22-27

Table of Contents

1 INTRODUCTION ...................................................................................................... 2

Company presentation .......................................................................................... 2

Product presentation ............................................................................................. 2

2 TECHNICAL SPECIFICATIONS .................................................................................. 3

3 DIMENSIONAL DIAGRAMS ..................................................................................... 4

4 GENERAL DESCRIPTION .......................................................................................... 5

5 MAIN COMPONENTS.............................................................................................. 6

6 SAFETY FEATURES ................................................................................................ 15

Safety support ...................................................................................................... 15

Location of the decals on the trailer .................................................................... 15

Presentation of decals ......................................................................................... 16

7 COUPLING/UNCOUPLING THE TRAILER ............................................................... 21

Safety aspects when coupling/uncoupling .......................................................... 21

COUPLING TO TRACTOR ....................................................................................... 22

8 DRIVING THE TRAILER .......................................................................................... 23

Safety aspects when driving ................................................................................ 23

ROAD DRIVING INSTRUCTIONS ............................................................................ 24

Load on towing eyelet and coupling .................................................................... 25

Working under extreme conditions ..................................................................... 26

EXCHANGE MECHANISM ..................................................................................... 27

9 EXCHANGE OPERATION ....................................................................................... 28

Safety aspects during exchange operation .......................................................... 28

Exchange procedure ............................................................................................ 29

10 TIPPING OPERATION ............................................................................................ 32

11 WIRING DIAGRAM ................................................................................................ 33

12 HYDRAULICS CHART ............................................................................................. 36

13 CARRYING OUT SERVICE/MAINTENANCE ............................................................ 37

14 MAINTENANCE/SERVICE ...................................................................................... 39

15 SPARE PARTS ........................................................................................................ 46

16 TROUBLESHOOTING ............................................................................................. 53

17 EC DECLARATION (sample) .................................................................................. 54

CONTACT INFORMATION:

Factory:

AS FORS MW

Tule 30

765 05 Saue

Estonia

Tel: + 372 679 00 00

Fax: + 372 679 00 01

E-mail:

info@forsmw.com

Aftermarket:

We speak English and Swedish.

FMW Farma Norden AB

Hornsväg 2

SE-605 97 Norrköping

Sweden

Tel: + 46 (0) 11 657 70

Fax: + 46 (0) 11 283 70

E-mail:

aftermarket@forsmw.com

© V7.1-2015W42–en Fors MW Ltd www.forsmw.com 1

22-27

1 INTRODUCTION

Stringent demands are placed on manufacturers to comply with the directives for

the product they produce. This product is covered by the Machinery Directive and

the CE marking indicates that it meets the requirements of the Directive. On delivery

of a product, the dealer is required to provide operating instructions for the product.

Company presentation

AS FORS MW was established in Estonia in 1992. The company develops,

manufactures, markets and sells, via dealers, its three market-leading brands. These

are BIGAB hook lift trailers and dump trailers, FARMA lumber trailers and cranes, and

NIAB tractor processors. The company comprises the parent company AS FORS MW,

as well as the subsidiary companies Farma Norden AB (Norrköping, Sweden) and

ForsMW/China. You can find out more about the product you have selected and our

20-year journey by visiting our websitewww.forsmw.com and our blog

www.forsmw.blogspot.com

Product presentation

The BIGAB hook lift exchange system includes a range of models, all offering the

same high level of versatility. A wide and varied range of accessories is also available.

The versatility lies in its ability to handle different kinds of loads on one and the same

chassis. You will find your BIGAB indispensible for a wide range of tasks.

The 22 – 27 is our largest hook lift trailer. Simple, impressive and powerful are all

fitting ways to describe the BIGAB 22 – 27. This is the ideal trailer for transporting

particularly heavy loads. For your safety, it is extremely important that you follow

the instructions in this instruction manual for your BIGAB model.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

2

Brakes:

Hydraulic drum

*

Depending on

Pressure & return, 1 single

-

action brake/

Load on towing eyelet:

