Page 1

11

1

11

R

Thank You for SelectingThank You for Selecting

Thank You for Selecting

Thank You for SelectingThank You for Selecting

The Powerful

QUIET BLOW

® BLOWER

Operator Owner's Manual

Fo r Models:

QB882, QB882IC, QB882H, QB882CARB, QB1102IC,

QB1102H

33

3

33

QB882 QB882IC QB882H Q B882CARB QB1102IC QB1102H

ENGINE: HP 8.0 HP (5.97 kW) 8.0 (5.97 kW) 8.0 (5.97 kW) 11.0 HP (8. kW) 11.0 HP (8.2kW) 11. 0HP (8.2kW)

ENGINE:TYPE B & S B & S IC HONDA OHV B & S IN. PLUS B & S IC HONDA OHV

ENGINE: FUEL CAP. 4.0 qt. ( 3.8 L) 4.0 qt (3.8 L) 6.4 qt. (6.1 L) 4.0 qt. (6.1L) 6.0 qt. (5.7 L) 7.4 qt. ( 7.0 L)

ENGINE: OIL CAP. 1.38 qt. (1.3 L) 1.38 qt. (1.3 L) 1.16 qt. (1.1 L) 1.16 pt. (1.1L) 1.5 qt. ( 1.4 L) 1.2 qt.(1.13L)

WEIGHT: UNIT 124 # ( 56.3 Kg) 126 # (57.2 Kg) 136 # (61.7 Kg) 126 # (57.2 Kg) 150 # (68.0 Kg) 152 # (68.9 Kg)

WEIGHT: SHIPPING 141 # (63.97 Kg) 143 # (64.9Kg) 153 # (69.4 Kq) 143 # (64.9 Kg) 167 # (75.8 Kg) 169 # (76.7 Kg)

ENGINE WEIGHT: 46 # (20.8 Kg) 49 # (22.2 Kg) 48.5 # (22.0 Kg) 49 # (22.2 Kg) 64.25 # (29.1 Kg) 68.4 #(31.0 Kg)

UNIT SIZE:

OVERALL LENGTH: 51.75"(1.31m) OVERALL WIDTH 28.5" (0.72m) OVERALL HEIGHT 39" (0.99m)

Specifications

Part No. 430187 Form No. F060496C

Page 1 of 8

Page 2

55

5

55

IN THE INTEREST OF SAFETYIN THE INTEREST OF SAFETY

IN THE INTEREST OF SAFETY

IN THE INTEREST OF SAFETYIN THE INTEREST OF SAFETY

BEFORE STBEFORE ST

BEFORE ST

BEFORE STBEFORE ST

ENGINE MANUAL.”ENGINE MANUAL.”

ENGINE MANUAL.”

ENGINE MANUAL.”ENGINE MANUAL.”

THIS SYMBOL MEANS THIS SYMBOL MEANS

THIS SYMBOL MEANS

THIS SYMBOL MEANS THIS SYMBOL MEANS

DD

AMAAMA

D

AMA

DD

AMAAMA

GE MAGE MA

GE MA

GE MAGE MA

ARAR

TING ENGINE,TING ENGINE,

AR

TING ENGINE,

ARAR

TING ENGINE,TING ENGINE,

Y OCCUR UNLESS INSTRY OCCUR UNLESS INSTR

Y OCCUR UNLESS INSTR

Y OCCUR UNLESS INSTRY OCCUR UNLESS INSTR

READ AND UNDERST READ AND UNDERST

READ AND UNDERST

READ AND UNDERST READ AND UNDERST

WW

ARNING OR CAARNING OR CA

W

ARNING OR CA

WW

ARNING OR CAARNING OR CA

AND AND

THE THE

AND

THE

AND AND

THE THE

UTION.UTION.

UTION.

UTION.UTION.

UCTIONS ARE FOLLOUCTIONS ARE FOLLO

UCTIONS ARE FOLLO

UCTIONS ARE FOLLOUCTIONS ARE FOLLO

DEA DEA

DEA

DEA DEA

TH,TH,

PERSONAL INJUR PERSONAL INJUR

TH,

PERSONAL INJUR

TH,TH,

PERSONAL INJUR PERSONAL INJUR

“ENTIRE OPERA“ENTIRE OPERA

“ENTIRE OPERA

“ENTIRE OPERA“ENTIRE OPERA

WED CAREFULLWED CAREFULL

WED CAREFULL

WED CAREFULLWED CAREFULL

TT

OR'S MANUOR'S MANU

T

OR'S MANU

TT

OR'S MANUOR'S MANU

Y AND/OR PRY AND/OR PR

Y AND/OR PR

Y AND/OR PRY AND/OR PR

YY

..

Y

.

YY

..

AL &AL &

AL &

AL &AL &

OPEROPER

OPER

OPEROPER

TYTY

TY

TYTY

WARNING!

WW

ARNING:ARNING:

W

ARNING:

WW

ARNING:ARNING:

DO NOTDO NOT

1.

D O N O T run engine in an enclosed area.

