Billy Goat DL2900V, DL2900VMM, DL3700V Owner's Manual

DL2900V, DL2900VMM, DL3700V Owner’s Manual

DL Truck Loader Vacuum Owner’s Manual

DL2900V, DL2900VMM, DL3700V

Beginning Serial #: 100515001

NOT FOR SALE IN CALIFORNIA

Original Instructions

IMPORTANT- READ CAREFULLY BEFORE USE AND KEEP FOR FUTURE REFERENCE

Part No. 792504 Form No. F070617B

1

Table of Contents

Specications/Accessories

Instruction Labels/Packing Checklist

Packing Checklist

Assembly

Operation

Maintenance

Troubleshooting

3

4

5-6

6-8

9-10

10-13

14

Service Kits

Illustrated Parts and Part Lists

Declaration of Conformity

15-16

17-24

25-27

Part No. 792504 Form No. F070617B

2

Specications

DL2900V DL2900VMM DL3700V

Engine: HP 29 HP (21.6kW) 29 HP (21.6kW) 37 HP (27.6kW)

Engine: Model 5424770004J1 5424770004J1 61E3770030J1

Engine: Type Briggs and Stratton Vanguard Briggs and Stratton Vanguard Briggs and Stratton Vanguard

Engine: Fuel Capacity 6 gal. (22 L) 6 gal. (22 L) 6 gal. (22 L)

Engine: Oil Capacity 2.4 qt. (2.3 L) 2.4 qt. (2.3 L) 2.4 qt. (2.3 L)

Total Unit Weight 475 lb. (215.5 kg) 475 lb. (215.5 kg) 475 lb. (215.5 kg)

Max. Operating Slope 25° 25° 25°

Overall Length 60” (1.52m) 60” (1.52m) 60” (1.52m)

Overall Width 32.25” (0.82m) 32.25” (0.82m) 32.25” (0.82m)

Overall Height 74 7/8” (1.90m) 54” (1.37m) 74 7/8” (1.90m)

In accordance with 2000/14/EEC 122 dB(a) 122 dB(a) 122 dB(a)

Sound at Operator’s Position 100 dBa 100 dBa 100 dBa

Vibration at Operator’s Position 0.32g (2.96 m/s2) 0.32g (2.96 m/s2) 0.32g (2.96 m/s2)

Note: Battery is not included! Your DL requires a 12V battery

(40AH, 240CCA min., U1 series group) for proper t and

function.

