Page 1

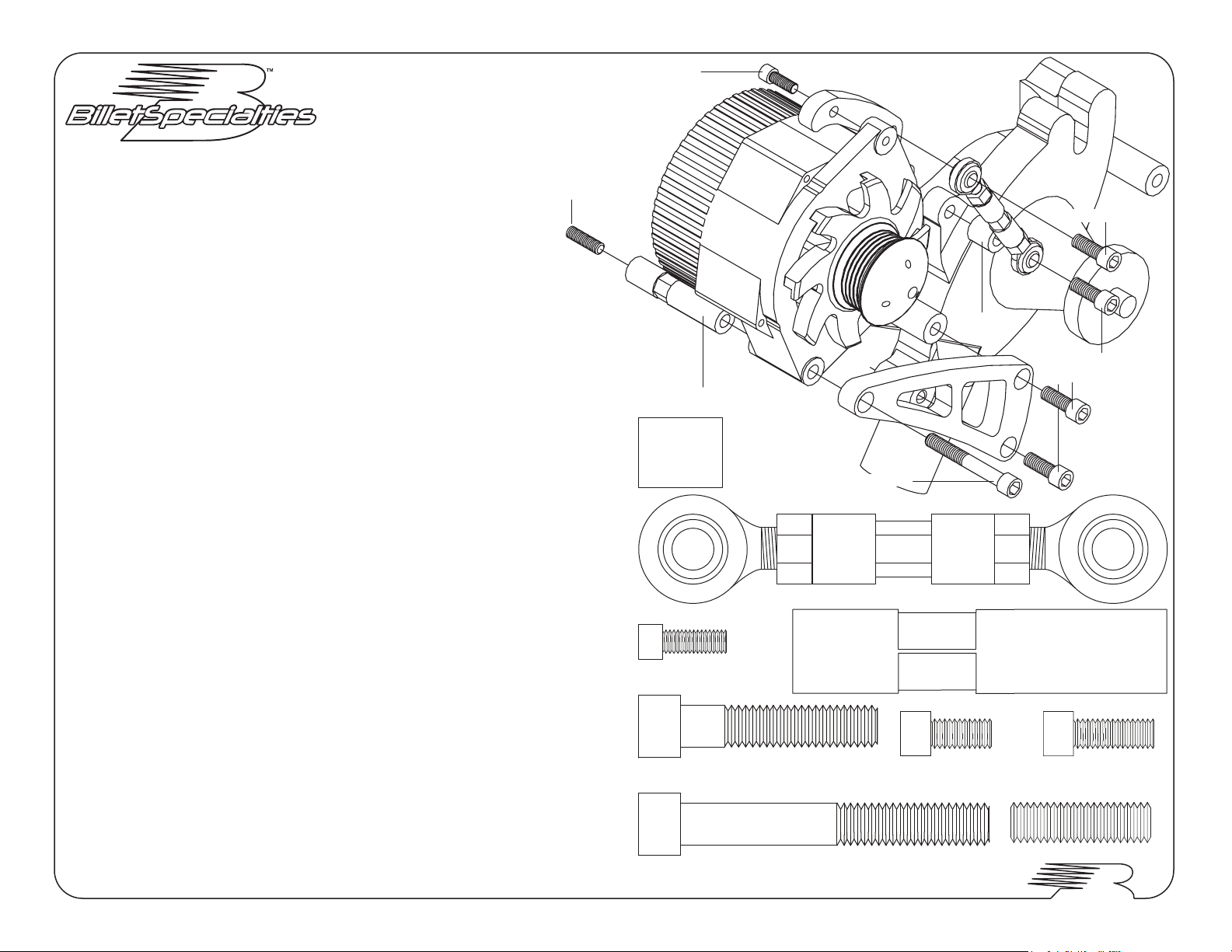

5/16-18 x 3/4" SHCS

FM0109PC SBC Top Mount Alternator Bracket

Tools Required:

1/4” Allen Wrench

5/16” Allen wrench

1/2” Open End Wrench

9/16” Open End Wrench

3/8-16 Thread Chaser (If necessary)

Anti-Seize

We recommend applying Anti-Seize to all threads when assembling bracket.

Recommended Belt: Goodyear 6 Rib #4060445 (44.5”) or Dayco 6 Rib #5060445 (44.5”)

1) Disconnect battery. Remove existing accessory drive brackets.

2) Clean & prep threads in passenger cylinder head (outside hole) and left side of water pump. Run a

3/8-16 thread chaser if necessary. Thread chasers are available at your local auto parts store or tool

dealer and are different from a thread cutting tool.

