Page 1

KD Owner’s Manual

HOSE KIT

P/N 890209

P/N 890041

(STD. ON

P/N 8904

13

P/N 890412

DEBRIS

BAG

P/N 890028

DEBRIS BAG

P/N

900801

conditions that

P/N

890309

BILLY GOAT KD VACUUM

Owner's Manual

KD612, KD512HC, KD512HCS

Accessories Optional Debris bags

SHREDDER

KIT

Shreds

leaves,

reducing total

volume.

ON BOARD

VACUUM

4"(102mm) x

7' (2.13m)

For

vacuuming in

hard to reach

areas.

NOZZLE WEAR

PLATES

KD512HCS)

Extends nozzle

life when used

along curbs and

hard surfaces.

CASTER KIT

For use on

hard surface.

STANDARD

TURF PRO

For use in

leaves and

grass in nondusty

conditions.

COVER

Directs dust

downward

away from

operator.

ZIPPERLESS

QUICK BAG

For non-dusty

are damaging

to zippers.

Part No 890033 Form No F062306A

1

Page 2

KD Owner’s Manual

ABOUT THIS MANUAL

THANK YOU for purchasing a BILLY GOAT ® KD Vacuum. Your new machine has been carefully designed and

manufactured to provide years of reliable and productive service. This manual provides complete operating and

maintenance instructions that will help to maintain your machine in top running order. Read this manual carefully

before assembling, operating, or servicing your equipment.

