Page 1

#77900 - Power Steering Hose Kit

If your application is not listed below...

Do Not Attempt To Install This Kit*

* A power steering adapter kit (#77901) is available for other applications, call for info 1 (708) 588-0505.

Tools needed:

• 1” open end wrench

• 15/16” open end wrench

• 11/16” open end wrench

• Electrical/vinyl tape

• Hacksaw with ne tooth metal blade OR cut off wheel

Applications:

• GM metric rack & pinion

• 1978 - present GM metric 800 gear box

• 1965 - 77 GM SAE 800 gear box

• Classic Performance Products - 500 Series box

• Flaming River rack & pinion

• Dodge Omni rack & pinion

• 1974-77 Ford Mustang II rack & pinion

Before Installing This Hose Kit:

Install the Tru Trac or V Trac system in vehicle.

•

Position the remote power steering reservoir as close to the power

•

steering pump as possible. The remote power steering reservoir

should also be mounted higher than the power steering pump. The

radiator core support works well as a mounting location for the

reservoir in most cases.

Tech Tip:

Install the proper adapter into the Rack/Box. Do not use Teon tape or pipe dope,

this can get into the system and do substantial damage. Inverted are ttings should

be torqued to 25-24 ft/lbs and O-ring ttings should be torqued to 20 ft/lbs.

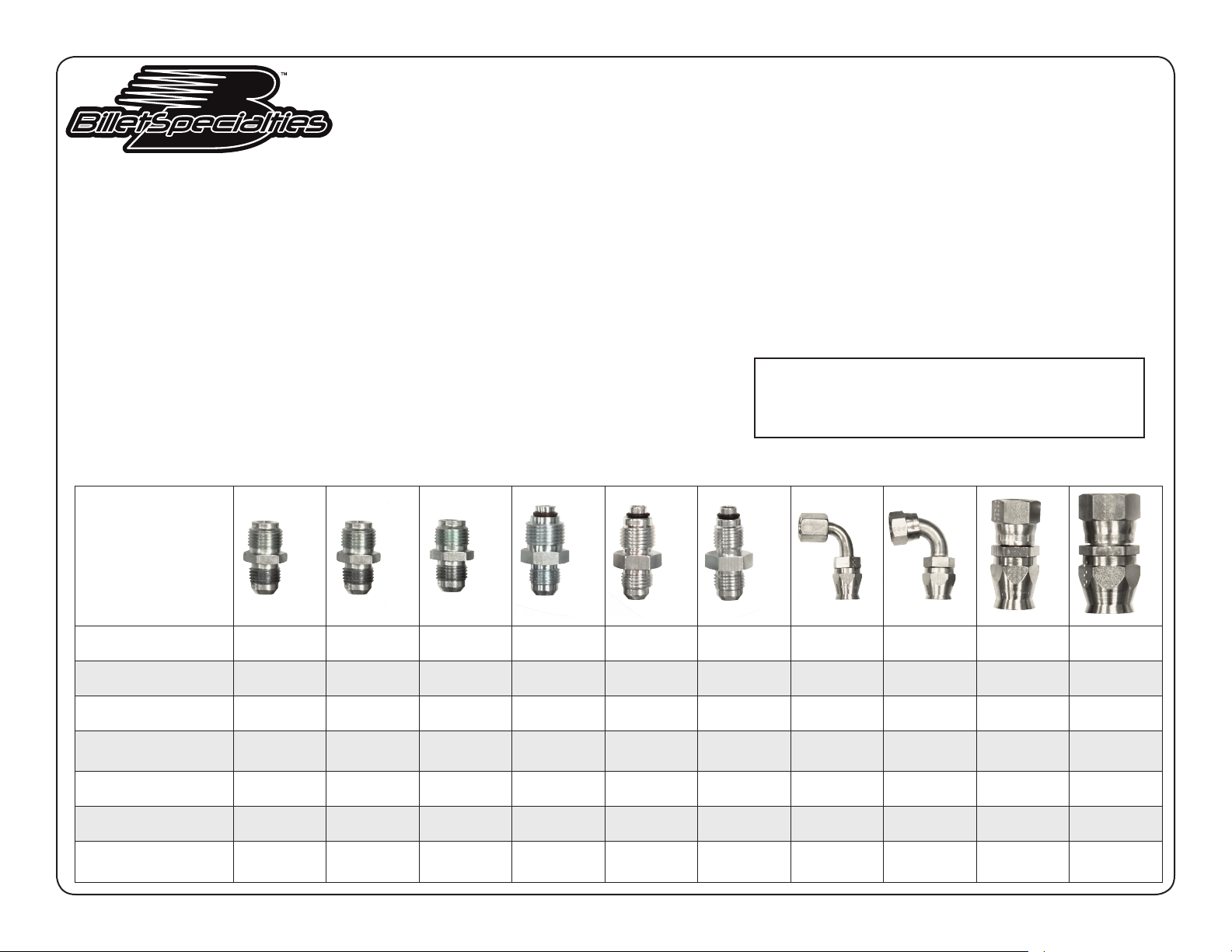

Step 1: Prepare the ttings and adapters for installation. Use the guide below to select the correct adapters for your application.