3) Thread the 3/8-16 x 1-1/4” threaded stud into the outside passenger side cylinder head and finger

tighten. There should be no more than 5/8” of thread left exposed (if more than 5/8” thread is showing,

remove stud and clean out threads then reinstall threaded stud and check again). Apply anti-seize to

the exposed threads on the stud. Also apply anti-seize to the threads of all the remaining fasteners at

this time.

4) Thread the 3-11/32” spacer nut onto the exposed stud and tighten firmly.

5) Attach the alternator bracket to the water pump with the two 3/8-16 x 3/4” stainless socket head cap

screws and finger tighten.

3/8-16 x 1-1/4"

Threaded Stud

3/8-16 x 1" SHCS

3/4" Spacer

3/8-16 x 1-3/4" SHCS

3/8-16 x 3/4" SHCS

3-11/32" Spacer Nut

3/4" Spacer

3/8-16 x 2-3/4" SHCS

6) Thread the 3/8-16 x 1-3/4” stainless socket head cap screw through one end of the turnbuckle

assembly and the 3/4” spacer into the water pump boss and tighten firmly. Swing the turnbuckle to the

right and lay to rest out of the way.

7) Attach the alternator ear bracket to the top alternator boss with the 5/16-18 x 3/4” stainless socket

head cap screw and tighten (26 ft./lb.).

8) Place the alternator between the spacer nut and alternator bracket and thread the

3/8-16 x 2-3/4” stainless socket head cap screw through the Alternator bracket & alternator into the

spacer nut and finger tighten.

9) Swing the alternator up into position and match up to the turnbuckle assembly, thread the 3/8-16 x 1”

stainless socket head cap screw through the turnbuckle rod end into the alternator ear bracket and

tighten(46ft./lb.).

10) Route belt around alternator, water pump and crank pulleys. Twist turnbuckle by hand until proper

belt tension is achieved. Do not over-tighten belt! Serious damage may occur to the accessory drive

bearings resulting in premature wear.

11) Tighten jam nuts on turnbuckle. Tighten alternator socket head screw (46ft./lb.) Tighten alternator

bracket screws on water pump (46ft./lb.) Re-check belt tension.

12) Reconnect electrical and test run motor. Re-check belt tension after 100 miles.

Billet Specialties, Inc. 500 Shawmut Avenue La Grange, Illinois 60526 PH 800.245.5382 Fax 708.588.7181 www.billetspecialties.com

5/16-18 x 3/4" Socket Head

Cap Screw (x1)

3/8-16 x 1-3/4" Socket Head

Cap Screw (x1)

3/8-16 x 2-3/4" Socket Head Cap Screw (x1)

Turnbuckle Assembly

3/8-16 x 3/4" Socket Head

Cap Screw (x2)

3-11/32" Spacer Nut (x1)

3/8-16 x 1" Socket Head

Cap Screw (x1)

3/8-16 x 1-1/4" Threaded Stud

Page 2

FM0130PC SBC Power Steering Bracket

Tools Required:

5/16” Allen wrench

1/2” Open-end wrench

9/16” Open-end wrench

3/8-16 Thread chaser (If necessary)

New water pump to engine block gaskets

RTV silicone sealer

Anti-seize

Swing the rear steel bracket up and align with engine block lower mount boss, thread a 3/8-16 x

1-1/4” socket head cap screw through the thin 3/8” ID slide spacer, the rear steel bracket and the

21/32” long rear spacer into the engine block and finger tighten.

Note: the spacers have a lip that locates them in the adjustment slot of the bracket.

10) Thread a 3/8-16 x 1” socket head cap screw through one thin 3/8” ID slide spacer, the

aluminum power steering bracket and one more thin 3/8” ID slide spacer and into the power

steering pump. Finger tighten.

11) Thread the two remaining 3/8-16 x 3/4" socket head cap screws through the aluminum

bracket and into the water pump spacer nuts and tighten firmly (46 ft/lbs).

Do not install top bolt if installing kits with A/C #FM2113PC or #FM2114PC.

It is recommended that you use the proper tools to remove and install the power

steering pulley. KD Tools P/N2897 puller and installer set or similar will insure

proper pulley service. Some auto parts stores rent out tool sets.

Recommended Belt: Goodyear 6 Rib #4060355 (35.5”)* or Dayco #5060358 (35.8”)*

*If running power steering only

1) Disconnect Battery; remove all existing accessory drive brackets and components from motor.

Disconnect all existing power steering lines and cap.

2) Remove water pump, scrape away any existing gasket material.

3) Remove existing power steering bracket and pulley (press on pulleys require the use of a

special puller to avoid damage to power steering pump and pulley – see tool list)

4) Clean and prep threads in cylinder heads, use a 3/8–16 thread chaser if necessary. Thread

chasers are available at your local auto parts store or tool dealer and are different from a tread

cutting tool.

