Billy Goat BC2600 Owner's Manual

BC26 MECHANICAL DRIVE Owner’s Manual

BC2600 Mechanical Drive Series Brush Cutter

Owner’s Manual

Beginning Serial #: 100515001

Original Instructions

IMPORTANT- READ CAREFULLY BEFORE USE AND KEEP FOR FUTURE REFERENCE

Part No 501513 1 F100515E

BC26 MECHANICAL DRIVE Owner’s Manual

CONTENTS

SPECIFICATIONS AND SOUND/VIBRATION 3

INSTRUCTION LABELS 4

ASSEMBLY INSTRUCTIONS 5-6

OPERATION 7-8

MAINTENANCE AND BATTERY MAINTENANCE 9-12

TROUBLESHOOTING 13

ILLUSTRATED PARTS LIST 14-21

DECLARATION OF CONFORMITY 22-24

Part No 501513 2 F100515E

BC26 MECHANICAL DRIVE Owner’s Manual

BC2600ICM

BC2600HM

BC2600HMF

Engine Type

Briggs and Stratton

Honda GXV390

Honda GXV390

Model Number

219972 0151 F1

GXV390UT2DABG

GXV390UT2DABG

Displacement

344 cc

390 cc

390 cc

Fuel Capacity

3.0 qt (2.80 L)

3.0 qt (2.80 L)

3.0 qt (2.80 L)

Oil Capacity

1.5 qt (1.4L)

1.2 qt (1.1L)

1.2 qt (1.1L)

Unit Weight

316 lb (147.4 kg)

316 lb (147.4 kg)

326 lb (147.4 kg)

Overall Length

72 in (1.83 m)

72 in (1.83 m)

72 in (1.83 m)

Overall Width

31 in (0.78 m)

31 in (0.78 m)

31 in (0.78 m)

Overall Height

48 in (1.21 m)

48 in (1.21 m)

48 in (1.21 m)