/REF:150706

22-27

2 TECHNICAL SPECIFICATIONS

Hook lift trailer 22-27

Frame: Rectangular sections 300*100

Bogie: Parabolic sprung triple axles Axle distance 1525 mm

Hubs: 130*130, 10 bolts

Tyres: 560/60-22.5

market

Towing eyelet: For hitch hook

Stabiliser legs: Manual Yes

Light system: 12 volt Yes

Tractor hydraulics: *For brakes

Oil volume: With full system 23 l

Oil volume: Press 89 l, draw 66 l

Oil flow: 60-120 l/min

Max working pressure: Max. 22 MPa

Tipping angle: 50 degrees

Chassis weight (±1%): Standard equipped 6600 kg

Chassis length (±50mm): 7550 mm

Distance eyelet to centre tridem (±20mm): Centered tridem axle 5155 mm

Distance eyelet to ground surface: Min. 475 mm

Height unloaded: 1330mm excl. load carrier frame

1 double-action with floating position

406*120 on 6 wheels

Width across wheels (±30mm): 2590 mm

Bridge length: 5700-6500 mm

Total weight (±1%): 28 600 kg

Max. load incl. bridge: tipping (±1%): 22 000 kg

Max. load incl. bridge: roll on/roll off (±1%): 21 000 kg

Depending on the position of the trailer bed

Max. speed 40 km/h

REF: 150923

2500 – 3500 kg

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

3

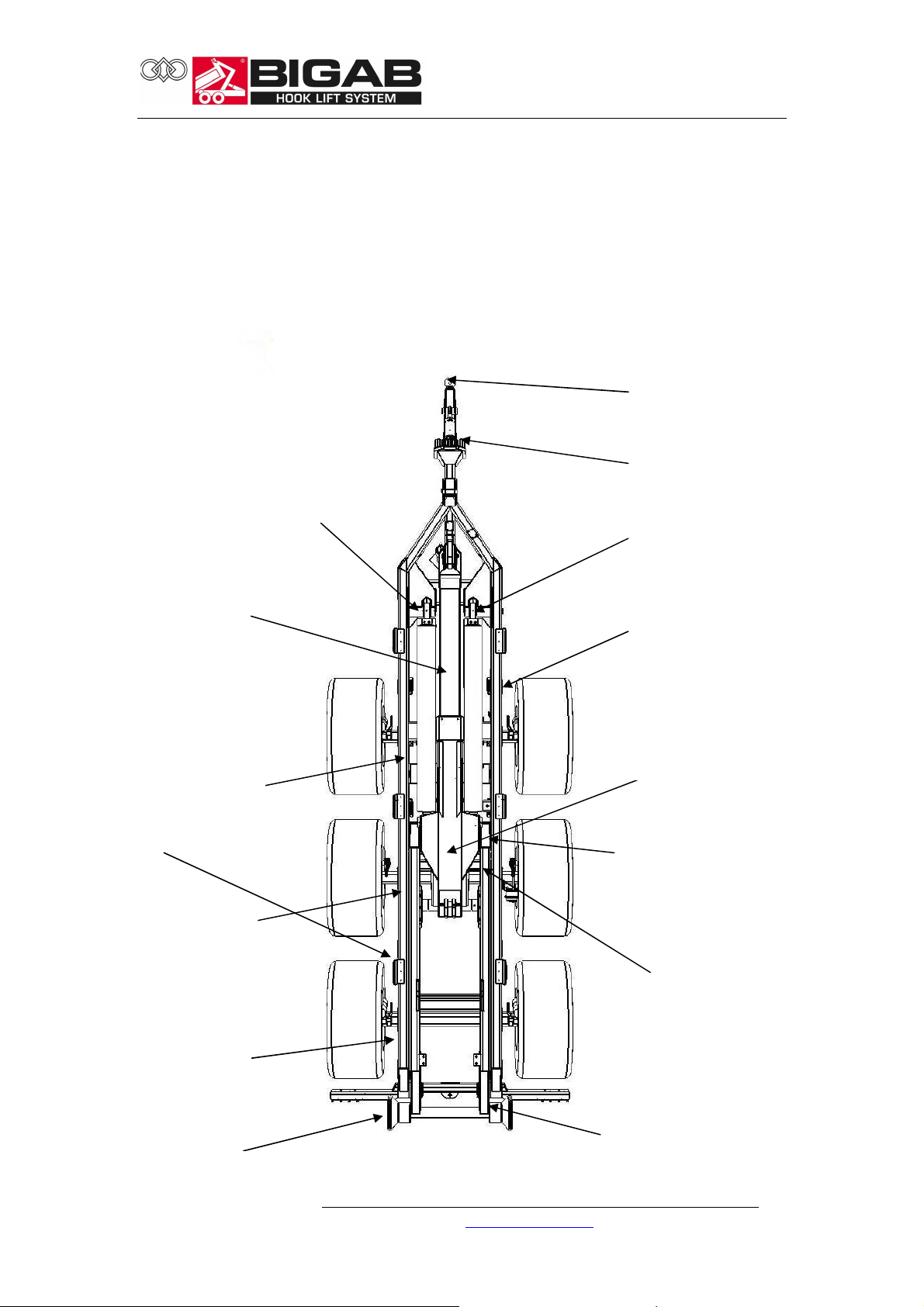

3 DIMENSIONAL DIAGRAMS

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

4

Chassi

Hook

Wheels

Towing

22-27

4 GENERAL DESCRIPTION

The trailer is steady when used for both tipping and exchanging. The trailer is

equipped with a torsional parabolic spring bogie on three axles with brakes on all

wheels.

Steering

roller

Rear

Hook

Telescop

Stabilise

Exchange

Tipping

position

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

5

Rear frame

22-27

5 MAIN COMPONENTS

The trailer comprises the following principal components and functional devices.

Chassis

Side

Rear beam

Suspension

Rear frame

Bracket for frame

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

6

Brake cylinder

x 3

bogie

Telescope

Hydraulic cylinder (inside)

Hook frame

Hook

22-27

Hook

frame

Extended tower

1300 mm

Bogie

The trailer is equipped with a powerful sprung tridem bogie with brakes on all six

wheels.

Sprung tridem

Axle with brake

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

7

Stabiliser leg

Pin

Chassis

Standard height: 1450

Standard height: 1570

Hook

The trailer is equipped with an adjustable hook for two different heights.

22-27

Stabiliser leg

The stabiliser leg is designed to support the trailer when not in use. The stabiliser leg

must not be used when the trailer is loaded. The stabiliser leg must be raised and

secured in place with the pin before moving off.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

8

Locking bolt

Chassis

Towing eyelet

Hydraulic cylinder

Locking lug

Exchange unit

The unit is designed for

the procedure when switching between

tipping and exchange.

The lever is located in the middle

of the rear frame.

Exchange unit container lock

The trailer is equipped with a

hydraulic container lock

that secures the container to the frame

Rear frame

22-27

Hydraulic cylinder

Towing eyelet

The towing eyelet is adapted to the hitch on the towing vehicle. It is extremely

important that the towing eyelet is inspected for defects every time the trailer is

used.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

9

Rear beam

Steering roller Left/Right

Chassis

Drawbar

The drawbar is used for coupling other equipment to the trailer. It is also used for

attaching the warning triangle. Note! Do not couple excessively heavy loads to the

drawbar. The maximum permitted trailer weight is 10 tonnes.

Steering rollers

The steering rollers are designed to guide the bed correctly. The bed frame must be

inside the steering rollers during exchange operations.

Pin

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

10

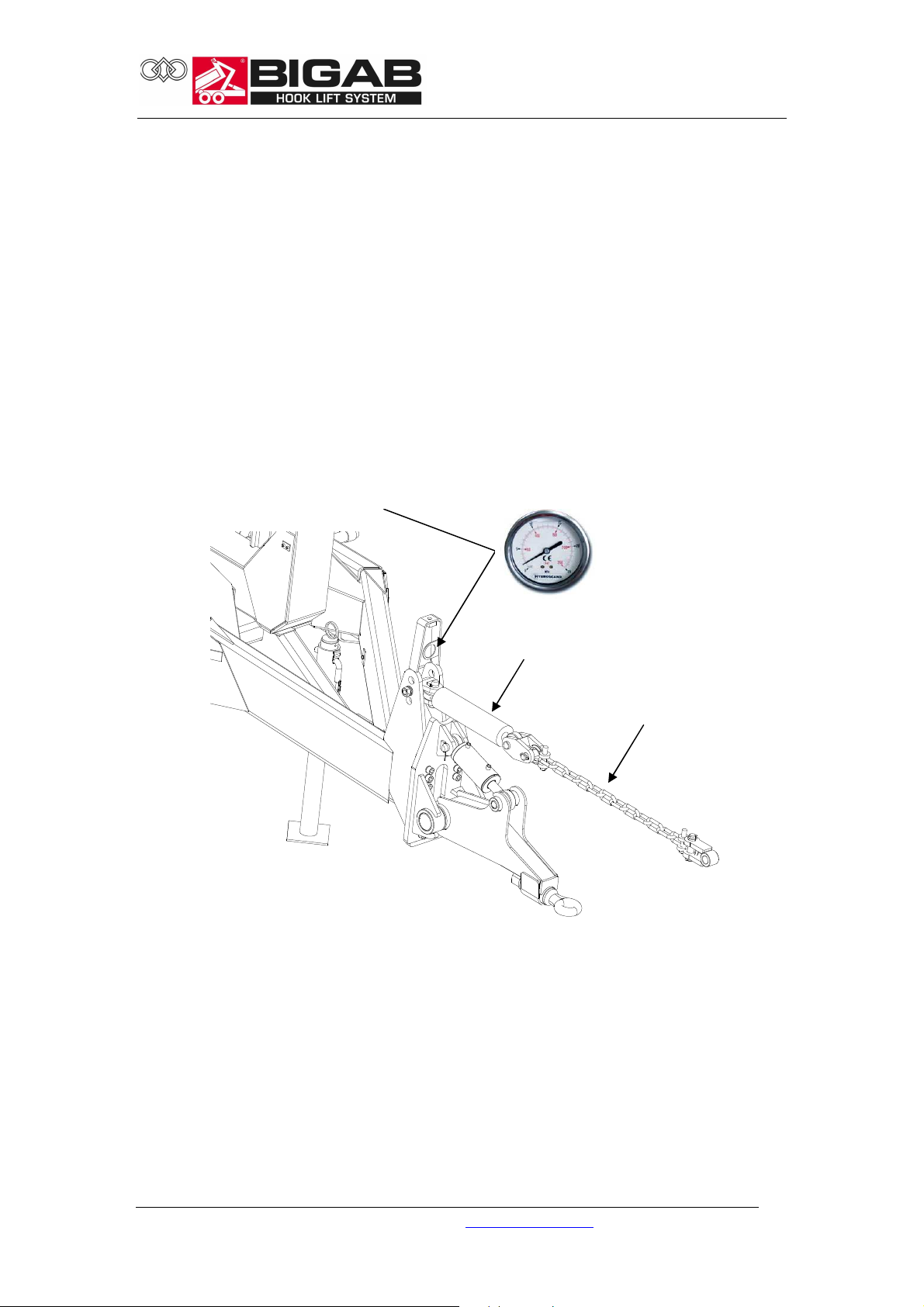

Frame lock

The hydraulic frame lock is used to lock the frame during heavy exchange operations.