5) Thread the 3/8-16 x 2-1/2” threaded studs from the power steering skin board into the driver

side water pump mount holes and tighten. The studs can easily be tightened by threading two

3/8-16 nuts (not included) onto the stud and tighten them against each other to act as a drive nut.

Apply RTV silicone sealer to engine block and water pump.

12) Install pulley:

For pumps with a keyed shaft – Place the pulley onto shaft, install thrust washer and nut. Tighten

nut.

For Pumps with a press on shaft – Always use a pump pulley installer to push the pulley onto the

shaft. The hub of the pulley should be flush with the end of the pump drive shaft. Follow the

instructions provided with the pulley installation tool.

Do not press or hammer the pulley onto the shaft, this will destroy the pump.

13) For bracket kits that are included with a serpentine conversion kit skip the next step and go

on to step 15

14) Install belt (34-3/4” recommended); adjust belt tension by moving pump in brackets.

When proper belt tension has been achieved, tighten all fasteners firmly. Check belt tension again

and adjust if necessary. Do not over tighten belt! Serious damage may occur to the accessory

drive bearings resulting in premature wear. Go to step 16.

15) Only if you have purchased a complete serpentine conversion kit. Align pump so that the fill

cap is level, tighten all fasteners firmly. Install power steering lines and fittings at this time. Return

to the main kit instructions at this time.

16) Install power steering lines and fittings, inspect hoses for kinks or nicks and replace as

necessary. Fill reservoir to the proper level and test run motor. Re-check belt tension and adjust if

necessary. Re-check belt tension after 100 miles.

6) Install gaskets and then water pump. There should be no more than 5/8” of thread left exposed

on studs. If more than 5/8” thread is showing, remove stud(s) and clean out threads then reinstall

threaded stud(s) and check again. Apply anti-seize to the exposed threads on the studs. Also

apply anti-seize to the threads of all the remaining fasteners at this time.

