Billy Goat QV550EU, QV550HEU Owner's Manual

1

QVEU PUSH Operator’s Manual

STANDARD

DEBRIS BAG

Standard on QV

models. For

dusty

conditions.

P/N 831225

DEBRIS AND

DUST SOCK

Traps dust

keeping it

away from

the operator.

P/N 831282

VACUUM HOSE

KIT

5" (127mm) x 10'

(3m) collapsible

hose for

vacuuming in

hard-to-reach

areas

P/N 831018

HOOD FILTER

Filters out dust

from vacuum

exhaust.

P/N 831226

DEBRIS BAG

SKIRT

Directs dust

away from the

operator.

P/N 831268

Accessories Debris bags and Filter

Part No 831508 Form No F021213D

Owner's Manual

QV550EU, QV550HEU

2

QVEU PUSH Operator’s Manual

SPECIFICATIONS AND SOUND/VIBRATION ___ _____ 3

INSTRUCTION LABELS 4

PACKING CHECKLIST AND ASSEMBLY ______ _5

OPERATION AND BAG CARE 6-7

MAINTENANCE AND TROUBLESHOOTING _______8

ILLUSTRATED PARTS & PART LISTS 9-12

CONTENTS

Part No 831508 Form No F021213D

3

QVEU PUSH Operator’s Manual

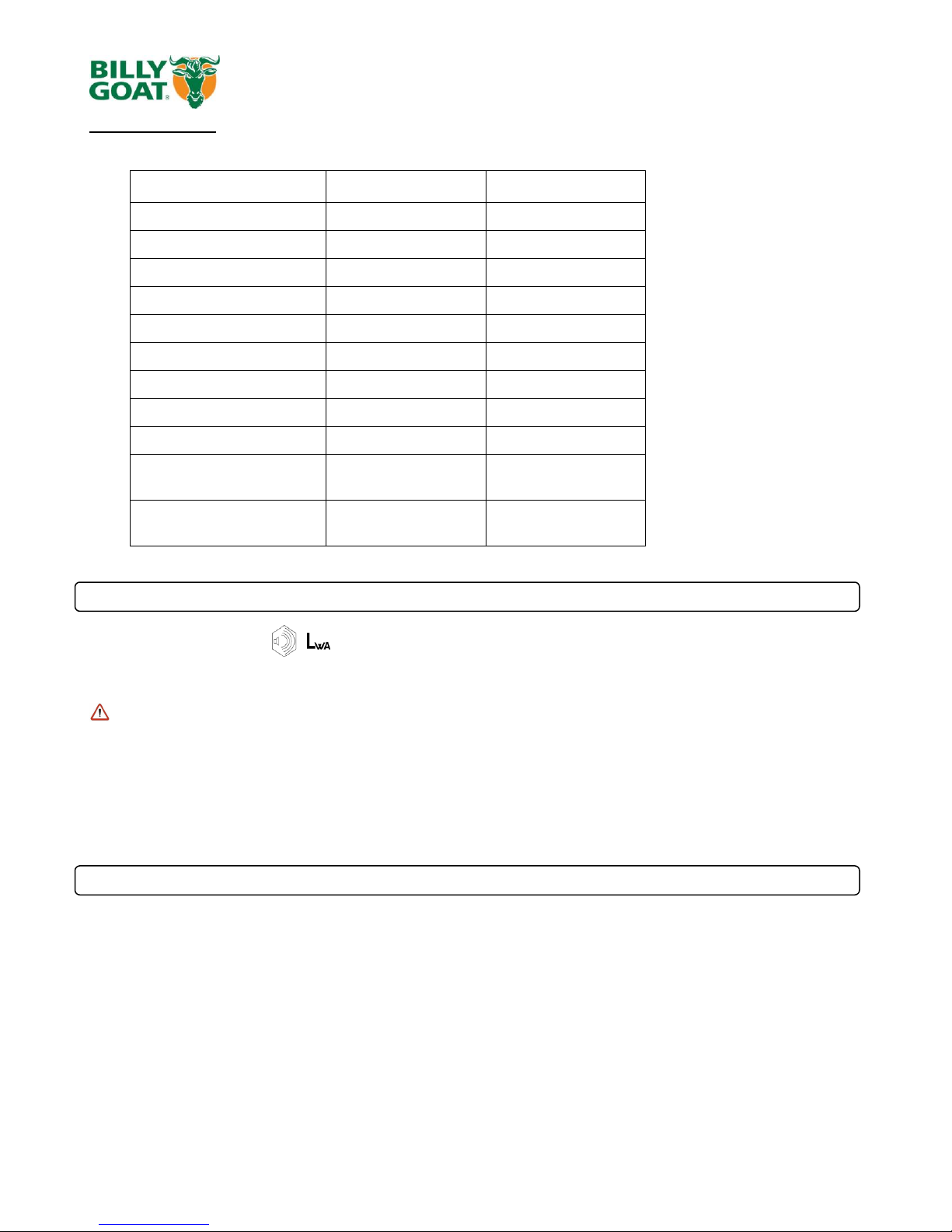

HP

5.5 (4.1 kW)

5.5 (4.1 kW)