When mounting the chain on the tractor for the first time, adjust the length of the

chain so that it is slack when the cylinder is half extended.

When you then tension the cylinder, the pressure relief valve is set at about 100 bar

and it can be adjusted to the size of the tractor.

It is very important to slacken it after exchanging so as not to impede the tractor

during transport.

22-27

Frame lock hydraulic

cylinder

Chain to tractor

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

11

Suspended drawbar

22-27

Drawbar functions

The trailer is equipped with an adjustable drawbar that can be used for the following

three functions. Use the position switch on the control unit to regulate the drawbar.

Select a function and regulate the pressure with the toggle switch.

Suspended drawbar

Set the mode switch to suspension mode and then apply pressure. Watch the

manometer to see how much pressure you apply. The valve has a pressure

limiter that controls the amount of pressure you can apply. Check at regular

intervals during transport that the pressure remains constant.

Fixed drawbar

This function is used to stabilise the trailer when exchanging containers. Set the

mode switch to fixed mode and apply pressure to stabilise the drawbar.

Swinging drawbar

Set the mode switch to swinging mode. No pressure is applied to the drawbar.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

12

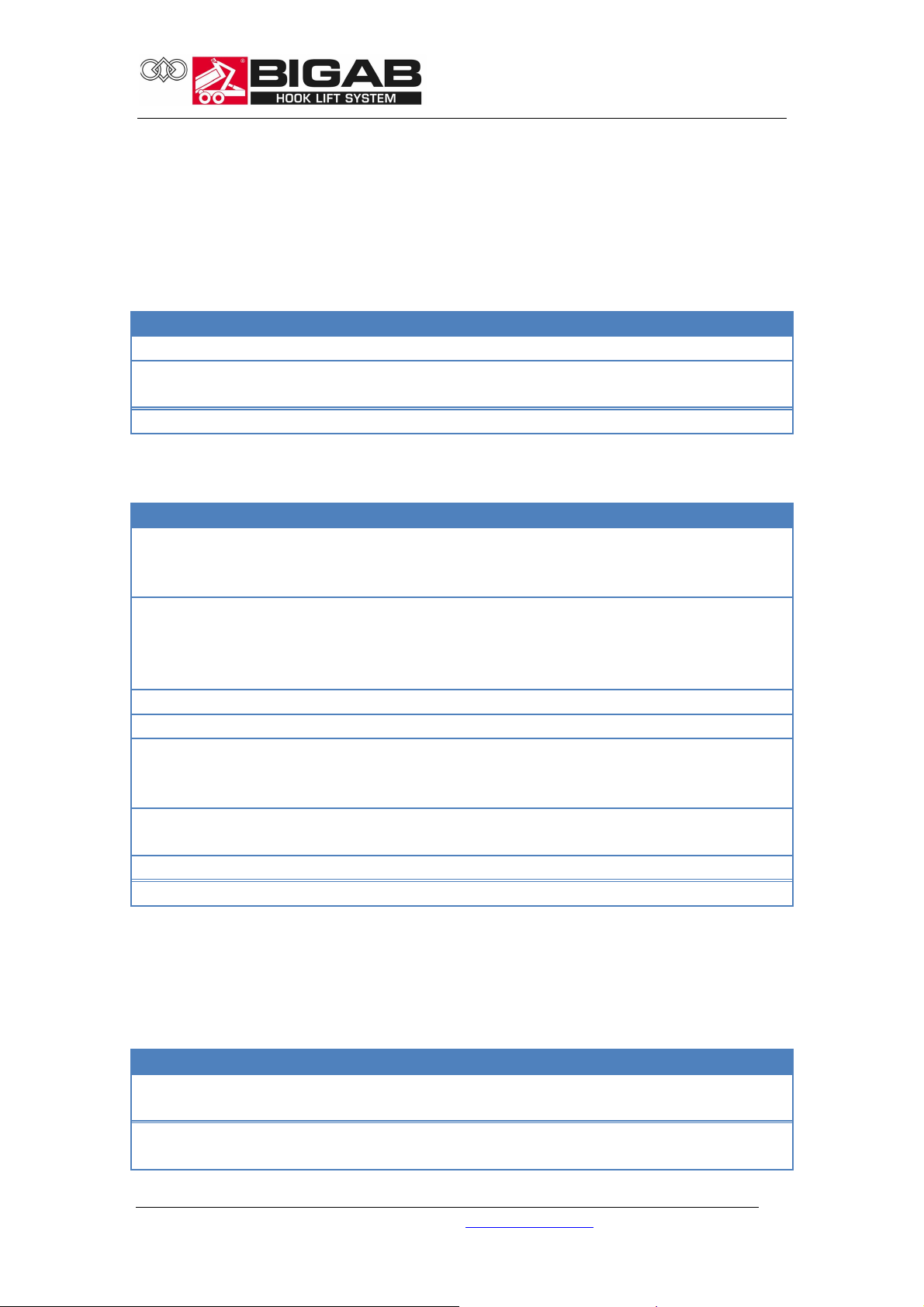

Tyres

List of standard tyres and alternative tyres that are used for the different trailer

models.

Model

22-27 560/60-22.5 3.6 40

445/65R-22.5 5-10 40

650/50R-22.5 TL

* The air pressure may vary slightly depending on the make of tyre. Contact the tyre

manufacturer for exact air pressures.

Hydraulic system

The trailer is equipped with a hydraulic system for the various work operations. For

more information, see the Hydraulics Chart chapter.

Electrical system

The trailer has a 12 volt electrical system. For more information, see the Wiring

Diagram chapter.

Brake system

The trailer is equipped with a hydraulic brake system. A pneumatic brake system is

also available as optional equipment. Note! The hydraulic pressure in the brake lines

should not exceed 16 Mpa. Too much hydraulic pressure can cause the brake arm

cam to go over-centre and lock the brakes.

Standard tyres Alternative tyres Air pressure

(bar)

4.0 40

10B -70

22-27

Speed

(km/h)

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

13

No. Description

1 Tipping/Exchange

2 Telescope in/out

3 Exchange/tip/container lock

4 Frame lock

5 Hydraulic outlet

6 Suspended drawbar up

-

down

7 Suspended drawbar locked

-

sprung

-

floating

8 On-Off

22-27

Electric on-off control

The trailer is equipped with a hydraulic system that is operated via a control unit.

With regard to position 3, it is important to run this function until the signal lights

come on. This indicates that the locks have reached their end stop position.

With regard to position 3, it is important to run

this function until the signal lights come on.

This indicates that the locks have reached their

end stop position.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

14

22-27

6 SAFETY FEATURES

Safety support

Always use the safety support when carrying out service work when the trailer bed is

raised. The safety support must not, under any circumstances, be used when the

trailer bed is loaded.

Chassis

Safety support

Location of the decals on the trailer

The trailer is marked with various signs relating to safety and information. Check that

all signs are correctly positioned.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

15

22-27

Presentation of decals

WARNING!

Warning triangle and instruction manual decal.

The trailer has a warning triangle next to the instruction manual decal to emphasis

the importance of reading the entire instruction manual carefully before using the

trailer. Failure to observe this may result in serious or fatal injury.

INFORMATION!

Decal for the use of safety equipment.

These decals encourage the use of appropriate safety equipment in order to avoid

injury when using the trailer.

DANGER!

Risk of crushing injuries

There is a risk of trapping and crushing injuries during work and maintenance.

WARNING!

