown in figure 2, ref. C, engage

the forward gear for loading, or the reverse gear for unloading.

During loading/unloading operations on the ramps avoid operating the blade clutch

(Fig. 1, ref. A) and the gear lever (Fig. 1, ref. H) because such actions may prove

extremely dangerous.

Line the front wheels up with the centre of the loading ramps.

Take care when the machine passes from the loading ramps to the vehicle bed, because

a shift in balance occurs.

Once loaded, turn off the engine using the relative switch (Fig. 1, ref. I), make sure

that the service brake has automatically come into operation upon release of the forward

clutch control lever ( fig. 1, ref. C), block the machine wheels using chocks and firmly

tie the machine to the vehicle.

370406 F103104A

15

Page 16

10. DESCRIPTION OF THE SAFETY AND GUARD SYSTEMS

WARNING

The safety devices must never be tampered with. It is necessary to understand how they

work and safeguard their efficiency and correct operation. In the instance of doubt, problems

or malfunction contact your dealer.

FORWARD CONTROL AND BLADE MOVEMENT LEVERS

When released both of these levers instantly disengage the transmission connected to

them. In this way they act as safety devices.

In the instance of difficulty or sudden emergency, the quick release of these levers will

return them to their standard position (raised).

COVER

The cover ( Fig. 1 point F) partially protects the machine from any projected objects and

contact with the moving blade. Use of the machine without the said cover is strictly

probhited.

The cover should only be removed when replacing belts with the machine switched off.

11. OPERATIONS TO BE CARRIED OUT BEFORE SWITCHING ON

Position the turf cutter outdoors on sufficiently firm, flat soil. Read the instructions provided

by the engine manufacturer in the relative manual and follow them carefully to prevent

situations arising which may endanger either persons or the machine.

WARNING

New machines straight from the factory do not have any engine oil.

Then check:

- the state of the blade by inspecting them;

- that all the screws are tightened, particularly those securing the blade;

- that the guards and safety devices are securely tightened.

- Before switching on the turf cutter make sure that there are no persons in the vicinity.

- During operation do not allow persons near the machine, especially children. The

operator is responsible for any harm done persons in the working area of the machine.

Oil recommendations

The engine is supplied without oil. Before starting up the engine fill with oil and check the

oil level with the engine in a horizontal position. Do not overfill.

Use of a high-grade detergent oil is recommended (refer to the enclosed engine manual).

Fuel recommendations

Use of fresh, clean lead-free petrol is advised.

WARNING

It is advisable to consult the engine manual before switching on the machine.

370406 F103104A

16

Page 17

12. STARTING AND DRIVING THE TURF CUTTER

The machine can be switched on once all the aforementioned preliminary operations

have been carried out.

Place the feed cock in the OPEN position (direction shown by the arrow, Fig. 4).

Bring the choke to the CLOSED position for a cold start (direction shown by the arrow,

Fig. 4a).

Set the accelerator lever at the minimum position.

Grip the engine pull lead handle ( fig. 4b ) and pull gently until you feel the “bite”, then pull

on the lead sharply to overcome the pressure, prevent kickback and switch on the engine.

Repeat the procedure, if necessary, with the accelerator lever in INTERMEDIATE position.

Once the engine is running, set the accelerator in the MINIMUM position and gently return

the choke to the OPEN position (Fig. 4a).

Cleaning of the machine is recommended after use (see the section “Cleaning the

machine”).

Figure 4 Figure 4a

Figure 4b

370406 F103104A

17

Page 18

DRIVING THE MACHINE

WARNING

When using the machine for the first time it is advisable to get the feel of it by executing

manoeuvres on flat ground free of foreign objects.

After switching on the engine following the instructions given in the previous paragraph:

1. Move the gear lever ( fig. 2) to the 1st speed position.

WARNING

If the gear engages with difficulty, partially engage the clutch for an instant before trying to

engage the gear again.

2. Engage the blade control level using the relative lever ( Fig. 1, ref. A).

WARNING

Choose a cutting height suitable for the type of terrain the machine is to be used on.

