Page 1

PR & OS Owner’s Manual

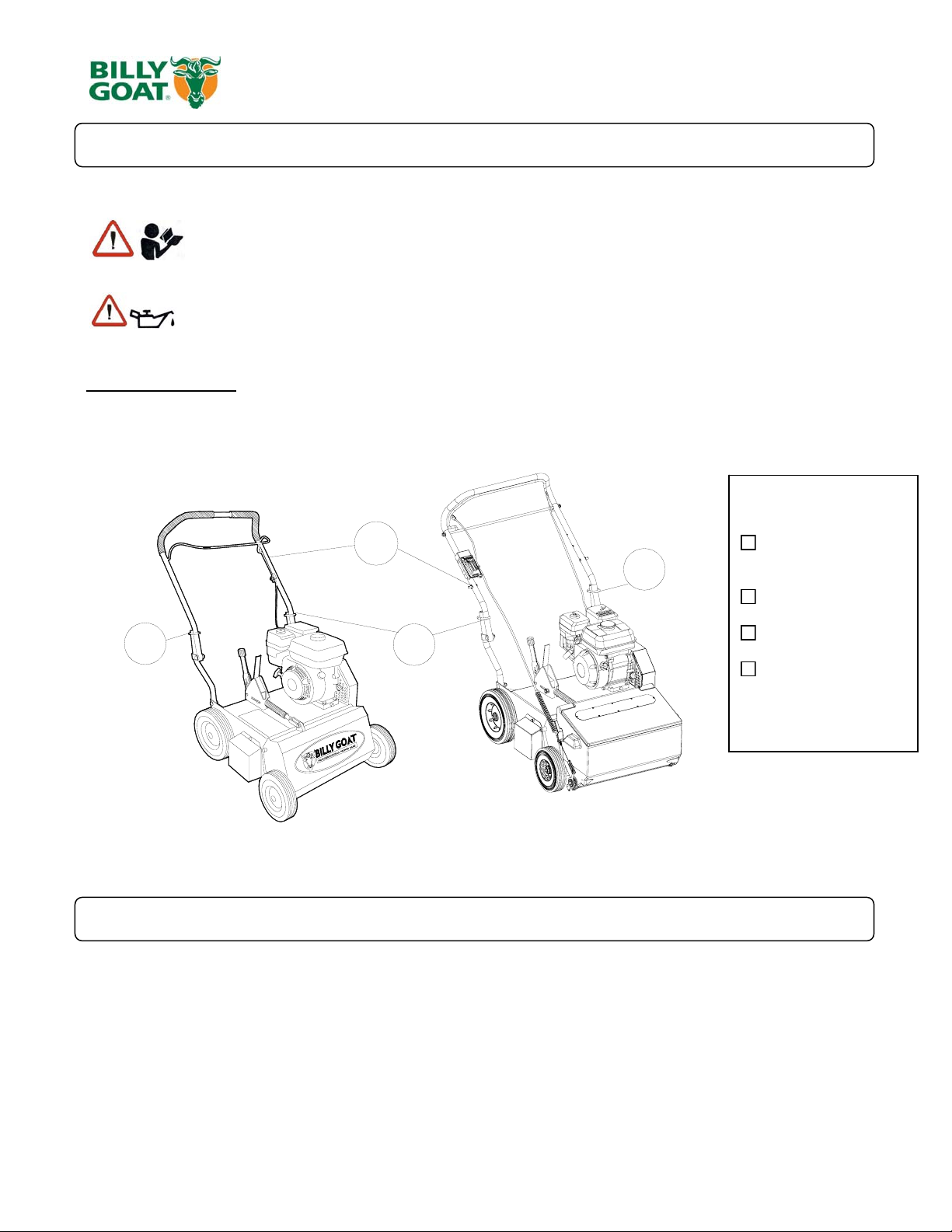

BILLY GOAT POWER RAKE AND OVERSEEDER

Accessories Replacement Parts

SLICING REEL

A complete vertislicing reel for your

PR. 20" wide reel for

use in grasses that

require vertical

cutting, and for

assisting in lawn

overseeding projects.

P/N 350113

Patent 6253416 and other patents pending

SLICING BLADES

A full set of blades for

replacement. Includes

new lockwashers for

replacement

installation.

P/N 350187

PR550, PR550H, OS552, OS552H

Owner's Manual

OVERSEEDER KIT

The new light weight Plastic Overseeding

Kit is constructed of durable High Density

Polypropylene with two lift handles on

each side to assist in lifting the entire unit

and easily converts a PR Series Power

Rake into an overseeder with 4 bolts and

minimal tools.

NOTE: Overseeder Conversion Kit

(350328) includes Slicing Reel (350113).

Part No. (350325) comes with the

Overseeder Box only

P/N 350325 / 350328

.

FLAIL BLADES

A complete set of

our high quality flail

blades for your PR.

Includes new lock

clips for

replacement

installation.

P/N 350186

FLAIL SHAFTS

A full set of shafts

for replacement.

Includes new lock

clips for

replacement

installation.

