ENG

Instructions for use

automatic pressure controller

Version 2018-07-31

40-202-01

IMPORTANT

These directions are essential for operating the device. They must

therefore be kept in a suitable place near the device, and should be kept

with the device if it is given to other users.

This manual is valid for devices with serial number 381000 or higher.

For proper and safe use of this device, it is essential that the following

warnings and safety instructions, as well as the operating instructions,

are read and carefully observed by all users before first using the device.

It is the responsibility of those using the device to fully acquaint

themselves with its proper use and operation. If a malfunction is

suspected, the device is to be taken out of service immediately and

suitable warning signs should be attached to the device to ensure that it

is not used before the required service and repair work has been carried

out.

2

TABLE OF CONTENTS

1. Warnings and Safety Instructions ............................................................. 4

2. Description .................................................................................................. 6

2.1 General Discription ..................................................................................... 6

2.2 Scope of Delivery ........................................................................................ 6

3. Initial Operation ........................................................................................... 7

4. Maintenance ................................................................................................ 9

5. Cleaning and Disinfection .......................................................................... 9

6. Periodic Inspections ................................................................................. 10

7. Manufacturer Liability ............................................................................... 10

8. Warranty Conditions ................................................................................. 11

9. Return of Devices ...................................................................................... 12

10. Disposal ................................................................................................... 12

11. Symbols ................................................................................................... 13

12. Operating and Storage Conditions ........................................................ 14

13. EMC Tables .............................................................................................. 14

14. Technical Data ......................................................................................... 18

15. Manufacturer’s Declaration .................................................................... 19

16. Manufacturer ........................................................................................... 19

3

1. WARNINGS AND SAFETY INSTRUCTIONS

In the event of any suspected malfunction while in operation, the device should

be immediately removed from service.

Unplugging the mains plug is the only safe way to disconnect from the mains

power supply.

The device may only be fastened to infusion stands, tripods or equipment rails

which have sufficient stability and load capacity to support the device.

Only pressure infusion bags specified by BIEGLER or approved by BIEGLER

for use with this device may be used in conjunction with the autopress.

The device must only be used in areas in which the electrical installations are in

accordance with the standards and regulations in force.

The device must not be used in rooms with potential explosion hazard.

The device must not be immersed in liquids or sterilized with steam or by

thermochemical methods.

All extraneous influences such as electromagnetic waves or high temperatures

are to be kept to a minimum.

Avoid exerting force on the device or its accessories.

If the device is dropped, damaged due to force, or functions in a way other than

described in the operating instructions, stop using the device immediately and

return it to the service centre.

Periodic technical safety inspections must be carried out as described in the

"Periodic inspections" section.

Persons and services authorized by BIEGLER must carry out repairs and

modifications on the device.

No mechanical or electrical changes may be made to the components of the

device.

4

Only infusion bags that are capable of 300 mmHg must be used. Adhere to the

instructions for use for this bags.

The pressure infusion bags must be securely fastened at least 20 cm above the

patient to prevent air embolism. Prevent the connecting hose from kinking.

Always position the autopress in such a way that it is easy to operate without

obstacles. No other devices or infusion stands shall be positioned shortly before.

Make sure, that mains plug of the autopress is easily reachable to the operator.

(The mains plug is used to disconnect the device from mains)

The automatic pressure controller autopress is a class I ME equipment and

therefore only intended to be connected to supply mains with protective earth.

The autopress may not be used if:

the housing is damaged or one of the front film layers becomes detached

the device has been exposed to a hard physical shock (e.g. dropped, hit or

shaken)

the device has been immersed in water

the mains power cord or plug is damaged

the device has given someone an electric shock

the fixing clamp is damaged in such a way that safe clamping to the infusion

stand is no longer guaranteed.

The autopress may not be used if there is a malfunction:

e. g. display error, no pressure, …

If there is a malfunction, suitable warning signs should be attached to the device

to ensure that it is not used until the required service and repair work has been

carried out.

Safety Instructions for consumable materials:

Consumables are only for one-time use (disposable). The reuse of disposable

products results in possible infection risks for the patient or user.

5

2. DESCRIPTION

2.1 GENERAL DISCRIPTION

Description Article number

autopress LG4000003

The automatic pressure controller autopress is used when liquids are to be

supplied under constant pressure.

