Page 1

KVSP/TKVSP Owner’s Manual

BILLY GOAT KV VACUUM

Owner's Manual

KV600SP, KV650SPH, TKV650SPH, KV600SPFB, KV650SPHFB,

TKV650SPHFB

Accessories

ON BOARD

VACUUM

HOSE KIT

4"(102mm) x

7.5' (2.13m)

For vacuuming

in hard to reach

areas.

P/N 891125

OPTIONAL

FELT/MESH

DEBRIS BAG

For use in

leaves and

grass in dusty

conditions.

P/N 891126

FELT BAG/

891132

MESH BAG

NOZZLE WEAR

GUARD KIT

For use in

increasing the

life of your

nozzle by

protecting it from

damage

P/N 891127

CASTER KIT

To allow for

easy rolling and

maneuverability

on smooth

surfaces.

P/N 891128

SHREDDER

KIT

Shreds

leaves,

reducing total

volume.

P/N 890209

KV LINER KIT

Increases the

life of the

housing by

protecting it from

damage.

P/N 891134

PROTECTIVE

COVER

Protects the

machine from

the environment

when not in use.

P/N 891137

Part No 891204 Form No F060911E

1

Page 2

KVSP/TKVSP Owner’s Manual

CONTENTS

SPECIFICATIONS AND SOUND/VIBRATION 3

INSTRUCTION LABELS 4

PACKING CHECKLIST & ASSEMBLY 5

OPERATION 6-7

MAINTENANCE _ 8-10

TROUBLESHOOTING ____________________________ 11

ILLUSTRATED PARTS & PARTS LISTS 12-14

Go to http://www.billygoat.com for French-Canadian translations of the product manuals.

Visitez http://www.billygoat.com pour la version canadienne-française des manuels de produits

Part No 891204 Form No F060911E

2

Page 3

KVSP/TKVSP Owner’s Manual

g (

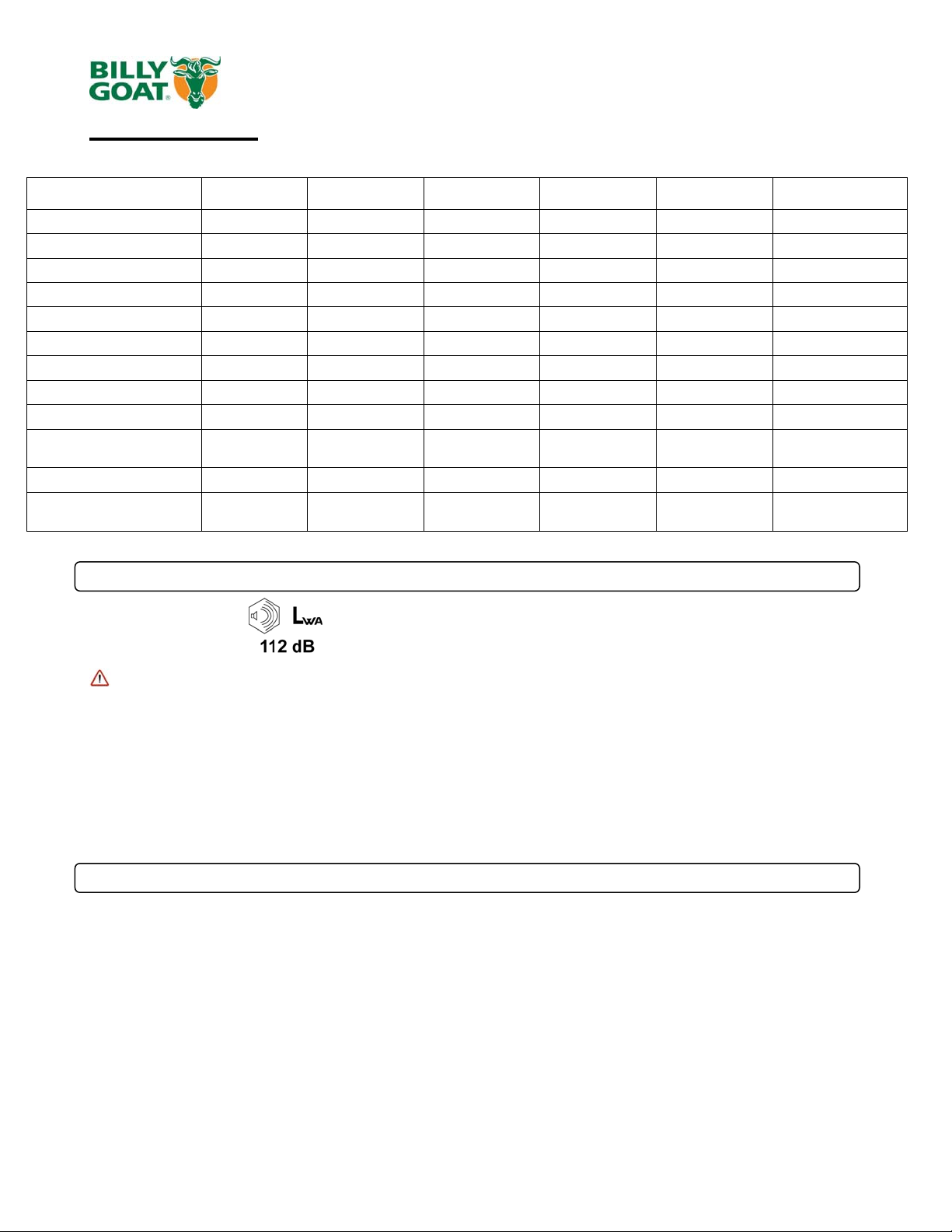

Specifications

KV600SP KV650SPH TKV650SPH KV600SPFB KV650SPHFB TKV650SPHFB

Engine: HP 6.0 (4.47kW) 6.5 (4.85kW) 6.5 (4.85 kW) 6.0 (4.47kW) 6.5 (4.85kW) 6.5 (4.85 kW)