DO NOTDO NOT

Exhaust gases contain carbon monoxide, an

odorless and deadly poison.

DO NOTDO NOT

2.

D O NOT place hands or feet near moving

DO NOTDO NOT

or rotating parts.

DO NOTDO NOT

3.

D O N O T store, spill or use gasoline near

DO NOTDO NOT

an open flame, or devices such as a stove,

furnace, or water heater which use a pilot

light or devices which can create a spark.

DO NOTDO NOT

4.

D O N O T refuel indoors where area is not

DO NOTDO NOT

well ventilated. Outdoor refueling is recommended.

DO NOTDO NOT

5.

D O N O T fill fuel tank while engine is

DO NOTDO NOT

running. Allow engine to cool for 2 minutes

before refueling. Store fuel in approved

safety containers.

DO NOTDO NOT

6.

D O N O T remove fuel tank cap while

DO NOTDO NOT

engine is running.

DO NOT DO NOT

7.

DO NOT operate engine when smell of

DO NOT DO NOT

gasoline is present or other explosive

conditions exist.

DO NOTDO NOT

8.

D O N O T operate engine if gasoline is

DO NOTDO NOT

spilled. Move machine away from the spill

and avoid creating any ignition until the

gasoline has evaporated.

DO NOTDO NOT

9.

D O N O T transport unit with fuel in tank.

DO NOTDO NOT

DO NOTDO NOT

10.

D O N O T smoke when filling fuel tank.

DO NOTDO NOT

DO NODO NO

11.

Whenever possible, gradually reduce engine

speed before stopping.

12.

This may result in injury & /or damage

to unit.

TT

DO NO

T choke carburetor to stop engine.

DO NODO NO

TT

DO NOTDO NOT

D O N OT run engine at excessive speeds.

DO NOTDO NOT

66

6

66

TT

ABLE OF CONTENTSABLE OF CONTENTS

T

ABLE OF CONTENTS

TT

ABLE OF CONTENTSABLE OF CONTENTS

SAFETY INSTRUCTIONSSAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONSSAFETY INSTRUCTIONS

GENERAL SAFETYGENERAL SAFETY

GENERAL SAFETY

GENERAL SAFETYGENERAL SAFETY

ASSEMBLASSEMBL

ASSEMBL

ASSEMBLASSEMBL

LABELSLABELS

LABELS

LABELSLABELS

PP

ARAR

TS BTS B

P

PP

OPERAOPERA

OPERA

OPERAOPERA

PP

P

PP

MAINTENANCEMAINTENANCE

MAINTENANCE

MAINTENANCEMAINTENANCE

TROUBLESHOOTINGTROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTINGTROUBLESHOOTING

WW

W

WW

Part No. 430187 Form No. F060496C

AA

AR

TS B

A

ARAR

TS BTS B

AA

TIONTION

TION

TIONTION

ARAR

TS DRATS DRA

AR

TS DRA

ARAR

TS DRATS DRA

ARRANTY PRARRANTY PR

ARRANTY PR

ARRANTY PRARRANTY PR

DO NO DO NO

DO NO

DO NO DO NO

○○○○○○○○

YY

Y

YY

○○○○○○○○

G & CONTRG & CONTR

G & CONTR

G & CONTRG & CONTR

○○○○○○○

WING & LISTWING & LIST

WING & LIST

WING & LISTWING & LIST

○○○○○○

OCEDUREOCEDURE

OCEDURE

OCEDUREOCEDURE

cancer, birth defects or other reproductive harm.

DO NOTDO NOT

13.

D O N O T tamper with governor springs,

DO NOTDO NOT

governor links or other parts which may

change the governed engine speed.

DO NOTDO NOT

14.

D O NOT tamper with the engine speed

DO NOTDO NOT

selected by the engine manuf acturer.

DO NOTDO NOT

15.

D O N O T check for spark with spark plug

DO NOTDO NOT

or spark plug wire removed. Use an

approve d tester.

DO NOTDO NOT

16.

D O N O T crank engine with spark plug

DO NOTDO NOT

removed. If engine is flooded, place throttle

in “FAST” position and crank until engine

starts.

DO NODO NO

17.

D O N O T strike flywheel with a hard

DO NODO NO

object or metal tool as this may cause

flywheel to shatter in operation. Use proper

tools to service engine.

DO NOTDO NOT

18.

D O N O T operate engine without a

DO NOTDO NOT

muffler. Inspect per iodically and replace, if

necessary. If engine is equipped with

m uffler deflector, inspect per iodically and

replace , if necessar y, with correct deflector.

DO NOTDO NOT

19.

D O N O T operate engine with an

DO NOTDO NOT

accumulation of grass, leaves, dirt or other

combustible material in the muffler area.

DO NOTDO NOT

20.

D O N O T use this engine on any forest

DO NOTDO NOT

covered, brush covered, or grass covered

unimproved land unless a spark arrester is

installed on the m uffler. The arrester must

be maintained in effective working order by

the operator. In the State of Califor nia the

above is required by law (Section 4442 of

the California Public Resources Code).