Engine: Type

12H1320118B8

GX160T1QX2

Engine: Fuel Capacity

3.0 qt. (2.84 L)

3.88 qt. (3.6 L)

Engine: Oil Capacity

0.66 qt. (0.62 L)

0.69 qt. (0.65 L)

Total Unit Weight:

180# (81.6 kg)

175# (73.4 kg)

Overall Length

63” (1.6m)

63” (1.6m)

Overall Width

33” (0.84m)

33” (0.84m)

Overall Height

51” (1.3 m)

51” (1.3 m)

Max. operating slope

200

200

Sound at operators ear

77 dBa

77 dBa

In accordance with

2000/14/EEC

97 dBa

97 dBa

Vibration at operator

position

0.47g (4.64m/s2)

0.47g (4.64m/s2)

General Conditions: Sunny

Temperature: 61oF (16oC)

Wind Speed: 6 mph (10 kmh)

Wind Direction: East North East

Humidity: 86%

Barometric Pressure: 30.01”Hg (762 mm Hg)

General Conditions: Sunny

Temperature: 57oF (14oC)

Wind Speed: 16 mph (25.7kph)

Wind Direction: East

Humidity: 89%

Barometric Pressure: 29.9Hg (101.3kpa)

Specifications

QV550EU QV550HEU

SOUND

97 dB

Sound tests were conducted in accordance with 2000/14/EEC, and were performed on 3-28-12 under the conditions listed below.

Sound power level listed is the highest value for any model covered in this manual. Please refer to serial plate on the unit for the sound

power level for your model.

SOUND LEVEL 77 dB(a) at Operator Position

VIBRATION DATA

VIBRATION LEVEL 0.47g (4.64m/s2)

Vibration levels at the operator’s handles were measured in the vertical, lateral and longitudinal directions using calibrated vibration test

equipment. Tests were performed on 3-29-12 under the conditions listed below.

Part No 831508 Form No F021213D

4

QVEU PUSH Operator’s Manual

HONDA BRIGGS & STRATTON

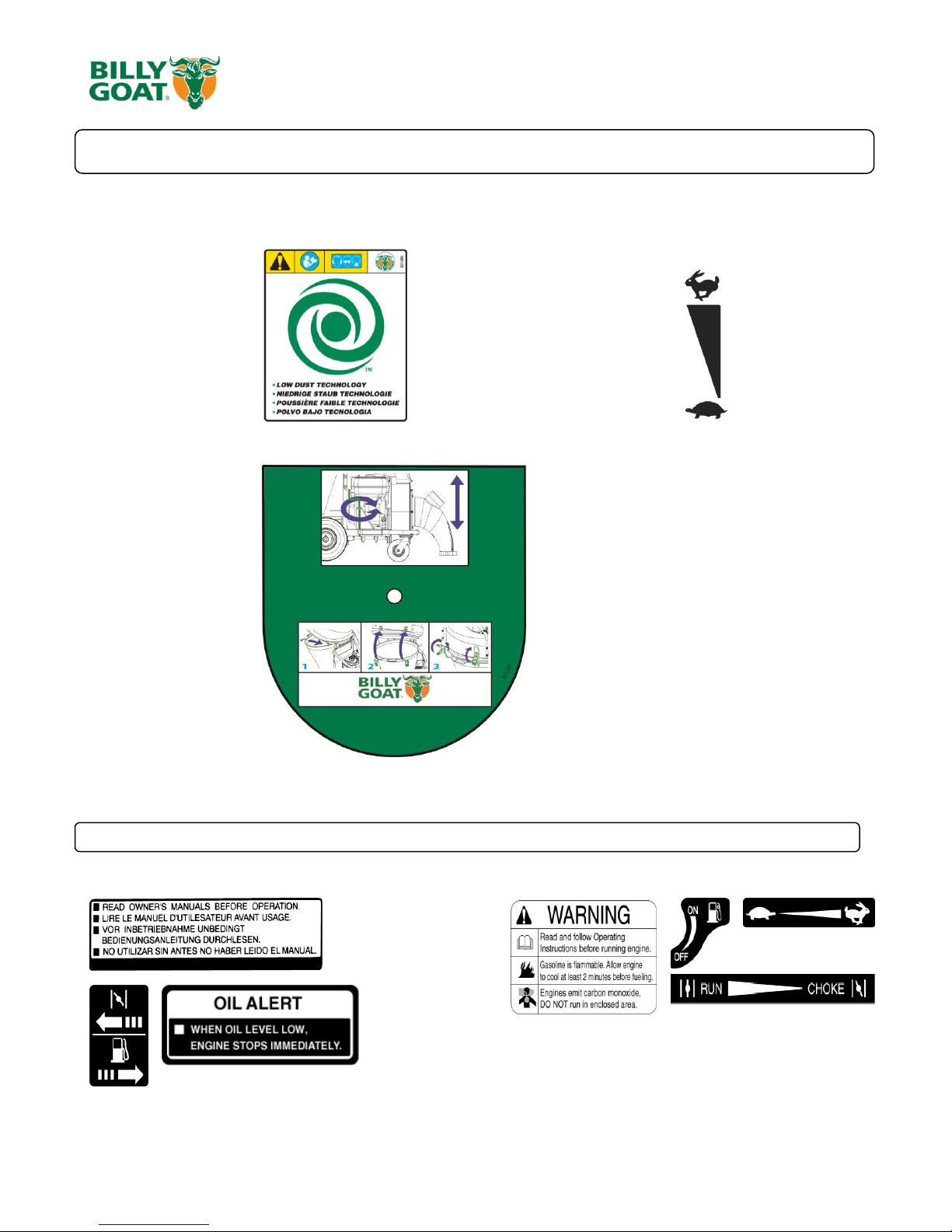

INSTRUCTION LABELS

The labels shown below were installed on your BILLY GOAT ® QVEU Vacuum. If any labels are damaged or missing, replace them before