Engine: Type B&S Quantum HONDA HONDA B&S Quantum HONDA HONDA

Engine: Model 112K020124E1 GSV190AN1L GSV190AN1L 112K020124E1 GSV190AN1L GSV190AN1L

Engine: Fuel Capacity 1.5 qt. (1.4 L) 1.6 qt. (1.5 L) 1.6 qt. (1.5 L) 1.5 qt. (1.4 L) 1.6 qt. (1.5 L) 1.6 qt. (1.5 L)

Engine: Oil Capacity 0.63 qt. (0.6 L) 0.58 qt (0.54L) 0.58 qt (0.54L) 0.63 qt. (0.6 L) 0.58 qt (0.54L) 0.58 qt (0.54L)

Total Unit Weight: #129 (58.5 kg) #132 (58.9 kg) 141# (64 kg) #129 (58.5 kg) #132 (58.9 kg) 141# (64 kg)

Overall Length 59” (1.5m) 59” (1.5m) 59” (1.5 m) 59” (1.5m) 59” (1.5m) 59” (1.5 m)

Overall Width 25.5” (.6 m) 25.5” (.6 m) 25.5” (.6 m) 25.5” (.6 m) 25.5” (.6 m) 25.5” (.6 m)

Overall Height 42.75” (1.1m) 42.75” (1.1m) 42.75” (1.1 m) 42.75” (1.1m) 42.75” (1.1m) 42.75” (1.1 m)

Max. operating slope 200 200 200 200 200 200

Sound in accordance with

2000/14/EEC standards

Sound at operator’s ear 88 dBa 89 dBa 91 dBa 88 dBa 89 dBa 91 dBa

Vibration at operator

position

SOUND

Sound tests were conducted in accordance with 2000/14/EEC, and were performed on 7-25-07 under the conditions listed below.

Sound power level listed is the highest value for any model covered in this manual. Please refer to serial plate on the unit for the sound

power level for your model.

General Conditions: Sunny

Temperature: 88

Wind Speed: 2 mph (3.8 kmh)

Wind Direction: South South East

Humidity: 44%

Barometric Pressure: 30.07”H

VIBRATION DATA

Vibration levels at the operator’s handles were measured in the vertical, lateral and longitudinal directions using calibrated vibration test

equipment. Tests were performed on 12-19-2007 under the conditions listed below.

General Conditions: Sunny

Temperature: 50

Wind Speed: 4 mph (6.4kph)

Wind Direction: South Southeast

Humidity: 68%

Barometric Pressure: 30 Hg (101.6kpa)

109 dBa 109 dBa 112 dBa 109 dBa 109 dBa 112 dBa

0.71 g

(6.96m/s

2

)

0.32 g (3.16m/s

2

) 0.43 g (4.25m/s2) 0.71 g (6.96m/s2) 0.32 g (3.16m/s2) 0.43 g (4.25m/s2)

SOUND LEVEL 92 dB(a) at Operator Position

o

F (31.1oC)

VIBRATION LEVEL 0.34g (3.29m/s

2

)

o

F (10oC)

764 mm Hg)

