Page 1

®

BILLY GOAT

MV650SPH Self-Propelled Vacuum

Owner’s Manual

Accessories

Caster Kit Hose Kit Bag Liner Kit Felt Bag Kit

Use on hard surface

for maneuverability.

P/N 840129 P/N 840116 P/N 840134 P/N 840194

For vacuuming hard

to reach areas.

To collect leaves,

thatch, and grass.

Use on all dusty

conditions.

Part No 840099 1 Form No F082206A

Page 2

MV650SPH Self-Propelled Vacuum Owner’s Manual

ABOUT THIS MANUAL

THANK YOU for purchasing a BILLY GOAT

manufactured to provide years of reliable and productive service. This manual provides complete operating and

maintenance instructions that will help to maintain your MV Vacuum in top running order. Read this manual carefully

before assembling, operating, or servicing your equipment.

®

MV Vacuum. Your new machine has been carefully designed and

CONTENTS

Serial Plate Data ................................................................................................................................................ 3

Specifications ..................................................................................................................................................... 3

Common Replacement Parts ............................................................................................................................ 3

General Safety Instructions and Symbols ......................................................................................................... 4

Sound Data ........................................................................................................................................................ 6

Vibration Data .................................................................................................................................................... 6

Intended Use ..................................................................................................................................................... 6

Instruction Labels ............................................................................................................................................... 7

Engine Labels .................................................................................................................................................... 7

Assembly Instructions ........................................................................................................................................ 8

Operation ........................................................................................................................................................... 12

Operator Controls ........................................................................................................................................ 13

Starting ........................................................................................................................................................ 13

Height/Nozzle Door Adjustment .................................................................................................................. 14

Self Propel ................................................................................................................................................... 16

Handling and Transporting ................................................................................................................................ 18

Storage .............................................................................................................................................................. 18

Maintenance ...................................................................................................................................................... 19

Periodic Maintenance .................................................................................................................................. 19

Impeller Removal ......................................................................................................................................... 19

Drive Clutch Cable Adjustment ................................................................................................................... 20

Drive Belt Removal and Replacement ........................................................................................................ 21

Drive Chain Alignment/Tension .................................................................................................................. 21

Wiring Diagrams........................................................................................................................................... 23

Troubleshooting ................................................................................................................................................. 23

Engine Maintenance and Repair ....................................................................................................................... 24

Warranty Claim Procedure ................................................................................................................................ 24

Maintenance Record .......................................................................................................................................... 25

Illustrated Parts List ........................................................................................................................................... 26

Part No 840099 2 Form No 082206A

Page 3

MV650SPH Self-Propelled Vacuum Owner’s Manual

SERIAL PLATE DATA

Record the model number, serial number, date of

purchase, and where purchased.

Purchase Date:

Purchased From:

MV 650 SERIES SPECIFICATIONS

MV650SPH

Engine Type Honda GSV190AA1A

Horsepower 6.5 (4.85 kW)

Fuel Capacity 1.6 qt (1.5 L)

Oil Capacity 0.69 qt (0.65L)

Engine Weight 28 lbs (12.7 kg)

Unit Weight 179 lbs (81.2 kg)

Shipping Weight 208 lbs (94.3 kg)

Overall Dimensions 28” Wide x 62.5” Long x 45.5”

Maximum Operating Slope 20o

Lw(a) at Operator position 103 dB(a) at 3320 rpm

Lp(a) at Operator position 83 dB(a) at 3320 rpm

High

COMMON REPLACEMENT PARTS

• Bag. P/N 840189. Original equipment replacement bag.

• Skid. P/N 840041. Nozzle wear guard skid.

• Drive Belt P/N 840066, Original equipment replacement belt.

Form No F082206A 3 Part No 840099

Page 4

MV650SPH Self-Propelled Vacuum Owner’s Manual

GENERAL SAFETY INSTRUCTIONS and SYMBOLS

The safety symbols shown below are used throughout this manual. You should become familiar with them before

assembling, operating, or servicing this equipment.

This symbol indicates important information that will prevent injury to yourself or others.

This symbol indicates ear protection is recommended when operating this equipment.

This symbol indicates eye protection is recommended when operating this equipment.

This symbol indicates gloves should be worn when servicing this equipment.

This symbol indicates that this manual and the engine manufacturer’s manual should be read

carefully before assembling, operation, or servicing this equipment.

This symbol indicates important information that will prevent damage to your BILLY GOAT ®

MV Vacuum.

This symbol indicates the engine oil level should be checked before operating this

equipment.

Read and make sure you thoroughly understand the following safety precautions before assembling, operating or

servicing this equipment:

READ this manual and the engine manufacturer’s manual carefully before assembling,

operating, or servicing this equipment.

EAR PROTECTION is recommended when operating this equipment.

EYE PROTECTION is recommended when operating this equipment.

EXHAUST from this product contains chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

DO NOT operate this equipment on any unimproved forested, brushy, or grass covered land

unless a spark arrester is installed on the muffler as required by Section 4442 of the

California Public Resources Code. The arrester must be maintained in good working order.

Other states may have similar laws. Federal laws apply on federal lands.

DO NOT run engine in an enclosed area. Exhaust gases contain carbon monoxide, an

odorless and possibly fatal poison.

Part No 840099 4 Form No 082206A

Page 5

MV650SPH Self-Propelled Vacuum Owner’s Manual

DO NOT run this equipment indoors or in any poorly ventilated area. Refueling outdoors

is recommended.

DO NOT refuel this equipment while the engine is running. Allow engine to cool for at

least two minutes before refueling.

DO NOT store gasoline near an open flame.

DO NOT remove gas cap while engine is running.

DO NOT start or operate engine if strong odor of gasoline is present.

DO NOT start or operate engine if gasoline is spilled. Move equipment away from spill

until gasoline has completely evaporated.

DO NOT smoke while filling the fuel tank.

DO NOT check for spark with spark plug or spark plug wire removed. Use an approved

spark tester.

DO NOT operate engine without a muffler. Inspect muffler periodically and replace if

necessary. If equipped with muffler deflector, inspect deflector periodically and replace if

necessary.

DO NOT operate engine with grass, leaves or other combustible material near the

muffler.

DO NOT touch muffler, cylinder, or cooling fins when hot. Contact with hot surfaces may

cause severe burns.

DO NOT leave equipment unattended while in operation.

DO NOT park equipment on a steep grade or slope.

DO NOT operate equipment with bystanders in or near the work area.

DO NOT start equipment with drive clutch engaged.

DO NOT operate equipment with guards removed.

DO NOT operate equipment in areas containing rock, glass, string-like material, wire,

rags, cans, metal or other non-organic material.

DO NOT operate equipment on slopes greater than specified in Specifications section of

this manual.

DO NOT operate equipment near hot or burning debris or any toxic or explosive

materials.

DO NOT allow children to operate this equipment.

ALWAYS remove spark plug wire when servicing equipment to prevent accidental

starting.

ALWAYS check fuel lines and fittings frequently for cracks or leaks. Replace if

necessary.

ALWAYS keep hands and feet away from moving or rotating parts.

ALWAYS store fuel in approved safety containers.

Form No F082206A 5 Part No 840099

Page 6

MV650SPH Self-Propelled Vacuum Owner’s Manual

SOUND DATA

SOUND LEVEL 103 Dba at Operator Position

Sound tests were conducted in accordance with 2000/14/EC as well as ISO11094, and were performed on 5-172005 under the conditions listed below.

Sound power level listed is the highest value for any model covered in this manual. Please refer to

serial plate on the unit for the sound power level for your model.

General Conditions: Sunny

Temperature: 66.2

Wind Speed: 8.5 mph (13.7kph)

Wind Direction: South Southwest

Humidity: 59%

Barometric Pressure: 29.9” Hg (101.35kPa)

o

F (19oC)

VIBRATION DATA

VIBRATION LEVEL 1.43g(14.00m/s2)

Vibration levels at the operator’s handles were measured in the vertical, lateral and longitudinal directions using

calibrated vibration test equipment. Tests were performed on 5-24-2006 under the conditions listed below.