Other states may have similar laws.

Federal laws apply on federal lands.

SOUNDSOUND

SOUND

SOUNDSOUND

Sound tests were conducted on model QB882IC

in accordance with 79/113/EEC and were

performed on

listed:

GENERAL CONDITION:

TEMPERATURE:

WIND SPEED:

WIND DIRECTION:

HUMIDITY:

BAROMETRIC PRESSURE:

SOUND TESTS

1/12/19961/12/1996

1/12/1996 under the conditions

1/12/19961/12/1996

Page 2 of 8

○○

○○○○○

OLSOLS

OLS

OLSOLS

6 - 7

○○○

TT

T

TT

77

7

77

2

3

3

4

4

5

8

8

8

89

96

OPERATO R

SUNNY

47

9

W

58%

30.04

DO NODO NO

21.

D O N OT touch hot mu ffler, cylinder, or

DO NODO NO

fins because contact may cause burns.

DO NOTDO NOT

22.

D O N O T run engine without air cleaner

DO NOTDO NOT

or air cleaner cove r.

DO NOTDO NOT

23.

D O N OT operate during excessive

DO NOTDO NOT

vibration!

DO NOTDO NOT

24.

D O N O T leave machine unattended

DO NOTDO NOT

while in operation.

DO NOTDO NOT

25.

D O NO T park machine on a steep grade

DO NOTDO NOT

or slope.

WW

ARNING:ARNING:

W

ARNING:

WW

ARNING:ARNING:

ALAL

WW

AA

1.

spark plug when servicing the engine or

equipment TO PREVENT ACCIDENTAL

STA RTING.

2.

free of grass and other debris which can

affect engine speed.

3.

is felt. Then pull cord rapidly to avoid

kickback and prevent hand or ar m injur y.

4.

sure it is functioning eff ectiv ely. A wo rn o r

leaking muffler should be repaired or

replaced as necessary.

5.

gum carburetor and cause leakage.

6.

for cracks or leaks. Replace if necessary

7.

and maintenance instructions.

8.

starting unit.

YS DOYS DO

AL

W

A

Y S DO remo ve the wire from the

ALAL

WW

AA

YS DOYS DO

DODO

D O keep cylinder fins and governor parts

DODO

DODO

D O pull starter cord slowly until resistance

DODO

DODO

D O examine muffler periodically to be

DODO

DODO

D O use fresh gasoline. Stale fuel can

DODO

DODO

D O check fuel lines and fittings frequently

DODO

FollowFollow

Follow engine manufacturer operating

FollowFollow

Inspect Inspect

Inspect machine and work area before

Inspect Inspect

88

8

88

VIBRA TION LEVELS 1.9g

Vibration levels at the operators handles were

measured in the vertical, lateral, and longitudinal

directions using calibrated vibration test equipment.

Tests w ere perf o rmed on

conditions listed:

GENERAL CONDITION:

TEMPERATURE:

WIND SPEED:

WIND DIRECTION:

HUMIDITY:

BAROMETRIC PRESSURE:

The engine exhaust from this product contains chemicals known to the State of California to cause

DO DO

DO

DO DO

VIBRAVIBRA

TIONTION

VIBRA

TION

VIBRAVIBRA

TIONTION

2/9/19962/9/1996

2/9/1996 under the

2/9/19962/9/1996

SUNNY

63

18

SW

32%

29.8

Page 3

99

9

99

GENERAL SAFETY

For your safety and the safety of others, these directions should be followed:

Do not operate this machine without first reading

owner's manual and engine manufacturer's manual.

Use of Ear Protection is recommended while

operating this machine.

Use of Eye and breathing protection is recom mended when using this machine, especially in

dry and dusty conditions.

·DO NOT place hands or feet inside air intake opening, near

exhaust outlet or near any moving parts.

·DO NOT start engine without deflector attached to exhaust

outlet.

