Billy Goat MV601SPE, MV650SPHDS, MV650SPH Owner's Manual

MVSP Owner’s Manual

CASTER KIT

Use on hard surface

P/N 840129

HOSE KIT

For vacuuming hard

P/N 840116

BAG LINER KIT

To collect leaves,

P/N 840134

FELT BAG KIT

Use on all dusty

P/N 840194

LINER KIT

Interior housing liner

P/N 840201

NOT FOR REPRODUCTION

lf-Propelled Multi-Vac Owner’s Manual

Se

MV650SPH, MV601SPE, and MV650SPHDS

for maneuverability.

IMPORTANT- READ CAREFULLY BEFORE USE AND KEEP FOR FUTURE REFERENCE.

Part No 840245 1 840245_B_LO

to reach areas.

Beginning Serial #: 020516001

Accessories

thatch, and grass.

Original Instructions

conditions.

to decrease housing

wear.

MVSP Owner’s Manual

Go to http://www.billygoat.com for French-Canadian translations of the product manuals.

Visitez http://www.billygoat.com pour la version canadienne-française des manuels de produits

NOT FOR REPRODUCTION

CONTENTS

SPECIFICATIONS AND SAFET 3

INSTRUCTION LABELS 4

ASSEMBLY INSTRUCTIONS 5-6

OPERATION 7-9

MAINTENANCE AND TROUBLESHOOTING 10-15

ILLUSTRATED PARTS LIST 16-24

DECLARATION OF CONFORMITY 25-27

Part No 840245 2 840245_B_LO

MVSP Owner’s Manual

NOT FOR REPRODUCTION

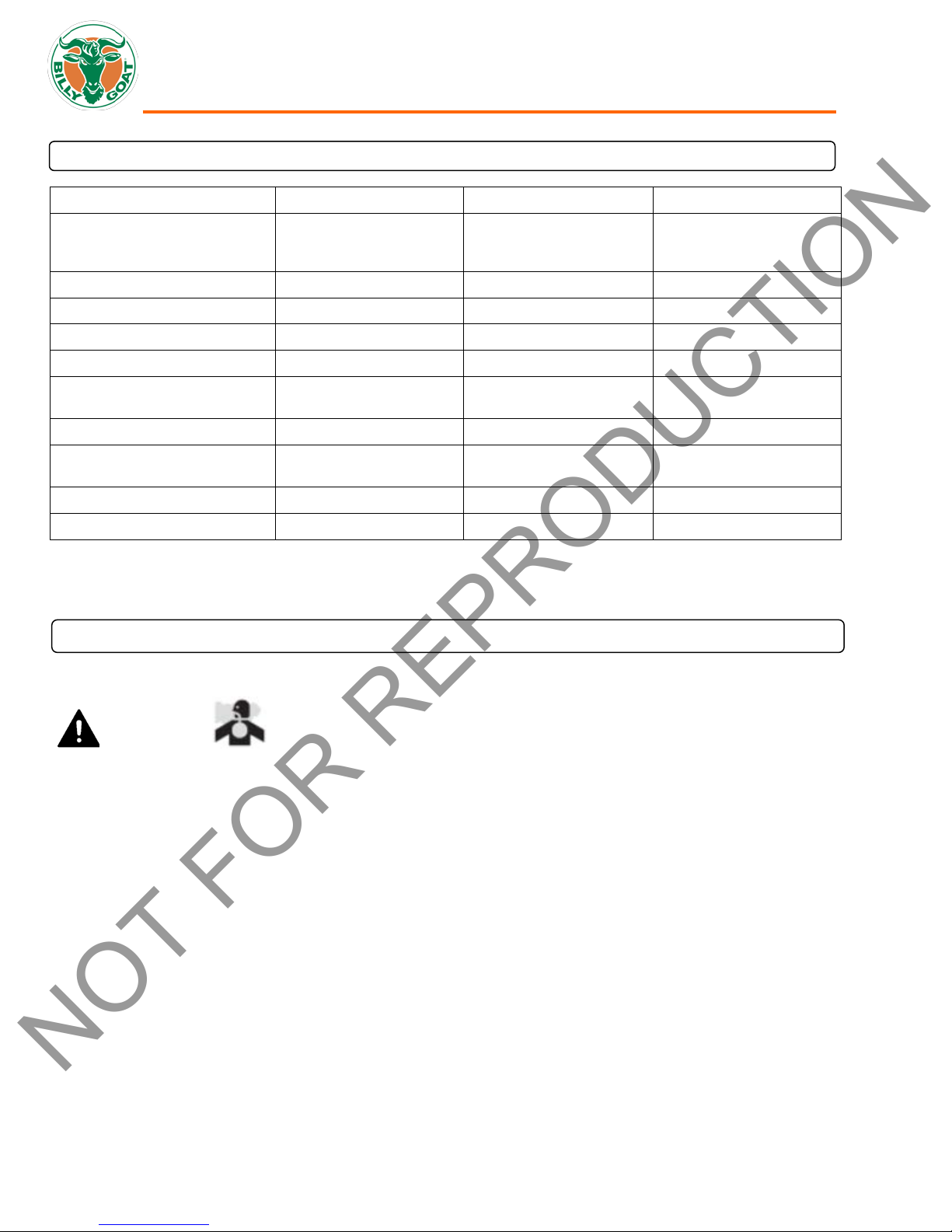

SPECIFICATIONS

MV650SPH MV601SPE MV650SPHDS

Engine Type Honda GSV190LN1L Briggs and Stratton

Professional Series

121S02-0110-F1

Horsepower 6.5 (4.85 kW) 5.0 (3.73 kW) 6.5 (4.85 kW)

