Billy Goat PL1802, PL1802VB Owner's Manual

PL1802 Owner’s Manual

NOT FOR REPRODUCTION

PL1802VB Owner's Manual

U.S. PATENT #6892821

Original Instructions

IMPORTANT- READ CAREFULLY BEFORE USE AND KEEP FOR FUTURE REFERENCE

Part No. 382513 382513_B_HI

1

Table of Contents

NOT FOR REPRODUCTION

Specications

Intended Use

Labels

Throttle Controls

Packing Checklist

Initial Set-Up Assembly

Operation

3

3

4

5

5

6

6-7

Maintenance

Troubleshooting

Spare Parts List

Warranty Information

Part Illustrations and Lists

7-17

18

19

19

20-23

Part No. 382513 382513_B_HI

2

Specications

NOT FOR REPRODUCTION

PL1802VB

Engine: B&S VANGUARD 6.5HP w/6:1

Engine Model No. 12V3520006F1

Engine Fuel Capacity 3.7 qt. (3.1 L)

Engine Oil Capacity 0.63 qt. (0.59 L)

Total Unit Weight 242 lb (109.8 kg)

Length 57” (1.45 m)

Width 24”( .61 m)

Height 40” (1 m)

Maximum Operating Slope 15

o

Intended Use

AERATOR

This machine is designed for aerating established lawns and large grass covered areas. The machine should

not be used for any other purpose than that stated above.

DO NOT OPERATE IF EXCESSIVE VIBRATION OCCURS!

If excessive vibration occurs, shut engine off immediately and check for damaged or worn reel, loose reel

bearing, loose engine or lodged debris. To remove debris from the machine, see the machine specic trouble

shooting section. Note: See parts list for proper bolt torque specications.

HANDLING & TRANSPORTING

Always use two or more people to lift these machines. Lift holding on either side of the machine, using the handles and the frame. Secure in place during transportation. See specications for unit weight.

For safety, use gloves when lifting.

Never lift any machine while the engine is running.

Part No. 382513 382513_B_HI

3

Warning Labels

NOT FOR REPRODUCTION

The labels shown below were installed on your BILLY GOAT® Aerator. If any labels are damaged or

missing, replace them before operating this equipment. Item numbers from the Illustrated Parts List and part

numbers are provided for convenience in ordering replacement labels. The correct position for each label may

be determined by referring to the Figure and Item numbers shown.

DANGER

PINCH

POINT

DANGER KEEP HANDS

Fig. 1

LABEL PINCH POINT PLP/N

AND FEET AWAY

P/N 440424

Instruction Labels

PULL TO ENGAGE TINES

JALE HACIA ARRIBA PARA ENGRANAR LOS DIENTES

100356

Fig. 5

LABEL TINE ENGAGE PL

Fig. 2

100355

100355

Fig. 3

DECAL, WARNING, HAND IN BELT,

ENG. ONLY P/N 5103184

FORWARD TO LOWER TINES

BACK TO RAISE TINES

AVANCE PARA BAJAR LOS DIENTES

100357

Fig. 6

LABEL LOWER TINES PL

GREASE ALL FITTINGS EVERY 10 HOURS OF OPERATION.

CHECK OIL BEFORE EACH USE.

Fig. 4

R

R

100354

WE RECOMMEND ALMAGARD #3752 GREASE FROM

LUBRICATION ENGINEERS INC.