1010

10

1010

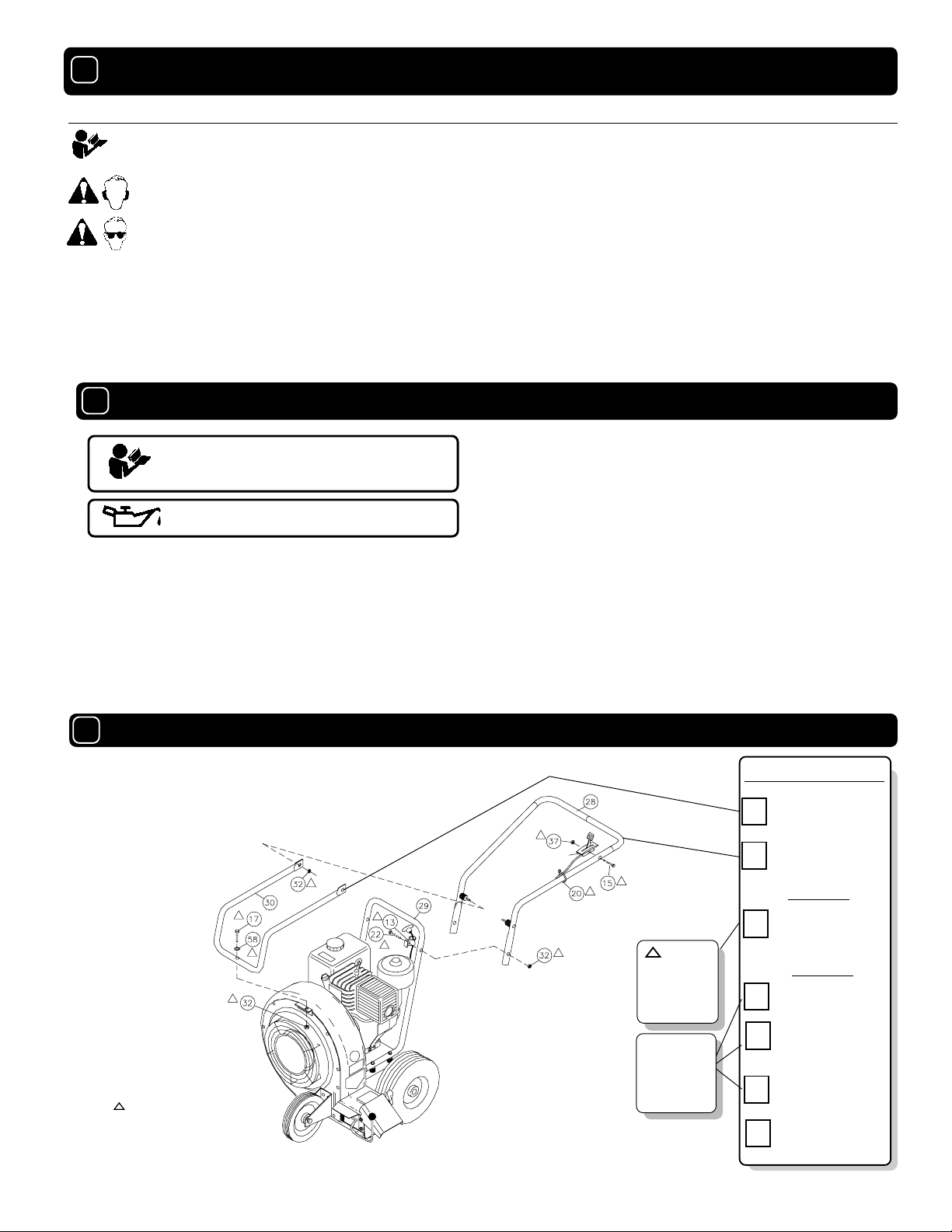

ASSEMBLY

·DO NOT direct exhaust outlet toward any bystanders.

·DO NOT operate this equipment without first inspecting

work area.

·DO NOT operate this equipment during excessive vibration.

·DO NOT start engine without housing front plate attached.

·DO NOT operate this machine on slopes greater than 20%.

·DO NOT blow any hot or burning debris, or any toxic or

explosive material.

·DO NOT allow children to operate this equipment.

Read all safety and operating instructions before assembling or starting this

unit.

PUT OIL IN ENGINE BEFORE ST ARTING

Your Billy Goat is shipped from the factory in one carton,

completely assembled except f or the upper handle assemb ly ,

handle brace, plate deflector and throttle control.

1111

11

1111

PACKING CHECKLIST

These items should be included in your carton.

If any of these parts are missing, contact your

dealer.

Denotes parts found in

Parts Bag Assembly

(shown on page 4).

1. Install upper handle (Item 28), to preassembled lower handle (item 29),

using two screws (Item 17), and two lock nuts, (Item 32). Hand tighten only.

2. Install front of handle brace (Item 30), to blower housing using one

screw (Item 17), one washer (Item 58) and one lock nut (item 32). Install

rear of handle brace (item 30) to upper handle vibration mounts using two

lock nuts (item 32). Hand tighten only.

3. Securely tighten all hardware listed above in steps 1 thru 2.

4. Attach throttle control assembly to inside of upper handle using screw

(item 15), lock nut (item 37) and clamp cables (item 20).

5.Connect spark plug wire.

Boxing Checklist

Check

Handle Brace

400951

Check

Handle Upper

Assembly

400957

Per Model

Check

Parts Bag &

Literature Assy

430186

Parts Bag

& Litera-

ture Assy

Engine

Manual

Per

Model

Check

Check

Check

Check

Per Model

Briggs & Stratton 8

Multi-Language

HP

MS2558

Briggs & Stratton

Multi-Language

11 HP

MS2558

Honda 8 & 11 HP

P/N 31ZH9602

00X31-ZH9-6020

English

Briggs & Stratton 8

Industrial Plus

HP

P/N 270367

Part No. 430187 Form No. F060496C

Page 3 of 8

Page 4

1212

DANGER

KEEP HANDS and FEET AWAY

12

1212

PARTS BAG & LITERATURE ASSY P/N 430186

PARTS BAG ASSEMBLY CHECKLIST P/N 430194

1313

13

1313

CONTROLS

Screw Cap

1/4-20 x 1 3/4

15

8041009 Qty.

1

Screw Cap

17

5/16-18 x 1 3/4

8041031 Qty. 2

17

Screw Cap

5/16-18 x 2 1/2

8041034 Qty. 1

58

Washer 5/16

FLA T CUT

8171003 Qty. 1

Nut Lock 5/16-18

32

8160002 Qty. 5

13

Rope Guide

830533 Qty. 2

37

20

Clamp Cable 1"