The autopress can be used in combination with all BIEGLER Blood- and

Infusionwarmers or used as standalone device.

Only the following single-use pressure infusion bags can be used:

Description Article number

BIEGLER Pressure Infusion Bag 500 ml JR2000500

BIEGLER Pressure Infusion Bag 1000 ml JR2001000

BIEGLER Pressure Infusion Bag 3000 ml JR2003000

2.2 SCOPE OF DELIVERY

Quantity Description

1 autopress

2 BIEGLER Pressure Infusion Bag 500 ml

1 Instructions for use

6

3. INITIAL OPERATION

Observe the instructions for use! Handling of this device requires

knowledge and adherence to these instructions. The autopress and

accessories may only be used by physicians, physician assistants or

other qualified specialized staff. The condition of the patient has to be

monitored during the application.

1. Fix the autopress firmly on a stand using the clamps at the

back. Only use infusion stands, tripods or equipment rails

that are sufficiently stable.

2. Before connecting to the mains power supply, check that the

voltage specified on the device label matches the mains

voltage.

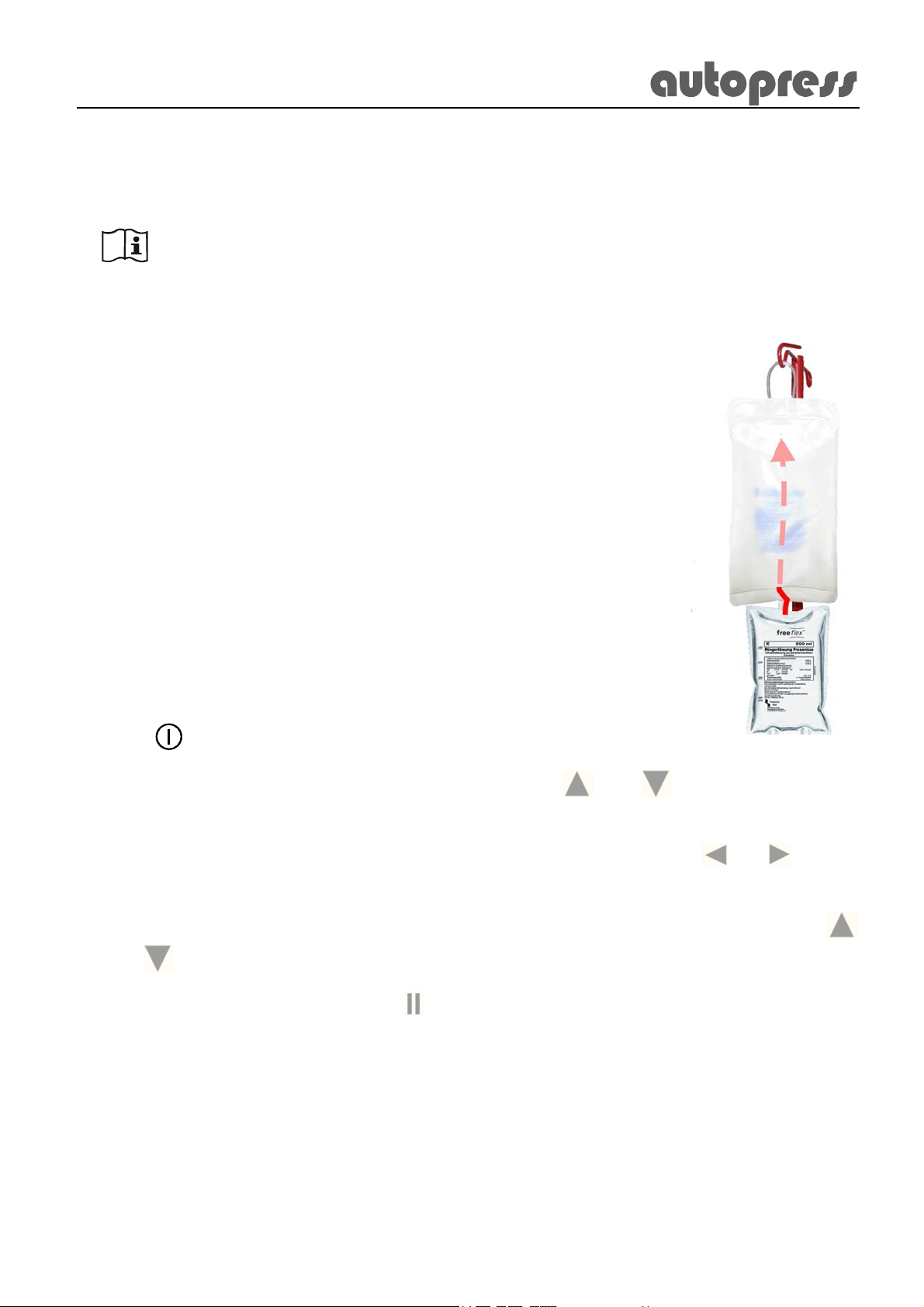

3. Before switching on the device place the infusion bag in an

appropriate pressure infusion bag and then connect the

infusion to the patient.

4. Connect the pressure infusion bag to the Luer-Connector of

the autopress

5. Switch on the device by pressing the button in the upper

right.

Figure 1 - placing the

infusion bag

6. Set the desired pressure with the arrow buttons and .

(in steps of 10 mmHg)

7. Start the pressure build-up by pressing the START-buttons or to the

corresponding channel.

8. If necessary the pressure in both channels can be changed by pressing the

and buttons.

9. By pressing the PAUSE-button the pressure in the corresponding channel is

released and the channel is vented.

If the patient has to be moved the device can be unplugged without switching off

– the pressure is maintained.

7

Operation:

clamp

set pressure

ratio

actual to set

pressure

actual pressure

vent left

channel

activate left

channel

ON / OFF

Power supplied

Standby-LED

increase

pressure

vent right

channel

activate right

channel

8

decrease

pressure

Figure 2 - Operation, Display

4. MAINTENANCE

The autopress was largely designed as a maintenance-free device. For long-term

maintenance of quality and functional safety, we would like to ask you to observe

the following points:

Always keep the device clean (see the "Cleaning and disinfection" section).

Periodic technical safety inspections must be carried out as described in the

"Periodic inspections" section.

5. CLEANING AND DISINFECTION