3. To move the machine, accelerate and then engage the forward clutch using the relative

lever (Fig. 1, ref. C).

4. To select a different gear the forward clutch and the blade clutch must first be

disengaged by releasing their levers (Fig. 1, ref. C and Fig. 1, ref. A). Then select the

desired FORWARD position (1°- 2°, in fig. 2) using the gear lever (Fig. 2), then reengage the forward clutch control lever (Fig. 1, ref. C) to set the machine in motion

again.

5. To stop the blade release the relative lever ( Fig. 1 ref. A).

6. To stop forward movement of the machine release the relative lever ( Fig. 1, ref. C),

then switch off the engine by moving the switch to the position (O) (Fig. 1, ref. I).

370406 F103104A

18

Page 19

13. CUTTING TIPS

1. Before commencing cutting operations, read the safety instructions given in the previous

sections.

2. At first the setting of a relatively high cutting height is recommended (using the relative

lever in figure 2, ref. A), lowering it gradually according to working conditions.

3. Engage the blade clutch (Fig. 1, ref. A) only after having carried out the machine

switch-on and gear engagement operations.

4. Before engaging the blade clutch (Fig. 1, ref. A), gradually move the accelerator (Fig.

1, ref. B) until the required speed is reached.

WARNING

Take great care because the blade moves at very high speed.

14. CHECKS

- Adjust the belt and cable control tension after the first few working hours to compensate

initial loosening.

- Briefly operate all the machine’s components to detect any abnormal noises or

overheating.

- During the initial running in period avoid heavy-duty usage to encourage proper settling

of the mechanical parts.

- Never neglect maintenance operations after work and carry out all prescribed checks

regularly.

A) TYRE PRESSURE

Regularly check the tyre pressure. If both two tyres are not inflated to average pressure

the machine will tend to travel sideways during operation.

B) CABLE CONTROL ADJUSTMENT

To adjust the cables place the machine on flat ground, switch off the engine and disconnect

the wire from the spark plug.

B1)BLADE CONTROL CABLE

Make sure that there is no play between the upper end of the cable and the adjustment

screw. If there is, or if the cable has stretched, restore to ideal position using the relative

adjustment screw(Fig. 5, ref. A).

If adjustment using the relative screw proves ineffective, the belts, and hence the engine

mounting, must be adjusted. To perform this operation refer to section 14C “ BELT

REPLACEMENT AND ADJUSTMENT” of this manual.

370406 F103104A

19

Page 20

B2) FORWARD CONTROL CABLE

Make sure that there is no play between the upper end of the cable and the adjustment

screw. If there is, or if the cable has stretched, restore to ideal position using the relative

adjustment screw ( Fig. 5, ref. A).

If adjustment using the relative screw proves ineffective, the belts, and hence the engine

mounting, must be adjusted. To perform this operation refer to section 14 C “ BELT

REPLACEMENT AND ADJUSTMENT” of this manual.

Figure 5

C) BELT REPLACEMENT AND ADJUSTMENT

Switch off the engine and disconnect the spark plug wire before carrying out any

maintenance or repair work on the machine.

If a belt is worn or breaks it should be replaced as follows:

- remove the metal guard ( fig. 6 ref. A), by unscrewing and taking out the screws shown

in figure 6 ref. B and C.

C1)BLADE BELT

Disconnect the connecting rod (Fig. 7 Ref. B) by removing the nut and loosening the

screw that secure it to the arm (Fig. 7 Ref. C)

- Once the connecting rod has been disconnected the belt can be slipped off (Fig. 7

Ref. A) by manually turning the relative lower pulley anticlockwise (Fig. 7 Ref. D).

- To fit the new belt follow the procedure in the reverse order.

- Afterwards check that the belt is correctly positioned by using the relative blade control

lever. When this lever is lowered and the belt is at maximum tension, the distance

between the belt and the relative belt guides (Fig. 7 Ref. E) should be approximately 2

mm.