Fuel Capacity 1.6 qt (1.5 L)

Oil Capacity 0.58 qt (0.54L)

Unit Weight 179 lbs (81.2 kg) 204 lbs (92.5 kg) 179 lbs (81.2 kg)

Overall Dimensions 28” Wide x 62.5” Long x

45.5” High

Maximum Operating Slope 20o 20o 20o

In compliance with 2000/14/EEC

standards

Sound at Operators Ear 83 dB(a) at 3320 rpm 89 dB(a) 83 dB(a) at 3320 rpm

Vibration at operator position 1.43g(14.00 m/s2) 1.28g (12.57 m/s2) 1.43g(14.00 m/s2)

103 dB(a) at 3320 rpm 105.5 dB(a) 103 dB(a) at 3320 rpm

1.2 qt. (1.14 L)

0.56 qt. (0.53 L)

28” Wide x 62.5” Long x

45.5” High

Honda GSV190LN1L

1.6 qt (1.5 L)

0.58 qt (0.54L)

28” Wide x 62.5” Long x

45.5” High

SAFETY

WARNING

his product can expose you to chemicals including gasoline engine exhaust, which is known to the State

T

of California to cause cancer, and carbon monoxide, which is known to the State of California to cause

birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

Part No 840245 3 840245_B_LO

MVSP Owner’s Manual

NOT FOR REPRODUCTION

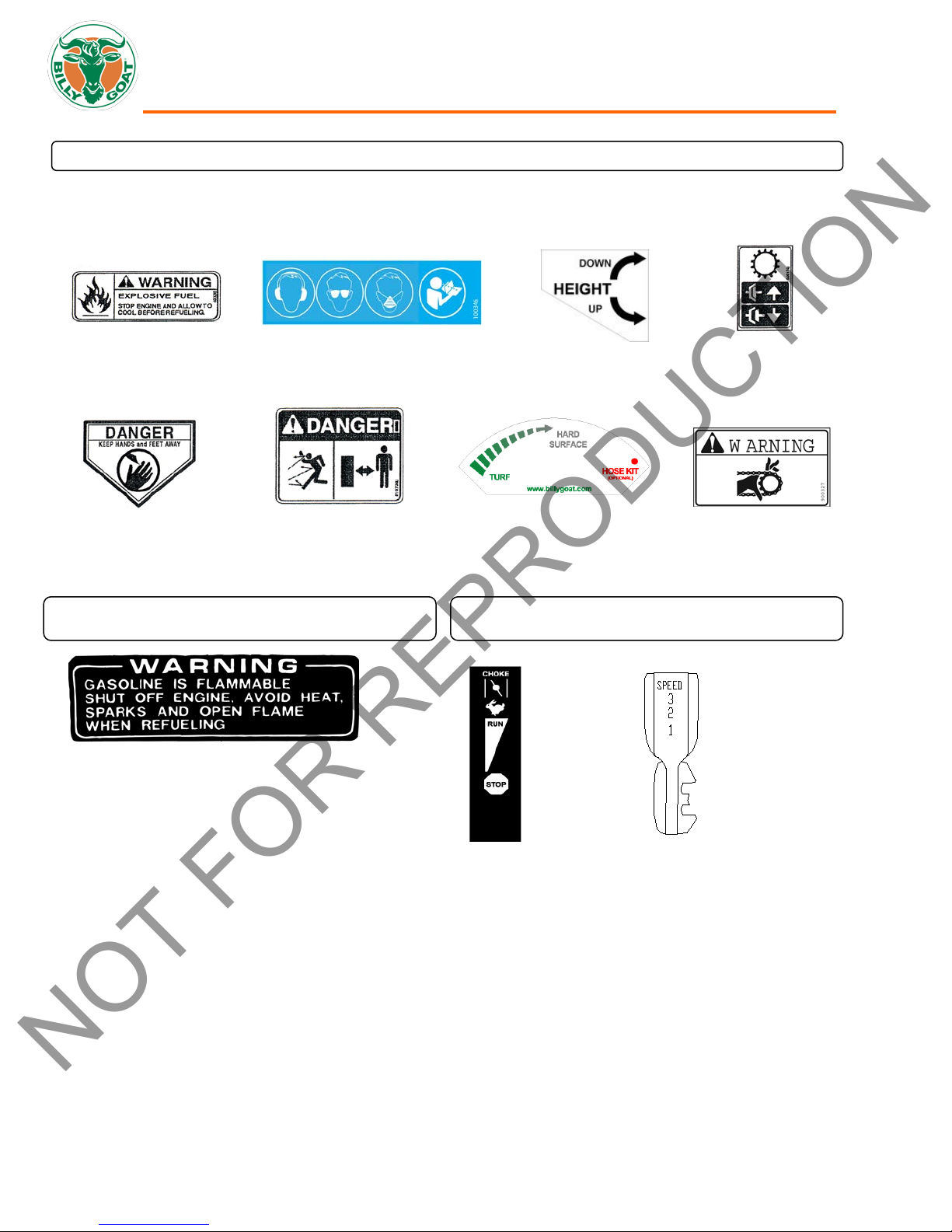

INSTRUCTION LABELS

The labels shown below were installed on your BILLY GOAT® MV Vacuum. If any labels are damaged or missing, replace them

before operating this equipment. For your convenience in ordering replacement labels, part numbers are included in the Illustrated

Parts List. The correct position for each label may be determined by referring to the Figure and Item numbers shown.