Hazardous area

Standing between the trailer and the towing vehicle when the trailer is being driven,

moved with frame steering or when other functions are activated between the

trailer and towing vehicle, can be potentially fatal. As the driver, you must always

ensure that no one is in the area around the machinery.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

16

WARNING!

Warning - It is a hazardous movement if the rear end of the tractor lifts

Note! This warning label is included in the delivery of your trailer. It must be

attached in a conspicuous position in the tractor cab. If you would like more of these

labels, they are available to order, free of charge, from our after sales department.

Contact details are printed on the first page in the instruction manual.

WARNING!

22-27

It is absolutely forbidden to board the trailer when it is moving

Anyone doing so may be at risk of serious or fatal injury.

WARNING!

Risk of slipping

There is a risk of slipping as the surfaces of the trailer can be slippery due to a

combination of precipitation and oil and/or clay on the surface. The ground around

the trailer can also become slippery, as the tyres can tear up the surface and expose

clay and soil.

DANGER!

Hydraulic fluid under pressure

Hot hydraulic fluid at high pressure levels can occur in the hydraulic system. Take

care when connecting. Replace worn or damaged hoses.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

17

INFORMATION!

Using the exchange unit

Do not operate the exchange unit unless the frame is folded down. During transport

with the trailer, the hook must be folded down in the parking position.

WARNING!

22-27

Use the safety support during all service operations

It is absolutely forbidden to lean under a raised frame unless it is secured with the

safety support. Under no circumstances may the trailer be carrying a load or

container when the safety support is being used.

WARNING!

Maximum load

It is absolutely prohibited to load more than the amount your model of trailer is

designed to handle. This can be dangerous for you and your surroundings.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

18

WARNING!

Max. pressure on towing eyelet

Do not load so much that the pressure on the towing eyelet exceeds the permitted

laws and regulations. The trailer is designed for a maximum pressure of 3000 kg on

the towing eyelet. The pressure is largely determined by the way the load is

distributed on the container bridge, and it is the user’s responsibility to ensure that

this is not exceeded.

INFORMATION!

Tyre inspection

The tyres must be tightened and the brakes must be inspected regularly.

INFORMATION!

22-27

Lubrication

This decal is used to show the importance of regular lubrication of the trailer.

INFORMATION!

ID- plate

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

19

Marking of hydraulics

All of the hydraulic hoses are marked with coloured labels. See the table below for

more detailed information. The functions depend on the configuration of the

hydraulic system.

Hydraulic hose label (example tipping cylinder)

Hose label colors:

• Red - Oil from pump

• Blue - Oil to tank

• Yellow - Brake

Marking of the hydraulic hoses

.

No. Colour Function

1 Yellow Brakes

26 Red Steering (p)

27 Blue Steering (t)

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

20

22-27

7 COUPLING/UNCOUPLING THE TRAILER

Safety aspects when coupling/uncoupling

The following must be checked each time before use;

Inspect the trailer carefully.

Check the air pressure in the tyres. The tyres must always have at least the

recommended air pressure. See maintenance/service for more detailed information.

Check that all couplings are correctly connected.

Check that the trailer is locked to the towing vehicle.

Check the towing eyelet and the coupling device on the tractor.

Check the lights.

Check the brakes by testing them a few times without a load.

Check that hydraulic hoses and couplings are intact and not cracked.

Check that all hydraulic functions are working.

It is absolutely forbidden to use the trailer for any other purpose than as a hook lift

trailer.

Make absolutely sure that no unauthorized persons are in the working area of the

trailer.

Respect the safety distance. The hazard zone is 30 metres.

Never stand by the drawbar when coupling or uncoupling or when functions

between the towing vehicle and trailer are activated.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

21

Do not exceed the maximum loading limit for the model of trailer. See Technical

Data for more detailed information.

Make sure that the trailer's SMV sign is in place and is clean.

Always examine the towing vehicle's parking system before loading. If necessary,

secure the wheels by placing chocks or obstacles in front of the wheels.

Study the safety regulations carefully.

WARNING! If the trailer is coupled behind another

trailer, the load capacity of the first trailer must be

reduced. The load capacity must be reduced by a load

equal at least to the second trailer's ball coupling

pressure on the first trailer.

22-27

COUPLING TO TRACTOR

When the tractor is connected and the drawbar is locked, always engage the

tractor’s parking brake before connecting hydraulic hoses and/or electrical cables.

Connect the trailer’s brake line to the tractor’s brake outlet.

Then connect the thick return line with the female coupling to the tractor’s free

return outlet. Free return is important to ensure optimal operation and

performance.

Connect the thick pressure hose with the male coupling to the tractor’s pressure

outlet.

Finally, connect both the lines that are to the steering axles to a double-action

hydraulic outlet with floating position.

Plug the 7-pole electrical connector into the tractor’s electrical outlet.

Connect the control unit to an electrical outlet rated at 16 amps or higher to obtain

sufficient power to the electromagnets on the manifold.

Connect the chain on the load transfer cylinder to the tractor’s top link bracket.

Adjust the chain so that when about 60% of the cylinder has been extended, the

chain is slack, and when the cylinder is retracted the chain is tensioned.

Disengage the parking brake NOTE! It is important that the parking brake is engaged

when the trailer is separated from the tractor.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

22

22-27

8 DRIVING THE TRAILER

READ THE ENTIRE INSTRUCTION MANUAL BEFORE USING THE TRAILER.

CONSULT THE MANUAL IF YOU ENCOUNTER ANY PROBLEMS. THE TRAILER HAS A

MANUFACTURING PLATE. BEFORE USING THE TRAILER, MAKE SURE THAT THE

FACTORY SETTINGS HAVE NOT BEEN CHANGED AND THAT NO PARTS HAVE COME

LOOSE DURING TRANSIT. MAKE SURE THAT ALL SAFETY FEATURES AND SIGNS ARE IN

PLACE.

Safety aspects when driving

It is the responsibility of the user to ensure that a sufficiently powerful and heavy

towing vehicle is coupled to the trailer in all situations. The use of a towing vehicle

that is too small and insufficiently powerful can pose a risk of serious or fatal injury

for the user, be hazardous for the surrounding environment and cause damage to

the vehicle and trailer.

The load in the trailer must be evenly distributed. Loose items and loads that

protrude over the back or sides must be secured.

Remember that the weight of the trailer can adversely affect the tractor making it

more difficult to maneuver.

Do not forget to raise the stabilizer leg before moving off.

Never make tight turns at high speeds.

Do not exceed the maximum loading limit for the model of trailer.

Adapt your driving to the load, road conditions and your level of experience. The

trailer is designed for driving at a maximum speed of 40 km/h.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

23

Maximum load is shown in

the Technical Data section.

Remember that with a long trailer bed and large overhang, the trailer needs more

room to maneuver and turn.

WARNING!

The trailer may only be driven in transport position. It

must never be driven with a raised bed. If you drive with a

raised bed, there is a risk of driving into bridges, electrical

power lines and other obstacles.

WARNING!

The manufacturer accepts no responsibility for damage that arises

as a result of overloading or, in the event of failure of the drawbar,

that arises if the trailer becomes detached from the vehicle.

22-27

It is absolutely forbidden to board the trailer

when it is moving. Anyone doing so may be at risk

of serious or fatal injury.

ROAD DRIVING INSTRUCTIONS

The steered axles are controlled by the tractor’s double-action outlet with

floating position. When driving forward, the lever is placed in floating mode so that

the trailer automatically follows the tractor. NOTE: Be very careful if a road has

sharp bends or is heavily cambered. Be extremely careful when roads are slippery.

When reversing the trailer, apply slight pressure in both directions using the doubleaction outlet. This will remove any accumulated air from the system.