Compare the existing hose ends to the adapter if you are unsure of the box/rack that you have.

•Denotes number of ttings

required for the listed application

11/16-18 inverted are to

-6AN power steering adapter

GM Metric Rack & Pinion

1/2-20 inverted are to

-6AN power steering adapter

5/8-18 inverted are to

-6AN power steering adapter

M18 x 1.5 O-ring to -6AN

power steering adapter

M16 x 1.5 O-ring to -6 AN

power steering adapter

M14 x 1.5 O-ring to -6 AN

power steering adapter

• • ••• • • •

-6 AN 90˚ hose end

-10 AN 90˚ hose end

-6 AN straight hose end

-10 AN straight hose end

1978-up GM Metric 800 gear box

1965-77 GM SAE 800 gear box

Classic Performance Products

500 Series gear box

Flaming River Rack & Pinion

Dodge Omni Rack & Pinion

1974-77 Ford Mustang II

Rack & Pinion

• • ••• • • •

• • ••• • • •

• • ••• • • •

• • ••• • • •

• • ••• • • •

• • ••• • • •

500 Shawmut Avenue • La Grange, Illinois 60526 • Tech Line 708/588-0505 • Fax 708/588-7181

Rev. 07/08

Page 2

Step 2: Measure For Hose

•

Double check your measurements.

•

Start with the -10 supply line from the reservoir to the pump.

•

Keep this as straight as possible as this hose is under severe vacuum. Sharp bends are

Measure twice, cut once.

not recommended and may allow the hose to collapse. If a bend is required keep the

radius open.

Supply line length

• Next measure the length needed from the pressure side of the pump to the rack/box.

• Again, tight bends in the hose are not recommended.

Pressure line length

• Finish by measuring the return line length from the rack/box back to the reservoir.