Maximum Operating Slope

15o

20o

20o

100 dB

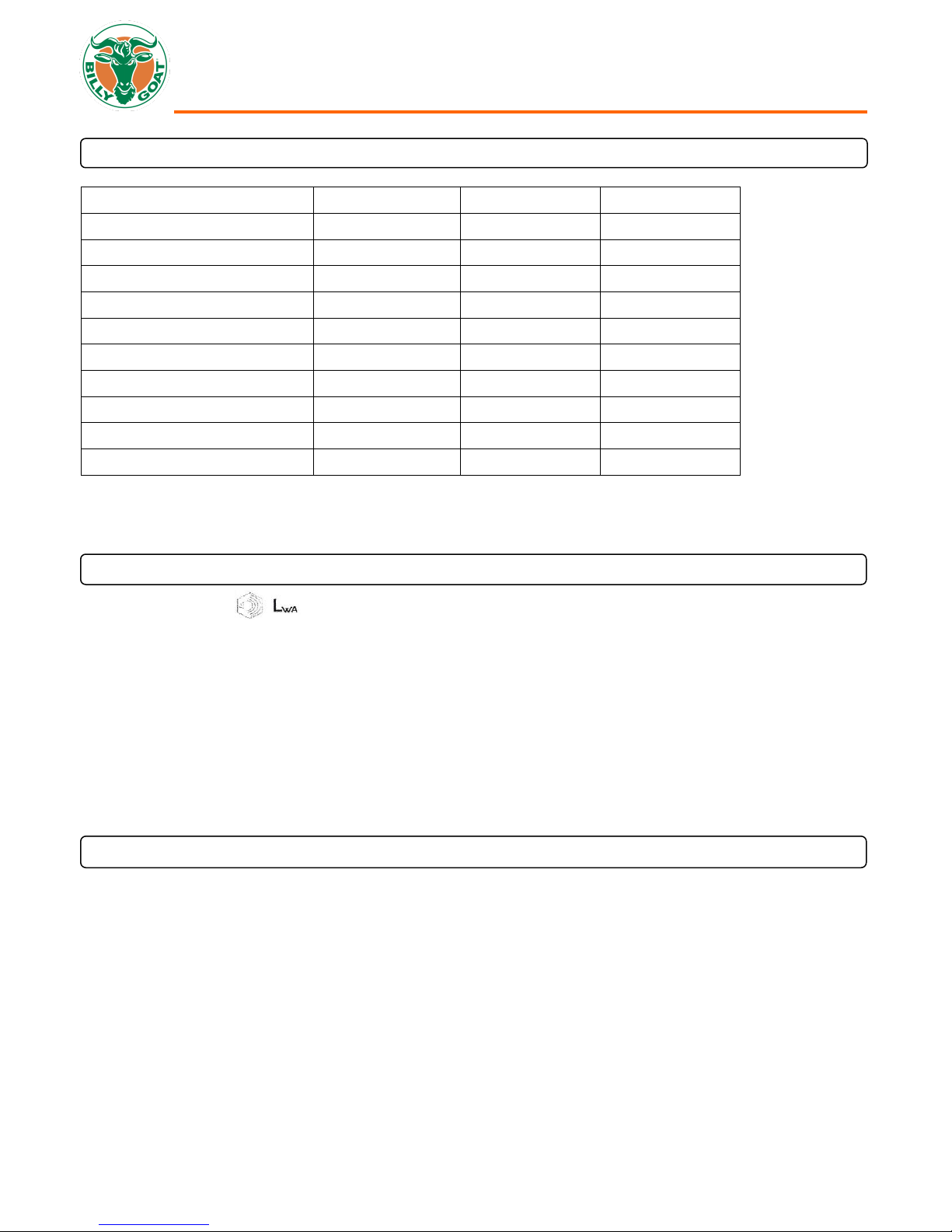

BC 2600 SERIES SPECIFICATIONS

SOUND DATA

SOUND LEVEL 80 Dba at Operator’s position

Sound tests were conducted in accordance with 2000/14/EEC and were performed on 9/6/13 under the conditions listed below.

NOTE: Sound power level listed is the highest value for any model covered in this manual. Please refer to serial plate on the

unit for the sound power level for your model.

General Conditions: Sunny

Temperature: 70oF (21oC)

Wind Speed: 6 mph (9.7kph)

Wind Direction: South Southeast

Humidity: 73%

Barometric Pressure: 30.12” Hg (102 kPa)

VIBRATION DATA

VIBRATION LEVEL .2g (1.84 m/s2)

Vibration levels at the operator’s handles were measured in the vertical, lateral and longitudinal directions using calibrated

vibration test equipment. Tests were performed on 11/30/11 under the conditions listed below.

General Conditions: Sunny

Temperature: 70oF (21oC)

Wind Speed: 6 mph (9.7 kph)

Wind Direction: South Southeast

Humidity: 73%

Barometric Pressure: 30.12” Hg (102 kPa)