operating this equipment. Item numbers from the Illustrated Parts List and part numbers are provided for convenience in ordering replacement

labels. The correct position for each label may be determined by referring to the Figure and Item numbers shown.

LABEL WARNING LABEL THROTTLE

ITEM #35 P/N 831265 ITEM #104 P/N 810656

INSTRUCTION LABEL

ITEM # 37 P/N 831259

ENGINE LABELS

Part No 831508 Form No F021213D

5

QVEU PUSH Operator’s Manual

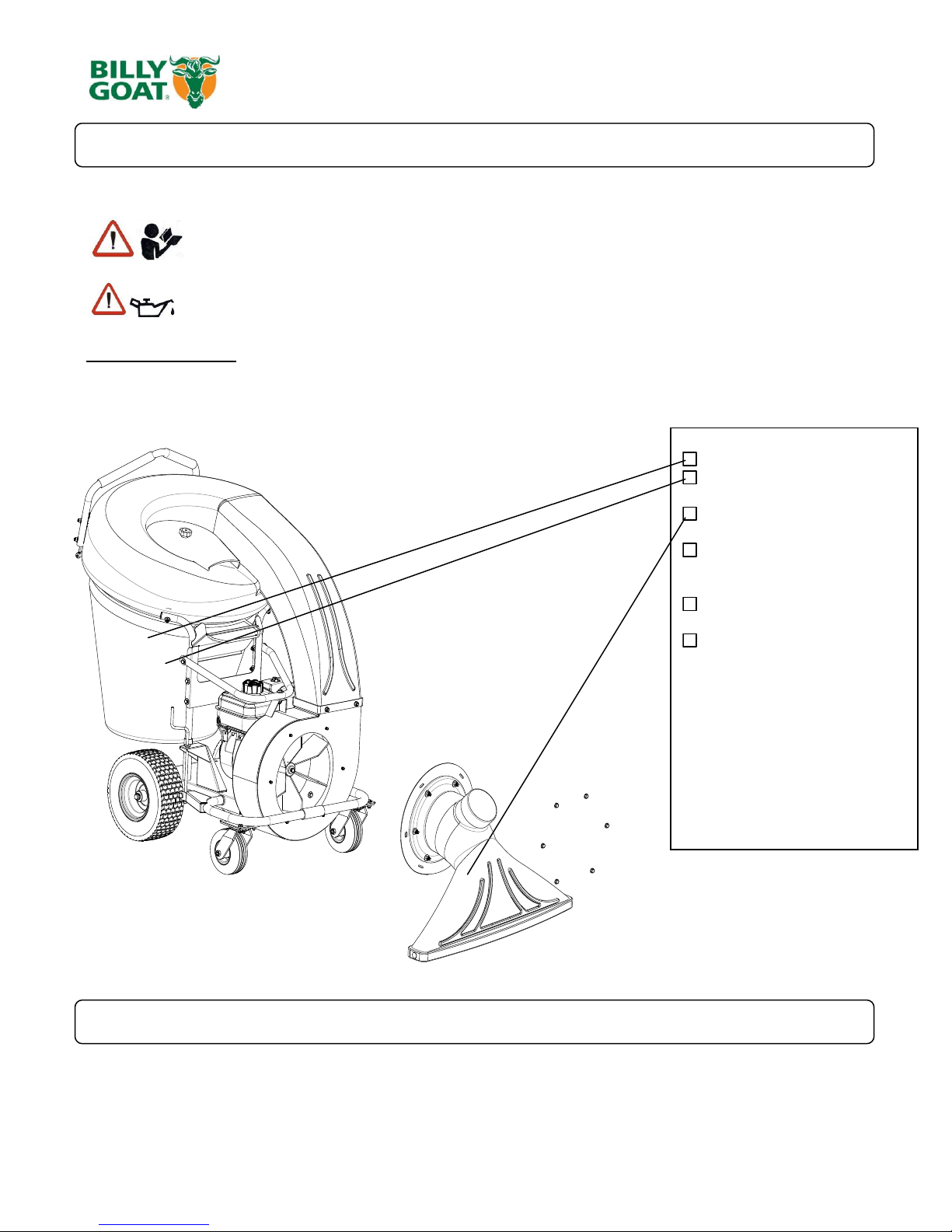

READ all safety instructions before assembling unit.