- Then make sure that the belt works properly by tugging lightly on the self-winding

starter cable with the engine switched off and the spark plug wire disconnected. If

everything is working properly the pulley will turn on the engine but will not engage the

belt.

If the belt engages push the engine back slightly towards the rear of the machine (in

the direction of the handlebars) until the belt is in the correct position.

370406 F103104A

20

Page 21

C2)FORWARD CONTROL BELT

Remove the blade control belt following the instructions given in the preceding

paragraph.

- Remove the blade (Fig.1 Ref. G) following the instructions provided in the section

entitled “Blade removal and replacement”.

- Then remove the forward control belt from the lower pulley by turning the belt

anticlockwise (Fig. 8 Ref. A e B)

- To fit the new belt follow the procedure in the reverse order.

- Afterwards check that the belt is positioned and working correctly using the relative

forward control lever. When this lever is lowered and the belt is at maximum tension,

the distance between the belt and the relative belt guides (Fig. 8 Ref. C) should be

approximately 2 mm.

- Then make sure that the belt works properly by tugging lightly on the self-winding

starter cable with the engine switched off and the spark plug wire disconnected. If

everything is working properly the pulley will turn on the engine but will not engage the

belt. If the belt engages push the engine back slightly towards the rear of the machine

(in the direction of the handlebars) until the belt is in the correct position.

D) SERVICE BRAKE CONTROL LEVER

The service brake (Fig. 9 Ref. A) is connected to the forward control lever (Fig. 1 Ref. C).

With the forward control lever released and the brake engaged ensure that there is play

of approximately 2 or 3 mm between the adjustment screw and the brake cable (Fig. 9 Ref

B and C).

WARNING

If there is no such play restore it immediately since the brake will not stop the machine

once the forward control lever is released. Make sure that the front part of the brake in

direct contact with the pulley (Fig. 9 Ref. D) is not worn. If so, replace it.

370406 F103104A

21

Page 22

Figure 6

Figure 7

370406 F103104A

22

Page 23

Figure 8

Figure 9

370406 F103104A

23

Page 24

E) CHECKING AND REPLACING THE BLADE

Always check the state of the blade before commencing work. Do not forget to switch the

engine off!

- During work operations if the blade (Fig. 10, ref. A ) strikes stones or stumps stop

straightaway and make sure that it has not become bent or broken. A damaged blade

must be replaced.

- If the blade is very worn, cracked or bent, it makes snap and projects objects outwards,

risking serious accident.

- Use heavy-duty work gloves to check or replace the blade to avoid risk of injury to

hands.

- The blade fixing screws and relative nuts are also subject to wear. Always replace

them at the same time as the blade, using bolts and screws of the same strength and

type.

- The blade wears more quickly on dry, sandy ground. In these conditions it should be

replaced more frequently.

To remove the blade proceed as follows:

1. Switch off the engine and disconnect the spark plug wire

2. Adjust the cutting height to maximum

3. Check the state of the blade.

Check that the blade is not cracked, bent, excessively worn or broken.

Figure 10

370406 F103104A

24

Page 25

15. MAINTENACE AND STORAGE

All operations on the machine must be carried out exclusively by authorized personnel.

Always switch off the engine when checking, adjusting or servicing the machine.

Allow the machine to cool down before inspection.

The cover ( Fig. 1 ref. F) must always be correctly installed and intact. If it becomes

damaged, have it repaired before the machine is used again.

Make sure that all the guards of rotating and moving parts are in place.

For greater safety, when replacing the blade replace all the fixing screws and nuts at

the same time, as described in section 14, point D.

Inspect the fuel lines. These should be replaced if damaged or after a maximum of

three years, along with the fixing bands. Old lines may leak fuel.

Check and regularly adjust the forward clutch control, blade clutch control, accelerator.

Cover the machine with a sheet after the engine and silencer have cooled down.

It is strictly forbidden to place/leave unattended on the turf cutter any potentially

dangerous objects which may put the safety of persons or the machine at risk.

Keep the machine in a good, clean state; do not leave it outside exposed to inclement

weather conditions.

After use store the machine in a place where children have no access. Always allow

the machine to cool down before putting it away.