General Conditions: Sunny

Temperature: 73.7

Wind Speed: 8.05 mph (3.6m/s)

Wind Direction: South

Humidity: 83.5%

Barometric Pressure: 29.91” Hg (101.31 kPa)

o

F (23.2oC)

INTENDED USE

Your BILLY GOAT ® MV Vacuum is designed for vacuuming leaves, grass clippings, and other types of organic

litter, as well as, debris mixed with cans, bottles, and small amounts of sand; however, vacuuming cans, bottles and

sand will affect the longevity of your machine.

Like all mechanical tools, reasonable care must be used when operating the machine.

Do not operate if excessive vibration occurs. If excessive vibration occurs, shut engine off immediately and check for

damaged or worn impeller, loose impeller bolt, loose impeller key, loose engine or lodged foreign objects. Note: See

parts list for proper impeller bolt torque specifications. (See trouble shooting section on page 25).

Part No 840099 6 Form No 082206A

Page 7

MV650SPH Self-Propelled Vacuum Owner’s Manual

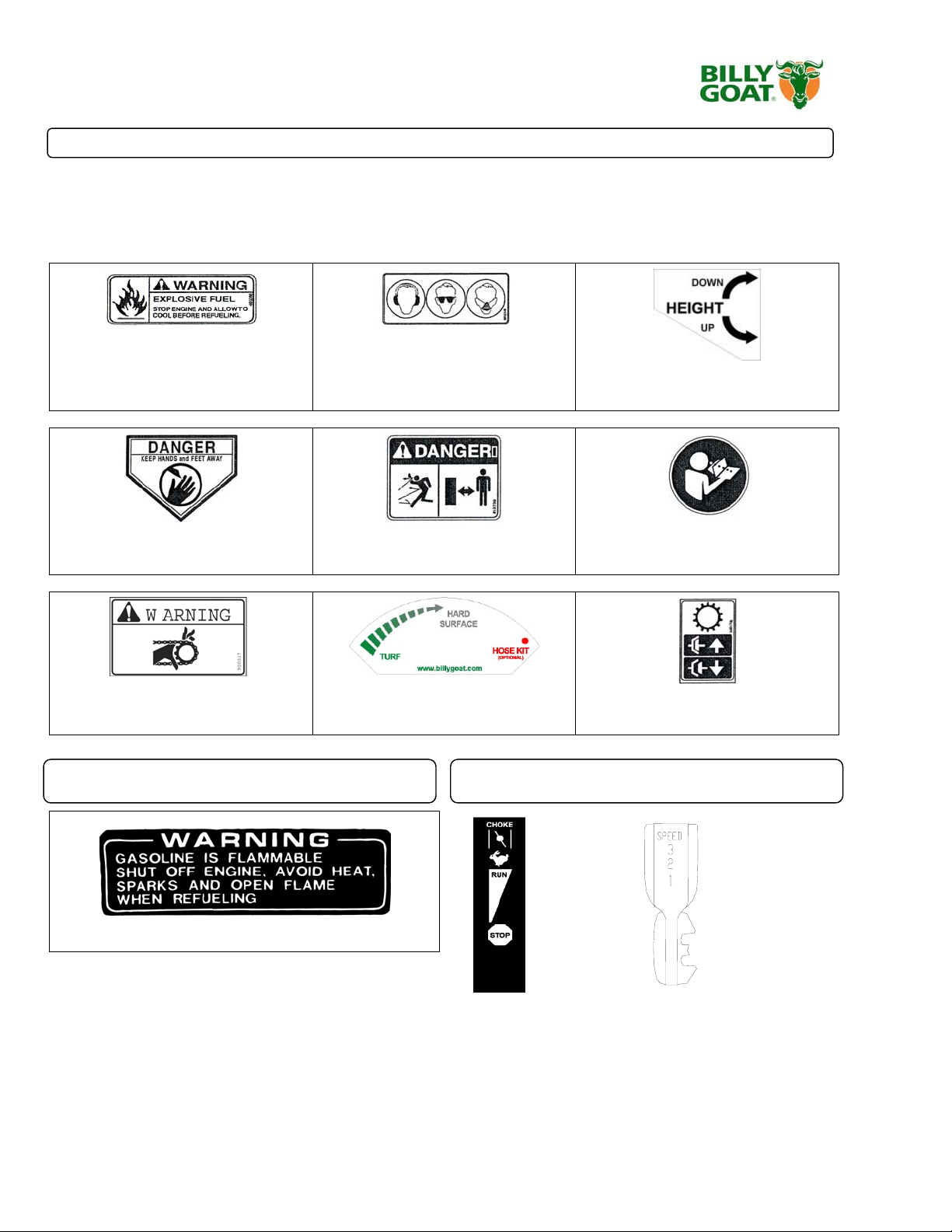

INSTRUCTION LABELS

The labels shown below were installed on your BILLY GOAT

replace them before operating this equipment. Item numbers from the Illustrated Parts List and part numbers are

provided for convenience in ordering replacement labels. The correct position for each label may be determined by

referring to the Figure and Item numbers shown.

®

MV Vacuum. If any labels are damaged or missing,

PN 400268

(See Figure 3 Item 55)

PN 400424

(See Figure 1 Item 11)

PN 900327

(See Figure 2 Item 118)

PN 890254

(See Figure 4 Item 162)

PN 810736

(See Figure 4 Item 174)

PN 840080

(See Figure 4 Item 175)

ENGINE LABELS CONTROLS

PN 840054

(See Figure 1 Item 34)

PN 890301

(See Figure 4 Item 163)

PN 500176

(See Figure 2 Item 120)