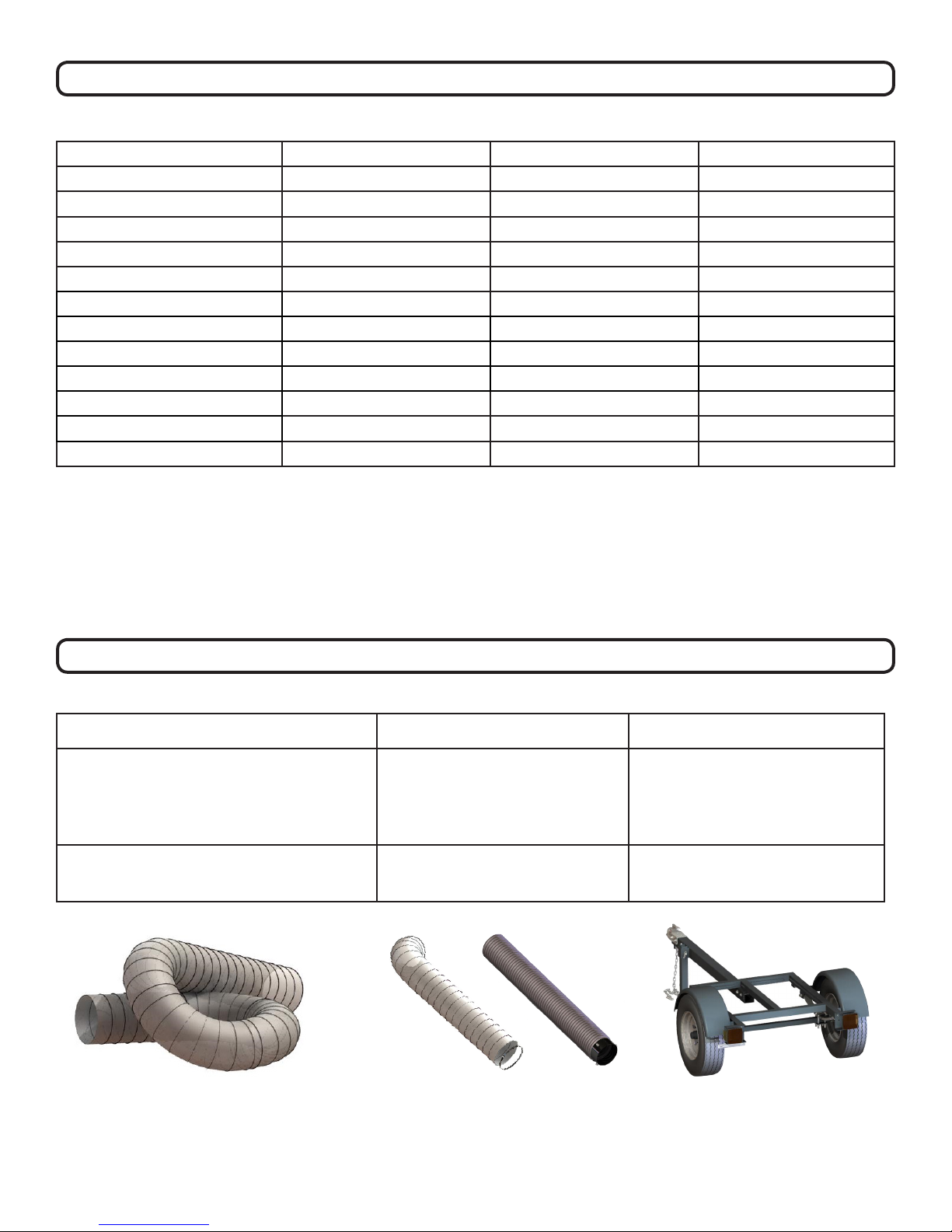

Accessories

Hose Replacement Kit Exhaust Hose Kit Trailer DL

Standard on DL units. 10’ (3.0m) long, clear

polyurethane hose

12” Hose P/N 791034 (DL2900V,DL2900VMM)

14” Hose P/N 792208 (DL3700V)

8” x 5’ (203mm x 1.5m) exible hose

increases exhaust distance. 8” x 5’

(203mm x1.5m) exible steel hose

increases exhaust distance.

8” Flexible Hose P/N 791107

8” Flexible Steel Hose P/N 791106

Heavy duty spring axle trailer designed

for towing your DL. Allows unit to be

mounted for pickup from rear.

