Page 1

Small Block Ford

289 / 302 / 351W / 5.0

Installation Manual

For Systems without A/C

#13605 / #13625

Billet Specialties, Inc.

500 Shawmut Avenue.

La Grange, Illinois 60526

Tech Line (708) 588-0505

Fax (708) 588-7181

Page 2

PLEASE READ ALL INSTRUCTIONS BEFORE INSTALLING ANY

COMPONENTS OF THE TRU TRAC SERPENTINE SYSTEM

Tech Line: 708.588.0505

Fax: 708.588.7181

www.billetspecialties.com

This kit is designed to be used with the following or similar 4 hole crankshaft

damper (not included)

289/302/351w 1970-1980 302, 1970-1997 351w

Professional Products #80045

Summit Racing #163289

Pioneer #DA-3513

Dimensions: 3.950” overall length 6.400” Dia.

5.0 1981-1995 5.0L

Ford Racing #M-6316-M50

Professional Products #80007

Summit Racing #163302

Pioneer #DA-3021

Dimensions: 3.950” overall length 6.400” Dia.

Other aftermarket dampers must be 3.950” overall length or less (space to 3.950”)

and cannot exceed 6.400” in diameter to clear water pump mount boss and

bolt. Damper must be 4-bolt pattern for crank pulley.