1. Retract Tines With Center Control Lever.

2. Begin Forward Motion of Aerator Manually.

3. Engage Drive Lever With Aerator Already in Motion.

TO AERATE

LABEL AERATING INST PL

Part No. 382513 382513_B_HI

4

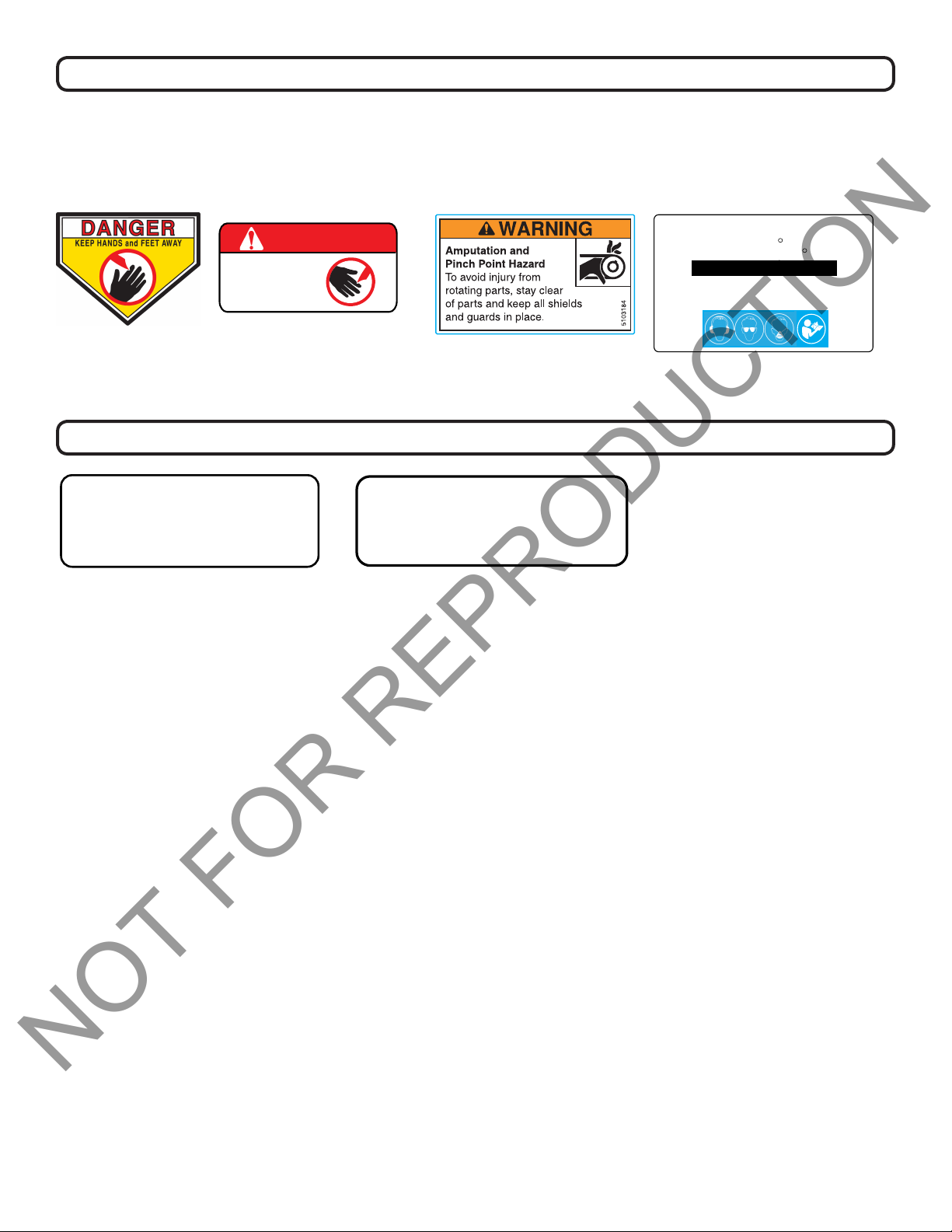

Throttle Controls

NOT FOR REPRODUCTION

Set lever to choke when starting cold.

Set lever to dictate engine speed. To stop

the engine, move the lever completely to

the left.