CONTENTS

SERIAL PLATE DATA AND SPECIFICATIONS 3

GENERAL SAFETY 4 -5

SOUND AND VIBRATION 6

INSTRUCTION LABELS 7

PACKING CHECKLIST & ASSEMBLY 8

OPERATION 9-10

MAINTENANCE 11

TROUBLESHOOTING AND WARRANTY PROCEDURE 12

MAINTENANCE RECORD 13

ILLUSTRATED PARTS & PARTS LISTS 14-15

Part No 890033

2

Form No F062306A

Page 3

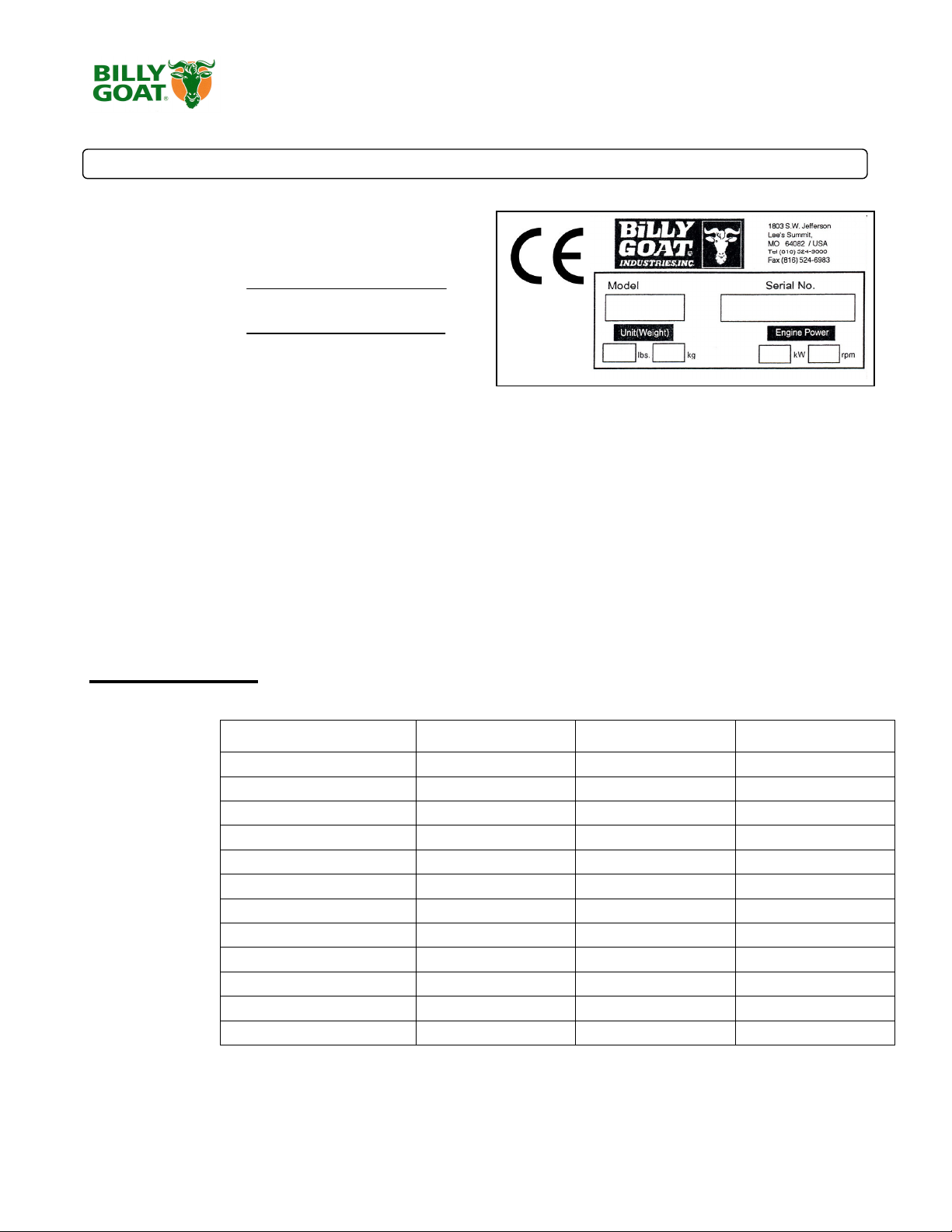

SERIAL PLATE DATA

KD Owner’s Manual

Record the model number, serial number, date of

purchase, and where purchased.

Purchase Date:

Purchased From:

Specifications

Engine: HP 6.0 (4.47 kW) 5.5 (4.11 kW) 5.5 (4.11 kW)

Engine: Type B & S QUANTUM HONDA OHC HONDA OHC

Engine: Model 112K020124E1 GCV160AN1A GCV160AN1A

Engine: Fuel Capacity 1.5 qt. (1.4 L) 1.16 qt. (1.1 L) 1.16 qt. (1.1 L)

Engine: Oil Capacity 0.63 qt. (0.6 L) 0.58 qt. (0.6 L) 0.58 qt. (0.6 L)

Total Unit Weight: 98# (44.5 kg) 99# (45.0 kg) 99# (45.0 kg)

Overall Length 62” (1.57m) 62” (1.57m) 62” (1.57m)

Overall Width 26.75” (0.68 m) 26.75” (0.68 m) 26.75” (0.68 m)

Overall Height 42” (1.07m) 42” (1.07m) 42” (1.07m)

Max. operating slope 200 200 200

Lwa at operator position 111 dBa 111 dBa 111 dBa

Lpa at operator position 97 dBa 97dBa 97dBa

Vibration at operator position 0.34 g (3.29m/s2) 0.27 g (2.86m/s2) 0.27 g (2.86m/s2)

Part No 890033 Form No F062306A

KD612 KD512HC KD512HCS

3

Page 4

KD Owner’s Manual

GENERAL SAFETY INSTRUCTIONS and SYMBOLS

The safety symbols shown below are used throughout this manual. You should become familiar with them before

assembling, operating, or servicing this equipment.

This symbol indicates important information that will prevent injury to yourself or others

.

This symbol indicates ear protection is recommended when operating this equipment.

This symbol indicates eye protection is recommended when operating this equipment.

This symbol indicates gloves should be worn when servicing this equipment.

This symbol indicates that this manual and the engine manufacturer’s manual should be read

carefully before assembling, operation, or servicing this equipment.

This symbol indicates important information that will prevent damage to your BILLY GOAT ®

KD Vacuum.

This symbol indicates the engine oil level should be checked before operating this

equipment.

Read and make sure you thoroughly understand the following safety precautions before assembling, operating or

servicing this equipment:

READ this manual and the engine manufacturer’s manual carefully before assembling,

operating, or servicing this equipment.

EAR PROTECTION is recommended when operating this equipment.

EYE PROTECTION is recommended when operating this equipment

.

BREATHING PROTECTION is recommended when operating this equipment.