LABEL FUEL WARNING LABEL EAR EYE BREATHE READ LABEL HEIGHT ADJUST LABEL CLUTCH

ITEM 55 P/N 400268 ITEM 162 P/N 100346 ITEM 34 P/N 840054 ITEM 120 P/N500176

LABEL DANGER LABEL DANGER LABEL DOOR OPENING LABEL GUARDS

ITEM 11 P/N 400424 ITEM 174 P/N 810736 ITEM 175 P/N 840080 ITEM 118 P/N 900327

ENGINE LABELS CONTROLS

Throttle Drive

P/N 840045 P/N 510127

Part No 840245 4 840245_B_LO

MVSP Owner’s Manual

1st

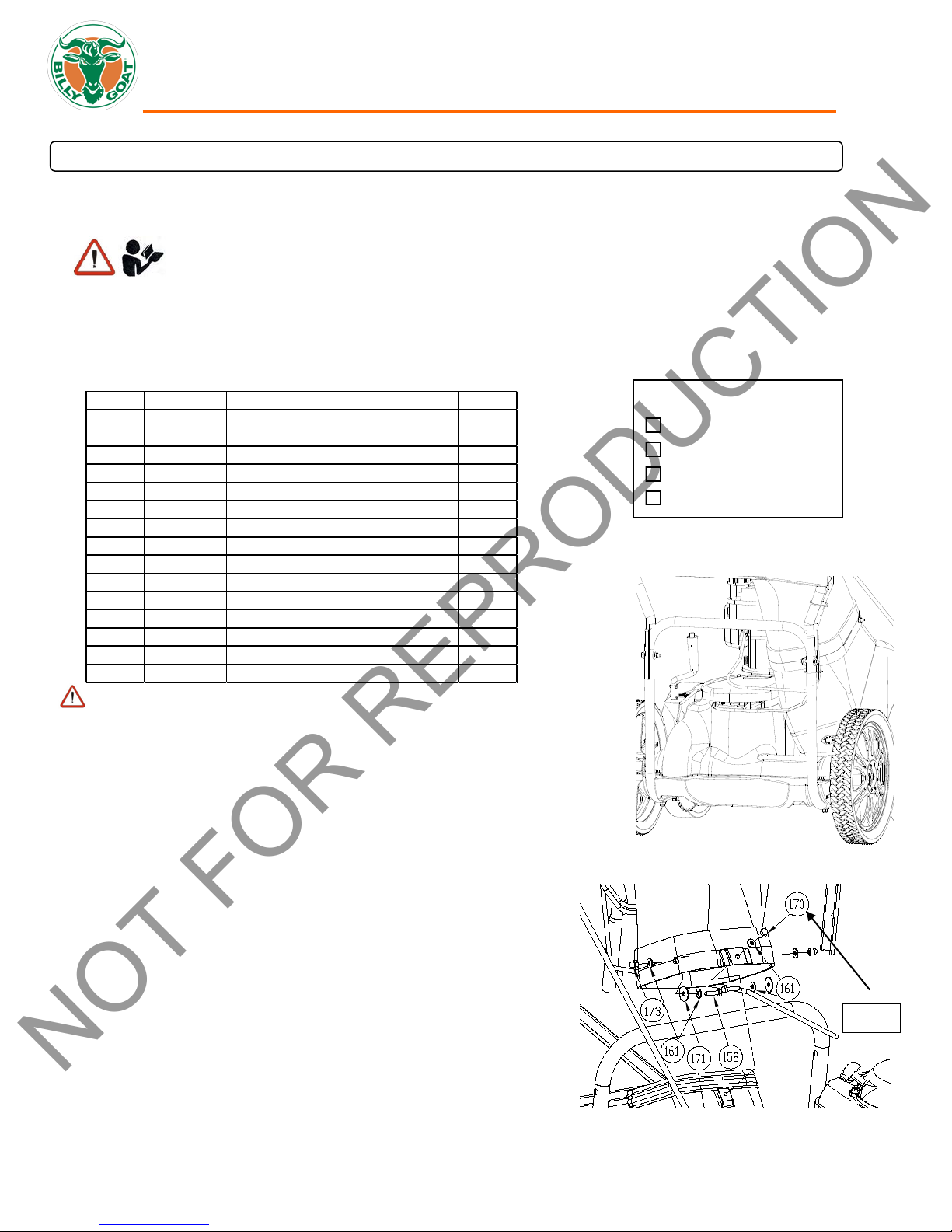

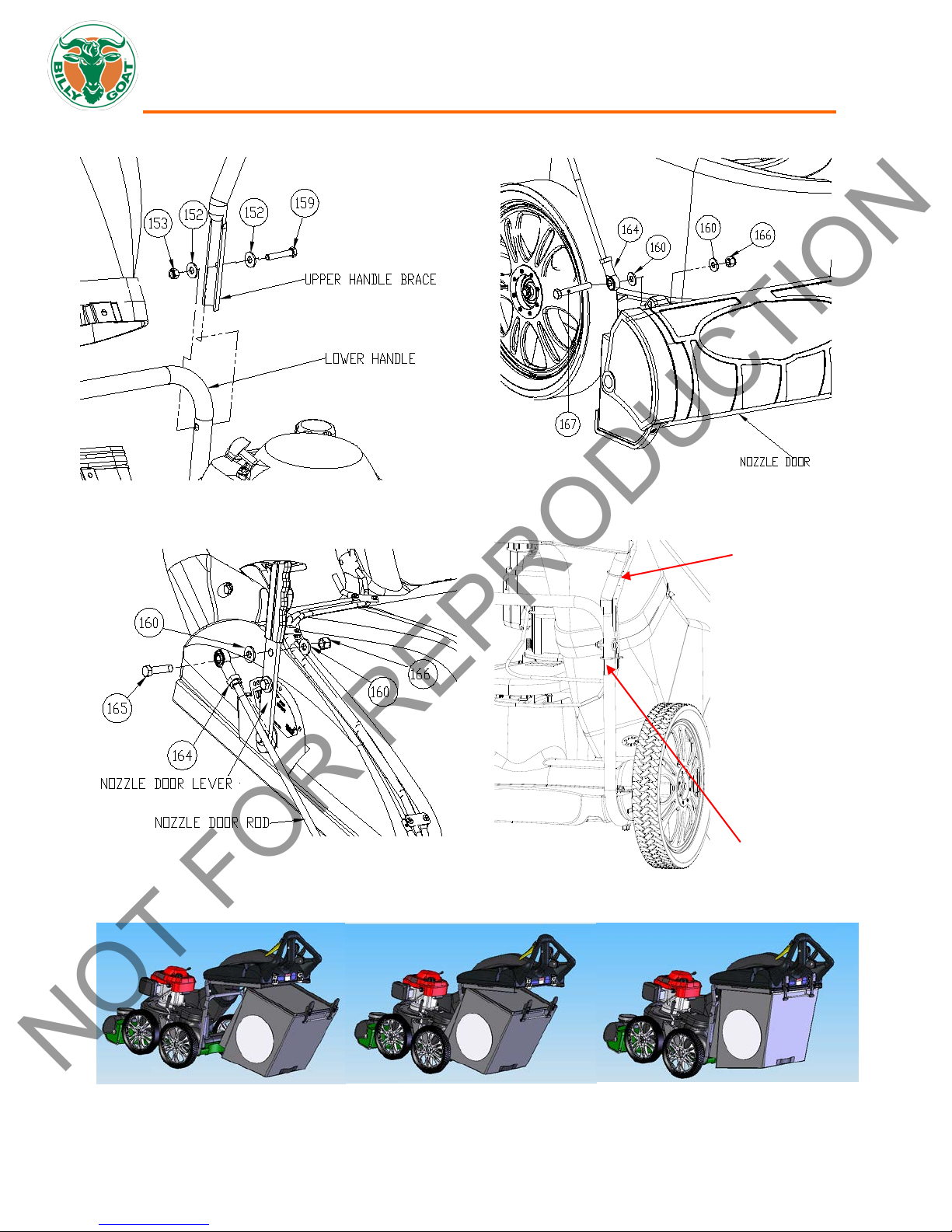

ITEM NO. PART NO. DESCRIPTON QTY

139 840061 ROD LIFT NOZZLE DOOR 1

150 900407 TY- WRAP 2

152 8171003 WASHER 5/16" FLAT ZP 4

153 8160002 NUT LO CK 5/16"- 18 2

158 8041006 SCREW CAP 1/4"- 20 X 1" Z P 2

159 8041031 SCREW CAP 5/16" X 1 3/4" ZP 2

160 8171004 WASHER 3/8 FLAT 4

161 8172007 WASHER 1/4" SAE Z P 5

164 400886 ROD END BALL JOINT 3/8" NF 2

165 8041052 SCREW CAP 3/8" - 16 X 1 1/2" Z P 1

166 8160003 NUT LO CK 3/8"-16 2

167 8041056 SCREW CAP 3/8" - 16 X 2 1/2" Z P 1

170 8041004 S CRE W CAP 1/4"-20 X 3/4" HCS ZP 1

171 8172019 WASHE R FENDER 1/4" ZP 2

173 840071 NUT ACORN 1/ 4"-20 2

READ all safety instructions before assembling unit.