Important: Before cleaning or disinfecting, the device must always be

disconnected from the mains power supply by pulling the plug.

The device may only be cleaned using a soft cloth with a water-soluble, nonaggressive cleaning agent or a special cleaning agent for plastics.

For the purposes of disinfection, only ready-made alcohol-based spray

disinfectants (e.g. Meliseptol Foam pure, BRAUN) must be used and the

manufacturer‘s instructions must be followed.

Do not disinfect the device with steam (i.e. in autoclaves), hot air or

thermochemical cleaning solutions.

9

6. PERIODIC INSPECTIONS

The periodic technical safety inspections (according to the local standards in force

- e.g. in Austria, EN 62353) on the autopress must be carried out at least every

12 months, by persons authorized to carry out such inspections based on their

training, knowledge and practical experience. The device cannot be used during

inspection. The pressure limitation, as essential performance of the device, is

tested during inspection.

The device should be checked for mechanical damage (general condition) and for

the completeness of the device label.

Furthermore, the device must not display any contamination or corrosion which

could impair safety, particularly in the area of the plug connector.

If there is mechanical damage to the device which could cause risk of injury or

impair its functionality, this constitutes a malfunction.

The results of the periodic inspection must be documented, along with the date,

the inspecting agency and the device number.

Important: If a malfunction is discovered during the periodic inspection,

suitable warning signs should be attached to the device to ensure that it

is not used before the required service and repair work has been carried

out.

7. MANUFACTURER LIABILITY

The manufacturer and the supplier of the device reject any liability if:

the device is not used in accordance with the directions for use.

the user is not sufficiently informed about the functioning of the device

corresponding with the directions for use and the safety instructions

repairs are not performed exclusively by the manufacturer or by persons and

service centers expressly authorized by the manufacturer

the device is used in places in which the electrical installations do not comply

with the applicable national standards, or if the power supply during the

period of use of the device is not guaranteed

original spare parts are not used or the maintenance interval is not adhered

to.

10

8. WARRANTY CONDITIONS

The manufacturer guarantees that all flaws of material and

workmanship which arise within 24 months from the date of purchase

will be repaired free of charge.