After use store the machine in a place where fuel vapours cannot reach a naked flame

or sparks.

In the instance of a long period of non-use, drain the fuel tank completely.

Use of the machine does not require specific lighting.

However, the recommended minimum amount of light (e.g. 200 lux) is enough to be able

to read the notices on the machine and to operate it without running risks caused by poor

light.

CHECKING AND REPLACING THE TRANSMISSION OIL

Check the transmission oil level using the relative oil level screw ( fig. 11 ref. C). If oil

leaks out upon removal of this screw then there is enough of it in the transmission. If not,

remove the filling cap shown in fig. 11 ref. A, then top up with SAE 90.

The oil should be replaced after the first 20 hours of use and after this every 100 working

hours.

Remove the drainage cap shown in fig. 11 ( ref. B) and allow all the oil to run out. After

refitting the drainage cap, fill the transmission from the filling cap with SAE 90 transmission

oil.

Refit the lid securely to prevent any leakage of oil.

370406 F103104A

25

Page 26

Figure 11

16. CLEANING THE MACHINE

Proceed in the following order:

- Switch off the engine and disconnect the spark plug wire;

- Clean the engine and the outside of the machine with a cloth soaked in a little oil.

- Clean all parts of the machine, particularly the starting unit, air filter, exhaust and

carburetor. It is advisable to follow the instructions given in the engine manual.

- Clean the inside of the belt guard (fig. 1, ref. F) with a blast of compressed air.

- To clean the blade ( fig. 1 ref. G), wash with a jet of water straight after use while still

damp. When washing carefully cover and protect the electrical parts of the engine, the

carburetor, the air filter and the exhaust from the water to prevent engine problems.

- To clean the blade area a tool should be used (stick of wood).

17. SEASONAL LONG-TERM STORAGE PERIODS

To store the turf cutter for prolonged periods of non-use, proceed as follows:

- Park the machine on flat, firm, clean ground.

- Oil deposits on the ground where the machine is positioned may cause irreparable

damage to the tyres.

- Disconnect the spark plug wire;

- Clean the machine carefully as described in section 16 (Cleaning the machine)

- Make sure that all screws and nuts are fully tightened.

- Retouch with paint any parts which have become exposed during use.

- Store the machine in a clean, dry place.

- Empty the fuel tank, following the instructions given in the engine manual;

- Regularly check the tyre pressure, and adjust if necessary.

- Lubricate all moving parts and have any necessary repairs to the machine carried out.

370406 F103104A

26

Page 27

18. DECOMMISSIONING AND SCRAPPING

After the working life of the turf cutter the user must have it dismantled and its components

removed as per EEC directives or in accordance with current legislation in force in his

country, taking particular care over the dismantling of the following materials of

environmental impact:

- plastic parts

- rubber parts

- coated electric wiring

- petrol engine

- metal parts

- toxic substances

19. TECHNICAL ASSISTANCE

Routine maintenance must be carried out as per the instructions given in this Manual. For

any instances not covered herein and for technical assistance in general contact your

dealer referring to the data given on the identification plate affixed to the machine.

The right reference will ensure swift, precise answers.

For swift delivery of spare parts always quote the following information on the order:

- Machine model and serial number

- Part description and quantity required

For assistance concerning the engine it is advisable to contact the service centre authorized

by the engine manufacturer (see engine manual supplied).

20. WARRANTY

Should a Billy Goat Machine fail due to a defect in material and / or workmanship, the

owner should make a warranty claim as follows:

- The Machine must be taken to the dealer from whom it was purchased or to an

authorized Servicing Billy Goat Dealer.

- The owner must present the remaining half of the Warranty Registration Card, or,

if this is not available, the invoice or receipt.

- The Warranty Claim will be completed by the authorized Billy Goat Dealer and

submitted to their respective Billy Goat Distributor for their territory. Attention: Service

Manager. Any parts replaced under warranty must be tagged and retained for 90

days.

- The distributor service manager will sign off on the claim and submit it to Billy Goat

for consideration.