HONDA

Throttle Drive

P/N 840045 P/N 510127

Form No F082206A 7 Part No 840099

Page 8

MV650SPH Self-Propelled Vacuum Owner’s Manual

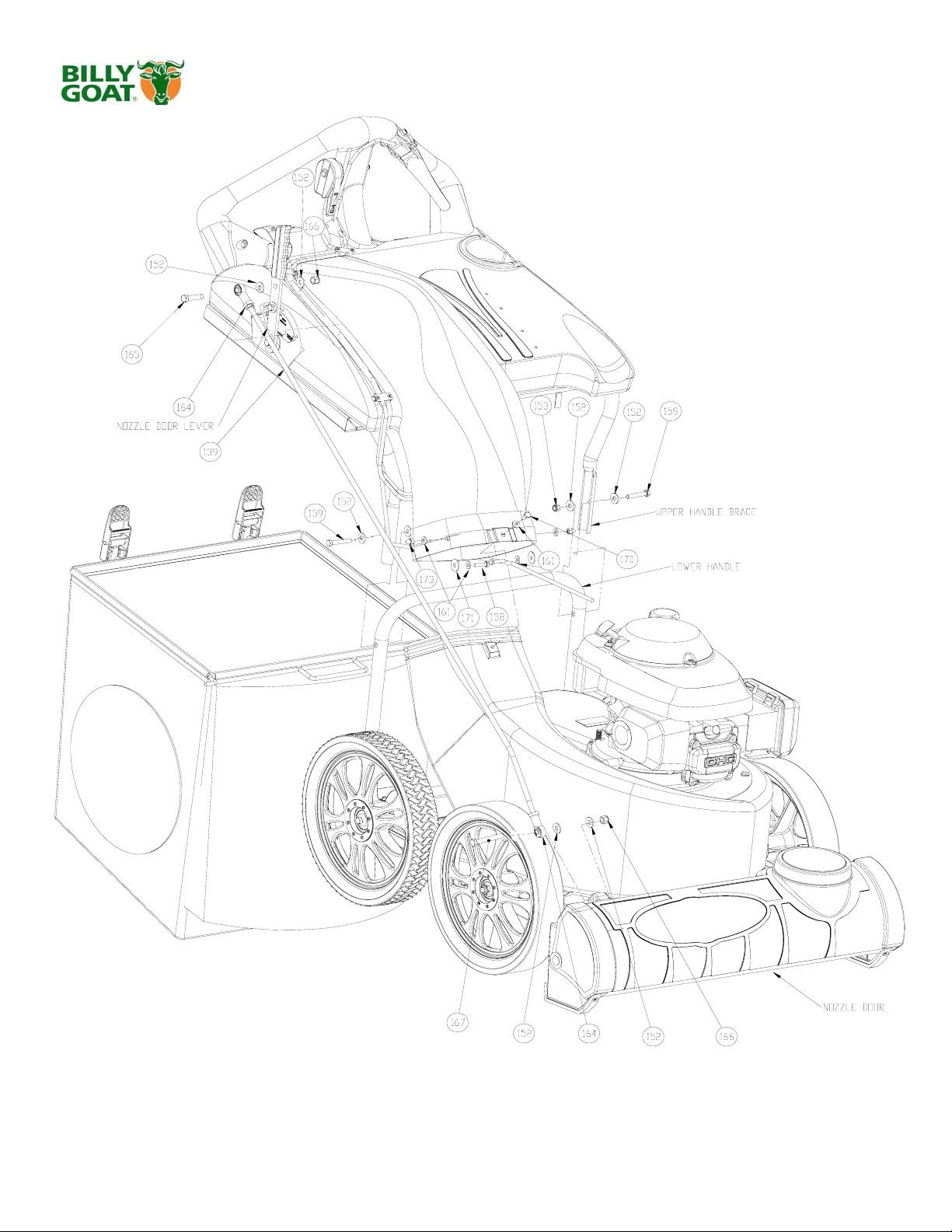

MV Vacuum Assembly Drawing

Part No 840099 8 Form No 082206A

Page 9

MV650SPH Self-Propelled Vacuum Owner’s Manual

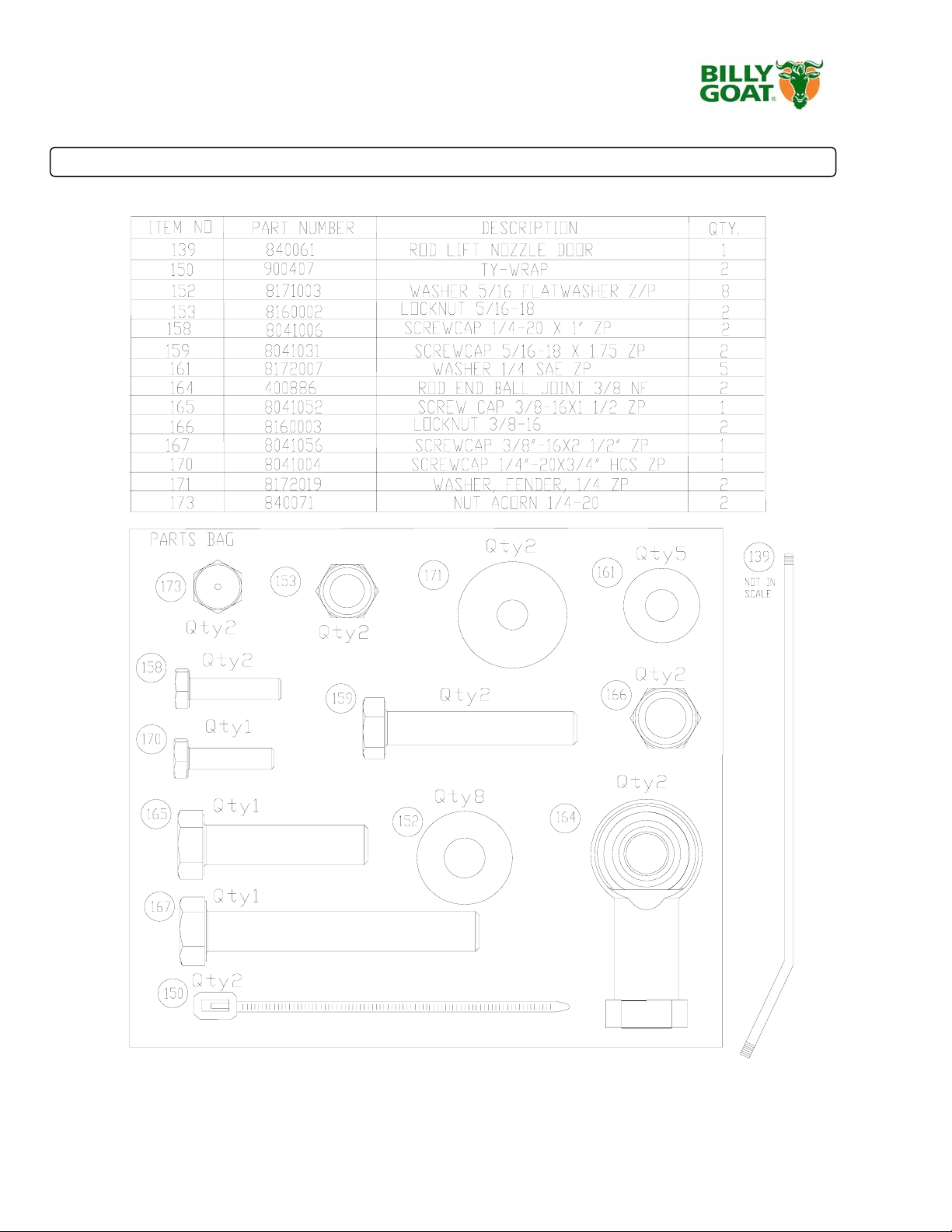

PARTS LIST

Form No F082206A 9 Part No 840099

Page 10

MV650SPH Self-Propelled Vacuum Owner’s Manual

ASSEMBLY INSTRUCTIONS

Your BILLY GOAT

Handle Assembly. Mounting hardware for the Hood/Upper Handle Assembly is temporarily installed on the lower

handle and the Housing assembly.

Remove unit from carton. Make sure the following items that have been packed with unit:

Parts bag P/N 840187

Owner’s Manual, P/N 840099

Declaration of Conformity, P/N 840204

Honda Engine Manual

Warranty Card, P/N 400972

Ty-Wraps (2 ea)

