Page 1

OPTIONAL ACCESSORIES

22

2

22

SHREDDER KIT

P/N 890209.

leaves, dramatically reducing

total volume.

Shreds

HOSE KITS

For vacuuming in hard to

reach areas.

Heavy Duty Vacuum

Hose Kit P/N 900943.

4"(102mm) x 10' (3.05m)

Homeowners Vacuum

Hose Kit P/N 900942.

4"(102mm) x 10' (3.05m)

NOZZLE WEAR PLA TES

P/N 890413.

(STD. ON KD510HS)

nozzle life when used along

curbs and hard surfaces.

ST AND ARD TURF QUICK

DEBRIS BAG

P/N 890307.

For use in leav es and grass in nondusty conditions.

Extends

(STD. O N TKD)

11

1

11

R

OPTIONAL DEBRIS BAGS

QUICK DEBRIS BAG

P/N 890305

For use in dusty conditions.

DEBRIS BAG COVER

P/N 900801

downward awa y from operator .

ZIPPERLESS QUICK BAG

P/N 890309

conditions that are damaging

to zippers.

(STD. ON KD)

Directs dust

For non dusty

Thank You for Selecting

The P owerful

KD or TKD TERMITE

VACUUM CHIPPER

®

Operator Owner's Manual

CASTER KIT

P/N 890412

surface

33

3

33

ENGINE:H.P. 5.0 (3.73k W) 5.0 (3.73k W) 5.5 (4.1kW) 5.5 (4.1kW) 5.0 (3.73kW ) 5.5 (4.1kW)

ENGINE:TYPE B&S B&S I/C HONDA OHV HONDA OHV B&S I/C HONDA OHV

ENGINE:FU EL CAP. 1.5qt. (1.4L) 1.5qt. (1.4L) 1.2qt. (1.1L) 1.2qt. (1.1L) 1.5qt. (1.4L) 1.2qt. (1.1L)

ENGINE:OIL CAP. 0.63qt. (0.6L) 0.63qt. (0.6L) 0.63qt. (0.6L) 0.63qt. (0.6L) 0.63qt. (0.6L) 0.63qt. (0.6L)

WEIGHT:UNIT 103# (46. 7 kg) 103# (4 6.7 kg) 112# (5 0.8 kg) 122# (55.3 kg) 12 1# (57.2 kg) 130# (59.0 kg)

WEIGHT:SHIPPING 126# (57.2 kg) 12 6# (57.2 kg) 135# (61.2 kg) 145# (65. 8 kg) 126# (5 7.2 kg) 153# (69.4 kg)

ENG INE W EIGHT: 24. 8# (1 1. 05 k g) 24.8# (1 1. 05 k g) 36# (16.3 k g) 36# (16. 3 k g) 24.8# (11. 05 k g) 36# (16 . 3 k g)

For use on hard

KD510 KD510IC KD510H KD510HS TKD510IC TKD510H

KD510, KD510IC, KD510H, KD510HS

TKD510IC, TKD510H

Specifications

UNIT SIZE:

Part No. 890394 Form No. F011398B

OVERALL LENGTH: 62"(1.57m) OVERALL WIDTH 26.75" (0.68m) OVERALL HEIGHT 42" (1.07m)

Page 1 of 12

Page 2

55

5

55

IN THE INTEREST OF SAFETY

BEFORE STAR TING ENGINE, READ AND UNDERST AND THE “ENTIRE OPERA T OR'S MANU AL & ENGINE MANUAL.”

THIS SYMBOL MEANS W ARNING OR CAUTION. DEA TH, PERSONAL INJURY AND/OR PROPER TY

DAMAGE MAY OCCUR UNLESS INSTRUCTIONS ARE FOLLOWED CAREFULLY.

WARNING: The Engine Exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects or other reproductive harm.

21. DO NOT touch hot muffler, cylinder , or

13. DO NOT tamper with governor springs,

WARNING: DO NOT

governor links or other parts which may

change the governed engine speed.

1. DO NOT run engine in an enclosed area.

Exhaust gases contain carbon monoxide, an

odorless and deadly poison.

2. DO NOT place hands or feet near moving

or rotating parts.

3. DO NOT store, spill or use gasoline near

an open flame, or devices such as a stove,

furnace, or water heater which use a pilot

light or devices which can create a spark.

4. DO NOT refuel indoors where area is not

well ventilated. Outdoor refueling is

recommended.

5. DO NOT fill fuel tank while engine is

running. Allow engine to cool for 2 minutes

before refueling. Store fuel in approved

safety containers.

6. DO NOT remove fuel tank cap while

engine is running.

7. DO NOT operate engine when smell of

gasoline is present or other explosive

conditions exist.

8. DO NOT operate engine if gasoline is

spilled. Move machine away from the spill

and avoid creating any ignition until the

gasoline has evaporated.

9. DO NOT transport unit with fuel in tank.

10. DO NOT smoke when filling fuel tank.

11. DO NOT choke carburetor to stop

engine. Whenever possible, gradually

14. DO NOT tamper with the engine speed

selected by the engine manufacturer.

15. DO NOT check for spark with spark

plug or spark plug wire removed. Use an

approved tester.

16. DO NOT crank engine with spark plug

removed. If engine is flooded, place

throttle in “FAST” position and crank until

engine starts.

17. DO NOT strike flywheel with a hard

object or metal tool as this may cause

flywheel to shatter in operation. Use

proper tools to service engine.

18. DO NOT operate engine without a

muffler. Inspect periodically and replace, if

necessary. If engine is equipped with

muffler deflector, inspect periodically and

replace, if necessary, with correct deflector.

19. DO NOT operate engine with an

accumulation of grass, leaves, dirt or other

combustible material in the muffler area.

20. DO NOT use this engine on any forest

covered, brush covered, or grass covered

unimproved land unless a spark arrester is

installed on the muffler. The arrester must

be maintained in effective working order by

the operator. In the State of California the

above is required by law (Section 4442 of

the California Public Resources Code).

