Page 1

HEMI / BB Chrysler

Installation Manual

For Systems without A/C

#14805 / #14825

Billet Specialties, Inc.

500 Shawmut Avenue.

La Grange, Illinois 60526

Tech Line (708) 588-0505

Fax (708) 588-7181

Page 2

PLEASE READ ALL INSTRUCTIONS BEFORE INSTALLING ANY

COMPONENTS OF THE TRU TRAC SERPENTINE SYSTEM

Tech Line: 708.588.0505

Fax: 708.588.7181

www.billetspecialties.com

IMPORTANT: Must use thin crank vibration damper Mopar Performance number

P3830183 or similar with this kit.

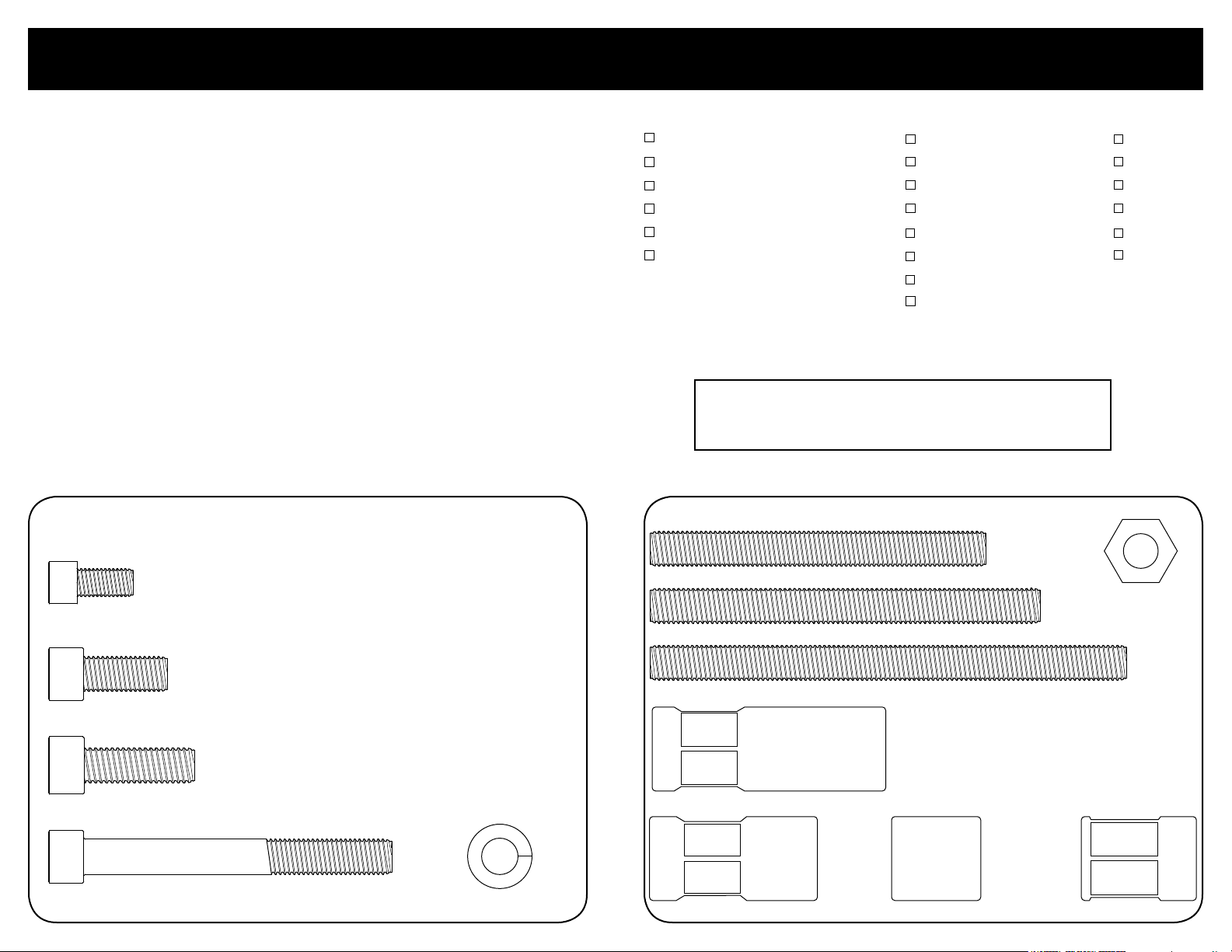

Skin Board #1 - Packaged with Power Steering Pump

x2

1/4-28 X 1/2” Socket Head Cap Screw

Power Steering Support Bracket To Bridge Bracket

Required Tools & Materials

Anti-seize Compound

RTV Silicone

Permatex Hylomar® gasket dressing

Gasket Scraper

Scotch-Brite® Pad

3/8-16 Thread Chaser* & Holder

*Thread chasers are available at your

local parts store and are different from

a thread cutting tap.

TECH TIP:

Billet Specialties recommends the use of Anti-Seize on all

fasteners to prevent thread lock-up.