Part No 891204 Form No F060911E

3

Page 4

KVSP/TKVSP Owner’s Manual

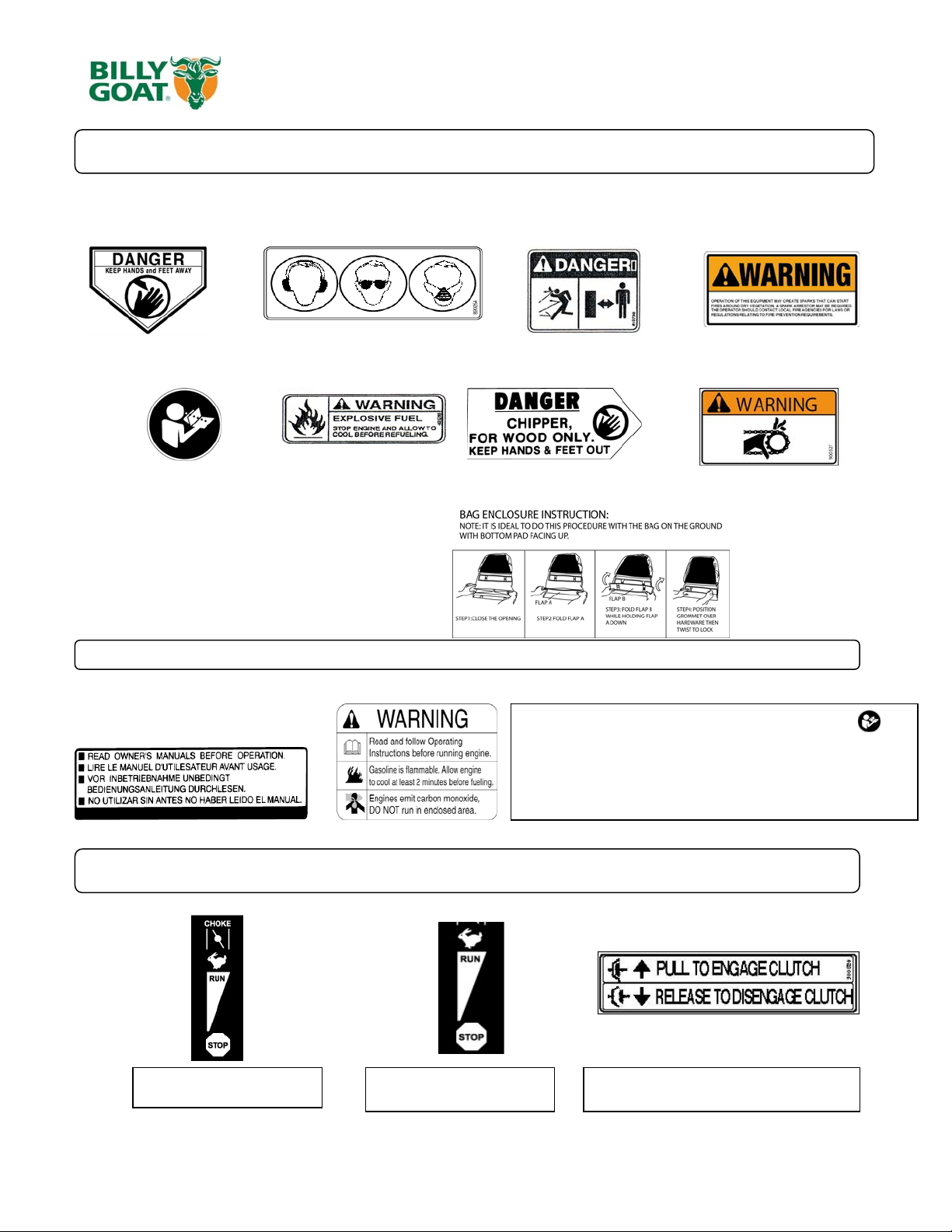

INSTRUCTION LABELS

The labels shown below were installed on your BILLY GOAT ® KV Vacuum. If any labels are damaged or missing, replace them before operating

this equipment. Item numbers from the Illustrated Parts List and part numbers are provided for convenience in ordering replacement labels. The

correct position for each label may be determined by referring to the Figure and Item numbers shown.

LABEL DANGER KEEP HANDS

AND FEET AWAY

ITEM #18 P/N 400424

LABEL READ MANUAL LABEL EXPLOSIVE FUEL CHIPPER WARNING LABEL LABEL DANGER GUARD

ITEM #17 P/N 890301 ITEM # 16 P/N 400268 ITEM #82 P/N 890152 (TKV ONLY) ITEM #39 P/N 900327

ENGINE LABELS

ENGINE and Transmission CONTROLS

HONDA BRIGGS & STRATTON

Honda Throttle Control

LABEL EAR EYE BREATHING ITEM #20

P/N 890254

BAG FOLDING INSTRUCTIONS

LOCATED ON BAG

Briggs Throttle Control Bail Drive Engage/Disengage label

DANGER FLYING DEBRIS

ITEM # 19 P/N 810736

Read Owner’s Manual Before Operating.

Lire le manuel d’utilisation avant la mise en route.

Vor Inbetriebnahme Bedienungs - und Wartungsanleitung lesen.

Favor leer las instrucciones de operacion antes de operar el motor.

Consultare il Manuale Uso e Manutenzione prima dell utilizzo.

Las Skotselinstruktionen Innan Start.