Other states may have similar laws.

Federal laws apply on federal lands.

reduce engine speed before stopping.

12. DO NOT run engine at excessive

speeds. This may result in injury & /or

7

damage to unit.

L

A

T ABLE OF CONTENTS

6

SAFETY INSTRUCTIONS

GENERAL SAFETY

ASSEMBLY

PARTS BA G & CONTROLS

LABELS

OPERATION

MAINTENANCE

PA R TS DRAWING & LIST

TROUBLESHOOTING

WARRANTY PROCEDURE

Part No. 890394 Form No. F011398B

○○○○○○○○

○○○○○○○○

○○○○○○○

○○○○○○

○○

○○○○○

5 - 7

8 - 9

10 -

○○○

12

12

12

2

3

3

4

4

98

108

OPERA T O R

TEMPERATURE:

L

A

p

WIND DIRECTION:

HUMIDITY:

BAROMETRIC PRESSURE:

SOUND

SOUND TESTS

Sound tests conducted were in accordance

with 79/113/EEC and were performed on 05/

22/95 under the conditions listed:

GENERAL CONDITION:

Page 2 of 12

Sunny

72 F (22.2 C)

10 MPH (16.1 kmh)

S.E.

71 %

30.02" Hg (763mm Hg)

fins because contact may cause burns.

22. DO NOT run engine without air cleaner

or air cleaner cover.

23. DO NOT operate during excessive

vibration!

24. DO NOT leave machine unattended

while in operation.

25. DO NOT park machine on a steep

grade or slope.

WARNING: DO

1. ALWAYS DO remove the wire from the

spark plug when servicing the engine or

equipment TO PREVENT ACCIDENTAL

STARTING.

2. DO keep cylinder fins and governor

parts free of grass and other debris

which can affect engine speed.

3. DO pull starter cord slowly until resistance is felt. Then pull cord rapidly to avoid

kickback and prevent hand or arm

injury.

4. DO examine muffler periodically to be

sure it is functioning effectively. A worn or

leaking muffler should be repaired or

replaced as necessary.

5. DO use fresh gasoline. Stale fuel can

gum carburetor and cause leakage.

6. DO check fuel lines and fittings frequently for cracks or leaks. Replace if

necessary

7. Follow engine manufacturer operating

and maintenance instructions.

8. Inspect machine and wor k area before

startin g unit.

8

VIBRATION LEVELS 1.5g

Vibration levels at the operators handles were

measured in the vertical, lateral, and longitudinal

directions using calibrated vibration test equipment.

T ests w ere perf ormed on 05/19/95 under the conditions

listed:

GENERAL CONDITION:

TEMPERATURE:

WIND SPEED:

WIND DIRECTION:

HUMIDITY:

BAROMETRIC PRESSURE:

VIBRA TION

Sunny

62 F (16.7 C)

5 MPH (8.0 kmh)

South

67 %

30.06" Hg (764mm Hg)

Page 3

9

GENERAL SAFETY

For your safety and the safety of others, these directions should be followed:

Do not operate this machine without first reading

owner's manual and engine manufacturer's manual.

Use of Ear Protection is recommended while

operating this machine.

Use of Eye and Breathing protection is recom mended when using this machine, especially in dry

and dusty conditions. Optional bag cover directs dust

toward ground, a wa y from the operator .

·DO NOT place hands or feet inside nozzle intake opening,

near debris outlet or near any moving parts.

·DO NOT start engine without debris bag and quick discon-

nect connected firmly in place to exhaust outlet.

·DO NOT start or operate machine with debris bag zipper

open.