P/N 791152

Part No. 792504 Form No. F070617B

3

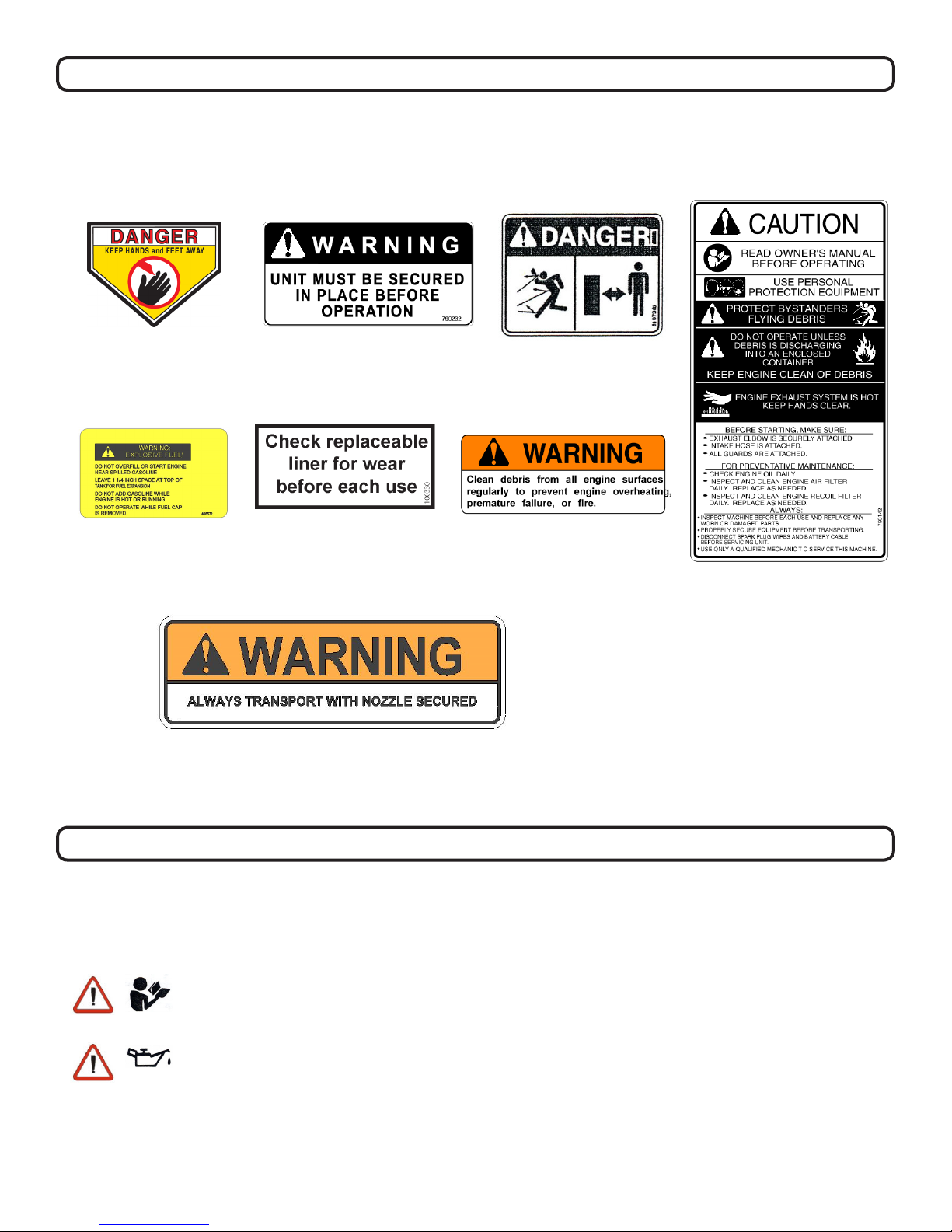

Instruction Labels

The labels shown below were installed on your BILLY GOAT® DL Vacuum. If any labels are damaged or

missing, replace them before operating this equipment. For your convenience in ordering replacement labels,

part numbers are included in the Illustrated Parts List. The correct position for each label may be determined

by referring to the Figure and Item numbers shown.

DANGER KEEP HANDS

Fig. 1

AND FEET AWAY

P/N 440424

Fig. 4

EXPLOSIVE FUEL

Fig 2.

WARNING SECURE

P/N 790232

Fig. 5

WARNING LINER DL

P/N 100330

Fig. 8

SECURE NOZZLE

P/N 790232

DANGER FLYING DEBRIS

Fig. 3

P/N 810736

Fig. 6

WARNING ENGINE OVERHEAT

P/N 811215

Fig. 7

DL INSTRUCT/WARN

P/N 790142

Packing Checklist

Your Billy Goat is shipped from the factory in one carton and is completely assembled except for the

exhaust elbow, nozzle, handle loop for nozzle, hose booms, hose bands, hose coupler, hose clamps

and related hardware.

READ all safety instructions before assembling unit.

TAKE CAUTION when removing the unit from the box.