LABEL SPARK ARRESTOR

P/N 100252

Part No 891204 Form No F060911E

4

Page 5

KVSP/TKVSP Owner’s Manual

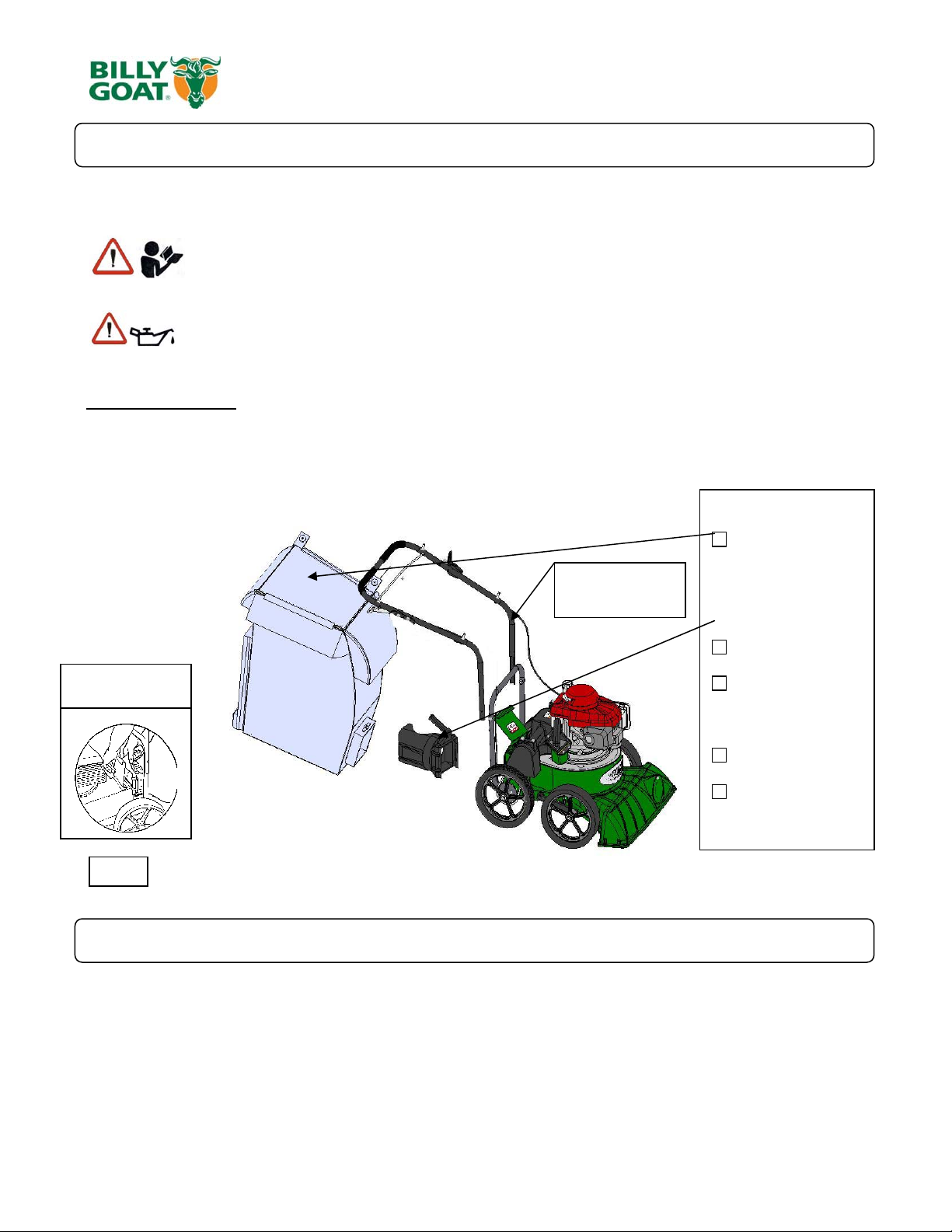

PACKING CHECKLIST

Your Billy Goat KV Vacuum is shipped from the factory in one carton, completely assembled except for the

upper handle, debris bag, and bag quick disconnect.

READ all safety instructions before assembling unit.

TAKE CAUTION

cables and folded over

when removing the unit from the box the Handle Assembly is attached by

PUT OIL IN ENGINE BEFORE STARTING

PARTS BAG &

LITERATURE ASSY

Warranty card P/N- 400972, Owner’s Manual P/N-891204, General Safety and Warnings Manual P/N100294, Declaration of Conformity P/N-891057, Ty-wraps 900407 qty 2.

Use Ty-wraps

here

Quick disconnect

Boxing Parts

Checklist

Debris Bag

P/N-891132

OR

Felt Bag

P/N-891126

Literature Assy

P/N-891121

Connector Quick

Disconnect

P/N-890176

Honda 6.5

GSV 190

Briggs & Stratton

6.0 HP Quantum

Fig. 2

ASSEMBLY

1. ASSEMBLE Lift upper handle (item 11), remove items 49, 50, & 51 from lower handle (item 10). Attach and

secure upper handle as shown using same hardware.

2. UNFOLD the debris bag (item 21) and fasten bag neck to bag quick disconnect (item 12). Attach firmly to

housing exhaust (item 1) see fig. 2.

3. ATTACH bag to four posts (item 13), preassembled to upper handle.

4. CONNECT spark plug wire.

Part No 891204 Form No F060911E

5

Page 6

KVSP/TKVSP Owner’s Manual

p

OPERATION

VACUUMING OPERATION

VACUUM NOZZLE HEIGHT ADJUSTMENT: Nozzle height is raised and lowered by rotating the red knob

near the left rear wheel. Nozzle height should be adjusted based on the task being performed.

FOR MAXIMUM PICKUP: Adjust nozzle close to debris, but without blocking airflow into the nozzle. NOTE:

Never bury nozzle into debris.

CLEARING A CLOGGED NOZZLE & EXHAUST: Turn engine off and wait for impeller to stop completely

and disconnect spark plug wire. Wearing durable gloves, remove clog. Danger, the clog may contain sharp

materials. Reconnect s

ark plug wire.

DEBRIS BAG

(OPTIONAL DEBRIS BAGS ARE AVAILABLE FOR CHANGING CONDITIONS)

Debris bags are normal replaceable wear items.

Note: Frequently empty debris to prevent bag overloading with more weight than you can lift.

An optional felt bag is available for use where debris will be vacuumed in dusty conditions (see Optional Accessories

shown on page 1).

DO NOT place bag on or near hot surface, such as engine. Be sure engine has come to a complete stop before removing or

emptying bag.

This vacuum is designed for picking up trash, organic material and other similar debris (see Safety Warnings

page 4-5).

However, many vacuums are used where dust is mixed with trash. Your unit can intermittently vacuum in dusty areas.