10

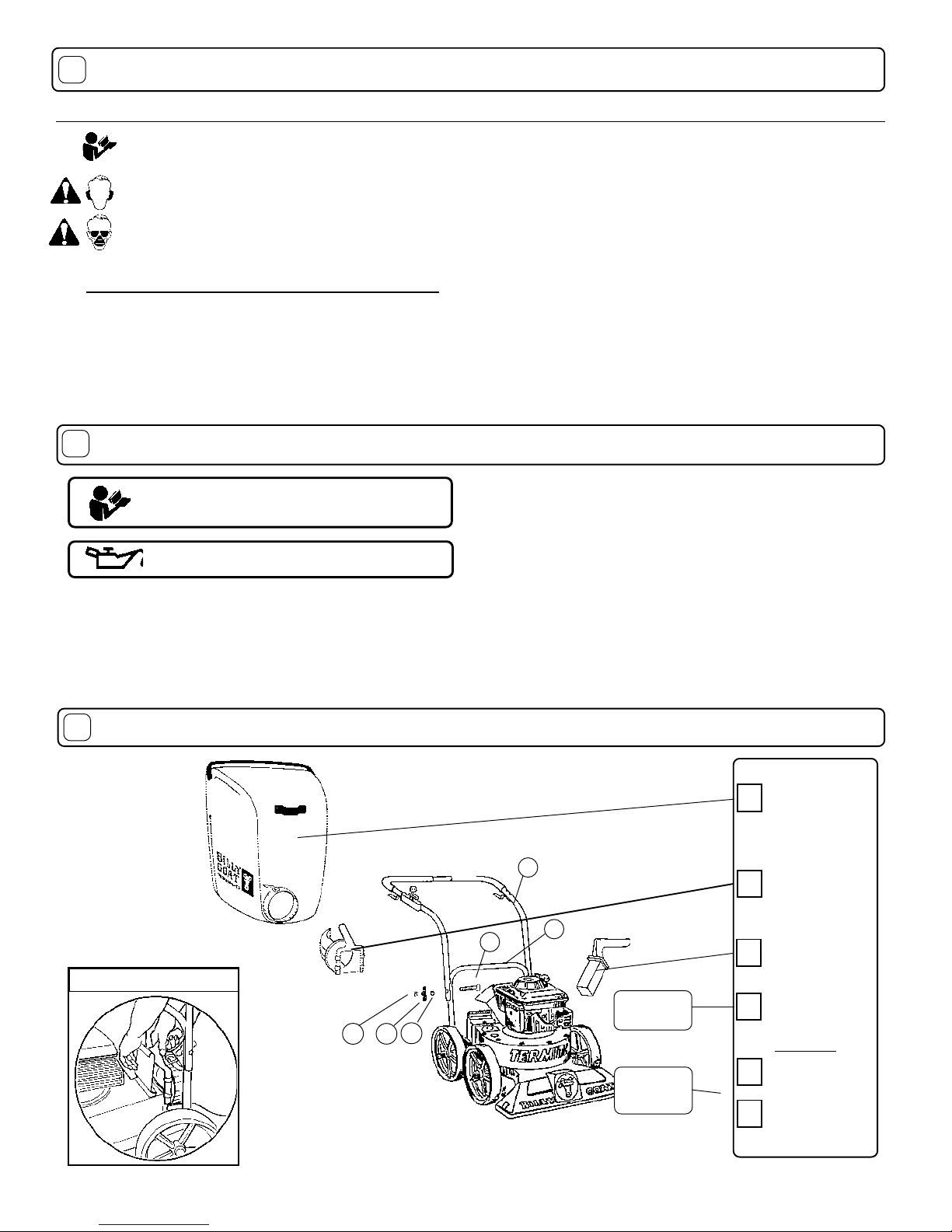

ASSEMBLY

Read all safety and operating instructions

before assembling or starting this unit.

PUT OIL IN ENGINE BEFORE STARTING

Your Billy Goat is shipped from the factory in one carton,

completely assembled except for the upper handle, debris bag,

and bag quick disconnect.

·DO NOT operate during excessive vibration.

·DO NOT remove bag until engine has been turned off and has

come to a complete stop.

·DO NOT remove hose kit cap on nozzle until engine has been

turned off and has come to a complete stop.

·DO NOT operate machine with hose cap, bag or hose removed.

·DO NOT use this machine for vacuuming exclusively sand,

dust, fine dirt, rock, glass, string like material, grain, rags,

cans, metal, bark or water.

·DO NOT operate this machine on slopes greater than 20%.

·DO NOT pick up any hot or burning debris, or any toxic or

explosive material.

·DO NOT allow children to operate this equipment.

1. ASSEMBLE Lift upper handle (item 6), remove items 8, 73, 74, & 30 from

lower handle (item 27). Attach upper and lower handle as shown,

and securely tighten folding handle knobs(item 73),while holding head of

screw(item 8) firmly against upper handle.

2. UNFOLD the debris bag (item 1) and fasten bag neck to bag quick

disconnect (item 83). Attach firmly to housing exhaust (item 52) see fig. 2.

3. ATTACH bag hanger strap to bag supports (item 11), preassembled to

upper handle.

4. INSTALL tamper (item 85) in chipper hopper (see page 7)(TERMITE

ONLY).

5. CONNECT spark plug wire.

11

PACKING CHECKLIST

QUICK DISCONNECT

Fig. 2

These items should be included in your carton. If

any of these parts are missing, contact your dealer.