Claims are only accepted under the following terms:

The manufacturer and/or supplier is informed immediately of the

fault for which the warranty claim is being made.

The instructions of the manufacturer and/or supplier regarding

storage or return of the device are complied with.

Presentation of a legible copy of the invoice for the device

concerned, showing the date of purchase.

An exact description of the defects or malfunctions identified by the

customer.

The manufacturer's warranty will be void if it is found that the

maintenance, disinfection and inspection instructions have not been

followed according to the operating instructions, the device has been

damaged by force or operating error, or has been used in any way

contrary to the operating and safety instructions. The warranty will also

be void if original BIEGLER materials were not used as replacement

parts, or measures for repair were undertaken by persons not

authorized by the manufacturer or supplier.

If the manufacturer is required to meet a warranty claim in accordance

with these terms, the customer shall bear the costs and risks of transport

of the device from and to the place of use.

The manufacturer and/or supplier shall under no circumstances assume

liability for slight negligence. The compensation for lost earnings and

profits is likewise excluded.

11

9. RETURN OF DEVICES

Devices must be carefully cleaned and disinfected before being placed in the

original packaging for returning.

If the original packaging is no longer available, the product has to be suitably

packaged for the method of dispatch.

10. DISPOSAL

Dispose of the device at the end of its expected service life and its accessories in

accordance with the applicable local regulations.

Do not dispose of this product

as unsorted municipal waste

12

11. SYMBOLS

compliance with Directive

Serial number

93/42/EEC

Consult instructions for use

Attention, consult

accompanying documents

Defibrillation-proof type CF

Catalogue number

Manufacturer

manufacturing date

applied part

On / OFF

activate right channel

AC voltage

increase pressure

activate left channel

decrease pressure

Degree of protection

pause button –

IPX4

against ingress of water -

vent the channel

splashing water

Batch code

Latex free

Fragile, handle with care

Keep dry

Use by

Humidity limitation

Temperature limit

Protect from heat and

radioactive sources

Do not dispose of this product

as unsorted municipal waste

authorized in the European

Community

13

12. OPERATING AND STORAGE CONDITIONS

Permissible environmental conditions for transporting and storing the autopress

and accessories:

Transport and storage Operating

Temperature 10 – 40 °C 10 – 30 °C

Relative humidity 30 – 75 % 30 – 75 %

Ambient pressure 700 – 1060 hPa 700 – 1060 hPa

Values higher or lower than the ranges specified above may cause

damage to the device or its accessories.