THIS KIT DOES NOT HAVE A PROVISION FOR MECHANICAL FUEL PUMP

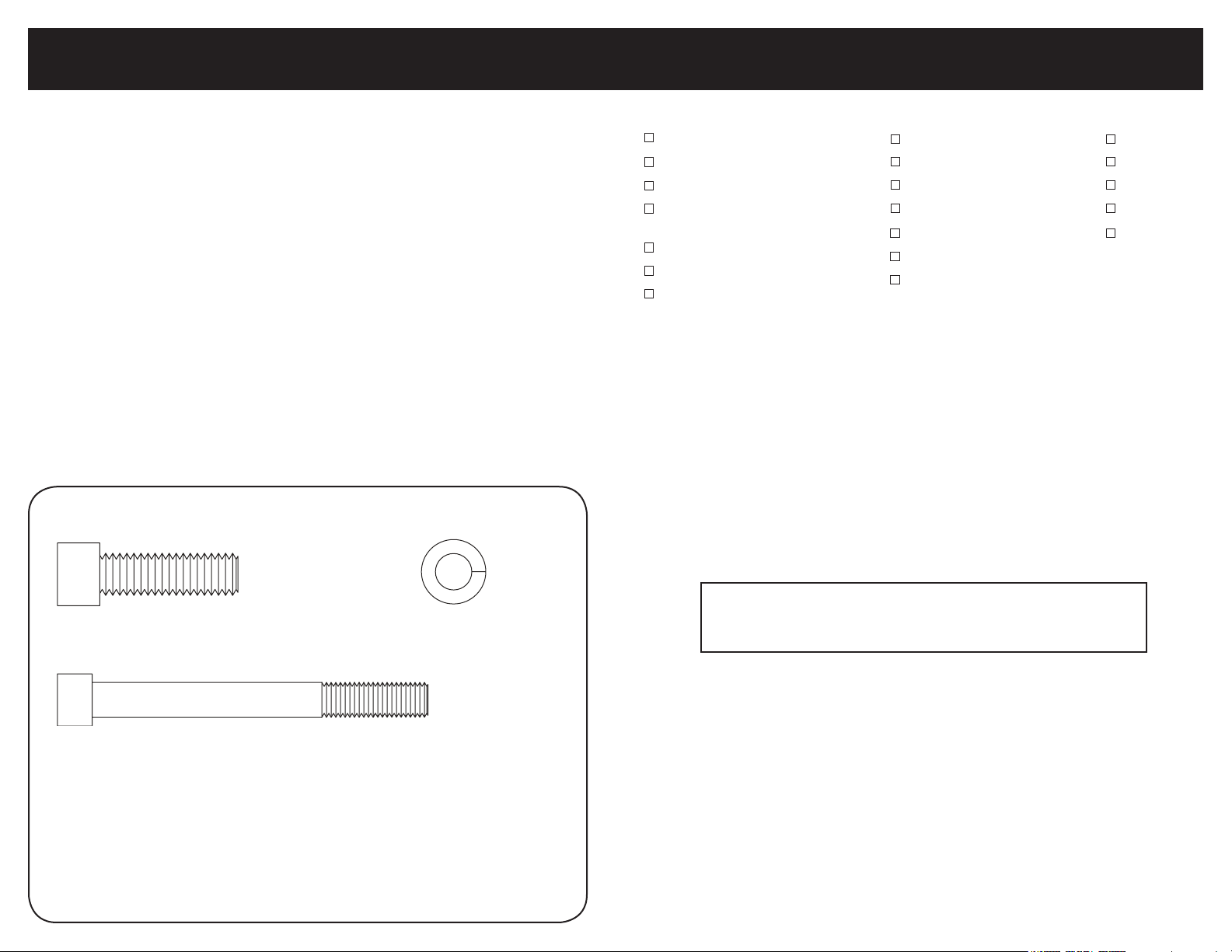

Skin Board #1 - Packaged with Power Steering Pump

Required Tools & Materials

Anti-seize Compound

RTV Silicone

New Oil Pan Gasket

Damper Puller

(Lisle P/N 45500 or similar)

Gasket Scraper

Scotch-Brite® Pad

5/16-18 Thread Chaser* & Holder

*Thread chasers are available at your

local parts store and are different from

a thread cutting tap.

1/2” Box End Wrench

5/8” Box End Wrench

3/4” Box End Wrench

11/16” Box End Wrench

Socket Wrench & Extension

10mm 12pt. socket

1/2” Socket

3/16” Allen

5/16” Allen

1/4” Allen

5/32” Allen

5mm Allen

x2

3/8-16 x 1-1/4” - Socket Head Cap Screw

(Power Steering Bracket)

5/16-24 x 3” - Socket Head Cap Screw

(Power Steering Pump)

x2

5/16”

Medium Split Lock Washer

(Power Steering Pump)

x2

TECH TIP:

Billet Specialties recommends the use of Anti-Seize on all

fasteners to prevent thread lock-up.