5/8” Box End Wrench

9/16” Box End Wrench

3/4” Box End Wrench

11/16” Box End Wrench

Socket Wrench & Extension

10mm 12pt. socket

12mm 12pt. socket

3/8” 12pt. Socket

Skin Board #2 - Packaged with Water Pump

3/8-16 x 3” Block Mounting Stud

3/8-16 x 3-1/2” Block Mounting Stud

3/16” Allen

5/16” Allen

1/4” Allen

7/32” Allen

5mm Allen

6mm Allen

x1

x1

x2

3/8-16 Zinc Coated

Hex Nuts

x3

5/16-18 x 3/4” Socket Head Cap Screw

Power Steering Bracket To Alternator Bracket

x1

8mm-1.25 x 25mm Socket Head Cap Screw

Power Steering Pump To Power Steering Support Bracket

5/16-18 x 2-3/4” Socket Head Cap Screw

Power Steering Pump To Bracket

x1

3/8-16 x 4-1/4” Block Mounting Stud

x1

2-3/32” Spacer Nut

x2

x2

5/16” Lock Washer

x1x1x1

13/16” Spacer 1-1/32” Spacer Nut1-1/2” Spacer Nut

Page 3

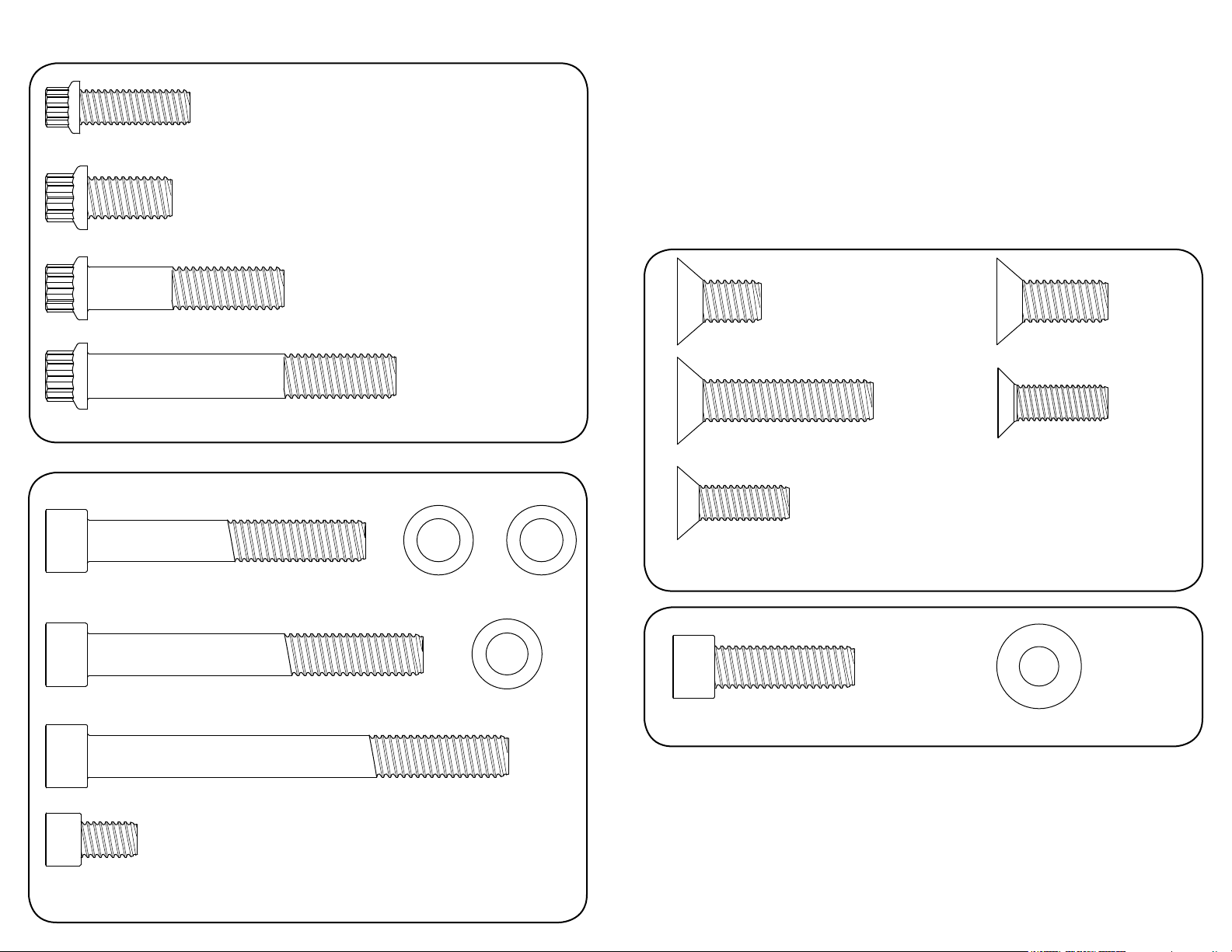

Skin Board #3 - Packaged In Main Box

x1

8mm-1.25 x 25mm 12pt. Cap Screw

Bridge Bracket To Alternator

x1

3/8-16 x 3/4” 12pt. Cap Screw

Tensioner Pulley

3/8-16 x 1-3/4” 12pt. Cap Screw

Idler Pulleys

10mm-1.5 x 70mm 12pt. Cap Screw

Bridge Bracket To Alternator

3/8-16 x 2-1/2” Socket Head Cap Screw

Water Pump Housing To Block

3/8-16 x 3” Socket Head Cap Screw

Compressor Bracket To Block

x4

