Bi-Line Multi-Loop Accumulator User Manual

Soiled Tray Accumulator

saves space...increases efficiency

(2M) 5/00

QUICK FACTS

Frame

12 gauge stainless steel

Tables

14 gauge counter height tabling

Floor drain applications without tabling

Motor

Type A.C. motor with variable speed A.C.

inverter control

Tray Carriers

Choice of open or 3-sided closed design

Carriers hold either 4 or 5 trays

Anti-jam Protection

Anti-jam switch prevents accumulator from

turning when tray is improperly inserted

STANDARD FEATURES

• Stainless steel construction

• Accumulator is free-standing

• Customized length and capacity

• 1-5/8" [41mm] O.D. stainless steel

tubular legs

• Stainless steel access panels

• 16 gauge stainless steel

welded wire carriers

• Low-friction drive rollers

• Low maintenance components

• A.C. motor with variable speed

A.C. inverter control

• Removable tray shelving

• Easy access controls

• Open design facilitates cleaning

Multi-Loop

Accumulator

The Bi-line soiled tray accumulator system provides the

maximum efficiency, style and function in a

minimum amount of space.

State-of-the-art design reduces the

labor required for bussing operations.

®

®

CUS

DETAILED SPECIFICATIONS

Design and Construction: Multi-Loop

Accumulator frame is constructed of 12

gauge stainless steel channel crossbraces

on approx. 3' [914mm] centers, supporting

the frame. The accumulator comes

equipped with 14 gauge tables or without

specified at time of order.

The accumulator is a free-standing unit

supported by 1-5/8" O.D. stainless steel

legs with adjustable feet and bracing. All

bracing is welded and finished. Optional

adjustable flanged feet are available for

bolting the unit to flooring.

Motor/Drive. Accumulator is driven by a

gear-head-type, variable-speed motor controlled by an On/Off switch wired to a watertight AC solid state inverter with overload

protection in NEMA-rated enclosure.

Access panels to motor area and radius

panels on ends are 18 gauge stainless

steel. Top is removable for access to

motor and gearing.

Tray Carriers. Standard tray carriers are

open type design constructed of Type 304

stainless steel. Carriers are removable for

easy cleaning.

Optional tray carriers are enclosed on

3 sides, removable and constructed of

Type 304 stainless steel.

Tray carriers are designed to receive all

size trays. The number of carriers is determined by the overall length of the accumulator. Each carrier may hold either 4 or 5

trays (specified at time of order).

Tray carriers are mechanically connected,

to form a continuous chain for either CW

or CCW rotation.

Anti-Jam Switch. The accumulator is

equipped with an anti-jam switch in the

event that a tray is improperly loaded.

Approvals. This machine is manufactured

to the highest standards including applicable CSA and NSF standards.

Bi-line Systems 2674 North Service Rd.

P. O. Box 16009 Jordan Station

Winston-Salem Ontario, Canada L0R 1S0

NC 27115

Tel: 336/661-1951 Tel: 905/562-6630

Fax: 336/661-0498 Fax: 905/562-5422

bi-line@bi-line.net www.bi-line.net

Multi-Loop

Accumulator

Due to an ongoing value analysis program at Bi-line,

specifications contained in this catalog are subject to change without notice.