6

27

Manual Per

74

73

8

30

Literature

Assembly

Engine

Model

Check

890304 KD

Check

Check

Check

Check

Check

{

Debris Bag

890306 TKD

Connector

Quick

Disconnect

890176

Tamper (TKD

MODELS

ONLY) 890229

Literature Assy

890392

Per Model

Briggs & Stratton

MS9984 Multi-Language

Honda

P/N 31ZG9630

00X31-ZG9-6030

Part No. 890394 Form No. F011398B

Page 3 of 12

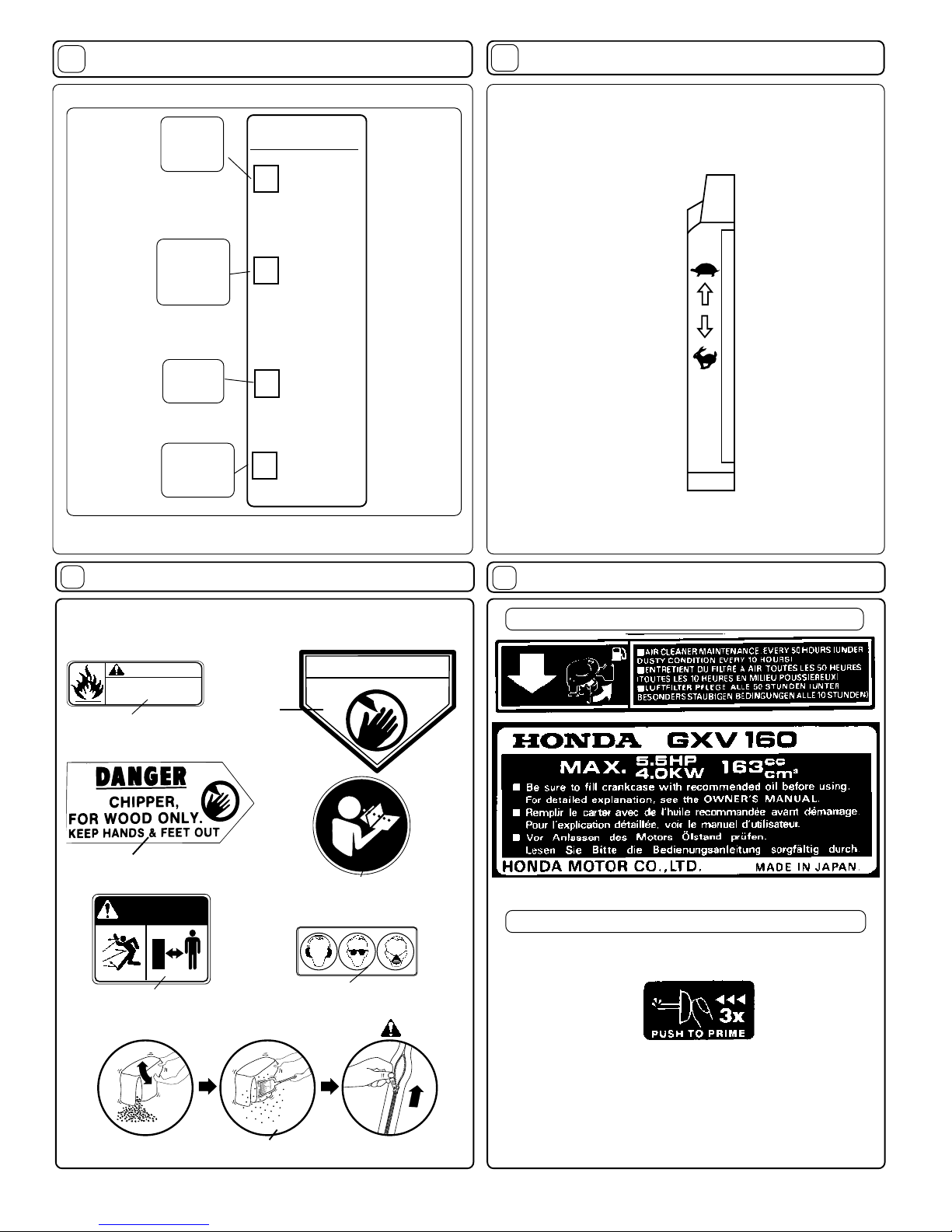

Page 4

DANGER

KEEP HANDS and FEET AWAY

1212

12

1212

LITERATURE ASSY P/N 890392

1313

13

1313

CONTROLS

Owner's

Manual

Literature

KD / TKD

Accessories

Warranty

Card

EU Declaration

of Conformity

& EU

Distributor List

Literature Checklist

Check

Owner's

Manual

890394

Check

Check

Check

Literature

KD / TKD

Accessories

890409

Warranty

Card 400972

EU Declaration

of Conformity &

EU Distributor

List 890393

Throttle

Control

Briggs

engines have

a primer

button

carburetor

rather than

choke type

carburetor.

Honda - Place

in fast position

to start.

Start

position

STOP

SLOW

FAST

1414

14

1414

INSTRUCTION LABELS

These labels should be included on your Vacuum. If any of

these labels are damaged, replace them before putting this

equipment into operation. Item and part numbers are given to

help in ordering replacement labels..

WARNING

EXPLOSIVE FUEL

STOP ENGINE AND ALLOW TO

COOL BEFORE REFUELING.

Label Do Not Fill While

Engine Is Hot

Item 63 Part No.400268

Label Danger Chipper For Wood

Only Item 48 Part No. 890152

(TKD MODELS ONL Y)

DANGER

Label Danger Flying Material

Item 62 Part No.810736

400268

810736

Label Danger

Keep Hands

and Feet

Away

Item 29 Part

No.400424

DANGER

KEEP HANDS and FEET AWAY

Label Read Owner's

Manual Item 84

Part No.890301

Label Ear Eye Breathing

Item No. 86 Part No. 890254

890254

1515

15

1515

ENGINE LABELS

Honda

Briggs & Stratton

UPDATE

Debris Bag

Label item 1

Part No. 890394 Form No. F011398B

Page 4 of 12

Page 5

1616

16

1616

Operation

INTENDED USE: This machine is designed for vacuuming

leaves, grass clippings and other types of organic litter and

for chipping brush, limbs, corn and sunflower stalks and

palm fronds.

Debris mixed with cans, bottles and small amounts of sand

can be vacuumed; however, it is not this machine's primary

purpose. Vacuuming cans, bottles and sand will affect the

longevity of your machine.

Do not operate if excessive vibration occurs. If excessive

vibration occurs, shut engine off immediately and check for

damaged or worn impeller, loose impeller bolt, loose impeller

key, loose engine or lodged foreign objects. Note: See parts

list for proper impeller bolt torque specifications. (See trouble

shooting section on page 12).

Like all mechanical tools, reasonable care must

be used when operating machine.

Inspect machine work area and machine before operating. Make sure that all operators of this equipment are

trained in general machine use and safety .

PUT OIL IN ENGINE BEFORE ST ARTING.

16.116.1

16.1

16.116.1

Engine must be level when checking and filling oil and

gasoline.

ENGINE SPEED: Controlled by throttle lever on the handle.

Under normal conditions, operate at minimum throttle to

accomplish your current cleaning task.

FUEL V ALVE: Move fuel valve to "ON" position (when

provided on engine).

CHOKE: Operated with throttle control (Honda only).

PRIMER: Push primer per engine instructions ( B&S only).

THROTTLE: Move remote throttle control to fast position.

Pull starting rope to start engine.

IF YOUR UNIT F AILS TO START :

See Troubleshooting on page 12.

16.216.2

16.2

16.216.2

STARTING

ENGINE: See engine manufacturer’s instructions

for type and amount of oil and gasoline used.

VACUUMING OPERATION

VACUUM NOZZLE HEIGHT ADJUSTMENT: is

raised and lowered by pulling slightly upward on handle

and pulling height adjust rod (item 23) up at left rear of

machine.

FOR MAXIMUM PICKUP: Adjust nozzle close to debris,

NOTE

but without blocking airflow into the nozzle.

nozzle into debris.

CLEARING A CLOGGED NOZZLE

& EXHAUST : Turn engine off and wait for impeller to

stop completely and disconnect spark plug wire.

Wearing durable glov es, remo ve clog. Danger, the

clog may contain sharp materials. Reconnect spark

plug wire.

: Never bury

16.716.7

16.7

16.716.7

CHIPPING OPERATION

(TKD MODLES ONLY)

Wearing Eye Protection and Durable

Gloves is recommended while operating

chipper.

Use caution when using chipper

Your

TERMITE

and limbs up to 2" (50.8mm) diameter.

2

® chipper is designed to process tree branches

"

(50.8 mm)

Maximum

Diameter

Several small branches can be grouped together and fed

together into the chipper (see fig 2.).