Page 3

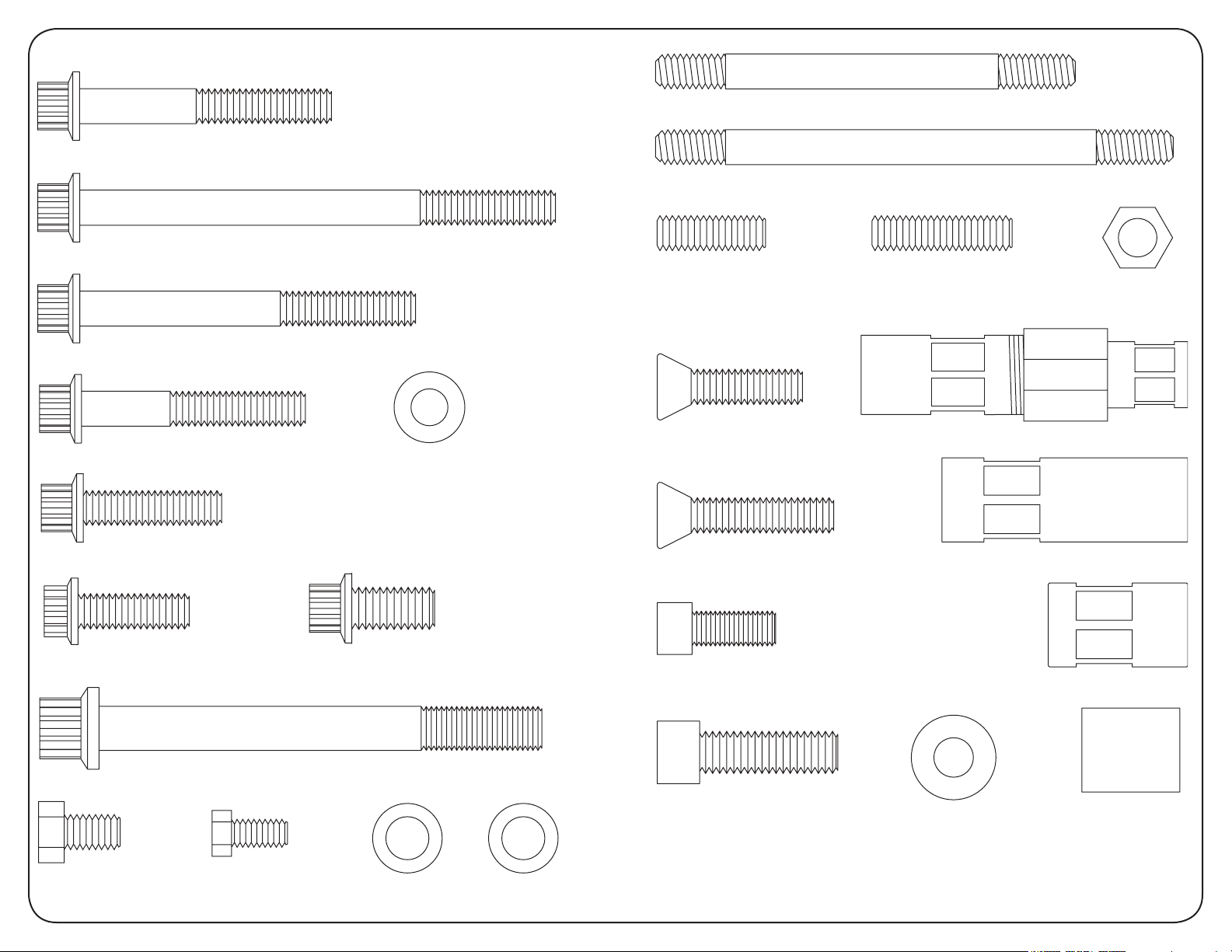

Skin Board #2 - Packaged In Main Box

x3

5/16-18 x 2-1/4” - 12pt. Cap Screw

(Water Pump & Timing Marker)

5/16-18 x 4-1/4” - 12pt. Cap Screw

(Water Pump)

5/16-18 x 3” - 12pt. Cap Screw

(Water Pump)

5/16-18 x 2” - 12pt. Cap Screw

(Timing Cover & Timing Marker)

x2

5/16-18 x 1-1/4” - 12pt. Cap Screw

(Water Pump)

x3

x2 x5

5/16” Flat Washer

(Water Pump)

x1

x1

5/16-18 x 3-3/4” - Block Mounting Stud

5/16-18 x 4-5/8” - Block Mounting Stud

x1

5/16-18 x 1” Socket Set Screw

(To Tensioner Spacer)

3/8-16 x 1-1/4” Threaded Stud

x1

8mm-1.25 x 25mm

Tensioner Coupler Nut Assembly x1

Flat Socket Cap Screw

(Bridge Bracket)

x2

8mm-1.25 x 30mm - Flat Socket Cap Screw

(To Tensioner)

x1

x2

5/16-18

Zinc Coated

Hex Nut

Spacer Nut - 2.197”

x1

x3

8mm-1.25 x 25mm

12pt. Cap Screw (Bridge Bracket)

10mm-1.5 x 100mm - 12pt. Cap Screw

(Alternator)

x2

1/4-20 x 1/2”

Hex Head Cap Screw

(Oil Pan)

x4

x2

5/16-18 x 1/2”

Hex Head Cap Screw

(Oil Pan)

x1

3/8-16 x 3/4” - 12pt. Cap Screw

(Tensioner Pulley)

x1

x2

10mm x .5mm

Shim Washer

(Alternator)

x2

10mm x 1mm

Shim Washer

(Alternator)

x4

5/16-24 x 3/4”