TAKE CAUTION when removing the unit from the box

1. Remove the unit from the box. Be careful as not to damage the unit.

2. Attach the front nozzle (item 7) to the housing and secure it with the serrated hex nuts (item 40) located in the parts bag.

Boxing Parts Checklist

Debris Bag P/N-831225

Dust Sock P/N-831268

Front Nozzle P/N-831606

Literature Assy

P/N-831021

Briggs & Stratton 5.5 HP

Honda 5 HP

PARTS BAG &

LITERATURE ASSY

Warranty card P/N- 400972, Operator’s Manual P/N-831504, Declaration of Conformity P/N-831503.

General Safety and Warnings Manual P/N-100294

PACKING CHECKLIST

Your Billy Goat is shipped from the factory in one carton, completely assembled except for the nozzle.

ASSEMBLY

PUT OIL IN ENGINE BEFORE STARTING

Part No 831508 Form No F021213D

6

QVEU PUSH Operator’s Manual

VACUUMING OPERATION

VACUUM NOZZLE HEIGHT ADJUSTMENT: Is adjusted by turning the knob clockwise increases height and counter-clockwise to

lower it. Adjust nozzle height according to surface conditions and debris size; For vacuuming on flat surfaces, set nozzle 1/2" (12.7

mm) to 5/8" (15.8 mm) above ground; Higher for uneven terrain and turf.

FOR MAXIMUM PICKUP: Adjust nozzle close to debris, but without blocking airflow into the nozzle.

NOTE: Never bury nozzle into debris.

CLEARING A CLOGGED NOZZLE & EXHAUST: Turn engine off and wait for impeller to stop completely and

disconnect spark plug wire. Wearing durable gloves, remove clog, this may require removing the front nozzle. Danger, the clog

may contain sharp materials. Reconnect spark plug wire.

DEBRIS BAG

Debris bags are normal replaceable wear items.

Note: Frequently empty debris to prevent bag overloading with more weight than you can lift.

Use the dust skirt when debris will be vacuumed in dusty conditions.

DO NOT place bag on or near hot surface, such as engine. Run engine at 1/2 throttle for first 1/2 hour to condition new bag. Your

new bag requires a break-in period to condition the pores of the material against premature blockage. The entire bag surface serves

as a filter, and must be able to breathe to have good vacuum performance. Be sure engine has come to a complete stop before

removing or emptying bag.

HOOD FILTER

Hood filters are normal replaceable wear items.

The hood filter is for use in dry dusty conditions only. DO NOT get the filter wet. Clean with light compressed air only.

DUST SOCK

Dust Skirts are normal replaceable wear items.

See next page for Dust sock care.

This vacuum is designed for picking up trash, organic material and other similar debris.

However, many vacuums are used where dust is mixed with trash. Your unit can intermittently vacuum in dusty areas. Dust is the

greatest cause of lost vacuum performance. However, following these rules will help maintain your machine's ability to vacuum in

dusty conditions:

•Run machine at idle to quarter throttle.

•The debris bag must be cleaned more frequently. A vacuum with a clean, pillow soft bag will have good pickup performance. One

with a dirty, tight bag will have poor pickup performance. If dirty, empty debris and vigorously shake bag free of dust.

Having one or more spare debris bags is a good way to reduce down time while dirty bags are being cleaned.

•DO NOT leave debris in bag while in storage.

OPERATION

Part No 831508 Form No F021213D

7

QVEU PUSH Operator’s Manual

6”-12”

(152mm-305mm)

