Bi-Line Bi-Loop 2000 User Manual

Performance Plus Service

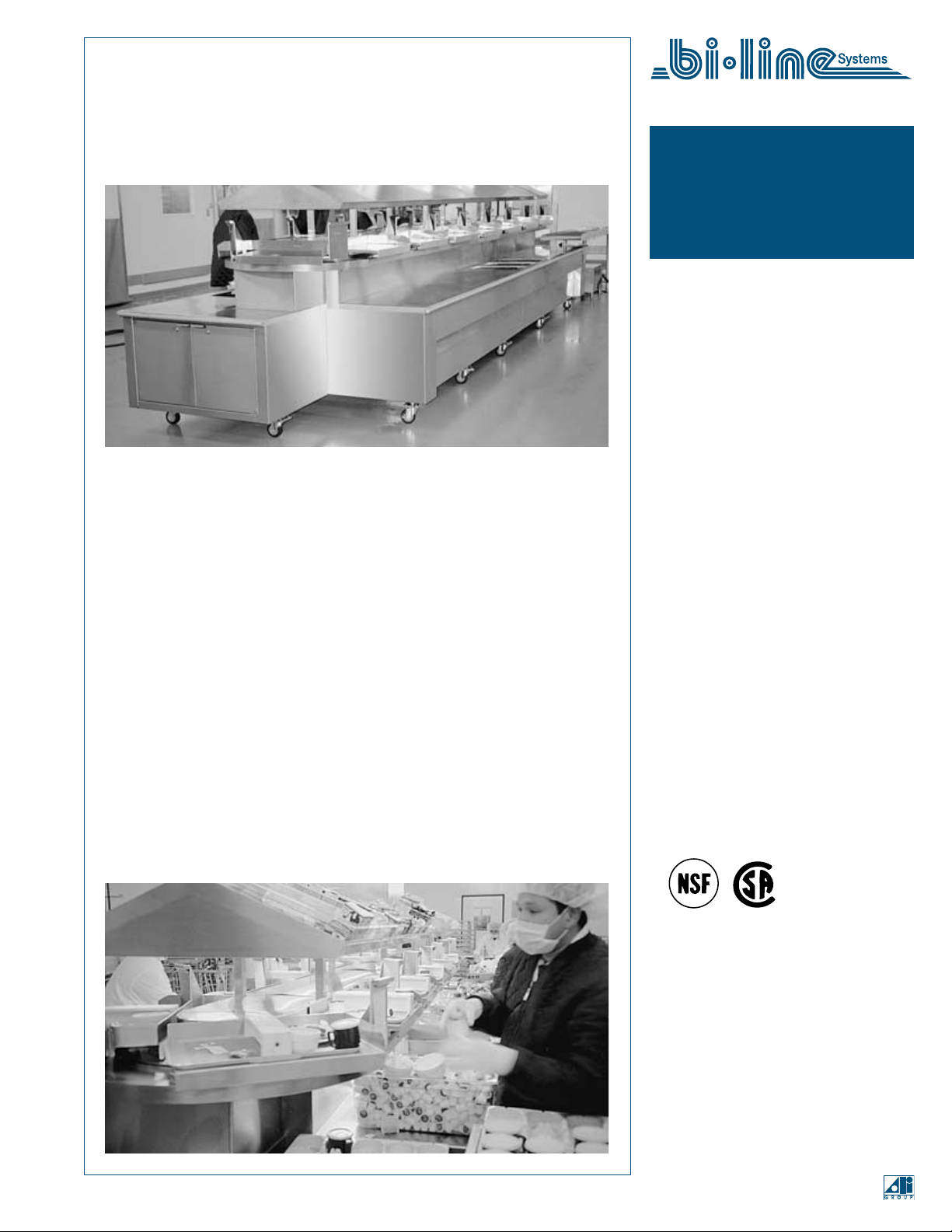

The Bi-Loop 2000 is the result of many years of conveyor experience

from the design specialists at Bi-line Systems. Attention to detail and

an appreciation for the customer’s needs and requirements make every

Bi-line system a performer capable of years of trouble-free service.

Space-saving mobility for your tray make-up operations

The Bi-Loop 2000 includes many advanced features such as removable

rotating tray carriers, wear-resistant low-friction tracks, and cantilevered

shelving combined in an ergonomic design that facilitates labor’s

efforts and maximizes efficiency and workflows.

Convenient controls make operation easy

Easy to operate Start/Stop stations are conveniently mounted for

operating the tray conveyors. In addition, an integral main disconnect

for the drive mechanism allows one operator to easily move the tray

carriers around the conveyor track if necessary.

High quality stainless steel construction throughout

Framing, tabletops, doors and access panels are constructed of

heavy-duty Type 304 stainless steel for long-life and durability. Units

come equipped with stainless steel splash shields and neoprene

bumper guards.