900813 Qty. 3

Nut Lock 1/4-20

8160001 Qty. 1

Owner's

Manual

Literature

Parts Bag

Warranty

Card

EU Declaration

of Conformity

& EU

Distributor List

Literature Checklist

Check

Owner's

Manual

430187

Check

Literature

Parts Bag

430195

Check

Check

Warranty

Card

400972

EU Declaration

4

of Conformity

& EU Distribu-

tor List

430189

Throttle

Control

Stop

position

Briggs and

HONDA

engines have

a choke type

carburetor that

is operated by

moving the

throttle control

to the full fast

position.

Start

position

START

STOP

1414

14

1414

INSTRUCTION LABELS

These labels should be included on your Blower. If any

of these labels are damaged, replace them before

putting this equipment into operation. Item and part

numbers are given to help in ordering replacement

labels.

Label Do Not Fill While

Engine Is Hot

Item 11 Part No.400268

Label Read Owner's Manual

Item No. 59 Part No. 890301

WARNING

EXPLOSIVE FUEL

STOP ENGINE AND ALLOW TO

COOL BEFORE REFUELING.

400268

Label Danger Keep

Hands and Feet Away

Item 41 Part No.400424

DANGER

810736

Label Danger Flying Material

Item No. 44 Part No. 810736

Label Ear Eye Breathing

Item No. 63 Part No. 890254

890254

1515

15

1515

ENGINE LABELS

Briggs & Stratton

Read Owner’s Manual Before Operating.

Lire le manuel d’utilisation avant la mise en route.

Vor Inbetriebnahme Bedienungs - und Wartungsanleitung lesen.

Favor leer las instrucciones de operacion antes de operar el

motor.

..

..

Consultare il Manuale Uso e Manutenzione prima dell utilizzo.

Las Skotselinstruktionen Innan Start.

'

'

'

Honda

READ OWNER’S MANUAL BEFORE OPERATION.

LIRE LE MANUEL D UTILISATEUR AVANT USAGE.

VOR INBETRIEBNAHME UNBEDINGHT BEDIENUNGSANLEITUNG DURCHLESEN.

NO UTILIZAR SINANTES NO HABER LEIDO EL MANUAL

HONDA MOTOR CO. , LTD. MADE IN JAPAN

OIL ALERT

WHEN OIL LEVEL LOW,

Part No. 430187 Form No. F060496C

Page 4 of 8

ENGINE STOPS IMMEDIATELY.

Page 5

1616

16

1616

OPERATION

INTENDED USE: This machine is designed for cleaning

outdoor surfaces, where the debris can be effectively

blown into a consolidated area for convenient pickup and

removal.

Do not operate if excessive vibration occurs. If excessive

vibration occurs, shut engine off immediately and check

for damaged or worn impeller, loose impeller bolt, loose

impeller key, loose engine or lodged foreign objects.

Note: See parts list for proper impeller bolt torque

specifications. (See trouble shooting section on page 8).

Like all mechanical tools, reasonable care must

be used when operating machine.

Inspect machine work area and machine before operating. Make sure that all operators of this equipment are

trained in general machine use and safety .

PUT OIL IN ENGINE BEFORE ST ARTING

16.116.1

16.1

16.116.1

STARTING

ENGINE: See engine manufacturer’s instructions

for type and amount of oil and gasoline used.

Engine must be level when checking and filling oil and

gasoline.

ENGINE SPEED: Controlled by throttle lever on the handle.

Under normal conditions, operate at minimum throttle to

accomplish your current cleaning task.

FUEL V ALVE: Move fuel valve to "ON" position (when

provided on engine).

CHOKE: Operated with choke lever on side of engine .

THROTTLE: Move remote throttle control to fast position.

Pull starting rope to start engine.

IF YOUR UNIT FAILS TO START:

See Troubleshooting on page 8.

16.216.2

16.2

16.216.2

Adjust diverter rod to side discharge for normal blowing or to

forward discharge for blowing along walls, fences or hard-toreach areas (see right).

BLOWING OPERA TION

Front Discharge

Side Discharge

16.416.4

16.4

16.416.4

Using two people to lift machine is recommended. Lift holding the

handle and handle brace. Secure in place during transport.

16.516.5

16.5

16.516.5

HANDLING & TRANSPORTING:

STORAGE

Never store engine indoors or in enclosed poorly ventilated areas with fuel in tank, where fuel fumes may reach an

open flame, spark or pilot light, as on a furnace, water heater,

clothes dryer or other gas appliance.