- The Technical Service Department at Billy Goat will study the claim and may request

parts to be returned for examination. Billy Goat will notify their conclusions to the

distributor service manager from whom the claim was received.

- The decision by the Quality / Service department at Billy Goat to approve or reject

a Warranty claim is final and binding.

Note: To process a Warranty Claim, it is necessary to quote the Model & Serial Number

which are printed on the Billy Goat Serial Plate (See owner’s manual).

370406 F103104A

27

Page 28

21. TROUBLESHOOTING

The following table illustrates some problems which may arise during operation.

FAULT CAUSE MEASURES TO BE TAKEN

Belt slips 1. Belt tension inadequate

2. Too great a working depth

3. Belt worn

Machine vibrates excessively 1. Belt damaged

2. Blade bent or broken

Engine overloads during work

operations

1. Engine speed too low.

2. Blade worn

3. Forward speed too high

4. Too great a working depth

ENGINE

FAULT CAUSE MEASURES TO BE TAKEN

Engine sluggish at switch on 1. accelerator not in start-up

position

2. Choke not closed

3. Petrol does not arrive

4. Air bubbles or water inside

the petrol lines

5. Thick oil prevents rotation

6. Winding or start

mechanism faulty

7. Spark plug in poor

condition

Poor power 1. No fuel

2. Air filter blocked

3. Elastic bands worn

Engine stalls 1. no fuel

2. feed cock shut off

Exhaust fumes dark 1. low grade fuel

2. too much engine oil

Engine emits black smoke and

power is poor

Exhaust fumes bluish 1. too much engine oil

Silencer becomes red through

overheating

1. air filter blocked

2. choke not fully opened

2. elastic bands worn

1.

ir filater blocked

Inside of self-winding

2.

starter blocked with grass

cuttings

1. Adjust the belt tension

2. Reduce the working depth

3. Replace belt

1. Replace belt

2. Replace blade

1. Accelerate to maximum

2. Replace blade

3. Decrease the forward

speed

4. Reduce the working depth

1. move the accelerator to the

intermediate position

2. Close the choke when cold.

3. Check the fuel tank and

remove any water or

sediment.. Make sure that

the feed cock is open.

4. Check the lines and bands.

Repair or replace if

damaged

5. Use oil with a viscosity

suited to the temperature

6. Replace winding or start

mechanism

7. Clean or replace spark

plug. Adjust the distance

between the electrodes.

1. refill tank with petrol

2. clean air filter

3. replace elastic bands

1.

refill tank with petrol

2.

open feed cock

1. replace with high grade

fuel

2. restore engine oil to correct

level

1. clean air filter

2. open the choke completely

1. restore engine oil to correct

level

2. replace elastic bands

clean air filter

1.

clean self-winding starter

2.

housing

For any problems not easily resolved or in case of doubt you are advised to contact

your dealer.