Socket Head Cap Screw

(Water Pump Pulley)

3/8-16 x 1-1/4”

Socket Head Cap Screw

(Crankshaft Pulley)

x4

x4

3/8” Belleville Washer

(Crankshaft Pulley)

Spacer Nut - 1.25”

Alternator Spacer

.875”

Other Hardware / Gaskets

Oil Pan Corner Gaskets & Oil Pan End Seal

Goodyear Poly-V Serpentine Belt - 57.75” #4060575 (with power steering)

Goodyear Poly-V Serpentine Belt - 55.5” #4060555 (without power steering)

x1

x1

Page 4

www.billetspecialties.com • Tech Line 708.588.0505

6

Small Block Ford Tru Trac - 13605 / 13625

7

Figure 1: Engine Block Preparation

- Disconnect battery

- Remove existing alternator, air conditioning compressor and

associated brackets

- Remove all pulleys and water pump

- Use damper puller to remove damper

- Remove Timing cover

- Remove oil pan hardware and drop oil pan

If you are unable to remove the oil pan: First Cut the exposed oil pan

gasket flush with engine block using a sharp blade, then remove the first

three bolts from the oil pan on each side and loosen the remaining bolts

enough to allow the front of the oil pan to drop 3/8” to 1/2”.

- Remove all traces of gasket and sealer with gasket scraper and

Scotch-Brite® pad

- Clean crank snout with Scotch-Brite® pad

- Clean threads in block by chasing with a 5/16-18 thread chaser

A

B

5/16-18 x 4-5/8"

C

Figure 2: Install Mounting Studs

A,B] Apply RTV Silicone to two 5/16-18 x 3-3/4” threaded studs and thread studs

into passenger side of motor near water outlet and finger tighten.

C] Apply RTV Silicone to one 5/16-18 x 3-3/4” threaded stud and thread into

driver side top hole and finger tighten.

C] Take remaining 5/16-18 x 4-5/8” threaded stud, apply RTV Silicone and thread

into bottom hole.

TECH TIP:

Billet Specialties recommends the use of Anti-Seize on all

fasteners to prevent thread lock-up.

Important:

Remove fuel pump eccentric from cam gear; replace bolt & washer. Torque to

recomended spec.

Page 5

www.billetspecialties.com • Tech Line 708.588.0505

8

Small Block Ford Tru Trac - 13605 / 13625

9

Figure 3: Install Mounting Studs (Continued)

Figure 4: Prepare Timing Cover For Installation

Thread the two 5/16-18 zinc coated hex nuts onto one of the studs and tighten

against each other to act as a drive nut (see illustration below*); then seat the

stud firmly into the block. Repeat this for the three remaining studs.

Remove zinc coated hex nuts and discard.

Apply anti seize to exposed stud threads at this time.

*Example

Install oil pan end seal with a thin film of RTV silicone. If you were unable to

remove the oil pan install new corner gaskets at this time too.

Page 6

www.billetspecialties.com • Tech Line 708.588.0505

10

Small Block Ford Tru Trac - 13605 / 13625

11

B

B

C

A

Figure 5: Install Timing Cover & Gasket

Apply a thin film of RTV to back of timing cover and engine block surface.

A] Align and install timing cover gasket to block. Place timing cover over studs

and crank snout.

B] Thread one 5/16-18 x 2-1/4” ARP 12pt. bolt into driver side bottom hole on

timing cover and finger tighten.

D

Figure 6: Install Factory Timing Marker

A,B] Take factory steel timing marker and install one 5/16-18 x 2-1/4” ARP 12pt.

bolt through bottom hole of timing marker and thread into timing cover.

Thread one 5/16-18 x 2” ARP 12pt. bolt into other hole and finger tighten both

bolts.

C] Thread one 5/16-18 x 2” ARP 12pt. bolt into remaining driver side bottom hole

in timing cover and finger tighten.

If you did not remove the oil pan?