Boxing Parts Checklist

Ty-wraps (2 ea)

PARTS BAG & LITERATURE ASSY

Warranty card P/N- 400972, Owner’s Manual P/N-840245, General Safety and Warnings Manual P/N-100294, Declaration of

Fig. 1

1. Attach hood assembly to the housing then hold in place during step 2.

Fig. 2

NOT FOR REPRODUCTION

ASSEMBLY INSTRUCTIONS

Your BILLY GOAT® MV Vacuum was shipped in one carton, completely assembled except for the Hood/Upper Handle Assembly.

Mounting hardware for the Hood/Upper Handle Assembly is temporarily installed on the lower handle and the Housing Assembly.

TAKE CAUTION when removing the unit from the box. The Hood/Upper Handle Assembly is attached to the

unit by cables.

Conformity P/N-840204

PARTS BAG HARDWARE

Honda 6.5 Engine

B&S 6 Engine

Parts bag P/N-840187

DISCONNECT spark plug wire before assembling unit.

NOTE: be sure all cables are routed on the underside of the hood and

housing. (See Fig. 1)

2. Install (item 170) center bolt first when aligned with a nut on the housing.

(See Fig. 2)

3. Attach rest of hood assembly to the housing using corr esp onding

hardware. NOTE: You will have to insert the bolt/washer from the inside

by reaching through the hood. (See Fig. 2)

4. Attach upper handle brace to lower handle using corresponding hardware.

Then repeat this step on the other side

5. Attach rod end (i

tightening jam nut. (See Fig. 4 next page)

6. Attach nozzle door rod to the nozzle door using corresponding hardware.

NOTE: It is easier to do this with nozzle door closed.

7. Attach rod end to rod (See Fig. 5 next page).

8. Attach nozzle door rod to the lever with nozzle door closed and lever in

hose kit position. NOTE: Check to see that the nozzle door opens and

closes all the way (see page 15). Tighten or loosen the rod end (item 164)

for any adjustments. (See Fig. 4 and 5 next page)

9. Install cable ty wraps.

10. Reconnect spark plug wire.

11. Attach the bag.

Part No 840245 5 840245_B_LO

tem 164) to the nozzle door rod then secure in place by

(See Fig. 7)

. (See Fig. 3 next page)

MVSP Owner’s Manual

HERE

HERE

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

NOT FOR REPRODUCTION

Part No 840245 6 840245_B_LO

MVSP Owner’s Manual

1 2 3 4 6

5

Secure unit at the handle with left

hand during start.

Pull rope starter with right

hand.

On Electric

DO NOT START equipment without the debris bag in place.

2. Pull the throttle control all the way back to the STOP position.

Fig. 8

Fig. 9

NOT FOR REPRODUCTION

OPERATION

This vacuum is designed for picking up trash, organic material and other similar debris. It should not be used for other purposes

than what is intended.