Tray Assembly System

compact, versatile...scalable

(2M) 5/00

QUICK FACTS

Frame

12 gauge stainless steel

Tables

14 gauge counter height tabling

Motor

Type A.C. motor with variable speed

A.C. inverter controller

STANDARD FEATURES

• Stainless steel construction

• Free-standing unit with

stainless steel legs

• Customized length and capacity

• Stainless steel access panels

• A.C. motor with variable speed A.C.

inverter controller

• Start/Stop stations

• Removable tray carriers

• Menu holders

• Low maintenance components

OPTIONS

• Tray unloading stations

• Heavy-duty casters

• Hot/Cold food wells

• Frost top units

• Angled double-sided overshelf

• Fluorescent lighting

• Door locks

• Tray guides

Bi-Loop

2000

Tray Assembly System

®

®

CUS

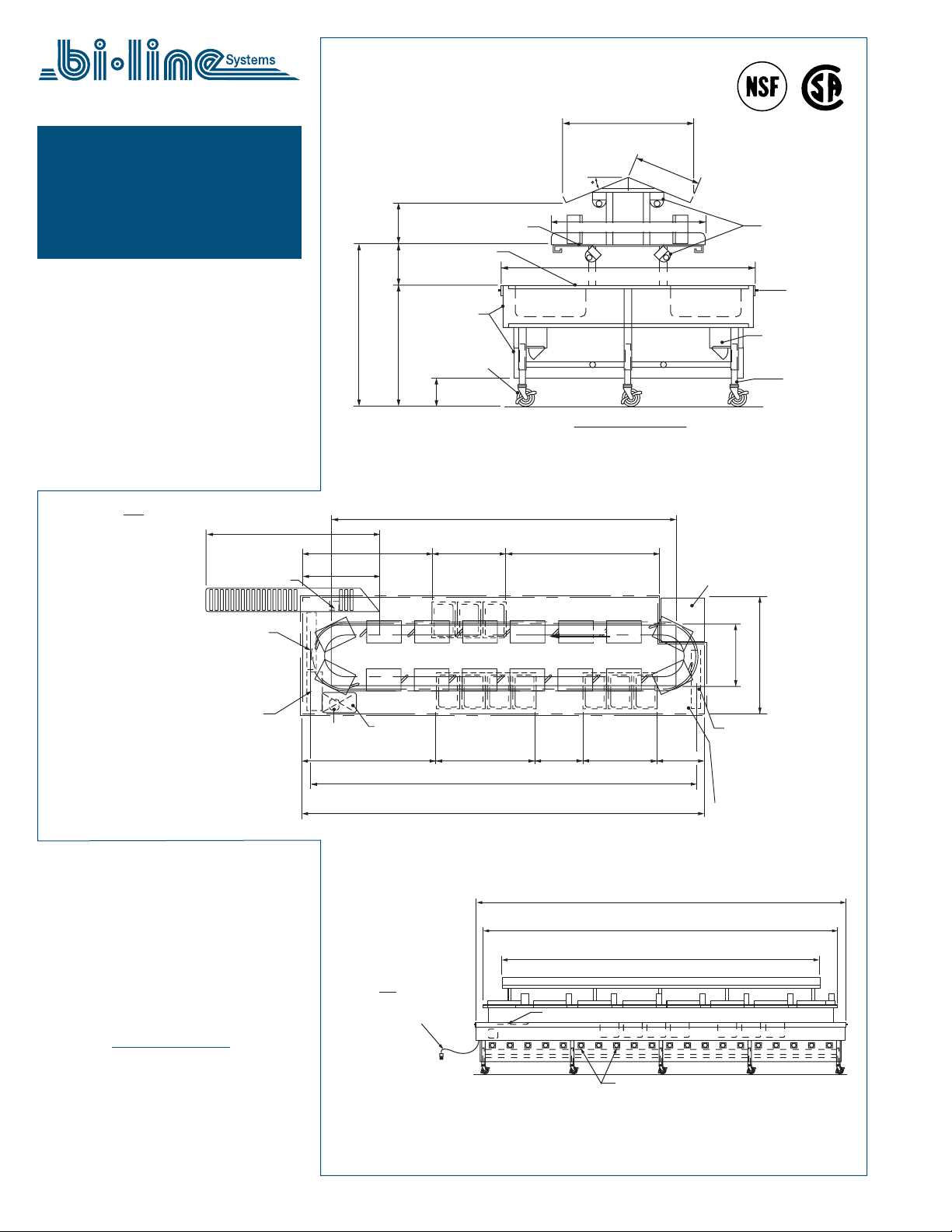

DETAILED SPECIFICATIONS

Design and Construction: The Bi-Loop

2000 is constructed of Type 304 stainless

steel framing, tabletops, and doors. Units

come equipped with neoprene bumpers

guards and integral stainless steel splash

shields over the work surfaces.