Dust is the greatest cause of lost vacuum performance. However, following these rules will help maintain your

machine's ability to vacuum in dusty conditions:

• Run machine at idle to quarter throttle.

• The debris bag must be cleaned more frequently. A vacuum with a clean, pillow soft bag will have good pickup

performance. One with a dirty, tight bag will have poor pickup performance. If dirty, empty debris and vigorously shake

bag free of dust.

• Pressure-wash debris bag if normal cleaning does not fully clean bag. Bag should be thoroughly dry before use.

NOTE: Having one or more spare debris bags is a good way to reduce down tim e while dirty bags are being cleaned.

DO NOT leave debris in bag while in storage.

Part No 891204 Form No F060911E

6

Page 7

KVSP/TKVSP Owner’s Manual

COMPOST

Vacuumed leaves, grass and other organic material from your own yard can be emptied into a pile or composter to

provide enriched soil for later use as fertilizer in gardens and flower beds

NOTE: Allow green chips to dry before spreading around living plants.

MULCH

Wood chips made from branches in your own yard make excellent mulch. A thick blanket of wood chi ps around

plants and flowers to keeps weeds out and moisture in.

CHIPPER OPERATION (TKV only)

Your TKV chipper is designed to process tree branches and limbs up to 2"

(50.8mm) diameter.

Several small branches can be grouped together and fed together into the

chipper (see figure right).

When feeding forked branches, squeeze forks together and feed into chipper

entrance (DO NOT overload). If forks are too large, use a pair of loppers to trim

forks down to size. A lopper storage bracket is provided on every unit (loppers

are not included)

Clearing a clogged chipper (TKV only)

Under normal circumstances, allow time for machine to clear all wood

from chipper hopper before stopping engine. Otherwise, remaining

pieces of wood will jam inside of chipper when engine stops. (See

Tamper below).

Disconnect spark plug wire.

Remove debris bag quick disconnect from debris outlet on machine.

Wearing durable gloves, access impeller through debris outlet on fan housing

and rotate impeller counter clock wise to dislodge and remove jam and remove

debris from hopper with tongs or equivalent. Reconnect debris bag quick

disconnect to machine.

Reconnect spark plug wire.

TAMPER (TKV only)

Before turning machine off, use the Tamper to slowly push remaining pieces of

wood through the chipper. This can prevent any remaining wood from jamming

in the chipper when machine is turned off.

Do not leave tamper on the ground, store tamper in the chipper hopper.

Part No 891204 Form No F060911E

7

Page 8

KVSP/TKVSP Owner’s Manual

MAINTENANCE

PERIODIC MAINTENANCE

Periodic maintenance should be performed at the following intervals:

Maintenance Operation Every Use (daily) Every 5 hrs (daily) Every 25 Hours

Inspect for loose, worn or damaged parts.

Clean Debris bag

Check bag strap tightness

Engine (See Engine Manual)

Check for excessive vibration

IMPELLER REMOVAL

1. Wait for engine to cool and disconnect spark plug.

2. Drain fuel and oil from the engine.

3. Remove bag, quick release and upper handle. Do not kink, stretch, or break control cables, control

housings, or end fittings while removing handles.

4. Remove the transmission cover, idler pulley, transmission and the belt from the transmission.

5. Remove the transmission plate and the housing top plate by removing bolts around outside of housing.

6. Leaving engine fastened to top plate; turn it upside down so the impeller is on top.

7. Remove impeller bolt and lock washer.

8. Lift impeller upward. If impeller slides freely, proceed to (step 10).

9. If the impeller does not loosen, obtain a 3/4-16x3” (Billy Goat part #440192) or longer bolt. Thread bolt by

hand into nut until bolt rests against the shaft. Tighten the bolt slowly, which will pull the impeller away from the

shaft, remove impeller from shaft. Using a penetrating oil can help loosen a stuck impeller.

10. Using a new impeller bolt, lockwasher, and washer, reinstall new impeller in reverse orde r.

11. Tighten impeller bolt. Torque impeller bolt to 33-38 Ft. Lbs. (44-51 N.m) (see item 45 on page 15).

12. Reinstall engine onto housing in reverse order of removal make sure the belt is inside the two fingers on

the belt plate and that the belt is on the transmission pulley before securing the transmission.

13. Gas and oil.

14. Reconnect spark plug wire.

z

z

z

z

DRIVE CHAIN REPLACEMENT AND ALIGNMENT

1. Wait for engine to cool and disconnect spark plug.

2. To replace a chain, first prop up the rear of the machine with small blocks to get the rear wheels off of the

ground.

3. Remove the transmission cover, and the belt from the transmission.

4. Remove the bolts on both sides of the transmission holding the flange bearings; this should give enough

slack to slip the chain off.

4. Replace the old chain with a new one.

5. Once the chain is on, put the bolts back into the flange bearings and tighten.

6. Finally, make sure the wheels rotate freely. If not, loosen the bearings and shift them to get the chain

running straight up and down.

7. Reassemble the transmission components removed in steps 1-3 in reverse order.

Part No 891204 Form No F060911E

8

Page 9

KVSP/TKVSP Owner’s Manual

p

BELT TENSION ADJUSTMENT

DO NOT ADJUST WHILE THE MACHINE IS RUNNING!