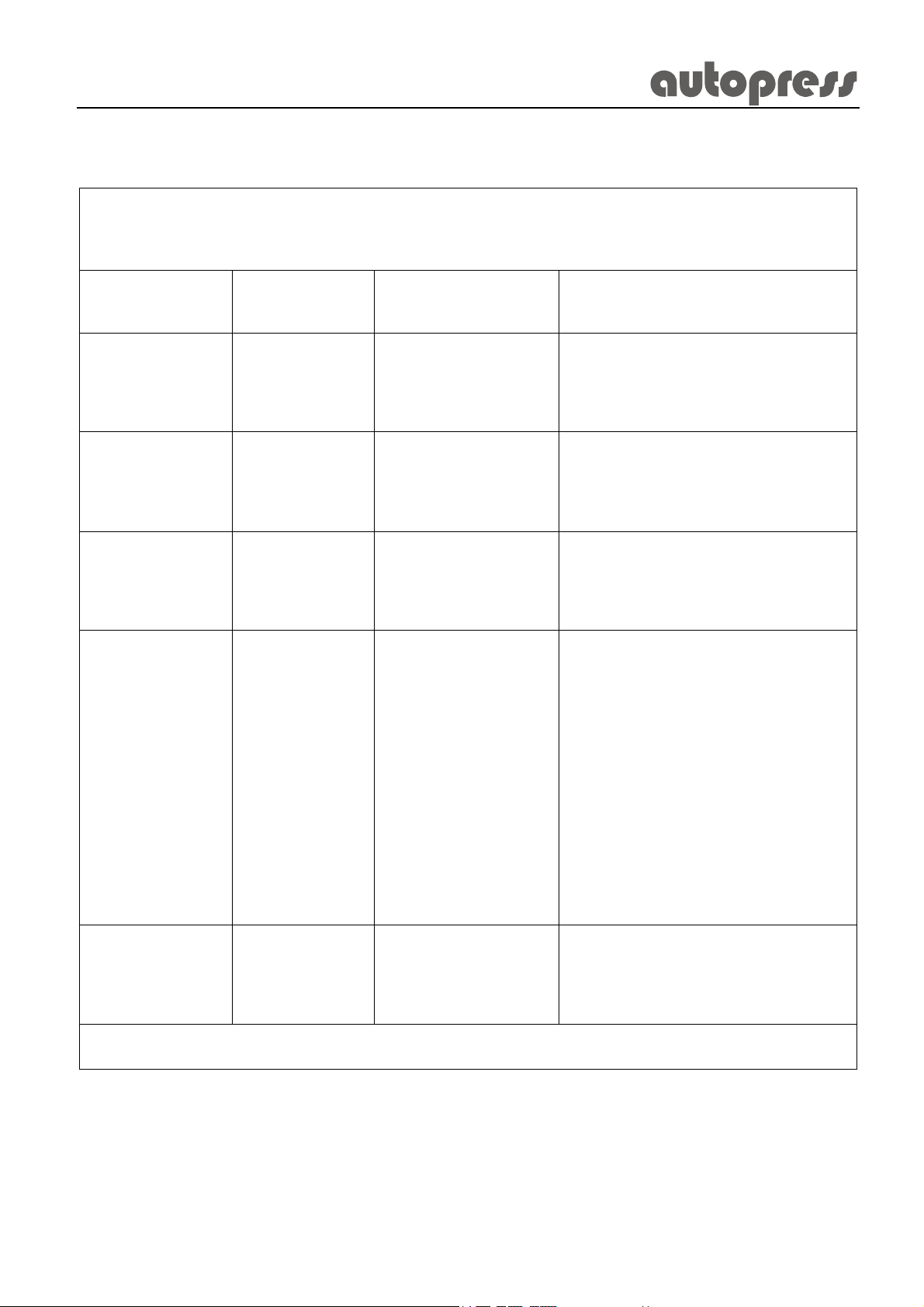

13. EMC TABLES

Table 1

Guidelines and manufacturer's declaration – electromagnetic emissions

The autopress is intended for use in the environment specified below. The customer or the user of the

autopress should ensure that it is used in such an environment.

Interference

emission

measurements

RF emissions

acc. to CISPR 11

RF emissions

acc. to CISPR 11

Emission of

harmonics

according to

IEC 61000-3-2

Emission of

harmonics

according to IEC

61000-3-3

Compliance Electromagnetic environment - guidelines

Group 1

Class B The autopress is suitable for use in all establishments, including domestic

Class A

Compliant

The autopress uses RF energy only for its internal function. Therefore, its

RF emissions are very low and are not likely to cause any interference to

nearby electronic equipment.

establishments and those directly connected to the public power supply

network that also supplies buildings used for domestic purposes.

14

Table 2

Guidelines and manufacturer's declaration – electromagnetic interference resistance

The autopress is intended for use in the electro-magnetic environment specified below. The customer or the

user of the autopress should assure that it is used in such an environment.

Interference

resistance test

Electrostatic

discharge

IEC 61000-4-2

Fast transient

/electrical bursts

acc. to IEC 61000-44

Surges as per

IEC 61000-4-5

Voltage dips, short

interruptions

and voltage

variations of the

supply voltage

acc. to IEC 61000-411

IEC 60601-test

level

± 8 kV contact

± 15 kV air

± 2 kV

100kHz repetition

frequency

± 1 kV

differential mode

± 2 kV

common mode

< 5 % UT

(> 95 % fall in U

T

for ½ period

40 % U

(60 % fall in U

T

)

T

for 5 periods

70 % U

(30 % fall in U

T

)

T

for 25 periods

< 5 % U

(> 95 % fall in U

T

T

for 5 s

Compliance

level

± 8 kV contact

± 15 kV air

± 2 kV

100kHz repetition

frequency

± 1 kV

differential mode

± 2 kV

common mode

< 5 % U

(> 95 % fall in U

)

T

for ½ period

40 % U

T

(60 % fall in U

for 5 periods

70 % U

T

(30 % fall in U

for 25 periods

< 5 % U

(> 95 % fall in U

)

T

for 5 s

Electromagnetic environment guideline

Floors should be wood, concrete or

ceramic tile. If floors are covered with

synthetic material, the relative humidity

should be at least 30 %.