P/N 350185

Part No 350412 Form No F061311C

1

Page 2

PR & OS Owner’s Manual

CONTENTS

SPECIFICATIONS AND SOUND/VIBRATION 3

INSTRUCTION LABELS 4

PACKING CHECKLIST & ASSEMBLY 5

OPERATION 6-8

MAINTENANCE 9

TROUBLESHOOTING___________________________ 10

ILLUSTRATED PARTS LIST 11-16

Part No 350412 Form No F061311C

2

Page 3

PR & OS Owner’s Manual

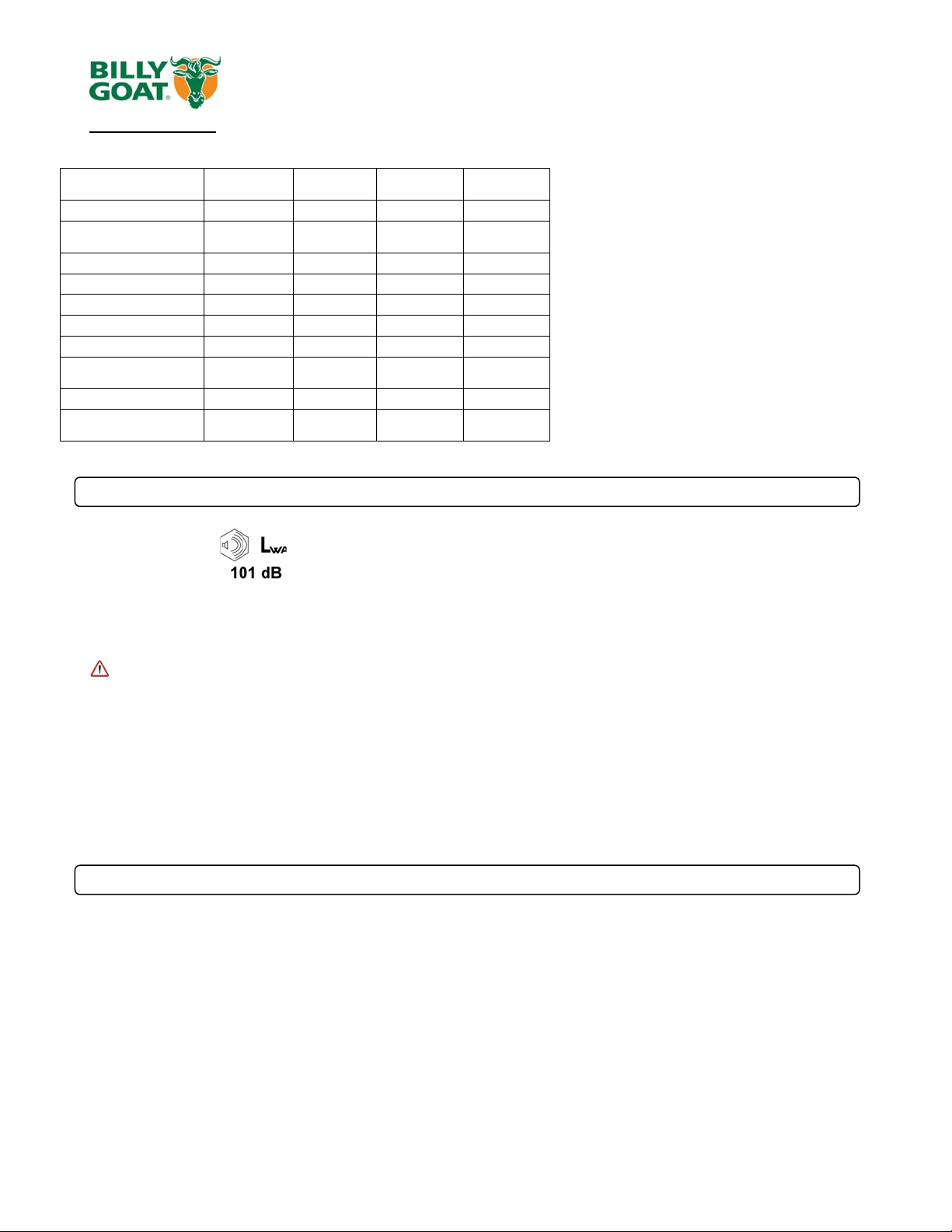

Specifications

PR550 PR550H OS552 OS552H

Engine: HP 5.5 (4.1 kW) 5.5 (4.1 kW) 5.5 (4.1 kW) 5.5 (4.1 kW)

Engine: Model 12H1320118B8 GX160T1QX2 12H1320118B8 GX160T1QX2

Engine: Type B&S

Engine: Fuel Capacity 3.0 qt. (2.84 L) 3.88 qt. (3.6 L) 3.0 qt. (2.84 L) 3.88 qt. (3.6 L)

Engine: Oil Capacity 0.66 qt. (0.62 L) 0.69 qt. (0.65 L) 0.66 qt. (0.62 L) 0.69 qt. (0.65 L)

Total Unit Weight: 149# (67.7 kg) 147# (66.8 kg) 162# (73.6 kg) 160# (72.7 kg)

Engine weight: 36# (16.3 kg) 34# (15.4 kg) 36# (16.3 kg) 34# (15.4 kg)

Max. operating slope 15o 20o 15o 15o

Sound test in accordance with

2000/14/EC

Sound at operators ear 82 dB(a) 82 dB(a) 82 dB(a) 82 dB(a)

Vibration at operator position 0.82g (8.04 m/s2) 0.82g (8.04

VANGUARD

101 dB(a) 101 dB(a) 101 dB(a) 101 dB(a)

SOUND

Sound tests were conducted in accordance with 2000/14/EC, and were performed on 2-13-2002 under the

conditions listed below.

Sound power level listed is the highest value for any model covered in this manual. Please refer to serial plate on

the unit for the sound power level for your model.

General Conditions: Sunny

Temperature: 48

Wind Speed: 2 mph (3.2 kmh)

Wind Direction: South East

Humidity: 29%

Barometric Pressure: 30.34Hg (770 mm Hg

VIBRATION DATA

Vibration levels at the operator’s handles were measured in the vertical, lateral and longitudinal directions using

calibrated vibration test equipment. Tests were performed on 5-25-2006 under the conditions listed below.

General Conditions: Sunny

Temperature: 72.32

Wind Speed: 3.8 mph (6.12kph)

Wind Direction: East

Humidity: 62.2%

Barometric Pressure: 29.9Hg (101.3kpa

Part No 350412 Form No F061311C

HONDA OHV B&S

m/s2)

VANGUARD

3.2g 3.2g

HONDA OHV

SOUND LEVEL 82 dB(a) at Operators Position

VIBRATION LEVEL .82g (8.04m/s2)

3

o

F (8.9oC)

o

F (22.4oC)

)

)