Part No 501513 3 F100515E

BC26 MECHANICAL DRIVE Owner’s Manual

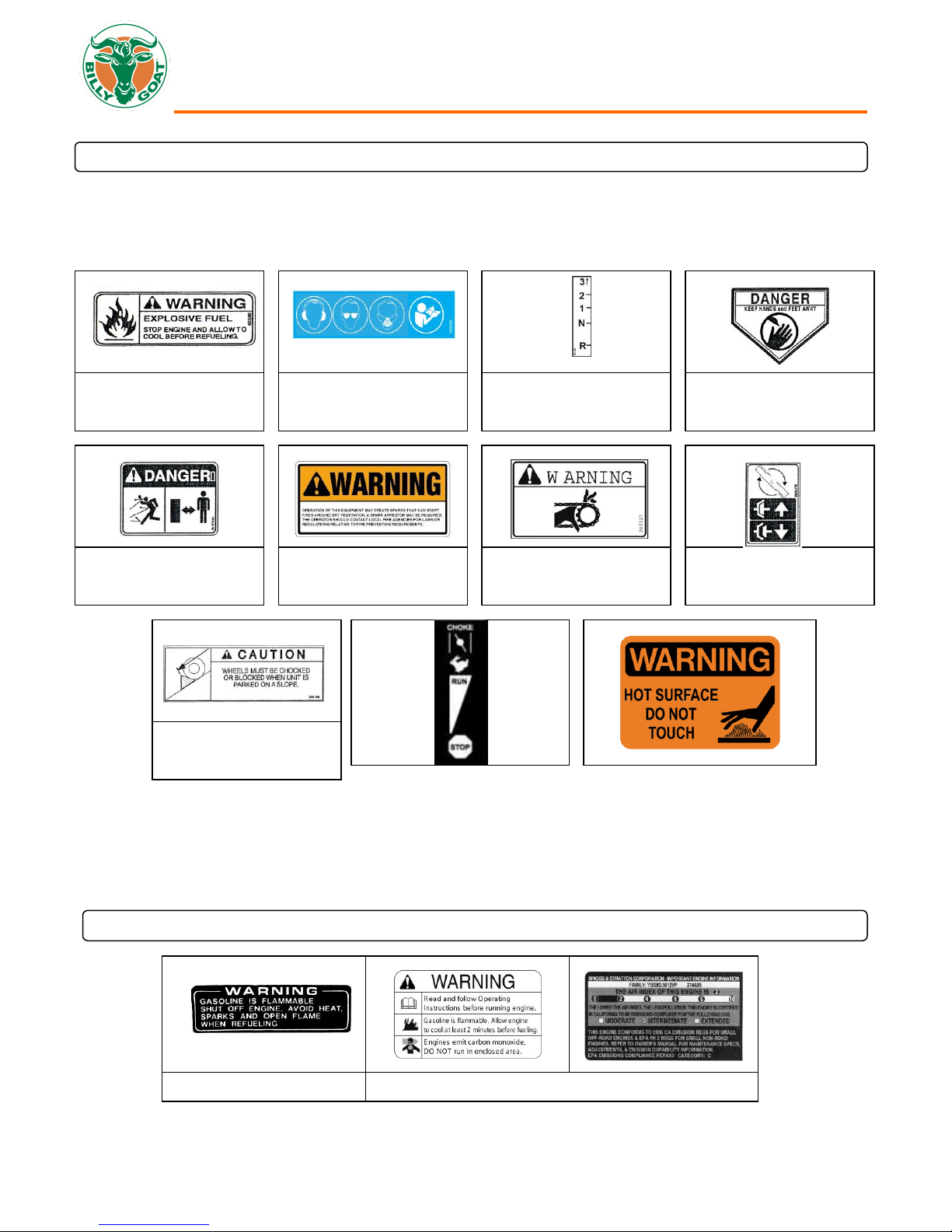

PN 100261

(Item 88)

PN 100346

(Item 68)

PN 810736

(Item 76)

PN 100256

(Item 123)

PN 900327

(Item 122)

PN 500177

(Item 86)

PN 501503

(Item 74)

PN 400424

(Item 53)

PN 500168

(Item 72)

Honda

Briggs and Stratton

INSTRUCTION LABELS

The labels shown below were installed on your BILLY GOAT® Mechanical Drive Brush Cutter. If any labels are damaged or

missing, replace them before operating this equipment. Item numbers from the Illustrated Parts List and part numbers are

provided for convenience in ordering replacement labels. The correct position for each label may be determined by referring to

the Figure and Item numbers shown.