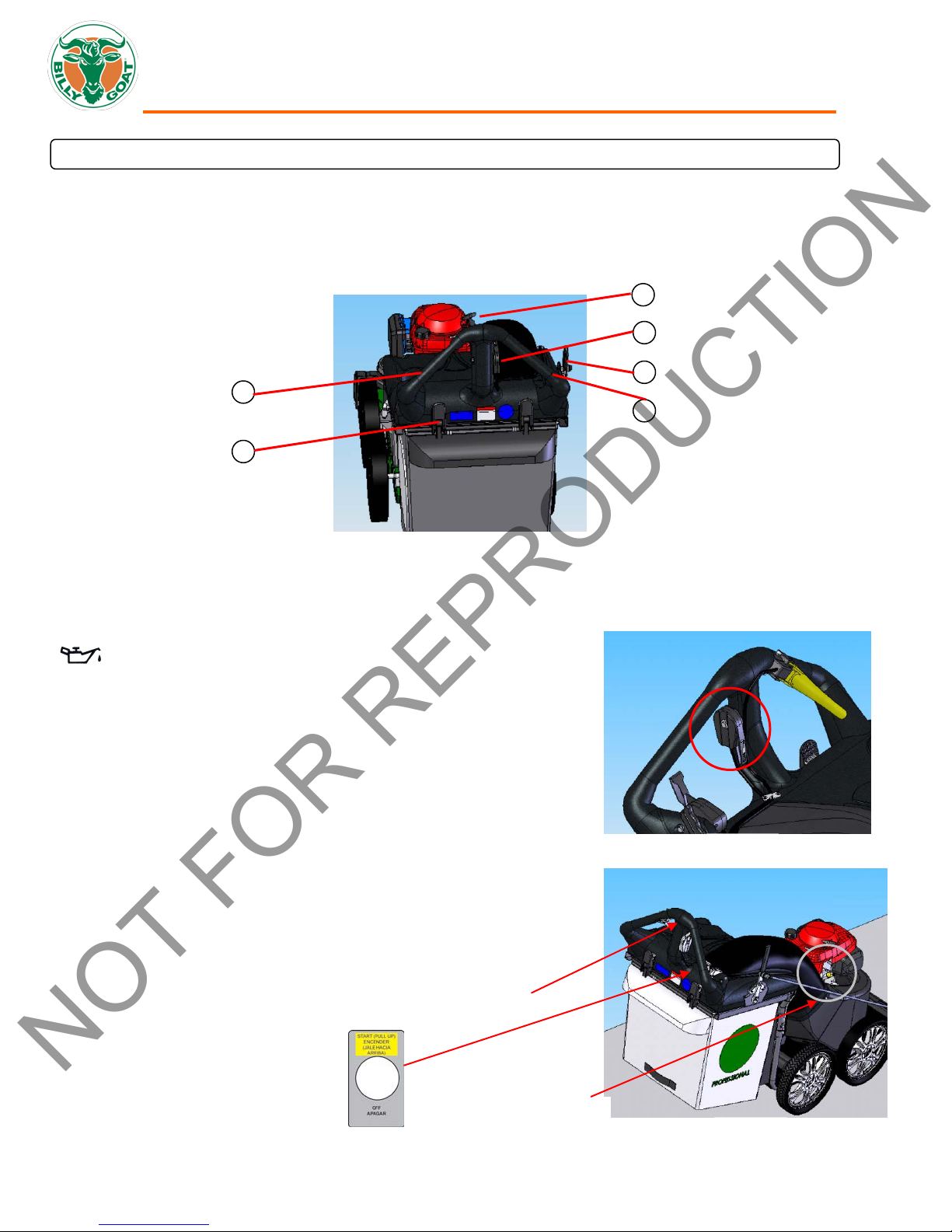

OPERATOR

The operator’s position is at the rear of the machine between the handlebars. The operator should STAND in a position to allow

both handlebars to be grasped firmly, which allows sufficient leverage to steer the machine. Operator’s controls are shown below.

CONTROLS

1 Drive Clutch Lever 2 Bag Latch 3 Pull Starter

4 Throttle Control 5 Drive Shifter Control 6 Nozzle Door Adjuster

STARTING

CHECK engine oil level before operating machine.

1. Place equipment on a level, firm surface that is free of rocks or other

debris.

2. Place throttle in START position.

3. Secure the unit with left hand at the handle then pull starter rope with right

hand to start engine. NOTE: Pull starter cord slowly until resistance is felt.

Then pull cord rapidly to avoid kickback.

4. Move throttle control back to FAST position and allow engine to reach

correct operating speed.

5. For Electric models: Set the throttle to the fast position, then pull up and

push forward on the start switch. Choke if needed.

DOWN

SHUT

1. Release the drive clutch lever to disengage the drive.

Operator Control Locations

models only.