370406 F103104A

28

Page 29

NOTES

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

370406 F103104A

29

Page 30

370406 F103104A

30

Page 31

1/6PART LIST

A

LEVER CONTROL ( righthand ) 1001 370252

GRIP 2002 370257

LEVER TIGHTENER (LEFTHAND) 1003 370253

SCREW M6X55 UNI 5931 2004 370178

NUT LOCK M6 H6 2005 370107

LEVER HAND ACCELERATOR 1006 370255

WASHER FLAT M6 1007 370112

CABLE ACCELERATOR 1008 370254

NUT LOCK M6 H8 10009 370148

SCREWCAP M10X20 2010 370281

CLAMP ACCELERATOR 1011 370256

SPRING GUIDE 2012 370186

SPRING 10X25 C X F 2013 370143

CABLE GUIDE 2014 370187

HANDLE 1015 370274

SCREWCAP M10X50 P.F. 1018 370283

NUT LOCK M10 1019 370149

SUPPORT LEVER HEIGHT ADJUSTMENT 1020 370248

WASHER FLAT M8 9021 370110

SCREWCAP M8X16 3022 370126

FORK 03216055 2023 370259

CLIP FORK 2024 370260

NUT M10 2028 370146

ROD TIE HEIGHT-ADJUSTMENT 1029 370235

NUT LOCK M8 4038 370125

PLATE STOPPING REVERSE GEAR 1039 370280

WAASHER FLAT M6X18 6040 370108

SCREWCAP M8X25 2041 370118

BRACKET REAR 1042 370191

SUPPORT REAR GUARD 1043 370250

SCREWCAP M8X20 4044 370130

GUARD BELT 1047 370268

WASHER FLAT M6 10048 370112

SCREWCAP M6X14 10049 370128

GUARD SIDE ( LEFTHAND) 1050 370269

GUARD SUPPORT FRAME 1054 370267

NUT LOCK MS H6.5 6060 370129

SCREW CROSSHEAD MSX30 6062 370152

NUT 8 H 6.5 1072 370102

DJUSTER M6 X 40 1112 370294

CABLE CONTROL BRAKE 1113 370295

BUSHING SHEAT 1114 370296

NUT M6 H4 1115 370297

370406 F103104A

31

Page 32

370406 F103104A

32

Page 33

2/6PART LIST

A

NUT LOCK M6 H6 1005 370107

LEVER 1016 370243

SCREWCAP M6X45 P.F. 1017 370282

WASHER FLAT M8 2021 370110

FORK 03216055 2023 370259

CLIP FORK 1024 370260

NUT M10 1028 370146

SCREWCAP M10X50 P.F. 4030 370147

WASHER WAVE M10 4031 370145

SUPPORT HANDLE 2032 370228

NUT SPECIAL FOR HANDLE SUPPORT 2033 370247

SCREWCAP M8X16 1034 370292

LEVER HEIGHT ADJUSTMENT 1035 370425

EXTENSION HEIGHT ADJUSTMENT LEVER 1036 370275

GRIP 0 22 1037 370189

NUT LOCK M8 2038 370125

SCREWCAP M8X25 1041 370118

SCREWCAP M8X20 2044 370130

WASHER FLAT M6 1048 370112

CONNECTION TIE-ROD 1055 370236

PIN ROLL M30X2.5 1056 370151

PIVOT Ø 10 1057 370258

SCREWCAP M6X10 1059 370134

SCREW BUTTON HEAD M8X12 4063 370111

QUADRANT TOOTH HEIGHT 1064 370424

SPRING 13X25 1065 370144

SUPPORT FRONT GUARD 1066 370251

BODY SOD CUTTER 1070 370215

DOWEL M8X16 2071 370153

NUT 8 H 6.5 3072 370102

DAMPENER VIBRATION INTERNAL TUB 12X10X28 4073 370284

DAMPENER VIBRATION HANDLE SUPPORT 30X12X28 4074 370285

BLOCK SLIDING BELT No. 1 1079 370239

PIVOT AXLE FRONT 1084 370271

XLE FRONT COMPLETE 1085 370218

BUSHING SELF-LUBRICATING 16X20X22 2086 370276

TIRE FRONT WHEEL T090700 2087 370206

TUBE INNER FRONT WHEEL 2088 370204

FRONT STEEL WHEEL 3.00 2089 370401

WASHER FLAT M8X32 2090 370119

SCREWCAP M8X16 2091 370126