EXHAUST from this product contains chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

DO NOT operate this equipment on any unimproved forested, brushy, or grass covered land

unless a spark arrester is installed on the muffler as required by Section 4442 of the

California Public Resources Code. The arrester must be maintained in good working order.

Other states may have similar laws. Federal laws apply on federal lands.

DO NOT run engine in an enclosed area. Exhaust gases contain carbon monoxide, an

odorless and possibly fatal poison.

Part No 890033

4

Form No F062306A

Page 5

KD Owner’s Manual

DO NOT run this equipment indoors or in any poorly ventilated area. Refueling outdoors is

recommended.

DO NOT refuel this equipment while the engine is running. Allow engine to cool for at least

two minutes before refueling.

DO NOT store gasoline near an open flame.

DO NOT remove gas cap while engine is running.

DO NOT start or operate engine if strong odor of gasoline is present.

DO NOT start or operate engine if gasoline is spilled. Move equipment away from spill until

gasoline has completely evaporated.

DO NOT smoke while filling the fuel tank.

DO NOT check for spark with spark plug or spark plug wire removed. Use an approved spark

tester.

DO NOT operate engine without a muffler. Inspect muffler periodically and replace if

necessary. If equipped with muffler deflector, inspect deflector periodically and replace if

necessary.

DO NOT operate engine with grass, leaves or other combustible material near the muffler.

DO NOT touch muffler, cylinder, or cooling fins when hot. Contact with hot surfaces may

cause severe burns.

DO NOT leave equipment unattended while in operation.

DO NOT park equipment on a steep grade or slope.

DO NOT operate equipment with bystanders in or near the work area.

DO NOT allow children to operate this equipment.

DO NOT operate equipment with guards removed.

DO NOT operate equipment near hot or burning debris or any toxic or explosive materials.

DO NOT operate equipment on slopes greater than specified in Specifications section of this

manual.

DO NOT place hands or feet underneath unit, or near any moving parts.

ALWAYS remove spark plug wire when servicing equipment to prevent accidental starting.

ALWAYS check fuel lines and fittings frequently for cracks or leaks. Replace if necessary.

ALWAYS keep hands and feet away from moving or rotating parts.

ALWAYS store fuel in approved safety containers.

WARNING: Important

Remove all rocks, wire, string, plastic, etc. that can present a hazard during work prior to

starting.

DO identify and mark all fixed objects to be avoided during work such as sprinkler heads,

water valves, buried cables, or clothes line anchors, etc.

Part No 890033 Form No F062306A

5

Page 6

KD Owner’s Manual

SOUND

SOUND LEVEL 97 dB(a) at Operator Position

Sound tests were conducted in accordance with 2000/14/EEC, and were performed on 2-21-2002 under the

conditions listed below.

Sound power level listed is the highest value for any model covered in this manual. Please refer to serial plate on

the unit for the sound power level for your model.

General Conditions: Sunny

Temperature: 45oF (7.2oC)

Wind Speed: 5 mph (8.1 kmh)

Wind Direction: South West

Humidity: 60%

Barometric Pressure: 30.18”Hg (767 mm Hg)

VIBRATION DATA

VIBRATION LEVEL 0.34g (3.29m/s2)

Vibration levels at the operator’s handles were measured in the vertical, lateral and longitudinal directions using

calibrated vibration test equipment. Tests were performed on 5-25-2006 under the conditions listed below.

General Conditions: Sunny

Temperature: 89oF (31.7oC)

Wind Speed: 13.6 mph (21.9kph)

Wind Direction: East

Humidity: 22.8%

Barometric Pressure: 29.9Hg (101.3kpa)

INTENDED USE

INTENDED USE: This machine is designed for vacuuming leaves, grass clippings and other types of organic litter

and for chipping brush, limbs, corn and sunflower stalks and palm fronds.

Debris mixed with cans, bottles and small amounts of sand can be vacuumed; however, it is not this machine's

primary purpose. Vacuuming cans, bottles and sand will affect the longevity of your machine.

Do not operate if excessive vibration occurs. If excessive vibration occurs, shut engine off immediately and check

for damaged or worn impeller, loose impeller bolt, loose impeller key, loose engine or lodged foreign objects.

Note: See parts list for proper impeller bolt torque specifications. (See trouble shooting section on page 12).