The mains power supply quality should be

that of a typical commercial or hospital

environment.

The mains power supply quality should be

that of a typical commercial or hospital

environment.

)

T

The mains power supply quality should be

that of a typical commercial or hospital

environment.

If the user of the autopress requires

continued operation even in the case of

)

T

power supply interruptions it is

recommended to connect the autopress

to an uninterruptible power source or a

battery.

)

T

)

T

Power frequency

(50 Hz/60 Hz)

magnetic field IEC

61000-4-8

3 A/m 3 A/m Magnetic fields at this power frequency

should be at levels characteristic of a

typical location in a typical commercial or

hospital environment.

NOTE UT is the AC mains voltage prior to application of the test level.

15

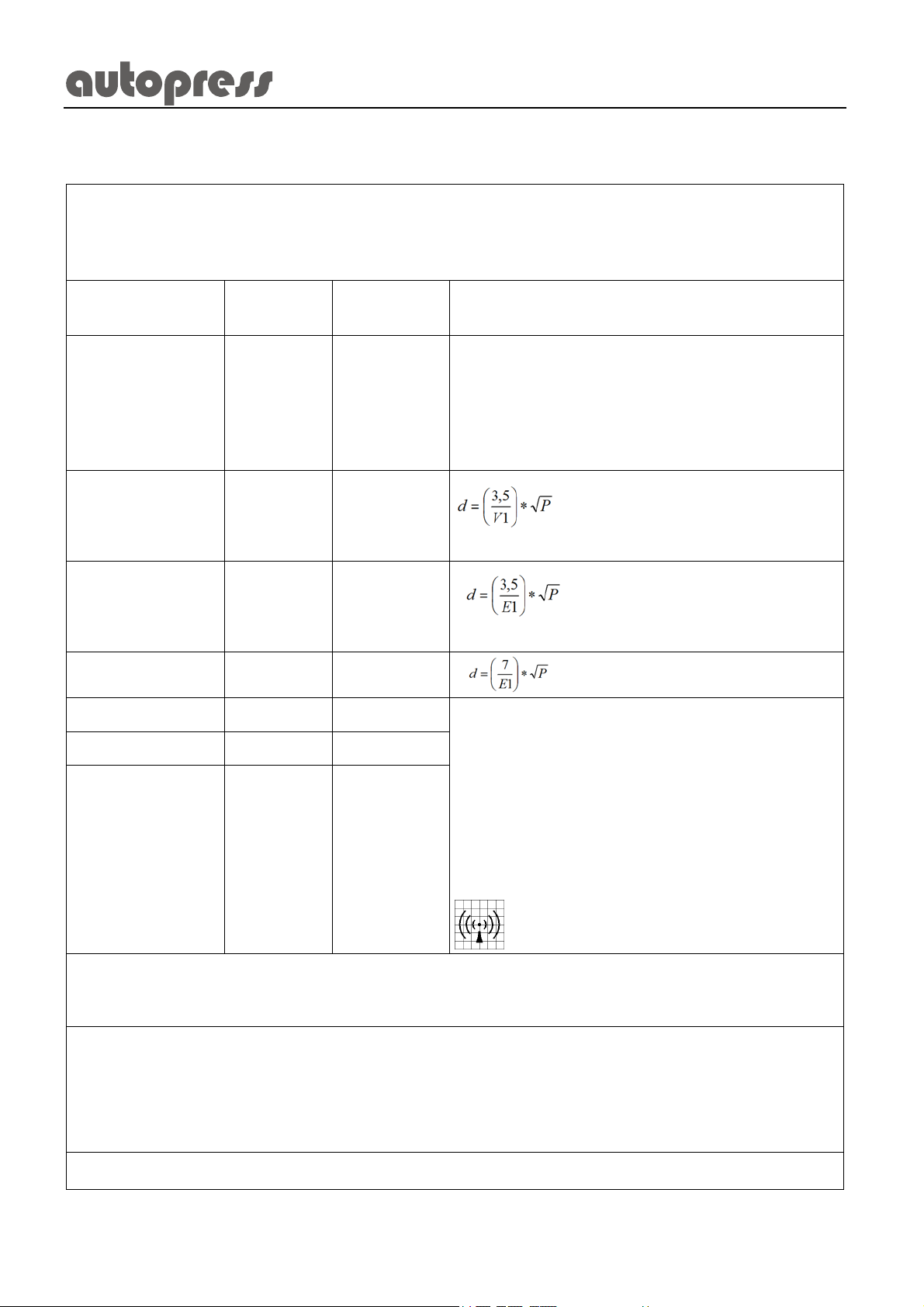

Table 4

Guidelines and manufacturer's declaration – electromagnetic interference resistance

The autopress is intended for use in the electro-magnetic environment specified below. The customer or the

user of the autopress should ensure that it is used in such an environment.

Interference

resistance test

IEC 60601test level

Compliance

level

Electromagnetic environment - guidelines

Portable and mobile RF communications equipment

should be used no closer to any part of the autopress,

including cables, than the recommended protection

distance calculated from the equation applicable to the

frequency of the transmitter:

Recommended protection distance:

Conducted RF

disturbance variables

acc. to

3 V

eff

150 kHz to 80

MHz

1V

in V

IEC 61000-4-6

Radiated RF

disturbance variables

according to IEC

3 V/m

80 MHz to 2.5

GHz

in V/m

1E

for 80 MHz to 800 MHz

61000-4-3

for 800 MHz to 2.5 GHz

Where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended protection

distance in meters (m).

Field strengths from fixed RF transmitters, as

determined by an electromagnetic site survey

a

should

be less than the compliance level in each frequency

b

range.

Interference may occur in the vicinity of equipment

marked with the following symbol:

NOTE 1 At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption

and reflection from structures, objects and people.

a

Field strengths from stationary transmitters, such as base stations for radio (cellular /cordless) telephones

and land mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted

theoretically with accuracy. To assess the electromagnetic environment resulting from stationary RF

transmitters, an electromagnetic site survey should be considered. If the measured field strength in the

location in which the autopress is used exceeds the applicable RF compliance level above, the

autopress should be observed to verify normal operation. If abnormal performance characteristics are

observed, additional measures may be necessary, such as reorienting or relocating the autopress.

b

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than [V1] V/m.