3/8-16 x 3/4” Flat Head Cap Screw

Thru Bridge Bracket Into Spacer Nut

x1

3/8-16 x 1-3/4” Flat Head Cap Screw

Thru Bridge Bracket To Water Pump Housing

x1

x2

10mm x .5mm

Shim Washer

x1

x2

10mm x 1mm

Shim Washer

x3

3/8” Flat Washer

x1

5/16-18 x 1” Flat Head Cap Screw

Bridge Bracket To Spacer Nut &

Tensioner To Bridge Bracket

5/16-18 x 1” Socket Head Cap Screw

Crankshaft & Water Pump Pulley

x1

3/8-16 x 1” Flat Head Cap Screw

Tensioner To Bridge Bracket

x1

8mm-1.25 x 25mm Flat Head Cap Screw

Bridge Bracket To Tensioner

x1

x10

5/16” Belleville Washer

Crank Pulley

x6

x1

x2

3/8-16 x 3-3/4” Socket Head Cap Screw

Water Pump Housing To Block

x1

5/16-18 x 1/2" Socket Head Cap Screw

Backside Of Tensioner Thru Bracket

Other Hardware / Gaskets

Goodyear Poly-V Serpentine Belt - 74.50” #4060745 (with power steering)

Goodyear Poly-V Serpentine Belt - 64.25” #4060642 (without power steering)

Page 4

www.billetspecialties.com

www.billetspecialties.com

7

[A]

1/2"

Figure 1 – Prepping The Block

Disconnect battery; remove all existing accessory drive brackets and components

from motor.

Remove water pump and housing, scrape away any existing gasket material with

a gasket scraper and dress surface with a Scotch Brite® pad.