Then watch the wheels and steer them in the intended direction.

Do not steer at too sharp an angle as this can make it difficult for the tractor to

follow the trailer.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

24

NOTE: Reset to floating mode before driving the trailer forward.

When steering with steerable axles with a double – active valve with float

position from tractor which is standard on 22 – 27, it is imperative to stand still with

the trailer when you switch between blocking force controlled axles and floating

position on the axles.

When driving on normal road the axles should always be unlocked, by having the

tractor lever in the float position. It is absolutely forbidden to change the statues of

the axles from floating to the locked position when driving. If you lock or unlock

them while driving, there may be tension and pressure on the axles that make them

stand in improper angels, and then you can lose control of the trailer.

When you start to roll after putting the axles into floating position, caution should be

taken since the axles need to align themselves in the direction after being locked in a

different angle. This must be done at low speed. Even at sharp turns and bumpy

roads the speed needs to be adapted so that the trailer follows the tractor.

Remember that in cold weather, the oil is thick and that it then takes longer time for

the axles to come in the right position.

Axles locked = Axles standing still and straight after the trailer. To be used when

reversing and when you hook on the bridge this so that the trailer rolls underneath

the container when hooking.

Axles unlocked = Axles move freely and follow the trailer. The tractor lever is in the

float position. Note! The conversation to unlocked axles may only be done when

standing still.

Forced axles with double – active jack should only be used when reversing and when

you need to control the trailer to a given direction at very low speed.

22-27

Load on towing eyelet and coupling

Always adapt your driving to the load, road conditions and your level of experience.

Do not exceed the maximum speed specified for the trailer. Make sure that you have

the correct pressure on the tow hook when you are driving. Do not exceed the

intended upward and downward pressures on the trailer’s towing eyelet and the

coupling to the hitch. The given ideal conditions and theoretical calculations indicate

the following maximum load values, and it is recommended that the user observes

these load values.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

25

22-27

The above table provides information and examples of how many different loads can

weigh. This table should only be used as a general guide. The manufacturer cannot

be held responsible for measurements or volumes stated in the table. The

information in the table is intended only as a recommendation.

WARNING!

An incorrectly distributed load can adversely affect

the steering of the tractor and trailer making them

difficult to maneuver.

Working under extreme conditions

The recommended working temperature for a BIGAB dump trailer is –20°C to +40°C.

When working in temperatures below the recommended temperature, the trailer

should not be loaded as heavily. When working in low temperatures, always allow

the oil to circulate freely through the system for a few minutes before starting work.

In very hot conditions, you should be aware that the hydraulic oil heats up

drastically. At temperatures above +80°C, the oil evaporates and the seals in the

system will be damaged.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

26

IF A DANGEROUS SITUATION ARISES

If the trailer comes into contact with high voltage electric wires, you should do the

following:

IF YOU ARE OUTSIDE THE TRAILER

Do not attempt to get into or close to the trailer. Keep everybody well away from the

trailer. Do not touch any part of the trailer.

IF YOU ARE INSIDE THE TOWING VEHICLE

Get out of the vehicle by jumping. Avoid touching any part of the vehicle. Avoid

making your body into a channel through which the electricity can flow. Get out of

the vehicle by jumping but make sure that your feet do not touch the ground at the

same time. An electric field at ground level can cause fatal voltage between the legs.

You should be safe at a distance of about 20 meters from the vehicle, but this

naturally depends on circumstances such as the voltage in the overhead power lines,

ground conditions, etc.

22-27

EXCHANGE MECHANISM

The illustrations below show a hydraulic frame lock which controls the handling of

the exchange mechanism and the hydraulic container lock. The exchange mechanism

is located in the middle of the rear frame.

Tipping position

Hook frame

Locking pin

Rear frame

Hydraulic cylinder

Exchange mode

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

27

22-27

9 EXCHANGE OPERATION

Safety aspects during exchange operation

The hook lift trailer must only be operated by one person in order to avoid injury

when working with the trailer. There should be no one inside the hazard zone, which

is 25 meters around the trailer.

Unauthorized persons must keep well away from the trailer when it is being used or

repaired. It is strictly forbidden for anyone under the influence of alcohol or drugs to

work with the trailer.

Exchange and tipping must be operated from the towing vehicle!

Make sure that the frame lock is activated. Make sure that the hook is properly

locked on to the container eyelet.

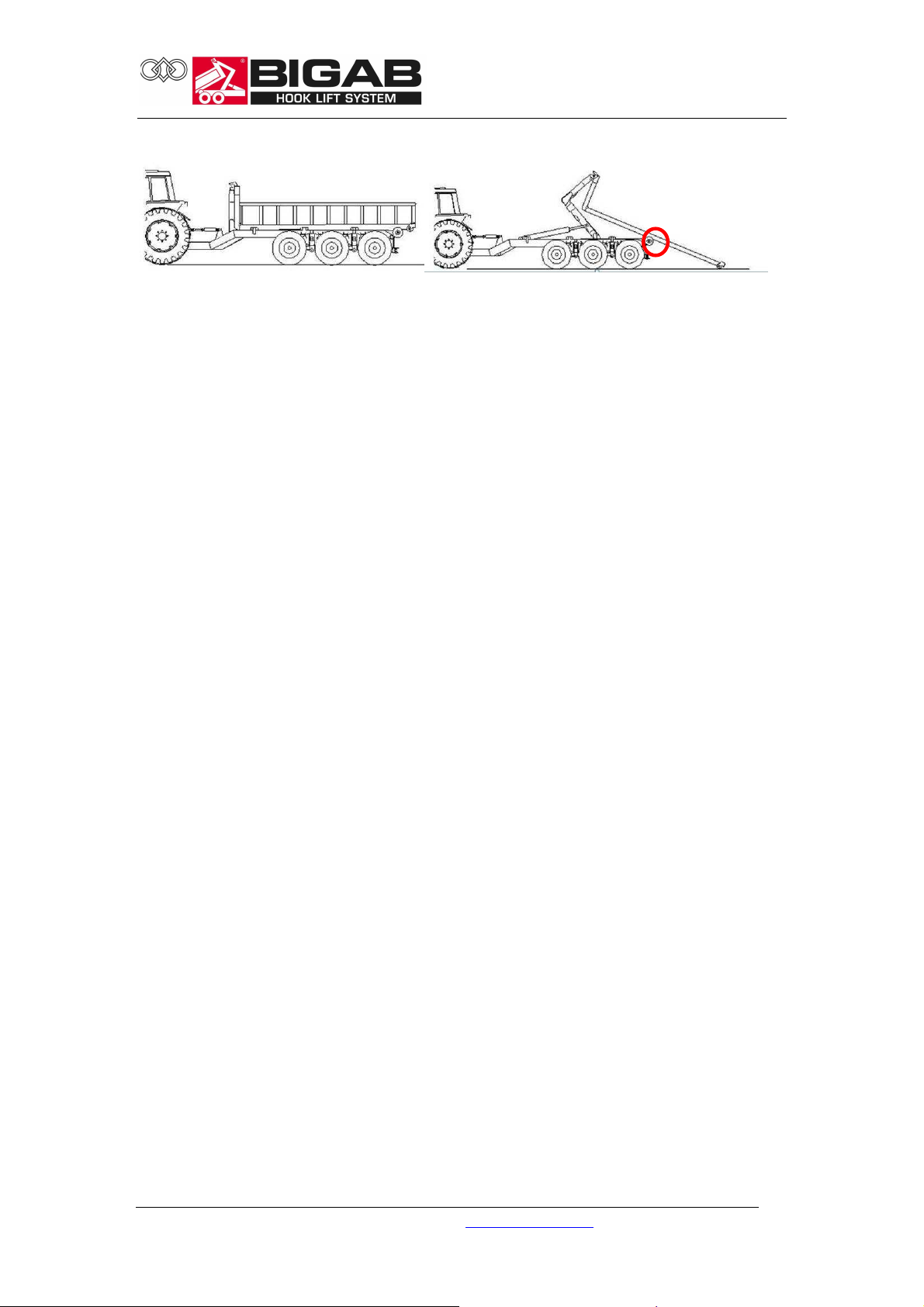

WARNING!