When feeding forked branches, squeeze forks together and

feed into chipper entrance (DO NOT overload). If forks are too

large, use a pair of loppers to trim forks down to size. A lopper

storage bracket is provided on every unit (loppers are not

included)

16.816.8

CLEARING A CLOGGED CHIPPER HOPPER

16.8

16.816.8

Under normal circumstances, allow time for machine

to clear all wood from chipper hopper before stopping

engine. Otherwise, remaining pieces of wood will jam

inside of chipper when engine stops. (See Tamper page 7).

Disconnect spark plug wire.

Remove debris bag quick disconnect from debris outlet on

machine.

Wearing durable gloves, access impeller through

debris outlet on fan housing and rotate impeller

counter clock wise to dislodge and remove jam and

remove debris from hopper with tongs or equivalent.

Reconnect debris bag quick disconnect to machine.

Reconnect spark plug wire.

Part No. 890394 Form No. F011398B

Page 5 of 12

Page 6

1616

16

1616

OPERATION continued

(fig. 2) Note: Dry wood is

harder to chip than

green wood. (SP model

shown)

16.16.

33

16.

3

16.16.

33

DEBRIS BA G

Debris bags are normal replaceable wear items.

Note: Frequently empty debris to prevent bag overloading with

more weight than you can lift.

An optional bag and dust cover is av ailable for use where debris will be

vacuumed in dusty conditions (see Optional Accessories shown on

page 1).

DO NOT place bag on or near hot surface, such as engine. Run

engine at 1/2 throttle for first 1/2 hour to condition new bag. Y our

new bag requires a break-in period to condition the pores of the

material against premature blockage. The entire bag surface serve s

as a filter, and m ust be able to breath to hav e good v acuum

performance.

Be sure engine has come to a complete stop before removing

or emptying bag.

This vacuum is designed for picking up trash, organic

material and other similar debris

(see Safety Warnings page 2-3).

However, many vacuums are used where dust is mixed with

trash. Your unit can inter mittently vacuum in dusty areas. Dust

is the greatest cause of lost vacuum performance. However,

following these rules will help maintain your machine's ability to

vacuum in dusty conditions:

•Run machine at idle to quarter throttle.

•The debris bag must be cleaned more frequently. A vacuum

with a clean, pillow soft bag will have good pickup performance. One with a dirty, tight bag will have poor pickup

performance. If dirty, empty debris and vigorously shake bag

free of dust.

•Machine or pressure-wash debris bag if normal cleaning does

not fully clean bag. Bag should be thoroughly dry before use.

Having one or more spare debris bags is a good way to reduce down time

while dirty bags are being cleaned.

16.16.

99

16.

9

16.16.

99

MULCH

Wood chips made from branches in your own yard make excellent

mulch. A thick blanket of wood chips around plants and flowers to

keeps weeds out and moisture in.

16.16.

1010

16.

10

16.16.

1010

COMPOST

Vacuumed lea ves, grass and other organic material from your own

yard can be emptied into a pile or composter to provide enriched soil

for later use as fertilizer in gardens and flower beds (see fig. 3).

Note: Allow green chips to dry before spreading around living plants.

•DO NOT leave debris in bag while in storage.

Part No. 890394 Form No. F011398B

Page 6 of 12

Page 7

OPERATION continued

1616

16

1616

16.16.

16.

16.16.

1212

12

1212

TAMPER

16.416.4

16.4

16.416.4

HANDLING & TRANSPORTING:

Before turning machine off, use the Tamper to slowly push

remaining pieces of wood through the chipper. This can

prevent any remaining wood from jamming in the chipper

when machine is turned off.

Do not leave tamper on the ground, store tamper in the

chipper hopper.

Using two people to lift machine is recommended. Lift holding the

handle and front of nozzle. Secure in place during transport.

16.516.5

16.5

16.516.5

STORAGE

Never store engine indoors or in enclosed poorly ventilated areas with fuel in tank, where fuel fumes may reach an

open flame, spark or pilot light, as on a furnace, water heater,

clothes dryer or other gas appliance.

If engine is to be unused for 30 days or more, prepare as

follows:

Be sure engine is cool. Do not smoke. Remove all

gasoline from carburetor and fuel tank to prevent gum deposits

from forming on these parts and causing possible malfunction

of engine. Drain fuel outdoors, into an approved container,

away from open flame. Run engine until fuel tank is empty

and engine runs out of gasoline.

NOTE: Fuel stabilizer (such as Sta-Bil) is an acceptable

alternative in minimizing the formation of fuel gum deposits

during storage. Add stabilizer to gasoline in fuel tank or

storage container. Always follow mix ratio found on stabilizer

container. Run engine at least 10 min. after adding stabilizer to

allow it to reach the carburetor.

Tamper Storage Position (SP model shown).

Do not store with debris in bag.

Part No. 890394 Form No. F011398B

Page 7 of 12

Page 8

1717

DANGER

KEEP HANDS and FEET AWAY

17

1717

MAINTENANCE

Use only a qualified mechanic for

any adjustments, disassembly or

any kind of repair .

WARNING: TO AVOID PERSONAL INJURY, ALWAYS

TURN MACHINE OFF, MAKE SURE ALL MOVING

PARTS COME TO A COMPLETE STOP.

DISCONNECT SP ARK PLUG WIRE

BEFORE SERVICING UNIT .

ENGINE: See engine manufacturer

operator's instructions.

DEBRIS BAG: See page 6.

RECONNECT SP ARK PLUG WIRE,

GUARDS, BA G, CAPS AND / OR

HOSE BEFORE ST ARTING ENGINE.

17.117.1

IMPELLER REMOVAL and CHIPPER ADJUSTMENT

17.1

17.117.1

IMPELLER REMOV AL

1. Wait for engine to cool and disconnect spark plug.

2. Drain fuel and oil from the engine.

3. Remove bag, quick release, and upper handle. Do not kink, stretch,

or break control cables, control housings, or end fittings while removing

handles.

4. Remove housing top plate by removing bolts around outside of

housing.