Hardware Bag

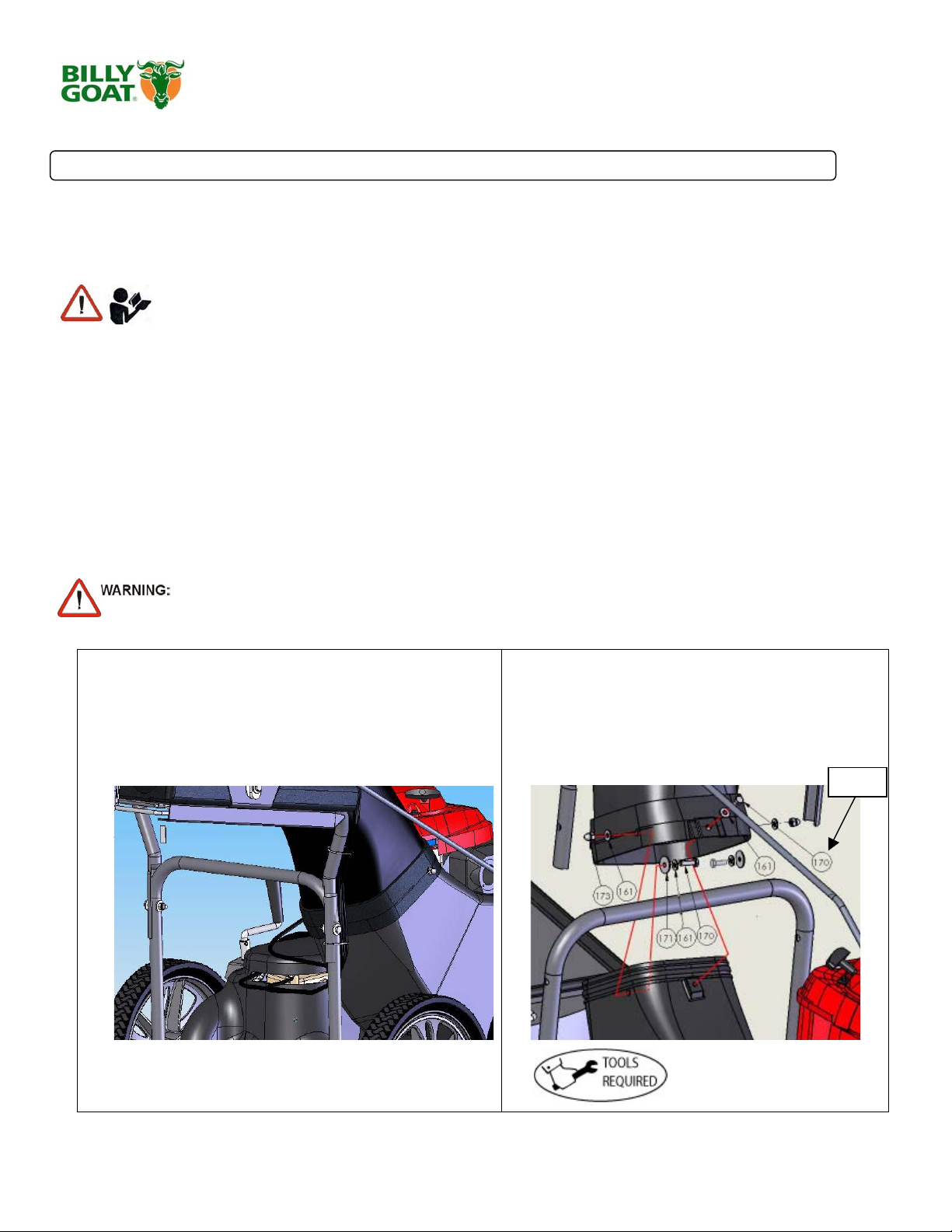

1. Attach hood assembly to the housing then hold in place

during the step 2.

NOTE: BE SURE ALL CABLES ARE ROUTED ON THE

UNDERSIDE OF THE HOOD AND HOUSING.

®

MV Vacuum was shipped in one carton, completely assembled except for the Hood/Upper

READ all safety instructions before assembling unit.

TAKE CAUTION

attached to the unit by cables.

when removing the unit from the box since Hood/Upper Handle Assembly is

DISCONNECT spark plug wire before assembling unit.

2. Install item #170 center bolt first when aligned with

a nut on the housing.

3. Attach rest of hood assembly to the housing using

corresponding hardware.

NOTE: You will have to insert the bolt/washer from

the inside by reaching through the hood.

- Two 7/16” wrenches.

Part No 840099 10 Form No 082206A

Page 11

MV650SPH Self-Propelled Vacuum Owner’s Manual

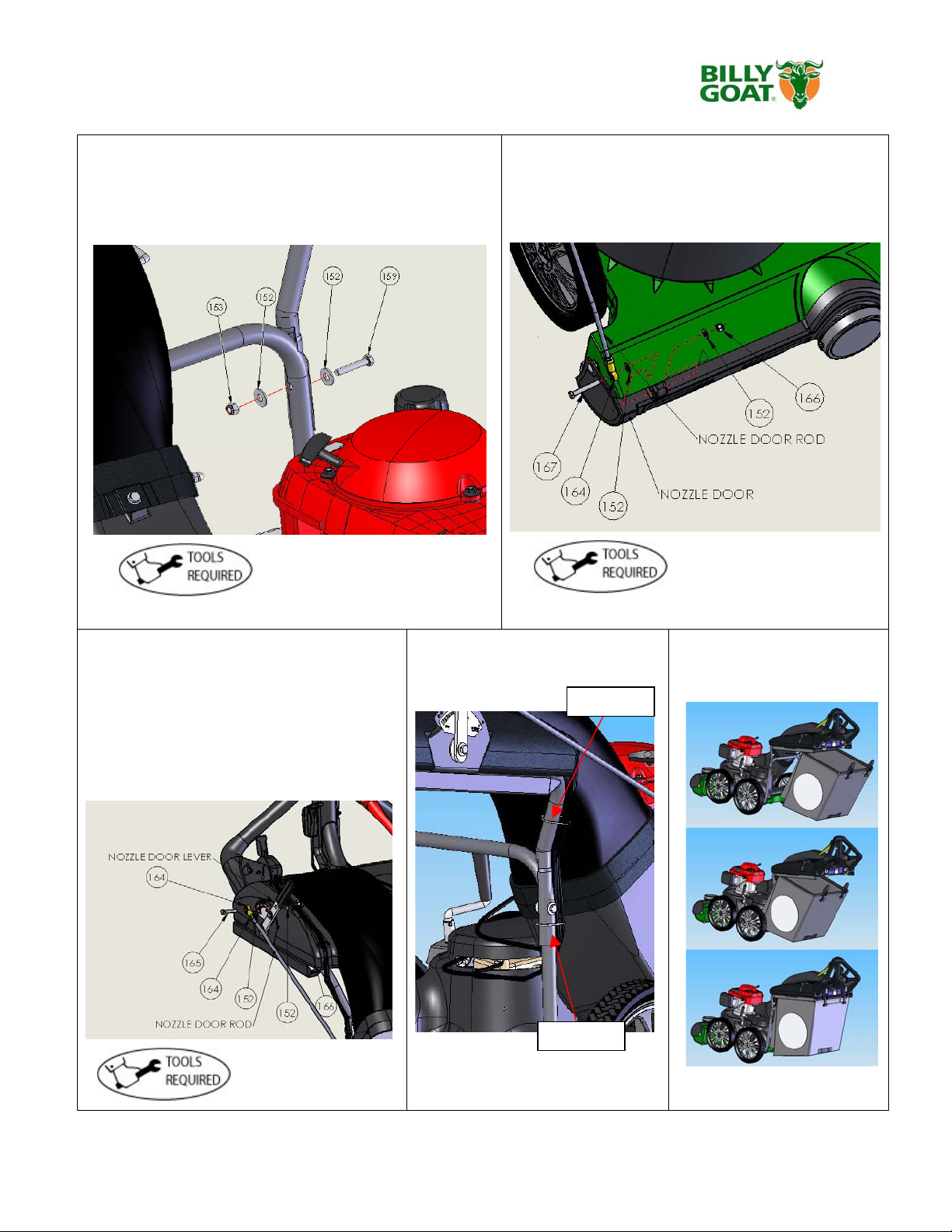

4. Attach upper handle brace to lower handle using

corresponding hardware. Then repeat this step on the

other side.

- Two 1/2” wrenches.

5. Attach rod end (164) to the nozzle door rod then

secure in place by tightening jam nut.

6. Attach nozzle door rod to the nozzle door using

corresponding hardware.

NOTE: It is easier to do this with nozzle door closed.

- Two 9/16” wrenches.

7. Attach rod end to rod (as in step 5).

8. Attach nozzle door rod to the lever with

nozzle door closed and lever in hose kit

position.

NOTE: Check to see nozzle door open and

close all the way (see page 15). Tighten or

loosen the rod end (164) for any

adjustments.

Two 9/16”

wrenches.

9. Install cable ty wraps.

10. Reconnect spark plug

wire.

11. Attach the bag.

Form No F082206A 11 Part No 840099

Page 12

OPERATION

MV650SPH Self-Propelled Vacuum Owner’s Manual

DO NOT run engine in an enclosed area. Exhaust gases contain carbon monoxide, an

odorless and possibly fatal poison.