1. Wait for engine to cool and disconnect spark plug.

2. Remove the transmission cover

3. Using two ½” wrenches loosen the two nuts on the cable that connects to the idler arm.

4. The setting of the tension on the belt is controlled by the distance on the threads of the cable. To loosen

tension, move the position towards the end of the threads and in the opposite direction to tighten.

5. Check the travel of the idler arm by engaging the bail, which the drive should start to engage when the bail

is 2 ½ inches away from the handle. The spring, at a relaxed state should be 1.5 inches long on the coil, and

when the bail is in contact with the handle it should be 1.75 inches long. If the belt is too tight it can cause

premature failure and if it is too loose it can come off of the pulley.

6. When satisfied with the position, place the transmission cover back into place and secure. Then run the

machine to make sure the transmission is engaging properly. If the drive will not engage or will not disengage

repeat the previous steps.

Spring length

1.5”- resting

1.75”- bail at

handle

BELT REPLACEMENT

1. Wait for engine to cool and disconnect spark plug.

2. Drain fuel and oil from the engine.

3. Remove bag, quick release and upper handle. Do not kink, stretch, or break control cables, control

housings, or end fittings while removing handles.

4. Remove the transmission cover, idler pulley, transmission and the belt from the transmission.

5. Remove the transmission plate and the housing top plate by removing bolts around outside of housing.

6. Leaving engine fastened to top plate, turn it upside down so the impeller is on top.

7. Remove impeller bolt and lock washer.

8. Lift impeller upward. If impeller slides freely, proceed to (step 10).

9. If the impeller does not loosen, obtain a 3/4-16x3” (Billy Goat part #440192) or longer bolt. Thread bolt by

hand into nut until bolt rests against the shaft. Tighten the bolt slowly, which will pull the impeller away from the

shaft, remove impeller from shaft. Using a penetrating oil can help loosen a stuck impeller.

10. Place the new belt on the shaft.

11. Using a new impeller bolt and lockwasher, reinstall new impeller in reverse order.

12. Tighten impeller bolt. Torque impeller bolt to 33-40 Ft. Lbs. (44-54 N.m) (see item 45 on page 15).

13. Make sure the belt is in the groove on the impeller and feed it through the hole in the top plate.

14. Reinstall engine onto housing in reverse order of removal make sure the belt is inside the two fingers on

the belt plate and that the belt is on the transmission pulley before securing the transmission.

15. Gas and oil.

16. Reconnect s

ark plug wire.

Part No 891204 Form No F060911E

9

Page 10

KVSP/TKVSP Owner’s Manual

CHIPPER BLADE REMOVAL AND SHARPENING (TKV ONLY)

Chipper blades are normal replaceable wear items.

DANGER Chipper blade is sharp. Replace any damaged blade.

Depending on the type and amount of wood being chipped, the chipper blade will eventually get dull, losing it’s

cutting ability. Evidence of a dull blade is a noticeably reduced chipping abilit y or a rough cut on end of branch.

Note: The chipper blade gap is factory set and should be checked each time impeller is removed from engine

crankshaft and reset if required. If reassembly requires a different quantity of shim washers, Billy Goat® shim

washer must be used.

1. Follow the steps 1-6 on the impeller removal instructions.

2. Using a 3/16" Allen wrench and 1/2" open end wrench, remove chipper blade from impeller.

3. Sharpen blade by lightly grinding the cutting edge of the blade at 40 degrees (see figure below). It is not

necessary to remove all nicks from the cutting edge. CAUTION: Be careful to avoid heat buildup in the blade

during sharpening. This will reduce it’s heat- treated hardness properties and will reduce blade life. Evidence of

too much heat build-up is a change of color along sharpened edge.

4. The same chipper blade can be sharpened several times. However, blade replacement is required when

blade no longer overhangs the chip relief hole in impeller back plate or if increased vibration occurs (see fig

below).

5. Chipper blade installation is in reverse order of removal.

Correct Incorrect

Blade

400

Edge of chip

relief hole

Part No 891204 Form No F060911E

10

Page 11

g

(

)

g

Troubleshooting

Abnormal vibration. · Loose or out of balan ce impeller or

Will not vacuum or has poor

vacuum performance

Problem Possible Cause Solution

Engine will not start. · Throttle in off position. Engine not in full

Engine is locked, will not pull

over.

Nozzle scrapes ground in

lowest height setting.

No self-propellin

Self propelled drive will not

release

Noisy or broken chain · No chain lubrication. · Lubricate chain.

Unit does not free-wheel

backwards

Too much dust coming from

bag.

KVSP/TKVSP Owner’s Manual

loose engine

· dirty debris bag. Hose kit cap missing.

·Clogged nozzle or exhaust. Excessive

quantity of debris.

· Improper nozzle height

choke position. Out of gasoline. Bad or

old gasoline. Sparkplug wire

disconnected. Dirty air cleaner

· Debris lock ed in impeller. Engin e

problem.

Nozzle height out of adjustment

· Drive bail not engaged · Engage the drive bail.

· Drive belt worn or broken · Check the drive belt.

· Drive clutch cable out of adjustment or

broken.

· Drive chain off the sprocket. · Check the drive chain

· Improper dr ive clutch cable adjustment

or cable is kinked.

· Chain misali

· None · Push the unit slightly forward then the

· Vacuuming very dry, brittle or small

debris

nment or tension. · Check the drive chain (see page 12).

· Check impeller and replace if required.