RETAINER CAP 4116 370402

ROLLER CAGE BEARING 2117 370403

LOCKING LEVER 1118 370426

PLASTIC KNOB 10 1119 370427

WASHER WAVE M8 1120 370123

NUT M5 2121 370428

SCREWCAP M5x14 1122 370429

SPRING CABLE RETURN 1123 370262

SCREWCAP M5x20 1124 370430

NUT M8 H5 2125 370136

HEIGHT ADJUST ASSY 1126 370431

370406 F103104A

33

Page 34

370406 F103104A

34

Page 35

3/6PART LIST

A

A

NUT LOCK M6 H6 1005 370107

WASHER FLAT M6 1007 370112

NUT M8 H5 4025 370136

WASHER GROWER U 1751 8 4026 370407

RM CONTROL BLADE (RIGHT) 1027 370501

KEY 8X7X25 1045 370157

SCREW ALLEN M6 X 25 4046 370177

SCREWCAP M6X14 1049 370128

PULLEY FOR SHAFT WITH ECCENTRICS 1051 370211

NUT M12 2052 370150

BELT SHORT XDV48/290 1053 370197

WASHER FLAT M12X24 2058 370124

SCREW SPECIAL 2061 370287

BEARING 17X40X12 6203-2RS 4067 370138

SHIM ADJUSTMENT 17X24X0.5 2068 370135

BUSHING 1069 370232

RM CONTROL BLADE (LEFT) 1075 370502

WASHER SPLIT M6 1076 370120

SCREWCAP M6X85 P.F. 1077 370154

COVER PLASTIC CONNECTING ROD 2078 370286

ROD CONNECTING 2080 370217

RING SNAP INTERNAL E35 1081 370155

SHIM ADJUSTMENT 35X45X0.5 2082 370156

BEARING 35X62X14 6007-2RS 2083 370137

BLADE CUTTING 1092 370279

SCREW M8X26 4093 370408

WASHER WAVE M8 4094 370123

RING SNAP INTERNAL E17 2095 370122

RING SNAP INTERNAL 140 2096 370166

SPRING 1097 370309

SHAFT WITH ECCENTRICS 1098 370216

PULLEY LOCKING HUB 1099 370212

SEMI-CONE 4100 370231

PAD RUBBER 2101 370261

SPRING HOOK 1102 370298

SCREW BUTTON M6 X 16 2103 370299

NUT M6 H4 2104 370297

BRAKE 1105 370300

SCREWCAP M4 X 14 3106 370301

CLAMP 7 X 20 1107 370302

NUT M6 1108 370127

PAD BRAKE 1109 370303

RING RADIAL ELASTIC D 10 1110 370173

BUSHING SELF LOCK 2111 370304

370406 F103104A

35

Page 36

370406 F103104A

36

Page 37

4/6PART LIST

A

SCREWCAP M8X16 6001 370126

WASHER FLAT M8 6002 370110

REAR WHEEL 3.00-4 TRACTOR 2003 370194

TIBE INNER REAR WHEEL 2004 370277

TIRE 3.00-4 TRACTOR 2005 370409

HUB WHEEL 2006 370195

PIN ELASTIC 10X40 2007 370158

COVER DUST 2008 370288

FELT PROTECTION 2009 370289

RING SEAL 25 X 52 X 7 2010 370305

RING SNAP INTERNAL 152 2011 370114

BEARING 25X52X15 6205 2012 370131

GEAR REDUCTION-CROWN 1013 370199

DOWEL M8X14 1014 370180

XLE REAR 1015 370196

SHIM ADJUSTMENT 25X35X1 1016 370142

SEEGER E25 1017 370290

NUT M8 H5 6052 370136

KEY 7X8X35 1064 370170

SHIM ADJUSTMENT Ø 42X52X0.5 1065 370121

370406 F103104A

37

Page 38

370406 F103104A

38

Page 39

5/6PART LIST

PLASTIC KNOB Ø 12 1018 370182

CAP PLASTIC 1019 370162

WASHER FIBER 1020 370163

SCREW ALLEN M 8 X 16 4021 370159

LEVER ENGAGE-DISENGAGE 1022 370226

SPRING GEAR FORK 6X25 1023 370264

BALL 1024 370160

FORK 1st-2nd 1025 370410

CASING 1026 370161

PIN FORK 1027 370411

NUT LOCK M8 1028 370125

GEAR Z8 1029 370412

KEY 5X5X18 1030 370164