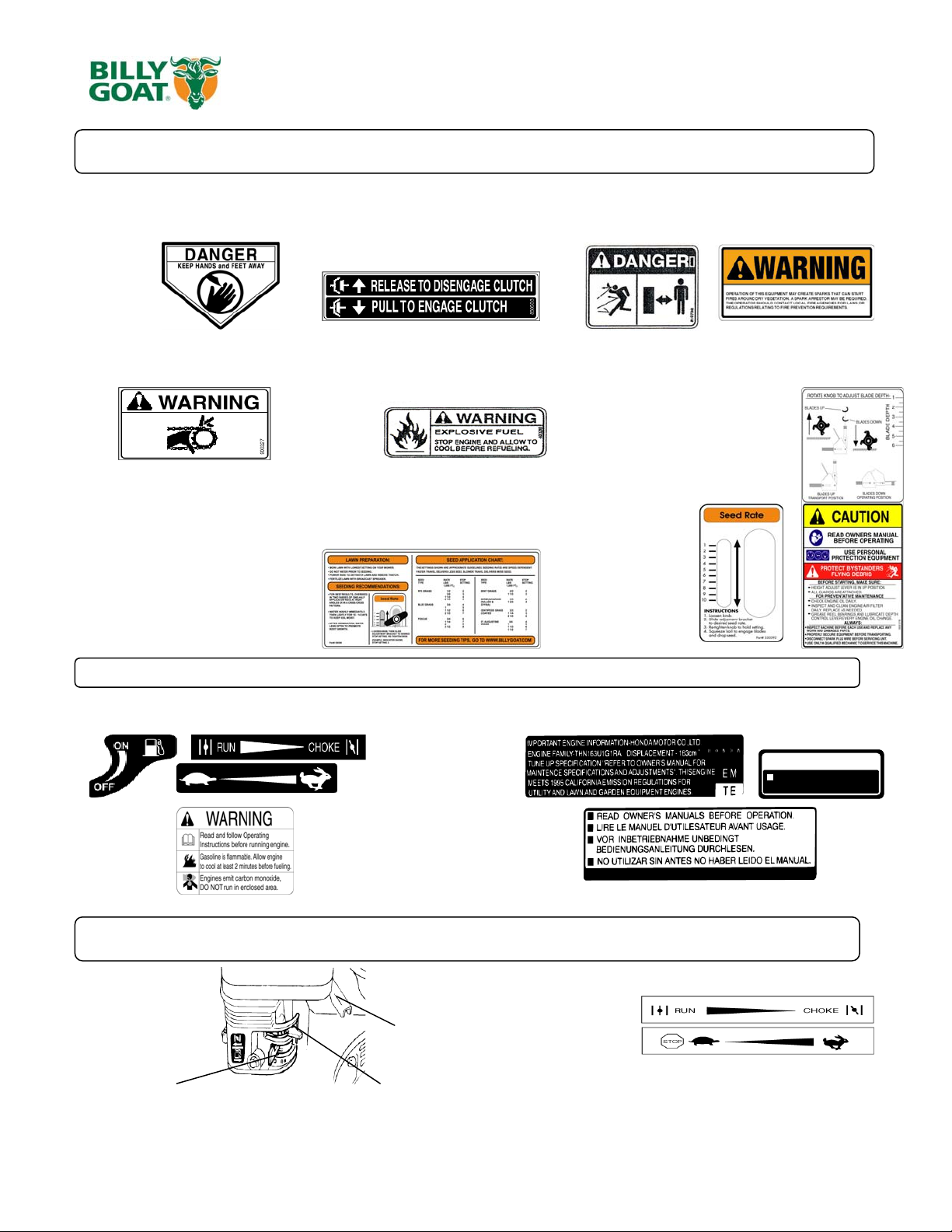

Page 4

PR & OS Owner’s Manual

INSTRUCTION LABELS

The labels shown below were installed on your BILLY GOAT ® Power Rake/Overseeder. If any labels are damaged or missing, replace them

before operating this equipment. Item numbers from the Illustrated Parts List and part numbers are provided for convenience in ordering

replacement labels. The correct position for each label may be determined by referring to the Figure and Item numbers shown.

LABEL DANGER KEEP HANDS LABEL CLUTCH ITEM #49 DANGER FLYING DEBRIS LABEL SPARK ARREST

AND FEET AWAY P/N 830503 ITEM # 48 P/N 810736 ITEM #81 100252

ITEM #51 P/N 400424

LABEL CAUTION GUARDS LABEL EXPLOSIVE FUEL LABEL INSTRUCTION HEIGHT ADJ.

ITEM #52 P/N 900327 ITEM # 50 P/N 400268 ITEM #35 P/N 350176

LABEL INSTRUCTIONS SEEDER BOX LABEL SEED METERING

ITEM #30 P/N 350386 ITEM #29 P/N 350392

(page 15) (page 15)

ENGINE LABELS

BRIGGS & STRATTON HONDA

OIL ALERT

WHEN OIL LEVEL LOW,

ENGINE STOPS IMMEDIATELY.

ENGINE CONTROLS

Honda Briggs & Stratton Set lever to choke when starting cold

Fuel valve Choke lever Move lever completely to the left to

Part No 350412 Form No F061311C

Throttle lever

Set lever to desired engine speed.

stop engine

4

Page 5

PR & OS Owner’s Manual

00295,

350139

PACKING CHECKLIST

Your Billy Goat Power Rake is shipped from the factory in one carton, completely assembled.

READ all safety instructions before assembling unit.

TAKE CAUTION

unit by cables.

when removing the unit from the box the Handle Assembly is attached to the

PUT OIL IN ENGINE BEFORE STARTING

PARTS BAG &

LITERATURE ASSY

Warranty card P/N- 400972, Owner’s Manual P/N-350412, General Safety and Warnings Manual P/N1

Declaration of Conformity P/N-

28

26

28

.

Boxing Parts

Checklist

Briggs & Stratton

28

5.5 B&S VANGUARD

Honda 5.5 OHV

Subaru 6HP EX17

Literature Assy

P/N-430334

PR550, PR550H,

PR550T, PR550HT,

PR600S

OS552, OS552H,

and OS602S

ASSEMBLY

1. UNFOLD the upper handle (item 26) and slide handle lock loops (item 28) into place to secure the upper handle

to the lower.

2. CHECK engine oil level and fill to proper level with engine manufacturers recommended grade of oil. Move

height adjust lever to down position, to level engine during checking. See engine manufacturers instruction

manual.