Part No 840245 7 840245_B_LO

MVSP Owner’s Manual

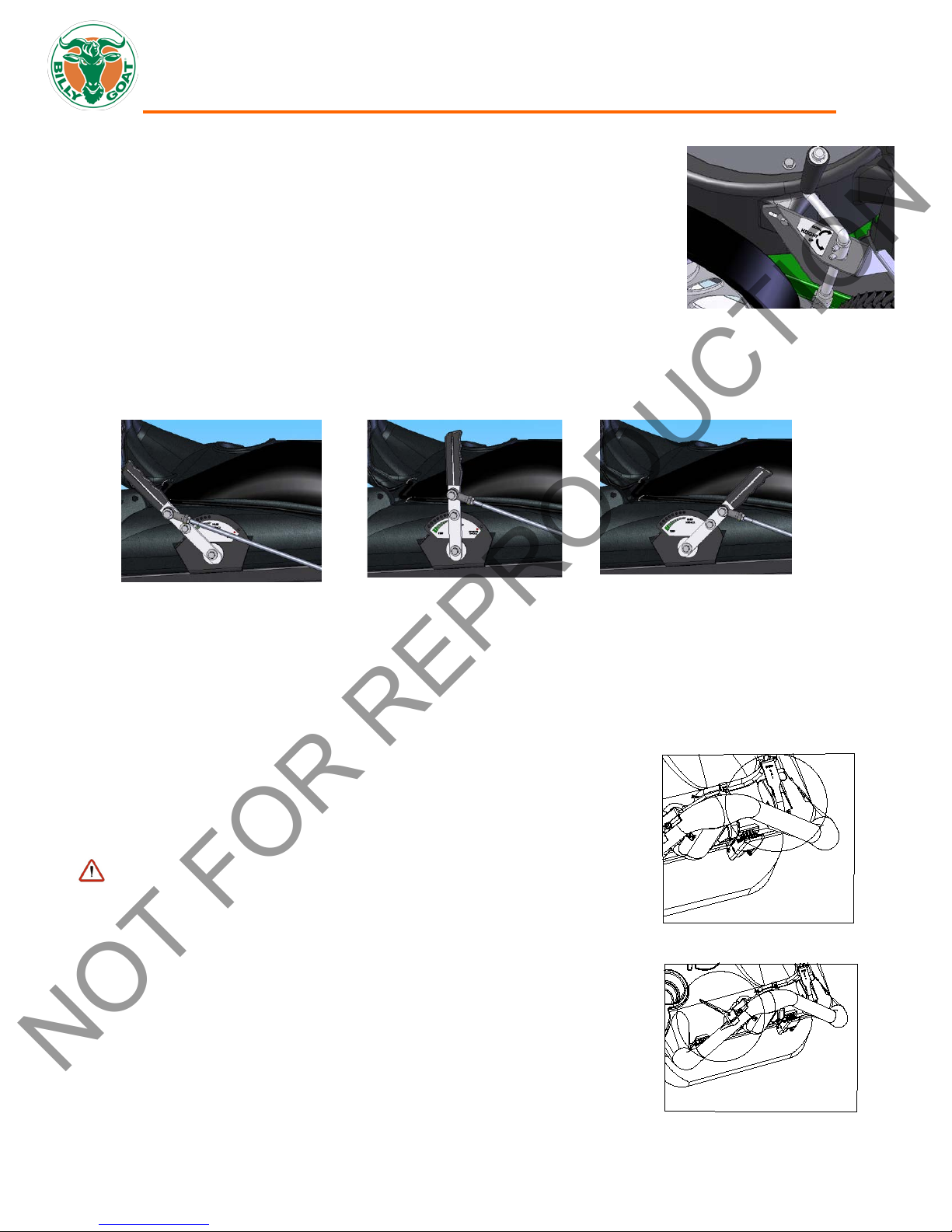

For maximum pickup: Adjust nozzle height as close to debris as possible, but

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Fig. 14

1. Move shift lever (right side) to correct position (1, 2, or 3) for desired gear. (See Fig. 14)

2. Squeeze the drive clutc h lever against the handle to engage the drive. (See Fig. 15)

Fig. 15

NOT FOR REPRODUCTION

VACUUM NOZZLE HEIGHT ADJUSTMENT

without blocking airflow into the nozzle. NOTE: Never bury nozzle into debris. The

vacuum nozzle is raised and lowered by turning the crank handle clock wise and

counter-clockwise. (See Fig. 10)

VACUUM NOZZLE DOOR ADJUSTMENT

The vacuum nozzle door adjusts for the maximum performance under various applications.

• W

ith the handle fully back the nozzle is fully opened. This is ideal for turf application. (See Fig. 11)

• For hard surface applications, set the handle midway. (See Fig. 12)

lose nozzle for use with the Optional Hose Kit (P/N 840116). This adjustment is ideal to use with the Hose Kit. (See

• C

Fig. 13)

VACUUMING OPERATION

This machine is designed for vacuuming leaves, grass clippings, and other types of organic litter.

Debris mixed with cans, bottles, and small amounts of sand can be vacuumed; however, it is not this machine's primary purpose.

Vacuuming cans, bottles, and sand will affect the longevity of your machine. In dusty conditions it maybe necessary to purchase

Felt Bag Kit (P/N 840022).

Do not operate if excessive vibration occurs . If excessive vibration occurs, shut engine off immediately and check for damaged or

worn impeller, loose impeller bolt, loose impeller key, loose engine or lodged foreign objects. Note: See parts list for proper

impeller bolt torque spec ifications. (See page 13 Impeller removal).

CLEARING A CLOGGED NOZZLE

DISCONNECT spark plug wire before servicing unit.