STOP

RUN

CHOKE

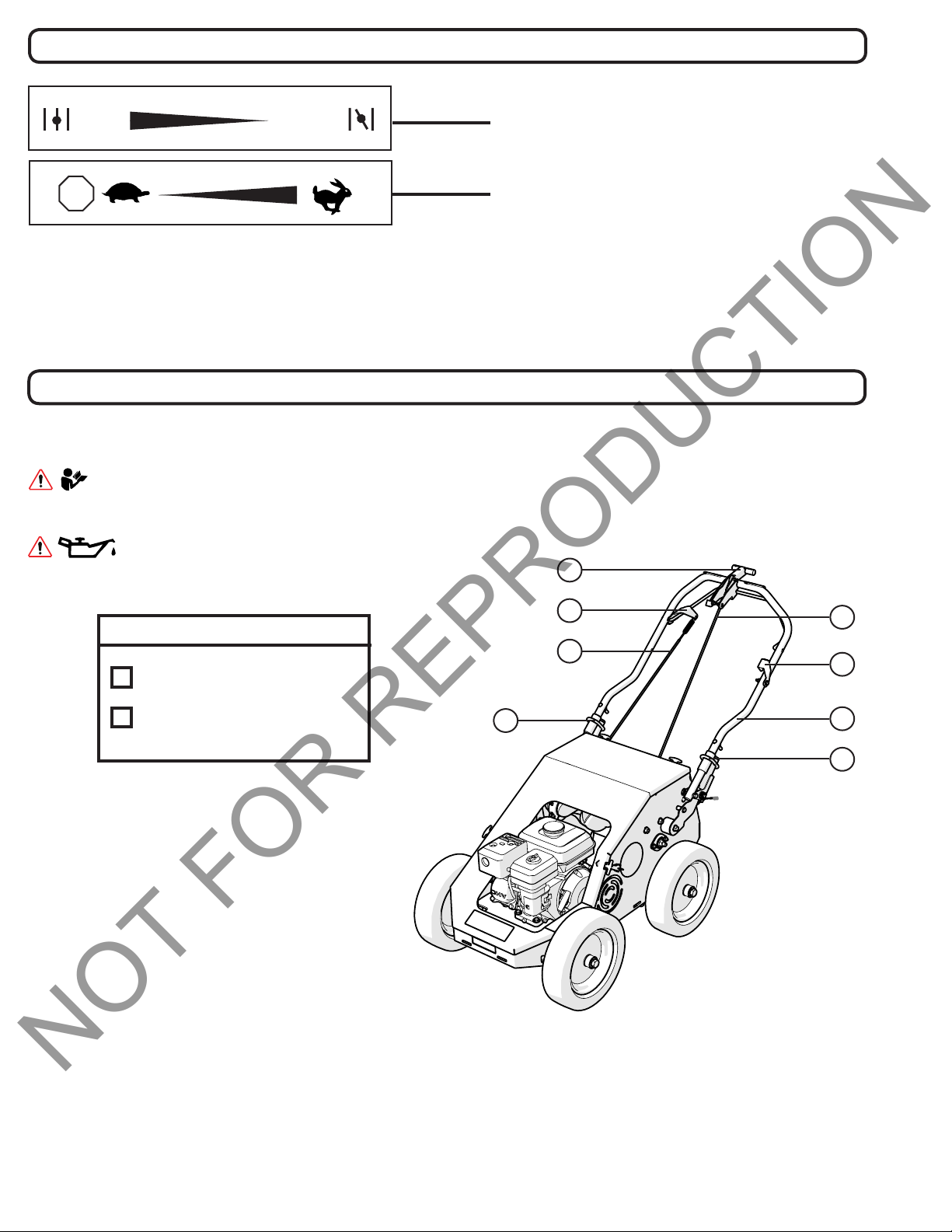

Packing Checklist

Your Billy Goat aerator is shipped from the factory in one carton, completely assembled with the cables detached.

READ all safety instructions before assembling unit.

TAKE CAUTION when removing the unit from its box or crate.

PUT OIL IN ENGINE BEFORE STARTING.

D

Boxing Parts Checklist

Operator’s Manual (382513)

Engine Manual (Briggs and

Stratton)

F

E

B

Figure A

C

G

A

B

Part No. 382513 382513_B_HI

5

Initial Set-Up Assembly

NOT FOR REPRODUCTION

Refer to Figure A in the Packing Checklist section to identify parts in Initial Set-Up Assembly.

1. UNFOLD the upper handle (A, Figure A) and slide handle lock loops (B, Figure A) into place to secure the

upper handle to the lower.

2. ATTACH the tine lift cable (C, Figure A) to the tine lever (D, Figure A) in the center of the handle by inserting

the pin into it. Then attach the bail cable (E, Figure A) to the bail (F, Figure A). Check to make sure the cables

are functioning properly before operation and not binding.

3. CHECK engine oil level and ll to proper level. Also check oil in gear reduction reservoir and ll if necessary.

See engine owner’s manual for type and amount of oil to use.

4. CONNECT spark plug wire. Set the engine stop switch (G, Figure A) to the ON position.

Operation

STARTING THE ENGINE

See engine manufacturer’s instructions for type and amount of oil and gasoline used. Engine must be level

when checking and lling oil and gasoline.

ENGINE SPEED: Controlled by lever on the engine. Under normal conditions, operate at the minimum

throttle speed to accomplish your task.

ON/OFF: Set the on/off switch to ON

FUEL VALVE: Move fuel valve to “ON” position. (Honda: Located below the air cleaner on the engine.)

CHOKE: Engage the choke when starting a cold engine. (Honda: Located below the air cleaner on the

engine.)

THROTTLE: Move the throttle control lever on the engine to fast position. Pull starting rope to start engine.

If your unit fails to start, check trouble shooting section in operator’s manual and also see engine

manual. Note: Honda engines are equipped with a low oil sensor to prevent engine damage. When it sens-

es a low oil condition (i.e. unit is operating or sitting on a steep slope) the engine shuts down. The low oil

condition must be corrected before the engine can be restarted. See the engine owner’

information.

AERATING OPERATION

Note: Never park this unit on a slope of any kind. Always keep tines in the up position when parking the unit.