If engine is to be unused for 30 days or more, prepare as

follows:

Remove all gasoline from carburetor and fuel tank to

prevent gum deposits from forming on these parts and

causing possible malfunction of engine. Drain fuel outdoors,

into an approved container, away from open flame. Be sure

engine is cool. Do not smoke. Run engine until fuel tank is

empty and engine runs out of gasoline.

NOTE: Fuel stabilizer (such as Sta-Bil) is an acceptable alternative in minimizing

the formation of fuel gum deposits during storage. Add stabilizer to gasoline in

fuel tank or storage container. Always follow mix ratio found on stabilizer

container. Run engine at least 10 min. after adding stabilizer to allow it to reach

the carburetor.

Part No. 430187 Form No. F060496C

Page 5 of 8

Page 6

1818

18

1818

P A RTS DRA WING

QB882, QB882IC,

QB882H,QB882CARB,

QB1102IC, QB1102H

R

Part No. 430187 Form No. F060496C

Page 6 of 8

Page 7

)

(

(

)

(

)

(

(

(

)

(

(3)

)

(

(

(

)

PARTS

1919

19

1919

LIST

QB882 QB882IC QB882CARB QB882H QB1102IC QB1102H

ITEM DESCR IPTI ON PART NO QTY PAR T NO QTY PART NO QTY PAR T NO QTY PART NO QTY PART NO Q TY

1 ENGINE - 11 HP HONDA - - - - - - - - - - 400931 1

ENGINE - 11 HP BRIGGS & STRAT TON IC - - - - - - - - 400466 1 - ENGINE - 8 HP HONDA - - - - - - 400937 1 - - - ENGINE - 8 HP BRIGGS & STRATTON 800136 1 - - - - - - - - - ENGINE - 8 HP BRIGGS & STRATTON IC - - 800880 1 - - - - - - - -

ENGINE- 8 HP BRIGGS & STRATTON INDUSTRIAL PLUS - - - - 430163 1 - - - - - 2 LOCK CLIP 400591 1 400591 1 400591 1 400591 1 400591 1 400591 1