Clean and prep threads on engine block at water pump, use a 3/8-16 thread

chaser if necessary. Thread chasers are available at your local auto parts store or

tool dealer and are different from a thread cutting tool.

Apply RTV sealer to one end of the 3/8-16 x 3” threaded stud and thread stud

into the driver side top water pump mount hole. Next apply RTV sealer to one

end of the 3/8-16 x 4-1/4” stud and thread into the lower driver side mount hole

and tighten. Apply RTV sealer to one end of the remaining 3/8-16 x 3-1/2” stud

and thread into the bottom passenger side mount hole and tighten. The studs

can easily be tightened by threading two 3/8-16 zinc coated nuts onto the stud

and tighten them against each other to act as a drive nut, see example. Apply

anti-seize to the exposed threads of the studs at this time. Check installed height

of studs by sliding water pump housing on to the studs. There should be 1/2” of

exposed threads on each stud, readjust as necessary.

[B]

[C]

Figure 2 – Install Water Pump Housing & Pump

Apply Permatex Hylomar® gasket dressing to both sides of water pump housing

gaskets and slip over studs on block. Install water pump housing onto studs make

sure top passenger gasket is still aligned.

(A) Apply anti-seize to the 3/8-16 x 2-1/2” socket head cap screw with 3/8”

washer and thread through water pump housing and into block, finger tighten.

(B) Thread the 2-3/32” long spacer nut to the driver side top stud and finger

tighten.

(C) Apply gasket dressing to both sides of water pump gasket and install water

pump to housing and tighten firmly. Seep hole on pump should point down.

Example

Page 5

www.billetspecialties.com

www.billetspecialties.com

9

[B]

[A]

[B]

[A]

Figure 3 - Install Tensioner Bracket

Place tensioner bracket (14827) on passenger side of water pump housing and

align with the two left mount bosses.

[A] Thread the 1-1/2" long spacer nut onto the lower stud and tighten firmly.

[B] Apply anti seize to the 3/8-16 x 3" socket head cap screw with 3/8" washer and

thread through tensioner bracket, water pump housing and into block,

tighten firmly.

Step 1

Figure 4 - Install Alternator Bracket

For kits without power steering proceed to Step 2.

Step 1: Attach the power steering pump bracket to the back of the alternator

bracket (14801) with three 5/16-18 x 3/4” socket head cap screws and tighten

firmly.

Step 2: [A] Place alternator bracket on driver side of water pump and thread the

1-1/32” spacer nut onto the bottom stud and finger tighten.

[B] Apply anti-seize to the 3/8-16 x 3-3/4” socket head cap screw with 3/8”

washers and thread through upper hole in bracket, water pump housing,

and into block.

Tighten all fasteners at this time firmly.

Page 6

www.billetspecialties.com

www.billetspecialties.com

11

[A]

[D]

[B]

[C]

Power Steering Support Bracket

Figure 5 - Install Bridge Bracket

For kits with power steering: attach the power steering support bracket to the

back of the driver side bridge bracket with two 1/4-28 x 1/2” socket head cap

screws and tighten firmly.

Place bridge bracket onto face of motor and align bracket mount holes with

spacer nuts and water pump bosses.

[A] Apply anti seize to the 3/8-16 x 3/4” flat head cap screw and thread through

the lower driver side of the bridge bracket and into the spacer nut, finger tighten.

[B] Apply anti seize to the 3/8-16 x 1” flat head cap screw and thread through the

top driver side bridge bracket and into upper spacer nut, finger tighten.

[B]

[A]

Figure 6 - Install Alternator

Apply anti-seize to the 10mm-1.5 x 70mm ARP 12pt cap screw. Place and align the

alternator between the bridge bracket and the alternator bracket with the long

mounting boss at the bottom.

[A] Thread the 10mm-1.5 x 70mm ARP 12pt cap screw through the bridge bracket

and alternator into the alternator bracket and finger tighten.

[B] Apply anti seize to the 8mm-1.25 x 25mm ARP 12pt cap screw, align top

alternator boss with the bridge bracket and thread cap screw through bridge

bracket and into alternator – finger tighten.