Check engine

· Clean debris bag. Shake bag clean or

wash. Check for hose kit cap. Unclog

nozzle or exhaust. Allow air to feed with

debris

· Adjust nozzle height so that it is closer

to the debris

· Check stop switches, throttle, choke

position and gasoline. Connect spark

plug wire. Clean or replace air filter. Or

contact a qualified service pers on.

· See page 5. Contact a engine service

dealer for engine problems

Adjust nozzle height (See Nozzle height

fine adjustment for hard surfaces on

page 5

· Check the drive clutch cable (see page

12).

· Check the drive clutch cable (see page

.

13

unit will free-wheel

· Switch to felt bag (see page 1

accessories)

see page 12).

Part No 891204 Form No F060911E

11

Page 12

KVSP/TKVSP Owner’s Manual

PARTS DRAWING KVSP/TKVSP

KVSP Top Plate

Assembly

Part No 891204 Form No F060911E

12

Page 13

KVSP/TKVSP Owner’s Manual

PARTS LIST KVSP/TKVSP

ITEM

NO.

1 MAIN FRAME HOUSING KV 891100-S 1 891100-S 1 891100-S 1

2 NOZZLE ASSEMBL Y TKV 891110-S 1 891110-S 1 891110-S 1

3 AXLE WA KV MICR O 891138 1 891138 1 891138 1

4 PLATE TOP WA KVSP 891101-S 1 891101-S 1 891107-S 1

5 IMP E LLE R SERR ATED 14. 25 W A KVSP 891104-S 1 891104-S 1 891109-S 1

6 DOOR EX H AUST ASSY RAW 890148-01 1 890148-01 1 890148-01 1

7 WASHER 1/ 2" SAE Z/P 8172011 4 8172011 4 8172011 4

8 WHEE L ASSY 12" X 2.5" TREAD 900509 2 900509 2 900509 2

9 ENGINE 6. 5 HP HON D A GSV190AN1L - - 840069 1 840069 1

EN G I NE 6 BRI GG SAND STRATTON 8906 22 1 - - - 10 L OW E R H AN D L E KV 891050 1 891050 1 891050 1

11 HAND LE UPPER K VSP 891054-S 1 891054-S 1 891054-S 1

12 QUICK D I SCON NEC T 890176 1 890176 1 890176 1

13 PIN CLEVI S 3/8" x 2. 125" L ON G 520120 4 520120 4 520120 4

14 RETAINER 360279 4 360279 4 360279 4

15 GRIP H ANDLE 1"X 9.5" LG 430342 2 430342 2 430342 2

16 LABEL HOT ENGINE EN /SP 100261 1 - - - 17 LABEL READ 890301 1 890301 1 890301 1

18 LABEL WARN ING DANGER 400424 2 400424 2 400424 2

19 LABEL DANGER FLYING DE BRIS 810736 1 810736 1 810736 1

20 LABEL EAR EYE BREATHING 890254 1 890254 1 890254 1

21 BAG DEBRIS NO ZIP P ER K V 891132 1 891132 1 891132 1

22 CABLE THROTTLE ASSY 42" W/ CHOK E 891036 1 891027 1 891027 1

23 J BOLT 3/8-16 X 6" 891071 1 891071 1 891071 1

24 C ABLE C LUTCH DRIVE ASSY 40" KVSP 891032 1 891032 1 891032 1

25 LABEL CLUTCH VQ 900328 1 900328 1 900328 1

26 BRACK ET TRANS MOUNT WA KV 891106 1 891106 1 891106 1

27 ARM IDLER D RI VE W A KV 891105 1 891105 1 891105 1

28 TRANS SINGLE SPEED W /DI FF 891020 1 891020 1 891020 1

29 SPROCKET 8 TOOTH #43 OR #65 891022 2 891022 2 891022 2

30 CHAIN #43 X 58 PI TCH E S 891023 2 891023 2 891023 2

31 GUARD DR IVE K V 891004-S 1 891004-S 1 891004-S 1

32 BEARING 1/2" P R ESSED STEEL HOUSING 891025 2 891025 2 891025 2

33 BRACKET TRANS FIX KV 891012 1 891012 1 891012 1

34 PLATE CHAIN R EI N FORC E K V 891014 2 891014 2 891014 2

35 PULLEY IDLE R 2" OD X 3/ 8" ID 840087 1 840087 1 840087 1

36 SPRIN G TEN SION 800242 1 800242 1 800242 1

37 BAIL CL UTCH WA KVSP 891102 1 891102 1 891102 1

38 BRACK ET ID L ER BELT FIN GER KV 891028 1 891028 1 891028 1

39 LABEL DANGER GUARD 900327 1 900327 1 900327 1

40 WH E EL ASSY SP 26T SPROC K E T 890242 2 890242 2 890242 2

41 SPACER 1.50OD X .890ID X . 5 THK - - 840083 1 840083 1

42 W ASHER LOC K 3/8 ST MED 8177012 1 8177012 1 8177012 1

43 SQ KE Y 2.125 X . 187 9201087 1 9201087 1 9201087 1