5. Leaving engine fastened to top plate, remove impeller bolt and lock

washer and slide impeller off crankshaft ( A puller may be required).

6. Retain shim washers used at end of crankshaft for use at impeller

reinstallation (see fig. 7). Howe ver , your unit ma y or may not ha ve

required the use of shim washers.

7. If impeller slides off freely, proceed to (step 11 or step 15).

(Do not drop impeller).

8. If impeller does not slide off crankshaft, place two crowbars between

impeller and housing on opposite sides. Pry impeller away from engine

until it loosens.

9. If the impeller cannot be loosened, obtain a 1” (25.4mm) longer bolt of

the same diameter and thread type as the impeller bolt. Invert engine

and impeller and support engine above ground to prevent recoil

damage. Thread longer bolt b y hand into the crankshaft until bolt

bottoms. Using a suitable gear or wheel puller against the bolt head and

the impeller back-plate (near the blades), remove impeller from shaft.

Using a penetrating oil can help loosen a stuck impeller.

CHIPPER BLADE REMOVAL AND SHARPENING

Chipper blades are normal replaceable wear items.

DANGER

KEEP HANDS and FEET AWAY

DANGER Chipper blade is sharp.

Replace any damaged blade.

Depending on the type and amount of wood being chipped, the

chipper blade will eventually get dull, losing it’s cutting ability.

Evidence of a dull blade is a noticeably reduced chipping ability or a

rough cut on end of branch.

Note: The chipper blade gap is factory set and should be checked

each time impeller is removed from engine crankshaft and reset if

required. If reassembly requires a different quantity of shim

washers, Billy Goat

10. Using a 3/16" Allen wrench and 1/2" open end wrench, remove

chipper blade from impeller.

11. Sharpen blade by lightly grinding the cutting edge of the blade at

40 degrees (see fig. 5). It is not necessary to remove all nicks from

the cutting edge.

blade during sharpening. This will reduce it’s heat- treated hardness

properties and will reduce blade life. Evidence of too much heat buildup is a change of color along sharpened edge.

12. The same chipper blade can be sharpened seve ral times.

Howev er, b lade replacement is required when blade no longer

overhangs the chip relief hole in impeller back plate or if increased

vibration occurs (see fig. 5).

13. Chipper blade installation is in reverse order of removal.

o

®

shim washer must be used.

CAUTION:

Be careful to avoid heat b uildup in the

Blade

INCORRECTCORRECT

Blade

40

EDGE OF CHIP

RELIEF HOLE

Fig. 5

14. T o reinstall impeller , use a new impeller bolt and loc kwasher and

use exactly the same crankshaft impeller shim washers as were

removed during disassembly (unless they were damaged). Note:

your unit may or may not have required the use of shim washers

15. Tighten impeller bolt. Torque impeller bolt to 50 Ft. Lbs. (68 N.m)

(see item 51 on page 11).

16. Slowly rotate impeller to insure proper chipper blade clearance.

Check to see that gap between chipper blade and anvil surface (on

lower side of housing top plate) measures between 0.040"(1.02mm)

and 0.080"(2.03mm).

17. If gap is less than 0.040"(0.51mm), add shim washer 890130

(0.060"{1.52mm} thick) and/or 890131 (0.020"{1.02mm} thick),

whichever is required. If gap is more than 0.080"(2.03mm), remove

one or more shim washers as needed to obtain correct gap (see fig. 6

& fig. 7). The chipper will function at up to a maxim um of

0.125"(3.18mm) gap.

.

Part No. 890394 Form No. F011398B

Page 8 of 12

Page 9

1717

17

1717

MAINTENANCE continued

17.117.1

17.1

17.117.1

IMPELLER REMOVAL continued

18. If chipper blade properly clears anvil surface, proceed to step . If

not, return to (step 14) and add or subtract shim washers as

needed to obtain a correct gap.

19. Reinstall engine and impeller onto housing in reverse order of

removal.

20. Before connecting spark plug wire, slowly pull engine starting

rope to insure that impeller rotates freely .

21. Reinstall spark plug wire.

17.217.2

17.2

17.217.2

Maintenance Schedule

Maintenance Operation

Engine (See Engine Manual)

Check for excessive vibration

Clean Debris Bag

Check bag strap tightness

Inspect for loose parts

Inspect for worn or damaged parts

Follow these hourly

maintenance intervals.

Every

Use

Every 5 hrs

or (Daily)