DO NOT start or operate engine if strong odor of gasoline is present.

DO NOT start or operate engine if gasoline is spilled. Move equipment away from spill

until gasoline has completely evaporated.

DO NOT operate engine without a muffler. Inspect muffler periodically and replace if

necessary. If equipped with muffler deflector, inspect deflector periodically and replace

if necessary.

DO NOT operate engine with grass, leaves, or other combustible material near the

muffler.

DO NOT touch muffler, cylinder or cooling fins while engine is running. Contact with hot

surfaces may cause severe burns.

DO NOT operate equipment with bystanders in or near the work area.

DO NOT operate equipment with guards removed.

DO NOT operate equipment in areas containing rock, glass, string-like material, wire,

rags, cans, metal, or other non-organic material.

DO NOT operate equipment on slopes greater than specified in Specifications section

of this manual.

DO NOT operate equipment near hot or burning debris or any toxic or explosive

materials.

DO NOT allow children to operate this equipment.

ALWAYS keep hands and feet away from moving or rotating parts.

EAR PROTECTION is recommended when operating this equipment.

EYE PROTECTION is recommended when operating this equipment.

Part No 840099 12 Form No 082206A

Page 13

MV650SPH Self-Propelled Vacuum Owner’s Manual

OPERATOR CONTROLS

The operator’s position is at the rear of the machine between the handlebars. The operator should STAND in a

position to allow both handlebars to be grasped firmly, which allows sufficient leverage to steer the machine.

Operator’s controls are shown below.

1

2

Operator Control Locations

3

4

6

5

1 Drive Clutch Lever 4 Throttle Control

2 Bag Latch 5 Drive Shifter Control

3 Pull Starter 6 Nozzle Door Adjuster

STARTING

CHECK engine oil level before operating machine.

1. Place equipment on a level, firm surface that is free of rocks or other debris.

2. Place throttle in START position.

Throttle

DO NOT START equipment without the debris bag in place.

Form No F082206A 13 Part No 840099

Page 14

MV650SPH Self-Propelled Vacuum Owner’s Manual

3. Secure the unit with left hand at the handle then pull starter rope with right hand to start engine.

PULL ROPE

STARTER WITH

RIGHT HAND

SECURE UNIT AT

THE HANDLE

WITH LEFT HAND

DURING START

PULL STARTER CORD slowly until resistance is felt. Then pull cord rapidly to avoid

kickback.

4. Move throttle control back to FAST position and allow engine to reach correct operating speed.

VACUUM NOZZLE HEIGHT ADJUSTMENT

FOR MAXIMUM PICKUP: Adjust nozzle height as close to debris as possible, but without blocking airflow into the

nozzle. NOTE: Never bury nozzle into debris. The vacuum nozzle is raised and lowered by turning the crank handle

clockwise and counter-clockwise.

Part No 840099 14 Form No 082206A

Page 15

MV650SPH Self-Propelled Vacuum Owner’s Manual

VACUUM NOZZLE DOOR ADJUSTMENT

The vacuum nozzle door adjusts for the maximum performance under various applications.

Nozzle fully opened. This is ideal for turf application

Nozzle half way opened. This is ideal for hard surface application

Nozzle closed for OPTIONAL hose kit. This is ideal for hard to reach places.

Form No F082206A 15 Part No 840099

Page 16

MV650SPH Self-Propelled Vacuum Owner’s Manual

VACUUMING OPERATION

This machine is designed for vacuuming leaves, gras s clippings, and other types of organic litter.

Debris mixed with cans, bottles, and small amounts of sand can be vacuumed; however, it is not this machine's

primary purpose. Vacuuming cans, bottles, and sand will affect the longevity of your machine. In dusty conditions it

maybe necessary to purchase Felt Bag Kit (P/N 840022).

Do not operate if excessive vibration occurs. If excessive vibration occurs, shut engine off immediately and check for

damaged or worn impeller, loose impeller bolt, loose impeller key, loose engine or lodged foreign objects. Note: See

parts list for proper impeller bolt torque specifications. (See trouble shooting section on page 23).

1. Move Shift Lever to correct position (1, 2, or 3) for desired gear.

Gear Shift Lever

2. Squeeze the Drive Clutch lever against the handle to engage the drive.

Drive Clutch Lever

SHUT DOWN

1. Release Drive Clutch Lever to disengage the drive.

2. Pull Throttle Control all the way back to the STOP position.

Part No 840099 16 Form No 082206A

Page 17

MV650SPH Self-Propelled Vacuum Owner’s Manual

CLEARING A CLOGGED NOZZLE

DISCONNECT spark plug wire before servicing unit.

1. Shut engine off and wait for impeller to stop completely.

2. Disconnect spark plug wire.

3. Wearing durable gloves, remove clog.

WEAR durable gloves. Clog may contain sharp materials.

4. Reconnect spark plug wire.

DEBRIS BAG

Debris bags are normal replaceable wear items.

Frequently empty debris to prevent bag overloading with more weight than you can lift.

Bag liners are available for use in various conditions where debris will be vacuumed. (see Bag Liner Options shown

on page 1).

DO NOT place bag on or near hot surface, such as engine.

This vacuum is designed for picking up trash, organic material and other similar debris (see Safety Warnings

page 4-5).

Many vacuums are used where dust is mixed with trash. Your unit can intermittently vacuum in dusty areas.

However, following these rules will help maintain your machine's ability to vacuum in dusty conditions:

•Run machine at idle to quarter throttle.

•Machine or pressure-wash debris bag if normal cleaning does not fully clean bag. Bag should be thoroughly dry

before use.

Having one or more spare Felt Filter (840194) is a good way to reduce down time while dirty bags are being

cleaned.

Be sure engine has come to a complete stop before removing or emptying bag!!.

Form No F082206A 17 Part No 840099

Page 18

MV650SPH Self-Propelled Vacuum Owner’s Manual

HANDLING and TRANSPORTING

Using two people to lift unit is recommended. Lift holding the handle and front of nozzle. Make sure equipment is

properly secured before transporting. See MV650 series specifications on page 3 for unit weight.

NEVER lift the machine while the engine is running.

STORAGE

DO NOT store engine in an enclosed or poorly ventilated area where fuel fumes may

reach an open flame or spark from a furnace, water heater, clothes dryer or similar

devices.

DO NOT drain fuel in an enclosed or poorly ventilated area.

DO NOT smoke when draining fuel.

DO NOT remove gas cap while engine is running.

DO NOT park equipment on a steep grade or slope.

ALWAYS remove spark plug wire when servicing equipment to prevent accidental

starting.

ALWAYS keep hands and feet away from moving or rotating parts.

ALWAYS store fuel in approved safety containers.

If the equipment will not be used for 30 days or more, prepare as follows:

1. Make sure engine is cool.

2. Drain gasoline from carburetor and fuel tank to prevent formation of gum deposits.

3. Run engine until tank is empty and engine runs out of gas.

Fuel stabilizer (such as Sta-Bil

gum deposits during storage. Add stabilizer to gasoline in storage container or fuel tank. Follow

TM

) is an acceptable alternative for minimizing the formation of

stabilizer manufacturer’s instructions to determine proper mix ratio. Run engine at least 10

minutes after adding stabilizer to allow it to reach carburetor.

Part No 840099 18 Form No 082206A

Page 19

MV650SPH Self-Propelled Vacuum Owner’s Manual

MAINTENANCE

PERIODIC MAINTENANCE

Periodic maintenance should be performed at the following intervals:

Maintenance Operation Every

Use

Inspect for worn or damaged parts.

Check for excessive vibration

Inspect for loose parts.

Clean Debris Bag

Lubricate clutch control lever (Use white lithium grease or equiv.)

LOCATION 1

Lubricate height adjuster LOCATION 2

Check drive clutch cable tension.

Replace drive belts.