3. CONNECT spark plug wire.

Part No 350412 Form No F061311C

5

Page 6

PR & OS Owner’s Manual

g

p

OPERATION

FOLDING HANDLE

This unit is equipped with a folding upper handle for easier storage and transportation. The handle can be folded by

sliding the handle lock loops (item 28) up. This releases the upper handle, allowing it to be folded over the unit.

ADJUSTING BLADE DEPTH

The depth of the blades can be raised or lowered by rotating the knob on the top of

the adjustment lever. The blades are lowered by rotating the knob clockwise, and

raised by rotating the knob counter-clockwise. The relative depth of the blades can be

gauged by using the depth scale located on the right front corner of the engine base.

With new blades installed the depth can be estimated as follows: 2.5 on the scale is

even with the

BLADE POSITION & DEPTH CONTROL LEVER

The blades can be raised or lowered into the ground by height adjustment lever on the

engine base. The height adjuster lock lever must be pushed back against the adjustment

lever in order to lower the blades into the ground. The resulting blade depth can be

adjusted higher or lower.

See ADJUSTING BLADE DEPTH.

round, 3 is equal to 0.25" deep, and 3.5is equal to 0.5" dee

SPRING TINE CONVERSION

If are converting your Power rake to a spring tine reel, you will need to

replace the spacer on the control lever to accommodate for the tine. First

remove the clip (item 18), then unscrew the yoke (item 17), remove the

washer (items 69) and insert the spacer (item 75) in front of the spring.

Reassemble in reverse order.

clockwise to

lower blades

blades up

transport

counter clockwise

to raise blades

blades down

running

blades up

transport

RAKING/SLICING TIPS

Before beginning, it is best to evaluate the condition of the lawn by cutting one or more core

samples from area to be treated. A core can be cut using a piece of pvc, or metal pipe.

Hammer the pipe into the ground, remove it, push the core out of the pipe and inspect it to

determine the depth of thatch in your yard.

THATCH: Thatch is a dense layer of dead grass, clippings, and roots that builds up over time

at the base of of the lawn preventing air, water, and fertilizer from reaching the soil. This can

cause shallow root development and make a lawn more susceptible to drought and disease.

Thatch also provides an ideal environment for insects to hide and multiply. Periodic removal of

thatch will keep your lawn in good health.

HEAVY THATCH: Lawns with an excessive amount of thatch will require multiple treatments

for effective removal. Trying to remove excessive thatch (greater than 3/4"[19 mm] deep) in

one treatment will damage or destroy the living part of the lawn. It is best to remove heavy

thatch in seasonal treatments (i.e. spring, and fall).

SLOPES: Rake slopes across not up and down. This is much easier and safer for the

operator and is better for the lawn. Raking across will help to reduce runoff during watering

and allow the sloped ground to hold more seed, fertilizer, and water. The units maximum

operating slope is 35% or 19°.

DEPTH: The wide range of depth adjustment on your unit is provided to allow for blade wear.

Setting the reel deeper will not produce better, or quicker results. The flail reel is intended to

be set so it just touches the surface on flat ground. The slicing reel should be set even with the

ground for verti-slicing work, and set to a maximum 1/2" depth for overseeding jobs. Setting

the reel deeper than this will only result in premature wear on the unit (i.e. failed belt). If you

desire to work the ground deeper than the above guidelines allow, it should be done gradually

in multiple passes..

SLICING / OVERSEEDING: Mow the lawn to shorter than the normal cut height before

starting (i.e. approximately 2" tall for fescue grass). For the best result, Slice/Overseed in crisscross pattern (See Fig. 1 and See Fig 2).

Fig. 1

Fig. 2

Part No 350412 Form No F061311C

6

Page 7

PR & OS Owner’s Manual

V

RAKING OPERATION-FLAIL REEL

NOTE: Must have the flail reel assembly (350112) for this operation.

MOW: Mow the lawn to it's normal cut height.

DRY: Be sure grass is dry. Wet conditions can cause increased damage to healthy gra ss.

SET DEPTH: With engine off, set the raking depth so that the blades just touch on a flat

surface (i.e. driveway, or sidewalk).

START ENGINE: See page 9 for further instruction.

ENGAGE BLADES: Pull back on the bail on the operators handle. NOTE: When engaging the

blades in heavy load conditions (i.e. heavy thatch, or very uneven turf), push down on the

operators handle lifting the front wheels slightly. Engage the blades. Slowly lower the unit into

the turf.

RAKE: Rake a small test area and examine the results. Thatch should be removed and

deposited on top of the healthy grass. If excessive damage occurs to healthy grass, adjust the

blade depth to decrease damage. Continue raking the yard, working in one direction (i.e.

north-south, or east-west). NOTE: If a large drop in engine RPM occurs, or the unit pulls you

forward and bounces during operation the blade depth is set too low.

REMOVE THATCH: After raking, a layer of thatch will be deposited over the top of the lawn.

This thatch must be removed prior to any fertilizing, seeding, or watering of the lawn. We

suggest the use of a lawn vacuum or wheeled blower for collection and removal of the thatch.

RAKING OPERATION-SPRING REEL

NOTE: Must have the spring tine reel assembly (350354) for this operation.

MOW: Mow the lawn to it’s normal cut height. Tall grass will not leave a manicured look when the

dethatching job is complete.

DRY: Be sure grass is relatively dry. Wet conditions can cause increased damage to healthy grass.

SET DEPTH: With engine off, set the raking depth so that the spring tines are just above touching the

flat surface (i.e. driveway, or sidewalk) the units height is being adjusted on. NOTE: Allowing the

spring tines to have substantial contact with the ground will cause premature wear and failure of the

spring tines.

START ENGINE: See page 9 for further instruction.

ENGAGE TINES: Pull back on the bail on the operators handle. NOTE: When engaging the spring

tines in heavy load conditions (i.e. heavy thatch, or very uneven turf), push down on the operators

handle lifting the front wheels slightly. Engage the spring tines. Slowly lower the unit into the turf.