Part No 890033

6

Form No F062306A

Page 7

KD Owner’s Manual

INSTRUCTION LABELS

The labels shown below were installed on your BILLY GOAT ® KD Vacuum. If any labels are damaged or missing, replace them before operating

this equipment. Item numbers from the Illustrated Parts List and part numbers are provided for convenience in ordering replacement labels. The

correct position for each label may be determined by referring to the Figure and Item numbers shown.

LABEL DANGER KEEP HANDS LABEL EAR EYE BREATHING ITEM #49 DANGER FLYING DEBRIS

AND FEET AWAY P/N 890254 ITEM # 62 P/N 810736

ITEM #29 P/N 400424

LABEL READ MANUAL LABEL EXPLOSIVE FUEL DEBRIS BAG LABEL

ITEM #84 P/N 430363 ITEM # 63 P/N 400268 ITEM #1

ENGINE LABELS

ENGINE CONTROLS

Choke Throttle Control

Control

Choke Control

Throttle

Control Fuel Shut Off

HONDA BRIGGS & STRATTON

Read Owner’s Manual Before Operating.

Lire le manuel d’utilisation avant la mise en route.

Vor Inbetriebnahme Bedienungs - und Wartungsanleitung lesen.

Favor leer las instrucciones de operacion antes de operar el motor.

Consultare il Manuale Uso e Manutenzione prima dell utilizzo.

Las Skotselinstruktionen Innan Start.

Honda

Briggs engines have a primer

button carburetor rather than

choke type carburetor.

Part No 890033 Form No F062306A

7

Page 8

KD Owner’s Manual

READ

ASSEMBLE

Lift upper handle (item 6), remove items 8, 30, & 32 from lower handle (item 27). Attach and secure

ect (item 64). Attach firmly to housing

LITERATURE ASSY

PACKING CHECKLIST

Your Billy Goat KD Vacuum is shipped from the factory in one carton, completely assembled except for the

upper handle, debris bag, and bag quick disconnect.

all safety instructions before assembling unit.

TAKE CAUTION when removing the unit from the box the Handle Assembly is attached by

cables and folded over

PUT OIL IN ENGINE BEFORE STARTING

PARTS BAG &

Warranty card P/N- 400972, Owner’s Manual P/N-890033, Declaration of Conformity P/N-890393.

Quick disconnect

Boxing Parts

Checklist

Debris Bag

P/N-890022

Literature Assy

P/N-890392

Connector Quick

Disconnect

P/N-890176

Honda 5.5GVC

160

Briggs & Stratton

6.0 HP Intek

Fig. 2

ASSEMBLY

1.

upper handle as shown using same hardware.

2. UNFOLD the debris bag (item 1) and fasten bag neck to bag quick disconn

exhaust (item 52) see fig. 2.

3. ATTACH bag hanger strap to bag supports (item 11), preassembled to upper handle.

4. CONNECT spark plug wire.

Part No 890033

8

Form No F062306A

Page 9

KD Owner’s Manual

STARTING

HANDLING & TRANSPORTING

OPERATION

Like all mechanical tools, reasonable care must be used when operating machine.

Inspect machine work area and machine before operating. Make sure that all operators of this

equipment are trained in general machine use and safety.

PUT OIL IN ENGINE BEFORE STARTING

ENGINE

must be level when checking and filling oil and gasoline.

ENGINE SPEED

throttle to accomplish your current cleaning task.

FUEL VALVE

CHOKE

PRIMER

THROTTLE

IF YOUR UNIT FAILS TO START

See Troubleshooting on page 12.

: See engine manufacturer’s instructions for type and amount of oil and gasoline used. Engine

: Controlled by throttle lever on the engine. Under normal conditions, operate at minimum

: Move fuel valve to "ON" position (when provided on engine).

: Located on engine and must be controlled manually.

: Push primer per engine instructions (B&S only).

: Located on engine and must be controlled manually.

:

:

This unit requires two people to lift it. With the handle in the folded position, lift holding the

lower handle and belt/shaft guard one on each side of the machine. Secure the machine in place

during transport. See page 3 for weight specifications

Never lift the machine while the engine is running.

STORAGE

Never store engine indoors or in enclosed poorly ventilated areas with fuel in tank, where fuel fumes may reach

an open flame, spark or pilot light, as on a furnace, water heater, clothes dryer or other gas appliance.