LIGHTLY CLEAN WITH COMPRESSED AIR ONLY, FROM THE

OUTSIDE IN. KEEP THE NOZZLE 6-12 INCHES FROM FABRIC

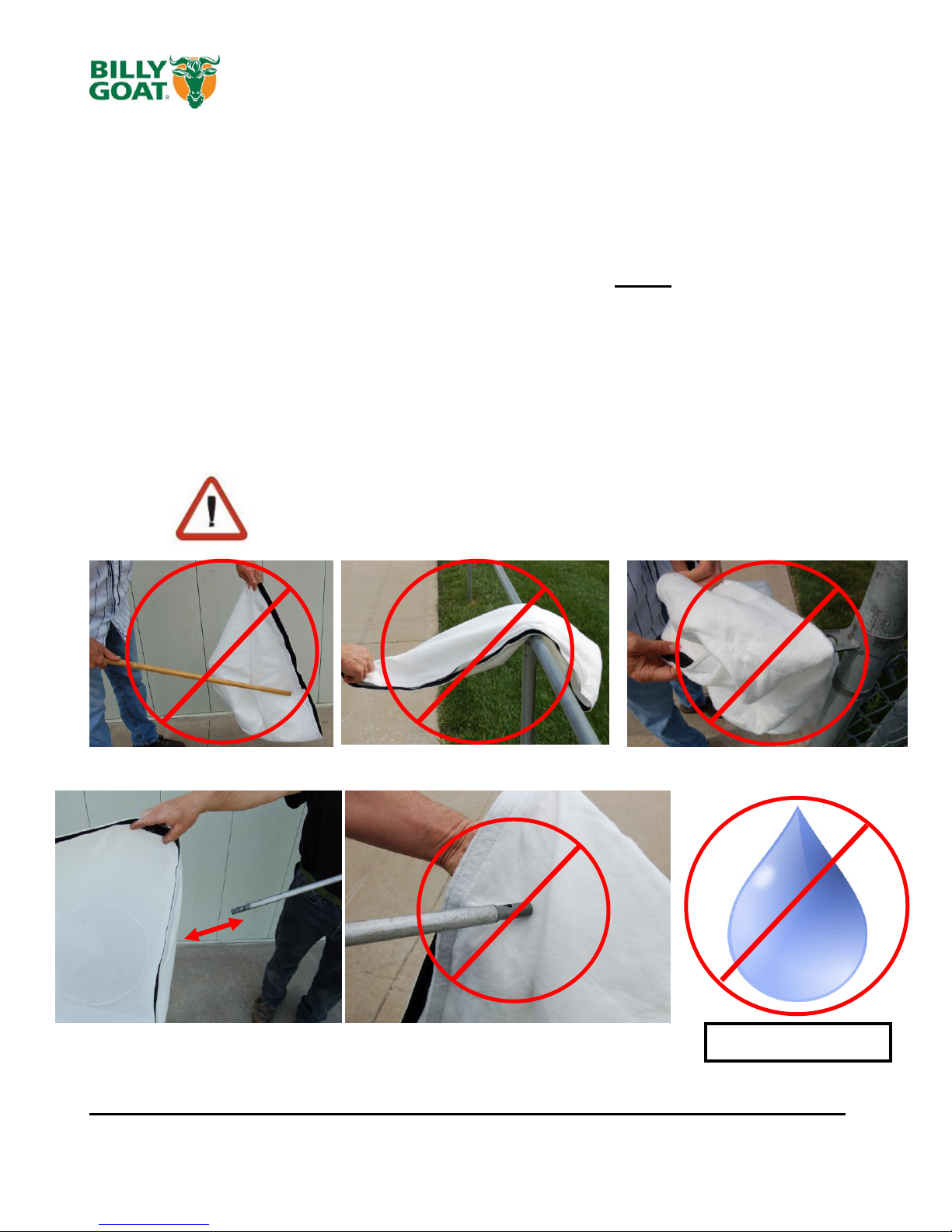

DUST SOCK CARE AND MAINTENANCE

Purpose:

The dust sock acts as a secondary filter lowering the amount of dust that escapes

the bag.

Dust socks are to be used in dry and dusty conditions ONLY. Using the dust sock

in damp or wet conditions may damage the dust sock and decrease the

effectiveness of the filter.

The dust sock may be installed by simply attaching the mating Velcro strips between the

bag and the dust sock. Over time the dust sock will begin to fill with dust during use.

Periodically remove the dust sock, empty the loose dust out and clean the sock. For a

light clean, simply shake the sock, for a deep clean, see below. To remove the sock,

simply separate the Velcro.

Dust Sock Care Information:

