Billy Goat OS900SPS, OS900SPH Owner's Manual

1

OS900SP Owner’s Manual

A convenient way to

enclose the seed box

P/N 351600

Allows the user to ride behind

the unit and decrease fatigue

from walking

P/N 351601

Use to replace worn or

damaged reels

P/N 351603

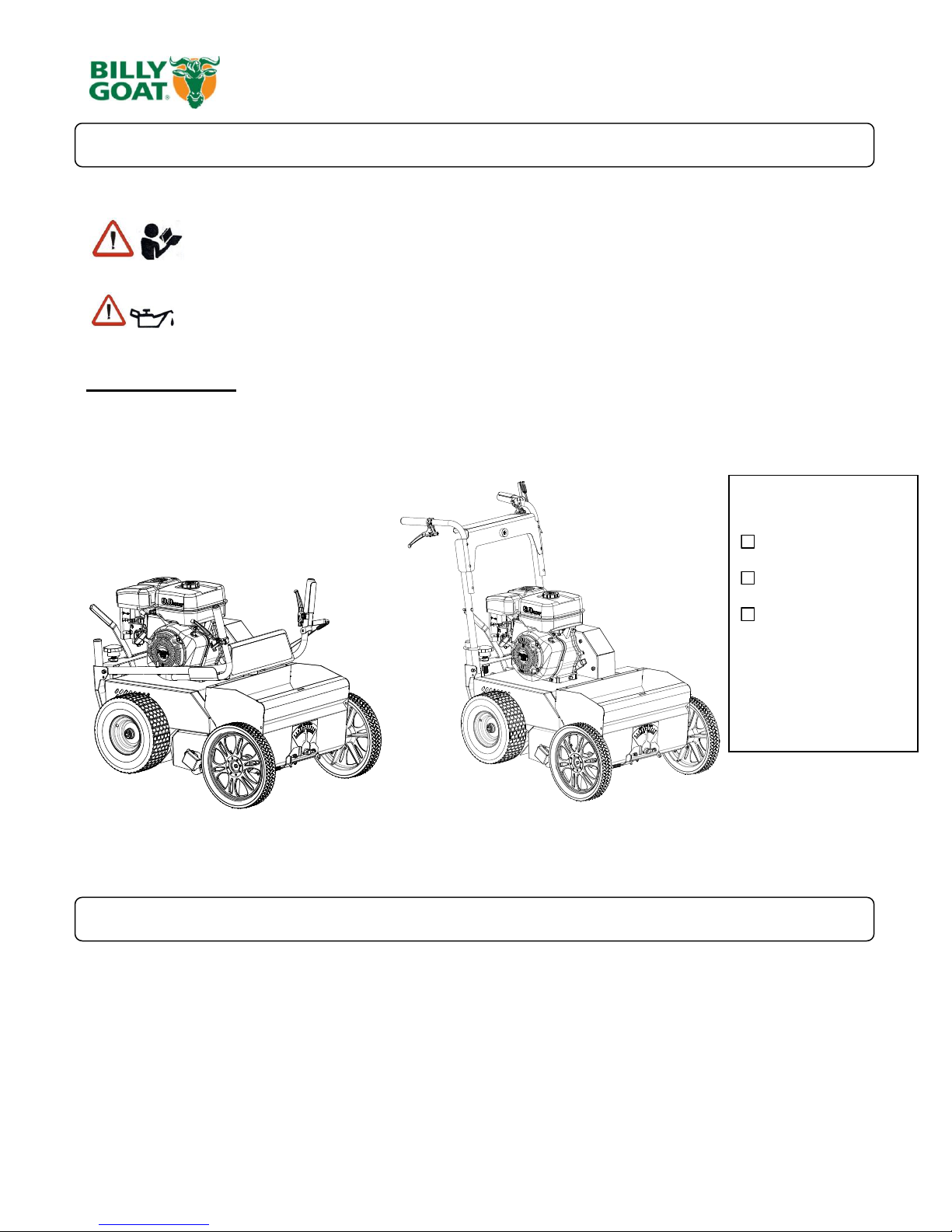

BILLY GOAT SELF PROPELLED OVERSEEDER

Accessories Replacement Parts

Part No 351502 Form No F030311A

Unit shown with Seed Box Lid, sold separately

OS900SPS, OS900SPH

Owner's Manual

2

OS900SP Owner’s Manual

SERIAL PLATE DATA AND SPECIFICATIONS 3

GENERAL SAFETY 4 -5

SOUND AND VIBRATION 6

INSTRUCTION LABELS 7

PACKING CHECKLIST & ASSEMBLY 8

OPERATION 9-12

MAINTENANCE 13

TROUBLESHOOTING AND WARRANTY PROCEDURE 14

PARTS LIST____________ 15-25

MAINTENANCE RECORD 26

ABOUT THIS MANUAL

THANK YOU for purchasing a BILLY GOAT ® Self-propelled Overseeder. Your new machine has been carefully

designed and manufactured to provide years of reliable and productive service. This manual provides complete

operating and maintenance instructions that will help to maintain your machine in top running order. Read this

manual carefully before assembling, operating, or servicing your equipment.