RAKE: Rake a small test area and examine the results. Thatch should be removed and deposited on

top of the healthy grass. If excessive damage occurs to healthy grass, adjust the spring tine depth to

decrease damage. Continue raking the yard, working in one direction (i.e. north-south, or east-west).

NOTE: If a large drop in engine RPM occurs, or the unit pulls you forward and bounces during

operation the spring tine depth is set too low.

REMOVE THATCH: After raking, a layer of thatch will be deposited over the top of the lawn. This

thatch must be removed prior to any fertilizing, seeding, or watering of the lawn. We suggest the use

of a lawn vacuum or wheeled blower for collection and removal of the thatch.

ERTI-CUTTING OPERATION

NOTE: Must have the slicing reel assembly (350113) for this operation.

MOW: Mow the lawn to shorter than the normal cut height (approximately 2" tall)

DRY: Be sure grass is dry. Wet conditions can cause increased damage to healthy gra ss.

SET DEPTH: With engine off, set the raking depth so that the blades just touch on a flat surface

(i.e. driveway, or sidewalk).

START ENGINE: See Page 9.

ENGAGE BLADES: Pull back on the bail on the operators handle. NOTE: When engaging the

blades in heavy load conditions (i.e. heavy thatch, or very uneven turf), push down on the

operators handle lifting the front wheels slightly. Engage the blades. Slowly lower the unit into the

turf.

SLICE: Verti-cut a small test area and examine the results. Some thatch and cut stems should

be removed and deposited on top of the healthy grass. Grass runners should be cut and ready

for removal. If excessive damage occurs to healthy grass, adjust the blade depth to decrease

damage. Continue raking the yard, working in one direction (i.e. north-south, or east-west).

NOTE: If a large drop in engine RPM occurs, or the unit pulls you forward and bounces during

operation the blade depth is set too low.

REMOVE THATCH/STEMS: After verti-cutting, a layer of thatch and cut stems will be deposited

over the top of the lawn. We suggest the use of a lawn vacuum or wheeled blower for collection

and removal of the thatch/stems.

Part No 350412 Form No F061311C

7

Page 8

PR & OS Owner’s Manual

OVERSEEDING OPERATION

NOTE: Must have the slicing reel assembly (350113) for this operation.

MOW: Mow the lawn to shorter than the normal cut height (approximately 2" tall)

DRY: Be sure grass is dry. Wet conditions can cause increased damage to healthy gra ss.

SEED: Spread grass seed according to the seed suppliers directions (e.g. 10 lbs. per 10 00 ft2 [4.5

kg. per 93 m2 ])

SET DEPTH: With engine off, set the raking depth so that the blades reach 1/4"-1/2"(6-12 mm)

below a flat surface (i.e. driveway, or sidewalk).

START ENGINE: See Page 9.

ENGAGE CLUTCH: Pull back on the bail on the operators handle. NOTE: When engaging the

clutch in heavy load conditions (i.e. heavy thatch, or very uneven turf), push down on the operators

handle lifting the front wheels slightly. Engage the clutch. Slowly lower the unit into the turf.

SLICE: Run machine over the area that has been seeded to incorporate the seed into the soil. If

excessive damage occurs to healthy grass, adjust the blade depth to decrease damage. Continue

raking the yard, working in one direction (i.e. north-south, or east-west). NOTE: If a large drop in

engine RPM occurs, or the unit pulls you forward and bounces during operation the blad e depth is

set too low.

WATER/FERTILIZE: After the seed has been worked into the soil, water and fertilize according to

the seed suppliers directions.

ADJUSTING SEED RATE LAWN PREPARATION

- MOW LAWN TO LOWEST SETTING ON

YOUR MOWER.

- DO NOT WATER PRIOR TO SEEDING.

- POWER RAKE TO DETHATCH LAWN

AND REMOVE THATCH.

- FERTILIZE LAWN WITH BROADCAST

SPREADER.

LAWN PREPARATION

- FOR BEST RESULTS OVERSEED IN

TWO PASSES OF ONE-HALF

APPLICATION RATE EACH, AT RIGHT

ANGLES OR IN A CRISS-CROSS

PATTERN.

- WATER HEAVILY IMMEDIATELY THEN

LIGHTLY FOR 10 - 14 DAYS, KEEPING

SOIL MOIST.

- AFTER GERMINATION, WATER LESS

OFTEN TO PROMOTE ROOT GROWTH.

Part No 350412 Form No F061311C

8

Page 9

PR & OS Owner’s Manual

MAINTENANCE

PERIODIC MAINTENANCE

Periodic maintenance should be performed at the following intervals:

Maintenance Operation Every Use (daily) Every 25 Hours

Inspect for loose, worn or damaged parts.

Check engine oil

Inspect belt

Engine (See Engine Manual)

Grease reel bearings

Inspect and clean engine air filter

Oil height adjustment linkage

z

z

FLAIL BLADE WEAR

1. Wait for engine to cool and disconnect spark plug.

2. Close fuel valve on engine (if available).

3. Lean unit back onto lower handles and secure in place.

4. Inspect blades for wear, and immediately replace any bent or cracked blades. Measure the

overall length of the blade. (See fig. 1)

5. If blades measure less than 3.25"(83 mm) in overall length they must be replaced. NOTE: We

recommend replacing all the flails at once.

SLICING BLADE WEAR

1. Wait for engine to cool and disconnect spark plug.

2. Close fuel valve on engine (if available).

3. Lean unit back onto lower handles and secure in place.

4. Inspect blades for wear, and immediately replace any bent or cracked blades. Measure

the overall length of the blade from the center of the attachment bolt to the tip of the worn

blade.

5. If blades measure less than 3"(76 mm) in length they must be replaced. NOTE: We

recommend replacing all the blades at once.

ROTATING FLAIL REEL END TO END

To maximize flail blade life and performance the reel can be rotated end to end periodically to provide a fresh lead cutting edge. Takes approx. 20 min.

and requires 1/2" and 9/16" socket wrenches with extension bar.

1. Wait for engine to cool and disconnect spark plug.

2. Close fuel valve on engine

3. Lean unit back onto lower handles and secure in place.

4. Remove (7) lock nuts (item 62 & 40) holding the belt and shaft guards (item 21 & 22) in place. It is necessary to lower the height adjust lever to reach

the locknuts on the guards. Remove the guards.