It is hazardous if the rear end of the tractor lifts

Do not, under any circumstances, reverse the towing vehicle or use it to push the

trailer when exchanging. This poses an immediate risk of damaging the trailer or

towing vehicle and can lead to serious or fatal injury.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

28

aligned straight in front of

Failure to read this instruction manual may lead to serious or

Exchange procedure

The trailer must be

Fig. 1

Fig. 2

22-27

Make sure that the hydraulic

mode switch for exchanging or

tipping is in exchange mode

and not in tipping mode. Make

sure that the container lock is

in its open position.

Park the hook lift trailer on a flat surface. It must not be

leaning sideways by an angle of more than 5 degrees.

fatal injury.

Do not, under any circumstances, reverse the towing vehicle or use it to push the trailer

when exchanging. This poses an immediate risk of damaging the trailer or towing vehicle

and can lead to serious or fatal injury. The load must be pulled on and the trailer and

towing vehicle must roll in under the freely suspended load.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

29

ground!

you have passed the rollers, always keep the hook lift trailer’s frame close

Fig. 3

Roll-on!

Make sure that the load carrier is inside the steering rollers. Release the

The tower must be fully retracted when rolling on the container bridge in

STOP

Stop if the tractor lifts off the

Make sure that the hook

hitches around the loop.

Make sure that the frame lock is activated.

brakes on both the towing vehicle and the trailer to make it easier to roll on

the load. Check the position of the tower during roll-on so that the container

bridge frame does not catch on the rollers from behind.

order to increase the lifting power and reduce the strain on the towing

eyelet. Ensure that the container frame does not catch in the rollers at the

back of the trailer. Adjust the tower upwards continually during exchange in

order to move past the rollers. If the tower is not adjusted upwards during

roll-on, there is a considerable risk of the exchange’s lock being damaged if

the container frame catches in the rollers.

IMPORTANT! Follow the movement with the retractable tower so that the

front of the hook lift trailer’s frame does not catch on the rollers. When

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

30

Fig. 4

22-27

Roll-off!

Release the brakes on both the towing vehicle and the trailer to make it easier to roll off the load. Check

the position of the tower during roll-off so that the container bridge frame does not catch on the rollers

from above.

Lock the frame and activate bogie blocking between the towing vehicle and trailer.

being damaged if the container frame catches in the rollers.

1. Raise the hook lift frame slightly so that the container bridge does not scrape against the frame

when it is pushed backwards.

2. Then retract the tower so that the locking rails/wings on the container bridge frame move freely and

cannot be damaged.

3. Adjust the tower upwards continually so that the container frame does not catch on the rollers at

the back of the trailer during roll-off.

4. If the tower is not adjusted during roll-off, there is a considerable risk of the exchange’s lock

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

31

22-27

10 TIPPING OPERATION

Note! The maximum container bridge length for models in this instruction manual is

6.5 metres during tipping. Make sure that the towing vehicle and trailer are securely

coupled before tipping.

Fig. 5

Fig. 6

Park the hook lift trailer on as flat a surface as possible. It must not be leaning

sideways by an angle of more than 5 degrees.

Note! With maximum load, the

telescope must be retracted 40 cm

(400 mm) to enable tipping.

Make sure that the frame lock is

in the correct position.

At maximum tipping, drive slowly forwards until the container bridge is empty.

Lower the bridge before driving off. Important! Make sure that the bridge is

locked in the correct position before driving off.

Fig. 7

IMPORTANT!

Apply the brakes when tipping so

that the tractor and trailer do not roll

away when the load is being

emptied.

Make sure that the frame lock is

activated before tipping.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

32

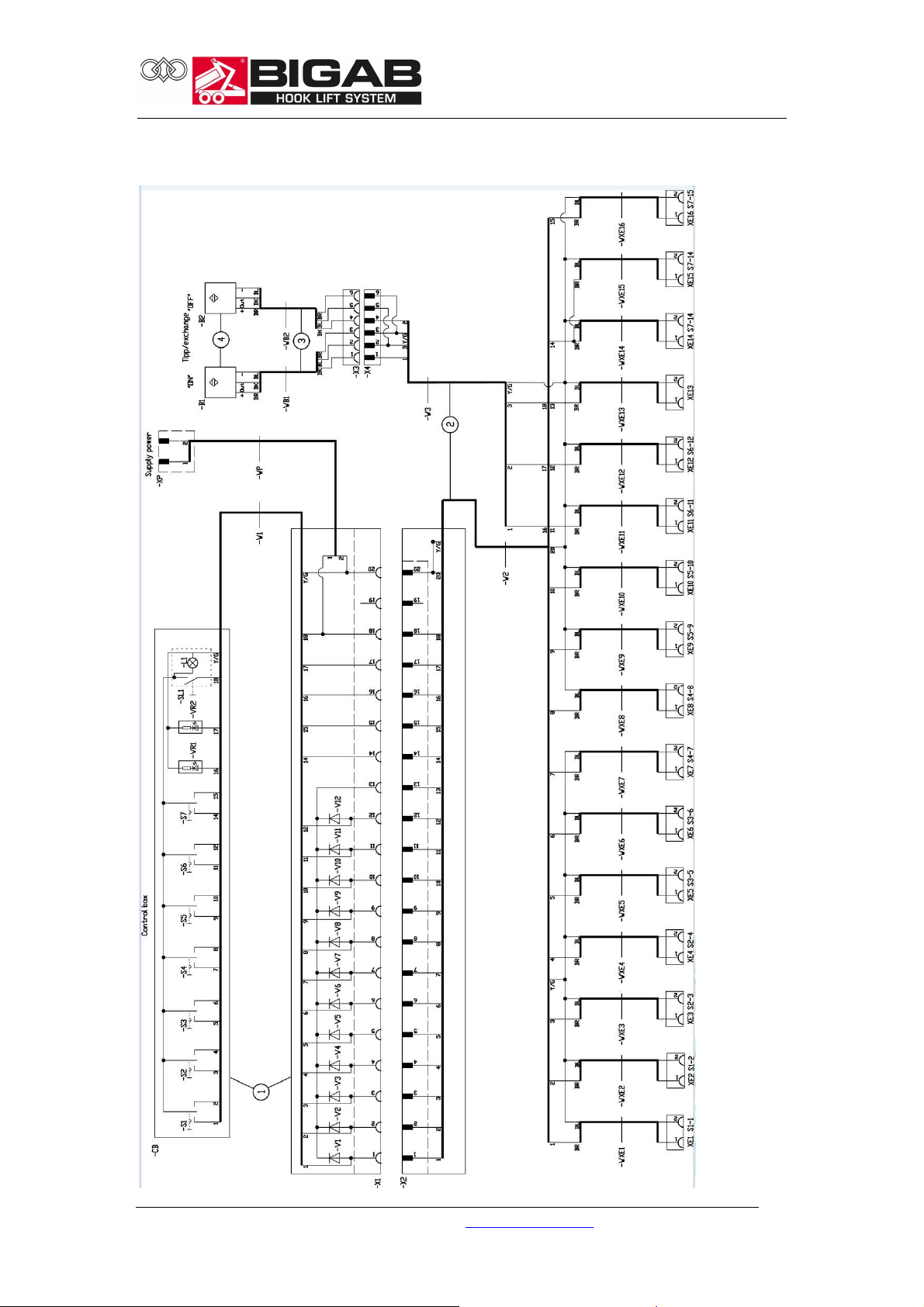

11 WIRING DIAGRAM

The trailer has a 12 volt electrical system.