CONTENTS

Part No 351502 Form No F030311A

3

OS900SP Owner’s Manual

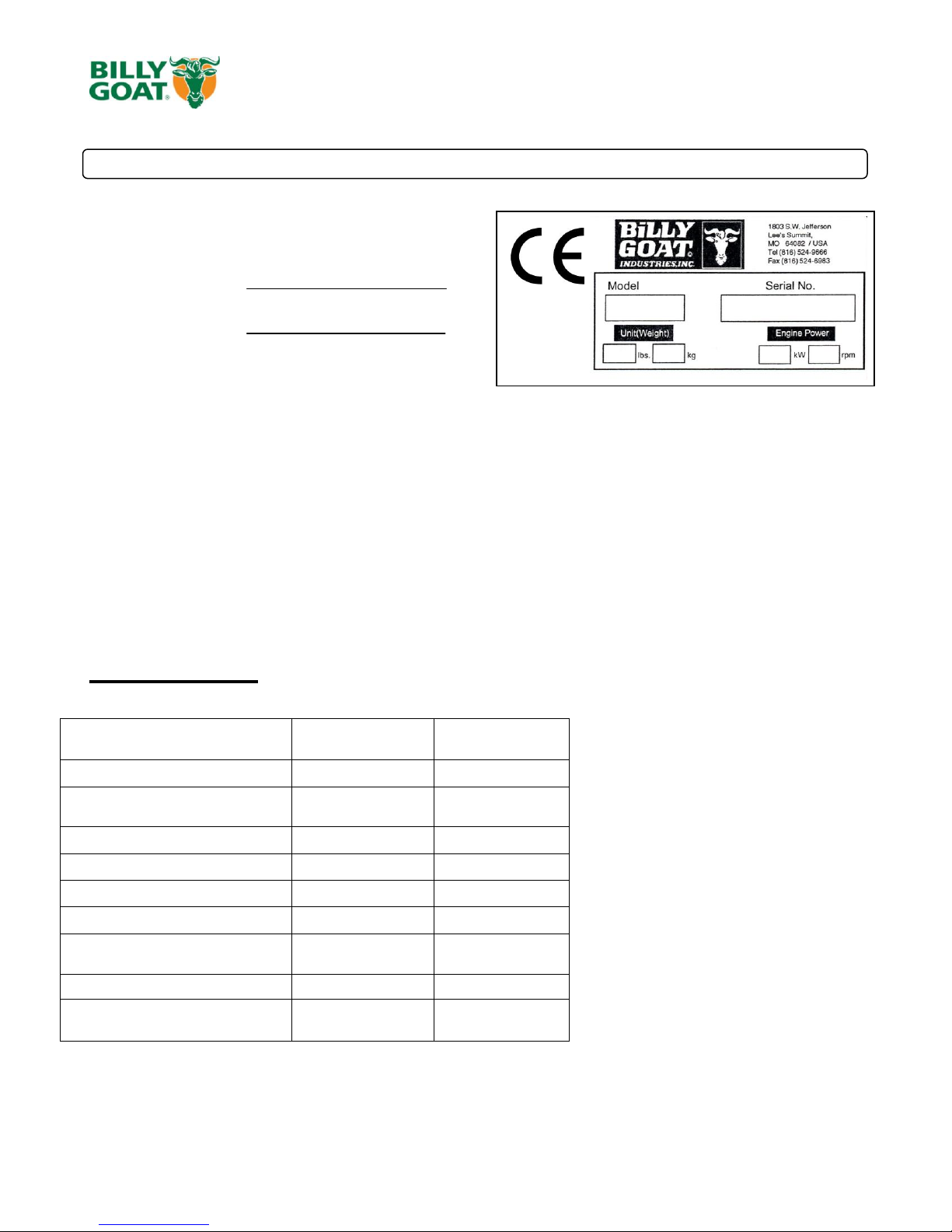

Record the model number, serial number, date of

purchase, and where purchased.