DO NOT STRIKE THE BAG WITH OR AGAINST OBJECTS DO NOT SNAG THE BAG

DO NOT GET WET

Dust Socks are normal replaceable wear items. Replacement P/N- 831282

Part No 831508 Form No F021213D

8

QVEU PUSH Operator’s Manual

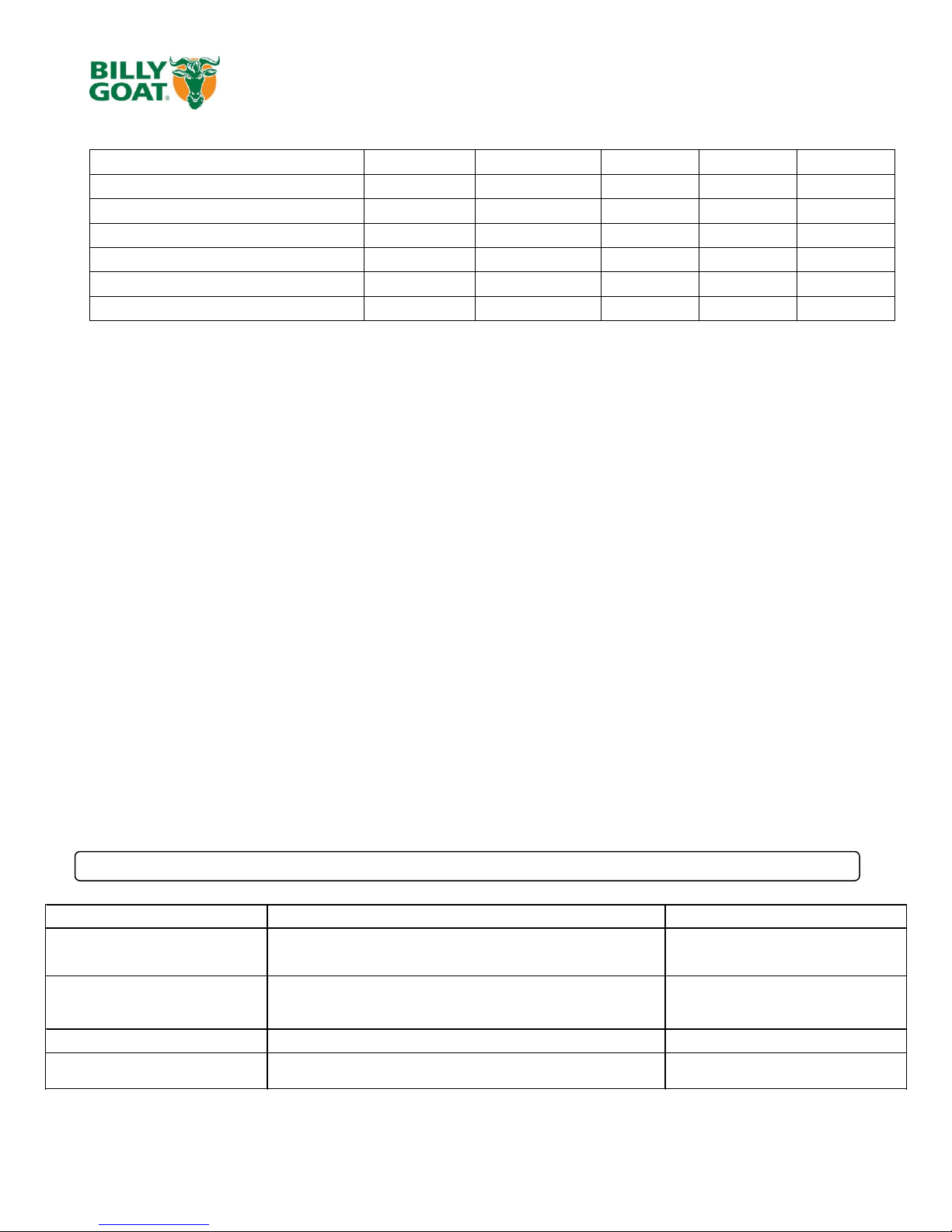

Maintenance Operation

Every Use (daily)

Every 5 hrs (daily)

Every 10 Hrs

Every 25 Hrs

Every 50 Hrs

Inspect for loose, worn or damaged parts.

Clean Debris bag

Check Tire pressure

Engine (See Engine Manual)

Check for excessive vibration

Grease zerks

Problem Possible Cause Solution

Abnormal vibration. · Loose or out of balance impeller or loose engine

· Check impeller and replace if required.

Check engine

Will not vacuum or has poor vacuum

performance

· dirty debris bag. Nozzle height set too high or low. Hose kit cap

missing. Clogged nozzle or exhaust. Excessive quantity of debris.

· Clean debris bag. Shake bag clean or

wash. Adjust nozzle height. Check for

hose kit cap. Unclog nozzle or exhaust.

Allow air to feed with debris

Engine will not start.

· Stop switch off. Throttle in off position. Engine not in full choke

position. Out of gasoline. Bad or old gasoline. Sparkplug wire

disconnected. Dirty air cleaner. Low oil (honda only)

· Check stop switches, throttle, choke

position and gasoline. Connect spark

plug wire. Clean or replace air filter. Or

contact a qualified service person.

Engine is locked, will not pull over. · Debris locked in impeller. Engine problem.

· See page 6. Contact a engine service

dealer for engine problems

Nozzle scrapes ground in lowest

height setting.

Nozzle height out of adjustment

Adjust nozzle height (See Nozzle height

fine adjustment for hard surfaces on

page 6

IMPELLER REMOVAL

1. Disconnect spark plug wire.

2. Secure the unit to keep it from moving.

3. Remove the nozzle (item 7) from the housing, then remove the plate it was attached to (item 30).

4. Walk the belt (item 22) off of the lower pulley (item 23) and then slide it off of the impeller groove. If you cannot walk

it off of the bottom pulley loosen the bearings (item 24) on the underside this will allow a little more play in the pulley.

5. Slide belt out of belt groove in impeller hub drive pulley.

6. Remove impeller bolt and lock washer.

7. If impeller slides off freely, proceed to (step 12). (Do not drop impeller).

8. If impeller does not slide off crankshaft, place two crowbars between impeller and housing on opposite sides. Pry

impeller away from engine until it loosens. Using a penetrating oil can help loosen a stuck impeller.

9. Slide impeller off of crank shaft and remove impeller from housing.

10. Reinstall new impeller, new impeller bolt and lock washer in reverse order of removal. (See the parts drawing on

pages 9-12 for parts break-down and parts list on page 10 for proper impeller bolt torque specifications.)

11. When impeller is installed, slide the belt back into the groove on the hub and walk it back onto the bottom pulley.

Retighten the bearings if they were loosened.

12. Reattach nozzle plate and nozzle in reverse order of removal.

13. Reconnect spark plug wire.

14. Check for proper operation.

PERIODIC MAINTENANCE

Periodic maintenance should be performed at the following intervals:

Grease: Wheels, Casters, and Shaft Bearings.

Tire air pressure: Check at regular intervals & maintain: Rear SP 13" tires at 20 psi. (137.9 kPa).