Wiring diagram tail lights

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

33

No. Item number

Name

Quantity

1 920695

7-

pole junction box (male)

1

2 920764R

Tail lights BIGAB 3 pole, right

-

hand side

1

3 920764L

Tail lights BIGAB 3 pole, left

-

hand side

1

4 920764G

Glass cover tail

light 2

5 920745

Bulb 12V, 21W

2

6 920768

Bulb 12V, 21W p21/5W

2

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

34

Electrical on-off system

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

35

Pos. Item No.

Name

1 913261L

Tipping/exchange cylinder

1 913262R

Tipping/exchange cylinder

2 913245

Telescopic cylinder with

pilot operated valve

3 913230

Exchange cylinder

4 313116

Cylinder container lock

5 313134

Cylinder frame lock

6 313140

Cylinder suspended drawbar

7 913235

Start cylinder

8 913630

Pilot operated check valve

9 913640

End of stroke valve

22-27

12 HYDRAULICS CHART

The hydraulic system is filled with oil and tested before delivery. The hydraulic

system consists of a number of different components illustrated below. Technical

data and configuration depend on the trailer model (see table 1). The hydraulic

system is filled with either VMGZ or SAE100R16 hydraulic oil. It is applied as a

working fluid for the hydraulic system for continuous operation outdoors at

temperatures from -50°C up to +60°C.

Spare parts list Hydraulic components

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

36

13 CARRYING OUT SERVICE/MAINTENANCE

22-27

Place the jack as illustrated when carrying out service and maintenance work, if a

jack is required.

To ensure the safe use of the product and trouble-free operation and for the

warranty to be valid, maintenance must be carried out as described in this chapter.

Clean the trailer thoroughly before carrying out repair work or storage.

The trailer must be standing on a flat surface during maintenance and service work.

Make sure that the trailer cannot move.

When servicing the trailer, turn off the vehicle engine.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

37

Make sure that the trailer cannot move when using a jack or similar equipment - it is

essential that the trailer is supported securely when raised.

Always use the safety support when carrying out service work when the trailer bed is

raised. There must be no load or container bridge on the trailer when carrying out

service work on the trailer in raised position. See illustration below.

Never attempt to carry out any maintenance work on the hydraulic system until you

are absolutely certain that there is no hydraulic pressure.

Do not attempt to seal or repair leaking hydraulic couplings while the system is still

pressurized.

Never attempt to locate a leakage from hoses or couplings with your hands. The

high-pressure oil in the system can penetrate the skin and cause serious injuries,

such as burns and blood poisoning. High pressure oil is highly flammable.

Avoid getting oil in your eyes. Wear safety goggles and safety gloves. If you do get oil

in your eyes, flush them immediately with cold water and seek medical help at once.

22-27

Raised bed

It is absolutely forbidden

to lean under a raised

frame unless it is secured.

WARNING!

The trailer may only be driven in transport position. It must

never be driven with a raised bed. If you drive with a raised

bed, there is a risk of driving into bridges, electrical power

lines and other obstacles.

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

38

22-27

14 MAINTENANCE/SERVICE

General information:

• Service and maintenance must be carried out regularly in order to guarantee

your safety and problem-free use.

• Maintenance work can be carried out without any specialist tools. Most of

the maintenance operations can be performed by the user.

• Locate the problem as well as you can to avoid having to open the system,

unless this is absolutely necessary.

• Any parts that are dismantled must not come into contact with dirt.

• Keep spare parts in their packaging until they are required.

• We recommend that adjustment and repair of valves is carried out by trained

service personnel.

Daily maintenance:

• Visually inspect the load equipment. Note any defects that might affect your

safety. Repair any defects. Carefully inspect the towing eyelet.

• Check the hydraulic system for leaks and hoses for damage.

• Inspect each feature carefully.

• Check oil level.

Weekly maintenance:

• Regularly wash the trailer with a sponge or soft brush and mild soap solution.

Never wash the trailer with hot water and high pressure. This dissolves the

grease at the bearing points.

• Inspect the operation of the trailer.

• Check the hydraulic pressure.

• Check that the brakes are working properly.

• Tighten all wheel nuts after a few hours and check them regularly. Refer to

the list of tightening torques in the chapter on safety devices.

• Check the direction indicators, lamp glass covers, reflectors and lighting.

Monthly maintenance:

• Check the air pressure in all tyres.

• Make sure there is sufficient lubrication on the sliding surfaces.

• Clean the hydraulic cylinders and lubricate their bearings.

• Inspect the hydraulic hoses for damage.

For recommended lubricating greases, see Requirements and test methods SS 15 54

70

http://www.sp.se/km/grease

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

39

Surface cleaning

Remove accumulated dirt and dust. Painted external surfaces should be cleaned

regularly with a sponge or soft brush and soap. When cleaning, never use warm

water in a high-pressure washer. This dissolves the grease at the bearing points.

Maintenance of the hydraulic units

See the hydraulics chart chapter for information about the hydraulic system.

• Clean the hydraulic cylinder piston rod.

• Inspect the hydraulic valves. If a leak is detected, replace the damaged valve.

• Inspect the hydraulic hoses:

• Visually inspect the hydraulic hoses and coupling pipe. If a leak or rupture is

detected, replace the hose.

• Check the oil level. If necessary, top up with oil or change the oil.

• Check the operation of the device.

Always use original parts when replacing hydraulic components such as hoses, seals,

etc. This ensures safe and reliable operation. Be sure to remove all dirt before

starting any work on hydraulic components.

Note! Never operate the hydraulic system if the oil level falls below the lowest

mark.

Changing seals

Replacement of seals should be carried out by an authorised workshop.

Maintenance of the pneumatic units (optional equipment)

• Clean and lubricate the piston rods on the pneumatic cylinders.

• Empty the water trap:

• Condensed water must be removed from the air tank located at the side of

the trailer.

• Check the pneumatic valves:

• Check the pneumatic valves by listening to them when they are working. If a

leak is detected, replace the damaged valve.

• Check the pneumatic hoses:

• Visually inspect the pneumatic hoses and coupling pipe. If a leak or rupture is

detected, replace the hose.

• Check the operation of the device.

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

40

Maintenance of the brake system

This trailer has a hydraulic brake system. Air brake system with negative or positive

action is optional.

The brake system must be inspected regularly. Test the brakes at least once a week

when the trailer is being used.

Make sure that no grease, lubricant or oil enters the brakes. If any type of oil enters

the brakes, there is a risk of it lubricating the brake discs and thereby reducing the

friction. This adversely affects brake performance.

Should this happen, remove the brake drums and change the brake discs.

Always check the play after removing the brake drum and adjust if necessary.

To adjust the brakes, lift the bogie frame off the ground and adjust the brakes by

spinning the wheel while adjusting. The brakes are correctly adjusted when the

wheel spins freely without any scraping noises. The brakes must always be tested

after adjustment.

If brake performance is uneven, apply the brakes, tow the trailer slowly for a couple

of hundred meters, then test the brakes again by braking the tractor and trailer at

normal speed. Repeat if necessary until the brakes work properly. If necessary,

contact our service department!

With the BIGAB 22-27, brake cylinder play is adjusted by slackening or tightening the

adjustment screw on the brake.