TINES RAISING/LOWERING: The tines are raised or lowered into the ground by operating the tine engagement lever on the upper handle. Tine penetration is very dependent on surface preparation. READ the

entire operation section before aerating.

s manual for more

ENGAGE TINES: With the aerator in the work area, lower the tines by releasing the center lever on the

handle. When the lever is in the forward position, pull up on the bail to engage the tines.

AERATE: Push the machine with the tines engaged. NOTE: In cold temperatures engage the tines in the

up position for two minutes to warm the cam grease. For maximum tine penetration apply downward pressure on the handle.

Part No. 382513 382513_B_HI

6

Operation

NOT FOR REPRODUCTION

TURNING: At the end of an aerating run, release the bail and raise the tines out of the ground. Then reposition the unit for another pass and lower the tines to begin another run.

TRANSPORT: Be sure to raise tines out of the ground (disengaging the bail and then raising the tines with

the center lever) before transporting away from the work area.

TIPS

MOW: Mow the lawn to its normal cut height.

WATER: For the best performance and maximum tine penetration the lawn should be thoroughly watered

the day before aeration.

INSPECT: Check the lawn before beginning work. Remove all rocks, wire, string, or other objects that can

present a hazard during work prior to starting.

IDENTIFY: Mark all xed objects to be avoided during work, such as sprinkler heads, water valves, buried

cables, or clothes line anchors, etc.

SLOPES: Do not operate the aerator on steep slopes (exceeding 15

ing on any sloped surface. For lesser sloped areas operate the unit, traversing up and down at a 45o angle

to the slope rather than straight across. Extended operation on steep slopes can cause engine damage.

o

). Use extreme caution when operat-

Maintenance

PERIODIC MAINTENANCE

Periodic maintenance should be performed at the following intervals:

Maintenance Operation Every

Use

Inspect for loose, worn or damaged parts

Check engine oil*

Clean debris from unit and tines

Grease cam bearings

Inspect belt for wear

Replace tine bushings

Grease shaft bearings

*Engine must be level when checking or lling oil. Refer to your Honda or Briggs and Stratton engine manual for

proper engine maintenance procedures.

•

•

•

Every 10

Hrs

•

Every 50

Hrs

•

Every 100

Hrs

•

•

Part No. 382513 382513_B_HI

7

Maintenance

NOT FOR REPRODUCTION

COMMON MAINTENANCE PROCEDURES

Note: Refer to Figure B for tools needed for common maintenance procedures outlined in this section.

H

G

C

F

E

D

Figure B

Letter Identication Tool

A Impact Wrench

B 1/2” socket

C 9/16” socket

D 1/2” wrench

B

A

E 9/16” wrench

F 1/8” Allen wrench

G 1/4” curved Allen wrench

H Pliers

Part No. 382513 382513_B_HI

8

Maintenance

NOT FOR REPRODUCTION

ADJUSTING BELT TENSION

1. Loosen the mounting bolts for the engine and then slide it to apply or relieve tension on the belt.

Note: Sliding the engine forward (away from the operator) increases belt tension. Sliding the engine rearward (towards the operator) relieves tension. Check and adjust belt tension after the rst 10 hours of use.

REPLACING THE DRIVE BELT

1. Lower the tines on the PL1801 unit and remove its hood. Use your hands to pull down on the rubber

latches (4 latches total; 2 in the rear of machine, 1 on each side of machine). See Figure C for latched position and Figure D for unlatched position.

Figure C Figure D

2. Locate the wave spring attached to the tineshaft and inner pillow block bearing. See Figure E. Loosen

the set screws with an 1/8” Allen wrench. Compress the wave spring by pressing against the end plate on

the tinshaft. Once the wave spring is compressed, re-tighten the set screws. This will allow you to more

easily move the tineshaft to remove the old or worn drive belt. See Figure F.

Note: If set-screws are missing, use a 0.250”-28 sized bolt.

Figure E Figure F

Part No. 382513 382513_B_HI

9

Maintenance

NOT FOR REPRODUCTION

3. Loosen the inner pillow block bearings on each side of the tineshaft. Simultaneously, use the impact

wrench tted with the 9/16” socket and the 9/16” wrench to remove the hardware from each pillow block

bearing. See Figures G-J. Note the heavy weight of the tineshaft.

Figure G Figure H

Figure I Figure J

4. Use the 1/4” curved Allen wrench to remove the top belt-guide-bolt. Do not remove the bottom beltguide-bolt. See Figure K. Note how the belt is positioned around the pulleys in the machine.

Figure K

Part No. 382513 382513_B_HI

10

Loading...

Loading...