ENGINE LABELS

Part No 501513 4 F100515E

BC26 MECHANICAL DRIVE Owner’s Manual

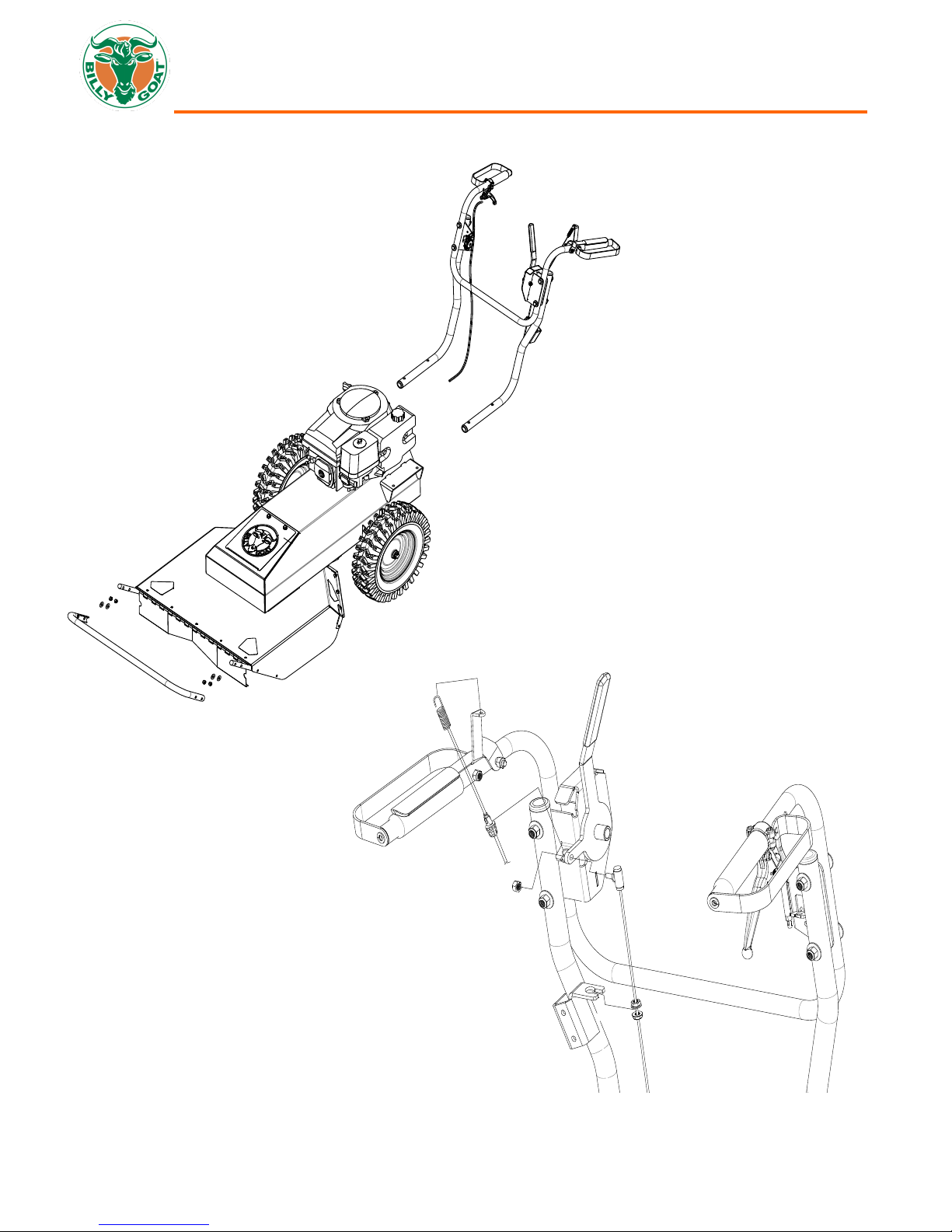

Brush Cutter Assembly Drawing

Part No 501513 5 F100515E

BC26 MECHANICAL DRIVE Owner’s Manual

READ all safety instructions before assembling unit.

DISCONNECT spark plug wire before assembling unit.

Boxing Parts Checklist

Owner’s Manual P/N 501513

Upper Handle Assembly, P/N 501010

Guard Bar, P/N 501403

Ty-Wraps (4 ea)

Screwcap 3/8” – 16 X 2” P/N 8041054 (qty 4)

Washer 3/8” flat P/N 8171004 (qty 4)

Nut Lock 3/8”-16 P/N 8160003 (qty 4)

Nut lock #10-24 hex P/N 8164005 (qty 2)

Screw machine flat HD Phil P/N 830514 (qty 2)

Washer 5/16” flat P/N 8171003 (qty 4)

Bolt carriage 5/16”-18 x 1 3/4” P/N 8024043 (qty 4)

Nut Lock 5/18”-18 hex ZP P/N 8160002 (qty 4)

Engine Manual Per Model

Honda

Briggs

PACKING CHECKLIST

Your BILLY GOAT® BC Self-Propelled Mechanical Drive Brush Cutter was shipped in one carton, completely assembled except

for the upper handle assembly and the front guard bar. Mounting hardware for the handle and guard bar is temporarily installed

on the lower handle and the front of the deck assembly. The throttle cable hardware is located on the bracket on the right side of

the handle

PARTS BAG & LITERATURE ASSY

Warranty Card- P/N 400972, Owner’s Manual- P/N 501513, General Safety and Warnings Manual- P/N 100296, Declaration of

conformity P/N 501506

ASSEMBLY

NOTE: Items in ( ) can be referenced in the Parts Illustrations and Parts Lists on pages 14-21.