Return line length

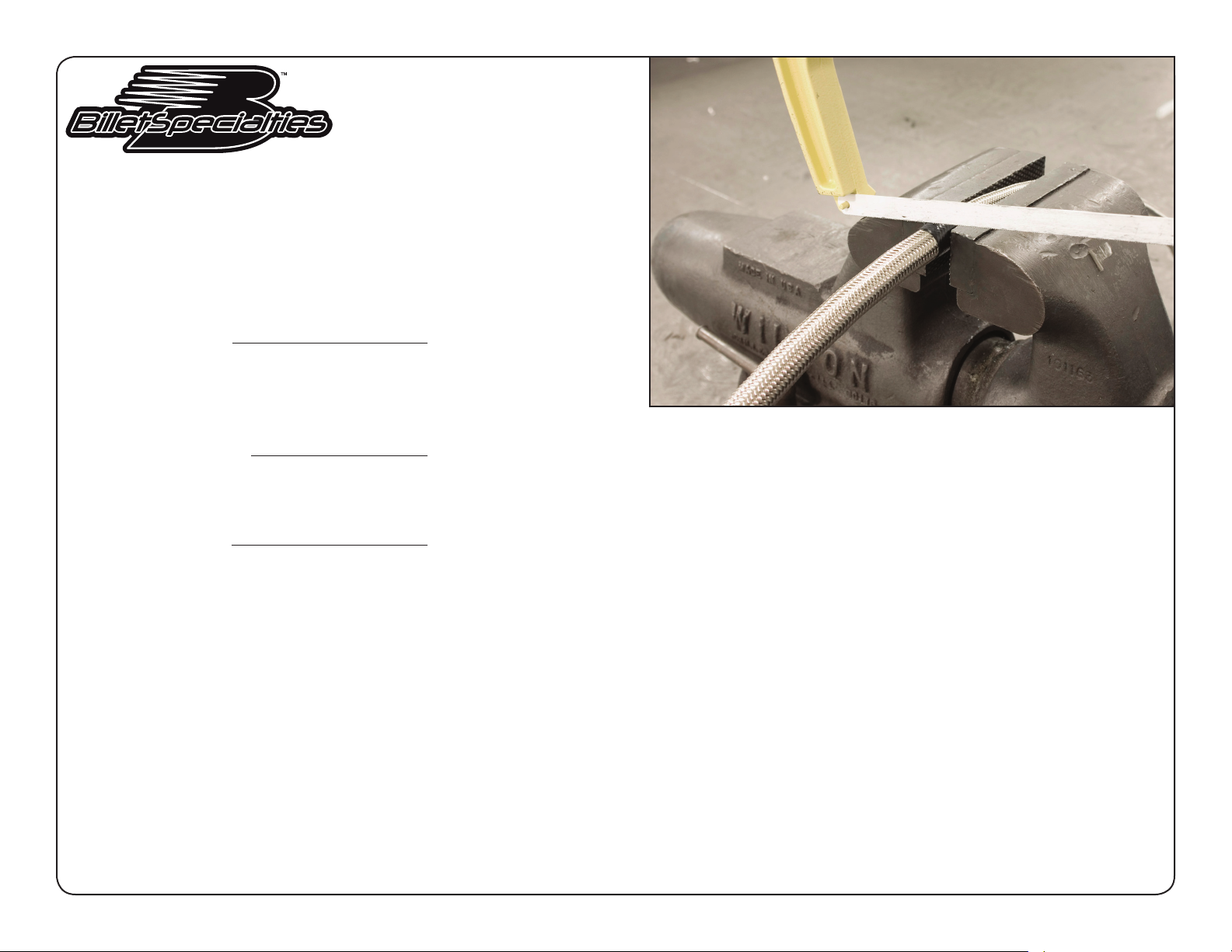

Step 3: Cutting The Hose

Start by tightly wrapping electrical/vinyl tape around the hose in the area to be cut.

•

Place hose in a vise without crushing it. Cut hose square to length with a ne tooth hack

•

saw or cut off wheel (Important! Make sure that your cut is square!).

Remove hose from vise and remove tape slowly. Deburr the inner Teon hose and trim

•

away any stray stainless braid.

Blow out the inside of the hose to clear any debris. Debris that is left in the line may

•

cause substantial damage.

Finish by cutting the pressure and return lines the same way.

•

500 Shawmut Avenue • La Grange, Illinois 60526 • Tech Line 708/588-0505 • Fax 708/588-7181

Page 3

Step 4: Assemble Hose Ends to Hose

Install the threaded socket end on the hose and

slide it back out of the way.

Insert the nipple portion of the hose end into

the Teon part of the hose to size it up then

remove it.

Follow by placing the hose end in a vise,

sparingly lubricate the threads with 30wt oil or

similar. Insert the hose over the nipple making

sure the ferrule does not pop of the Teon tube.

Finish by threading the socket end onto the

nipple by hand.

Next push the brass ferrule around the Teon

and in between the braided hose. Seat the

Teon hose squarely against the bottom of the

ferrule; this can be done by pushing the hose

and sleeve against a workbench or vise.

Example

Now tighten with a wrench until the gap

between the nipple and the socket is no more

than 1/16”.

Clean the hose and blow out with compressed air to clear any debris.

Repeat until nished.

Step 5: Install Hoses

Install hose assembly to each component. Check and make sure the lines are

free and clear of any moving parts.

500 Shawmut Avenue • La Grange, Illinois 60526 • Tech Line 708/588-0505 • Fax 708/588-7181

Page 4

Bleeding Procedure

Trouble Shooting

Fill the steering system with high quality uid and let it sit undisturbed for a few

•

minutes. Leave the power steering reservoir cap off.

Raise the front wheels of the vehicle off the ground and support vehicle with jack

•

stands. Without starting the engine slowly begin to turn the steering wheel left to right

– keyword being “slowly”; about 1 revolution per 8-10 seconds.

Continue to top off the power steering reservoir. When the level remains steady, inspect

•

for leaks and then prepare to start the engine.

Start the engine. Check the uid level with the engine running and inspect for leaks

•

once again.

Slowly cycle the steering wheel again in both directions from steering stop to steering

•

stop. Continue to check the uid level and add uid if necessary.

If the pump begins to get noisy, there is air in the system. Turn off the engine and let

it sit for 15 minutes. Air in the system will cause the pump to growl and the uid level

may rise when the engine is turned off.

Repeat the above steps until the system is operating normally. If air is still in the system

•

after several rest periods, it may be that air is entering the system faster than it can be

expelled at the reservoir ll. Check for leaks, even the smallest leak can be a source.

Growling noise from pump

First check uid level in reservoir.

•

Check supply hose for collapse.

•

Check for air in system and re-bleed. If this cures the noise temporarily and then

•

reoccurs again there may be a supply tting allowing air back into the system.

Debris in line or pump from assembly. Disassemble and clean. Re-bleed system.

•

Steering wheel moves violently from side to side OR

Steering wheel moves just to one side

Pressure and return line are reversed on box or rack.

•

Hissing noise traveling up the column

This is a normal power steering sound. Installing a vibration damper or isolator on

•

the steering shaft will help quiet this down.

Replace reservoir cap. Test drive the vehicle then check uid level.

•

500 Shawmut Avenue • La Grange, Illinois 60526 • Tech Line 708/588-0505 • Fax 708/588-7181

Loading...

Loading...