LOCATION 1 LOCATION 2

Daily or Every

5 Hours

z

z

z

z

Every 25

Hours

z

z

Every 50

Hours

z

Every 100-150

Hours

z

HERE

HERE

Apply lubricant on the zinc die cast barrel. Apply lubricant on the thread.

Form No F082206A 19 Part No 840099

Page 20

IMPELLER REMOVAL

READ all safety instructions before servicing unit.

MV650SPH Self-Propelled Vacuum Owner’s Manual

DISCONNECT spark plug wire before servicing unit.

Tools required:

- 1/2” socket, 3/8” drive

- ratchet, 3/8”

- drive extension, 3/8” drive

- universal joint, 3/8” drive

- pry bar or long screwdriver

- jack stands or similar device adequate to support weight of machine.

1. Wait for engine to cool and disconnect spark plug.

2. Drain fuel and oil from the engine.

3. Remove belt cover by removing 5 screws.

4. Detach drive belt from the transmission pulley by rotating the transmission assembly to relieve belt tension.

5. Remove engine, impeller and mounting plate by removing bolts around outside of housing.

6. Leaving engine fastened to plate, remove impeller bolt and lock washer and slide impeller off crankshaft ( A

puller may be required). CAUTION: Do not drop impeller.

7. If impeller does not slide off crankshaft, place two crowbars between impeller and housing on opposite

sides. Pry impeller away from engine until it loosens. Using a penetrating oil can help loosen a stuck

impeller.

8. If the impeller cannot be loosened, obtain a 1” (25.4mm) longer bolt of the same diameter and thread type as

the impeller bolt. Invert engine and impeller and support engine above ground to prevent recoil damage.

Thread longer bolt by hand into the crankshaft until bolt bottoms. Using a suitable gear or wheel puller

against the bolt head and the impeller back-plate (near the blades), remove impeller from shaft.

9. To reinstall impeller, use a new impeller bolt and lockwasher

10. Tighten impeller bolt. Torque impeller bolt to 50 Ft. Lbs. (68 N.m).

11. Reinstall engine, impeller, and mounting plate onto housing in reverse order of removal.

12. Before connecting spark plug wire, slowly pull engine starting rope to insure that impeller rotates freely.

13. Reconnect spark plug wire.

DRIVE CLUTCH CABLE ADJUSTMENT

READ all safety instructions before servicing unit.

DISCONNECT spark plug wire before servicing unit.

Tools required:

- Ratchet wrench with 6” extension and 3/8” socket.

- Two 10mm open end wrenches.

- Tape measure.

Procedure:

1. Wait for engine to cool and DISCONNECT SPARK PLUG!

Part No 840099 20 Form No 082206A

Page 21

MV650SPH Self-Propelled Vacuum Owner’s Manual

2. Engage the clutch lever then pull the unit back until it stops freewheeling. The clutch lever should engage

around 2 5/16” of travel or 4 inches from tip of lever to handle.

3. Tighten or loosen cable adjuster nut next to the clutch lever until drive engages at 4” from handle.

4. Holding the adjuster nut in place with one wrench tighten cable lock nut firmly.

5. Readjust as needed.

6. RECONNECT SPARK PLUG!

7. Test run unit to insure proper operation after this or any other maintenance procedure.

8. If clutch still will not engage at 4” from handle, remove guard retaining screws and guard.

9. Measure the amount of spring stretch. Spring should measure 1 1/8” when engaged (Lever 4” from handle).

10. Release clutch lever and then move it to engagement position again and hold it, check the spring length to

assure it stayed in adjustment.

11. Re-install guard and fasteners.

cable adjustment

INCREASE

1 1/8"

2 1/16”

4"

from

handle

Loosen

Tighten

DRIVE BELT REMOVAL AND REPLACEMENT

READ all safety instructions before servicing unit.

Tools required:

- 3/8” drive ratchet

- 3/8” and ½” socket wrenches

- 3/8” and 5/16” wrench

Procedure:

1. Wait for engine to cool completely and DISCONNECT SPARK PLUG.

2. Remove guard fasteners and guard.

3. Remove throttle control cable from engine.

4. Unplug wiring harness wire at engine.

5. Tilt transmission input pulley toward engine and remove the belt from it upward.

6. Remove all six screws fastening the engine base plate to the housing.

7. Lift engine assembly from housing.

8. Slide belt inward under the engine and off downward around impeller.

9. Install new belt in reverse order of belt removal.

10. Note: before placing new belt on transmission pulley look under the engine to insure the belt is properly in

11. Install engine assembly in reverse order of removal.

12. RECONNECT THE SPARK PLUG!

DISCONNECT spark plug wire before servicing unit.

the groove of the engine pulley.

Form No F082206A 21 Part No 840099

Page 22

MV650SPH Self-Propelled Vacuum Owner’s Manual

INSTALLING NEW DRIVE CHAIN/ALIGNMENT/TENSION

READ all safety instructions before servicing unit.

DISCONNECT spark plug wire before servicing unit.

Tools required:

- 3/8” drive ratchet with 8” or longer extension.

- 3/8” socket wrench.

- 7/16” and 1/2” socket.

- 7/16” and 1/2” combination wrench.

- “Needle nose” pliers

- Flat head screwdriver

Allow the engine to cool completely and DISCONNECT THE SPARK PLUG.

1. Unfasten and remove the guard.

2. Rotate left rear wheel to bring the chain “master link” into view on the axle

sprocket.

3. Using the needle nose pliers carefully remove master link retaining spring

clip.

4. Slide the master link from the chain and remove the chain.

5. Thread the new chain onto the sprockets, place the ends of the chain on the

axle sprocket, this makes it easier to hold the chain in place when you slide

the new master link in place.

6. Install the new master link and CAREFULLY install the retaining clip.

7. Rotate left rear wheel to find the location where the chain is tightest (there

are always slight variations in the sprockets that make the chain tighter at

places in its rotation).

8. Rotate the axle several times and listen for “popping” or “clacking” this

indicates too much tension on the chain or misalignment of the chain. Skip

to Step 12 if no “popping” or “crackling” occurs.

Improper Chain Tension

9. At the point where the chain is tightest check the chain to for ¼” to ½” total

slack halfway between the axle sprocket and the transmission sprocket.

Skip to Step 11 if the deflection is correct.

10. Loosen 4 nuts holding the bearing bracket (see Fig 1) slide it very slightly

forward to tighten the chain or slide backward to loosen. Tighten 4 nuts

back then check the chain deflection. Repeat this step if necessary.

Improper Chain Alignment

11. Loosen 5 bolts securing the drive system (see Fig 2) slide it left or right

then check the alignment using straight edge. Tighten 5 bolts then repeat

Step 8.

12. Reinstall the guard and all of its fasteners.

13. RECONNECT THE SPARK PLUG.

Fig 1

Fig 2

Part No 840099 22 Form No 082206A

Page 23

MV650SPH Self-Propelled Vacuum Owner’s Manual

WIRING DIAGRAMS

Bag Switch Circuit Schematic Diagram

TROUBLESHOOTING

Problem Possible Cause Solution

Will not vacuum or has poor vacuum

performance.

Abnormal vibration. · Loose or out of balance impeller. · Check impeller and replace if required.

Engine will not start. · Throttle in off position. · Check throttle control (see page 13).

· Dirty or full debris bag or filter. · Clean debris bag and filter. Shake bag clean or

wash.

· Nozzle height set too high or too low. · Adjust nozzle height (see page 14).

· Hose kit cap missing. · Check for hose kit cap.

· Clogged nozzle or exhaust. · Unclog nozzle or exhaust (see page 5)

· Excessive quantity of debris. · Allow air to feed with debris.

· Loose engine. · Check engine.

· Engine not in full choke position. · Check throttle, choke position (see page 13).

· Out of gasoline or bad, old gasoline. · Check gasoline.

· Spark Plug wire disconnected. · Connect spark plug wire.