The alternator mounting boss may vary in width due to the polishing process.

10mm shim washers are provided to shim the alternator if needed at the bottom.

[C] Apply anti seize to the 3/8-16 x 1-3/4” flat head cap screw. Place the 13/16”

stainless spacer between bridge bracket and the top of the water pump housing,

thread the 3/8-16 x 1-3/4” flat head screw through the bridge bracket, spacer and

into the housing, finger tighten.

[D] Apply anti-seize to the 5/16-18 x 1” flat head screw and thread through the

lower passenger side of the bridge bracket into the spacer nut and finger tighten.

Page 7

www.billetspecialties.com

www.billetspecialties.com

13

[A]

[A]

[B]

[C]

Figure 7 – Install Tensioner

Apply anti seize to the two 8mm-1.25 x 25mm flat head screws, place tensioner

body between the bridge bracket and the tensioner bracket.

[A,B] Align tensioner holes with bridge bracket and thread the two

8mm-1.25 x 25mm flat head cap screws through the bridge bracket and into the

tensioner and tighten firmly.

[C] Apply anti seize to the 5/16-18 x 1/2” socket head cap screw, thread the cap

screw through back of tensioner bracket and into tensioner and tighten firmly.

[B]

[C]

Figure 8 – Install Power Steering Pump With Pulley

Apply anti seize to the two 5/16-18 x 2-3/4” socket head cap screws and to the

8mm-1.25 x 25mm socket head cap screw.

Place the power steering pump between the bridge bracket and the

alternator bracket aligning the pump ears with the mount holes in the power

steering bracket.

[A,B] Thread the two 5/16-18 x 2-3/4" socket head cap screws with 5/16” medium

split lock washers through the power steering pump and into the power steering

bracket and finger tighten.

For kits without power steering: Tighten all bridge bracket fasteners and accessory

hardware at this time firmly - proceed to Figure 9.

[C] Thread the 8mm-1.25 x 25mm socket head cap screw through the small

support bracket into the power steering pump and tighten firmly. Tighten the

two other power steering fasteners firmly at this time.

Tighten all bridge bracket fasteners and accessory hardware at this time firmly.

Page 8

www.billetspecialties.com

www.billetspecialties.com

15

Figure 9 - Install Crankshaft & Water Pump Pulleys

Apply anti-seize to the ten 5/16-18 x 1” socket head cap screws.

Crankshaft Pulley: Place crank pulley on damper and align holes, thread six

5/16-18 x 1” socket head cap screws with 5/16" Belleville washers (cup of washer

facing damper) through pulley into damper and tighten firmly (26 ft/lb).

Water Pump Pulley: Place water pump pulley and nose cone on shaft and attach

with four 5/16-18 x 1” socket head cap screws and tighten firmly (26 ft/lb).

[B]

[A]

[C]

[D]

Figure 11 - Install Serpentine Belt & Tensioner Pulleys

Route belt as shown in diagram below allowing belt to rest on pulley boss.

[1] [2]

[4][3]

Figure 10 - Install Idler Pulleys

Apply anti seize to the four 3/8-16 x 1-3/4” ARP 12pt cap screws.

Thread the 3/8-16 x 1-3/4” ARP 12pt cap screw through the idler pulley polished

cover, idler pulley and boss into the bridge bracket and tighten firmly (46 ft/lbs).

Repeat step for other three idler pulleys.

[A] Place a 5/8” box end wrench on tensioner nut and align belt onto pulley

groove above tensioner boss.

[B] Pull up on wrench until tensioner pulley is able to slip onto tensioner boss.

[C] Slowly return wrench to starting position to apply tension to belt.

[D] Thread 3/8-16 x 3/4” 12pt ARP bolt and thrust washer onto tensioner pulley and

tighten firmly.

Connect electrical and fluid lines, test run motor. Inspect fittings and hardware,

tighten if necessary.

With Power Steering Without Power Steering

Page 9

#14805/ #14825

Billet Specialties, Inc.

500 Shawmut Avenue

La Grange, Illinois 60526

Tech Line 708.588.0505

Fax 708.588.7181

www.billetspecialties.com

Loading...

Loading...