fig. 6

fig. 7

Date of

Service

MAINTENANCE HISTOR Y

Service Performed

Part No. 890394 Form No. F011398B

Page 9 of 12

Page 10

1818

18

1818

PARTS DRAWING

KD510H, KD510HS, KD510,

R

Part No. 890394 Form No. F011398B

KD510IC, TKD510IC, TKD510H

Page 10 of 12

Page 11

item

PARTS

19

no. LIST

1 TURF QUICK DEBRIS BAG (service) 890305 1 890305 1 890305 1 890305 1 890307 1 890307 1

2 THROTTLE 850270 1 850270 1 850270 1 850270 1 850270 1 850270 1

3

4 NUT LOCK (1/4 - 20 ) *8160001 8 *8160001 8 *8160001 8 *8160001 8 *8160001 8 *8160001 8

5 SCREW CAP ( 1/4 - 20 x 1-1/2 HEX ) *8041008 4 *8041008 4 *8041008 4 *8041008 4 *8041008 5 *8041008 5

6 HANDLE ASS’Y (incl. items 4(5),5(5),11(2),75(2),76) 900054 1 900054 1 900054 1 900054 1 900056 1 900056 1

7 AXLE HEIGHT ADJUST 890389 1 890389 1 890389 1 890389 1 890389 1 890389 1

8 SCREW HANDLE 5/16 - 18 x 2-1/4 *900547 2 *900547 2 *900547 2 *900547 2 *900547 2 *900547 2

9 CLAMP CABLE 1" I.D. 900813 2 900813 2 900813 2 900813 2 900813 2 900813 2

10 SCREW CAP 1/4 - 20 x 1 3/4 *8041009 1 *8041009 1 *8041009 1 *8041009 1 *8041009 1 *8041009 1

11 BAR BAG SUPPORT 900039 2 900039 2 900039 2 900039 2 900039 2 900039 2

12 DOOR EXHAUST ASS’Y (incl. item 62 ) 890148 1 890148 1 890148 1 890148 1 890148 1 890148 1

13

14 BOLT-CARRIAGE 1/4x3/4 *8024021 2 *8024021 2 *8024021 2 *8024021 2 *8024021 6 *8024021 6

16 WASHER 1/4 FC ZP *8171002 2 *8171002 2 *8171002 2 *8171002 2 *8171002 2 *8171002 2

17

18 BRACKET - HEIGHT ADJUSTMENT 900932 1 900932 1 900932 1 900932 1 900932 1 900932 1

19

20 SPRING 900136 1 900136 1 900136 1 900136 1 900136 1 900136 1

21 TIRE - ONLY (PER ASSY) 900507 1 900507 1 900507 1 900507 1 900507 1 900507 1

22 PIN - HAIR COTTER 900471 1 900471 1 900471 1 900471 1 900471 1 900471 1

23 ROD SHORT HEIGHT ADJUSTMENT 890110 1 890110 1 890110 1 890110 1 890110 1 890110 1

24 BOLT - CARRIAGE 5/16 - 18 x 4 1/2 *8024054 4 *8024054 4 *8024054 4 *8024054 4 *8024054 4 *8024054 4

25

26 NUT LOCK 5/16 - 18 HEX *8160002 4 *8160002 4 *8160002 4 *8160002 6 *8160002 4 *8160002 4

27 HANDLE LOWER KD510 890346 1 890346 1 890346 1 890346 1 890346 1 890346 1

28 PLATE HANDLE SUPPORT 900933 1 900933 1 900933 1 900933 2 900933 1 900933 1

29 LABEL DANGER CUT FINGER 400424 2 400424 2 400424 2 400424 2 400424 2 400424 2

30 WASHER FLAT CUT 5/16 *8171003 2 *8171003 2 *8171003 2 *8171003 2 *8171003 2 *8171003 2

31

32 HUBCAP 1/2 WASHER 900927 4 900927 4 900927 4 900927 4 900927 4 900927 4

33

34 WHEEL ASS’Y (incl. items 21) 900509 4 900509 4 900509 4 900509 4 900509 4 900509 4

35 WASHER 0.75 “C” 900997 1 - 0 900997 1 - 0 900997 1 - 0 900997 1 - 0 900997 1 - 0 900997 1 - 0

36

37 SCREW SM 1/4x3/4 TYPE A *8122082 4

38 PLATE SKID (incl. items 78) 890413 1

39

40 SCREW CAP 1/4 - 20 x 1 - 1/4 *8041007 4 *8041007 4 *8041007 4 *8041007 4 *8041007 6 *8041007 6

41

42 SCREW SELF TAPPING 10 - 24 x 1/2 *8123086 1 *8123086 1 *8123086 1 *8123086 1 *8123086 1 *8123086 1

43 NOZZLE MAINFRAME ASS’Y (incl. one of items 29,44,42) 890391 1 890391 1 890391 1 890391 1 890391 1 890391 1

44 PLUG 900146 1 900146 1 900146 1 900146 1 900146 1 900146 1

45

46 BLADE CHIPPER - - - - - - - - 890101 1 890101 1

47 IMPELLER ASS’Y (incl. items 46, 49, 50, 51, 59, 65, 66, 67 ) 900215 1 900215 1 900003 1 900003 1 890144 1 890146 1

48 LABEL CHIPPER - - - - - - - - 890152 1 890152 1

49 KEY 900162 2 900162 2 900162 2 900162 2 9201060 1 900162 2

50 WASHER LOCK 3/8 TWISTED TOOTH 400502 1 400502 1 400502 1 400502 1 400502 1 400502 1

51 SCREW CAP 3/8 -24 x 1 (HARDENED)(TORQ.50 FT-LBS)(68N.m) 900154 1 900154 1 900154 1 900154 1 900154 1 900154 1

52 HOUSING ASS’Y (incl. items 12, 14, 15, 16, 86) 890371 1 890371 1 890371 1 890417 1 890371 1 890371 1

53 ENGINE HONDA 5.5 H.P. GXV160 KN12 - - - - 900615 1 900615 1 - - 900615 1

ENGINE BRIGGS & STRAT TON 5 H.P. QUANTUM 890404 1 - - - - - - - - - -

ENGINE BRIGGS & STRATTON 5 H.P. QUANTUM IC - - 890403 1 - 1 - 1 890403 1 - 54

55

56 SCREW CAP 3/8 - 1-1/2 TAPTITE 890408 3 890408 3 - - - - 890408 3 - -

SCREW CAP 5/16 - 24 x 1" - - - - 400164 3 400164 3 - - 400164 3

57 CAP HUB 900486 4 900486 4 900486 4 900486 4 900486 4 900486 4

58 WASHER FLAT 1/2 SAE *8172011 4 *8172011 4 *8172011 4 *8172011 4 *8172011 4 *8172011 4

59 SCREW SOCKET HD. 5/16 - 18 x 3/4 GR. 8 890103 2 890103 2

60 HT ADJUST ASSY 890110-01 1 890110-01 1 890110-01 1 890110-01 1 890110-01 1 890110-01 1

61 NUT LOCK 1/2 THIN 8161044 4 8161044 4 8161044 4 8161044 4 8161044 4 8161044 4

62 LABEL DANGER FLYING MATERIAL 810736 1 810736 1 810736 1 810736 1 810736 1 810736 1

63 LABEL DO NOT FILL WHEN ENGINE IS HOT 400268 1 400268 1 400268 1 400268 1 400268 1 400268 1

64

65 NUT KEPS 5/16 -18 - - - - - - - - 890104 2 890104 2

66 WASHER SHIM 0.060" (1.52mm) - - - - - - - - 890130 0-1 890130 0-1

67 WASHER SHIM 0.020" (0.51mm) - - - - - - - - 890131 0-2 890131 0-2

68 PLATE TOP ASS’Y (incl. items 14, 15, 29, 48, 69, 70, 71, 72) 890402 1 890402 1 890402 1 890402 1 890400 1 890400 1