PUT OIL IN ENGINE BEFORE STARTING

Part No. 792504 Form No. F070617B

4

Packing Checklist Continued

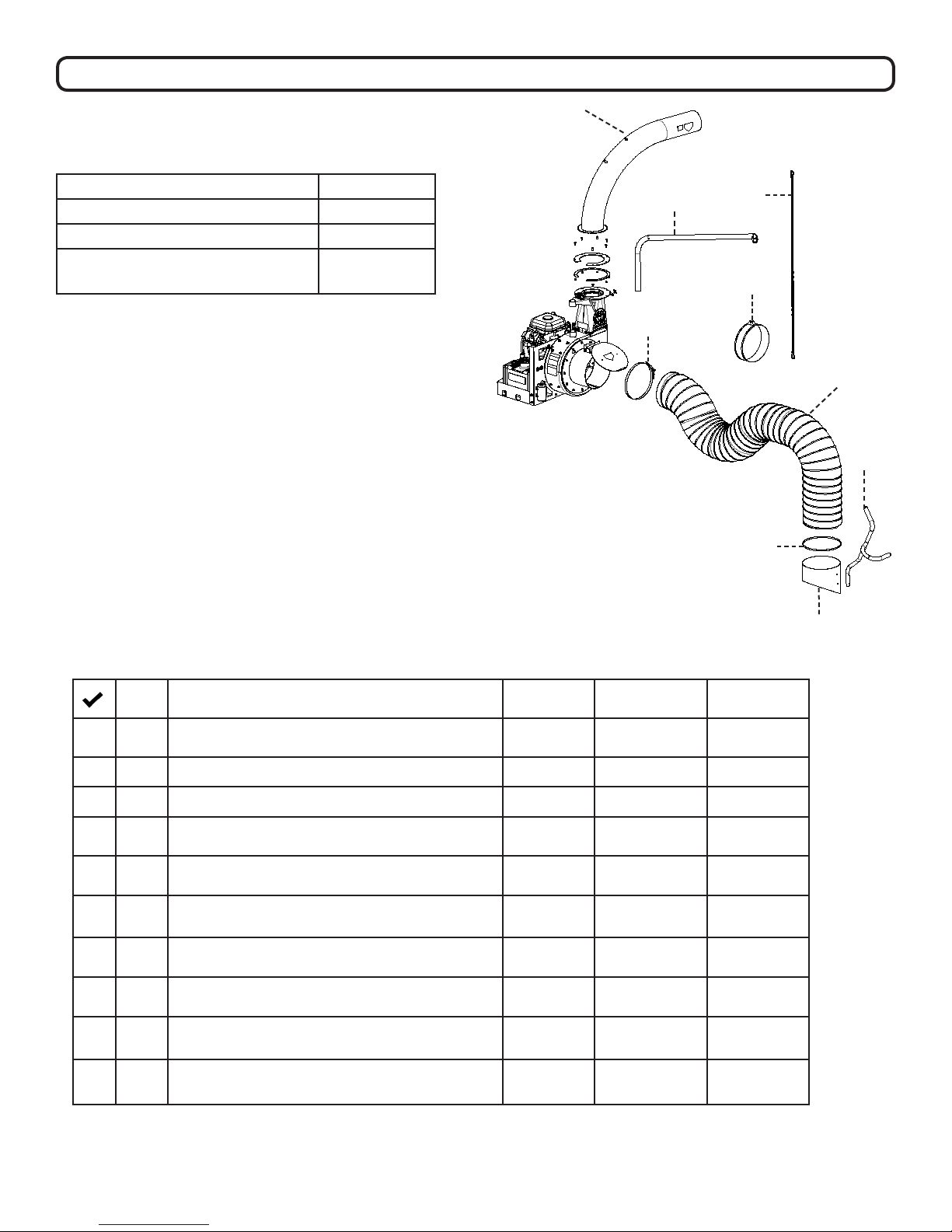

Parts Bag and Literature Assembly

Includes:

A

Item P/N

Warranty Card 400972

Owner’s Manual 792504

General Safety and Warnings

100294

Manual

NOTE: BATTERY IS NOT INCLUDED.

REQUIRES 12 V BATTERY, 40 AH, 240 CCA

MIN. U1 SERIES GROUP BATTERY FOR

PROPER FIT.

Boxing Parts Checklist

B

C

E

D

F

I

G

H

I.D. Item DL2900V

P/N

A Exhaust Elbow 791114-S 791140 791114-S

B Hose Boom Assembly 791113 791113 791113

C Boom Chain 791117 791117 791117

D -Clamp T-bolt Overcenter 12” Hose (DL2900V)

-Clamp T-bolt Overcenter 14” Hose (DL3700V)

E -Band hose boom 12” (DL2900V & DL2900VMM)

-Band hose boom 14.50” (DL3700V)

F Hose 12” X 10” (DL2900V & DL2900VMM)

Hose 14”x 10’ DL (DL3700V)

G -Hose clamps 12”

-Hose clamps 14”

H -Nozzle intake 12” (DL2900V)

-Nozzle intake 14” (DL3700V)