· Gas valve off. · Turn on gas valve.

· Dirty air cleaner. · Clean or replace air cleaner. Contact a qualified

service person.

· Safety Interlock disengaged on bag plate. · Latch the bag properly or check the bag rod to

see if it is bent.

Engine is locked, will not pull over. · Impeller plugged or clogged. · Remove debris (see page 16).

· Engine problem. · Contact an engine servicing dealer for engine

problems.

No self-propelling · Drive clutch not engaged · Engage the drive clutch lever.

· Transmission not in gear. · Check transmission shift control (see page 16).

· Drive belt worn or broken · Check the drive belt.

· Drive clutch cable out of adjustment or broken. · Check the drive clutch cable (see page 20).

· Spring tension too loose · Check spring legnth (see page 20).

· Drive chain off the sprocket. · Check the drive chain (see page 22).

Self propelled drive will not release · Improper drive clutch cable adjustment or

cable is kinked.

Noisy or broken chain · No chain lubrication. · Lubricate chain.

· Chain misalignment or tension. · Check the drive chain (see page 22).

Form No F082206A 23 Part No 840099

· Check the drive clutch cable (see page 20).

Page 24

MV650SPH Self-Propelled Vacuum Owner’s Manual

ENGINE MAINTENANCE AND REPAIR

Refer to the engine manufacturer’s manual for maintenance and service information. Warranty coverage on the

engine is the responsibility of the engine manufacturer. If your engine requires warranty repair contact your local

servicing engine dealer. Have your engine model number and serial number ready when you contact the dealer. If

you cannot locate a servicing dealer in your area, you may contact the manufacturer’s national service organization

at the following numbers:

American Honda (800) 426-7701

WARRANTY CLAIM PROCEDURE

Should a BILLY GOAT

warranty claim as follows:

• The machine must be taken to the dealer from whom it was purchased or to an authorized Servicing BILLY

GOAT Dealer.

®

machine fail due to a defect in material and/or workmanship, the owner should make a

• The owner must present the remaining half of the Warranty Registration Card, or, if this is not available, the

invoice or receipt.

• The Warranty Claim will be completed by the authorized BILLY GOAT Dealer and submitted to their

respective BILLY GOAT Distributor for their territory Attention: Service Manager. Any parts replaced under

warranty must be tagged and retained for 90 days. The model number and serial number of the unit must be

stated in the Warranty Claim.

• The distributor service manager will sign off on the claim and submit it to BILLY GOAT for consideration.

• The Technical Service Department at BILLY GOAT will study the claim and may request parts to be returned

for examination. BILLY GOAT will notify their conclusions to the distributor service manager from whom the

claim was received.

• The decision by the Technical Service Department at BILLY GOAT to approve or reject a Warranty Claim is

final and binding.

Part No 840099 24 Form No 082206A

Page 25

MV650SPH Self-Propelled Vacuum Owner’s Manual

MAINTENANCE RECORD

Date Service Performed

Form No F082206A 25 Part No 840099

Page 26

MV650SPH Self-Propelled Vacuum Owner’s Manual

ILLUSTRATED PARTS LIST

Nozzle Assembly

Figure 1

Part No 840099 26 Form No 082206A

Page 27

MV650SPH Self-Propelled Vacuum Owner’s Manual

Nozzle Assembly Parts List

PART

ITEM NO.

1 350127 YOKE 1/2 - 20 1

2 350128 PIN YOKE 1/2" 1

3 8024060 BOLT CARRIAGE 3/8-16X1 1/2" ZP 2

4 8172009 WASHER 3/8" SAE ZP 2

5 8161042 NUT LOCK 3/8-16 LT WT THIN ZP 2

6 8041038 SCREWCAP 5/16 -18 x 3 1/2 1

7 8160002 NYLON INSERT LOCKNUT 5/16-18 UNC 3

8 8172020 WASHER FLAT FENDER 5/16 1

9 8161044 NYLON INSERT LOCKNUT 1/2-13 UNC THIN 2

10 8171002 WASHER 1/4" FC ZP 3

11 400424 LABEL WARNING OPEI 1

12 8024050 BOLTCARRIAGE 5\16-18X3 1\2 2

13 520156 ROLL PIN 1/4 X 1 LONG 2

14 8172011 WASHER 1/2" SAE ZP 2

15 840118 NOZZLE MV VAC ASSEMBLY 1

16 840019 CAP 5 IN HOSE VAC 1

17 840024 HANDLE LOWER MV VAC 1

18 840101 WHEEL 14" ASSEMBLY WITH BEARING AND TIRE 2

19 840104 AXLE FRONT WA MV VAC 1

20 840155 BRACKET HGT ADJ WA W/LABEL MV VAC 1

21 8041004 SCREWCAP 1/4 - 20 x 0.75 HWH 1

22 840034 LINK HGT ADJ MV VAC 1

23 840041 BRACKET NOZZLE WEAR GUARD MV VAC 2

24 840029 ROD CONNECT HGT ADJ 1

25 840073 BUSHING 0.5" ID 0.625 OD X X 0.250 1

26 840119 ROD HANDLE CRANK ASSEMBLY 1

27 840057 HANDLE CRANK 0.5 ID X 3.72 LONG 1

28 840078 BUSHING 3/8" ID 1/2" OD X 3/8" LONG 2

29 840158 WASHER LOCK 1/4" TWISTED TOOTH 1

30 840207 NUT PAL 0.5" ID x 0.75 OD 2

31 840135 NOZZLE COVER MV VAC 1

32 840055 LABEL PRODUCT DECAL MV 1

33 840035 SCREW PLASTIC 5/8 8

34 840054 LABEL HGT ADJ MV VAC 1

35 8122082 SCREW SELF-TAP 5/16 NC X 3/4 HEX 2

36 840088 BRACKET NOZZLE COVER REINFORMENT MV 1

37 8024021 BOLT CARRIAGE 1/4-20X0.75 3

38 900455 NUT FLANGE 1/4-20 3

NUMBER DESCRIPTION

MV650SPH

QTY.

Form No F082206A 27 Part No 840099

Page 28

MV650SPH Self-Propelled Vacuum Owner’s Manual

Drive /Rear Axle Assembly

Figure 2

Part No 840099 28 Form No 082206A

Page 29

MV650SPH Self-Propelled Vacuum Owner’s Manual

Drive /Rear Axle Assembly Parts List

PART

ITEM NO.