Maintenance of wheels

Before the trailer is used, check the wheels by making sure the bolt connections are

secure and that they are regularly checked and tightened.

• Inspect the bolt connections.

• Check the air pressure.

For information about wheels, see the table in the chapter on main components.

For information about tightening torques, see the chapter on safety devices.

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

41

Maintenance of the hook lift trailer’s bogie system

Daily inspections

Inspect all spring brackets, springs with links and wheel axles.

Inspect wheel equipment, tires and rims.

Defects must be corrected before the trailer is used.

Weekly inspections

It is essential to lubricate the trailer’s grease nipples once a week, or after 20 hours

of use. Refer to the lubrication schedule. You need to get under the trailer for best

results when lubricating the grease nipples. This is easiest if the trailer is unloaded.

Changing tyres

When changing tyres, the jack must be placed as illustrated below.

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

42

Storage

Long term storage in cold and/or damp conditions is not advisable.

Repair welding

If repairs or modifications require welding work, first contact your dealer for

necessary instructions. Incorrect welding or lack of knowledge when welding can

result in sudden breaks in the structure.

Recycling

All metal parts can be recycled and must be taken to a recycling facility at the end of

the trailer's useful life.

Scrapping instructions

If the machine or its components are to be scrapped, the materials must be

dismantled, sorted and handed in for recycling or destruction at a location

designated for this purpose by the municipality.

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

43

foldable tower

Right; & Left

Right;&Left x1

Left&Right

Container lock

right x1

Lubrication

Recommended lubrication is once a week or every 20 hours of operation. A grease

gun is recommended for lubrication of grease nipples.

• Follow the lubrication schedule to ensure correct and regular lubrication of

your trailer.

• Keep flammable material away from heat, sparks and naked flames.

• Do not let oil run out onto the ground. Oil pollutes the environment.

Link bearing, left; x1

Apply grease to slide

bearings on the

Brake key

Brake arm

Steering spindle x2

Position end stop

Left & Right

Brake arm

Brake key

Brake key

Brake arm

Steering spindle

x2

Position end stop

Bearing steering rollers, left,

22-27

Towing eyelet

Cyl. link bearing x2

Glide bearing x1

Link bearing, right; x1

Glide bearing

Exchange

lock/Tipping/Exchange

Spherical bearing

Exchange frame

bearing, x1

Bearing load-bearing axle,

left, right, x1

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

44

+0

+0

+0

Tightening torque

• Tightening torque - Drawbar bolts

Thread Bolt

strenght

M16x2 12.9 333

M20x2 12.9 649

• Tightening torque - Wheel nuts

Tightening

torque, Nm

22-27

Thread Nut strenght Tightening

torque, Nm

M18x1,5 10 270 +20

M20x1,5 10 350 +30

M22x1,5 10 450 +60

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

45

Pos. Item No.

Name

Hook frame assembly

1 37221269

Telescopic linkage frame

2 37221079

Hook frame/extension

3 37221112

Axle

4 37221110

Axle

5 37221115

Axle

6 37211180

Distance rin

g

7 37203115

Distance ring

8 909125

Glide bearing

9 37221140

Direction plate

15 SPARE PARTS

Hook frame

22-27

Hook frame spare parts

4

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

46

Pos. Item No.

Name

1 37221500

Frame

2 372320370

Axle

3 320350

Steering roller

4 909115

Slide beari

ng Ǿ100

Rear frame

Rear frame spare parts

4

2

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

47

Pos. Item No.

Description

Mechanical

Pneumatic

1 917220

Sprung Tridem Parabolic 30 tonnes

* *

2 917171

Fixed axle 130x2000

*

2 917181

-PN

Fixed axle 130x2100

*

3 917172

Self-steering

axle 130x2000

*

3 917182

-PN

Self-steering axle 130x2100

*

4 913231

Hydr. cyl. 80/50x249 Steering

* *

4 FMWA20009

-01

Steering cylinder assembly kit

* *

5 920845

Air brake cylinder 20" M16

*

6 917160

-

SP1 Brake cylinder 30/37 Fixed axle

*

7 917160

-SP2 Brake cylinder 25/30 Steering axle

*

8 916498ADR

Brake shoe set 406x120

* *

9 916480

Wheel nut M22x1.5

* *

Bogie

1

22-27

Bogie spare parts

9

4

8

5.7 5.7 5.7

4

3 2 3

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

48

Pos. Item No.

Description

3 2024

-

000011.000

Linkage frame cylinder

4 2024

-

000027.000

Link frame lock chain

- tractor 15

-19-22-27

5 2024

-

000013.000

Link cylinder frame lock chain

12 2024

-

000015.000

Pin

14 2024

-

000010.001

-01

Pin

17 FMWP00001

-

030 Pin

22 908110

Split pin

24 920230

Ring pin

26 920222

Chain for frame lock

32 313135

Hydraul

ic cylinder

33 908640

Spring washer

34 907255

Nut

35 908275

Flat washer

36 FMWP00083

Ring

37 FMWP00083

-01

Ring

Frame lock

221732221714242414 37 3 36

22-27

12

33

34

35

26

Frame lock spare parts

5

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

49

Pos. Item No.

Name

Note:

Exchange unit assembly

1 37221120

Pin

2 920515

Spring

3 37221220

Sliding plate

4 37221210

Sealing ring

5 913230

Exchange cylinder

Exchange unit

3

5

22-27

Rear frame

1, 2, 4

Exchange unit spare parts

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

50

Pos. Ite

m No.

Description

1 920764R

Rear lamp Right

1 920764L

Rear lamp Left

2 920770

Side marker lights 111x40 (orange)

- optional

3 920715

Cable terminal

4 920695

Cable connector 7 pole (male)

5 920180

Cable connector 7 pole (female) special

6

920768

Bul

b 12V 21W p21/5W

7

920745

Bulb 12V, 21W

22-27

Electrical system

For information about the electrical system, see the wiring diagram chapter.

1

Electrical spare parts

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

51

Pos. Item No.

Description

Note

1 930105

Lubricating nipple

2 920120

Towing eyelet

3 37221002

Hook

4 37211068

Stabiliser leg

5 37203067

6 37203085

Safety support

7 920160

Reflector 94*44 (orange)

8 920150

SMV sign

9 920630

Parking chock

Optional

10 920631

Parking chock holder

Optional

Other parts

22-27

Other spare parts

Stabiliser leg pin

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

52

22-27

16 TROUBLESHOOTING

These troubleshooting instructions are intended to help you determine the cause of

a malfunction.

Problems with the electrical equipment

Fault symptoms Reason and action

Problem with lights Bulb not working. Replace the bulb.

Check and clean the electrical

connectors.

Wire damaged or broken. Check and repair the wire.

Problems with the hydraulic equipment

Fault symptoms Reason and action

Too slow movement or the cylinder

does not return from extended position

to neutral.

Air in the hydraulic system Locate the leak and eliminate the fault.

Low oil pressure. Adjust the oil level.

Hydraulic cylinder piston seal leaking. Replace the gasket.

Noise coming from the hydraulic

system.

Oil leak Replace ruptured hose. Adjust the hose

Problem with brake system

The valve has stuck. Clean the valve

parts. The valve should be able to move

freely.

Check the oil level. Check the quick

release couplings between the tractor

and trailer

Air has entered the system. Locate

where the air is entering and eliminate

the fault.

connections

Fault symptoms Reason and action

Poor brake operation.

Oil on brake linings or worn brake pads.

Check the play in the brake arm and

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

Replace the brake shoes

adjust if necessary.

53

17 EC DECLARATION (sample)

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

54

Loading...

Loading...