69 GUARD FLAPPER - - - - - - - - 890119 2 890119 2

70 PLATE FLAPPER ENTRANCE - - - - - - - - 890127 2 890127 2

71 SCREW CAP 1/4 - 20 x 1/2 HWH 890359 15 890359 15 890359 15 890359 15 890359 15 890359 15

72

73 KNOB WING 5/16 - 18 890108 2 890108 2 890108 2 890108 2 890108 2 890108 2

74 NUT LOCK 5/16 - 18 THIN HT. *8161041 2 *8161041 2 *8161041 2 *8161041 4 *8161041 2 *8161041 2

75 GRIP HANDLE 400570 2 400570 2 400570 2 400570 2 400570 2 400570 2

76 BRACKET LOPPER LOOP - - - - - - - - 890167 1 890167 1

77

Description

KD510 QTY KD510IC QTY KD510H QTY KD510HS QTY TKD510IC QTY TKD510H QTY

Part No. Part No. Part No. Part No. Part No. Part No.

* Denotes

standard

hardware

item that

may be

purchased

locally.

Part No. 890394 Form No. F011398B

Page 11 of 12

Page 12

1919

19

1919

PARTS LIST CONTINUED

( Continued from page 11 )

item

PARTS

no. LIST Description

78 BOLT CARRIAGE 5/ 16 -18 x3/ 4 " - - - - - - 8024039 2 - - - 79 LINE PVC - - - - - - 900732 1 - - - 80

81

82

83 CONNECTOR BAG QUICK 890176 1 890176 1 890176 1 890176 1 890176 1 890176 1

84 LABEL READ OWNER'S MANUAL 890301 1 890301 1 890301 1 890301 1 890301 1 890301 1

85 TAMPER - - - - - - - - 890229 1 - 86 LABEL EAR/EYE BREA TI NG 890254 1 89 0254 1 89025 4 1 89025 4 1 890254 1 890254 1

87

2020

20

2020

TROUBLESHOOTING

Problem

Will not vacuum or has poor vacuum performance.

Poor chipping performance.

Engine stalls or labors when chipping.

Abnormal vibration.

Engine will not start.

Engine is locked, will not

pull over.

KD510 QTY KD510IC QTY KD510H QTY KD510HS QTY TKD510IC QTY TKD510H QTY

Part No . Part No. P a r t No . Par t No . Part No. Part No.

Before Requesting Service Review These Suggestions

Possible Cause

Dirty debris bag. Nozzle height set too high or too low.

Hose kit cap missing. Clogged nozzle or e xhaust.

Excessive quantity of debris.

Extremely hard wood. Dull or damaged chipper blade.

Feeding branches into chipper too rapidly . Engine

service may be required.

Loose or out of balance impeller or loose engine.

Stop switch off (Honda only). Throttle in off position.

Engine not in full choke position (Honda only). Out of

gasoline. Bad or old gasoline. Spark Plug wire

disconnected. Dirty air cleaner.Saf ety Interlock engaged.

Debris locked in chipper blade, hopper or inside

impeller. Engine problem.

Clean debris bag. Shake bag clean or wash. Adjust

nozzle height. Check for hose kit cap. Unclog nozzle or

exhaust (see page 5). Allow air to feed with debris.

Avoid extremely hard wood. Sharpen or replace

chipper blade (see page 8).

Feed branches at a slower rate. Service engine.

Check impeller and replace if required. Check

Engine.

Check stop switches, throttle, choke position and

gasoline. Connect spark plug wire. Clean or replace

air cleaner. Or contact a qualified service person.

Quick Disconnect not fully engaged.

See page 5, Clearing a clogged chipper hopper.

Contact an engine servicing dealer for engine

problems.

Solution

* Denotes

standard

hardware

item that

may be

purchased

locally.

22.122.1

22.1

22.122.1

Contact your nearest engine manufacturer's autho-

Engine Service and Warranty

rized servicing dealer.

R

2121

21

Serial Plate

2121

L

A

98

L

A

p

108

Operator

Purchase

Date

Model Serial No.

ecord your machine model, serial number

and date-of-purchase and where purchased

1803 S. Jefferson

P.O. Box 308

Lee's Summit,

R

Unit(Weight) Engine Power

lbs. kg kW rpm

MO 64063 / USA

Tel (816) 524-9666

Fax (816) 524-6983

Purchased

from

Part No. 890394 Form No. F011398B

min

-1

2222

22

2222

Please fill in the WARRANTY CARD and send the upper part to Billy Goat.

The WARRANTY terms are stated on the lower part which remains with the

user. Whenever a Billy Goat Machine is faulty due to a defect in material

and / or workmanship, the owner should make a warranty claim as follows:

Note:

& Serial number who are printed on the Billy Goat Serial Plate.

Page 12 of 12

WARRANTY PROCEDURE

The Machine should be taken to the dealer from whom it was

purchased or to an authorized Billy Goat dealer.

The owner should present the remaining half of the Warranty

Registration Card, or, if this is not available, the invoice or receipt.

The Warranty Claim will be filled in by the authorized Billy Goat Dealer,

who will send it with the faulty part to Billy Goat headquarters.

The Quality / Service department at Billy Goat headquarters will study

the claim and parts and will notify their conclusions.

The decision by the Quality / Service department at Billy Goat

headquarters to approve or reject a Warranty claim is final and

binding.

To process a Warranty Claim, it is necessary to quote the Model

BILLY GOA T INDUSTRIES INC.

R

P . O. BO X 308 (1803 S JEFFERSON) LEE'S SUMMIT, MO 64063 / USA

PHONE: 816-524-9666 FAX: 816-524-6983

Loading...

Loading...