3

4 PLATE F RONT W.A. & GRILL 430183 1 430183 1 430183 1 430183 1 430183 1 430183 1

5 IMPELLER ASSY 400965 1 40 0965 1 400965 1 400965 1 400965 1 400965 1

6 KEY S QUARE 1/ 4 X 2 1/ 4 *9201123 1 * 9201123 1 *9201123 1 *9201123 1 *9201123 1 *9201123 1

7 DOOR DIVERTE R ASSEMB LY 430170 1 43 0170 1 430170 1 430170 1 430170 1 430170 1

8 AXLE 430181 1 430181 1 430181 1 430181 1 430181 1 430181 1

9 WASHER LOCK 7/ 16 TWISTED TOOTH 850132 1 850132 1 850132 1 850132 1 850132 1 - WASHER LOC K 3/ 8 TWISTED TOOTH

10 SCREW C AP 7/16-20 x 1-1/4 HEX. HD GR. 5

SCREW CAP 3/8 -24 x 1-1/2 HEX. HD GR. 8

11 LABEL DO NOT FILL WHEN ENGINE IS HOT 400268 1 40 0268 1 400268 1 40026 8 1 400268 1 400268 1

12 SHEET METAL SCREW 1/4 x 3/4 DRILL POINT 430208 9 430208 9 430208 9 430208 9 430208 9 430208 9

13 GUIDE ROPE 830533 2 830533 2 830533 2 830533 2 830533 2 830533 2

14 SCREW CAP 5/16-18 x 1 - 1/4 *8041029 6 *8041029 6 *8041029 6 *8041029 6 *8041029 6 *8041029 6

15 SCREW CAP 1/4 -20 x 1-3/ 4 *8041009 1 *8041009 1 *8041009 1 *8041009 1 *8041009 1 *8041009 1

16 NUT LOCK 3/8 -16 *8160003 1 *8160003 1 *8160003 1 *8160003 1 *8160003 1 *8160003 1

17 SCREW C AP 5/16-18 x 1¾ *8041031 2 *8041031 2 *8041031 2 *8041031 2 *8041031 2 *8041031 2

18 SPAC ER WHEEL 400302 1 40030 2 1 400302 1 40 0302 1 400302 1 40 0302 1

19 WASHER 1/2 SAE 8172011 2 8172011 2 8172011 2 8172011 2 8172011 2 8172011 2

20 CLAMP C ABLE PLASTIC 1 900813 3 900813 3 900813 3 900813 3 900813 3 900813 3

21 THR OTT LE CON TROL ASSY

22 SCREW C AP 5/16-18 X 2½ *8041034 1 *8041034 1 *8041034 1 *8041034 1 *8041034 1 *8041034 1

23 WHEEL F RONT 8" 900816 1 900816 1 900816 1 900816 1 900816 1 900816 1

24 SC REW C AP,

25 SCREW C AP 5/16-18 x 3/4 *8041026 1 * 8041026 1 *8041026 1 *8041026 1 *8041026 1 * 8041026 1

26 WHEEL, REAR 400295 2 400295 2 400295 2 400295 2 400295 2 400295 2

27 BR ACKET

28 HANDLE UPPER ASSY

29 HANDLE LOWER 400950 1 400950 1 400950 1 400950 1 400950 1 400950 1

30 HANDLE- BRACE 400951 1 400951 1 400951 1 400951 1 400951 1 400951 1

31 SCREW C AP 5/16 -18 x 1¾ *8041031 4 *8041031 4 * 8041031 4 *8041031 4 *8041031 4 * 8041031 4

32 NUT LOCK , 5/16-18 HEX *8160002 19 * 8160002 19 *8160002 19 *8160002 19 * 8160002 19 * 8160002 19

33 NUT LOCK 5/16-18 THIN HT *8161041 1 *8161041 1 *8161041 1 *8161041 1 *8161041 1 *8161041 1

34 SCREW C AP 5/16 -24 NF x 1½ *8042030 2 *8042030 2 *8042030 2 *8042030 2 - - *8042030 2

SCREW C AP 5/16 -24 NF x ¾ - - - - - - - - *8042026 2 - -

35 VIBRATION MOUN T 400173 6 400173 6 400173 6 400173 6 400173 6 400173 6

36 LOOSE PARTS ASSY

20

37 NUT LOCK 1/4 - 20 HEX *8160001 1 *8160001 1 *8160001 1 *8160001 1 *8160001 1 *8160001 1

38 RING RETAINING ¾ 850230 2 850230 2 850230 2 850230 2 850230 2 850230 2

39

40 DEFLECTOR 430193 1 430193 1 430193 1 430193 1 430193 1 430193 1

41 LABEL DANGER HAN DS & FEET 400424 1 400424 1 40 0424 1 400424 1 400424 1 400424 1

42 BOLT CARRIAGE 5/ 16 -18 x 1-3/ 4 *8024043 1 *8024043 1 *8024043 1 *8024043 1 *8024043 1 *8024043 1

43 WASHER - FLAT 3/ 4 S.A. E.

44 LABEL DANGER F LYING M ATERIAL 810736 1 81 0736 1 810736 1 810736 1 810736 1 810736 1

45

46 GRIP 400570 2 400570 2 400570 2 400570 2 400570 2 400570 2

47 KNOB 400339 1 400339 1 400339 1 400339 1 400339 1 400339 1

48 GUAR D MUFF LER (COMES W/ ITEM 1 ) 400010 1 40 0010 1 400010 1 YES - YES - 40093 3 1

49 WASHER 3/8 FLAT CUT 8171004 1 8171004 1 8171004 1 8171004 1 8171004 1 8171004 1

50

51

52

53

54

55 KNOB DIVERT ER 430198 1 430198 1 430198 1 430198 1 430198 1 430198 1

56 FR AME ASSY

57 SCREW C AP 5/16 - 18 X 1" *8041028 1 *8041028 1 *8041028 1 *8041028 1 *8041028 1 *8041028 1

58 WASHER FLAT CUT 5/16

59 LABEL RE AD OWNER' S M ANUAL 890301 1 89 0301 1 890301 1 89030 1 1 89030 1 1 8 90301 1

60

61

62

63 LABEL EAR EYE BREATHING 89025 4 1 890254 1 890254 1 89 0254 1 89025 4 1 89025 4 1

64 NUT 5/16-18 *8143002 1 * 8143002 1 *8143002 1 *8143002 1 *8143002 1 *8143002 1

FRONT AXLE) 3/8-16 x 3" *8041058 1 *8041058 1 *8041058 1 *8041058 1 *8041058 1 *8041058 1

FRONT WHEEL) 430192 1 430192 1 430192 1 430192 1 430192 1 430192 1

incl. items 14(2), 35(2), 46, 58(2

INCL ITEMS 32(5), 58 (1), 15(1), 37(1), 430185 1 430185 1 430185 1 430185 1 430185 1 430185 1

, 17(3

INCLUDES 41, 44, 63 ) 430171 1 430171 1 430171 1 430171 1 430171 1 430171 1

- - - - - - - - - - 400502 1

TORQUE 60 FT LBS)(81.4N.m)800554 1 800554 1 800554 1 800554 1 800554 1 - -

TORQUE 50 FT LBS)(68N.m

INCL. ITEMS 15, 37, 20

3/16 x 1-1/2 x 1/8 ) *8172015 2 *8172015 2 *8172015 2 *8172015 2 *8172015 2 *8172015 2

3/8 ID x 7/8 OD x1/16

------ - - - -900344-

430207 1 430207 1 430207 1 430207 1 430207 1 430207 1

400957 1 400957 1 400957 1 400957 1 400957 1 400957 1

*8171003 11 *8171003 11 *8171003 11 *8171003 15 *8171003 11 * 8171003 15

Denotes parts found in parts bag assembly.

Notes standard hardware that may be purchased locally.