If engine is to be unused for 30 days or more, prepare as follows:

Remove all gasoline from carburetor and fuel tank to prevent gum deposits from forming on these parts and

causing possible malfunction of engine. Drain fuel outdoors, into an approved container, away from open flame. Be

sure engine is cool. Do not smoke. Run engine until fuel tank is empty and engine runs out of gasoline.

Part No 890033 Form No F062306A

9

Page 10

KD Owner’s Manual

VACUUMING OPERATION

DEBRIS BAG

r

COMPOST

Vacuumed leaves, grass and other organic material from your own yard can be empt

OPERATION

VACUUM NOZZLE HEIGHT ADJUSTMENT

pulling height adjust knob on the handle (item 23) up at left rear of machine.

FOR MAXIMUM PICKUP

Never bury nozzle into debris.

CLEARING A CLOGGED NOZZLE & EXHAUST

and disconnect spark plug wire. Wearing durable gloves, remove clog. Danger, the clog may contain sharp

materials. Reconnect spark plug wire.

: Adjust nozzle close to debris, but without blocking airflow into the nozzle. NOTE:

: is raised and lowered by pulling slightly upward on handle and

: Turn engine off and wait for impeller to stop completely

Debris bags are normal replaceable wear items.

Note: Frequently empty debris to prevent bag overloading with more weight than you can lift.

An optional bag and dust cover is available for use where debris will be vacuumed in dusty conditions (see Optional

Accessories shown on page 1).

DO NOT place bag on or near hot surface, such as engine. Run engine at 1/2 throttle for first 1/2 hour to condition new bag. You

new bag requires a break-in period to condition the pores of the material against premature blockage. The entire bag surface

serves as a filter, and must be able to breath to have good vacuum performance. Be sure engine has come to a complete stop

before removing or emptying bag.

This vacuum is designed for picking up trash, organic material and other similar debris (see Safety Warnings

page 4-5).

However, many vacuums are used where dust is mixed with trash. Your unit can intermittently vacuum in dusty areas.

Dust is the greatest cause of lost vacuum performance. However, following these rules will help maintain your

machine's ability to vacuum in dusty conditions:

• Run machine at idle to quarter throttle.

• The debris bag must be cleaned more frequently. A vacuum with a clean, pillow soft bag will have good pickup

performance. One with a dirty, tight bag will have poor pickup performance. If dirty, empty debris and vigorously shake

bag free of dust.

• Pressure-wash debris bag if normal cleaning does not fully clean bag. Bag should be thoroughly dry before use.

NOTE: Having one or more spare debris bags is a good way to reduce down time while dirty bags are being cleaned.

DO NOT leave debris in bag while in storage.

provide enriched soil for later use as fertilizer in gardens and flower beds

NOTE: Allow green chips to dry before spreading around living plants.

ied into a pile or composter to

Part No 890033

10

Form No F062306A

Page 11

KD Owner’s Manual

IMPELLER REMOVAL

MAINTENANCE

P

ERIODIC MAINTENANCE

Periodic maintenance should be performed at the following intervals:

Maintenance Operation Every Use (daily) Every 5 hrs (daily) Every 25 Hours

Inspect for loose, worn or damaged parts.

Clean Debris bag

Check bag strap tightness

Engine (See Engine Manual)

Check for excessive vibration

Lubricate wheels

1.Wait for engine to cool and disconnect spark plug.

2.Drain fuel and oil from the engine.

3. Remove bag, quick release, and upper handle. Do not kink, stretch, or break control cables, control

housings, or end fittings while removing handles.

4. Remove housing top plate by removing bolts around outside of housing.

5. Leaving engine fastened to top plate, turn it upside down so the impeller is on top.

6. Remove impeller bolt and lock washer.

7. Lift impeller upward. If impeller slides freely, proceed to (step 10).

8. Place two crowbars between impeller and housing on opposite sides. Pry impeller away from engine until it

loosens. Using a penetrating oil can help loosen a stuck impeller.

9. If the impeller does not loosen, obtain a 1” (25.4mm) longer bolt of the same diameter and thread type as

the impeller bolt. Thread longer bolt by hand into the crankshaft until bolt bottoms. Using a suitable gear or

wheel puller against the bolt head and the impeller back-plate (near the blades), remove impeller from shaft.