16

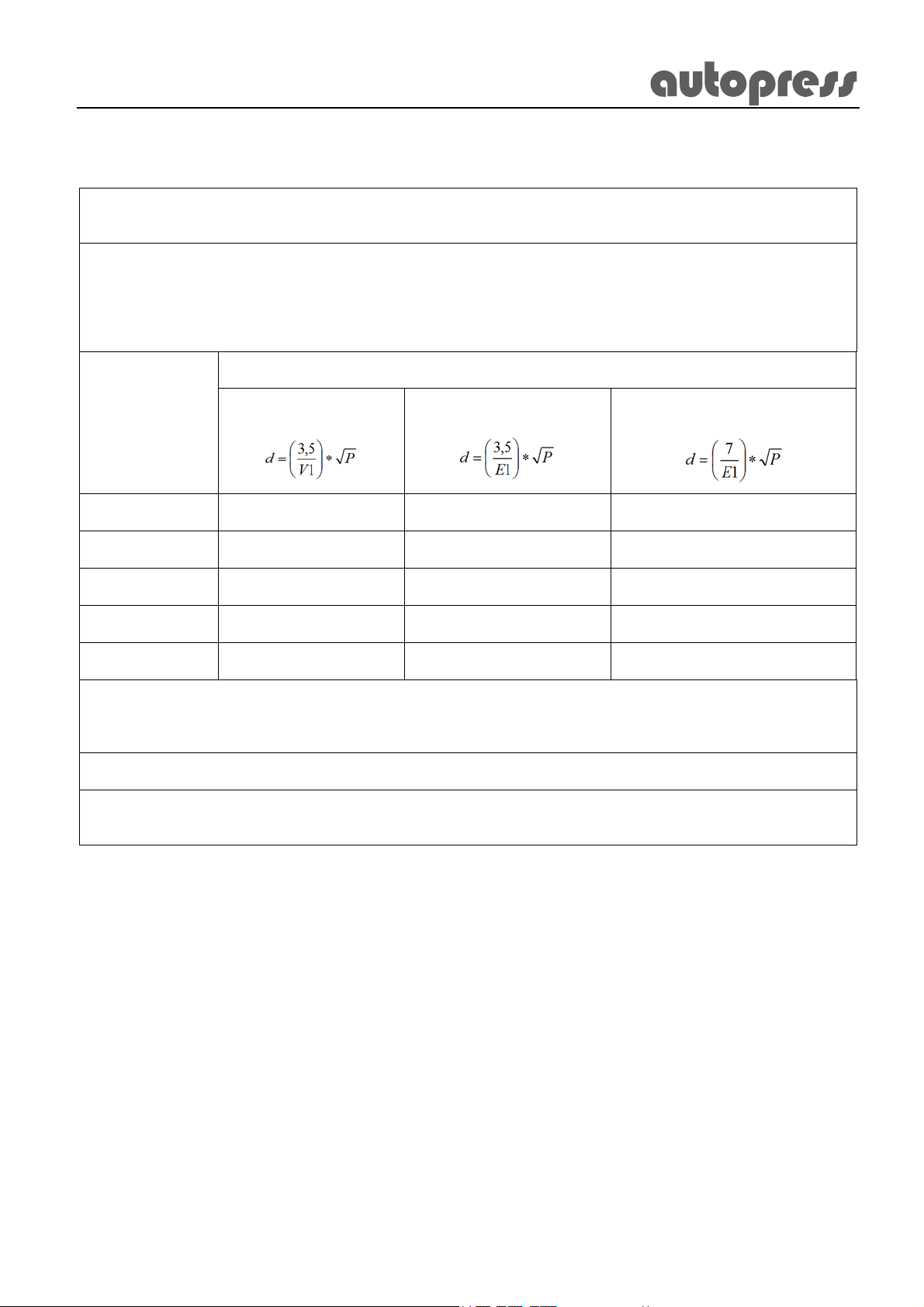

Table 6

Recommended safety distances between

portable and mobile RF telecommunications devices and the autopress

The autopress is intended for use in an electromagnetic environment in which radiated RF disturbance

variables are controlled. The customer or user of the autopress can help prevent electromagnetic interference

by maintaining a minimum distance between portable and mobile RF communications equipment (transmitters)

and the autopress as recommended below, according to the maximum output power of the communications

equipment.

Protection distance according to transmitter frequency m

Rated maximum

output power

of transmitter W

0.01 0.12 0.12 0.23

0.1 0.37 0.37 0.74

1 1.17 1.17 2.33

10 3.69 3.69 7.38

100 11.67 11.67 23.33

For transmitters rated at a maximum output power not listed above, the recommended distance can be

determined using the equation applicable to the frequency of the transmitter, where P is the maximum output

power rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE 1 At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by

150 kHz to 80 MHz

absorption and reflection from structures, objects and people.

80 MHz to 800 MHz

800 MHz to 2.5 GHz

17

14. TECHNICAL DATA

Device: automatic pressure controller

Type designation: autopress

Operating voltage: 100 – 240 Vac / 50 – 60 Hz

Power consumption: max. 36 VA

Supply type: mains operation

Protection class: I

Degree of protection

against electric shock Type CF, defibrillationproof

IP-classification (IEC 60529): IPX4

Classification (93/42/EEC): IIa according to Rule 9

Operation mode: continuous

Pressure range: 0 – 300 mmHg

Accuracy of values displayed: ± 5% of the measured value

Dimensions: 100 x 230 x 180 mm

Weight (device only): 2.1 kg

Applied part: venous access (not included)

Figure 3 – Applied part depiction

18

to patient

15. MANUFACTURER’S DECLARATION

The autopress is a medical product as defined by Directive 93/42/EEC.

This is documented through the CE mark.

Notified Body: TÜV SÜD Product Service, Approval Number CE0123

16. MANUFACTURER

Biegler GmbH

Allhangstrasse 18a

3001 Mauerbach

AUSTRIA

Tel. +43 1 979 21 05

Fax +43 1 979 21 05 16

office@biegler.com

www.biegler.com

19

Loading...

Loading...