1. Shut engine off and wait for impeller to stop c ompletely.

2. Disconnect spark plug wire.

3. Wearing durable gloves, remove clog. Caution: clog may contain sharp materials.

4. Reconnect spark plug wire.

Part No 840245 8 840245_B_LO

MVSP Owner’s Manual

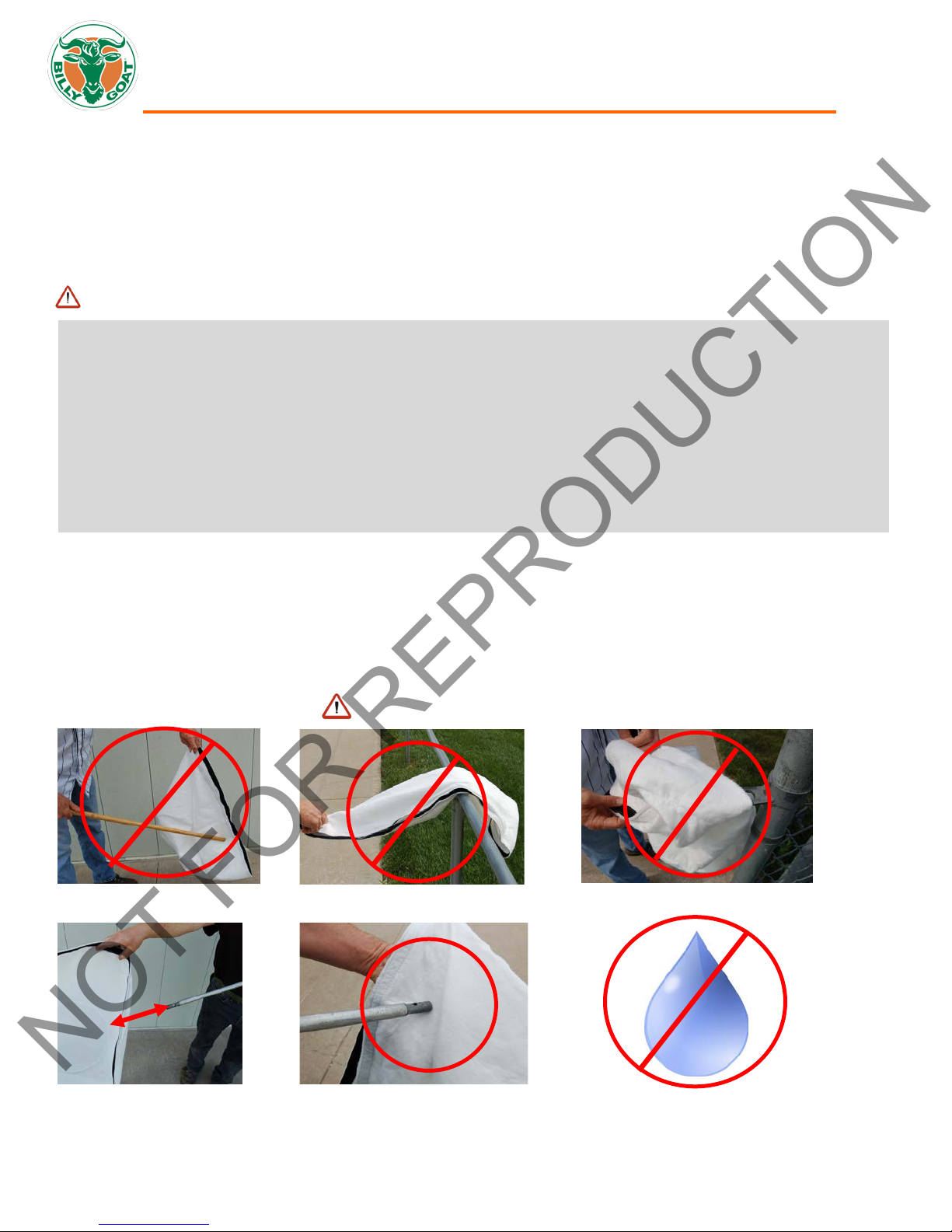

LIGHTLY CLEAN WITH COMPRESSED AIR ONLY, FROM THE OUTSIDE IN.

KEEP THE NOZZLE 6-12 INCHES FROM FABRIC

6”-12”

305mm)

*****TIPS*****

DO NOT GET WET

NOT FOR REPRODUCTION

DEBRIS BAG

Debris bags are normal replaceable wear items.

Bag liners are available for use in various conditions where debris will be vacuumed. (See Bag Liner Accessories shown on pg 1).

MV650SPHDS Only – The dust sock provided wi ll trap dust when vacuuming up dry debris only. The dust sock will need to be

removed periodically and the dust will need to be dumped out as it will accumulate over time. The dust sock can be easily

removed and reattached by separating it from the Velcro strip on the bag underneath.

DO NOT place bag on or near hot surface, such as engine.

Be sure engine has c ome to a complete stop before removing or emptying bag!

Frequently empty debris to prevent bag overloading with more weight than you can lift .

Many vacuums are used where dust is mixed with trash. Your unit can intermittently vacuum in dusty areas. However, following

these rules will help maintain your machine's ability to vacuum in dusty conditions:

• Run machine at idle to quarter throttle.

• Machine or pressure-wash debris bag if normal cleaning does not fully clean bag. Bag should be thoroughly dry before use.

Having one or more spare bags (P/N 840189) is a good way to reduce down time while dirty bags are being cleaned.

Felt Bag (P/N 840194) accessory is great when used in dusty conditions

.

DUST SOCK CARE AND MAINTENANCE (MV650SP HDS only)

Purpose: The dust sock acts as a secondary filter lowering the amount of dust that escapes the bag.

Dust socks are to be used in dry and dusty conditions ONLY. Using the dust sock in damp or wet condi tions may damage the

dust sock and decrease the effectiveness of the filt er.

The dust sock may be installed by simply attachi ng the mating Velcro strips between the bag and the dust sock. Over time the

dust sock will begin to fill with dust during use. Periodically remove the dust sock, empty the loose dust out and clean the sock.

For a light clean, simply shake the sock, for a deep clean, see below. To remove the sock, simply separate the Velcro.

Dust Sock Care Information:

DO NOT STRIKE THE BAG WITH OR AGAINST OBJECTS DO NOT SNAG THE BAG

(152mm-

Dust Socks are normal replaceable wear items. Replacement P/N 840261

Part No 840245 9 840245_B_LO

Loading...

Loading...