1. Remove unit from carton and check the contents of the parts bag with the list above.

2. Remove mounting hardware from the hardware bag.

3. Attach the handle to the engine base with the items 62, 97, and 119.

4. Tighten mounting hardware on handle braces (items 5 and 6).

5. Attach guard bar (item 16) to Skid bar by installing the side bolts into the top two holes on the skids with items 103, 104

and 116.

6. Attach the throttle (30) to the right hand bracket (item 27) using the hardware (items 63 and 64). Tighten securely and

make sure the cable isn’t binding.

7. Attach the Blade drive cable to the lever and seat the plastic insert into the bracket on the left side of the handle.

8. Secure the drive and blade cables with the ty-wraps provided.

9. Place the shifter cable (item 41) into the bracket on the lower handle (item 14) with the nuts on both sides of the bracket.

10. Then attach the upper part of the cable to the shifter lever (item 21) using the nut located on the end of it and tighten

securely. Then tighten the two nuts on the bracket where it was seated in step 9. Check to make sure the lever has full

travel. If the lever does not have full travel loosen the nuts and either raise or lower them on the barrel to provide the

proper travel for the lever. NOTE: Putting too much tension on the cable can cause excess wear on the cable and lead

to failure. Likewise, if the cable is loose it will result in poor shifting.