5. Remove the drive belt (item 9) by "walking" it out of the groove on the reel pulley (item 2).

6. Remove the (4) lock nuts (item 60) and washers (item 68) holding the bearings (item 23) to the frame of the unit.

7. The reel is now free from the machine. Slide the reel down and out of the machine.

8. Remove the capscrew (item 71), lockwasher (item 57), reel pulley (item 2), key (item 42), and reel spacer (item 10) from the end of the reel.

9. Rotate the reel end to end, and re-install these items on the opposite end of the reel.

10. Re-install the reel in reverse order of removal. Re-install the guards in reverse order of removal.

(if available).

z

z

z

z

Fig. 1

DRIVE BELT REPLACEMENT

NOTE: Takes approx. 10 min. and requires 1/2" socket wrench with extension.

1. Wait for engine to cool and disconnect spark plug.

2. Remove (4) lock nuts (item 62) holding the belt guard (item 21) in place. It is necessary to lower the height adjust lever to reach the locknuts on the

guard. Remove the guard.

3. Remove the belt (item 9) by rotating the reel pulley (item 2) and walking it out of the groove. Discard old belt

4. Install new belt using same procedure to walk the belt into the groove.

5. With new belt installed pull bail rod back to engaged position and measure extension of idler spring. Spring should stretch 3/4" - 1" (19 25 mm) with

bail engaged. Adjust clutch cable as necessary to achieve this extension.

6. Re-install the belt guard.

Part No 350412 Form No F061311C

9

Page 10

PR & OS Owner’s Manual

Troubleshooting

Abnormal vibration. · Damaged or m issing blades. Loose

Engine stalls or labors when

raking

Engine will not start. · Stop switch off (Honda only). Throttle

Problem Possible Cause Solution

handle bolts. Loose engine bolts

· Blades set too deep into ground. · Raise blades so that they just touch the

in off position

· Out of gasoline or bad, old gasoline. · Check gasoline.

· Stop work immediately. Replace any

damaged or m issing blades. Tighten all

loose nuts and bolts.

ground on a level surface

· Check choke position.

Engine is locked, will not pull

over.

· Spark Plug wire disconnected. · Connect spark plug wire.

· Gas valve off. · Turn on gas valve.

· Dirty air cleaner. · Clean or replace air cleaner. Contact a

· Debris locked against reel, or drive

pulleys. Engine problem.

qualified service person.

· Pull spark plug w ire and remove debris.

Contact an engine servicing dealer for

engine problems.

Part No 350412 Form No F061311C

10

Page 11

PR & OS Owner’s Manual

Y

POWER RAKE SEEDER BOX KIT P/N 350395

PAR TS LIST

ITEM NO. PART NO. DESCRIPTION QTY

1 350366 B OX AND LID ASS E M B LY

2 350390 B RA CK E T CAB LE M OUNTING 1

3 350385 CA B LE S E E D M E TERING ASSY 1

4 350320 S HA FT PLA S TIC DROP S EEDER 1

5 350271 P LA TE DOO R DROP S E E DE R 1

6 350272 P LA TE DOO R DROP S E E DE R E ND 1

7 350387 P LA TE DOO R DROP S E E DE R E ND A RM 1

9 350370 P ULLEY 3V GROOV E 0. 625" B O RE 1

10 8172009 WA S HE R #10 3/ 8 S A E 1

11 900321 BEARING CLIP 1.375 OD 4

12 890108 K NOB W ING 5/16-18 1

13 400217 S P RING TENSION 2

14 8024040 BOLT CARRIAGE 5/16 - 18 X 1 1

15 8024021 BOLT CARRIAGE 1/4-20 X 3/4" 1

16 8123087 SCREW S E LF TAP #10-24 X 3/8" HMS ZP 4

17 8160001 NUT LOCK 1/4 1

18 350389 B RA CK E T CAB LE S E E DE R B OX 1

19 8160002 NUT LOCK 5/16 1

20 8177011 WA S HE R LO CK 5/16 4

21 350369 P ULLE Y 3V GRO OV E 1. 530" BORE 1

22 350280 WA S HE R 0.906 O .D. X 0.656 I.D. X 0.062 7-8

Part No 350412 Form No F061311C

1

ITEM NO. PART NO. DESCRIPTION QT

23 8041026 SCREWCAP 5/16-18 x 3/4 4

24 350372 BELT O-RING 5/16 X 15 9/16" 1

25 8197031 PIN COTTER 1/8" X 1" 1

26 9195106 ROLL PIN 1/8 - 1 1/4 1

27 8172020 WASHER 5/16 FENDER 4

28 8172007 WASHER 1/4 SAE 3

29 350392 LABEL SEED METERING 1

30 350386 LABEL DROP SEEDER BOX 1

31 900230 WASHER 1/2 FC 2

32 8161044 NUT LOCK 1/2" THIN HGT 1

33 890456 LABEL HOSE PLUG KD/SV 1

34 350313 LABEL PRODUCT DECAL OS 1

35 8024061 CARRIAGE BOLT 3/8-16 X 1 3/4" 1

36 8024025 CARRIAGE BOLT 1/4-20 X 1 3/4" 1

37 350399 PIN CLEVIS .25 X .61 1

38 900471 PIN HAIR 1/4 ZP 1

39 8160003 NUT LOCK 3/8-16 HEX 1

40 8171004 WASHER 3/8 FC 2

41 350391 BRACKET MOUNTING METERING SEED 1

42 8059135 SCREW MACHINE #10-24 X 5/8 1

43 8164005 NUT LOCK LT #10-24 HEX 1

44 900407 TY-WRAP 1

11

Page 12

PR & OS Owner’s Manual

PARTS DRAWING

item

FLAIL SHAFT KIT 350185 FLAIL BLADE KIT 350186

PARTS

no. LIST

57 LO CK WASHER 3/8 S/T MED

68 WASHER 3/8 FLAT CUT

71 SCREWCAP REEL PULLEY

73 S HAFT FLAIL BLADE 350141 4

74 B LADE FLAIL 350100 30

76 SPACER BUMPER 5/8" x 1/2" 350144 54

77 S HAFT WA FLAIL REEL 350145 1

78 CLIP LOCK 1/2" 350146 8

79 WASHER 1/2 SAE 8172011 8

FLAIL REEL KIT 350112

Part No.