80 840110 BRACKET TRANS MOUNT WA MV VAC 1

81 350133 BEARING 3/4" W/PILLOW BLOCK 2

82 840009 DIFFERENTIAL 54 TOOTH D-CUT 1

83 840086 BRACKET TRANS ANTI ROTATION MV 1

84 840010 GUARD DRIVE SP VAC 1

85 840085 TRANSMISSION 3 SPD GENERAL TRANS. 1

86 510126 SPROCKET 8 TOOTH 1

87 840066 BELT 3L34 1

88 510125 BEARING 1/2" CLIP 2

89 840011 PLATE TRANS BEARING MOUNT MV VAC 2

90 520025 WASHER LOCK INTERNAL TOOTH 1/2" 1

91 8041004 1/4 - 20 x 0.75 HWH 1

92 430298 WASHER 5/16 LOCK TWISTED TOOTH 2

93 840102 WHEEL 14" ASSEMBLY DRIVE MV VAC 2

94 8024021 BOLT CARRIAGE 1/4-20X0.75 4

95 840028 BRACKET TRANS REINFORCE MV VAC 1

96 8024060 CARRIAGE BOLT 3/8 - 16 X 1 1/2 1

97 840087 PULLEY IDLER 2" OD X 3/8" ID 1

98 840027 TUBE 0.75 ID W HEEL SPACER SP MV VAC 1

99 840158 WASHER LOCK 1/4 TWISTED TOOTH 1

100 8172007 WASHER 1/4" SAE ZP 12

101 8160001 NYLON INSERT LOCKNUT 1/4-20 UNC 4

102 8041036 SCREWCAP 5/16"-18X3" HCS ZP 4

103 8160002 NYLON INSERT LOCKNUT 5/16-18 UNC 4

104 8041026 SCREWCAP 5/16"-18 X 3/4" LONG ZP 2

105 8172009 WASHER 3/8" SAE ZP 2

106 890359 1/4 - 20 x 5/8 HWH 8

107 8122082 SCREW SELF-TAP 5/16 NC X 3/4 HEX 2

108 840072 CHAIN #41 X 42 PITCH 1

109 800242 SPRING TENSION 1

110 8171002 WASHER 1/4" FC ZP 9

111 8172015 WASHER 3/4" SAE ZP 2-6

112 510180 WOODRUFF KEY 1/8 X 1/2 1

113 350146 CLIP 1/2" 3

114 840023 CONTROL SHIFT WESCON MV VAC 1

115 840063 CONTROL LEVER ASSY CLUTCH SP VAC 1

116 8172011 WASHER FLAT 1/2" SAE 2-3

117 8041018 SCREWCAP 1/4"-20X4" HCS ZP 1

118 900327 LABEL DANGER GUARD 1

119 8161042 NUT LOCK 3/8-16 LT WT THIN ZP 1

120 500176 LABEL CLUTCH DRIVE 1

121 840188 BRACKET BEARING FIX 2

122 8041038 SCREWCAP 5/16-18 X 3 1/2 HCS ZP 2

123 8041022 CARRIAGE BOLT 1/4 - 20 X 1 ZP 2

124 8172020 WASHER FENDER 5/16 2

NUMBER DESCRIPTION

MV650SPH

QTY.

Form No F082206A 29 Part No 840099

Page 30

MV650SPH Self-Propelled Vacuum Owner’s Manual

Engine Assembly

Figure 3

Part No 840099 30 Form No 082206A

Page 31

MV650SPH Self-Propelled Vacuum Owner’s Manual

Engine Assembly Parts List

Form No F120905A 31 Part No 840099

ITEM

NO.

50 840069 ENGINE HONDA 6.5 VERTICAL GSV190 1

51 840136 IMPELLER ASSEMBLY SP MV VAC 1

52 840107 PLATE TOP WA SP MV VAC 1

53 840205 HOUSING PLASTIC VAC 1

54 400502 WASHER LOCK 3/8 TWISTED TOOTH 1

55 400268 LABEL HOT ENGINE 1

56 9201087 SQ KEY 2.125 X .187 1

57 840045 CONTROL THROTTLE WESCON MV VAC 1

58 8160001 NYLON INSERT LOCKNUT 1/4-20 UNC 1

59 8172007 WASHER 1/4" SAE ZP 6

60 8172019 WASHER FENDER 1/4 ZP 6

61 8041004 SCREWCAP 1/4 - 20 x 0.75 HWH 6

62 790167 SCREWCAP 3/8-24X2 3/4" W/PATCH LOCK 1

63 900564 SCREWCAP 3/8"-16X2 1/2" TAPTITE 3

64 8177010 WASHER SPLIT LOCK 1/4" 6

65 8041018 SCREWCAP 1/4"-20X4" HCS ZP 1

66 8171002 WASHER 1/4" FC ZP 2

67 840083 SPACER 1.50OD X .890ID X .5 THK 1

80 840215

81 840213

PART

NUMBER DESCRIPTION

TERMINAL 18-14 BLUE T-TAP

SCREWCAP 1/4-20X5/8 GR. 5

MV650SPH

QTY.

1

6

Page 32

MV650SPH Self-Propelled Vacuum Owner’s Manual

Hood Assembly

Figure 4

Part No 840099 32 Form No 082206A

Page 33

MV650SPH Self-Propelled Vacuum Owner’s Manual

Hood Assembly

ITEM

NO.

130 840141 HOOD ASSY W / LABEL MV VAC 1

131 840153 BRACKET BAG CHANNEL RH W/SEAL MV VAC 1

132 840196 SEAL BAG MV VAC 1

133 840037 TUBE HANDLE BRACE RH MV VAC 1

134 840038 TUBE HANDLE BRACE LH MV VAC 1

135 840154 BRACKET BAG CHANNEL RH W/SEAL MV VAC 1

136 840152 BRACKET NOZZLE DOOR ADJ W /LABEL MV VAC 1

137 840195 BAG ASSEMBLY MV VAC 1

138 840138 BAR LIFT NOZZLE DO OR W / GRIP MV VAC 1

139 840061 ROD LIFT NO ZZLE DOOR SP VAC 1

140 840062 PLATE BAG LATCH MV VAC 2

141 840191 GRIP LEVER LIFT 1

142 840058 SW ITCH INTERLOCK VAC 1

143 840077 HARNESS W IRE ASSY MV VAC 1

144 8024025 BOLT CARRIAGE 1/4-20 X 1.75 7

145 8171002 W ASHER 1/4" FC ZP 14

146 8160001 NYLON INSERT LOCKNUT 1/4-20 UNC 13

147 520018 SCREW HEX HEAD #10-24 X 1" 4

148 8172005 W ASHER #10 SAE ZP 8

149 8164005 NYLON INSERT LOCKNUT 10-24 UNC 4

150 900407 Ty-Wrap 6

151 610347 PIN SCREW 1/4-28 1

152 8171003 W ASHER 5/16 FLATW ASHER Z/P 11

153 8160002 NYLON INSERT LOCKNUT 5/16-18 UNC 3

154 610429 SPRING LEVER GZ 1

155 610348 FIBRE W ASHER 1

156 8041032 SCREWCAP 5/16"-18 X 2 ZP 1

157 8041014 SCREWCAP 1/4"-20X3" ZP 1

158 8041006 SCREWCAP 1/4-20X1" ZP 2

159 8041031 SCREWCAP 5/16-18 X 1.75 ZP 2

160

161 8172007 W ASHER 1/4" SAE ZP 6

162 890254 LABEL EAR EYE BREATHING 1

163 890301 LABEL READ 1

164 400886 ROD END BALL JOINT 3/8 NF 2

165 8041052 SCREW CAP 3/8-16X1 1/2 ZP 1

166 8160003 NYLON INSERT LOCKNUT 3/8-16 UNC 2

167 8041056 SCREWCAP 3/8"-16X2 1/2" ZP 1

168 840197 SEAL BAG FRONT HOOD 20.5 LONG 1

169 8149003 NUT REG 3/8-24 NF 2

170 8041004 SCREWCAP 1/4"-20X3/4" HCS ZP 1

171 8172019 W ASHER FENDER 1/4 ZP 2

172 8041018 SCREWCAP 1/4"-20X4" HCS ZP 1

173 840071 NUT ACORN 1/4-20 2

174 810736 LABEL DANGER FLYING DEBRIS 1

175 840080 LABEL NO ZZLE DOO R MV VAC 1

178 8024021 BOLT CARRIAGE 1/4-20 X 3/4" 5

180 840214 BRACKET HOO D FRONT STRAIGHTENER 1

184 840180 PLATE SHIFT CONTROL ANTI ROT 1

185 8059140 SCREWCAP #10-24X1 1/4" 1

186 840179 LABEL HO OD DECAL 1

190 840040 ROD BAG W A MV VAC 1

191 840139 LATCH RUBBER ASSEMBLY MV VAC 2

192 360203 PAL NUT 0.312 2

193 840189 BAG DEBRIS MV VAC 1

194 840206 GROMMET RUBBER 5/8" OD X 3/8" ID 2

PART

NUMBER DESCRIPTION

MV650SPH

QTY.

Form No F120905A 33 Part No 840099

Page 34

NOTES:

MV650SPH Self-Propelled Vacuum Owner’s Manual

Part No 840099 34 Form No 082206A

Loading...

Loading...