11. Reconnect spark plug wire.

Part No 501513 6 F100515E

BC26 MECHANICAL DRIVE Owner’s Manual

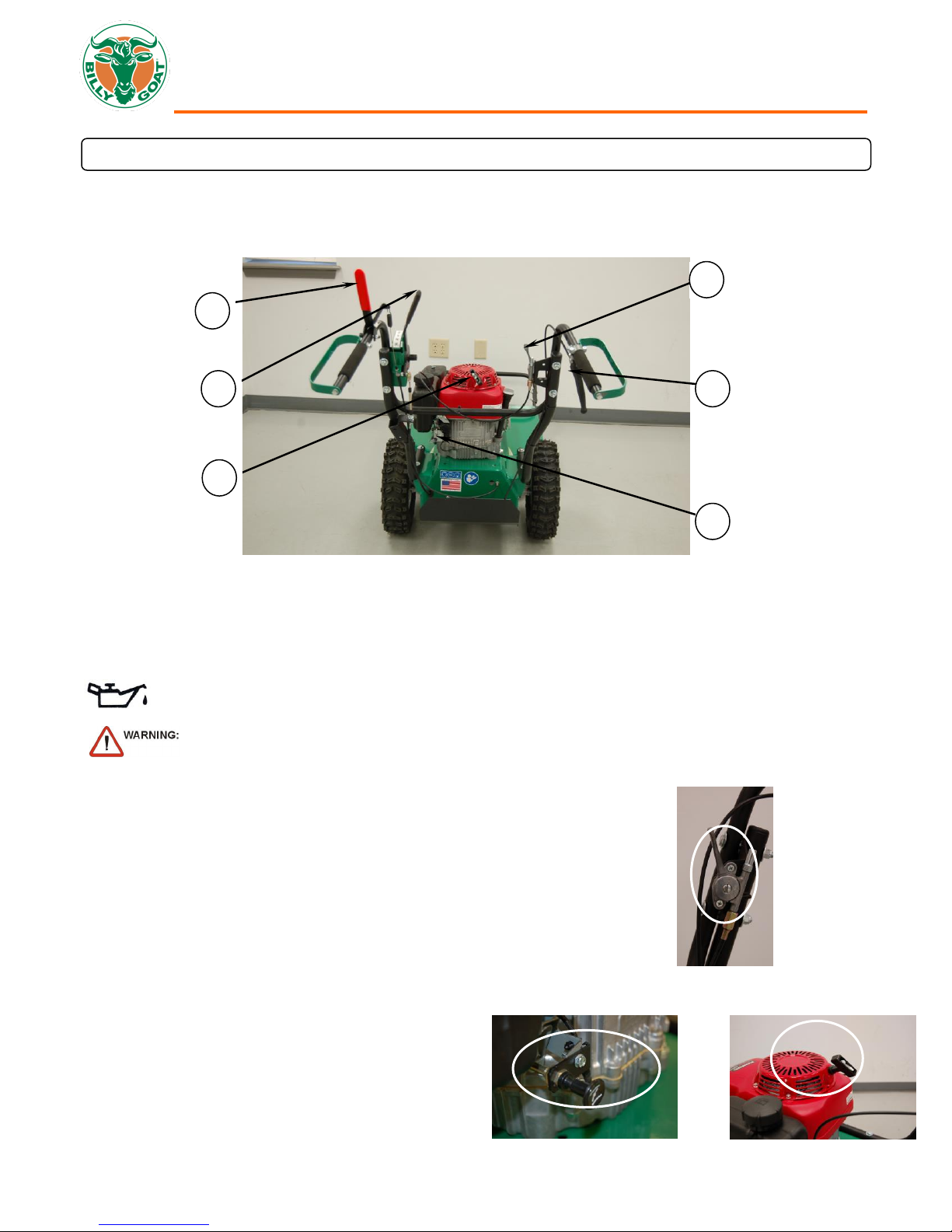

CHECK engine oil level before operating machine.

DO NOT START equipment with drive or blade clutch engaged.

1

3

6 4 2

5

1. Place equipment on a level, firm surface that is free of rocks or other debris.

2. Place throttle in “fast” position. (See Fig. 1)

3. Pull choke out (See Fig. 2, Honda engine only).

4. Pull starter rope to start engine. (See Fig. 3) NOTE: PULL STARTER CORD slowly

until resistance is felt. Then pull cord rapidly to avoid kickback.

5. Push choke in (Honda engine only).

6. Pull throttle control back to and allow engine to reach correct operating speed.

Fig. 1

Fig. 2

Fig. 3

OPERATION

OPERATOR CONTROLS

The operator’s station is at the rear of the machine between the handlebars. The operator should STAND in a position to allow

both handlebars to be grasped firmly and which allows sufficient leverage to steer the machine. Operator’s controls are shown

below.

Operator Control Locations

1 Blade Clutch Lever 5 Choke

2 Forward Lever 6 Pull Starter

3 Speed/direction shifter

4 Throttle

STARTING ENGINE

Part No 501513 7 F100515E

BC26 MECHANICAL DRIVE Owner’s Manual

CUTTING OPERATION

1. Select the desired direction and speed. (See Fig. 4)

2. Press blade clutch handle down (See Fig. 5) to engage blade. Allow

blade to spin up to normal operating speed.

3. Pull Up on the drive lever (See Fig. 6) to engage the transaxle in the

desired direction.

CLEARING A CLOGGED DECK

DISCONNECT spark plug wire before servicing unit.

1. Shut engine off and wait for blade to stop completely.

2. Disconnect spark plug wire.

3. Remove clog from cutting deck.

WEAR durable gloves. Clog may contain sharp materials.

4. Reconnect spark plug wire.

SHUT DOWN

1. Release drive lever (Fig. 6) to disengage transaxle.

2. Release blade clutch handle (Fig. 5) to disengage blade.

3. Move the throttle to the slowest possible position on the throttle control.

*****TIPS*****

The best performance is achieved when cutting in dry conditions. The quality of the cut is directly related to ground speed during

cutting. Under most conditions cutting should be done at a slower ground speed. Fast speeds should be reserved for conditions

where weeds and brush are thinned out or not very tall. If the quality of the cut is not satisfactory, attempt at slower speeds.

Fig. 4 Left Handle

Fig. 6 Right Handle

Fig. 5 Left Handle

Part No 501513 8 F100515E

Loading...

Loading...