8177012 1

8171004 1

8041050 1

QTY

PARTS

PA RTS

item

no. LIST

73 SHAFT FLAIL BLADE 350141 4

78 CLIP LOCK 1/2" 350146 8

SPACER BUMPER KIT 350258 SLICING BLADE KIT 350187

Part No. QTY

item

no. LIST

74 BLADE FLAIL 350100 60

78 CLIP LOCK 1/2" 350146 8

PARTS

item

no . LIST

76 SPACER BUMPER 5/8" x 1/2" 350144 54

Part No 350412 Form No F061311C

Part No.

QTY

12

PAR T S L IST

item

no.

81 BLADE 10" HEX SLICING 350147 20

85 SCR E W CA P 1/4-20 X 3/4 HCS Z P 8041004 40

86 NU T LO C K 1/4-20 8142004 40

Part No.

Part No. QTY

QTY

Page 13

PR & OS Owner’s Manual

PARTS DRAWING

PARTS

item

no. LIST

57 LOCK WASHER 5/16 S/T MED 8177011 1

71 SCREWCAP 5/16 - 24 x 1 1/4" HCS GR. 5 400389 1

80 SHAFT SLICING WA 350142 1

81 BLADE SLICING REEL 350147 20

82 PLATE BLADE MTG. 350148 20

83 SPACER BLADE MTG. 350149 10

84 SPACER BLADE ASSY 350150 9

85 SCREWCAP 1/4-20 x 3/4, HCS ZP 8041004 40

86 NUT LOCK 1/4-20 8142004 40

87 COLLAR SPACER 350152 1

88 WASHER 0.937 x 1.750 x 0.119 350153 1

89 WASHER LOCK 7/8 I NT . TOOTH 350154 1

90 NUT JAM 7/8"-14 350155 1

PR500 QTY

Part No.

SLICING REEL ASSY 350113

SPRING TINE REEL ASSY - 350355-S

item

no. LIST

item

PARTS

no. LIST

1 S HA FT WA SPRING TINE REEL 350353 1

2 SHAFT SPRING TINE REEL 350351 4

3 SPRING TINE 350352 108

4 RING RETAI NING 1/2" 350146 8

5 S CREWCAP3/8"-16 X 1" HCS ZP 8041050 1

6 WASHER LOCK 3/8 S/T MED 8177012 1

68 WASHER 3/8 FLAT CUT 8171004 1

SPRING REPLACEMENT KIT - 350356-S

PARTS

Part No.

3 SPRING TINE 350352 108

4 RING RETAINING 1/2" 350146 8

QTY

Part No. QTY

Part No 350412 Form No F061311C

13

Page 14

PARTS DRAWING

PR550, PR550H, OS552,

OS552H,

PR & OS Owner’s Manual

Part No 350412 Form No F061311C

14

Page 15

PR & OS Owner’s Manual

PARTS LIST

Part No 350412 Form No F061311C

PARTS

item

no. LIST Part No. Part No. Part No. Part No.