I Handle Nozzle 791116 791116 791116

Parts Bag & Literature Assy 792020 792020 792021

791065 791065 792219

790153 790153 792403

791034 791034 792208

790150 790150 792224

790149-S 790149-S 792605

DL2900VMM

P/N

DL3700V

P/N

Part No. 792504 Form No. F070617B

5

Packing Checklist Continued

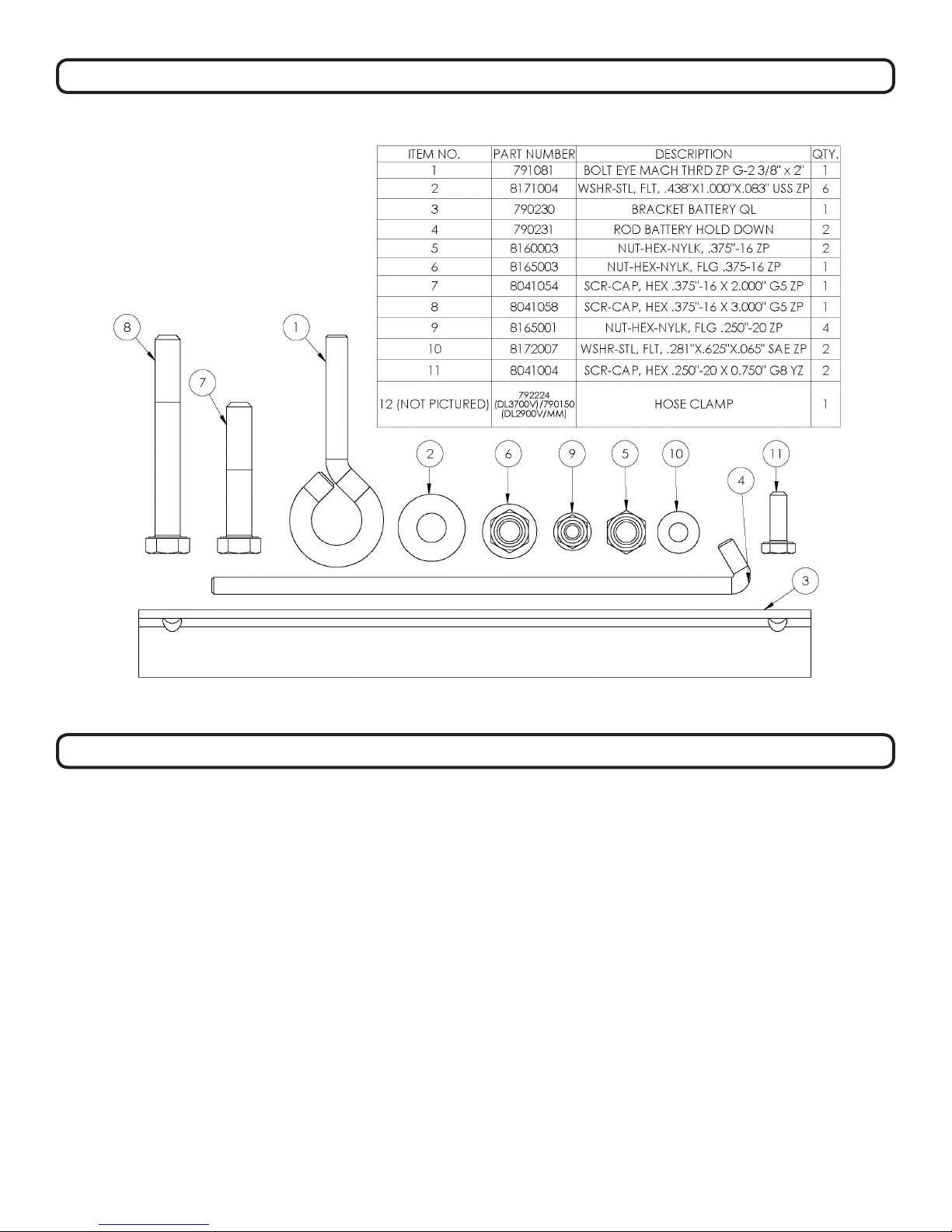

Parts Bag Hardware Includes:

Fig. 9

Assembly

NOTE: Items in ( ) can be referenced in the Parts Illustration and Parts List on pages 17-24.