10. Using a new impeller bolt and lockwasher, reinstall new impeller in reverse order.

11. Tighten impeller bolt. Torque impeller bolt to 50 Ft. Lbs. (68 N.m) (see item 51 on page 15).

12. Reinstall engine onto housing in reverse order of removal.

13. Gas and oil (0.69 quart).

14. Reinstall spark plug wire.

Part No 890033 Form No F062306A

11

Page 12

KD Owner’s Manual

lo o se e n gine

C h e ck en g ine

over.

prob lem .

dea ler fo r eng ine p ro b lem s

Troubleshooting

Ab n orm al v ibra tion. · L o os e or o u t o f ba lanc e im peller o r

W ill not v a cu u m or h a s po o r

vacu u m perform an ce

En g ine will n o t s tart. · S to p s w itc h off. T hro ttle in off p o sition.

P rob lem Po s sible C ause So lutio n

· d irty d e br is ba g . N o zzle h eight s et too

hig h or low . H os e kit c ap m iss ing .

C log g ed no z z le or e x ha u st. E x ce s siv e

qua n tity o f deb ris.

E n g ine not in fu ll c ho k e pos ition. O ut o f

gas o line . Ba d or old gaso lin e . S park p lug

w ire dis c on n ec ted . D irty air cle an e r

· C he ck im peller a nd rep lac e if req u ire d .

· C lean de b ris b a g. Sh a ke b a g cle an or

wa s h. A djus t nozzle heig ht. C h ec k fo r

hos e kit c ap . U n clog n o zzle or e x ha u st.

Allow air to fe e d w ith de b ris

· C he ck s top sw itche s , th rottle, c h ok e

pos ition a n d g a so line . C onne c t s pa rk

plu g wir e . C lean or r e p lace air filte r . O r

con tac t a q ua lified service pe rs o n .

En g ine is lo c ke d , w ill no t pull

N o zzle scrap e s g rou n d in

lo w es t height s etting .

When servicing engine refer to specific manufacturers engine owner's manual. Engine warranty is covered by the

specific engine manufacturer. If your engine requires warranty or other repair work contact your local servicing

engine dealer. When contacting a dealer for service it is a good idea to have your engine model number available

for reference (See table page 3). If you cannot locate a servicing dealer in your area you can contact the

manufacturers national service organization.

To reach:

American Honda: 800-426-7701

WARRANTY CLAIM PROCEDURE

Should a BILLY GOAT ® machine fail due to a defect in material and/or workmanship, the owner should make a

warranty claim as follows:

• The machine must be taken to the dealer from whom it was purchased or to an authorized Servicing BILLY

GOAT Dealer.

• The owner must present the remaining half of the Warranty Registration Card, or, if this is not available, the

invoice or receipt.

• The Warranty Claim will be completed by the authorized BILLY GOAT Dealer and submitted to their

respective BILLY GOAT Distributor for their territory Attention: Service Manager. Any parts replaced under

warranty must be tagged and retained for 90 days. The model number and serial number of the unit must

be stated in the Warranty Claim.

· D eb ris lock e d in im pe lle r . En g ine

N o zzle h eight o ut o f a d ju s tm ent

· S ee p a ge 5. C on tac t a eng ine se rvice

Ad jus t nozzle heig ht ( S ee N ozzle heig ht

fine ad ju s tm e nt f o r hard su rfac e s on

pag e 5

• The distributor service manager will sign off on the claim and submit it to BILLY GOAT for consideration.

• The Technical Service Department at BILLY GOAT will study the claim and may request parts to be

returned for examination. BILLY GOAT will notify their conclusions to the distributor service manager from

whom the claim was received.

•

The decision by the Technical Service Department at BILLY GOAT to approve or reject a Warranty Claim is

final and binding.

For online product registration go to www.billygoat.com

Part No 890033

12

Form No F062306A

Page 13

MAINTENANCE RECORD

Date Service Performed

KD Owner’s Manual

Part No 890033 Form No F062306A

13

Page 14

KD Owner’s Manual

PARTS DRAWING KD

Part No 890033

14

Form No F062306A

Page 15

KD Owner’s Manual

PARTS

LIST

IT EM

K D 61 2

K D 51 2H C

K D5 1 2H CS

P a rt N o.