1 Pulley 3" OD 350101 1 350101 1 350101 1 350101 1

1A Spacer 1" OD X .75" x .45 THK 350411 1 350411 1 350411 1 350411 1

2 Pulley 6.5" OD X ¾" 350102 1 350102 1 350102 1 350102 1

3 WHEEL 8.0" X 5/8" B EARING 350103 2 350103 2 350103 2 350103 2

4 WHEEL 10.0" X 5/8" B EARING 350104 2 350104 2 350104 2 350104 2

5 Height Adjust Assy 350107 1 350107 1 350107 1 350107 1

6 Reel Flail / Sl i cing / Spring Assy 350112 1 350112 1 350113 1 350113 1

7 Pulley Idler 2.75" 350114 1 350114 1 350114 1 350114 1

8 Arm Idl er WA 350115 1 350115 1 350115 1 350115 1

9 Belt 5L X 36 350116 1 350116 1 350116 1 350116 1

10

11 Bracket Mount Clutch Cable 350119 1 350119 1 350119 1 350119 1

12 Chassis WA W/ Label 350194 1 350194 1 350194 1 350194 1

13 Frame Front WA 350121 1 350121 1 350121 1 350121 1

14 Bushi ng 0.375 OD X 0.256 ID X 0.88 350309 1 350309 1 350309 1 350309 1

15 Spring H ei ght Adjust PR500 350125 1 350125 1 350125 1 350125 1

16 Li nk H eigh t Adjust PR500 350126 1 350126 1 350126 1 350126 1

17 Yoke ½ - 20 350127 1 350127 1 350127 1 350127 1

18 Pin Y ok e ½" 350128 1 350128 1 350128 1 350128 1

19 Bracket Mount Hgt. Adj. WA 350182 1 350182 1 350182 1 350182 1

20 Spacer Spanner Wheel PR500 350130 4 350130 4 350130 4 350130 4

21 Guard Belt WA W/ Label 350384 1 350384 1 350384 1 350384 1

22 Guard Shaft WA W/ Label 350196 1 350196 1 350196 1 350196 1

23 Bearing ¾" Cast Pill ow B l ock 350133 2 350133 2 350133 2 350133 2

24 Handle L ower LH WA 350134 1 350134 1 350134 1 350134 1

25 Handle L ower RH WA 350135 1 350135 1 350135 1 350135 1

26 Handle Upper PR500 350375 1 350375 1 350375 1 350375 1

27 Bail Cl utch WA 350374 1 350374 1 350374 1 350374 1

28 Loop Foldi n g H andl e 350138 2 350138 2 350138 2 350138 2

29 Deflector Rubber 350167 1 350167 1 350167 1 350167 1

30 Shiel d B earing 350168 2 350168 2 350168 2 350168 2

31 Bar Clam p D eflector 350171 1 350171 1 350171 1 350171 1

32 Bracket Height Adjust Lock WA 350173 1 350173 1 350173 1 350173 1

33 Guard Pull ey Back 350174 1 350174 1 350174 1 350174 1

34 Lever Height Control 350175 1 350175 1 350175 1 350175 1

35 Label Instr. Hgt. Adj. 350176 1 350176 1 350176 1 350176 1

36 Bol t Shoul der ¼" x 1 ¾" 350178 1 350178 1 350178 1 350178 1

37 Bol t Shoul der 5/16" x 1 ¾" 350179 1 350179 1 350179 1 350179 1

38 Cable Clutch PR 350408 1 350408 1 350408 1 350408 1

40 BOLT SH OUL D ER 1/2" X 1" 500114 1 500114 1 500114 1 500114 1

41 ENGIN E HON DA 5.5 H.P. GX160 - - 600115 1 - - 600115 1

ENGIN E 5.5 HP B & S V ANGU ARD 350379 1 - - 350379 1 - 42 KEY 3/ 16" X 1" 9201078 2 9201078 2 9201078 2 9201078 2

43 GRIP 1" x 13" 400570 2 400570 2 400570 2 400570 2

44 GRIP LEVER 1/8 x 1 x 5" 500181 1 500181 1 500181 1 500181 1

45LABEL INSTRUCTION SEEDER BOX----350288 1 350288 1

46 LABEL PRODUCT D ECAL OVAL 350193 1 350193 1 350193 1 350193 1

47 FINGER BE L T WIRE 350301 1 350301 1 350301 1 350301 1

48 LABEL D ANGE R TH ROWN OBJECT 810736 1 810736 1 810736 1 810736 1

49 LABEL CLUT CH V Q 830503 1 830503 1 830503 1 830503 1

50 LABEL WARNING FUEL EN/SP 100261 1 - - 100261 1 - 51 LABEL WARNING 400424 2 400424 2 400424 2 400424 2

52 LABEL D ANGE R GUARD 900327 1 900327 1 900327 1 900327 1

53 PLUG CAP 1" RD 890132 2 890132 2 890132 2 890132 2

54 BOLT CARRAIGE 3/8-16 x 1 3/4 8024061 4 8024061 4 8024061 4 8024061 4

55 BOLT CARRAIGE 5/16-18 x 1 3/4 8024043 2 8024043 2 8024043 2 8024043 2

56 BOLT CARRIAGE 5/16 -18 x 3/4 8024039 4 8024039 4 8024039 5 8024039 5

57 WASHER LOCK 3/8" S/ T M E D 8177012 1 8177012 1 - - - -

WASHER LOCK 5/16" TW TOOTH ----430298 1 430298 1

58 NUT L OCK #10-24 8164005 1 8164005 1 8164005 1 8164005 1

59 NUT LOCK 1/4-20 8160001 2 8160001 2 8160001 5 8160001 5

60 NUT LOCK 3/8-16 8160003 12 8160003 12 8160003 12 8160003 12

61

62 NUT L OCK 5/16-18 8160002 15 8160002 15 8160002 16 8160002 16

63 SCREWCAP 1/4-20 x 1 1/2 8041008 1 8041008 1 8041008 1 8041008 1

64 SCREWCAP 3/8 - 16 x 1 3/4 8041053 1 8041053 1 8041053 1 8041053 1

PR550

QTY

PR550H

QTY

OS552

QTY

OS552H

15

QTY

Page 16

PR & OS Owner’s Manual

PARTS

item

no. LIST

65 SCREWCAP 5/16-24 x 3/4" GR.5 8042026 2 8042026 2 8042026 3 8042026 3

65A Washer 3/4 SAE 8172015 5 8172015 5 8172015 5 8172015 5

65B Washer 5/16 Twi st Tooth 430298 1 430298 1 430298 1 430298 1

66 SCREWCAP 5/16 - 18 x 1 1/2 8041030 4 8041030 4 8041030 4 8041030 4

67 SCREWCAP 5/16-24 X 1 400164 1 400164 1 400164 1 400164 1

68 WASHER 3/8 FLAT CUT 8171004 9 8171004 9 8171004 8 8171004 8

69 WASHER 1/2 SAE ZP 8172011 2 8172011 2 8172011 5 8172011 5

70 NUT L OCK 1/2" - 13 T H IN H GT 8161044 4 8161044 4 8161044 4 8161044 4

71 SCREWCAP REEL PULL E Y 8041050 1 8041050 1 400164 1 400164 1

72 BUTT ON S OCKET 5/16-18X 5/8” 350266 4 350266 4 - - - 73 BOLT SH OUL D E R 1/2" x 2" 520031 2 520031 2 520031 2 520031 2

74 FLANGE SCREW 0.375 -16 X 0.75 791080 2 791080 2 791080 2 791080 2

75 SPACER 1/2" ID X 3/4"

76 WASHER 3/8 SAE 8172009 2 8172009 2 8172009 2 8172009 2

77 NUT PAL 3/8 360218 2 360218 2 360218 2 360218 2

78 WASHER 1/4 FLAT CUT 8171002 5 8171002 5 8171002 5 8171002 5

79 PIN CLEVIS 3/8" X 1.625 520119 2 520119 2 520119 2 520119 2

80 RETAINER 3/8" BOLT PUSH NUT 360279 2 360279 2 360279 2 360279 2

81 LABEL SPARK AR RE STOR EN /SP - - 100256 1 - - 100256 1

82 WASHER 1/4 SAE 8172007 1 8172007 1 8172007 1 8172007 1

83 LABEL LOGO PROD UCT SM CIRCLE 890456 1 890456 1 890456 1 890456 1

90 WASHER 1.125" OD X .344 ID X .25 THK - - - - 441150 1 441150 1

100 WASHER FLAT 5/16" 8171003 5 8171003 5 8171003 5 8171003 5

104 LABEL MADE IN U.S.A. 520116 1 520116 1 520116 1 520116 1

PR550

Part No.Part No.Part No.Part No.

--------

QTY

PR550H

QTY

OS552

QTY

OS552H

QTY

Part No 350412 Form No F061311C

16

Loading...

Loading...