GEAR 2nd SPEED 1031 370413

PINION 1032 370414

GEAR 1st and 2nd SPEED 1033 370415

PINION REDUCING GEAR 1034 370416

BEARING 15X35X11 6202-2RS 3035 370133

SCREWCAP M8X18 4036 370104

WASHER FLAT M12X24 1037 370124

WASHER WAVE M8 12038 370123

SCREWCAP M8X20 6039 370130

BELT BIG 48-430 L443 1040 370198

NUT M12 1041 370150

PULLEY CAST IRON PRIM. Ø =150 mm. 1042 370213

BUSHING SELF-LUBRICATING 1043 370141

SUPPORT BOX (RIGHTHAND) 1044 370209

RIGHT COVER 1045 370417

GASKET RIGHT COVER 1046 370418

O-RING 17X40X7 1047 370168

RING SNAP INTERNAL 140 1048 370166

BEARING 17x40x16 62203 1049 370179

PRIMARY PINION 1050 370419

SUPPORT TIE ROD 1051 370245

GEAR BOX 1053 370420

GASKET COVER 1054 370242

CAP METAL 1055 370190

VTCE BUTTON M6X08 1056 370183

WASHER FIBER M6X10 1057 370185

PIN CYLINDRICAL 8X18 2058 370167

SCREW BUTTON HEAD M8X16 1059 370109

BUSHING SELF-LUBRICATING PCM 252820 B 1060 370140

SUPPORT BOX (LEFTHAND) 1061 370210

COVER BOX 1062 370208

O-RING 108 (8.73 X1.78) 1063 370171

SCREW STUD M8 UNI 5911 6066 370291

GASKET LEFT COVER 1067 370421

NUT 8 H 6.5 6068 370102

LEFT COVER 1069 370422

PIN CYLINDRICAL 6X35 1070 370169

ROLLER CAGE BEARING HK 1412 2071 370423

1072

370406 F103104A

39

Page 40

370406 F103104A

40

Page 41

6/6PART LIST

SHIM ENGINE 20X6 2001 370193

WASHER FLAT M8 8002 370110

SUPPORT ENGINE 1003 370234

SCREW TTQST 8X40 4004 370172

WASHER TOROIDAL M24 4005 370175

NUT LOCK M8 2006 370125

SCREWCAP M8X16 2007 370126

GUIDE BELT No.1 1008 370238

WASHER FLAT M5 4009 370113

SCREW ALLEN M5X8 5010 370106

GUIDE BELT 1011 370237

DOWEL M8X35 1012 370176

SCREWCAP M8X20 2013 370130

BRACKET GUARD SUPPORT 1014 370266

NUT M8 H5 4015 370136

SCREW 5/16 X3/4 mm 19 2016 370181

PULLEY ENGINE SECT. H 1017 370214

WASHER FLAT M8X32 1018 370119

WASHER WAVE M8 1019 370123

RING RADIAL ELASTIC D 10 1020 370173

RING SNAP INTERNAL 132 2021 370117

ROLL TIGHTENING 2022 370219

SCREWCAP M8X25 2023 370103

BEARING 12X32X10 6201 2RS 2024 370116

BUSHING BEARING 2025 370221

TENSIONER BELT 1026 370223

SHIM ADJUSTMENT 12.2X24X0.8 1027 370101

BUSHING SELF-LUBRICATING 2028 370115

NUT M6 2029 370127

CLAMP 2030 370220

CLAMP SPACER 2031 370188

TENSIONER BELT THREADED 1032 370246

SCREW TENSIONER 1033 370273

SCREWCAP M8X40 2034 370306

NUT SPECIAL 1035 370270

BRACKET GUARD FIXING 1036 370265

SCREWCAP 5/16-24 X 5/8 1037 370184

BRACKET FRONT 15X3 1038 370192

WASHER FLAT M6 2039 370112

SCREWCAP M6X14 2040 370128

SPRING CABLE RETURN 2041 370262

ENGINE HONDA 5.5 GX160K1QX2 1042 600115

KEY 4.8X4.8X32 1043 370174

SPACER 2044 370222

SUPPORT TIGHTENER 1045 370225

SPRING ACCELERATOR RETURN 1046 370263

NUT LOCK M6 H6 2047 370107

DRUM WIRE HOLDER 1048 370307

NUT M6 H4 1049 370297

NUT 8 H 6.5 4050 370102

370406 F103104A

41

Loading...

Loading...