P a rt N o .

P a rt N o.

* Denotes

standard

hardware

item that

may be

purchase

d locally.

D E SC R IP TIO N Q T Y Q T Y Q TY

N O .

1 PR O D EB R IS BA G (se rvic e) 8903 0 5 1 89 00 23 1 89 002 3 1

2

3

4 NU T L O CK (1 /4 - 20 ) *8 16 00 0 1 7 *8 16 0 0 01 7 * 81 6 0 00 1 7

5 SC RE W C AP ( 1 /4 - 20 x 1 -1/ 2 H EX ) *8 04 10 0 8 8 *8 04 1 0 08 8 * 80 4 1 00 8 8

6 HA ND L E A S S’Y (inc l. ite ms 4(5),5(5), 1 1 (2),7 5 (2),7 6) 9000 5 4 1 90 00 54 1 90 005 4 1

7 AX LE H EIG HT A DJ US T 89 03 8 9 1 89 03 89 1 89 038 9 1

8 SC RE W H AN D LE 5/1 6 - 1 8 x 1 - 3/4 *8 04 10 3 1 2 *8 04 1 0 31 2 * 80 4 1 03 1 2

9 CL AM P C A BL E 9004 0 7 2 90 04 07 2 90 040 7 2

10 S CR E W C A P 1/4 - 2 0 x 1 3 /4 *8 04 10 0 9 1 *8 04 1 0 09 1 * 80 4 1 00 9 1

11 B AR B A G S UP PO RT 9 00 0 39 2 9 00 03 9 2 90 00 3 9 2

12 D OO R E XH AU ST A S S’Y (in cl. ite m 6 2 ) 8901 4 8 1 89 01 48 1 89 014 8 1

13 P LA TE T OP A S S’Y (incl. item s 2 9 , 57, 6 5) 8904 0 2 1 89 04 02 1 89 040 2 1

14 B OLT -C AR RIA GE 1/4 x3 /4 *8 02 40 2 1 2 *8 02 4 0 21 2 * 80 2 4 02 1 2

15 W A S HE R F LA T 5 /16 8172 0 08 1 817200 8 1 8172 0 08 1

16 W A S HE R 1 /4 FC ZP *817 1 00 2 10 *8 1 710 0 2 10 *8171 0 02 1 0

17

18 B RA C KE T - H E IG HT A D JU STM EN T 8900 2 1 1 89 00 21 1 89 002 1 1

19 P LA TE U PPE R H EI G HT AD JU ST 8900 0 5 1 89 00 05 1 89 000 5 1

20 S PR IN G 9001 3 6 1 90 01 36 1 90 013 6 1

21 T IR E - O NL Y (P ER A SS Y) 9005 0 7 1 90 05 07 1 90 050 7 1

22 P IN - H A IR C OT TE R 9 00 4 71 1 900 4 7 1 1 9 00 47 1 1

23 C AB L E H EIG HT A DJ US TM EN T 89 00 1 9 1 89001 9 1 89 00 1 9 1

24 B OLT - C ARR IAG E 5 /16 - 18 x 4 1/2 *8 02 40 5 4 4 *8 02 4 0 54 4 * 802 4 05 4 4

25

26 N UT LO CK 5/16 - 18 H E X *8 16 00 0 2 6 *8 16 0 0 02 6 * 81 6 0 00 2 6

27 H AN D LE LO WE R K D5 10 8903 4 6 1 89 03 46 1 89034 6 1

28 P LA TE H AND LE S U PP OR T 9 009 3 3 1 -2 90 0 933 1 -2 90093 3 1 -2

29 L AB EL D AN GE R C UT F IN G ER 4004 2 4 2 40 04 24 2 40042 4 2

30 W A S HE R F LA T C UT 5/1 6 *8 17 10 0 3 2 *8 17 1 0 03 2 * 81 7 1 00 3 6

31

32 N UT LO CK 5/16 - 18 T H IN H T . *8 16 10 4 1 4

33 G RIP H AN DLE 400 5 7 0 2 4 00 57 0 2

34 W H E EL A S S’Y ( in cl. it e ms 2 1) 90 0 50 9 4 900 5 0 9 4 9 00 50 9 4

35 W A S HE R 0 .75 “C ” 9009 9 7 0 -1 90099 7 0 -1 9 0 0 9 97 0 -1

36