Troubleshooting

Part No 831508 Form No F021213D

9

QVEU PUSH Operator’s Manual

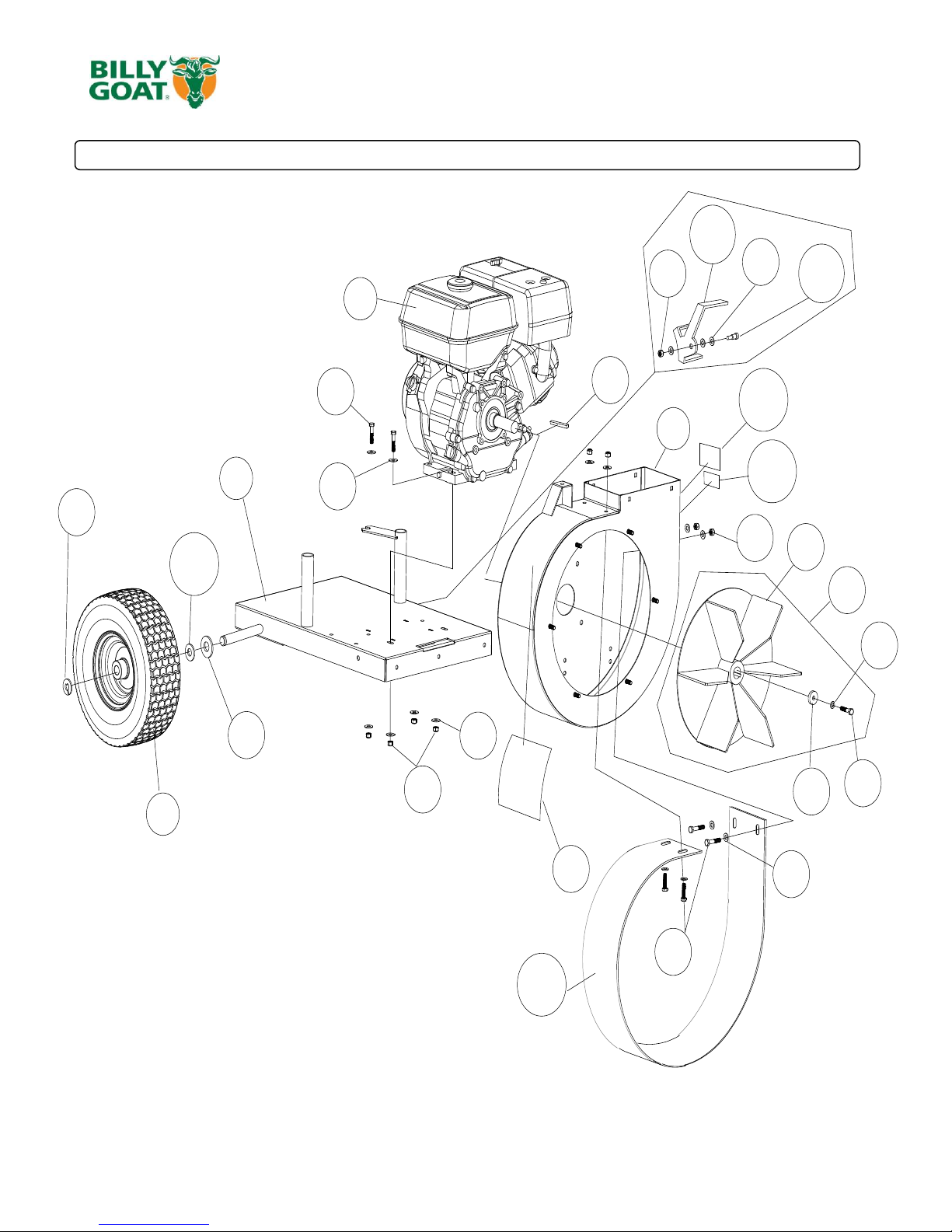

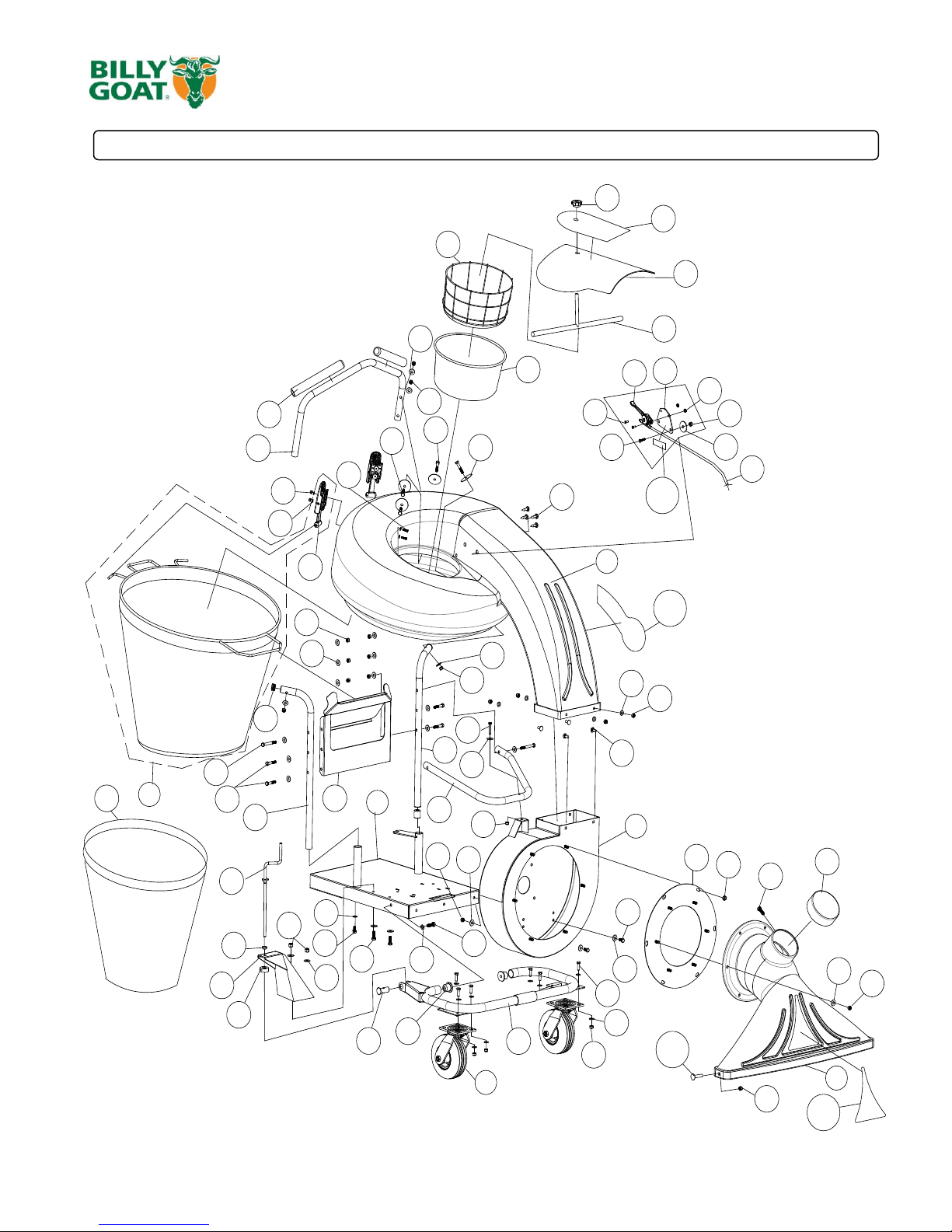

PARTS DRAWING QVEU

109

45

44

59

49

45

108

107

101

49

49

14

55

53

52

54

50

45

35

20

9

4

2

1

3

78

105

106

Part No 831508 Form No F021213D

10

QVEU PUSH Operator’s Manual

ITEM DESCRIPTION

QV550 PART

NO.

QTY

QV550H

PART NO.

QTY

1 ENGINE BRIGGS 5.5 HP

350379 1 - -

ENGINE HONDA 5.5 OHV GX160

- - 600115 1

2 HOUSING WA W/LABELS

831600 1 831600 1

3 SNAP RING 3/4

850230 1 850230 1

4 WHEEL 13" X 5" PNEU

440054 2 440054 2

9 ENGINE BASE WA

831106 1 831106 1

14 SCREWCAP 5/16"-18 X 1 1/2" HCS ZP

8041030 4 8041030 4

20 IMPELLER ASSY

831601 1 831601 1

35 LABEL WARNING QV

831265 1 831265 1

44 WASHER 5/16" SAE

8172008 8 8172008 8

45 NUT LOCK 5/16"-18 HEX ZP

8160002 14 8160002 14

49 WASHER 5/16" FLAT

8171003 7 8171003 7

50 KEY 3/16" SQ X 2 1/4"

9201087 1 9201087 1

52 WASHER LOCK 5/16" SPLIT

8177011 1 8177011 1