®

®

CUS

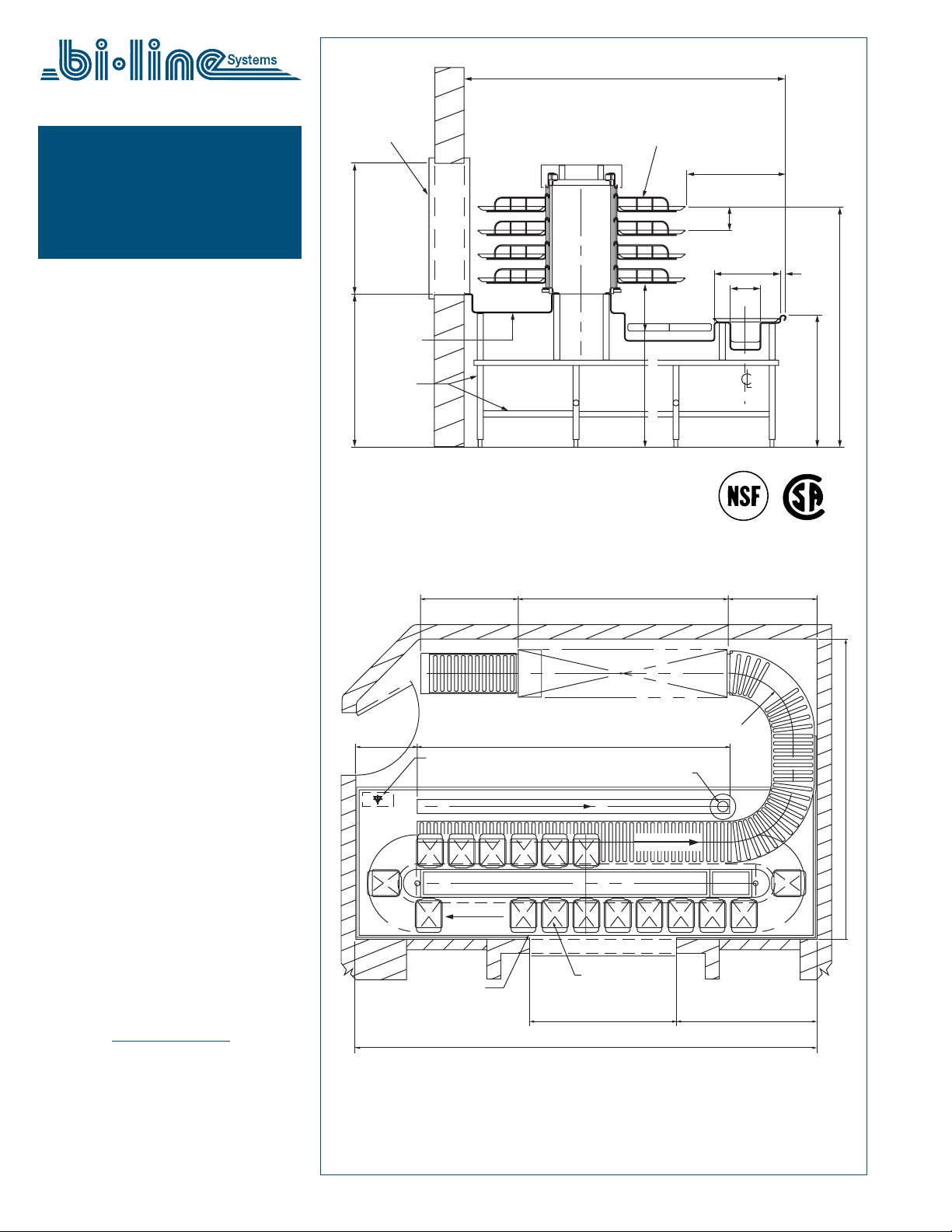

SOILED TRAY ACCUMULATING CONVEYOR

WITH (24)-4-TIER TRAY CARRIERS

(STAINLESS STEEL WIRE SLIDES & SIDES)

EACH CARRIER IS INTERCHANGABLE WITH

EACH OTHER & IS REMOVABLE WITHOUT

THE USE OF TOOLS.

PASS-THRU

FRAME,

SILL &

WINDOW

ASSEMBLY

38"

CLEAR OPENING

42"

PASS THRU HEIGHT

14 GA. S/S

TABLING

1 5/8" DIA.

S/S TUBE

LEGS &

SUPPORTS

7'-4" O/A

6 1/2"

27"

18"

1 1/2"

5'-6"

TO TOP TRAY CARRIER

34" 11"

CLEAR

36 1/2"

8"

TROUGH

TYPICAL

TYPICAL SECTION

TOP OF ROLLERS

DISPOSER

36"

MAIN CONTROL PANEL

MOUNTED BELOW TABLE

208V/15AMP/1PH/60Hz.

(TO BE VERIFIED)

VARIABLE SPEED

0 TO 15 FT. PER MIN.

INFRA-RED PHOTO

ELECTRIC SENSOR

DETECTS IMPROPER

LOADING OF TRAYS

TROUGH SLOPES

TOWARDS DISPOSER

EXISTING DISHWASHERCLEAN DISHTABLE

15'-0" (REF)

STRIPPING TROUGH

SOILED TRAY ACCUMULATING

CONVEYOR WITH A CAPACITY

TRAY SIZE = 14" x 18"

(TO BE VERIFIED)

7'-0" 6'-8" (REF)

SOILED TRAY DROP-OFF WINDOW

22'-0" (REF)

OF (96) TRAYS

WASTE

DISPOSER

GRAVITY ROLLER

SOILED DISHTABLE

R = 36"

TYPICAL

TO BE VERIFIED

14'-4" (REF)

Loading...

Loading...