37 S CR E W S M 1/4 x3 /4 T YP E A - - - - *8122 0 82 4

38 P LA TE S KID (inc l. it e ms 54 ) - - - - 89041 3 1

39 S PA C ER IM PE LLE R - - 89061 6 1 89 06 1 6 1

40

41

42 S CR E W S EL F TA PP IN G 1 0 - 24 x 1 /2 *8 12 30 8 6 1 *8 12 3 0 86 1 * 81 2 3 08 6 1

43 N OZ Z LE M AIN FR AM E A SS ’Y (in cl. on e of ite ms 2 9,44 ,42 ) 8903 9 1 1 89 03 91 1 89039 1 1

44 P LU G 9001 4 6 1 90 01 46 1 90014 6 1

45 L INE R H OLD P LA TE 8 9 0 6 18 2 890 6 1 8 2 8 90 61 8 2

46 - - - 47 IM PEL L ER A SS ’Y (in c l. it e m s 4 9, 5 0, 5 1 ) 9002 1 5 1 89 06 15 1 89061 5 1

48

49 K EY 9001 6 2 2 90 01 62 2 90016 2 2

50 W A S HE R L OC K 3/8 T W IS T ED T OO T H 4005 0 2 1 40 05 02 1 40050 2 1

51 S CR E W C A P 3/8 -2 4 x 1 G R 8 (T OR Q. 5 0 F T -LB S)(6 8N .m ) 900 1 5 4 1 900154 1 90 01 5 4 1

52 H OU SIN G A SS ’Y (incl. item s 1 2 , 1 4 , 15, 1 6 , 6 6) 89 03 71 -S 1 8 90 3 71-S 1 89 0 4 1 7-S 1

53 E NG INE H ON DA 5.5 H.P . G C1 6 0 - - 89061 4 1 89 06 1 4 1

E N GIN E B RIG GS & S T RA TTO N 6 H .P . Q UA NT UM IC 8906 2 2 1 - - - 54 B OLT C AR RIA GE 5/1 6-18x 3 /4" - - - - 8 02 4 039 4

55 L INE PV C - - - - 9 00 732 -S 1

56 S CR E W C A P 3/8 - 1 -1/2 T A PT IT E 8904 0 8 4 89 04 08 4 89040 8 4

57 S CR E W C A P 1/4 - 2 0 x 1/2 H W H 8903 5 9 1 5 8 90 359 15 8903 5 9 1 5

58 W A S HE R F LA T 1 /2 S AE *8 17 20 1 1 8 *8 17 2 0 11 8 * 81 7 2 01 1 8

59 S CR E W S O C KE T HD . 5 /16 - 18 x 3/4 G R. 8

60 H GT A D JU ST AS SY (IN CL. IT E MS 18, 2 0 , 2 2 , 2 3) 8900 1 3 1 89 00 13 1 89001 3 1

61 1 /2-1 3 C A P N UT N P W /P A TC H 89 05 3 0 4 89 05 3 0 4 89 05 30 4

62 L AB EL D AN GE R F LY IN G M AT E RIA L 8107 3 6 1 81 07 36 1 81073 6 1

63 L AB EL D O N O T F ILL W H EN E NG IN E IS HO T 4002 6 8 1 40 02 68 1 40026 8 1

64 C ON NE CTO R B AG Q UIC K 89 0 17 6 1 890 1 7 6 1 89 01 76 1

65 L AB EL R EA D O WN ER 'S M AN U AL 8903 0 1 1 89 03 01 1 89030 1 1

66 L AB EL E AR /EY E B RE ATH IN G 89025 4 1 890 2 5 4 1 8 90 25 4 1

Part No 890033 Form No F062306A

15

Page 16

KD Owner’s Manual

free to view our full line of quality lawn

BRUSH CUTTER

FORCE BLOWER

AERATOR

QL VACUUM

MULTI VACUUM

POWER RAKE

If you liked this product please feel

care, renovation, and debris removal

products at www.billygoat.com

Part No 890033

16

Form No F062306A

Loading...

Loading...