1. SECURELY ATTACH unit to the bed of a truck or to a trailer, so that the exhaust discharges into an

enclosed container. NOTE: This unit must be securely mounted to the bed of a truck or to a trailer before

operating.

2. ATTACH the hose boom (item 2) to hose (item 3) by sliding the boom through the rings on the top of the

housing.

3. ATTACH hose (item 3) to housing intake, using hose clamp (item 25) making sure to place the safety switch under the clamp. Then place the clamp (item 25) over and around the end of the hose to be

attached to the housing. Slide the hose onto the housing intake and place the shut off switch under the

clamp. Make sure the shut off switch is pressed in or the vacuum will not start, and clamp the hose to the

intake. (See page 8 for illustration)

4. ASSEMBLE nozzle handle (item 6), to nozzle intake (item 9), using screw (item 7), eye bolt (item 8),

washers (item 10) and lock nuts (item 11).

5. ATTACH assembled nozzle to hose using hose clamp (item 25). Before tightening hose clamp, position

nozzle handle upward when hose is stretched to prevent twisting. Load on hose assembly during operation.

Part No. 792504 Form No. F070617B

6

Assembly Continued

NOTE: Items in ( ) can be referenced in the Parts Illustration and Parts List on pages 17-24.

6. ASSEMBLE hose band (item 2) around hose and secure chain between the anges of the hose band using

capscrew and lock nut (not pictured in Parts Drawing 1). Attach the chain (item 12) to the boom and the screw

on the hose band. (See “ADJUSTING HOSE BOOM” on page 11).

7. SECURELY ATTACH exhaust elbow (item 31) capturing both anges inside the clamp, then rmly tighten

the clamp, securing the elbow to the housing (see “MOUNTING” below).

8. INSTALL a standard 12 volt lawn and garden battery “U1” series (not included) with at least 240 cold cranking amps anWd a 40 amp hour rating by using battery bracket (item 60), hold down rods (item 59), washers

and lock nuts (Not pictured in Parts Drawing 4).