*

Part No. 430187 Form No. F060496C

Page 7 of 8

Page 8

1717

17

1717

MAINTENANCE

Use only a qualified mechanic for

any adjustments, disassembly or

any kind of repair .

WARNING: TO AVOID PERSONAL INJURY, ALWAYS

TURN MACHINE OFF, MAKE SURE ALL MOVING

PARTS COME TO A COMPLETE STOP.

DISCONNECT SP ARK PLUG WIRE

BEFORE SERVICING UNIT .

ENGINE: See engine manufacturer

operator's instructions.

RECONNECT SP ARK PLUG WIRE AND

GUARDS BEFORE STARTING ENGINE.

17.117.1

17.1

17.117.1

Maintenance Schedule

Maintenance Operation

Engine (See Engine Manual)

Check for excessive vibration

Inspect for loose parts

Inspect for worn or damaged parts

Lubricate wheels

Follow these hourly maintenance intervals.

Every

Use

Every 5 hrs.

or (Daily)

Every 25

hrs.

17.217.2

17.2

17.217.2

IMPELLER REMOVAL

1. Wait for engine to cool and disconnect spark plug.

2. Remove front wheel (item 23),and front wheel bracket

(item 27).

3. Remove housing front plate (item 4), by removing nine

(9) screws (item 12), around outside of front plate.

4. Remove impeller bolt and lock washer.

NOTE: DO NOT PULL OR PRY ON IMPELLER BLADES.

5. Pull on center hub backplate area only of impeller. If

impeller slides off freely, proceed to (step 8).

6. Place two crowbars between center hub backplate area

of impeller and housing on opposite sides. Carefully pry

impeller away from engine until it loosens.

Using a

penetrating oil can help loosen a stuck impeller.

7. If the impeller does not loosen, obtain a 1” (25.4mm)

longer bolt of the same diameter and thread type as the

impeller bolt. Thread longer bolt by hand into the crankshaft until bolt bottoms. Using a suitable gear or wheel

puller against the bolt head and the impeller back-plate

(near the blades), remove impeller from shaft.

8. Reinstall new impeller in reverse order of removal.

9. Tighten impeller bolt. Torque impeller bolt (see parts

list on page 7 for proper impeller bolt torque specifications).

TIRE AIR PRESSURE: Check at regular intervals and

maintain.

Rear Tires only - 30 Psi. (21 kPa).

2020

20

2020

Poor air performance

Abnormal vibration.

Engine will not start.

Engine is locked, will not

pull over.

22.122.1

22.1

22.122.1

2121

21

2121

Purchase

Date

TROUBLESHOOTING

Prob lem Possible Cause

Air intake or exhaust clogged.

Loose or out of balance impeller or loose engine.

Stop switch off (Honda only). Throttle in off position. Engine not

in full choke position (Honda only). Out of gasoline. Bad or old

gasoline. Spark Plug wire disconnected. Dirty air cleaner.

Engine problem.

Engine Service and Warranty

Contact your nearest engine manufacturer's

Serial Plate

89

96

Operator

authorized servicing dealer.

R

ecord your machine model, serial number

and date-of-purchase and where purchased

1803 S. Jefferson

P.O. Box 308

Lee's Summit,

R

Model Serial No.

Unit(Weight) Engine Power

lbs. kg kW rpm

MO 64063 / USA

Tel (816) 524-9666

Fax (816) 524-6983

Purchased

from

Before Requesting Service Review These Suggestions

Clear clog.

Check impeller and replace if required. Check Engine.

Check stop switches, throttle, choke position and gasoline. Connect

spark plug wire. Clean or replace air cleaner. Or contact a qualified

service person.

Contact an engine servicing dealer for engine problems.

WARRANTY PROCEDURE

Please fill in the WARRANTY CARD and send the upper part to Billy Goat.

2222

22

2222

The WARRANTY terms are stated on the lower part which remains with the

user. Whenever a Billy Goat Machine is faulty due to a defect in material

and / or workmanship, the owner should make a warranty claim as follows:

The Machine should be taken to the dealer from whom it was

purchased or to an authorized Billy Goat dealer.

The owner should present the remaining half of the Warranty

Registration Card, or, if this is not available, the invoice or receipt.

The Warranty Claim will be filled in by the authorized Billy Goat Dealer,

who will send it with the faulty part to Billy Goat headquarters.

The Quality / Service department at Billy Goat headquarters will study

the claim and parts and will notify their conclusions.

The decision by the Quality / Service department at Billy Goat

headquarters to approve or reject a Warranty claim is final and

binding.

-1

min

Note:

To process a Warranty Claim, it is necessary to quote the Model

& Serial number who are printed on the Billy Goat Serial Plate.

BILL Y GO AT INDUSTRIES INC.

R

P . O. BO X 308 (1803 S JEFFERSON LEE'S SUMMIT, MO. 64063 / USA

PHONE: 816-524-9666 FAX: 816-524-6983

Solution

Part No. 430187 Form No. F060496C

Page 8 of 8

Loading...

Loading...