D] Install two 5/16-18 x 1/2" hex head cap screw through the holes nearest the

crankshaft and into the timing cover. Thread the two remaining 1/4-20 x 1/2" hex

head cap screws trough the corner holes of the oil pan into the timing cover.

Make sure corner gaskets line up with holes. Corner gaskets may need to be

trimmed to allow gaskets to sit flush with engine and

timing cover.

A

Page 7

www.billetspecialties.com • Tech Line 708.588.0505

12

Small Block Ford Tru Trac - 13605 / 13625

13

A

B

C

Figure 7: Install Water Pump

Apply a thin film of RTV silicone to water pump gasket and back of water pump.

Place water pump gasket on to timing cover and align. Install water pump over

studs and onto timing cover.

Figure 8: Install Spacer Nuts

A] Thread the two 2.197” spacer nuts with the hex end out onto the passenger

side water pump studs and finger tighten.

B] Thread the 1.569” spacer nut hex side out to the top driver side water pump

stud and finger tighten.

C] Thread the remaining short spacer nut on to the bottom water pump stud hex

side out (shown above) and finger tighten.

Page 8

www.billetspecialties.com • Tech Line 708.588.0505

14

Small Block Ford Tru Trac - 13605 / 13625

15

A

B

C

Figure 9: Complete Water Pump Installation

A] There are now five open holes remaining in the water pump, starting at the

top hole thread the 5/16-18 x 1-1/4” ARP 12pt. bolt and 5/16” flat washer into

hole and finger tighten.

B] Working in a clockwise direction, thread a 5/16-18 x 3” ARP 12pt. bolt and

5/16” flat washer into the next hole and finger tighten.

C] Continuing in a clockwise direction thread a 5/16-18 x 2-1/4” ARP 12pt. bolt

and 5/16” flat washer into the bottom right hole in the water pump and finger

tighten.

D] Thread a 5/16-18 x 1-1/4” ARP 12pt. bolt and 5/16” flat washer into the bottom

left hole in the water pump and finger tighten.

E] Moving on to the remaining hole in the water pump at the top, thread a

5/16-18 x 4-1/4” ARP 12pt. bolt and 5/16” flat washer into the hole and

finger tighten.

D

E

Figure 10: Oil Pan Installation (If Removed)

Install oil pan and gasket at this time, thread two 5/16-18 x 1/2" hex head cap

screw through the holes nearest the crankshaft and into the timing cover.

Thread the two remaining 1/4-20 x 1/2" hex head cap screws through the

corner holes of the oil pan into the timing cover.

Tighten all bolts at this time.

Note: Some aftermarket oil pans may require different length hardware.

Figure 10: Oil Pan Installation (If NOT Removed)

Tighten oil pan to motor and timing cover firmly

Tighten all bolts on the timing cover and then water pump at this time.

Page 9

www.billetspecialties.com • Tech Line 708.588.0505

16

Small Block Ford Tru Trac - 13605 / 13625

17

A

B

Figure 11: Install Power Steering Bracket & Pump

Figure 12: Install Crank Damper

At this time install the 4-bolt damper

and tigthen firmly.

A

If your kit does not include power steering proceed to Figure 12.

A] Place power steering bracket onto timing cover. Thread the two

3/8-16 x 1-1/4” socket head cap screws into bracket and tighten.

B] Attach power steering pump to bracket with two 5/16-24 x 3” socket head

cap screws and 5/16” split washers and tighten firmly.

B

Figure 13: Install Coupler Spacer & Stud

A] Apply anti-seize to the 3/8-16 x 1-1/4” threaded stud and thread into the top

passenger side ear of the timing cover & tighten.

B] Apply anti-seize to the exposed threads. Disassemble the tensioner coupler

assembly and thread the long spacer nut onto stud and tighten.

Page 10

www.billetspecialties.com • Tech Line 708.588.0505

18

Small Block Ford Tru Trac - 13605 / 13625

19

A

B

C

D

A

B

C D E

Figure 15: Install Tensioner

Figure 14: Install Bridge Bracket

Place the bridge bracket on the motor & align.