Purchase Date:

Purchased From:

Engine: HP’

9.0 HP (6.7kW)

9.0 HP (6.7kW)

Engine: Model

EX270DE5032

GX270K1QA2

Engine: Type

Subaru

Honda

Engine: Fuel Capacity

6.4 qt. (6.1 L)

5.6 qt. (5.3 L)

Engine: Oil Capacity

1.06 qt. (1 L)

1.16 qt. (1.1 L)

Total Unit Weight:

314# (142 kg)

323# (147 kg)

Max. operating slope

15o

20o

Sound test in accordance with 2000/14/EC

104 dB(a)

104 dB(a)

Sound at operators ear

84 dB(a)

84 dB(a)

Vibration at operator position

0.81g (7.95 m/s2)

0.81g (7.95 m/s2)

SERIAL PLATE DATA

Specifications

OS900SPS OS900SPH

Part No 351502 Form No F030311A

4

OS900SP Owner’s Manual

This symbol indicates important information that will prevent injury to yourself or others.

This symbol indicates ear protection is recommended when operating this equipment.

This symbol indicates eye protection is recommended when operating this equipment.

This symbol indicates gloves should be worn when servicing this equipment.

This symbol indicates that this manual and the engine manufacturer’s manual should be read

carefully before assembling, operation, or servicing this equipment.

This symbol indicates important information that will prevent damage to your BILLY GOAT ®

Overseeder.

This symbol indicates the engine oil level should be checked before operating this

equipment.

READ this manual and the engine manufacturer’s manual carefully before assembling,

operating, or servicing this equipment.

EAR PROTECTION is recommended when operating this equipment.

EYE PROTECTION is recommended when operating this equipment.

BREATHING PROTECTION is recommended when operating this equipment.

EXHAUST from this product contains chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

DO NOT operate this equipment on any unimproved forested, brushy, or grass covered land

unless a spark arrester is installed on the muffler as required by Section 4442 of the

California Public Resources Code. The arrester must be maintained in good working order.

Other states may have similar laws. Federal laws apply on federal lands.

DO NOT run engine in an enclosed area. Exhaust gases contain carbon monoxide, an

odorless and possibly fatal poison.

GENERAL SAFETY INSTRUCTIONS and SYMBOLS

The safety symbols shown below are used throughout this manual. You should become familiar with them before

assembling, operating, or servicing this equipment.

Read and make sure you thoroughly understand the following safety precautions before assembling, operating or

servicing this equipment:

Part No 351502 Form No F030311A

5

OS900SP Owner’s Manual

DO NOT run this equipment indoors or in any poorly ventilated area. Refueling outdoors is

recommended.

DO NOT refuel this equipment while the engine is running. Allow engine to cool for at least

two minutes before refueling.

DO NOT store gasoline near an open flame.

DO NOT remove gas cap while engine is running.

DO NOT start or operate engine if strong odor of gasoline is present.

DO NOT start or operate engine if gasoline is spilled. Move equipment away from spill until

gasoline has completely evaporated.

DO NOT smoke while filling the fuel tank.

DO NOT check for spark with spark plug or spark plug wire removed. Use an approved spark

tester.

DO NOT operate engine without a muffler. Inspect muffler periodically and replace if

necessary. If equipped with muffler deflector, inspect deflector periodically and replace if

necessary.

DO NOT operate engine with grass, leaves or other combustible material near the muffler.

DO NOT touch muffler, cylinder, or cooling fins when hot. Contact with hot surfaces may

cause severe burns.

DO NOT leave equipment unattended while in operation.

DO NOT park equipment on a steep grade or slope.

DO NOT operate equipment with bystanders in or near the work area.

DO NOT allow children to operate this equipment.

DO NOT operate equipment without guards in place.

DO NOT operate equipment near hot or burning debris or any toxic or explosive materials.

DO NOT operate equipment on slopes greater than specified in Specifications section of this

manual.

DO NOT start engine without height adjust lever in up position and clutch bail disengaged.

DO NOT place hands or feet underneath unit, or near any moving parts.

ALWAYS remove spark plug wire when servicing equipment to prevent accidental starting.

ALWAYS check fuel lines and fittings frequently for cracks or leaks. Replace if necessary.

ALWAYS keep hands and feet away from moving or rotating parts.

ALWAYS store fuel in approved safety containers.

WARNING: Important

Remove all rocks, wire, string, etc. that can present a hazard during work prior to starting.

DO identify and mark all fixed objects to be avoided during work such as sprinkler heads,

water valves, buried cables, or clothes line anchors, etc.