53 SCREWCAP 5/16"-24 X 2 1/4" GR.8 W/PATCH

831272 1 831272 1

54 WASHER 1.125 OD X 0.344 ID X0.25

441150 1 441150 1

55

IMPELLER 5HP WA (torque 17-22 ft.lbs [23-

30 N.m])

831104 1 831104 1

59

SCREWCAP 5/16"-18 X 3/4" GR 5 HCS ZP 8041026 4 8041026 4

78 WASHER 3/4" SAE

8172015 2 8172015 2

101 WASHER .765 ID X 1.25 OD X .06

850238 2 850238 2

105 LABEL MADE IN USA

520116 1 520116 1

106 LABEL PATENT PENDING

500183 1 500183 1

107 BRACKET BRAKE QV

831281 1 831281 1

108 BOLT SHOULDER 3/8" X 1/2"

830528 1 830528 1

109 LINER QV

831283 1 831283 1

Part No 831508 Form No F021213D

11

QVEU PUSH Operator’s Manual

PARTS DRAWING QVEU

104

102

103

60

100

51

26

5

6

7

8

2

9

11

12

13

18

10

15

16

17

19

27

22

29

30

31

32

34

36

37

45

49

40

78

49

47

49

45

45

49

60

63

64

48

45

49

65

48

66

68

49

45

43

45

49

79

47

46

45

25

69

49

45

39

42

67

23

52

49

21

24

56

TO

ENGINE

98

99

96

97

90

94

95

48

65

Part No 831508 Form No F021213D

Loading...

Loading...