A,B] Apply anti-seize to the two 8mm-1.25 x 25mm ARP bolts and thread through

the bridge bracket into the driver side spacer nuts and finger tighten.

C] Apply anti-seize to the remaining 8mm-1.25 x 25mm ARP bolt and thread

through the bottom passenger side hole on the bridge bracket and into the

bottom spacer nut. Finger tighten.

D] Apply anti-seize to the 8mm-1.25 x 25mm flat socket cap screw and thread

through the bridge bracket into the remaining spacer nut on the passenger side

and finger tighten.

A] Apply anti-seize to the 5/16-18 x 1” socket set screw and thread into the back

of the tensioner. Apply anti-seize to the remaining threads on stud.

B] Thread the tensioner coupler spacer nut onto the tensioner and tighten.

C] Slide coupler nut back against the tensioner body.

D,E] Apply anti-seize to the two 8mm-1.25 x 30mm flat socket cap screws. Thread

through the bridge bracket into the tensioner and tighten.

Page 11

www.billetspecialties.com • Tech Line 708.588.0505

20

Small Block Ford Tru Trac - 13605 / 13625

21

A

A

B

Figure 16: Install Alternator

Apply anti-seize to the 10mm-1.5 x 100mm ARP 12pt. bolt. Place alternator

between bridge bracket and timing cover, aligning the bottom alternator

mounting hole with bridge bracket and timing cover.

A] Thread the 10mm-1.5 x 100mm ARP 12pt. bolt through the bridge bracket and

halfway through the alternator. Slide the alternator spacer into position between

the alternator and timing cover. Push bolt through the rest of the way and finger

tighten.

B] Apply anti-seize to the 8mm-1.25 x 25mm ARP 12pt. bolt. Align top alternator

mounting hole with bridge bracket, thread in the 8mm-1.25 x 25mm ARP 12pt.

bolt and tighten firmly.

B

Figure 17: Complete Bridge Bracket Installation

A] At this time tighten all bridge bracket bolts firmly, leave the bottom alternator

bolt loose and check to see if a shim needs to be added at this time.

The alternator mounting boss may vary in thickness due to the polishing process.

10mm shim washers are provided to shim alternator to bridge bracket (washers

may or may not be needed).

B] Thread the coupler nut onto the coupler spacer and tighten firmly.

Page 12

www.billetspecialties.com • Tech Line 708.588.0505

22

Small Block Ford Tru Trac - 13605 / 13625

23

Figure 18: Install Crankshaft Pulley

Install crank pulley with four 3/8-16 x 1” socket head cap screws and four 3/8”

Belleville washers and tighten firmly.

Note:

In some application it may be necesary to use a crankshaft pulley spacer for

proper belt alingment. Crankshaft pulley spacers are available at any Ford Racing

performance parts dealer.

A B

C

Spacer

Thickness (in.)

.350 M-8510-A351

.950 M-8510-B351

.875 M-8510-C351

.909 M-8510-D351

Figure 19: Install Water Pump Pulley

Install water pump pulley with four

5/16-24 x 3/4” socket head cap

screws and tighten firmly.

Check All Bolts For Tightness At This Time

Part Number

Figure 20: Install Tensioner Pulley & Serpentine Belt

A] Route serpentine belt as shown below. Wrap belt around tensioner pulley and

hold pulley in place.

B] Place a 5/8" socket with extension onto the tensioner nut. Rotate socket

handle clockwise until tensioner pulley slips onto tensioner shaft.

C] Release tension and install 3/8-16 x 3/4” ARP 12pt. bolt and washer onto

tensioner. Tighten firmly.

Belt Path Without Power Steering Belt Path With Power Steering

Page 13

#13605 / #13625

9/06

Billet Specialties, Inc.

500 Shawmut Avenue

La Grange, Illinois 60526

Tech Line 708.588.0505

Fax 708.588.7181

www.billetspecialties.com

Loading...

Loading...