9. ATTACH the red battery cable to the + terminal and the black battery cable to – terminal on the battery.

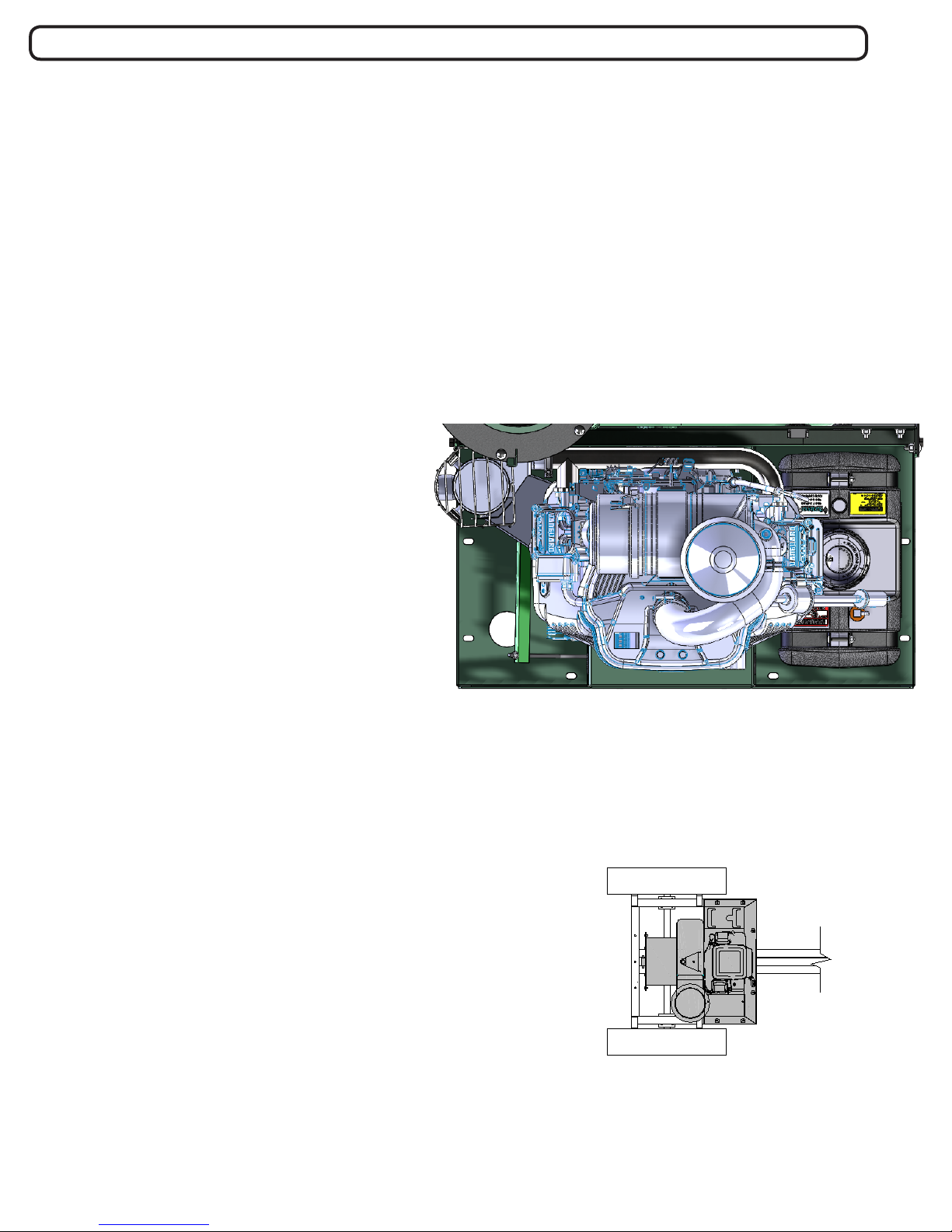

Mounting Main Unit

General: Unit must be securely mounted to a

trailer, truck bed, or other similar surface before

use. Do not use this unit in a freestanding position. Unit is not stable until it has been secured

in place.

Secure unit by bolting through the base of the

unit and through the mounting surface using

3/8" dia. bolts, with washers and locking nuts

(see Fig. 10).

Mounting: Fig. 11 illustrates the mounting position to the trailer (Billy Goat Part No. 791152)

available from your Billy Goat dealer. The unit

is only mounted one way.

Fig. 10

Fig. 11

Part No. 792504 Form No. F070617B

7

Assembly Continued

Mounting Exhaust Elbow (See Fig. 12)

Note: this process requires two people, one to

support the exhaust elbow and one to attach

plates and hardware.

1. Remove the hardware from the clamps (items

30 and 40).

2. Apply good quality grease to the top and

bottom of the toothed plate of the exhaust elbow

(item 31). Also grease top surface of housing and

bottom of clamp plates where the gear will rotate.

3. Place the exhaust elbow on the chute with the

teeth of the ange against the worm gear and the

exhaust holes, aligning.

4. Place the two bottom plates (item 35) on the

opposite edges beside the elbow teeth aligning

the holes.

5. Place the top plates (item 34) on top of the

lower plates aligning the holes.

6. Secure the assembly with a plate half on top of

the elbow ange and a plate half on bottom of the

housing ange using 6, 1” carriage bolts and 6

lock nuts (removed hardware in step 1).

Fig. 12

Part No. 792504 Form No. F070617B

8

Operation

Vacuuming Operation

Important

With the machine off and spark plug disconnected

check the condition of the replaceable liner before

every use and replace if necessary.

Exhaust Direction and Distance

Exhaust direction and distance are controlled by

the rotation of the exhaust elbow. Typically debris is

aimed to discharge to the rear of the container. The

direction of discharge is adjusted by turning the crank

on the exhaust elbow clamp and rotating the elbow to

the desired direction.

Note: Elbow is heavy. Use caution when adjusting.

Never stand directly under the elbow while adjusting

direction of exhaust. Never direct exhaust into an

area where bystanders may cross the path of the

debris.