Part No 351502 Form No F030311A

6

OS900SP Owner’s Manual

General Conditions: Sunny

Temperature: 73oF (23oC)

Wind Speed: 11 mph (17 kmh)

Wind Direction: South West

Humidity: 27%

Barometric Pressure: 30.34Hg (770 mm Hg)

General Conditions: Sunny

Temperature: 66oF (19oC)

Wind Speed: 3 mph (4.8kph)

Wind Direction: East

Humidity: 30.2%

Barometric Pressure: 29.9Hg (101.3kpa)

104

SOUND

SOUND LEVEL 84 dB(a) at Operators Position

Sound tests were conducted in accordance with 2000/14/EC, and were performed on 10-13-2010 under the

conditions listed below.

Sound power level listed is the highest value for any model covered in this manual. Please refer to serial plate on

the unit for the sound power level for your model.

VIBRATION DATA

VIBRATION LEVEL .81g (7.95m/s2)

Vibration levels at the operator’s handles were measured in the vertical, lateral and longitudinal directions using

calibrated vibration test equipment. Tests were performed on 10-13-2010 under the conditions listed below.

INTENDED USE

INTENDED USE: This machine is designed for removing thatch from your lawn, renovation of existing lawns, and to

assist in overseeding operations. The machine should not be used for any other purpose than that stated above.

Do not operate if excessive vibration occurs. If excessive vibration occurs, shut engine off immediately and check

for damaged or worn reel, loose pulley bolts or set screws, loose engine or lodged foreign objects. (See trouble

shooting section on page 14).

Part No 351502 Form No F030311A

7

OS900SP Owner’s Manual

SUBARU HONDA

INSTRUCTION LABELS

The labels shown below were installed on your BILLY GOAT ® Overseeder. If any labels are damaged or missing, replace them before operating

this equipment. Item numbers from the Illustrated Parts List and part numbers are provided for convenience in ordering replacement labels. The

correct position for each label may be determined by referring to the Figure and Item numbers shown.

LABEL DANGER KEEP HANDS LABEL CLUTCH ITEM #142 LABEL TRANS. RELEASE

AND FEET AWAY P/N 500177 ITEM #146 P/N 351507

ITEM #145 P/N 400424

LABEL CAUTION GUARDS LABEL DEPTH GAUGE

ITEM #133 P/N 900327 ITEM #59 P/N 351504

LABEL INSTRUCTIONS SEEDER BOX LABEL SEED METERING

ITEM #56 P/N 351501 ITEM #66 P/N 351503

(page 12) (page 12)

ENGINE LABELS

.

Part No 351502 Form No F030311A

8

OS900SP Owner’s Manual

READ all safety instructions before assembling unit.

TAKE CAUTION when removing the unit from the box the Handle Assembly is attached to the

unit and cables could snag.

1. UNFOLD the upper handle and slide handle lock loops (item 35) into place to secure the upper handle to the

lower.

2. CHECK engine oil level and fill to proper level with engine manufacturers recommended grade of oil. Move

height adjust lever to down position, to level engine during checking. See engine manufacturers’ instruction

manual.

3. CONNECT spark plug wire.

Boxing Parts

Checklist

Subaru 9 HP

Honda 9 OHV

Parts bag

P/N-351009

PARTS BAG &

LITERATURE ASSY

Warranty card P/N- 400972, Owner’s Manual P/N-351502, Declaration of Conformity P/N-351508.

PACKING CHECKLIST

Your Billy Goat Overseeder is shipped from the factory in one carton, completely assembled.

PUT OIL IN ENGINE BEFORE STARTING

ASSEMBLY

Part No 351502 Form No F030311A

9

OS900SP Owner’s Manual

Like all mechanical tools, reasonable care must be used when operating machine.

Inspect machine work area and machine before operating. Make sure that all operators of this

equipment are trained in general machine use and safety.

PUT OIL IN ENGINE BEFORE STARTING

STARTING

ENGINE: See engine manufacturer’s instructions for type and amount of oil and gasoline used. Engine must be

level when checking and filling oil and gasoline.

FUEL VALVE: Move fuel valve to "ON" position (when provided on engine).

STOP SWITCH: Located on the engine. "ON" position.

CHOKE: Operated with choke lever on side of engine.

THROTTLE: Controlled by throttle lever on the motor.

Forward/Reverse: The controls are found on the underside of the upper handle. Forward motion will be controlled

with the right hand lower lever and Reverse will be controlled with the left hand lower lever. DO NOT tie down the

control levers for use.

IF YOUR UNIT FAILS TO START:

See Troubleshooting on page 14.

HANDLING & TRANSPORTING:

This unit requires two people to lift it. With the handle in the folded position, lift holding the lower handle and

front wheel one on each side of the machine. Secure the machine in place during transport. See page 3 for

weight specifications

Never lift the machine while the engine is running.