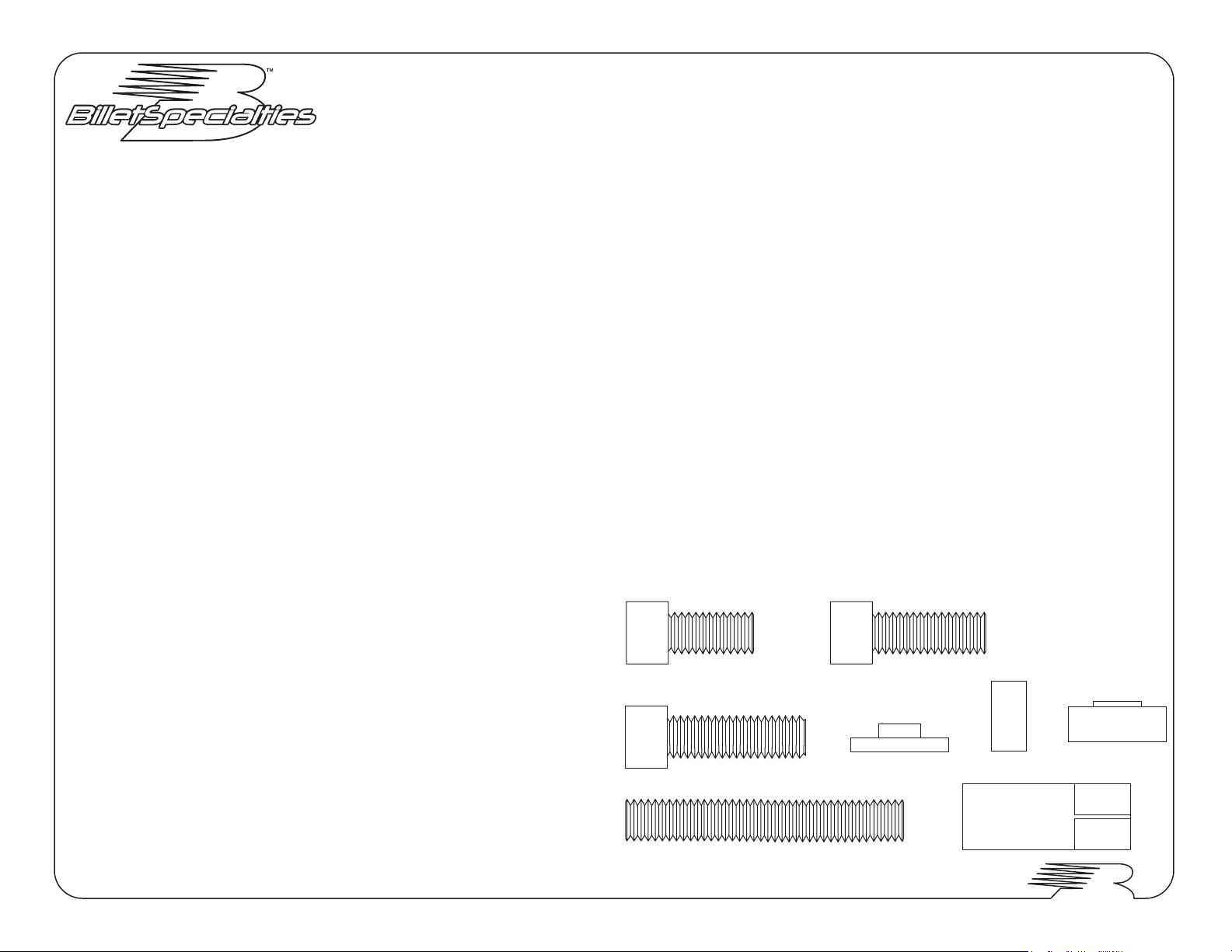

3/8-16 x 3/4" Socket Head Cap Screw

7) Thread the two 1-1/2” long spacer nuts (from the power steering kit) onto the exposed studs

with the hex end out and install the passenger side water pump bolts to complete installation of

water pump. Tighten firmly.

8) Attach the steel three hole power steering bracket to the front of pump with two

3/8-16 x 3/4” socket head cap screws and tighten firmly (46 ft/lb). Attach steel adjustment bracket

3/8-16 x 1-1/4" Socket Head Cap Screw

to the back of the power steering pump with one 3/8-16 x 3/4" socket head cap screw and finger

tighten.

9) Place pump assembly on motor and align three hole steel bracket with water pump boss by the

spacer nuts. Thread the 3/8-16 x 1" socket head cap screw through the bracket and through the

3/16” load washer into the water pump boss and finger tighten.

Billet Specialties, Inc. 500 Shawmut Avenue La Grange, Illinois 60526 PH 800.245.5382 Fax 708.588.7181 www.billetspecialties.com

x5

3/8-16 x 2-1/2" Threaded Stud

3/8-16 x 1" Socket Head Cap Screw

x1

x2

x3

3/8" Slide Spacer

x2

x1

3/16" Load Washer

1-1/2" Spacer Nut

x1

3/8" Rear Spacer

Length: 11/32"

x2

Page 3

FM0130PC SBC Power Steering Bracket

3/8-16 x 3/4" S.H.C.S.

Thru Bracket To Spacer Nut

Do not install top bolt if installing kit with A/C

*3/8-16 x 1"" S.H.C.S.

Thru Steel Bracket To Water Pump

(see below)

Billet Aluminum

Power Steering Bracket

3/8-16 x 1-1/4" S.H.C.S.

Rear Steel Bracket

Thru Bracket & Spacers To Block

3/8" Slide Spacer

3/8-16 x 1" S.H.C.S.

To Power Steering Pump

3/8" Slide Spacer

Power Steering Pulley Nut

Thrust Washer

Keyway power steering pulley

shown. Press-on pulley does not

require thrust washer or nut.

3/8 " Slide Spacer3/8" Rear Spacer

Hex End Out

1-1/2" Spacer Nut

3/8-16 x 3/4" S.H.C.S.

Thru Rear Bracket To Pump

Length 21/32"

3/8-16 x 2-1/2"

Threaded Stud

Billet Specialties, Inc. 500 Shawmut Avenue La Grange, Illinois 60526 PH 800.245.5382 Fax 708.588.7181 www.billetspecialties.com

*3/8-16 x 1" S.H.C.S.

To Water Pump

To Water Pump

3/16" Load Washer

3/8-16 x 3/4" S.H.C.S.

To Power Steering Pump

Three-Hole Steel Bracket

Page 4

FM3110PC SBC Serpentine Pulley Kit - LWP

ALTERNATOR PULLEY

5/8"

Alternator

Lock Washer

4-40 x 3/8"

Socket Head

Cap Screw (x3)

(x1)

5/8"

Alternator

Hex Nut

(x1)

WATER PUMP PULLEY CRANKSHAFT PULLEY

x3

3/8-24 x 1" Socket Head Cap Screw (x3)5/16-24 x 3/4" Socket Head Cap Screw (x4) 3/8" Belleville Washer

Tools Required:

3/32" Allen wrench

Tools Required:

1/4" Allen wrench

15/16" Socket

Billet Specialties, Inc. 500 Shawmut Avenue La Grange, Illinois 60526 PH 800.245.5382 Fax 708.588.7181 www.billetspecialties.com

Tools Required:

5/16” Allen wrench

Loading...

Loading...