The system consists of a series of rotating removable tray carriers riding on a

UHMW polyethylene wear strip embedded

in a SST track, cantilevered above the

finished floor and 12" [305mm] above the

food holding surfaces.

Motor/Drive. Units are powered by a 3/4

HP A.C. motor with variable A.C. inverter

controller. Drives are controlled by start/

stop stations conveniently located on the

unit.

Approvals. This machine is manufactured

to the highest standards including applicable CSA and NSF standards.

Bi-line Systems 2674 North Service Rd.

P. O. Box 16009 Jordan Station

Winston-Salem Ontario, Canada L0R 1S0

NC 27115

Tel: 336/661-1951 Tel: 905/562-6630

Fax: 336/661-0498 Fax: 905/562-5422

bi-line@bi-line.net www.bi-line.net

Bi-Loop

2000

Tray Assembly System

®

®

CUS

23

37"

44"

6'-0"

TABLE BASE DECK

TRAY CARRIERS

WITH MENU HOLDERS

COLD FOOD

STATION

RUBBER

BUMPER

STAINLESS STEEL

FLUORESCENT

LIGHT FIXTURES

STAINLESS STEEL

WIRE CHASE

1 5/8" DIA.

STAINLESS STEEL

TUBE LEGS

& SUPPORTS

HOT FOOD

STATION

TABLE BASE DECK

CONSTRUCTED OF

14 GA. S/S

SKIRT PANELS

CONSTRUCTED OF

16 GA. S/S

ADJUSTABLE HEIGHT

TABLE BASE DECK

CLEARANCE

ADJUSTABLE HEIGHT

TRAY CARRIER SECTION

5" DIA.

POLYURETHANE

SWIVEL CASTERS

WITH BRAKES

TRAY CARRIER SECTION

19"

SLOPED DOUBLE

SIDED OVERSHELF

8"

42 1/4" TO 46 1/2"

30 1/4" TO 34 1/2" 12" 11 1/2"

TYPICAL SECTION

NOTE:

THE TRAY UNLOAD STATION

FOR ONE TRAY ASSEMBLY SYSTEM

IS TO HAVE AN L-SHAPED CONVEYOR

THE LENGTH & DIRECTION IS TO

BE VERIFIED AT A LATER SITE CHECK

(1)-CIRCUIT BREAKER PANELS

WITH POWER SUPPLY CAPACITY

100amp-120/208 volt-3 phase-60Hz.

C/W 100 amp. MAIN DISCONNECT

FOR FUTURE SUPPORT EQUIPMENT

(1)-CIRCUIT BREAKER PANELS

WITH POWER SUPPLY CAPACITY

100amp-120/208 volt-3 phase-60Hz.

C/W 100 amp. MAIN DISCONNECT

FOR FUTURE SUPPORT EQUIPMENT

CONVEYOR CONTROL PANEL

WITH POWER SUPPLY OF

30amp-120/208volt-3 phase-60Hz.

& INTERNAL VARIABLE SPEED

CONTROL TO VARY SPEED

FROM 0 TO 30 FT. PER MIN.

& HOUR METER

TO BE LOCATED INSIDE A

LOCKABLE 16ga. S/S

ENCLOSURE AT THIS END

CONVEYOR

START/STOP

CONTROL

OPEN

STATION

7'-0"

STARTER STATION

TRAY CARRIER SECTION

20'-2"

TABLE BASE DECK

21'-0"

30"

HOLD

30"

HOLD

HOT FOOD STATION

HOT FOOD STATION

CONVEYOR

START/STOP

CONTROL

9'-0"

TRAY UNLOADING STATION

6'-9"

CHECKER STATION

8'-0"

MISCELLANEOUS STATION

COLD FOOD STATION

18'-0"

SLOPED DOUBLE SIDED OVERSHELF

BEVERAGE

STATION

38"

8'-0"

4'-0"

DECK DEPRESSION

FOR TRAY PLACEMENT

TRAY CARRIER TROUGH

VARIABLE SPEED

NOTE

UNIT IS TO BE SUPPLIED

WITH CORD & PLUG RATED FOR

20 amp - 120/208 volt - 3 phase

(4) POLE - (5) WIRE (NEMA #L21-20)

DECK DEPRESSION

FOR TRAY PLACEMENT

HOT FOOD STATION

21'-0"

20'-2"

TABLE BASE DECK

TRAY CARRIER SECTION

SLOPED DOUBLE SIDED OVERSHELF

18'-0"

HOT FOOD STATION

CONNECTION LINKS FOR

FUTURE SUPPORT EQUIPMENT

ON 12" CENTERS

BUILT INTO STAINLESS

STEEL WIRE CHASE

Loading...

Loading...