44 NUT LOCK 3/ 8-16 THIN 8161042 1 8161042 1 8161042 1

45

BAG DEBRIS FELT (FB MOD E LS) 891126 1 891126 1 891126 1

SCR EWCAP 3/8-24 x 3 1/2 GR. 8 W/PA TCH

Description

KV600SP/KV600SPFB

PART NUMBER

440151 1 440151 1 440151 1

KV650SPH/KV650SPHFB

QTY

PART NUMBER

TKV650SPH/TKV650SPHFB

QTY

PART NUMBER

QTY

Part No 891204 Form No F060911E

13

Page 14

KVSP/TKVSP Owner’s Manual

46 SCRE W CAP 1/ 4 - 20 x 5/8 H WH 890359 26 890359 26 890359 24

47 BOLT IDLE R 3/8-16 X 1 1/2 800888 1 800888 1 800888 1

48 WASHER 1/ 4" SAE ZP 8172007 17 8172007 17 8172007 17

49 WASHER 5/ 16 FLATWASHER Z/ P 8171003 19 8171003 19 8171003 19

50 SCRE WCAP 5/16-18 X 1. 75 ZP 8041031 8 8041031 8 8041031 8

51 NUT LOCK 5/ 16-18 8160002 8 8160002 8 8160002 8

52 NYLON IN SERT LOC KNUT, 3/ 8-16 UN C 8160003 2 8160003 2 8160003 2

53 SCR EWC AP 1/ 4-20 X 3/4" 8041004 2 8041004 2 8041004 2

54 NYLON IN SERT LOC KNUT, 1/ 4-20 UN C 8160001 12 8160001 12 8160001 15

55 SC R EWC AP #10-14 X 3/ 4" HWH ZP 891043 3 891043 3 891043 3

56 1/ 2-13 C AP N UT NP W/PATCH 890530 4 890530 4 890530 4

57 SCR E W CAP 1/4-20 x 1 3/ 4 H CS ZP 8041009 1 8041009 1 8041009 1

58 SCREW CAP 1/ 4-20x2" 8041010 1 8041010 1 8041010 1

59 BELT 3L310 891026 1 891026 1 891026 1

60

61 NOZZLE TOP H ALF KV 891002 1 891002 1 891002 1

62 NOZZLE BOTTOM HALF KV 891003 1 891003 1 891003 1

63 PLUG HOUSING K D LB 900146-01 1 900146-01 1 900146-01 1

64 SC R EW PL ASTIC 1/ 4-20 X 1 891039 8 891039 8 891039 8

65 WASHER 1.5 OD X . 453 I D X .25 THK 440153 1 440153 1 440153 1

66

67 SPROCKET 65A26 26 TOOTH 890238 2 890238 2 890238 2

68

69 SCREW SEL F TAP 1/4 x 0. 75 900505 10 900505 10 900505 10

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

91

92

93

94

95

96

97

98

99

100

105

SCREW PL ASTITE 1/4-20 X 3/4 H WH ZP 840082 3 840082 3 840082 3

SCREWCAP #10-24 X 5/ 8" - - - - 8059135 4

NYLON INSERT LOC K N UT 10-32 UNF ZIN C - - - - 8164005 4

SCREW SOCK ET HD 5/16-18 X 3/4 GR. 8 - - - - 890103 2

NUT KEP S 5/16-18 - - - - 890104 2

WASHER SHI M 0.875 ID X 0. 060 - - - - 891065 2

WASHER SHI M 0.875 ID X 0. 020 - - - - 891041 0-3

BLADE CH IPPE R KD501 - - - - 890101 1

GUARD FLAPPER - - - - 890119 2

PLATE FLAPPE R E NTRANCE - - - - 890127 2

LABEL SPARK ARRESTOR EN / SP - - 100252 1 100252 1

TAMP ER CHI P P E R - - - - 890229 1

LABEL DANGER CHI P P ER - - - - 890152 1

CLIP 1/2" 350146 4 350146 4 350146 4

WOODR UFF KE Y 1/8 X 1/ 2 510180 2 510180 2 510180 2

WASHER 1/ 2" FC 8171006 2 8171006 2 8171006 2

SPRIN G C OMPRE SSION 891072 1 891072 1 891072 1

LABEL DEC AL K V/ TKV 891046 1 891046 1 891047 1

SCREW SM 1/4 X 3/4 D RI L L P T 510208 4 510208 4 510208 4

WASHER 1/ 4" SAE BLACK OXI D E 510193 4 510193 4 510193 4

CARRI AGE BOLT 1/4"-20 X 3/ 4" 8024021 4 8024021 4 8024021 4

SCREWCAP 1/ 4-20 X 1" HCS ZP 8041006 6 8041006 6 8041006 6

KV RE INFORC EMEN T NOZZLE BRAC K ET LFT 891062 1 891062 1 891062 1

KV RE INFORC EMEN T NOZZLE BRAC K ET RT 891064 1 891064 1 891064 1

KNOB 3/ 8-16 RE D 891070 1 891070 1 891070 1

SPRIN G LE VER GZ 610429 1 610429 1 610429 1

TY WRAP 900407 4 900407 4 900407 4

NUT 1/4-20 ACORN 840071 2 840071 2 840071 2

RING CLASP FR ONT BAG KV 891155 2 891155 2 891155 2

LABE L M AD E IN U.S.A. 520116 1 520116 1 520116 1

KV600SP/KV600SPFB

PART NUMBER

KV650SPH/KV650SPHFB

QTY

PART NUMBER

TKV650SPH/TKV650SPHFB

QTY

PART NUMBER

QTY

Part No 891204 Form No F060911E

14

Loading...

Loading...