Fig. 13

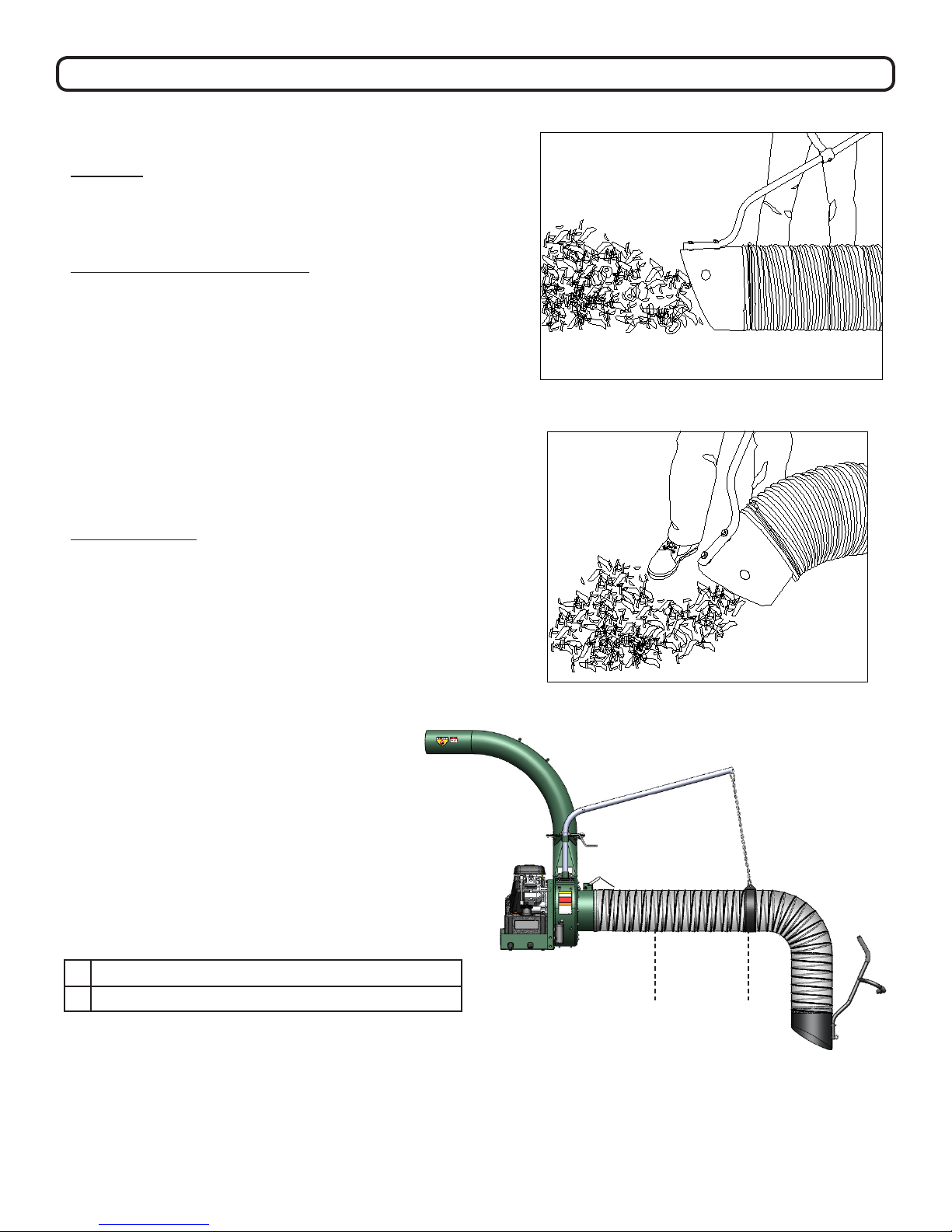

Intake Operation

With the fully assembled machine running, move

the nozzle in sweeping motions over debris. Always

allow air to ow into the nozzle along with the debris.

Do not completely block the nozzle when vacuuming,

it will reduce performance, and increase clogging

(See Fig. 13). For removal of heavier debris, or debris

that is stuck to the ground, rock nozzle forward to

concentrate suction power around the debris (See

Fig. 14

Fig. 14).

Adjusting Hose Boom

Properly adjusting the boom prevents most hose

clogs from occurring and maximizes vacuum

performance by keeping the hose straight and

perpendicular to the housing (see Fig. 15). Raise

or lower one of the attachment links to a different

area on the chain to make height adjustments.

A Hose

B Hose Band (stretch hose out before clamping).

A B

Fig. 15

Part No. 792504 Form No. F070617B

9

Loading...

Loading...