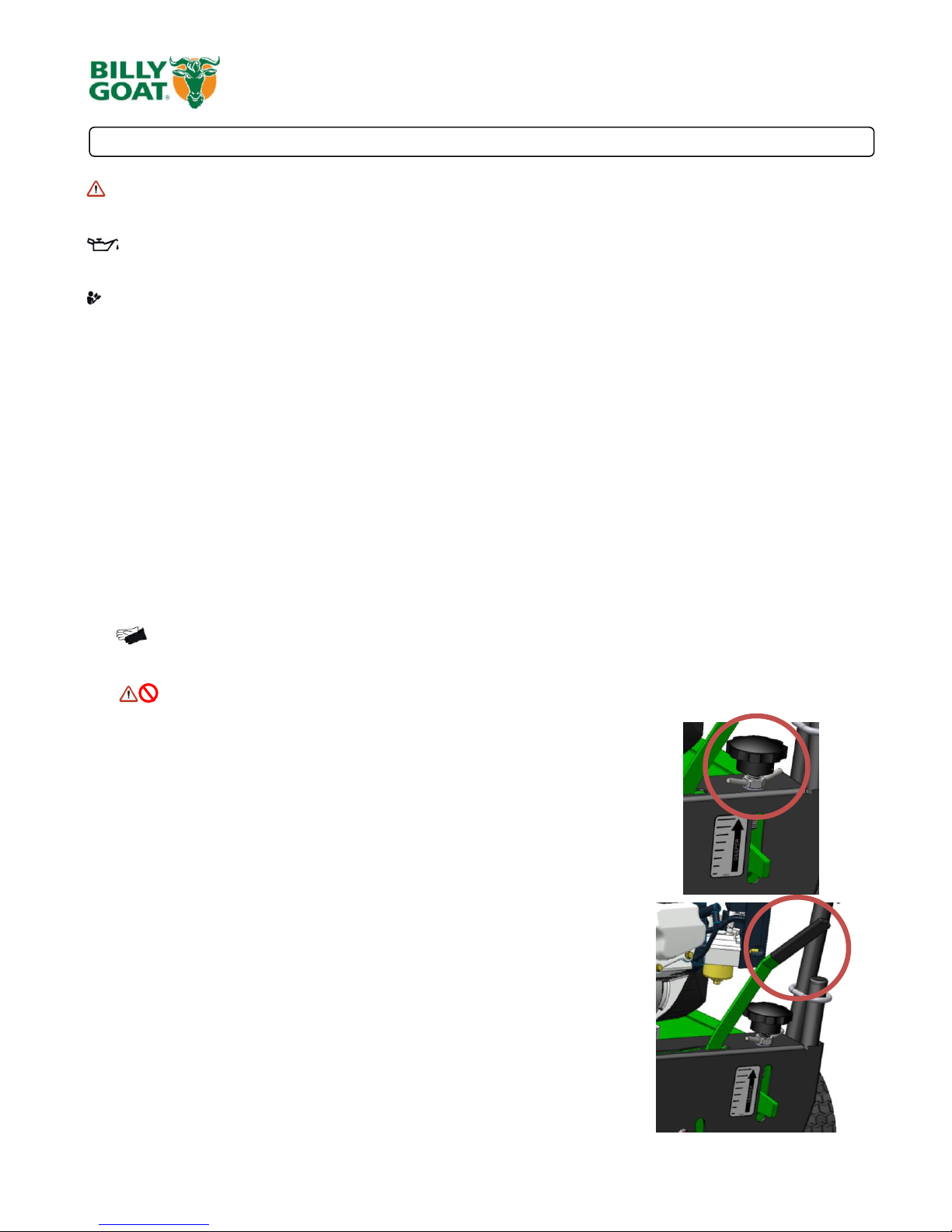

ADJUSTING BLADE DEPTH

The depth of the blades can be raised or lowered by rotating the knob

located at the rear of the machine. The relative depth of the blades can be

gauged by using the depth scale located on the rear of the machine and the

bar next to it.

FOLDING HANDLE

This unit is equipped with a folding upper handle for easier storage and transportation. The handle can be folded by

sliding the handle lock loops (item 35) up. This releases the upper handle, allowing it to be folded over the unit.

BLADE POSITION & DEPTH CONTROL LEVER

The blades can be raised or lowered into the ground by height adjustment lever

at the rear of the unit. The blades will be in their lowered position when the lever

is to the left and should be locked in the notch on the right when in transport. The

resulting blade depth can be adjusted higher or lower.

See ADJUSTING BLADE DEPTH above.

OPERATION

Part No 351502 Form No F030311A

Loading...

Loading...